A Study on the Lateral Load Capacity of a Novel Hybrid Monopile via a Centrifuge Model Test

Abstract

:1. Introduction

2. Centrifuge Model Test

2.1. Centrifuge Facility

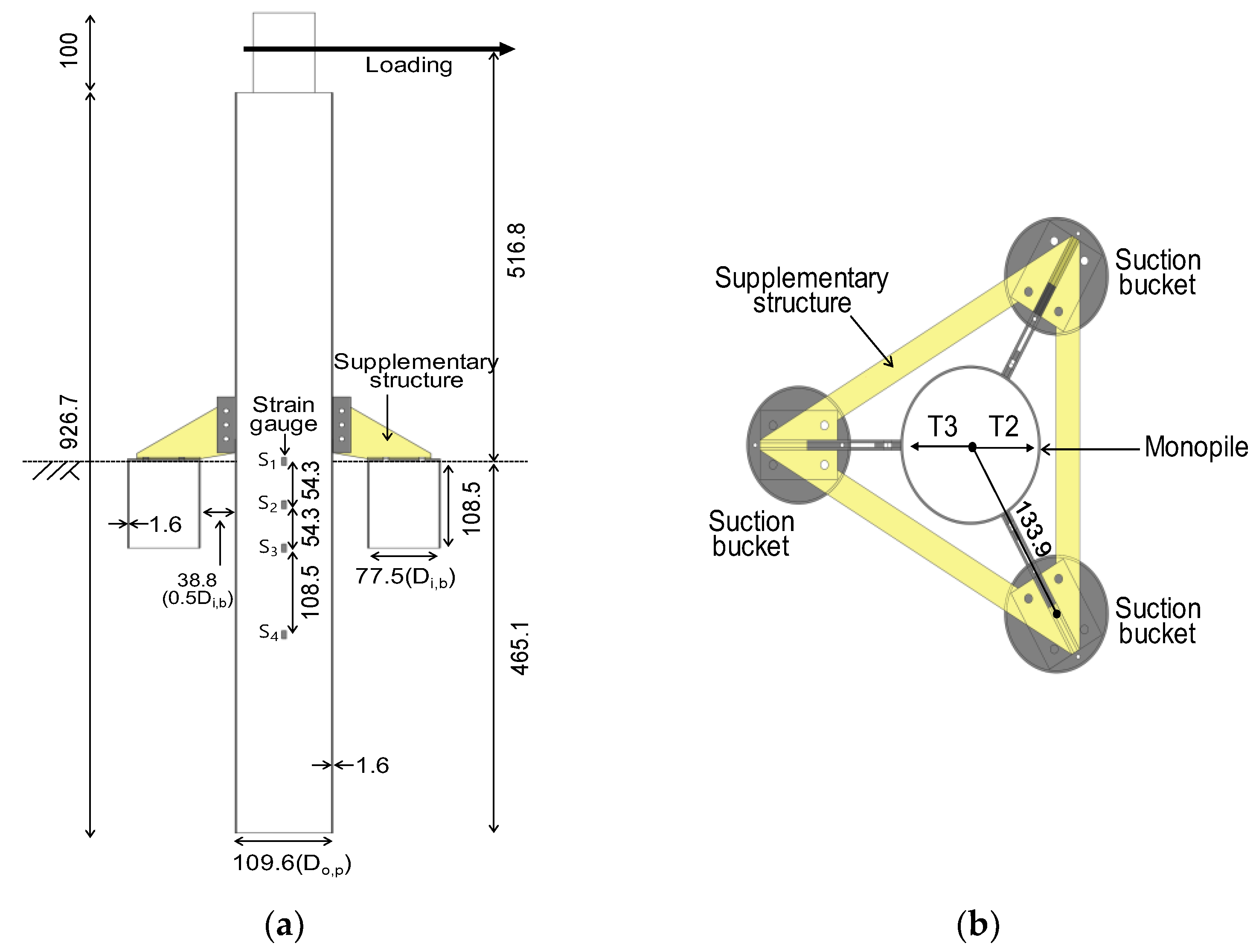

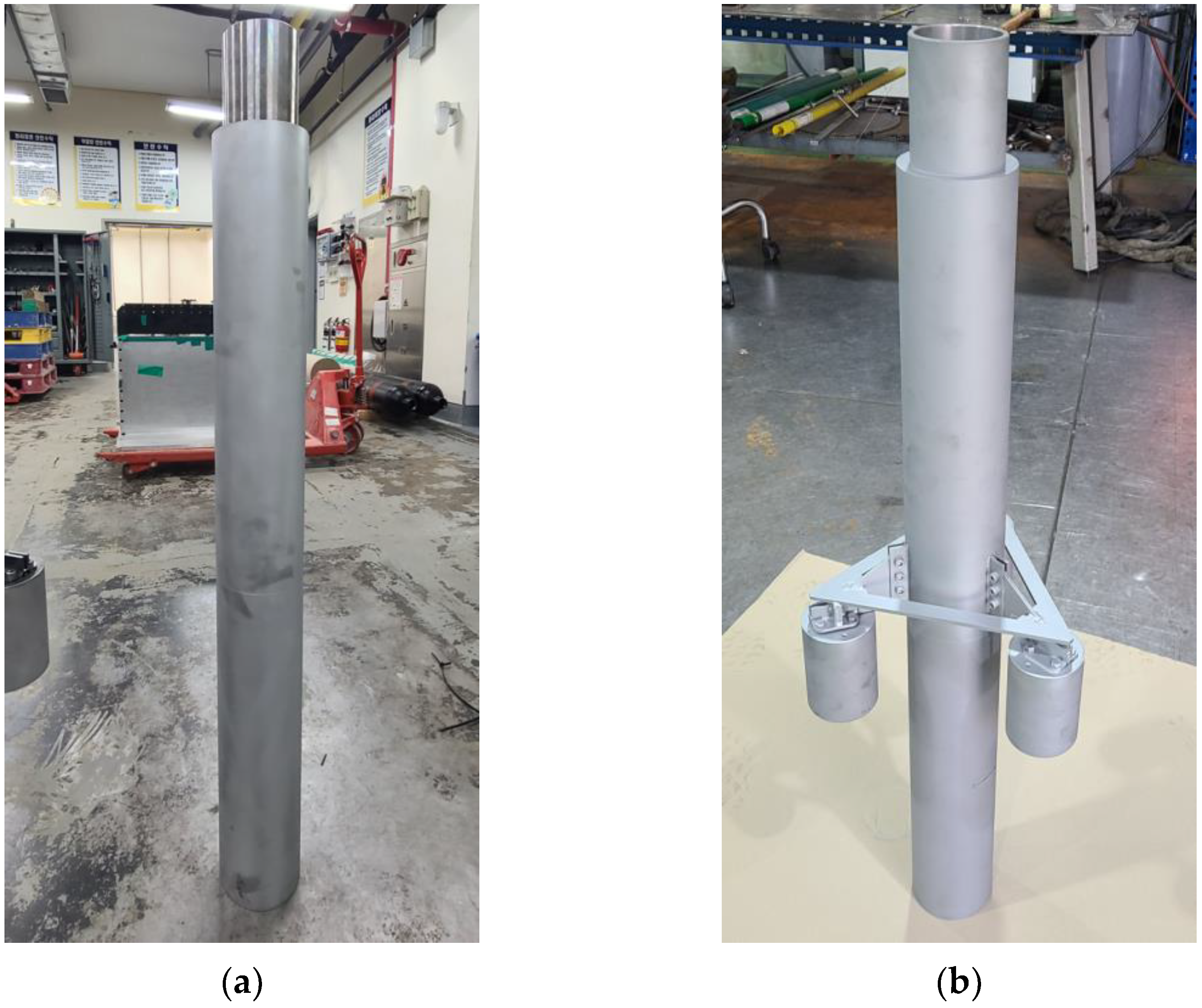

2.2. Hybrid Monopile Modelling

2.3. Experimental System

2.4. Soil Sample Preparation

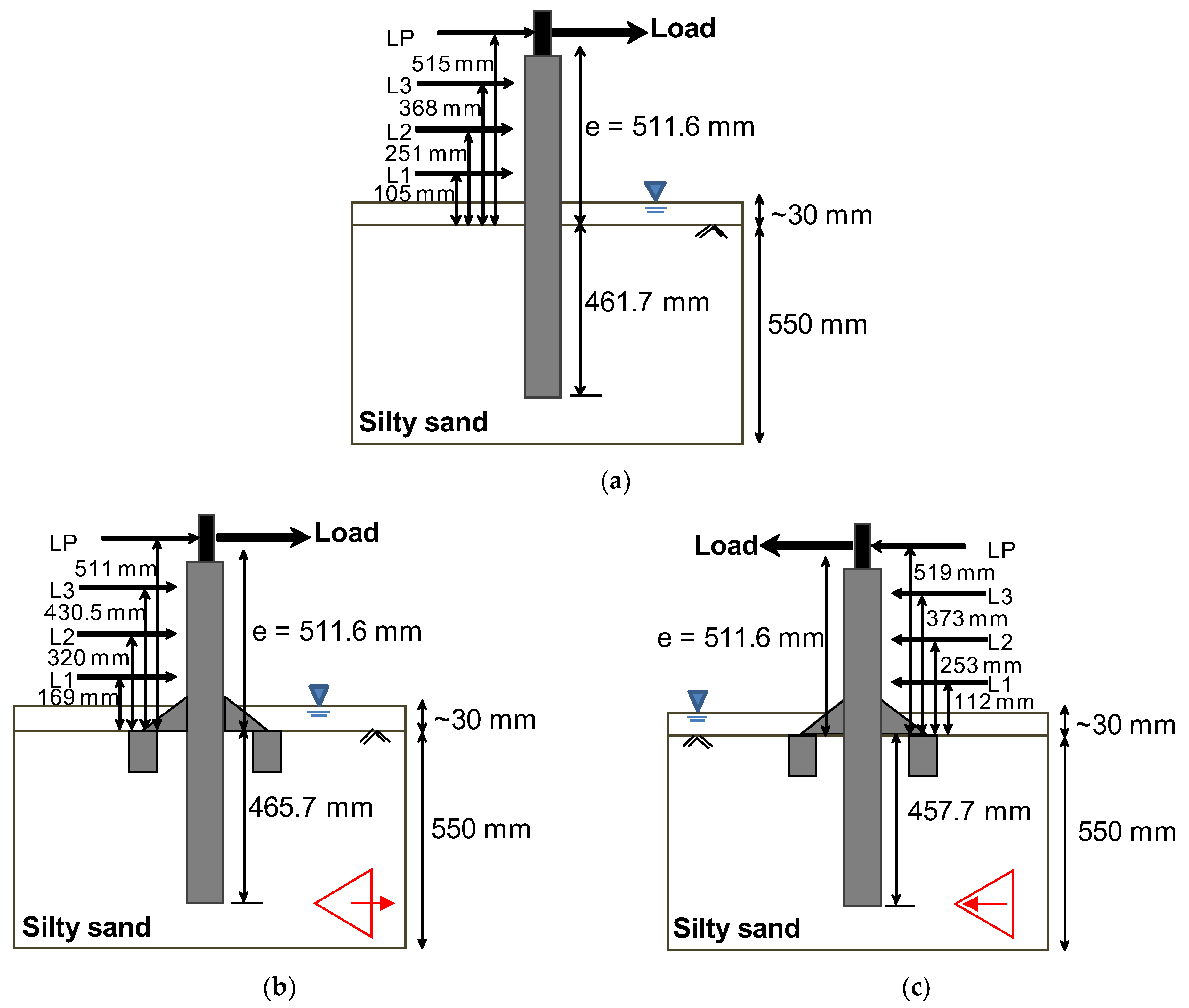

2.5. Experimental Condition

2.6. Experimental Procedure

3. Test Results

3.1. Cone Penetration Test

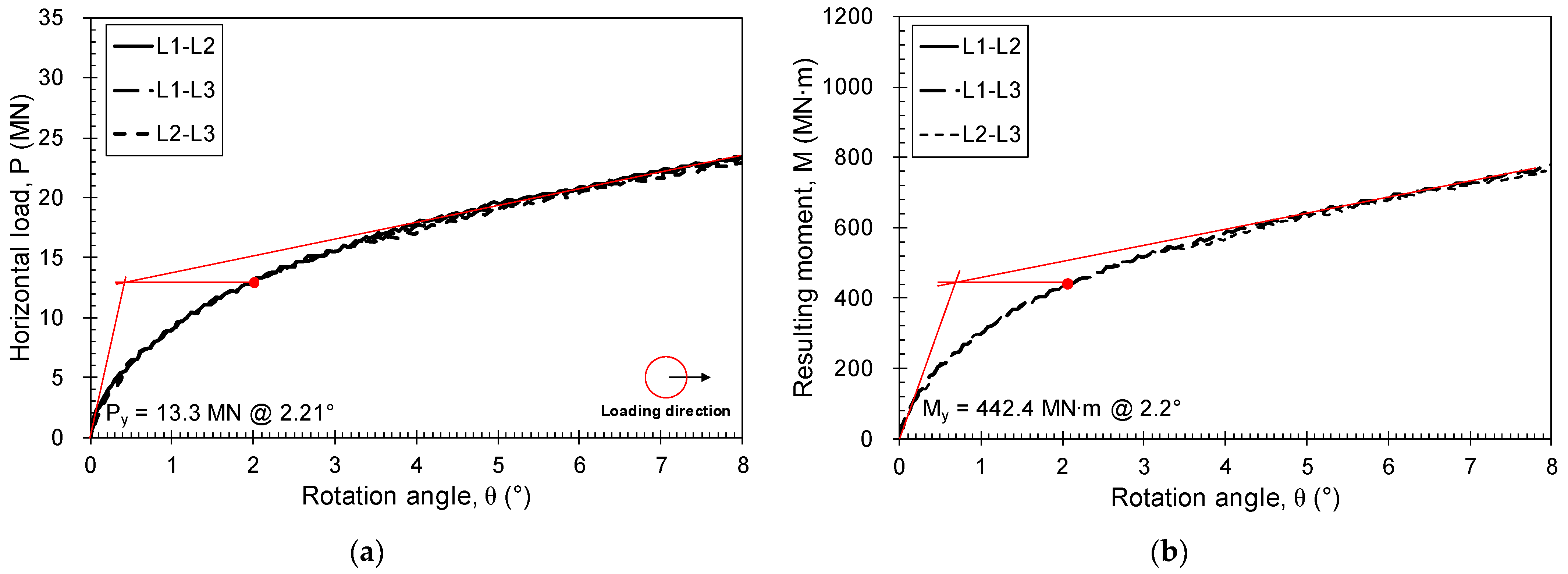

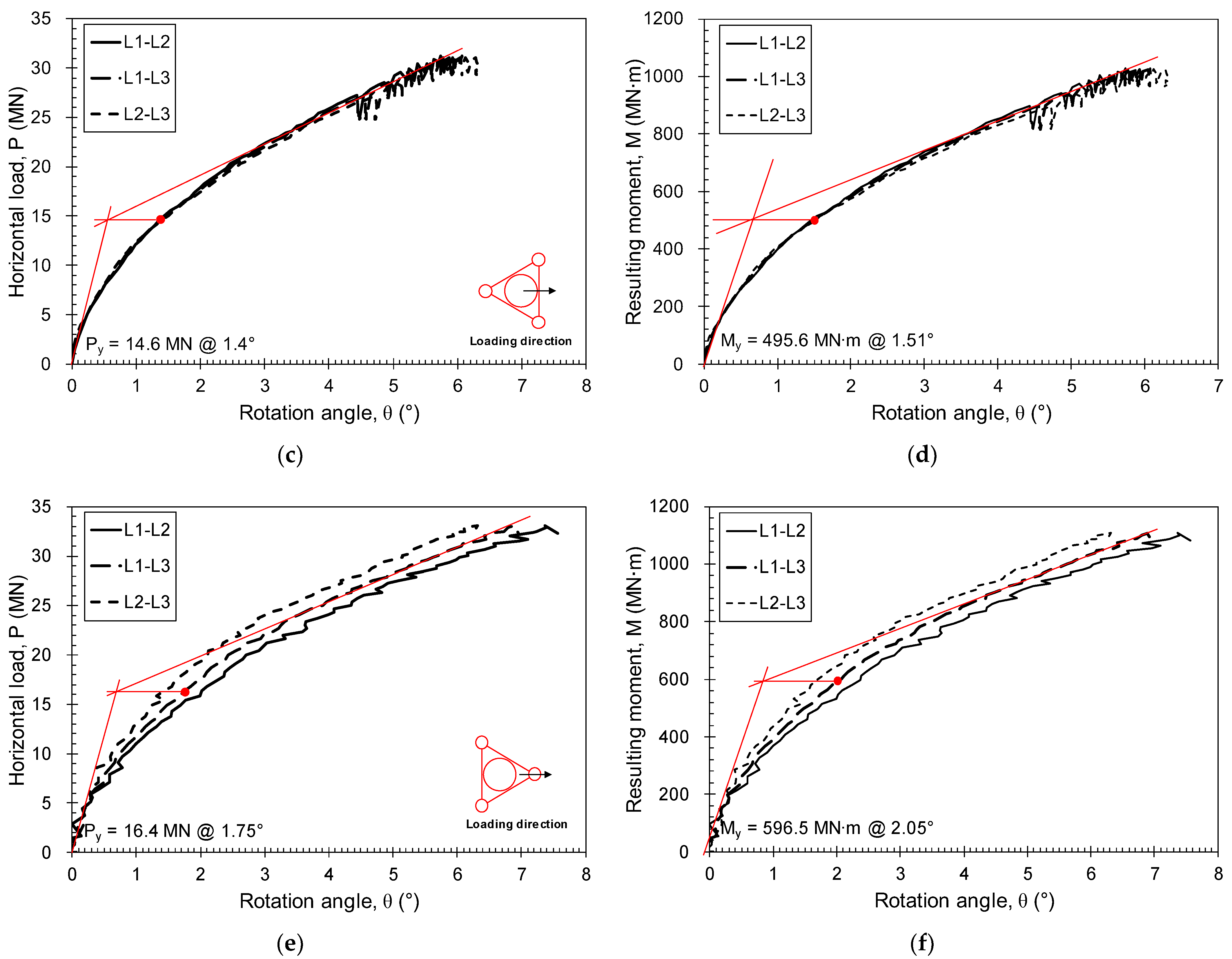

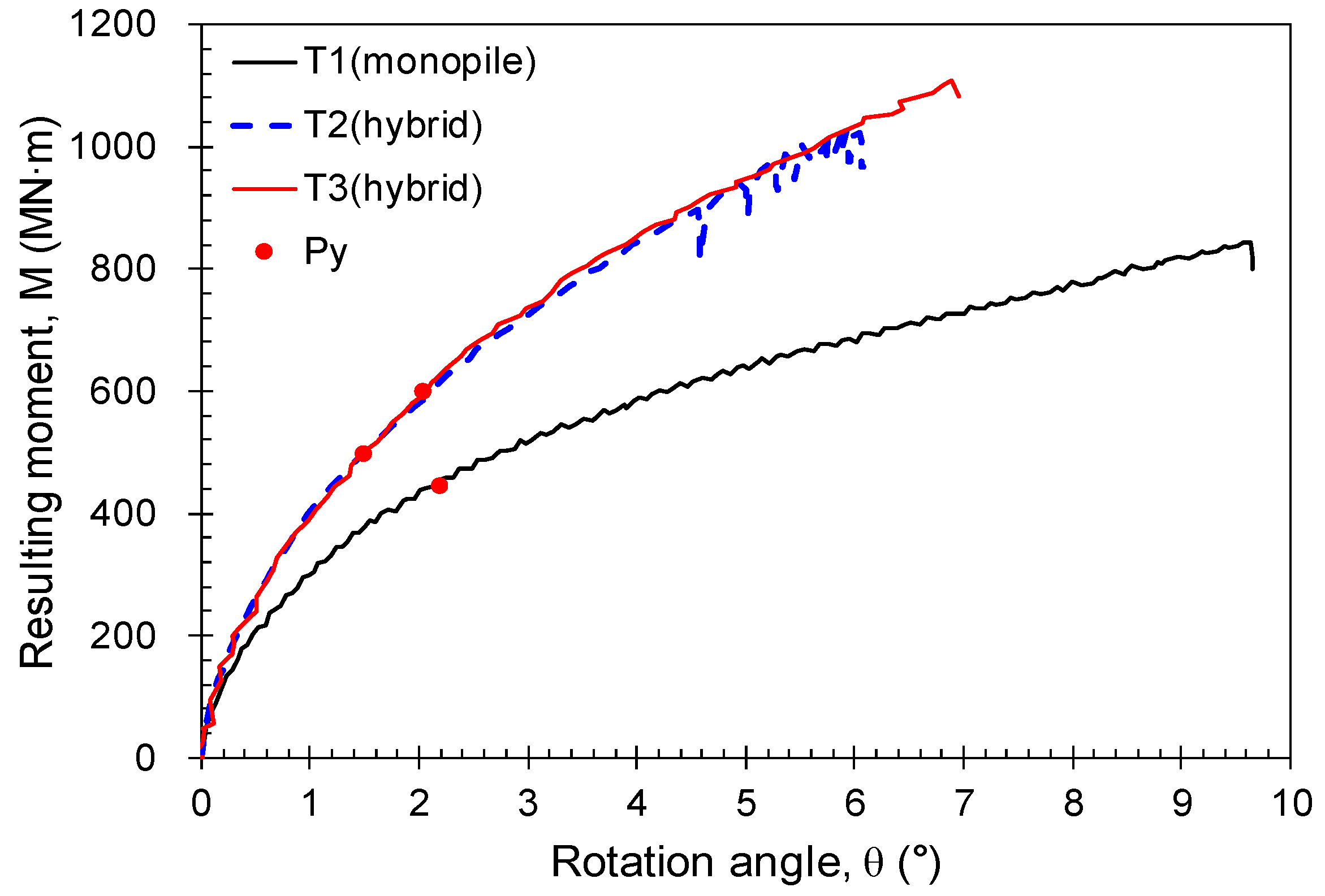

3.2. Load-Rotation Behavior

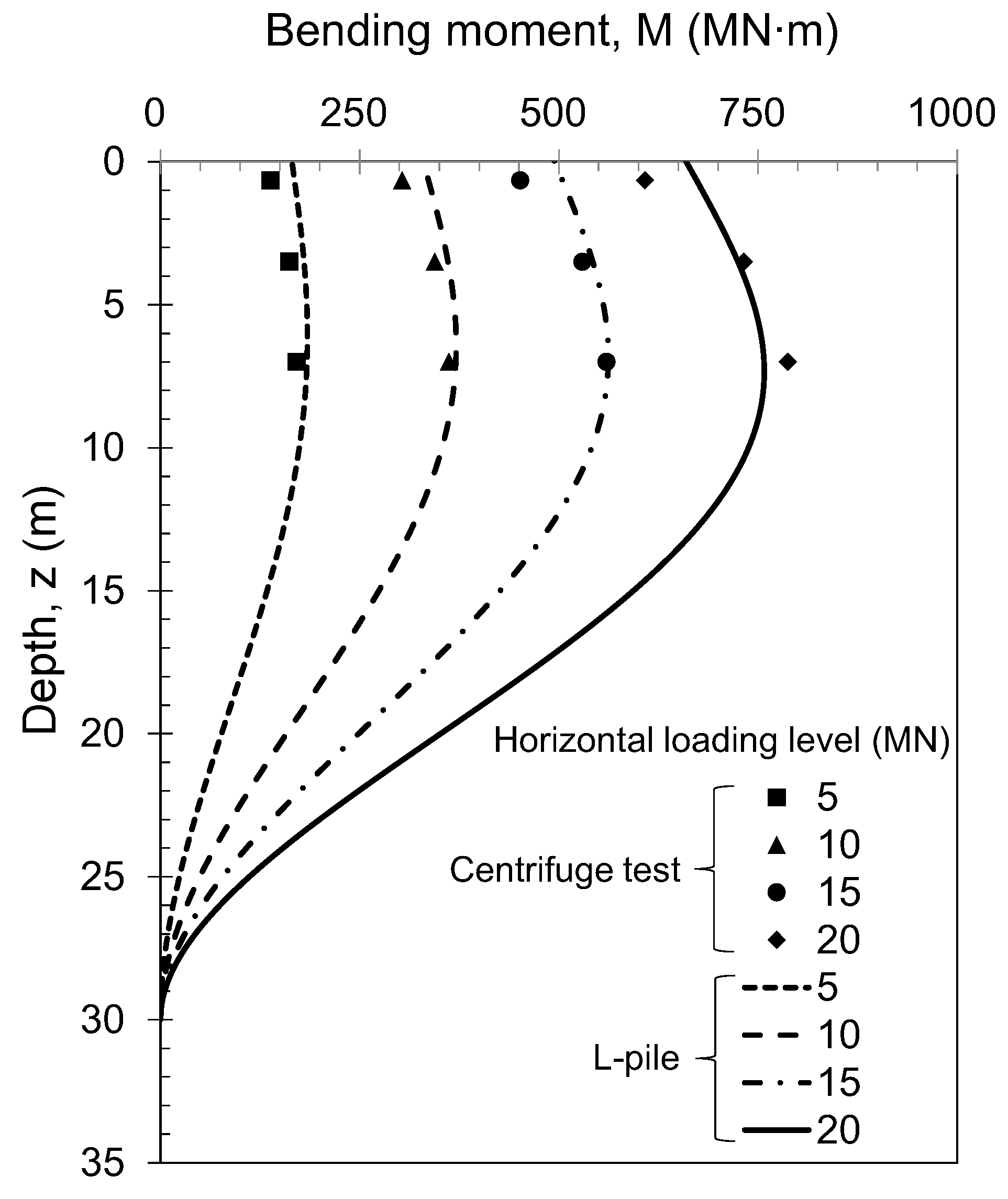

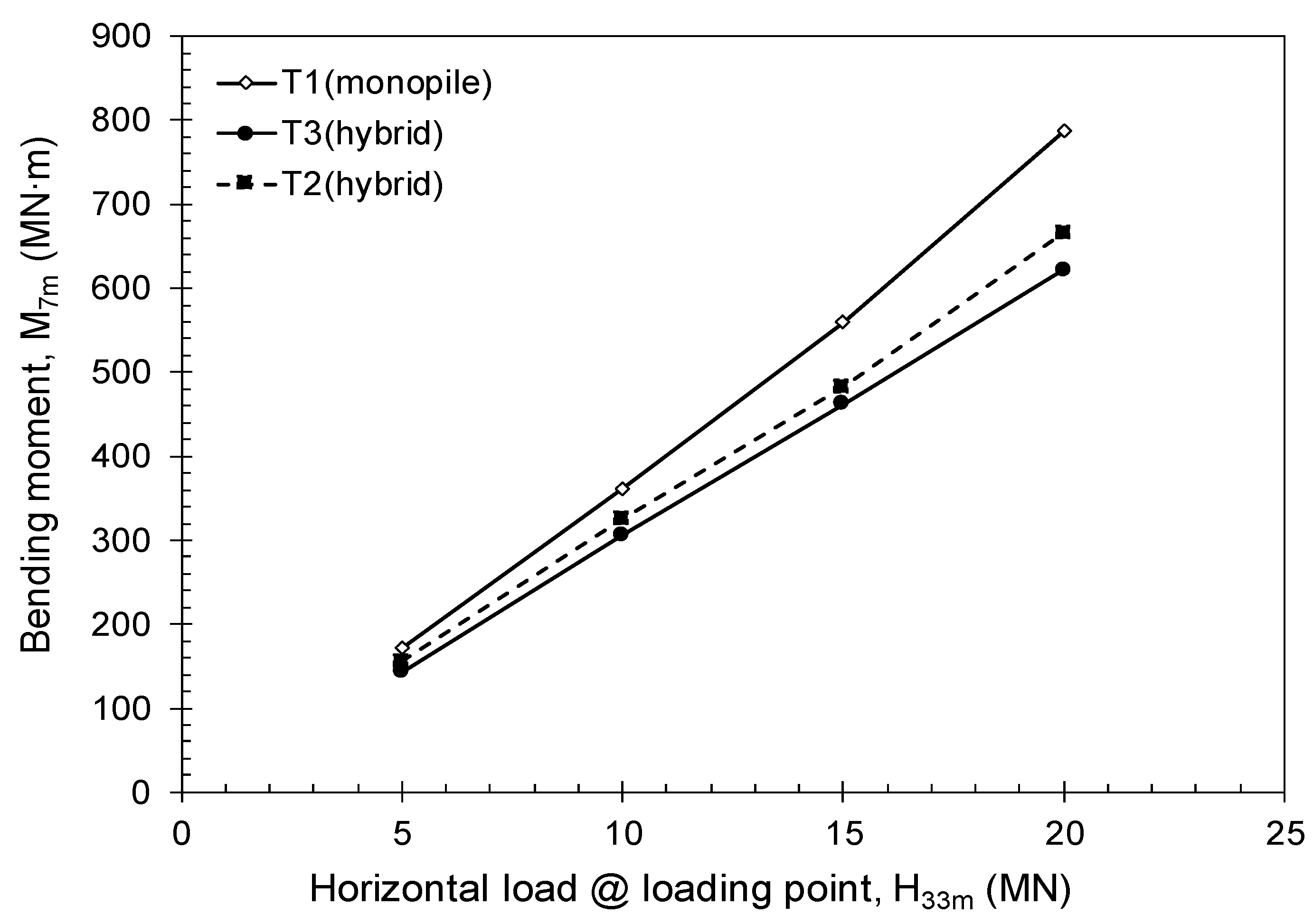

3.3. Bending Moment Acting on the Monopile

3.4. Load Sharing Mechanism of Appendages

4. Conclusions

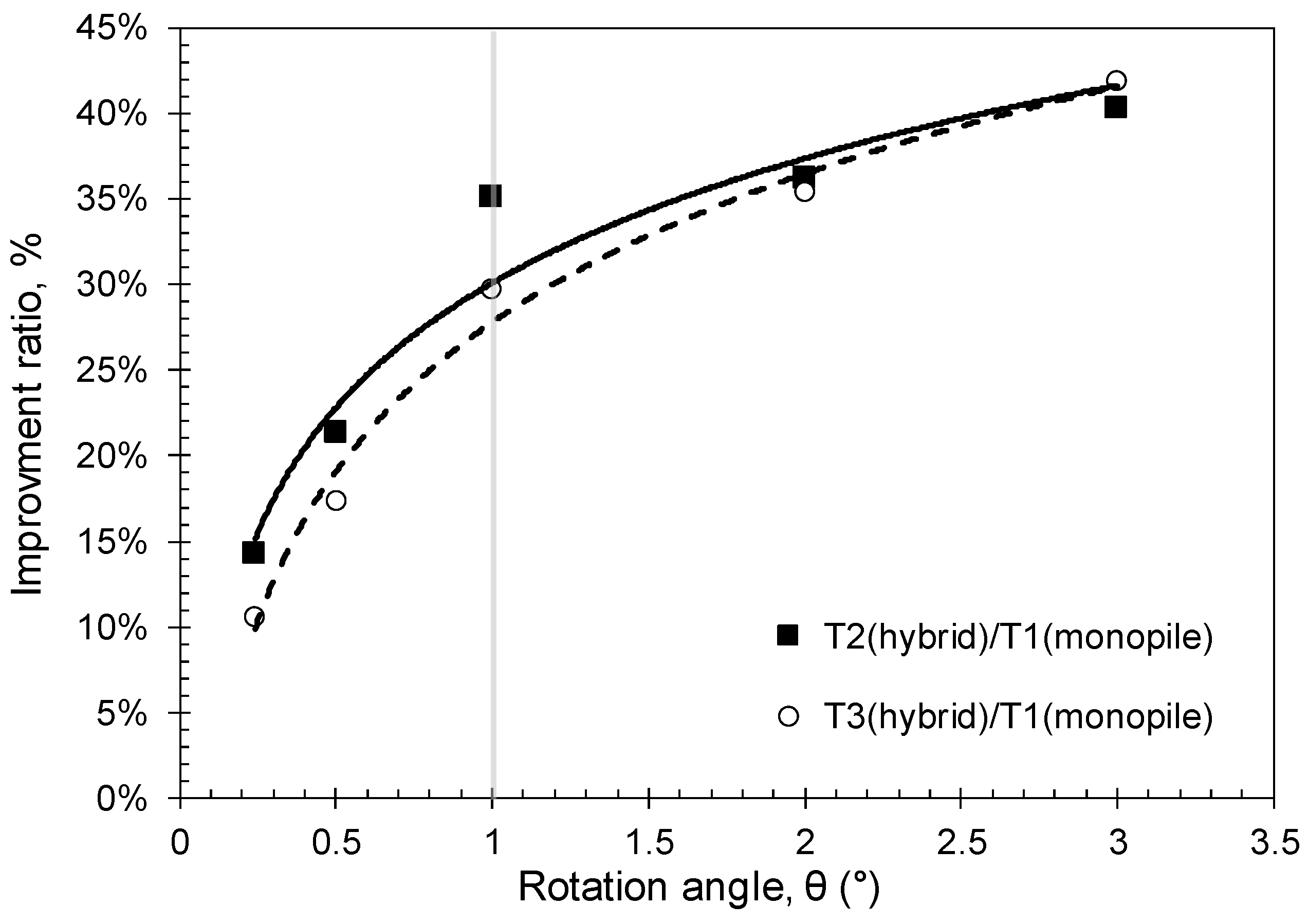

- The yield resistance of the hybrid monopile was 1.10–1.23 times greater than that of the typical monopile in loose silty sand regardless of the lateral load direction. In addition, as the rotation angle increased, the bearing capacity improvement ratio of the hybrid monopile compared to the monopile significantly increased, thereby confirming the bearing capacity improvement effect of the hybrid monopile.

- The hybrid monopile had a yield resistance 1.10–1.23 times greater than the conventional monopile in loose silty sand, independent of the lateral load direction. Furthermore, as the angle of rotation increased, the hybrid monopile showed a significantly higher load capacity than the conventional monopile, confirming the effectiveness of the hybrid monopile in improving load bearing capacity.

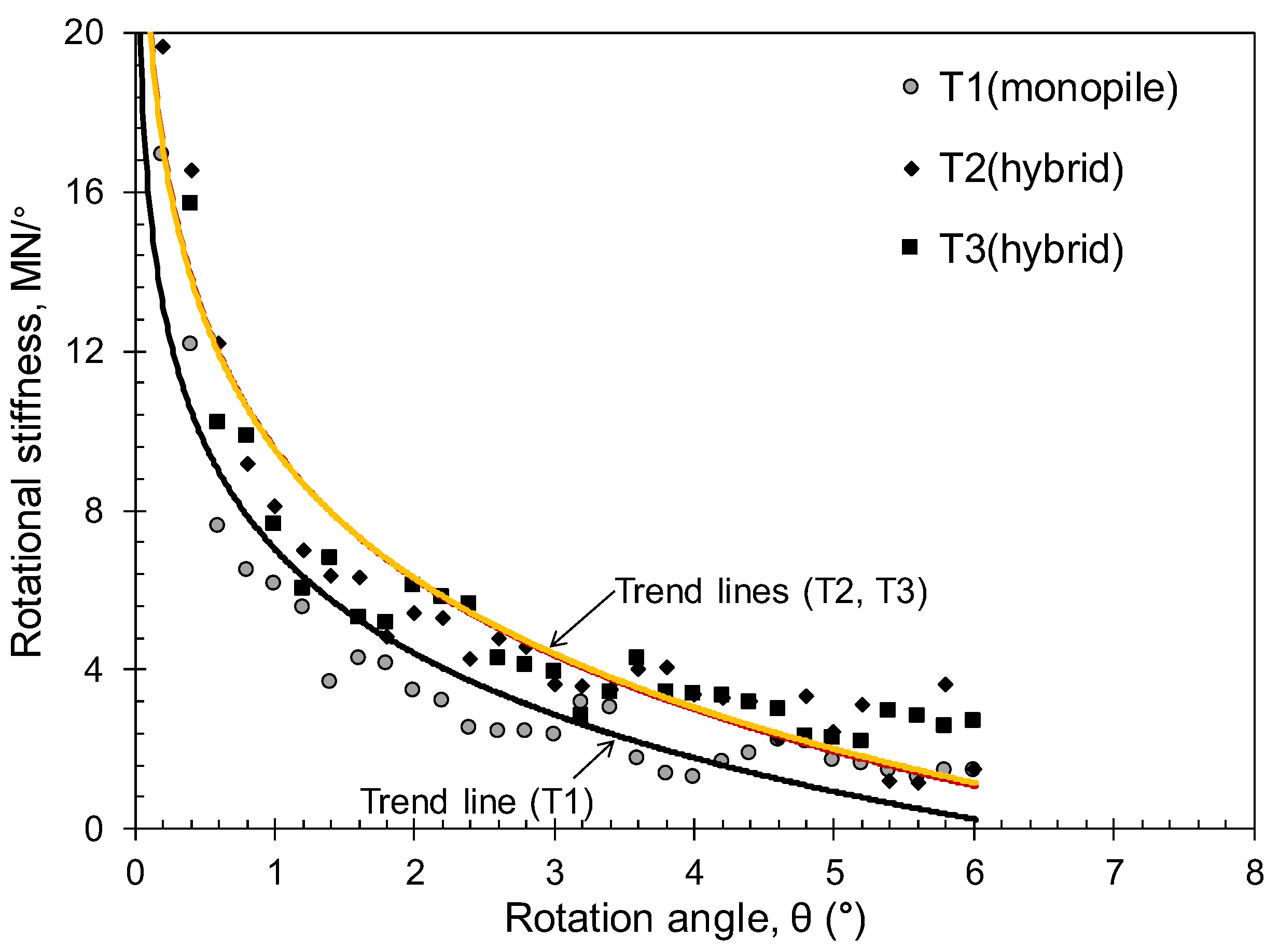

- The rotational stiffness of the hybrid monopile was approximately 1.6 times higher than that of the monopile. This appeared to be because the additional structure improved the resistance performance against the lateral load.

- The appendage of the hybrid monopile distributes the external load to the soil, thereby reducing the maximum moment acting on the monopile and improving structural stability.

- When the ground failure results were observed after the centrifuge model tests, it was confirmed that the additional structure of the hybrid monopile could induce larger ground resistance compared to the monopile by increasing the area of the ground failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Forum Offshore Wind. Global Offshore Wind Report 2021. Available online: https://wfo-global.org/wp-content/uploads/2022/02/WFO_Global-Offshore-Wind-Report-2021.pdf (accessed on 17 July 2023).

- Matlock, H. Correlation for design of laterally loaded piles in soft clay. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 21–23 April 1970; pp. 77–94. [Google Scholar]

- Reese, L.C.; Cox, W.R.; Koop, F.D. Analysis of Laterally Loaded Piles in Sand. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–7 May 1974; pp. 473–483. [Google Scholar]

- API. Geotechnical and Foundation Design Considerations, ANSI/API Recommended Practice 2 GEO, 1st ed.; API: Washington, DC, USA, 2011. [Google Scholar]

- DNV. Support Structures for Wind Turbines (DNVGL-ST-0126); Det Norske Veritas: Bærum, Norway, 2018. [Google Scholar]

- Kim, J.H.; Jeong, Y.H.; Ha, J.G.; Park, H.J. Evaluation of Soil–Foundation–Structure Interaction for Large Diameter Monopile Foundation Focusing on Lateral Cyclic Loading. J. Mar. Sci. Eng. 2023, 11, 1303. [Google Scholar] [CrossRef]

- Jostad, H.P.; Grimstad, G.; Andersen, K.H.; Saue, M.; Shin, Y.; You, D. A FE procedure for foundation design of offshore structures–applied to study a potential OWT monopile foundation in the Korean Western Sea. Geotech. Eng. J. SEAGS AGSSEA 2014, 45, 63–72. [Google Scholar]

- Wang, X.; Zeng, X.; Li, X.; Li, J. Investigation on offshore wind turbine with an innovative hybrid monopile foundation: An experimental based study. Renew. Energy 2019, 132, 129–141. [Google Scholar] [CrossRef]

- Byrne, B.; McAdam, R.; Burd, H.; Houlsby, G.; Martin, C.; Zdravković, L.; Taborda, D.; Potts, D.; Jardine, R.; Sideri, M.; et al. New design methods for large diameter piles under lateral loading for offshore wind applications. In Proceedings of the International Symposium on Frontiers in Offshore Geotechnics, Oslo, Norway, 10–12 June 2015; pp. 705–710. [Google Scholar]

- Duhrkop, J.; Grabe, J. Improving of lateral bearing capacity of monopiles by welded wings. In Proceedings of the 2nd International Conference on Foundations, Las Vegas, NV, USA, 24–27 June 2008; HIS BRE Press: Garston, UK, 2008; pp. 849–860. [Google Scholar]

- Dührkop, J.; Grabe, J. Design of laterally loaded piles with bulge. In Proceedings of the 28th International Conference on Ocean, Offshore and Arctic Engineering, OMAE, HI, USA, 31 May–6 June 2009. [Google Scholar]

- Bienen, B.; Dührkop, J.; Grabe, J.; Randolph, M.F.; White, D.J. Response of piles with wings to monotonic and cyclic lateral loading in sand. J. Geotech. Geoenviron. Eng. 2012, 138, 364–375. [Google Scholar] [CrossRef]

- Dixon, R.K. Marine Foundations. WO 2005/038146 28 April 2005. [Google Scholar]

- Stone, K.; Newson, T.; Sandon, J. An Investigation of the Performance of a ‘Hybrid’ Monopile-footing Foundation for Offshore Structures. In Proceedings of the 6th International Offshore Site Investigation and Geotechnics Conference: Confronting New Challenges and Sharing Knowledge, London, UK, 11–13 September 2007; pp. 11–13. [Google Scholar]

- Arshi, H.S.; Stone, K.J.L. Lateral resistance of hybrid monopile-footing foundations in cohesionless soils for offshore wind turbine. In Proceedings of the 7th International Conference on Offshore Site Investigation and Geotechnics, London, UK, 2–6 September 2012. [Google Scholar]

- Arshi, H.S.; Stone, K.J.L.; Vaziri, M.; Newson, T.A.; El-Marassi, M.; Taylor, R.N.; Goodey, R.J. Modelling of monopile-footing foundation system for offshore structures in cohesionless soils. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013. [Google Scholar]

- Wang, X.; Zeng, X.; Li, J.; Yang, X. Lateral bearing capacity of hybrid monopile-footing foundation for offshore wind turbines by centrifuge modelling. Ocean Eng. 2018, 148, 182–192. [Google Scholar] [CrossRef]

- Wang, X.; Zeng, X.; Yang, X.; Li, J. Feasibility study of offshore wind turbines with hybrid monopile foundation based on centrifuge modeling. Appl. Energy 2018, 209, 127–137. [Google Scholar] [CrossRef]

- Li, L.C.; Liu, X.; Liu, H.; Wu, W.B.; Lehane, B.M.; Jiang, G.S.; Xu, M.J. Experimental and numerical study on the static lateral performance of monopile and hybrid pile foundation. Ocean Eng. 2022, 255, 111461. [Google Scholar] [CrossRef]

- Chen, D.; Gao, P.; Huang, S.S.; Li, C.S.; Yu, X.G. Static and dynamic loading behavior of a hybrid foundation for offshore wind turbines. Mar. Struct. 2020, 71, 102727. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, G.; Yu, Y.; Shi, L. Model test study on bearing capacity and deformation characteristics of symmetric pile–bucket foundation subjected to cyclic horizontal load. Symmetry 2021, 13, 1647. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, Y.-J.; Park, J.; Lee, J.-H.; Kwak, T.; Kim, J.-H. Experimental and Finite Element-Based Investigation on Lateral Behaviors of a Novel Hybrid Monopile. Energies 2022, 15, 9095. [Google Scholar] [CrossRef]

- Kim, D.S.; Kim, N.R.; Choo, Y.W.; Cho, G.C. A newly developed state-of-the-art geotechnical centrifuge in Korea. KSCE J. Civ. Eng. 2013, 17, 77–84. [Google Scholar] [CrossRef]

- Garnier, J.; Gaudin, C.; Springman, S.M.; Culligan, P.J.; Goodings, D.; Konig, D.; Kuter, R.; Phillips, M.F.; Randolph, M.F.; Thorel, L. Catalogue of scaling laws and similitude questions in geotechnical centrifuge modelling. Int. J. Phys. Model. Geotech. 2007, 7, 1–23. [Google Scholar] [CrossRef]

- Kishida, H.; Uesugi, M. Tests of the interface between sand and steel in the simple shear apparatus. Géotechnique 1987, 37, 4–52. [Google Scholar] [CrossRef]

- Uesugi, M.; Kishida, H.; Uchikawa, Y. Friction between dry sand and concrete under monotonic and repeated loading. Soils Found. 1990, 30, 115–128. [Google Scholar] [CrossRef]

- Subba Rao, K.; Rao, K.; Allam, M.; Robinson, R. Interfacial friction between sands and solid surfaces. Proc. Inst. Civ. Eng. Geotech. Eng. 1998, 131, 75–82. [Google Scholar] [CrossRef]

- Porcino, D.; Fioravante, V.; Ghionna, V.N.; Pedroni, S. Interface behavior of sands from constant normal stiffness direct shear tests. Geotech. Test. J. 2003, 26, 289–301. [Google Scholar]

- Gavin, K.G. Experimental Investigations of Open and Closed-Ended Piles in Sand. Ph.D. Thesis, Trinity College, University of Dublin, Dublin, Ireland, 1998. [Google Scholar]

- Lehane, B.M.; Gavin, K.G. Base Resistance of Jacked Pipe Piles in Sand. J. Geotech. Geoenviron. Eng. 2001, 127, 473–480. [Google Scholar] [CrossRef]

- Arany, L.; Bhattacharya, S.; Macdonald, J.H.; Hogan, S.J. Closed form solution of Eigen frequency of monopile supported offshore wind turbines in deeper waters incorporating stiffness of substructure and SSI. Soil Dyn. Earthq. Eng. 2016, 83, 18–32. [Google Scholar] [CrossRef]

- Poulos, H.G.; Hull, T.S. The role of analytical geomechanics in foundation engineering. In Proceedings of the 1989 Foundation Engineering Conference, Evanston, IL, USA, 25–29 June 1989; pp. 1578–1606. [Google Scholar]

- Kim, D.-J.; Choo, Y.W.; Kim, J.-H.; Kim, S.; Kim, D.-S. Investigation of monotonic and cyclic behavior of tripod suction bucket foundations for offshore wind towers using centrifuge modeling. J. Geotech. Geoenviron. 2014, 140, 04014008. [Google Scholar] [CrossRef]

- Jeong, Y.H.; Lee, S.W.; Kim, J.H. Centrifuge modeling for the evaluation of the cyclic behavior of offshore wind turbine with tripod foundation. Appl. Sci. 2021, 11, 1718. [Google Scholar] [CrossRef]

- Kim, J.H.; Choo, Y.W.; Kim, D.J.; Kim, D.S. Miniature cone tip resistance on sand in a centrifuge. J. Geotech. Geoenviron. 2016, 142, 04015090. [Google Scholar] [CrossRef]

- Villalobos, F.A. Model Testing of Foundations for Offshore Wind Turbines. Ph.D. Thesis, University of Oxford, Oxford, UK, 2006. [Google Scholar]

- Reese, L.C.; Wang, S.T.; Isenhower, W.M.; Arrellaga, J.A. Computer Program Lpile Plus; Version 5.0 Technical Manual; Ensoft: Austin, TX, USA, 2004. [Google Scholar]

- Choo, Y.W.; Kim, D.; Park, J.H.; Kwak, K.; Kim, J.H.; Kim, D.S. Lateral response of large-diameter monopiles for offshore wind turbines from centrifuge model tests. Geotech. Test. J. 2014, 37, 107–120. [Google Scholar] [CrossRef]

- Haiderali, A.; Cilingir, U.; Madabhushi, G. Lateral and axial capacity of monopiles for offshore wind turbines. Indian Geotech. J. 2013, 43, 181–194. [Google Scholar] [CrossRef]

| Items | Specifications |

|---|---|

| Platform radius | 5.0 m |

| Maximum capacity | 240 g-tons |

| Maximum acceleration | 130 g with 1300 kg payload |

| Maximum model payload | 2400 kg up to 100 g |

| Type | Item | Prototype | Model (1/64.5) * | |

|---|---|---|---|---|

| Monopile | External diameter (Do,p) | 7.07 m | 109.6 mm | |

| Length (Lpile) ** | 30 m | 465.1 mm | ||

| Tip thickness (tpile) | 104.5 mm | 1.62 mm | ||

| Loading height from the seabed (e) | 33 m | 515.6 mm | ||

| Elastic modulus (E) | 210 GPa | 210 GPa | ||

| Moment of inertia (I) | 13.29 m4 | 7.68 × 10−7 m4 | ||

| Hybrid monopile | Monopile | External diameter (Do,p) | 7.07 m | 109.6 mm |

| Tip thickness (tpile) | 104.4 mm | 1.6 mm | ||

| Embedded depth (z) | 30 m | 465.1 mm | ||

| Loading height from the seabed (e) | 33 m | 516.8 mm | ||

| Supplementary buckets | Internal diameter (Di,b) | 5 m | 77.5 mm | |

| Length (Lb) | 7 m | 108.5 mm | ||

| Tip thickness (tbucket) | 104.1 mm | 1.6 mm | ||

| Pile–bucket spacing (s) | 2.5 m | 38.76 mm | ||

| Items | Specifications |

|---|---|

| Soil classification (USCS) | SM |

| Maximum dry density, ρd,max (g/cm3) | 1.65 |

| Minimum dry density, ρd,min (g/cm3) | 1.20 |

| Mean grain size, d50 (mm) | 0.08 |

| Specific gravity (Gs) | 2.67 |

| Uniformity coefficient (Cu) | 2.11 |

| Mean particle diameter, D50 (mm) | 0.08 |

| Permeability, k (m/s) | 1.5–2.0 × 10−6 |

| Peak friction angle (, °) * | 35.8 |

| Residual friction angle (, °) | 35.5 |

| Test Name | Loading Direction (°) | Soil Specimen Height (mm) | Loading Height from the Seabed, m for Prototype | Soil Water Contents (%) | Wetted Soil Density (tf/m3) | Soil Relative Density, Dr * (%) |

|---|---|---|---|---|---|---|

| T1 (MP) (Monopile) | 0 | 550 | 33 m | 16.3 | 1.59 | 45.7 |

| T2 (HB1) (Hybrid monopile) | 0 (direction of bucket) | 18.4 | 1.59 | 39.9 | ||

| T3 (HB2) (Hybrid monopile) | 180 (direction of bucket to bucket) | 18.7 | 1.59 | 39.2 |

| Test Name | Loading Direction (°) | Lateral Bearing Capacity, Py (MN) | Improvement Ratio | Resulting Moment Capacity, My * (MN·m) | Improvement Ratio ** |

|---|---|---|---|---|---|

| T1 (MP) (Monopile) | 0 | 13.3 | - | 442.4 | - |

| T2 (HB1) (Hybrid monopile) | 0 (direction of bucket) | 14.6 | 1.23 | 495.6 | 1.12 |

| T3 (HB2) (Hybrid monopile) | 180 (direction of bucket to bucket) | 16.4 | 1.10 | 596.5 | 1.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-H.; Kwak, T.-Y.; Jeong, Y.-J.; Park, J.; Kim, J.-H. A Study on the Lateral Load Capacity of a Novel Hybrid Monopile via a Centrifuge Model Test. Energies 2023, 16, 7234. https://doi.org/10.3390/en16217234

Lee J-H, Kwak T-Y, Jeong Y-J, Park J, Kim J-H. A Study on the Lateral Load Capacity of a Novel Hybrid Monopile via a Centrifuge Model Test. Energies. 2023; 16(21):7234. https://doi.org/10.3390/en16217234

Chicago/Turabian StyleLee, Ju-Hyung, Tae-Young Kwak, Youn-Ju Jeong, Joonsang Park, and Jae-Hyun Kim. 2023. "A Study on the Lateral Load Capacity of a Novel Hybrid Monopile via a Centrifuge Model Test" Energies 16, no. 21: 7234. https://doi.org/10.3390/en16217234

APA StyleLee, J.-H., Kwak, T.-Y., Jeong, Y.-J., Park, J., & Kim, J.-H. (2023). A Study on the Lateral Load Capacity of a Novel Hybrid Monopile via a Centrifuge Model Test. Energies, 16(21), 7234. https://doi.org/10.3390/en16217234