Geothermal Energy and Its Potential for Critical Metal Extraction—A Review

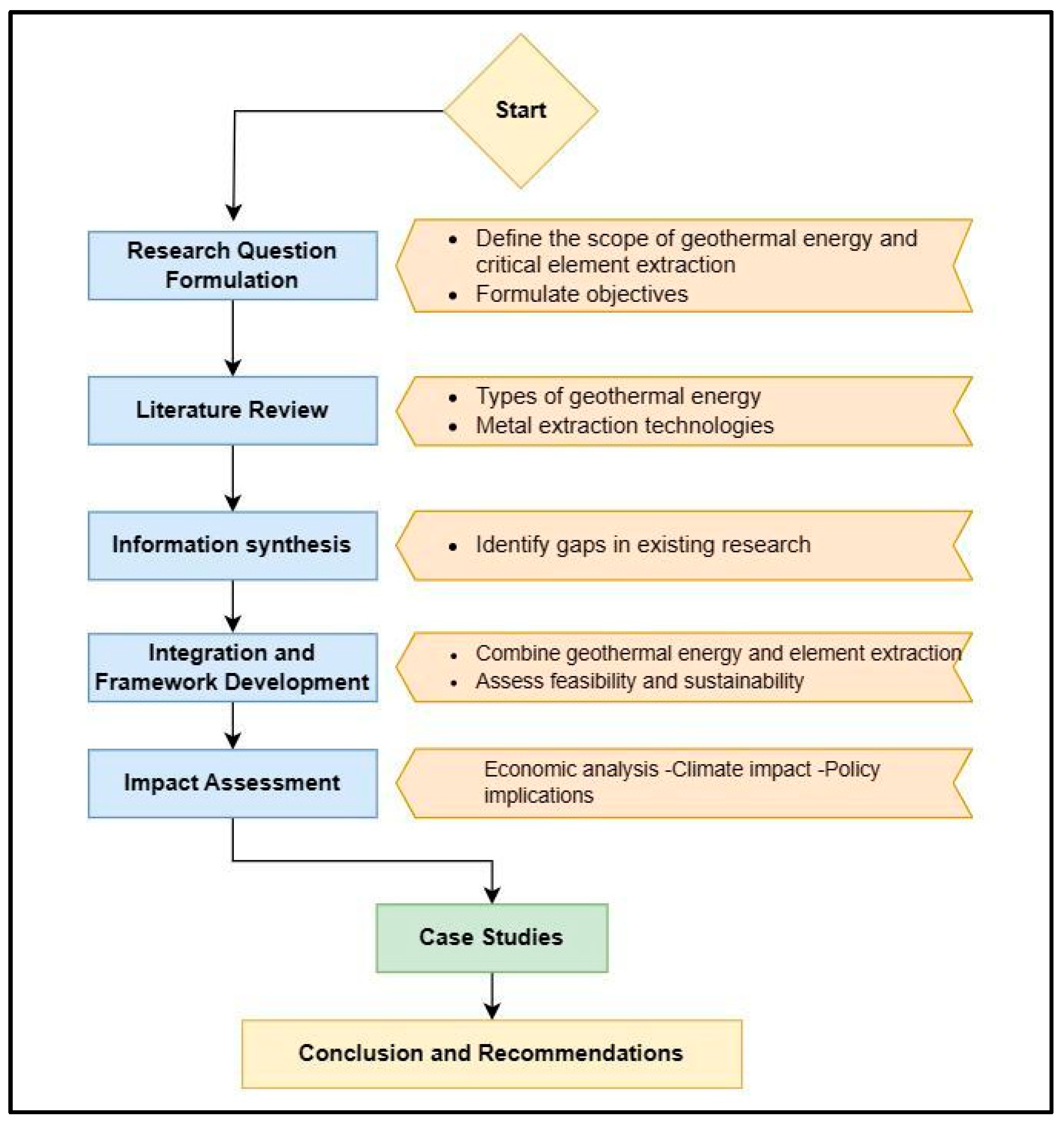

Abstract

1. Introduction

2. The Role of Metals in Human History and Their Extraction Technologies

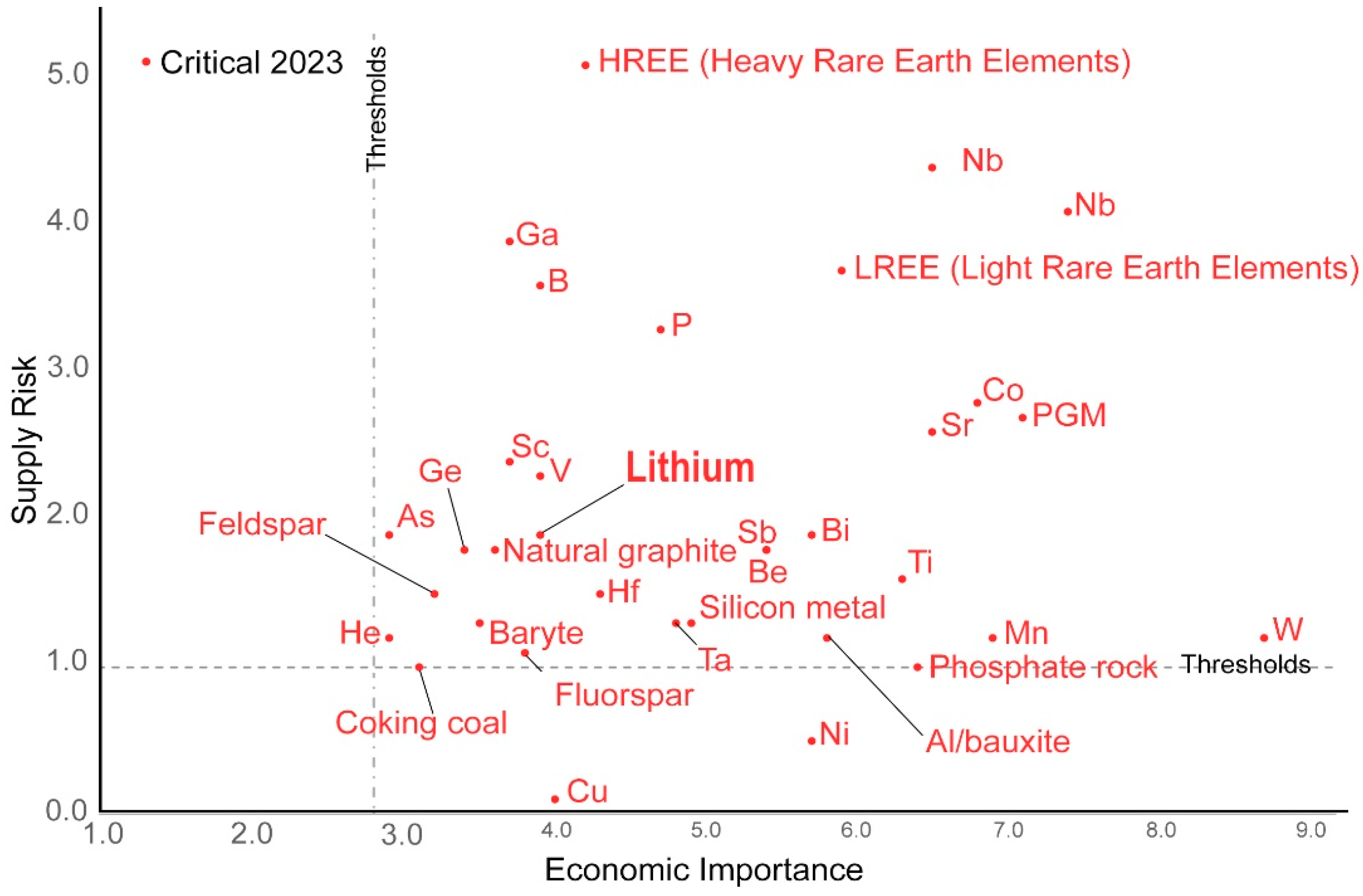

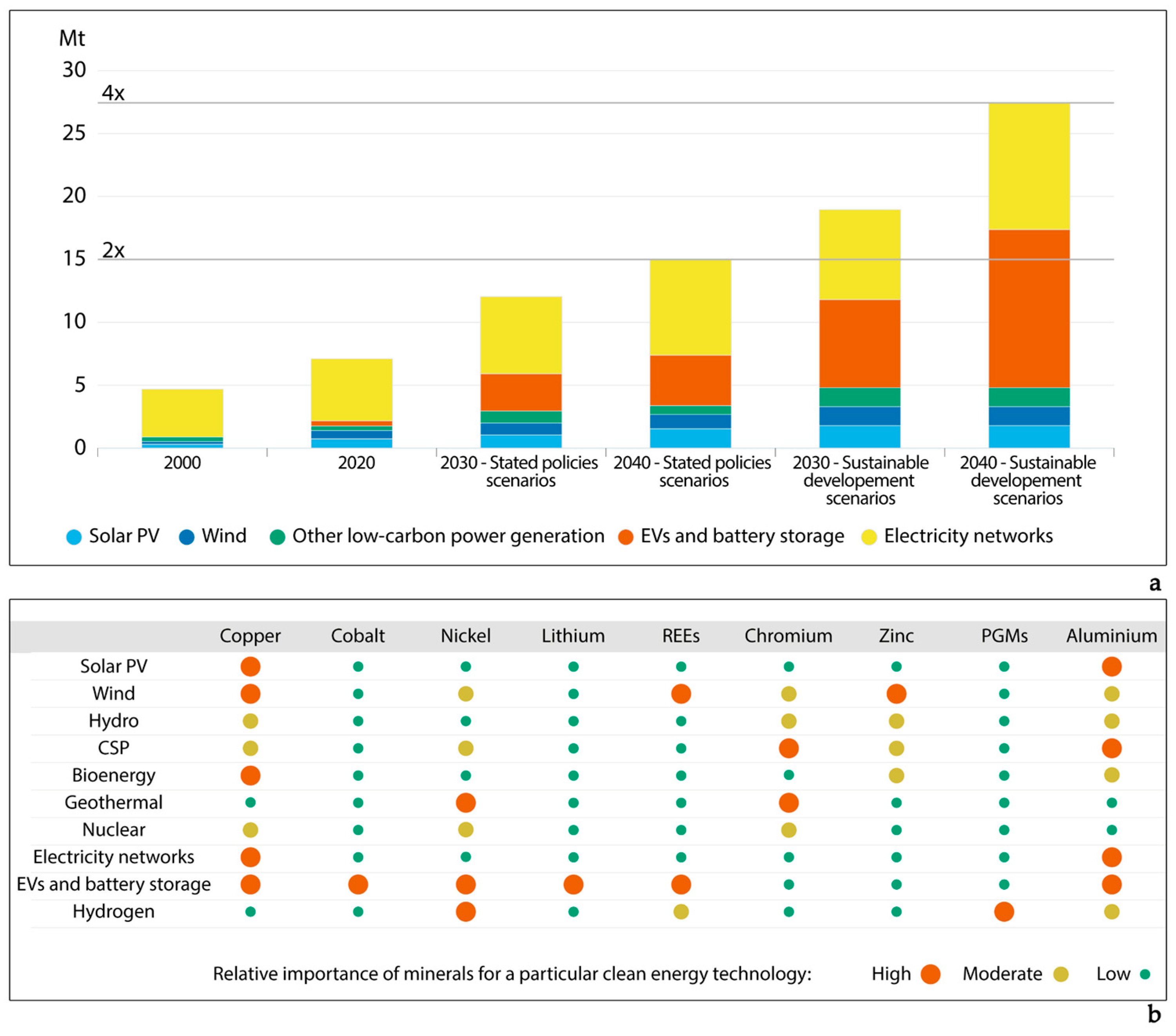

2.1. Importance of Metals

| Mine Name | Depth (km) | Country | Metal Mined |

|---|---|---|---|

| Mponeng Gold Mine | 4 | South Africa | gold |

| TauTona Mine | 3.9 | South Africa | gold |

| Savuka Gold Mine | 3.7 | South Africa | gold |

| East Rand Mine | 3.59 | South Africa | gold |

| Driefontein Mine | 3.42 | South Africa | gold, uranium |

| Kusasalethu Mine | 3.39 | South Africa | gold |

| Empire Mine | 3.36 | United States | gold |

| KDC Mine | 3.35 | South Africa | gold, uranium |

| Blyvooruitzicht Mine | 3.21 | South Africa | gold, uranium |

| Kolar Gold Fileds | 3.2 | India | gold |

2.2. A New Method for Metal Extraction

3. The Nature and Classification of Geothermal Energy

3.1. The Source of Geothermal Energy

3.2. Sustainability, Renewability

3.3. Types of Geothermal Energy

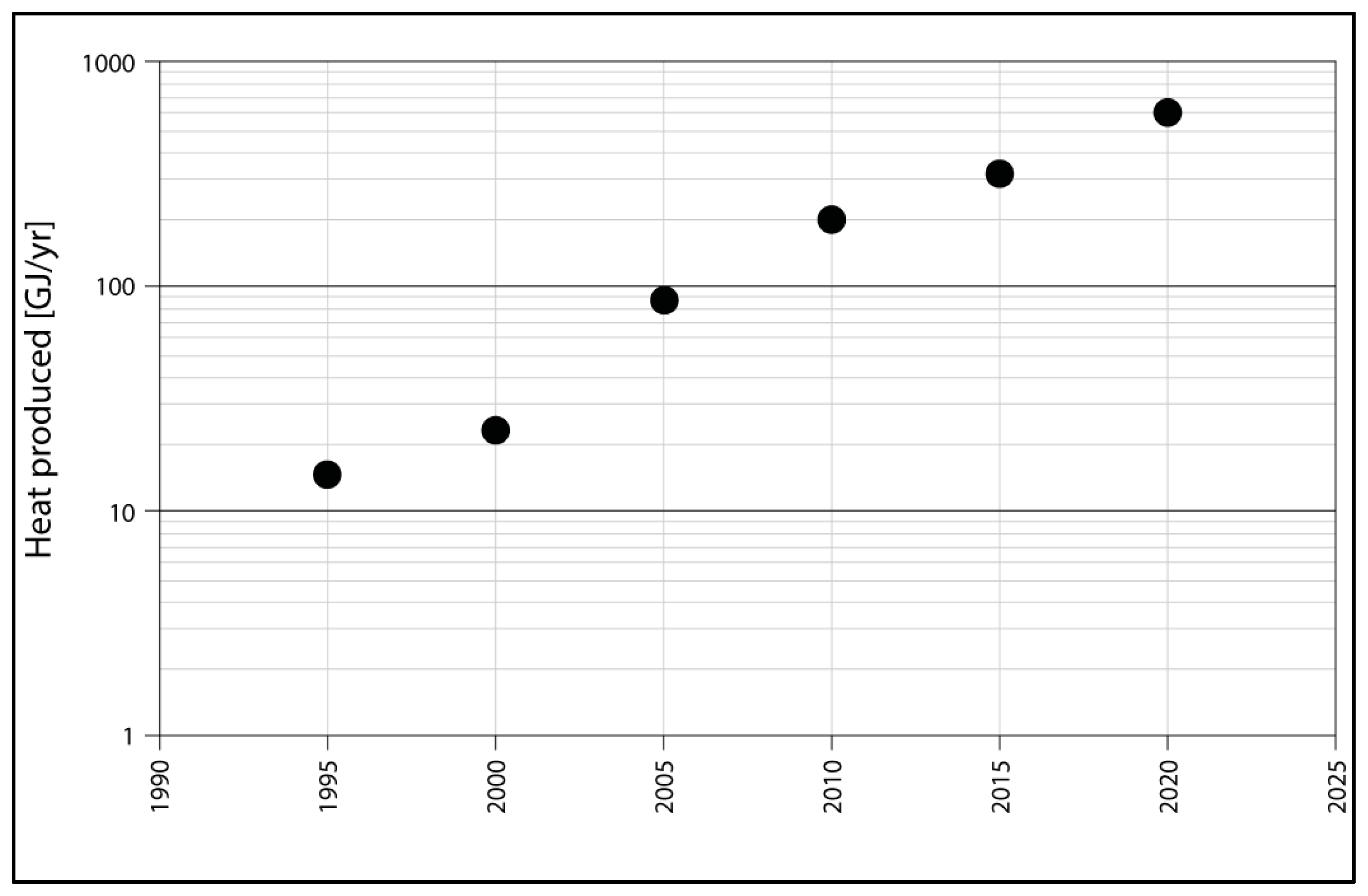

3.3.1. Shallow Systems

3.3.2. Hydrothermal Systems

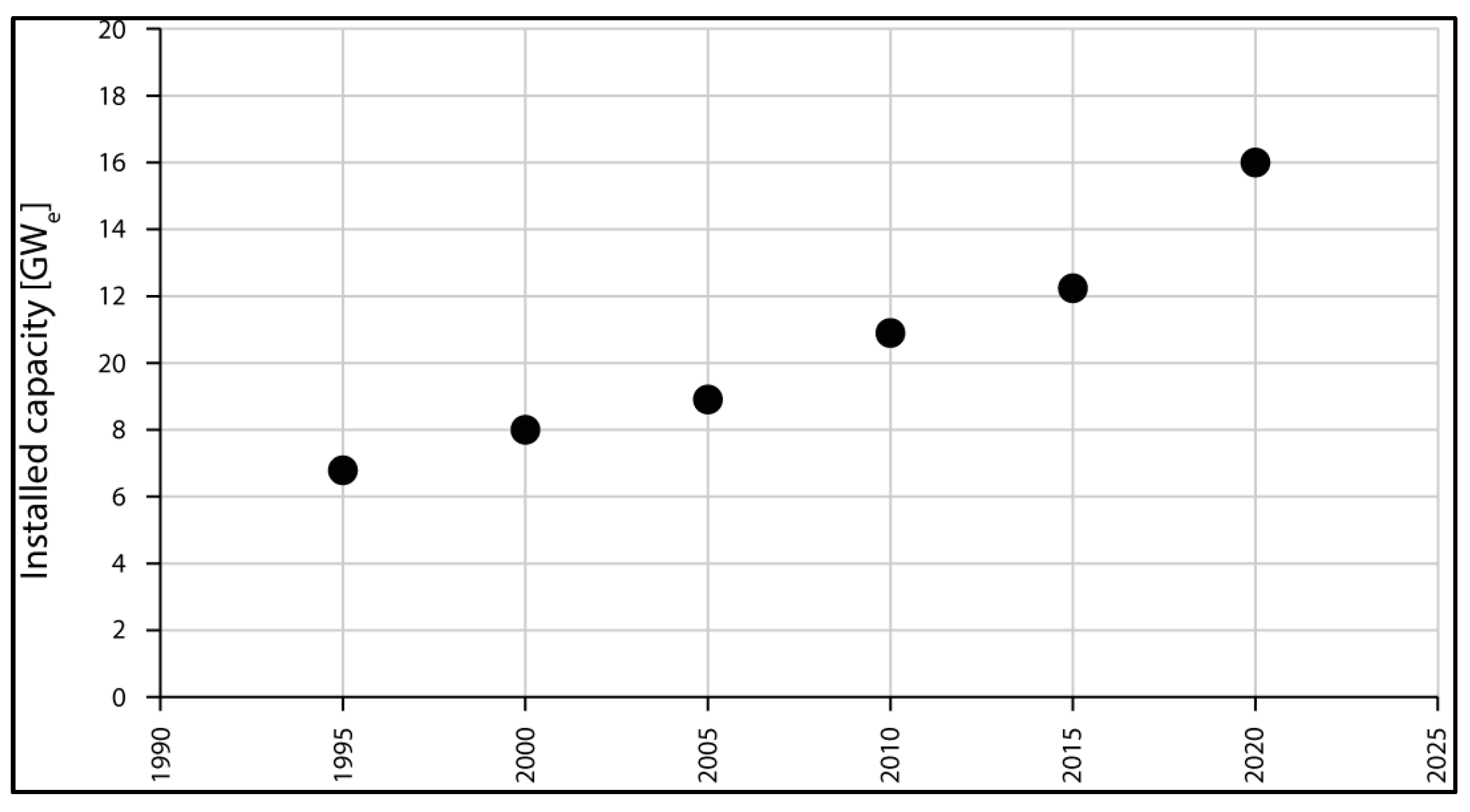

Geothermal Power Generation

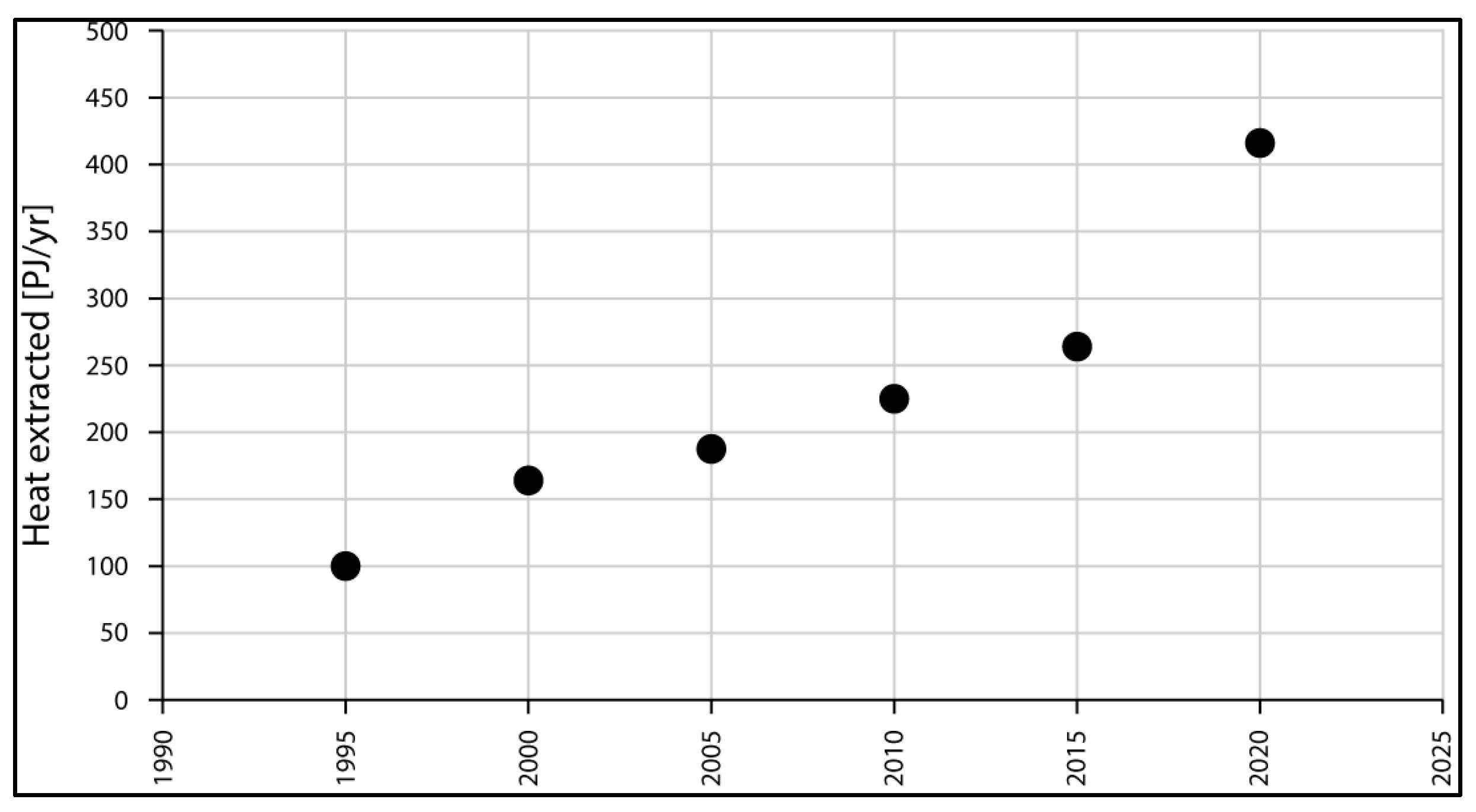

Geothermal Direct Use (Besides GHPs)

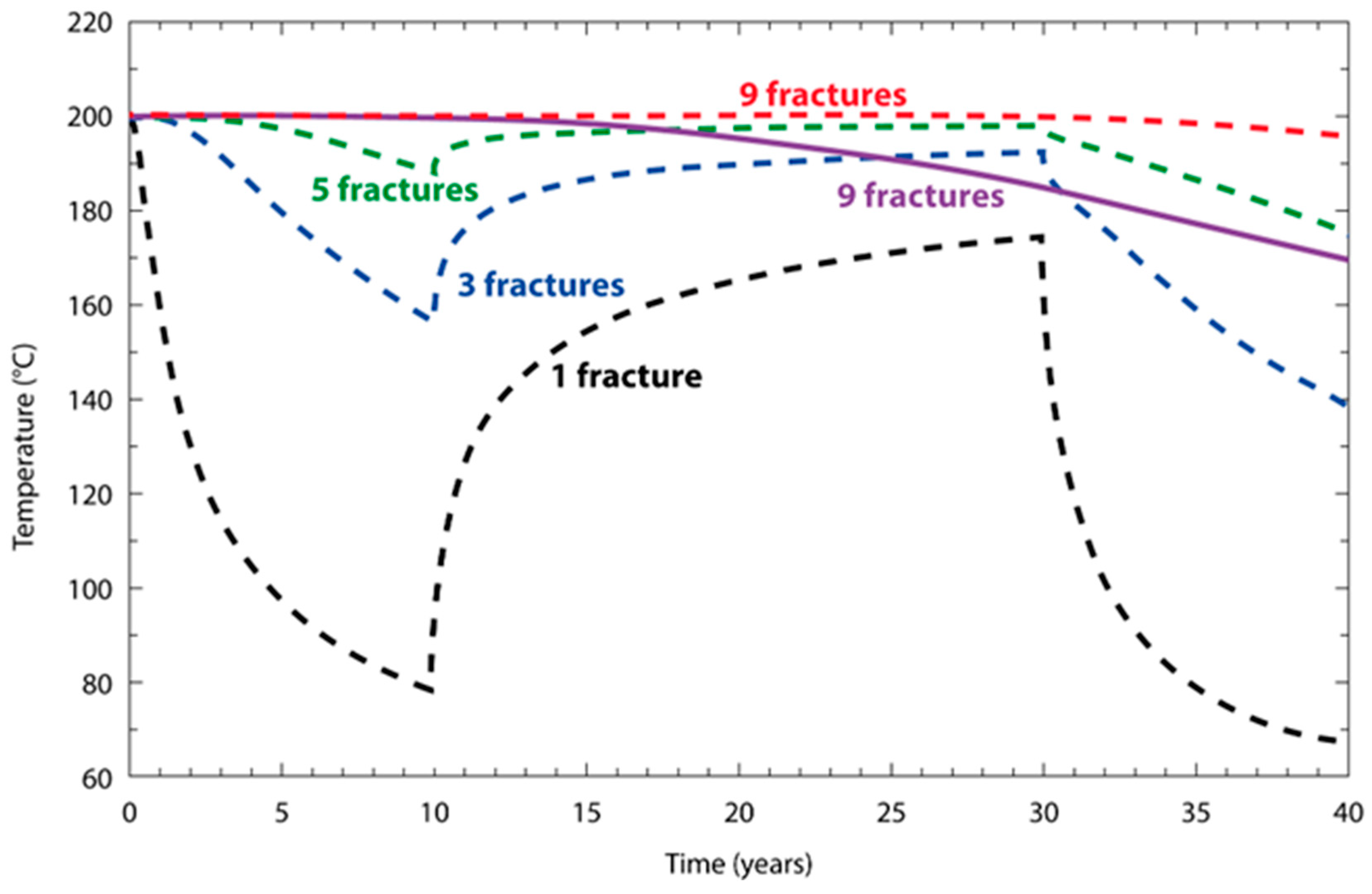

3.3.3. Petrothermal Systems

| Parameters | Values |

|---|---|

| Fluid production rate | 100 kg/s |

| Fluid temperature | 150–200 °C |

| Separation between wells | 600 m |

| Flow impedance | <0.1 MPa/kg/s |

| Water loss | <10% |

| Heat exchanger rock volume | >300 × 106 m3 |

| Total heat exchanger surface area | >10 × 106 m2 |

- The development of custom-designed PEGS heat exchangers that can be strategically located and are capable of functioning under varying local subsurface conditions (lithology, temperature, stress field, natural seismicity, etc.), with minimized induced seismicity;

- Evaluation of the long-term performance metrics of PEGS heat exchangers, particularly with regard to productivity and environmental impact;

- Assessment of the recovery factors of PEGS, defined as the ratio of extractable heat to the total heat in place. Contemporary estimations, such as those by Ladislaus Rybach [80], posit a mere 2% recovery factor, which is economically nonviable;

- Resolving scaling issues that affect both near-wellbore regions and the casing and tubing infrastructure;

- Enlarging the plant capacity from a modest few MWe to a more industrially relevant range of several tens to hundreds of MWe.

4. Combined Geothermal Energy and Mineral Extraction

4.1. Reservoir Stimulation

- Hydraulic Fracturing or Hydroshearing;

- Chemical or Acid Treatment;

- Thermal Fracturing (Secondary Treatment).

4.2. Metal Leaching Technologies

4.3. New Technologies

4.4. Reservoir Operation

- While pre-existing, highly permeable fracture zones and fault lines have been intermittently observed, their incidence is not consistent across all sites;

- There is a general trend indicating an enhancement in fluid injectivity and productivity within the investigated boreholes. However, this is substantiated predominantly in the immediate vicinity of the wells;

- The conditions beyond the immediate perimeter of the heat exchangers remain ambiguous;

- Three-dimensional mapping of microseismic activities during the hydraulic stimulation process has provided critical insights into the spatial expansion and morphological development of the heat exchanger, extending up to a kilometer from the injection well;

- Anomalies such as thermal breakdowns or loss of circulated water have also been documented;

- There were substantial variances in the heat exchanger volumes, which translated into production flow rates ranging between 1 and 25 L per second;

- Importantly, none of the field-scale experiments resulted in adverse environmental consequences, such as groundwater contamination, in contrast to what is often observed in shale-gas fracking operations.

5. Economic and Climate Impacts, Future Opportunities

5.1. Geothermal Energy and Sustainable Mining for SDG 7

5.2. Achieving a Low-Carbon Economy and Sustainable Mining Practices

5.3. Stakeholder Collaboration for Effective Geothermal Energy Governance

5.4. Future Challenges and Opportunities

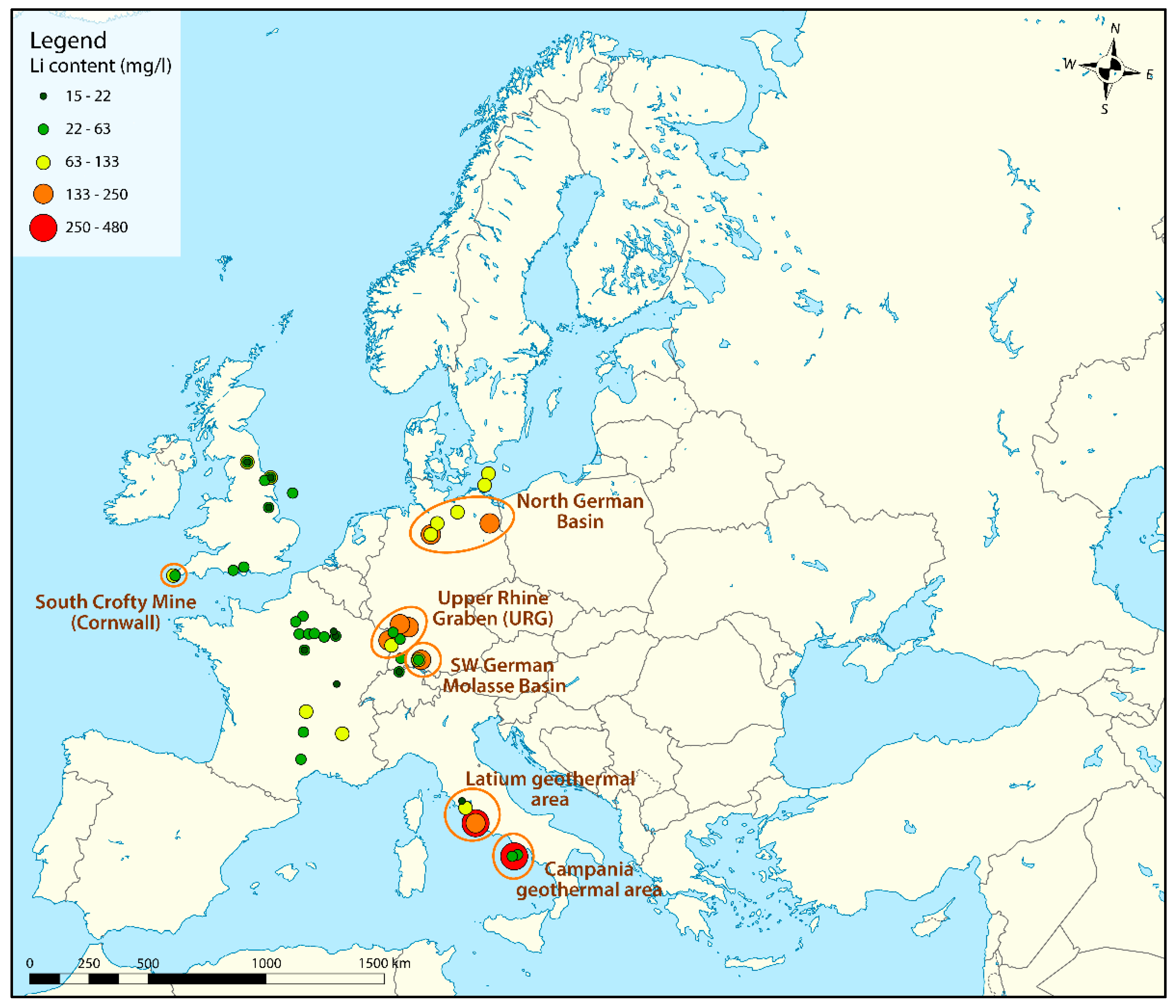

6. Projects, Future Options

- Precambrian Fennoscandian Shield province;

- Early Paleozoic Caledonian province;

- Late Paleozoic Variscan province;

- Mesozoic–Cenozoic Alpine province.

6.1. Upper Rhine Graben

6.2. Cornwall

6.3. Latium Geothermal Area

7. Discussion

7.1. Challenges in Upscaling: Spatial Constraints and Operational Limitations

7.2. Gaps in Deep Ore Body Understanding

7.3. Challenges in Resource Longevity

7.4. Economic Barriers to Implementation

7.5. The Necessity of a Geothermal Drilling Mitigation Risk Fund

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fridleifsson, I.; Bertani, R.; Huenges, E.; Lund, J.; Ragnarsson, Á.; Rybach, L. The Possible Role and Contribution of Geothermal Energy to the Mitigation of Climate Change. In Proceedings of the IPCC Scoping Meeting on Renewable Energy Sources, Lübeck, Germany, 20–25 January 2008; pp. 59–80. Available online: https://www.researchgate.net/publication/284685252 (accessed on 13 September 2023).

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Seyboth, K.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schlömer, S.; von Stechow, C.; et al. Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change, 1st ed.; Cambridge University Press: Cambridge, UK, 2011; ISBN 978-1-107-02340-6. [Google Scholar]

- Kulasekara, H.; Seynulabdeen, V. A Review of Geothermal Energy for Future Power Generation. In Proceedings of the 2019 5th International Conference on Advances in Electrical Engineering (ICAEE), Dhaka, Bangladesh, 26–28 September 2019; pp. 223–228. [Google Scholar]

- Kagel, A.; Bates, D.; Gawell, K. A Guide to Geothermal Energy and the Environment; Geothermal Energy Association: Washington, DC, USA, 2005. [Google Scholar]

- Barbier, E. Nature and Technology of Geothermal Energy: A Review. Renew. Sustain. Energy Rev. 1997, 1, 1–69. [Google Scholar] [CrossRef]

- Finster, M.; Clark, C.; Schroeder, J.; Martino, L. Geothermal Produced Fluids: Characteristics, Treatment Technologies, and Management Options. Renew. Sustain. Energy Rev. 2015, 50, 952–966. [Google Scholar] [CrossRef]

- Bourcier, W.L.; Lin, M.; Nix, G. Recovery of Minerals and Metals from Geothermal Fluids. In Proceedings of the UCRL-CONF-215135, Cincinnati, OH, USA, 8 September 2005. [Google Scholar]

- Bloomquist, R.G. Economic Benefits of Mineral Extraction from Geothermal Brines. In Sohn International Symposium; Advanced Processing of Metals and Materials Volume 6: New, Improved and Existing Technologies: Aqueous and Electrochemical Processing; Washington State University Extension Energy Program: Olympia, WA, USA, 2006; Volume 6, pp. 553–558. [Google Scholar]

- European Commission, Study on the Critical Raw Materials for the EU 2023—Final Report. 2023. Available online: https://single-market-economy.ec.europa.eu/publications/study-critical-raw-materials-eu-2023-final-report_en (accessed on 29 March 2023).

- Khalil, A.; Mohammed, S.; Hashaikeh, R.; Hilal, N. Lithium Recovery from Brine: Recent Developments and Challenges. Desalination 2022, 528, 115611. [Google Scholar] [CrossRef]

- Weinand, J.M.; Vandenberg, G.; Risch, S.; Behrens, J.; Pflugradt, N.; Linßen, J.; Stolten, D. Low-Carbon Lithium Extraction Makes Deep Geothermal Plants Cost-Competitive in Future Energy Systems. Adv. Appl. Energy 2023, 11, 100148. [Google Scholar] [CrossRef]

- Balaram, V. Potential Future Alternative Resources for Rare Earth Elements: Opportunities and Challenges. Minerals 2023, 13, 425. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, C.; Su, P.; Tang, Y.; Huang, Z.; Ma, T. A Review of Acid Mine Drainage: Formation Mechanism, Treatment Technology, Typical Engineering Cases and Resource Utilization. Process Saf. Environ. Prot. 2023, 170, 1240–1260. [Google Scholar] [CrossRef]

- Sanjuan, B.; Gourcerol, B.; Millot, R.; Rettenmaier, D.; Jeandel, E.; Rombaut, A. Lithium-Rich Geothermal Brines in Europe: An Update about Geochemical Characteristics and Implications for Potential Li Resources. Geothermics 2022, 101, 102385. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sharma, G.K. Demand Forecasting Techniques Vis-à-Vis Demand Forecast for Lead. Procedia Earth Planet. Sci. 2015, 11, 418–424. [Google Scholar] [CrossRef][Green Version]

- Ali, S.H.; Giurco, D.; Arndt, N.; Nickless, E.; Brown, G.; Demetriades, A.; Durrheim, R.; Enriquez, M.A.; Kinnaird, J.; Littleboy, A.; et al. Mineral Supply for Sustainable Development Requires Resource Governance. Nature 2017, 543, 367–372. [Google Scholar] [CrossRef]

- Ledésert, B.A.; Hébert, R.L.; Trullenque, G.; Genter, A.; Dalmais, E.; Herisson, J. Editorial of Special Issue “Enhanced Geothermal Systems and Other Deep Geothermal Applications throughout Europe: The MEET Project”. Geosciences 2022, 12, 341. [Google Scholar] [CrossRef]

- Savinova, E.; Evans, C.; Lèbre, É.; Stringer, M.; Azadi, M.; Valenta, R.K. Will Global Cobalt Supply Meet Demand? The Geological, Mineral Processing, Production and Geographic Risk Profile of Cobalt. Resour. Conserv. Recycl. 2023, 190, 106855. [Google Scholar] [CrossRef]

- Yu, D.; Wenhui, X.; Anser, M.K.; Nassani, A.A.; Imran, M.; Zaman, K.; Haffar, M. Navigating the Global Mineral Market: A Study of Resource Wealth and the Energy Transition. Resour. Policy 2023, 82, 103500. [Google Scholar] [CrossRef]

- Home-CRM-Geothermal. Available online: https://crm-geothermal.eu/ (accessed on 24 March 2023).

- Goldberg, V.; Winter, D.; Nitschke, F.; Held, S.; Groß, F.; Pfeiffle, D.; Uhde, J.; Morata, D.; Koschikowski, J.; Kohl, T. Development of a Continuous Silica Treatment Strategy for Metal Extraction Processes in Operating Geothermal Plants. Desalination 2023, 564, 116775. [Google Scholar] [CrossRef]

- Mroczek, E.; Climo, M.; Carey, B. From Waste to Wealth: Commercial Recovery of Products from New Zealand Geothermal Fluids. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 19–24 April 2015. [Google Scholar]

- Di Somma, M.; Buonanno, A.; Caliano, M.; Graditi, G.; Piazza, G.; Bracco, S.; Delfino, F. Stochastic Operation Optimization of the Smart Savona Campus as an Integrated Local Energy Community Considering Energy Costs and Carbon Emissions. Energies 2022, 15, 8418. [Google Scholar] [CrossRef]

- Yin, H.; Hu, L.; Li, Y.; Gong, Y.; Du, Y.; Song, C.; Zhao, J. Application of ORC in a Distributed Integrated Energy System Driven by Deep and Shallow Geothermal Energy. Energies 2021, 14, 5466. [Google Scholar] [CrossRef]

- Eras-Almeida, A.A.; Vásquez-Hernández, T.; Hurtado-Moncada, M.J.; Egido-Aguilera, M.A. A Comprehensive Evaluation of Off-Grid Photovoltaic Experiences in Non-Interconnected Zones of Colombia: Integrating a Sustainable Perspective. Energies 2023, 16, 2292. [Google Scholar] [CrossRef]

- Mehta, K.; Ehrenwirth, M.; Trinkl, C.; Zörner, W. Mapping Potential for Improving Rural Energy Services in Kyrgyzstan: Factors for Achieving Sustainable Development Goals in the Community Context. World 2022, 3, 586–606. [Google Scholar] [CrossRef]

- Plass, W.T. History of Surface Mining Reclamation and Associated Legislation. In Agronomy Monographs; Barnhisel, R.I., Darmody, R.G., Lee Daniels, W., Eds.; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 2015; pp. 1–20. ISBN 978-0-89118-233-7. [Google Scholar]

- Michael, C. The History of Mining: The Events, Technology and People Involved in the Industry That Forged the Modern World; Harriman House Limited: Petersfield, UK, 2012. [Google Scholar]

- Maus, V.; Giljum, S.; Gutschlhofer, J.; Da Silva, D.M.; Probst, M.; Gass, S.L.B.; Luckeneder, S.; Lieber, M.; McCallum, I. A Global-Scale Data Set of Mining Areas. Sci. Data 2020, 7, 289. [Google Scholar] [CrossRef]

- Maus, V.; Giljum, S.; Da Silva, D.M.; Gutschlhofer, J.; Da Rosa, R.P.; Luckeneder, S.; Gass, S.L.B.; Lieber, M.; McCallum, I. An Update on Global Mining Land Use. Sci. Data 2022, 9, 433. [Google Scholar] [CrossRef]

- We Need To Talk About Mining: Death, Dangers & Prevention. Available online: https://www.howden.com/en-us/articles/mining/we-need-to-talk-about-mining (accessed on 12 September 2023).

- Ghorbani, Y.; Nwaila, G.T.; Zhang, S.E.; Bourdeau, J.E.; Cánovas, M.; Arzua, J.; Nikadat, N. Moving Towards Deep Underground Mineral Resources: Drivers, Challenges and Potential Solutions. Resour. Policy 2023, 80, 103222. [Google Scholar] [CrossRef]

- Van Schoor, M.; Nkosi, Z.; Magweregwede, F.; Kgarume, T. Deep-Level Gold and Platinum Mining: The Application of Geophysics in South Africa; Springer International Publishing: Cham, Switzerland, 2022; ISBN 978-3-031-09490-3. [Google Scholar]

- Wagner, H. Deep Mining: A Rock Engineering Challenge. Rock Mech. Rock Eng. 2019, 52, 1417–1446. [Google Scholar] [CrossRef]

- Global Mine Ranking by Depth 2021. Available online: https://www.statista.com/statistics/1343524/deepest-global-mines/ (accessed on 12 September 2023).

- What Is Energy Transition? Available online: https://www.spglobal.com/en/research-insights/articles/what-is-energy-transition (accessed on 12 September 2023).

- Mineral Requirements for Clean Energy Transitions—The Role of Critical Minerals in Clean Energy Transitions—Analysis-IEA. Available online: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions/mineral-requirements-for-clean-energy-transitions (accessed on 12 September 2023).

- Critical and Strategic Raw Materials. Available online: https://www.sgu.se/en/mineral-resources/critical-raw-materials/ (accessed on 12 September 2023).

- Okada, K. A Historical Overview of the Past Three Decades of Mineral Exploration Technology. Nat. Resour. Res. 2021, 30, 2839–2860. [Google Scholar] [CrossRef]

- Clean Energy Demand for Critical Minerals Set to Soar as the World Pursues Net Zero Goals—News. Available online: https://www.iea.org/news/clean-energy-demand-for-critical-minerals-set-to-soar-as-the-world-pursues-net-zero-goals (accessed on 12 September 2023).

- Hartai, É.; Madarász, T.; Miklovicz, T. CHPM2030 Project—Combined Heat, Power and Metal Extraction from Ultra-Deep Ore Bodies. In Proceedings of the 1st Geoscience & Engineering in Energy Transition Conference, Strasbourg, France, 16–18 November 2020; pp. 1–5. [Google Scholar]

- Kalscheuer, T.; Juhojuntti, N.; Vaittinen, K. Two-Dimensional Magnetotelluric Modelling of Ore Deposits: Improvements in Model Constraints by Inclusion of Borehole Measurements. Surv. Geophys. 2018, 39, 467–507. [Google Scholar] [CrossRef]

- Strangway, D.W.; Swift, C.M.; Holmer, R.C. The Application of Audio-Frequency Magnetotellurics (AMT) to Mineral Exploration. Geophysics 1973, 38, 1159–1175. [Google Scholar] [CrossRef]

- Resistivity. Available online: https://www.eoas.ubc.ca/courses/eosc350/content/foundations/properties/resistivity.htm (accessed on 13 September 2023).

- Di, Q.; Xue, G.; Zeng, Q.; Wang, Z.; An, Z.; Lei, D. Magnetotelluric Exploration of Deep-Seated Gold Deposits in the Qingchengzi Orefield, Eastern Liaoning (China), Using a SEP System. Ore Geol. Rev. 2020, 122, 103501. [Google Scholar] [CrossRef]

- Moorkamp, M.; Heincke, B.; Jegen, M.; Roberts, A.W.; Hobbs, R.W. A Framework for 3-D Joint Inversion of MT, Gravity and Seismic Refraction Data: 3-D Joint Inversion. Geophys. J. Int. 2011, 184, 477–493. [Google Scholar] [CrossRef]

- World Energy Outlook 2021—Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2021 (accessed on 13 September 2023).

- World Energy Assessment: Energy and the Challenge of Sustainability|United Nations Development Programme. Available online: https://www.undp.org/publications/world-energy-assessment-energy-and-challenge-sustainability (accessed on 13 September 2023).

- Pollet, M.; Gosselin, L.; Dallaire, J.; Mathieu-Potvin, F. Optimization of Geothermal Power Plant Design for Evolving Operating Conditions. Appl. Therm. Eng. 2018, 134, 118–129. [Google Scholar] [CrossRef]

- Geothermal Energy: Clean Power from the Earth’s Heat. Available online: https://pubs.usgs.gov/publication/cir1249 (accessed on 13 September 2023).

- Rybach, L. Geothermal Sustainability or Heat Mining? Int. J. Terr. Heat Flow Appl. 2021, 4, 15–25. [Google Scholar] [CrossRef]

- Rybach, L.; Mégel, T.; Eugster, W.J. At What Time Scale Are Geothermal Resources Renewable? In Proceedings of the World Geothermal Congress 2000, Kyushu, Japan, 28 May–10 June 2000. [Google Scholar]

- Rybach, L. Geothermal Heat Pump Production Sustainability—The Basis of the Swiss GHP Success Story. Energies 2022, 15, 7870. [Google Scholar] [CrossRef]

- Axelsson, G.; Rybach, L.; Júlíusson, E. Sustainable Management of Geothermal Production. In Proceedings of the World Geothermal Congress 2020+1, Reykjavik, Iceland, 24–27 October 2021. [Google Scholar]

- Fox, D.B.; Sutter, D.; Beckers, K.F.; Lukawski, M.Z.; Koch, D.L.; Anderson, B.J.; Tester, J.W. Sustainable Heat Farming: Modeling Extraction and Recovery in Discretely Fractured Geothermal Reservoirs. Geothermics 2013, 46, 42–54. [Google Scholar] [CrossRef]

- White, D.E.; Williams, D.L. Assessment of Geothermal Resources of the United States-1975; Energy Research and Development Administration: Golden, CO, USA, 1975. [Google Scholar]

- Geothermal Heat Pumps. Available online: https://www.energy.gov/energysaver/geothermal-heat-pumps (accessed on 13 September 2023).

- Rybach, L. Shallow Systems—Geothermal Heat Pumps. In Comprehensive Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 197–219. ISBN 978-0-12-819734-9. [Google Scholar]

- García-Gil, A.; Goetzl, G.; Kłonowski, M.R.; Borovic, S.; Boon, D.P.; Abesser, C.; Janza, M.; Herms, I.; Petitclerc, E.; Erlström, M.; et al. Governance of Shallow Geothermal Energy Resources. Energy Policy 2020, 138, 111283. [Google Scholar] [CrossRef]

- Rybach, L.; Bayer, P.; Rivera, J.A.; Blum, P. Influence Factors in the Depth Domain of Borehole Heat Exchangers—Global Warming and Urban Heating. In Proceedings of the European Geothermal Congress 2016, Strasbourg, France, 19–24 September 2016. [Google Scholar]

- Lund, J.; Sanner, B.; Rybach, L.; Curtis, R.; Hellström, G. Geothermal (Ground-Source) Heat Pumps: A World Overview. Geo-Heat Cent. Q. Bull. 2004, 25. [Google Scholar]

- Global Geothermal Heat Pump Market Report and Forecast 2023–2028. Available online: https://www.expertmarketresearch.com/reports/geothermal-heat-pump-market (accessed on 13 September 2023).

- Rybach, L. Global Status, Development and Prospects of Shallow and Deep Geothermal Energy. Int. J. Terr. Heat Flow Appl. 2022, 5, 20–25. [Google Scholar] [CrossRef]

- Hydrothermal Resources. Available online: https://www.energy.gov/eere/geothermal/hydrothermal-resources (accessed on 13 September 2023).

- Rybach, L. Geothermal Power Growth 1995–2013—A Comparison with Other Renewables. Energies 2014, 7, 4802–4812. [Google Scholar] [CrossRef]

- DiPippo, R. Chapter 8—Binary Cycle Power Plants. In Geothermal Power Plants; DiPippo, R., Ed.; Elsevier Science: Oxford, UK, 2005; pp. 163–196. ISBN 978-1-85617-474-9. [Google Scholar]

- Dickson, M.H.; Fanelli, M. What Is Geothermal Energy; Istituto di Geoscienze e Georisorse: Pisa, Italy, 2006. [Google Scholar]

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies, and Environmental Impact, 3rd ed.; Butterworth-Heinemann: Amsterdam, The Netherlands; Boston, MA, USA, 2012; ISBN 978-0-08-098206-9. [Google Scholar]

- Think Geo Energy. An Overview of Geothermal Resources. Think Geo Energy Website. 2021. Available online: https://www.thinkgeoenergy.com/geothermal/an-overview-of-geothermal-resources/ (accessed on 13 September 2023).

- Roberts, D. The Earth Itself Could Provide Carbon-Free Heat for Buildings. Available online: https://www.vox.com/energy-and-environment/2020/11/13/21537801/climate-change-renewable-energy-geothermal-heat-gshp-district-heating (accessed on 13 September 2023).

- Nieva, D.; Barragán, R.M.; Arellano, V. Geochemistry of Hydrothermal Systems. In Power Stations Using Locally Available Energy Sources: A Volume in the Encyclopedia of Sustainability Science and Technology Series, 2nd ed.; Bronicki, L.Y., Ed.; Springer: New York, NY, USA, 2018; pp. 61–78. ISBN 978-1-4939-7510-5. [Google Scholar]

- MEET. Soultz-Sous-Forêts. Available online: https://www.meet-h2020.com/demonstration-sites/soultz-sous-forets/ (accessed on 13 September 2023).

- Olasolo, P.; Juárez, M.C.; Morales, M.P.; D´Amico, S.; Liarte, I.A. Enhanced Geothermal Systems (EGS): A Review. Renew. Sustain. Energy Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Mouchot, J.; Genter, A.; Nicolas, C.; Scheiber, J.; Olivier, S.; Bosia, C.; Ravier, G. First Year of Operation from EGS Geothermal Plants in Alsace, France: Scaling Issues; Stanford University: Stanford, CA, USA, 2018. [Google Scholar]

- Rybach, L.; Kohl, T. Geothermal Energy and a Future Earth. In Global Change and Future Earth; Beer, T., Li, J., Alverson, K., Eds.; Cambridge University Press: Cambridge, UK, 2018; pp. 364–376. ISBN 978-1-316-76148-9. [Google Scholar]

- Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G. A Systematic Review of Enhanced (or Engineered) Geothermal Systems: Past, Present and Future. Geotherm. Energy 2013, 1, 4. [Google Scholar] [CrossRef]

- Häring, M.O.; Schanz, U.; Ladner, F.; Dyer, B.C. Characterisation of the Basel 1 Enhanced Geothermal System. Geothermics 2008, 37, 469–495. [Google Scholar] [CrossRef]

- Woo, J.-U.; Kim, M.; Sheen, D.-H.; Kang, T.-S.; Rhie, J.; Grigoli, F.; Ellsworth, W.L.; Giardini, D. An In-Depth Seismological Analysis Revealing a Causal Link Between the 2017 M W 5.5 Pohang Earthquake and EGS Project. J. Geophys. Res. Solid Earth 2019, 124, 13060–13078. [Google Scholar] [CrossRef]

- Grant, M.A.; Garg, S.K. Recovery Factors for EGS; Stanford University: Stanford, CA, USA, 2012. [Google Scholar]

- Rybach, L. “The Future of Geothermal Energy” and Its Challenges. In Proceedings of the Proceedings World Geothermal Congress 2010, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Haimson, B.C.; Cornet, F.H. ISRM Suggested Methods for Rock Stress Estimation—Part 3: Hydraulic Fracturing (HF) and/or Hydraulic Testing of Pre-Existing Fractures (HTPF). Int. J. Rock Mech. Min. Sci. 2003, 40, 1011–1020. [Google Scholar] [CrossRef]

- Nami, P.; Schellschmidt, R.; Schindler, M.; Tischner, T. Chemical Stimulation Operations for Reservoir Development of the Deep Crystalline HDR/EGS System at Soultz-Sous-Forêts (France). In Proceedings, Thirty-Second Workshop on Geothermal Reservoir Engineering; Stanford University: Stanford, CA, USA, 2008. [Google Scholar]

- Portier, S.; André, L.; Vuataz, F.-D. Review on Chemical Stimulation Techniques in Oil Industry and Applications to Geothermal Systems; Enhanced Geothermal Innovative Network for Europe; Deep Heat Mining Association—DHMA: Basel, Switzerland, 2007. [Google Scholar]

- Xing, P.; McLennan, J.; Moore, J. In-Situ Stress Measurements at the Utah Frontier Observatory for Research in Geothermal Energy (FORGE) Site. Energies 2020, 13, 5842. [Google Scholar] [CrossRef]

- Osvald, M.; Kilpatrick, A.D.; Rochelle, C.A.; Szanyi, J.; Medgyes, T.; Kóbor, B. Laboratory Leaching Tests to Investigate Mobilisation and Recovery of Metals from Geothermal Reservoirs. Geofluids 2018, 2018, 6509420. [Google Scholar] [CrossRef]

- Dang, V.-D.; Steinberg, M. Preliminary Design and Analysis of Recovery of Lithium from Brine with the Use of a Selective Extractant. In Lithium Needs and Resources; Elsevier: Amsterdam, The Netherlands, 1978; pp. 325–336. ISBN 978-0-08-022733-7. [Google Scholar]

- Duyvesteyn, W.P.C. Recovery of Base Metals from Geothermal Brines. Geothermics 1992, 21, 773–799. [Google Scholar] [CrossRef]

- Kesler, S.E.; Gruber, P.W.; Medina, P.A.; Keoleian, G.A.; Everson, M.P.; Wallington, T.J. Global Lithium Resources: Relative Importance of Pegmatite, Brine and Other Deposits. Ore Geol. Rev. 2012, 48, 55–69. [Google Scholar] [CrossRef]

- Neupane, G.; Wendt, D.S. Assessment of Mineral Resources in Geothermal Brines in the US. In Proceedings of the 42nd Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 13–15 February 2017. [Google Scholar]

- Brewer, A.; Chang, E.; Park, D.M.; Kou, T.; Li, Y.; Lammers, L.N.; Jiao, Y. Recovery of Rare Earth Elements from Geothermal Fluids through Bacterial Cell Surface Adsorption. Environ. Sci. Technol. 2019, 53, 7714–7723. [Google Scholar] [CrossRef] [PubMed]

- Pruess, K. Enhanced Geothermal Systems (EGS) Using CO2 as Working Fluid—A Novel Approach for Generating Renewable Energy with Simultaneous Sequestration of Carbon. Geothermics 2006, 35, 351–367. [Google Scholar] [CrossRef]

- Dill, H.G. The ‘Chessboard’ Classification Scheme of Mineral Deposits: Mineralogy and Geology from Aluminum to Zirconium. Earth Sci. Rev. 2010, 100, 1–420. [Google Scholar] [CrossRef]

- Kohl, T.; Bremer, J.; Schill, E.; Kolditz, O.; Sass, I.; Zimmermann, G. GeoLaB—Geothermal Laboratory in the Crystalline Basement. In Proceedings of the European Geothermal Congress (EGC 2022), Berlin, Germany, 17–21 October 2022. KITopen-ID: 1000152230. [Google Scholar] [CrossRef]

- Holtzman, B.; Groebner, N.; Mittal, T. Quench-Spallation Drilling: A Novel Drilling Head Designfor Routine Heat Mining Above the Brittle-Ductile Transition. In Proceedings of the 48th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 6–8 February 2023. [Google Scholar]

- Bajcsi, P.; Bozsó, T.; Bozsó, R.; Molnár, G.; Tábor, V.; Czinkota, I.; Tóth, T.M.; Kovács, B.; Schubert, F.; Bozsó, G.; et al. New Geothermal Well-Completion and Rework Technology by Laser. Cent. Eur. Geol. 2015, 58, 88–99. [Google Scholar] [CrossRef]

- Szanyi, J.; Osvald, M.M.; Medgyes, T.; Kóbor, B.; Tóth, T.M.; Madarász, T.; Kolencsinké-Tóth, A.; Debreczeni, Á.; Vásárhelyi, B.; Rozgonyi-Boissinot, N. Recommendations for Integrated Reservoir Management. CHPM2030 Deliverable; University of Miskolc: Miskolc, Hungary, 2017; 122p. [Google Scholar]

- Smith, J.; Doe, M. Energy from the Earth: Deep Geothermal as a Resource for the Future; Hirschberg, S., Wiemer, S., Burgherr, P., Eds.; TA-SWISS (Series); VDF Hochschulverlag an der ETH Zürich: Zürich, Switzerland, 2015; ISBN 978-3-7281-3654-1. [Google Scholar]

- Norbeck, J.; Latimer, T. Commercial-Scale Demonstration of a First-of-a-Kind Enhanced Geothermal System. Engineering 2023. [Google Scholar] [CrossRef]

- Agusdinata, D.B.; Liu, W.; Eakin, H.; Romero, H. Socio-Environmental Impacts of Lithium Mineral Extraction: Towards a Research Agenda. Environ. Res. Lett. 2018, 13, 123001. [Google Scholar] [CrossRef]

- Agrawal, R.; Bhagia, S.; Satlewal, A.; Ragauskas, A.J. Urban Mining from Biomass, Brine, Sewage Sludge, Phosphogypsum and E-Waste for Reducing the Environmental Pollution: Current Status of Availability, Potential, and Technologies with a Focus on LCA and TEA. Environ. Res. 2023, 224, 115523. [Google Scholar] [CrossRef]

- Smith, Y.; Kumar, P.; McLennan, J. On the Extraction of Rare Earth Elements from Geothermal Brines. Resources 2017, 6, 39. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2017; U.S. Geological Survey: Reston, VA, USA, 2017; p. 206.

- U.S. Geological Survey. Mineral Commodity Summaries 2018; U.S. Geological Survey: Reston, VA, USA, 2018.

- U.S. Geological Survey. Mineral Commodity Summaries 2019; U.S. Geological Survey: Reston, VA, USA, 2019; p. 204.

- U.S. Geological Survey. Mineral Commodity Summaries 2020; U.S. Geological Survey: Reston, VA, USA, 2020.

- U.S. Geological Survey. Mineral Commodity Summaries 2021; U.S. Geological Survey: Reston, VA, USA, 2021.

- U.S. Geological Survey. Mineral Commodity Summaries 2022; U.S. Geological Survey: Reston, VA, USA, 2022.

- U.S. Geological Survey. Mineral Commodity Summaries 2023; U.S. Geological Survey: Reston, VA, USA, 2023.

- Global Lithium Production 2022. Available online: https://www.statista.com/statistics/606684/world-production-of-lithium/ (accessed on 29 March 2023).

- Igogo, T.; Awuah-Offei, K.; Newman, A.; Lowder, T.; Engel-Cox, J. Integrating Renewable Energy into Mining Operations: Opportunities, Challenges, and Enabling Approaches. Appl. Energy 2021, 300, 117375. [Google Scholar] [CrossRef]

- Preene, M.; Younger, P.L. Can You Take the Heat?—Geothermal Energy in Mining. Min. Technol. 2014, 123, 107–118. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, B.; Ji, G.; Wu, X. A Comprehensive Review of Geothermal Energy Extraction and Utilization in Oilfields. J. Pet. Sci. Eng. 2018, 168, 465–477. [Google Scholar] [CrossRef]

- Abid, K.; Sharma, A.; Ahmed, S.; Srivastava, S.; Toledo Velazco, A.; Teodoriu, C. A Review on Geothermal Energy and HPHT Packers for Geothermal Applications. Energies 2022, 15, 7357. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Sobczak, A.; Soboń, D. The Potential and Development of the Geothermal Energy Market in Poland and the Baltic States—Selected Aspects. Energies 2022, 15, 4142. [Google Scholar] [CrossRef]

- Moska, R.; Labus, K.; Kasza, P.; Moska, A. Geothermal Potential of Hot Dry Rock in South-East Baltic Basin Countries—A Review. Energies 2023, 16, 1662. [Google Scholar] [CrossRef]

- Malau, H.; Fajri, H.; Yuanjaya, P.; Saputra, B.; Maani, K.D. Knowledge of Local Communities Affected by the Development of Geothermal Energy. IOP Conf. Ser. Earth Environ. Sci. 2020, 448, 012112. [Google Scholar] [CrossRef]

- Soltani, M.; Moradi Kashkooli, F.; Souri, M.; Rafiei, B.; Jabarifar, M.; Gharali, K.; Nathwani, J.S. Environmental, Economic, and Social Impacts of Geothermal Energy Systems. Renew. Sustain. Energy Rev. 2021, 140, 110750. [Google Scholar] [CrossRef]

- Backer, S.N.; Bouaziz, I.; Kallayi, N.; Thomas, R.T.; Preethikumar, G.; Takriff, M.S.; Laoui, T.; Atieh, M.A. Review: Brine Solution: Current Status, Future Management and Technology Development. Sustainability 2022, 14, 6752. [Google Scholar] [CrossRef]

- Ibarra-Gutiérrez, S.; Bouchard, J.; Laflamme, M.; Fytas, K. Perspectives of Lithium Mining in Quebec, Potential and Advantages of Integration into a Local Battery Production Chain for Electric Vehicles. Mater. Proc. 2021, 5, 33. [Google Scholar] [CrossRef]

- Do Thi, H.T.; Pasztor, T.; Fozer, D.; Manenti, F.; Toth, A.J. Comparison of Desalination Technologies Using Renewable Energy Sources with Life Cycle, PESTLE, and Multi-Criteria Decision Analyses. Water 2021, 13, 3023. [Google Scholar] [CrossRef]

- Kavanagh, L.; Keohane, J.; Garcia Cabellos, G.; Lloyd, A.; Cleary, J. Global Lithium Sources—Industrial Use and Future in the Electric Vehicle Industry: A Review. Resources 2018, 7, 57. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Dallas, J.; Casanova, S.; Pelech, T.; Bournival, G.; Saydam, S.; Canbulat, I. A Review of Lithium Resource Availability, Challenges and Innovations in Mining, Extraction and Recycling, and Future Perspectives. Miner. Eng. 2021, 163, 106743. [Google Scholar] [CrossRef]

- Rowlatt, J. Why Electric Cars Will Take Over Sooner Than You Think. BBC News, 1 June 2021. [Google Scholar]

- Kelly, J.C.; Wang, M.; Dai, Q.; Winjobi, O. Energy, Greenhouse Gas, and Water Life Cycle Analysis of Lithium Carbonate and Lithium Hydroxide Monohydrate from Brine and Ore Resources and Their Use in Lithium Ion Battery Cathodes and Lithium Ion Batteries. Resour. Conserv. Recycl. 2021, 174, 105762. [Google Scholar] [CrossRef]

- Hartai, E.; Németh, N.; Földessy, J.; CHPM2030 Team. CHPM2030 Deliverable D1.1: EGS-Relevant Review of Metallogenesis; Published by the CHPM2030 project; University of Miskolc: Miskolc-Egyetemváros, Hungary, 2016; Available online: https://zenodo.org/records/580994 (accessed on 29 March 2023).

- Simmons, S.F.; Kirby, S.; Verplanck, P.; Kelley, K. Strategic and Critical Elements in Produced Geothermal Fluids from Nevada and Utah. In Proceedings of the 43rd Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 12–14 February 2018. [Google Scholar]

- Alekseeva, L.P.; Alekseev, S.V. Industrial Groundwater of the Olenek Artesian Basin: Geochemistry and Development Prospects. Water Resour. 2018, 45, 79–88. [Google Scholar] [CrossRef]

- Li, R.; Liu, C.; Jiao, P.; Wang, J. The Tempo-Spatial Characteristics and Forming Mechanism of Lithium-Rich Brines in China. China Geol. 2018, 1, 72–83. [Google Scholar] [CrossRef]

- Vulcan Energy Zero Carbon Lithium Project. Presented at the DFS Presentation 2023. Available online: https://v-er.eu/wp-content/uploads/2023/03/Vulcan-Energy-DFS-presentation-2023-FINAL.pdf (accessed on 29 March 2023).

- Beamish, D.; Busby, J. The Cornubian Geothermal Province: Heat Production and Flow in SW England: Estimates from Boreholes and Airborne Gamma-Ray Measurements. Geotherm. Energy 2016, 4, 4. [Google Scholar] [CrossRef]

- Farndale, H.; Law, R. The Effects of Soft Stimulation on Reservoir Growth and Injectivity at the United Downs Geothermal Project, Cornwall. In Proceedings of the PROCEEDINGS, 48th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 6 February 2023. [Google Scholar]

- Dentith, M.; Yuan, H.; Johnson, S.; Murdie, R.; Piña-Varas, P. Application of Deep-Penetrating Geophysical Methods to Mineral Exploration: Examples from Western Australia. Geophysics 2018, 83, WC29–WC41. [Google Scholar] [CrossRef]

- Labus, K.; Labus, M.; Leśniak, G. Thermal Properties of Rocks from Deep Boreholes in Poland in Terms of Obtaining Geothermal Energy from Enhanced Geothermal Systems. Adv. Geo-Energy Res. 2023, 8, 76–88. [Google Scholar] [CrossRef]

- Stringfellow, W.T.; Dobson, P.F. Technology for the Recovery of Lithium from Geothermal Brines. Energies 2021, 14, 6805. [Google Scholar] [CrossRef]

- Georisk. Available online: https://www.Georisk-Project.Eu/ (accessed on 18 October 2023).

- Tester, J.W.; Anderson, B.J.; Batchelor, A.S.; Blackwell, D.D.; DiPippo, R.; Drake, E.M.; Garnish, J.; Livesay, B.; Moore, M.C.; Nichols, K.; et al. Impact of Enhanced Geothermal Systems on US Energy Supply in the Twenty-First Century. Philos. Trans. R Soc. Math. Phys. Eng. Sci. 2007, 365, 1057–1094. [Google Scholar] [CrossRef] [PubMed]

| Energy Source | Capacity (EJ/yr) |

|---|---|

| Geothermal | 5000 |

| Solar | 1575 |

| Wind | 640 |

| Biomass | 276 |

| Hydro | 50 |

| TOTAL | 7541 |

| Reservoir (depth)/year | Country | Well Separation (m) | Circ. Duration (days) | Qprod (l/s) | Reservoir Impedance (MPa/Kg/s) | Thermal Break-Through | Swept Volume 1000 m³ | Loss (%) |

|---|---|---|---|---|---|---|---|---|

| Fenton Hill 2-well (2.8 km): 1980 | USA (New Mex) | 200 | 282 | 5.5 | 0.2 | Slight | 0.4–1.3 | 10 |

| Fenton Hill 2-well (4.2 km): 1992 | USA (New Mex) | 200∓50 | 183 | 5.5 | 4 | No | 2.2–5 | 16 |

| Rosemanowes 3-well (2.2 km): 1988–89 | UK | 120/150–250 | 200 | 3/16 | 3.3/0.6 | Yes | 13–19 | 21 |

| Hijiori 4-well (1.8 km): 1991 | Japan | 40/50/55 | 90 | 12.8 | 0.4–0.7 | No | 23 | 23 |

| Hijiori 3-well (2.2 km): 2000 | Japan | 90/130 | 300 | 5.8 | 1.4/2.1 | Yes | 64 | 64 |

| Soultz, 2-well (3.5 km): 1997 | France | 450 | 135 | 25 | 0.2 | No | 16 | 0 |

| Soultz, 3-well (5 km): 2005 | France | 600 | 150 | 12 | 0.6 | No | 10.4/0.1 | 0 |

| Soultz, 2-well (5 km): 2009 | France | 600 | 60 | 3 | ~0.55 | No | 0 | 0 |

| Fjällbacka, 2-well (~0.5 km): 1989 | Sweden | 100 | 40 | 1 | 4.9 | No | 45 | 45 |

| Le Mayet, 2-well (0.8 km): 1987 | France | 100 | 66 | 5.2 | 1.7 | No | 38 | 38 |

| Habanero, 2-well (4.2 km): 2009 | Australia | 560 | 60 | 17 | 0.7 | No | 18.5 | 0 |

| Fervo Energy 2-well (2.3 km): 2023 | USA | 100 | 37 | ~40/max. 63 | Not specified | No | * | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szanyi, J.; Rybach, L.; Abdulhaq, H.A. Geothermal Energy and Its Potential for Critical Metal Extraction—A Review. Energies 2023, 16, 7168. https://doi.org/10.3390/en16207168

Szanyi J, Rybach L, Abdulhaq HA. Geothermal Energy and Its Potential for Critical Metal Extraction—A Review. Energies. 2023; 16(20):7168. https://doi.org/10.3390/en16207168

Chicago/Turabian StyleSzanyi, János, Ladislaus Rybach, and Hawkar A. Abdulhaq. 2023. "Geothermal Energy and Its Potential for Critical Metal Extraction—A Review" Energies 16, no. 20: 7168. https://doi.org/10.3390/en16207168

APA StyleSzanyi, J., Rybach, L., & Abdulhaq, H. A. (2023). Geothermal Energy and Its Potential for Critical Metal Extraction—A Review. Energies, 16(20), 7168. https://doi.org/10.3390/en16207168