Numerical Investigation and Optimization of a District-Scale Groundwater Heat Pump System

Abstract

:1. Introduction

2. Materials and Methods

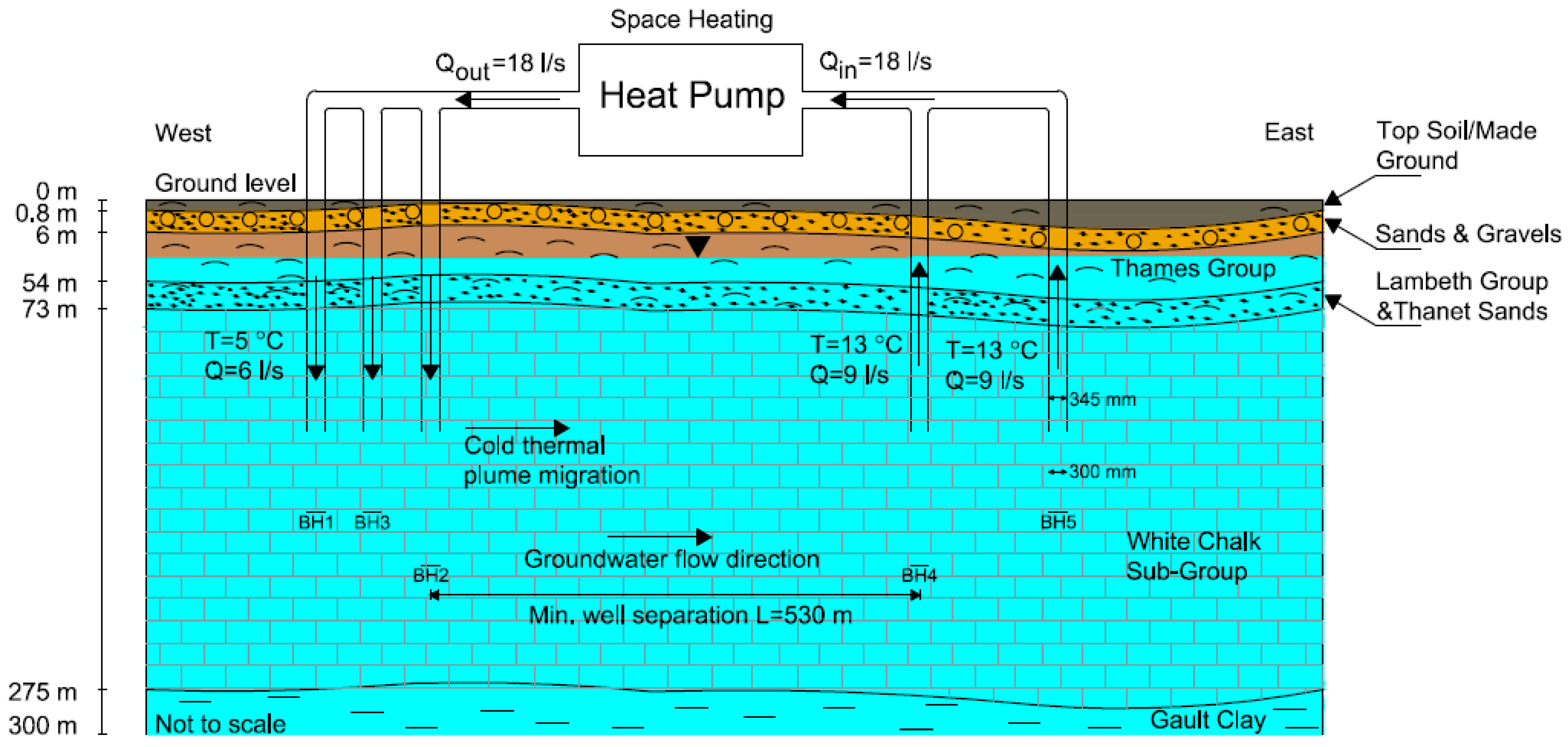

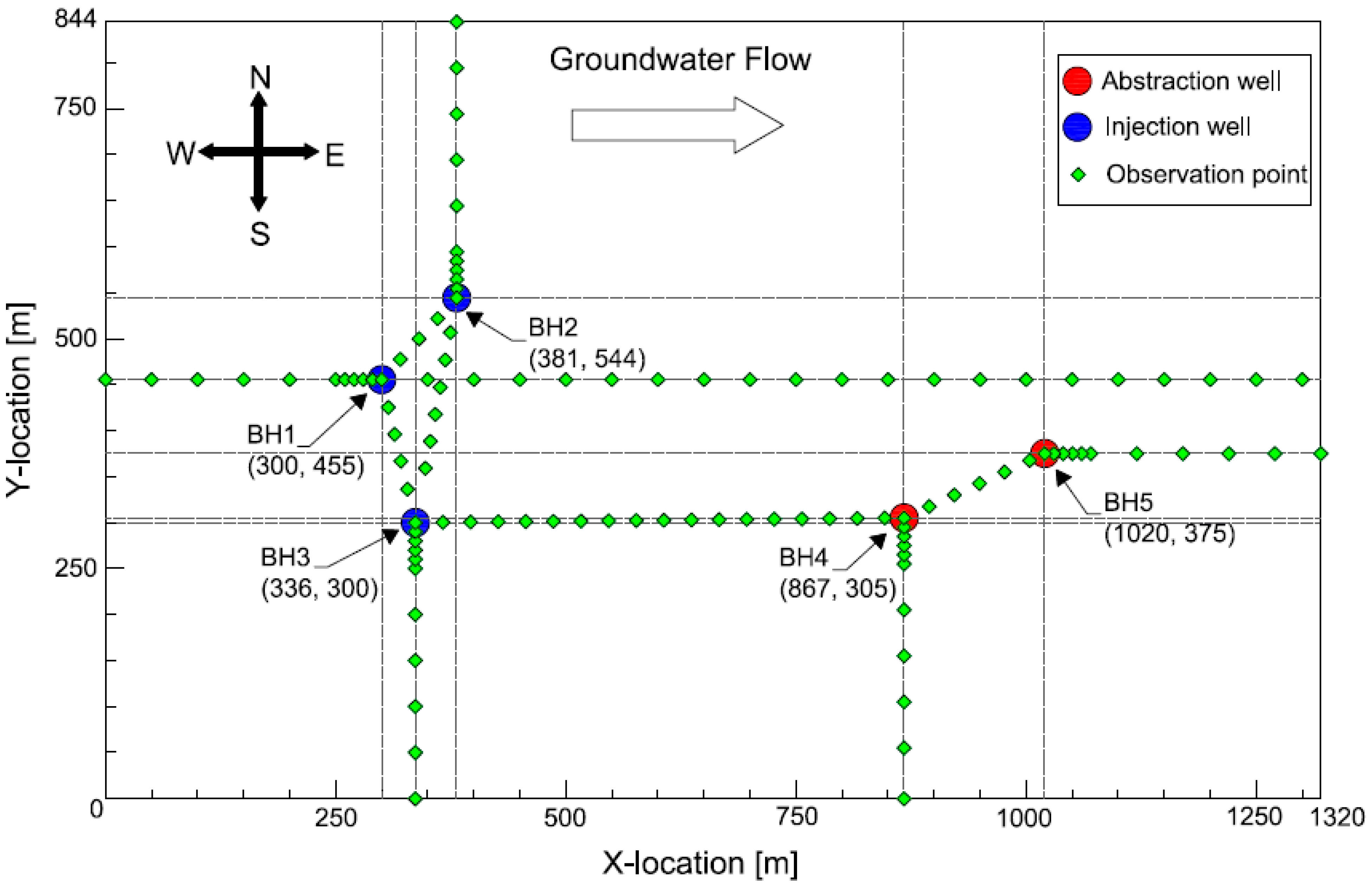

2.1. Site Description

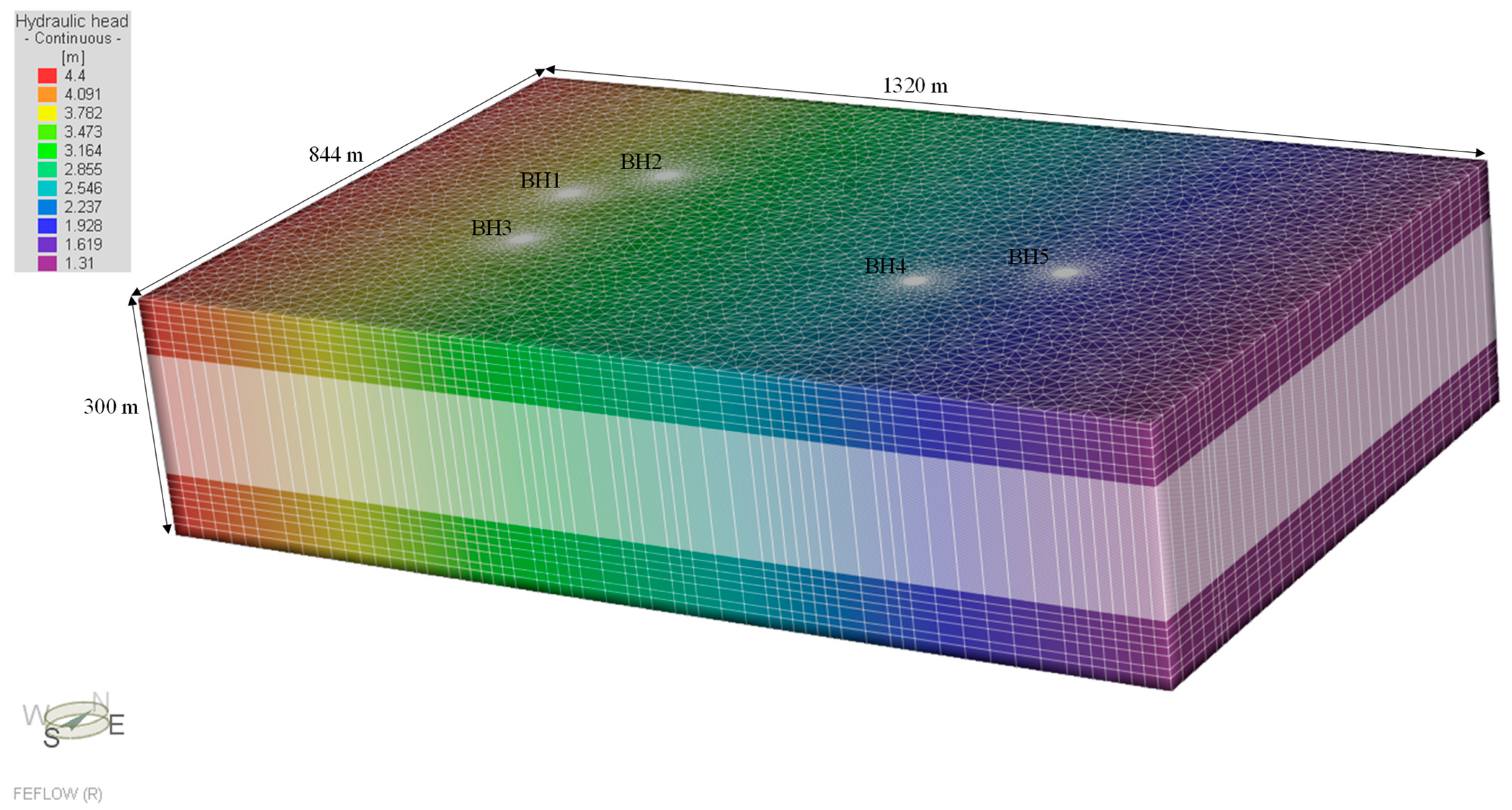

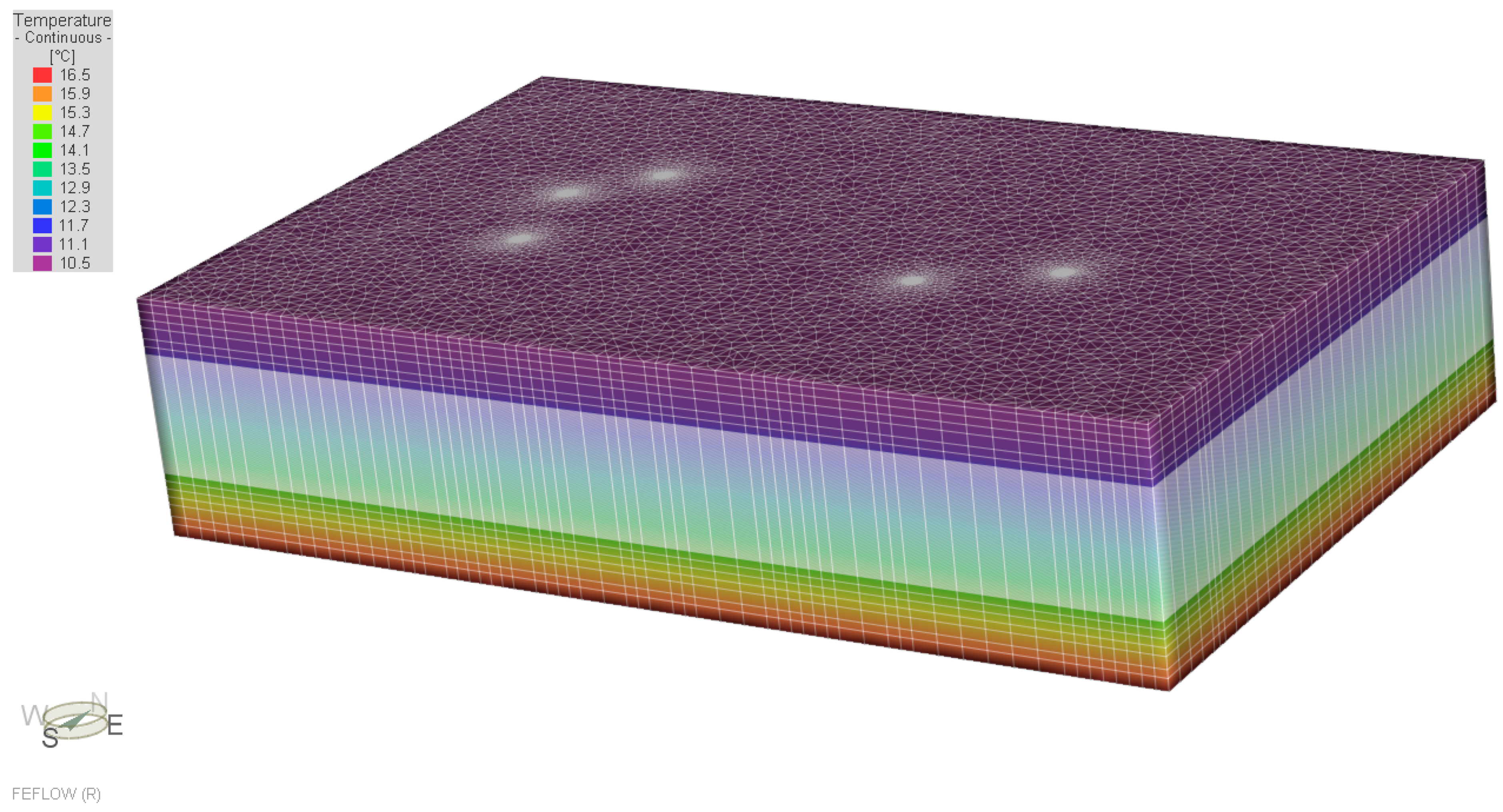

2.2. Model Description

2.3. Numerical Simulation

2.4. Initial and Boundary Conditions

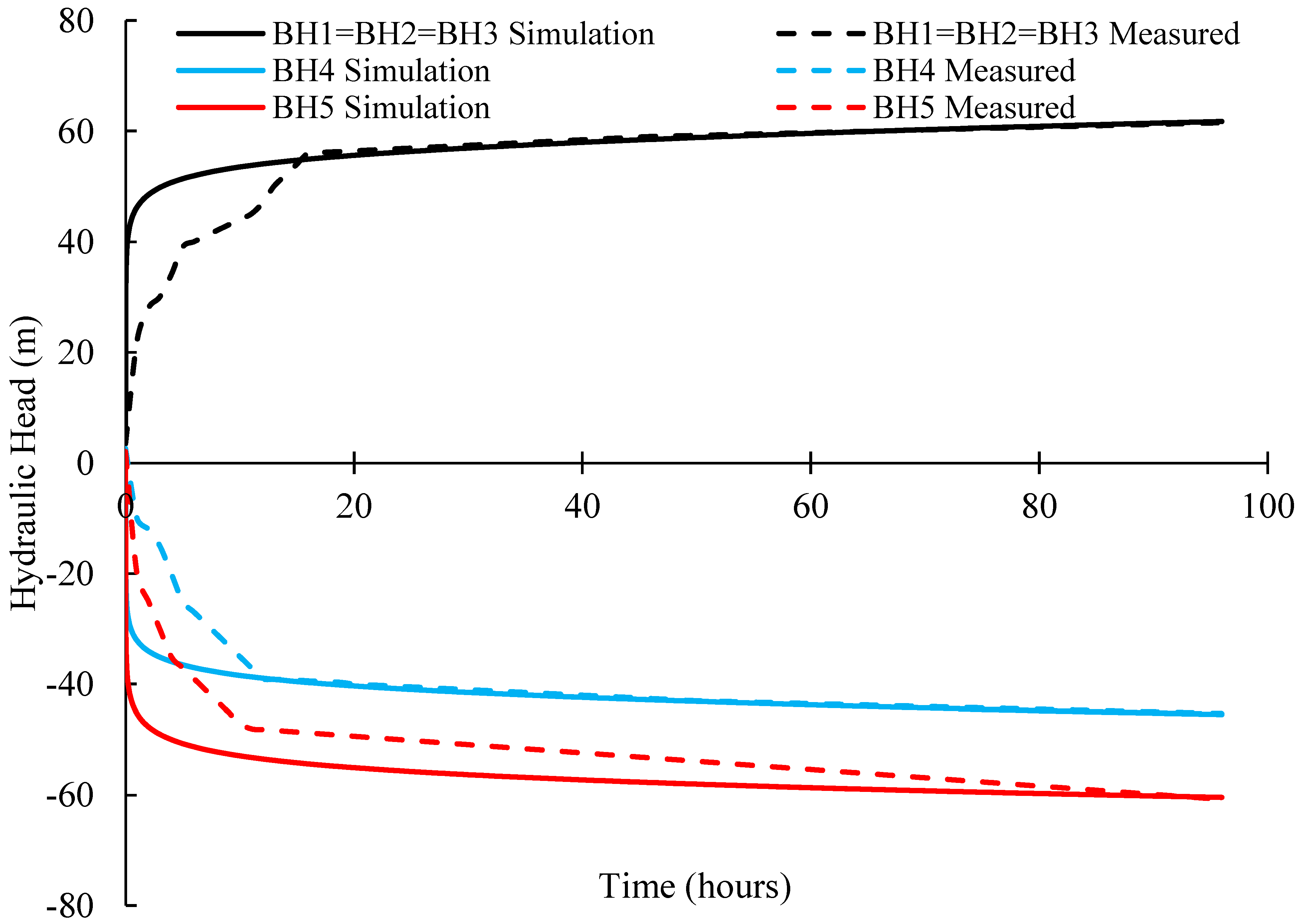

2.5. Model Validation

2.6. Material Properties

2.7. Scenarios

2.8. Optimization

3. Results and Discussion

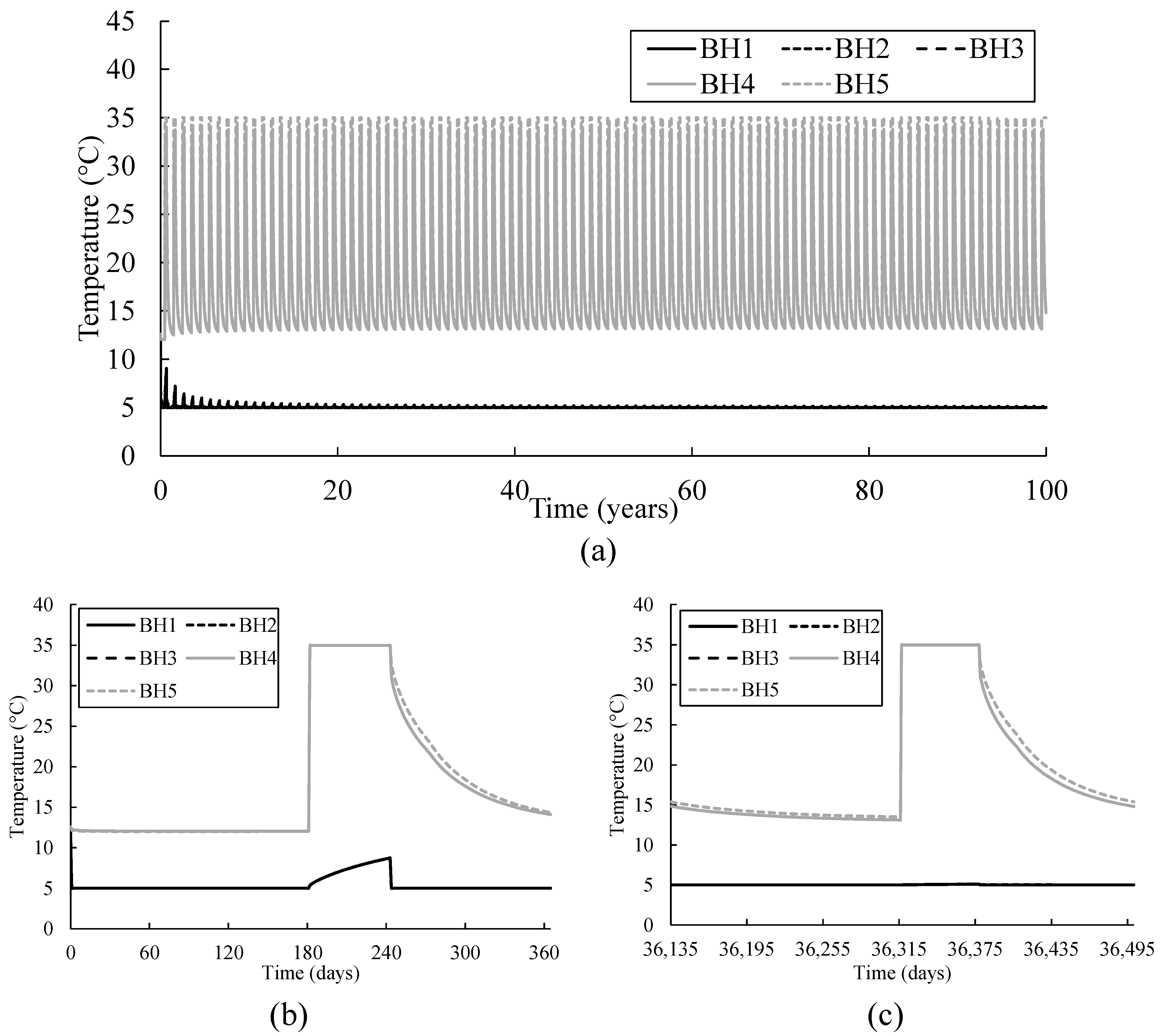

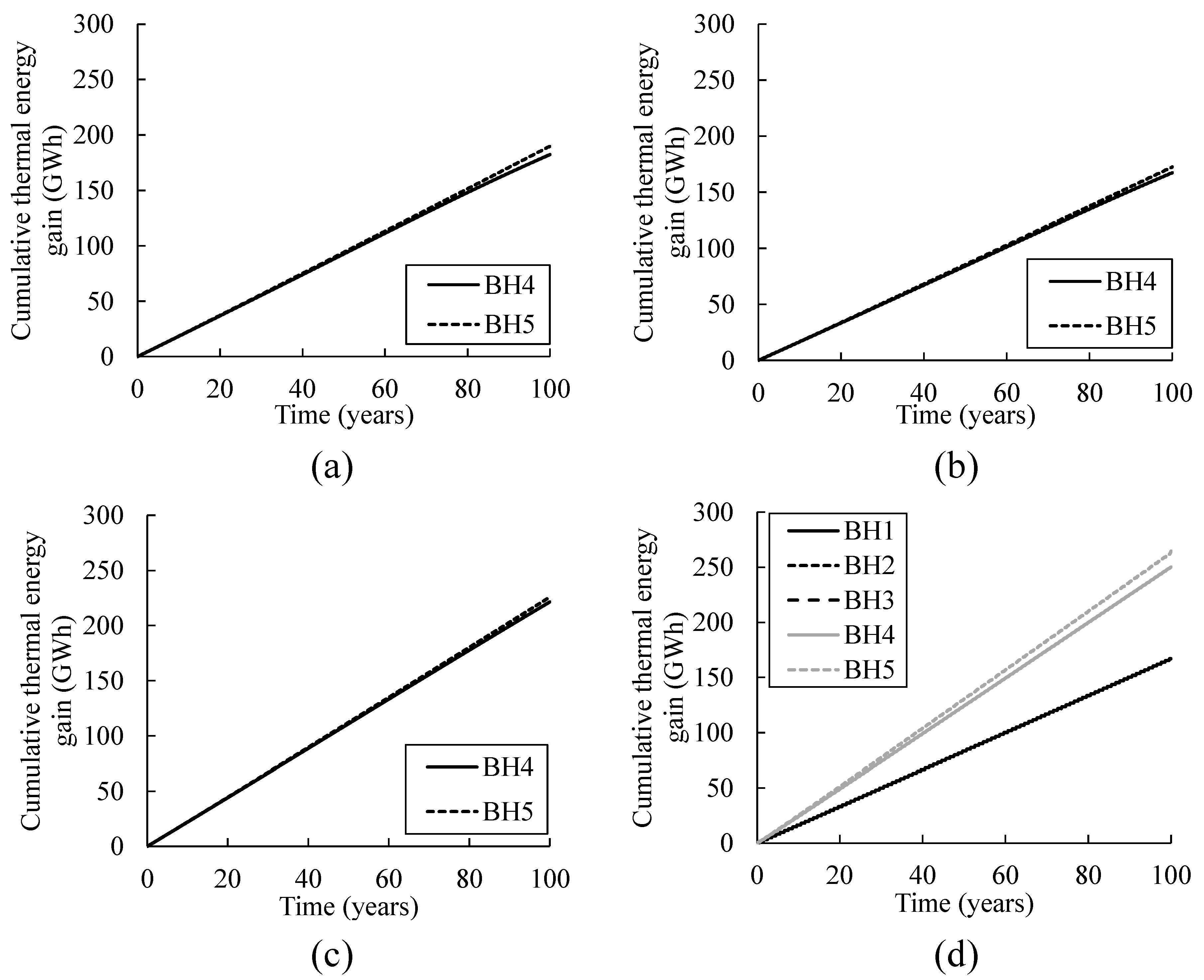

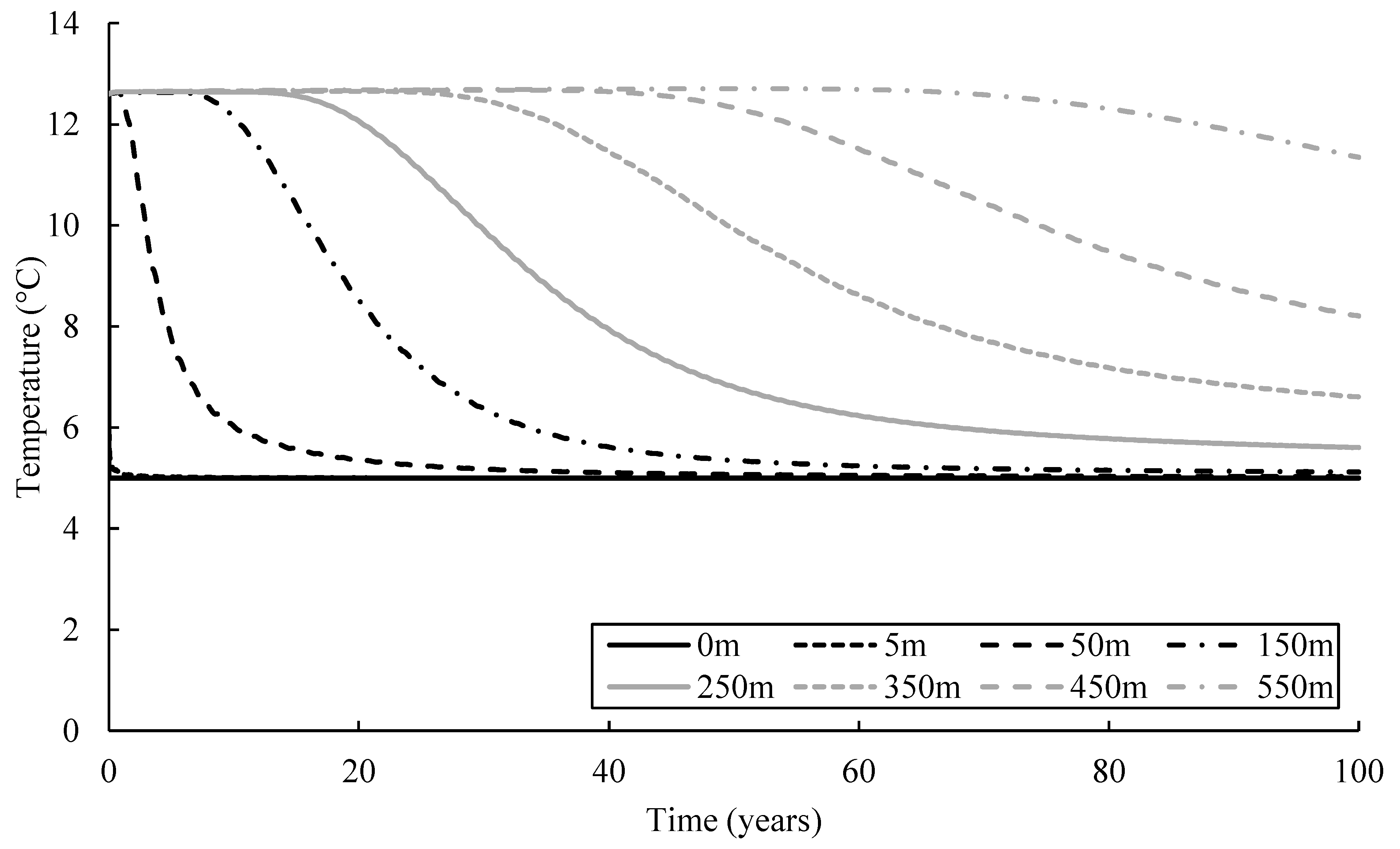

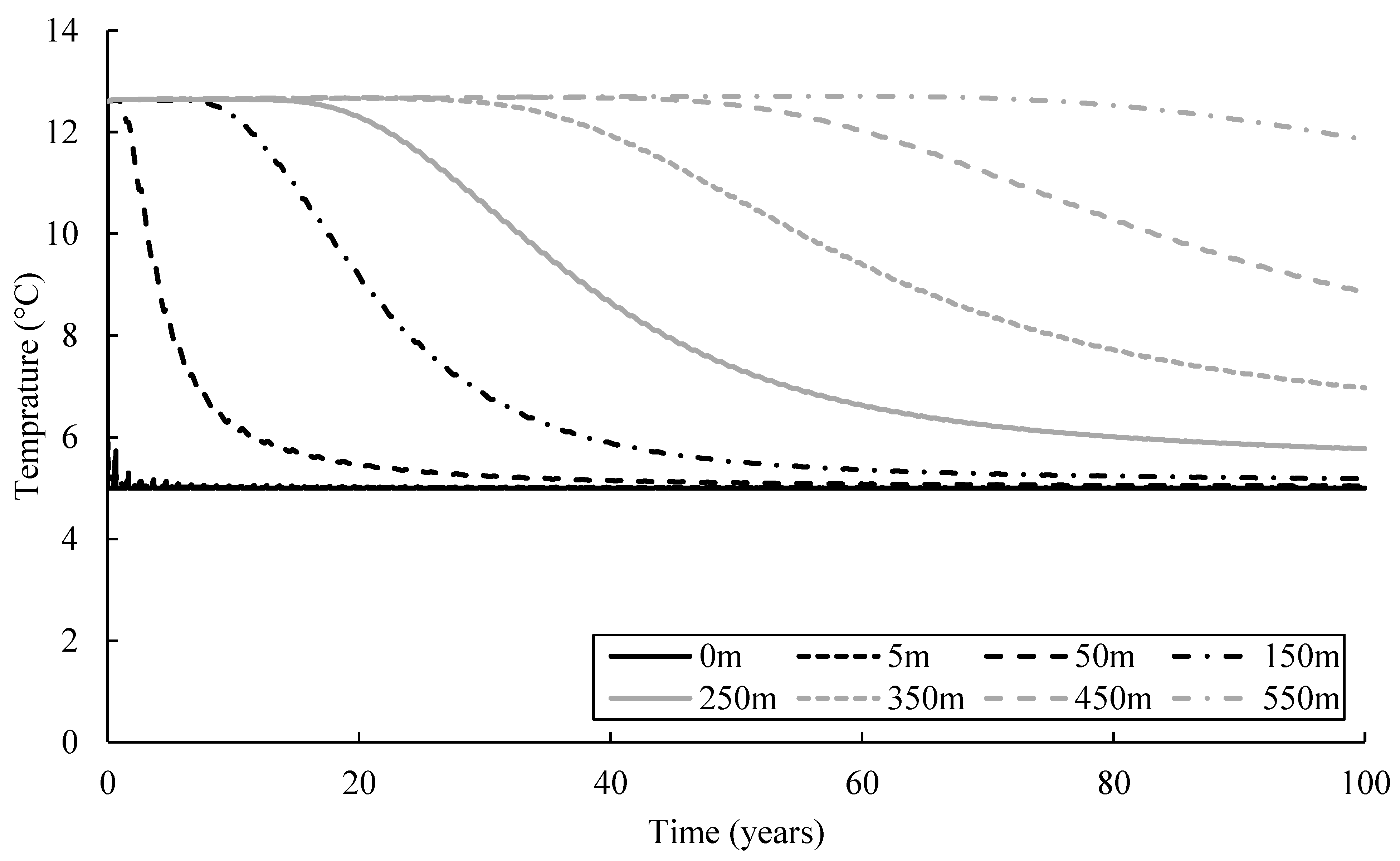

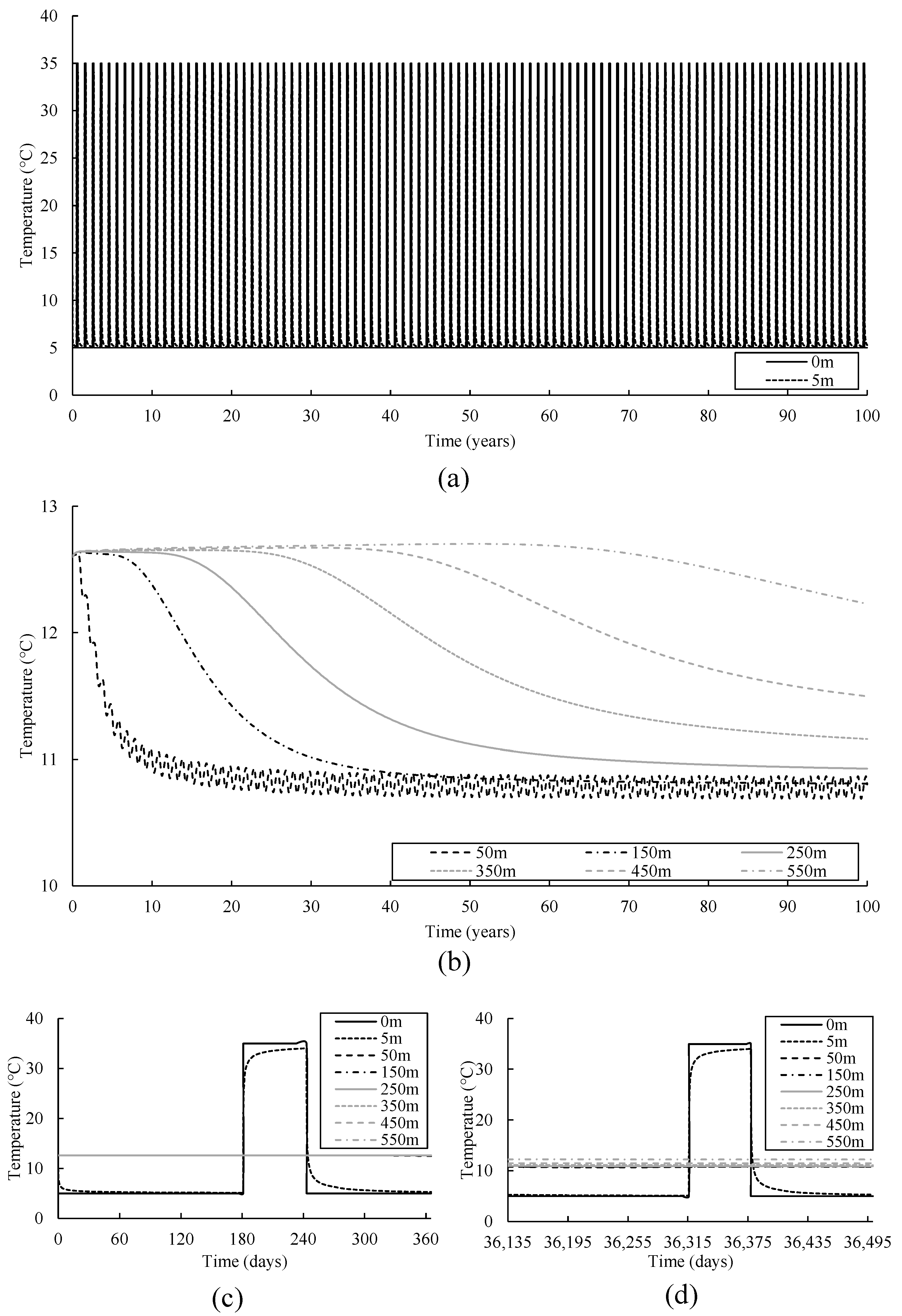

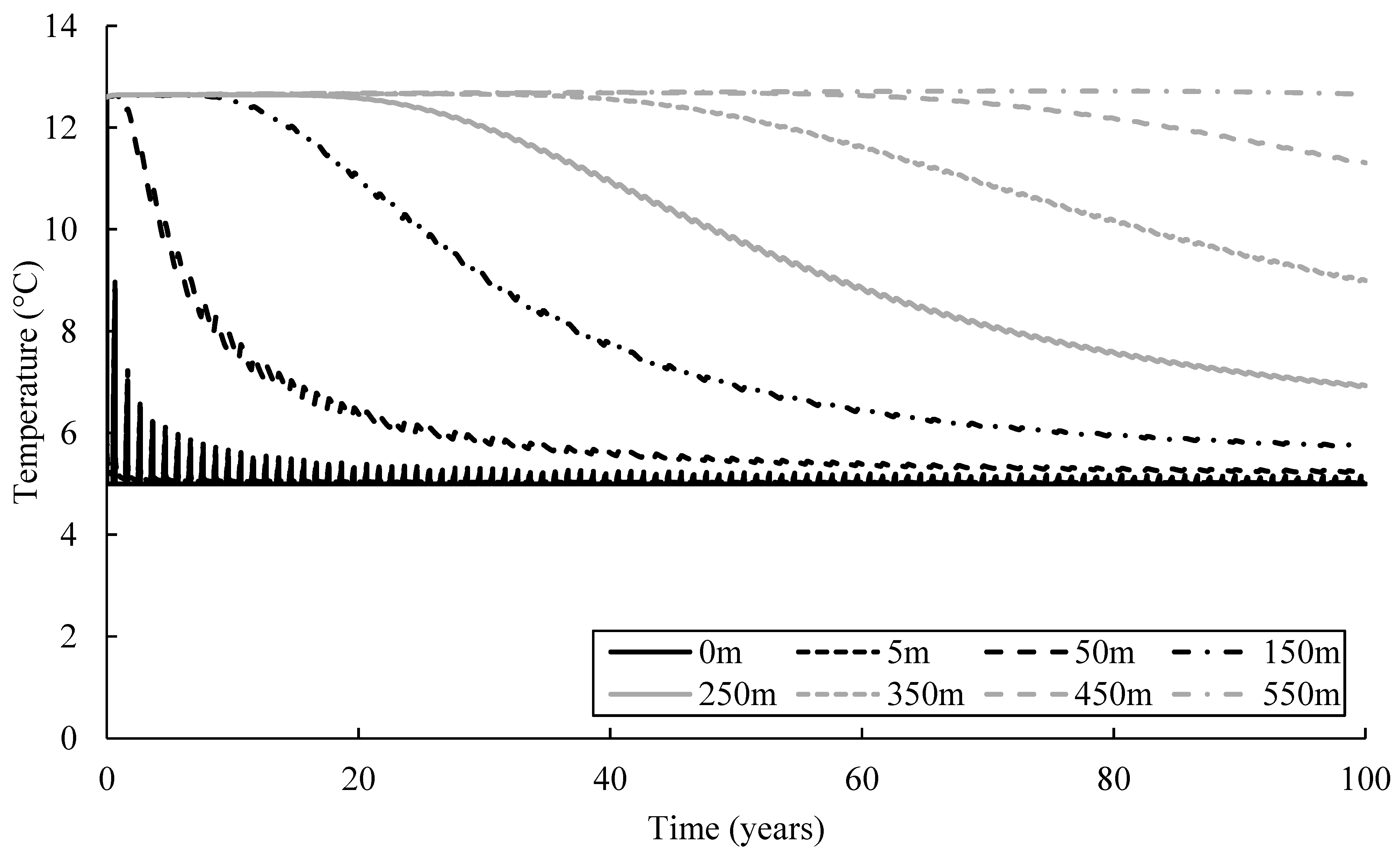

3.1. Impact of Thermal Feedback on Abstraction Temperature

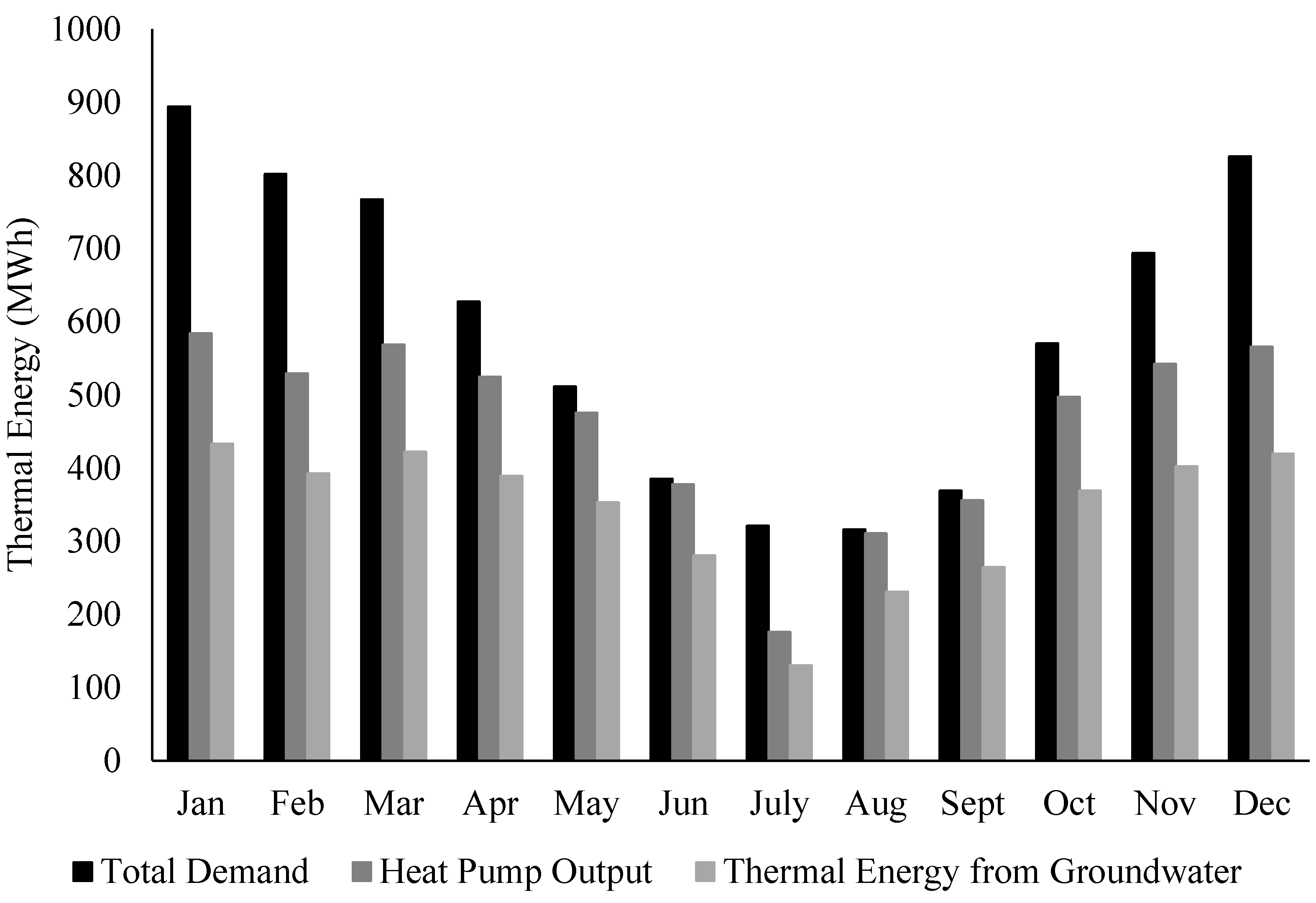

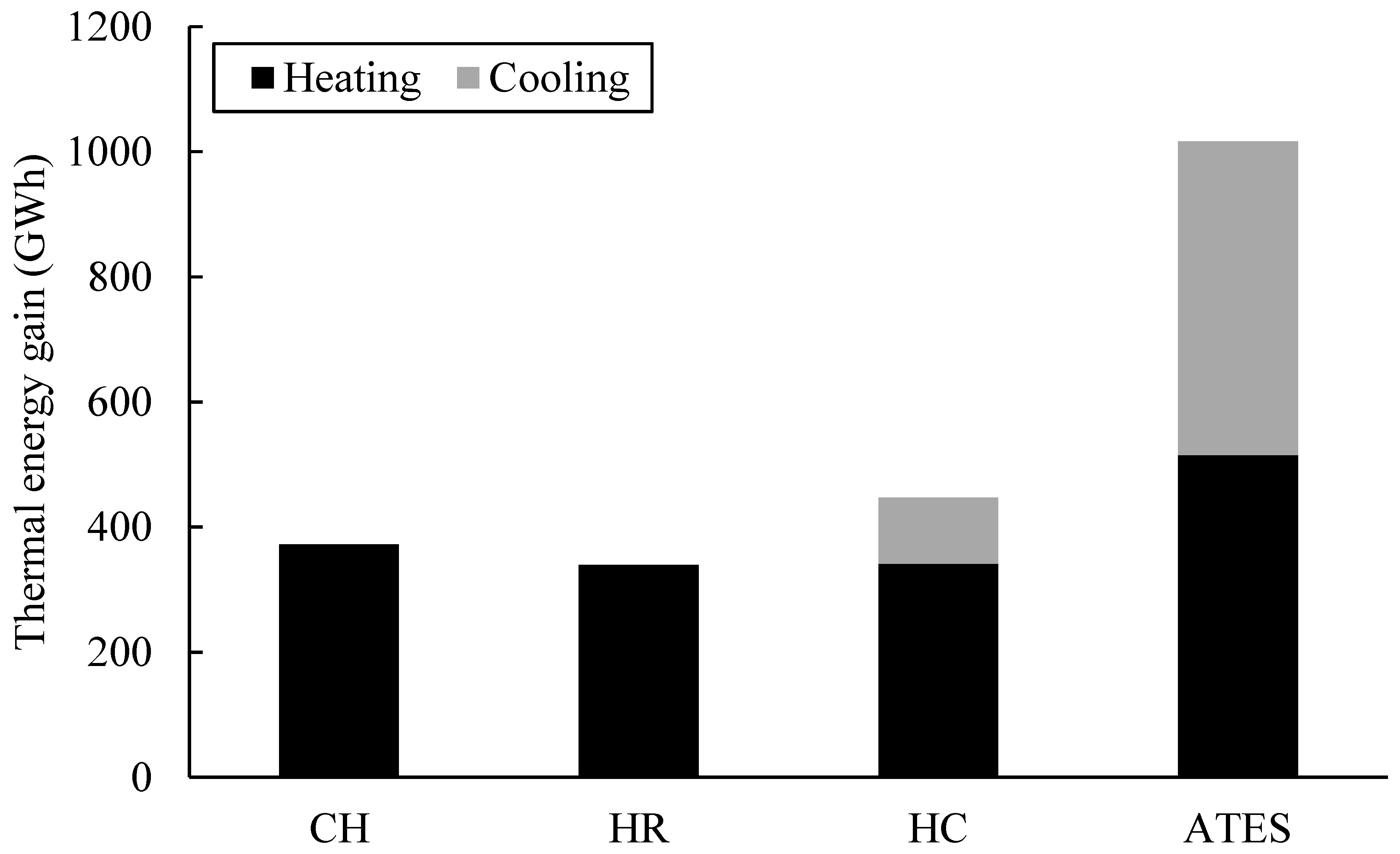

3.2. Thermal Energy Calculations

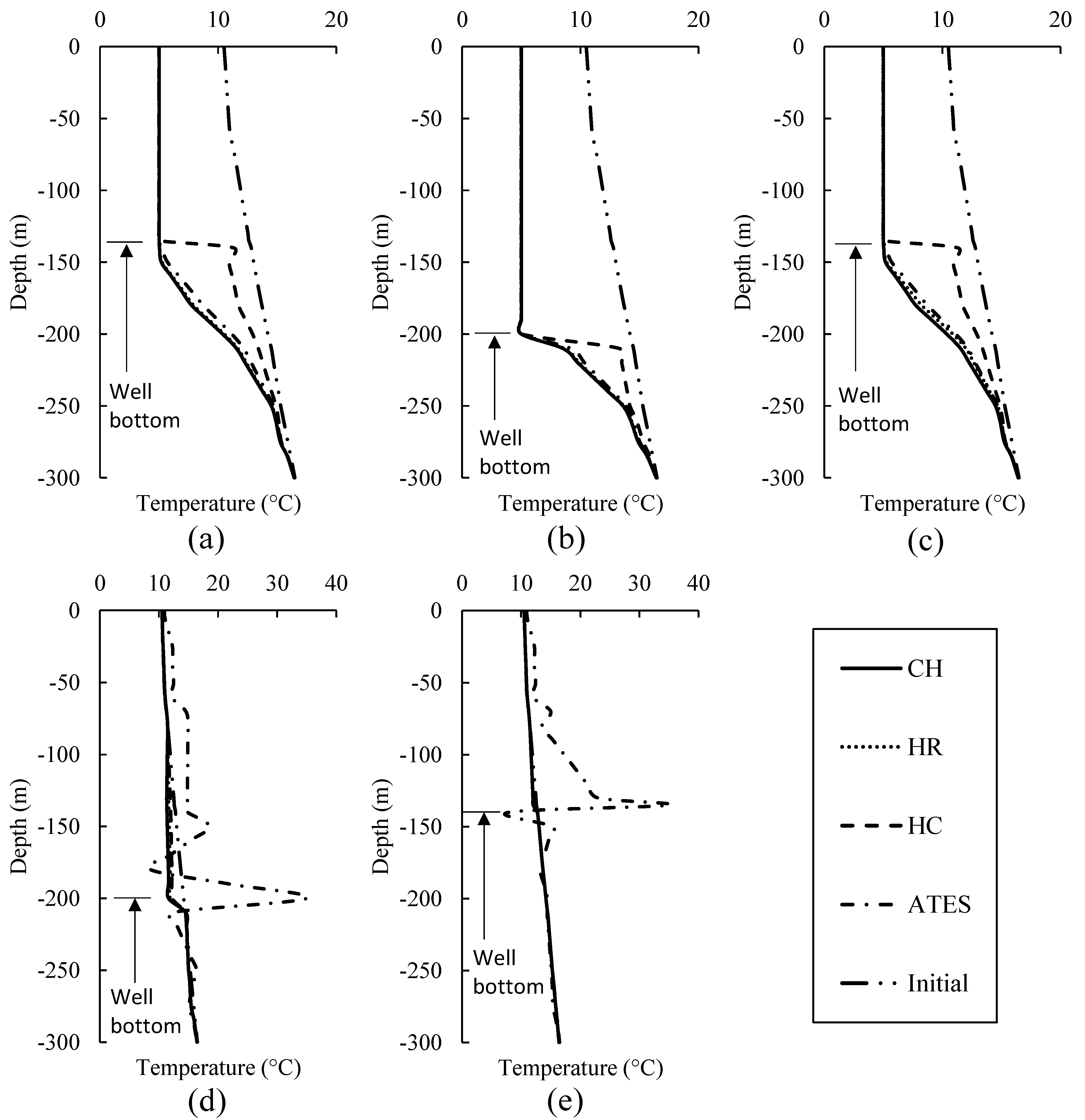

3.3. Vertical Thermal Distribution

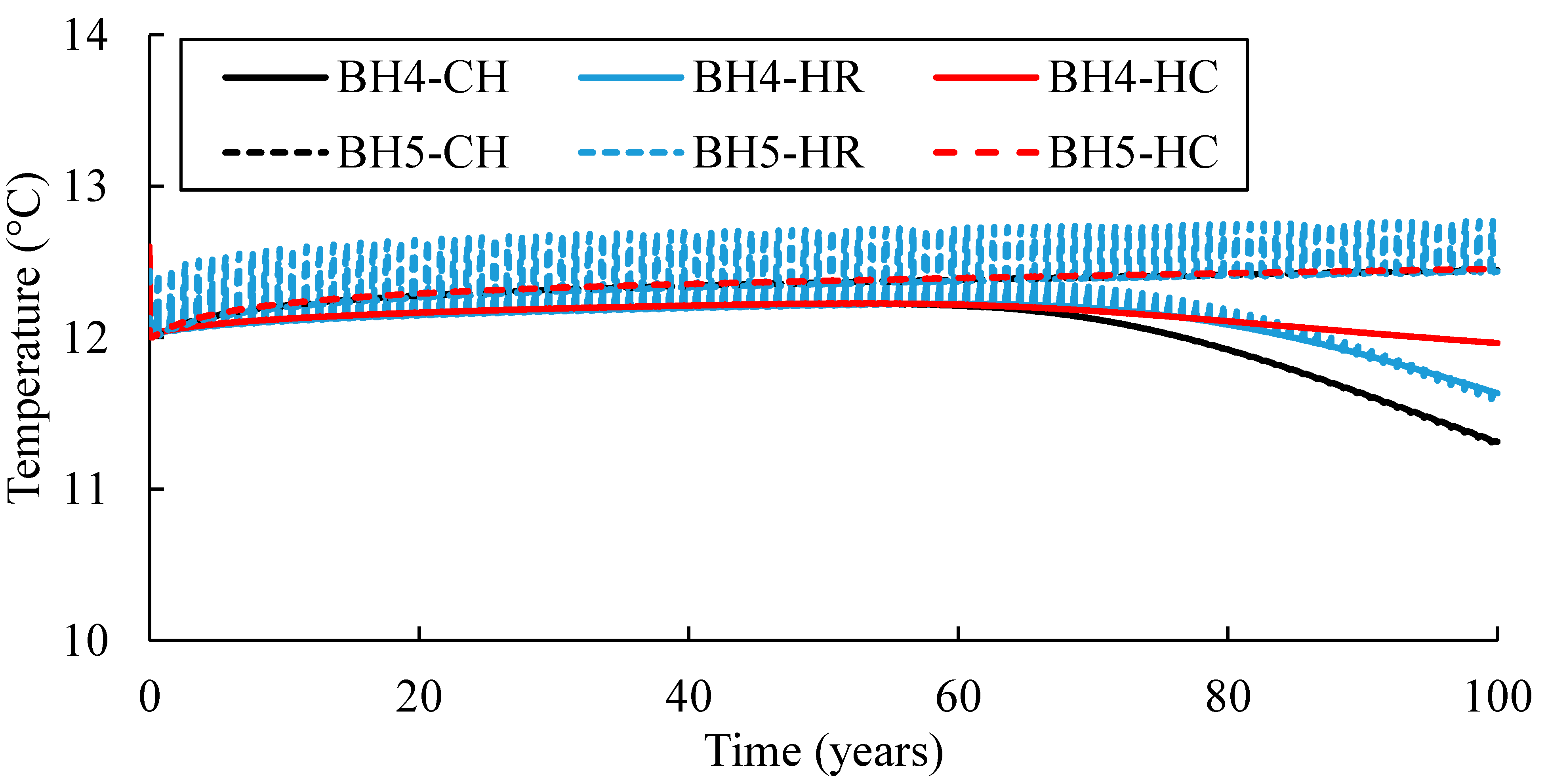

3.4. Temperature Evolution

- (a)

- Continuous heating test (CH test)

- (b)

- Heating and recovery test (HR test)

- (c)

- Heating and cooling test (HC test)

- (d)

- ATES test

- (e)

- Comparison

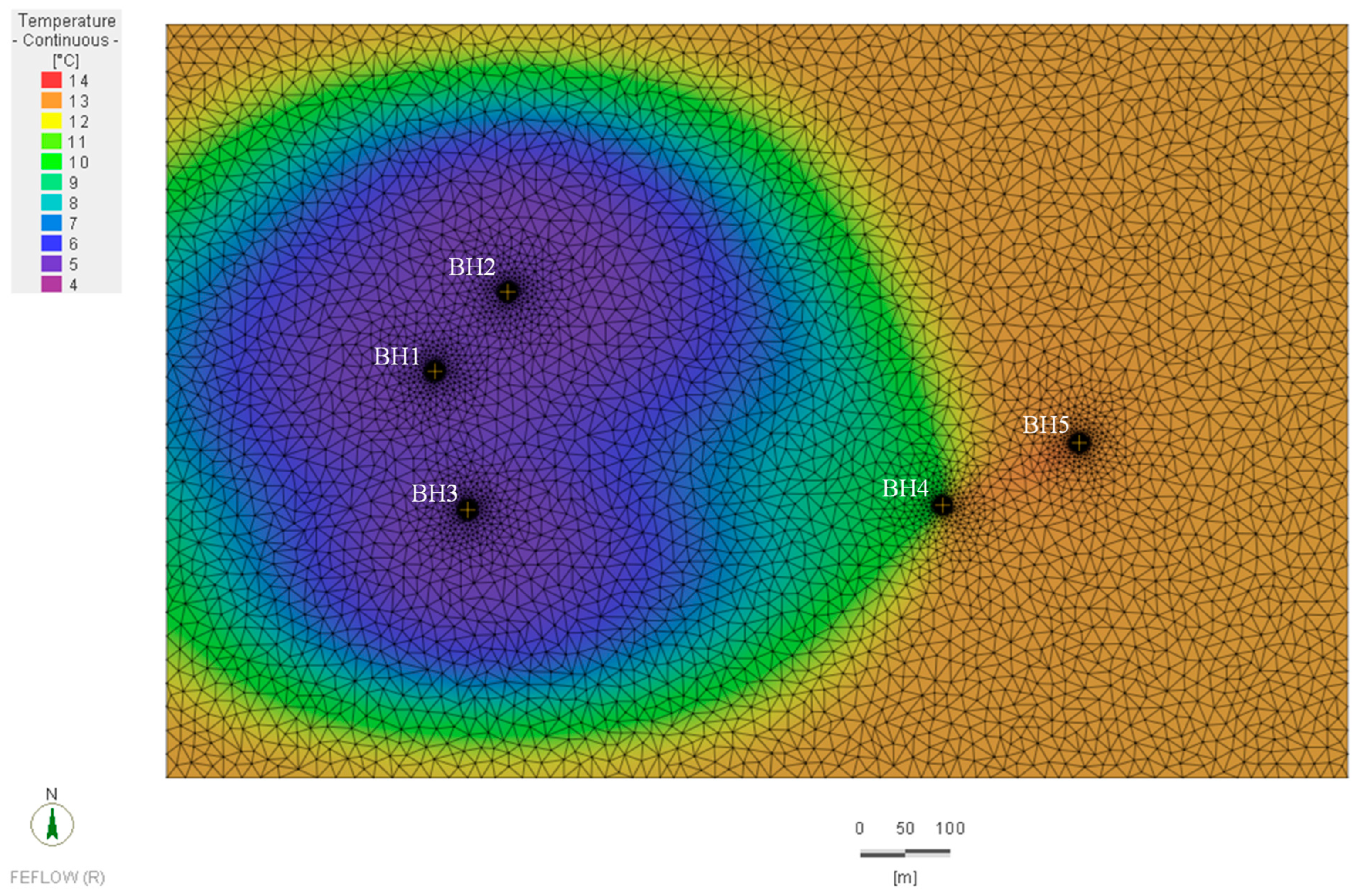

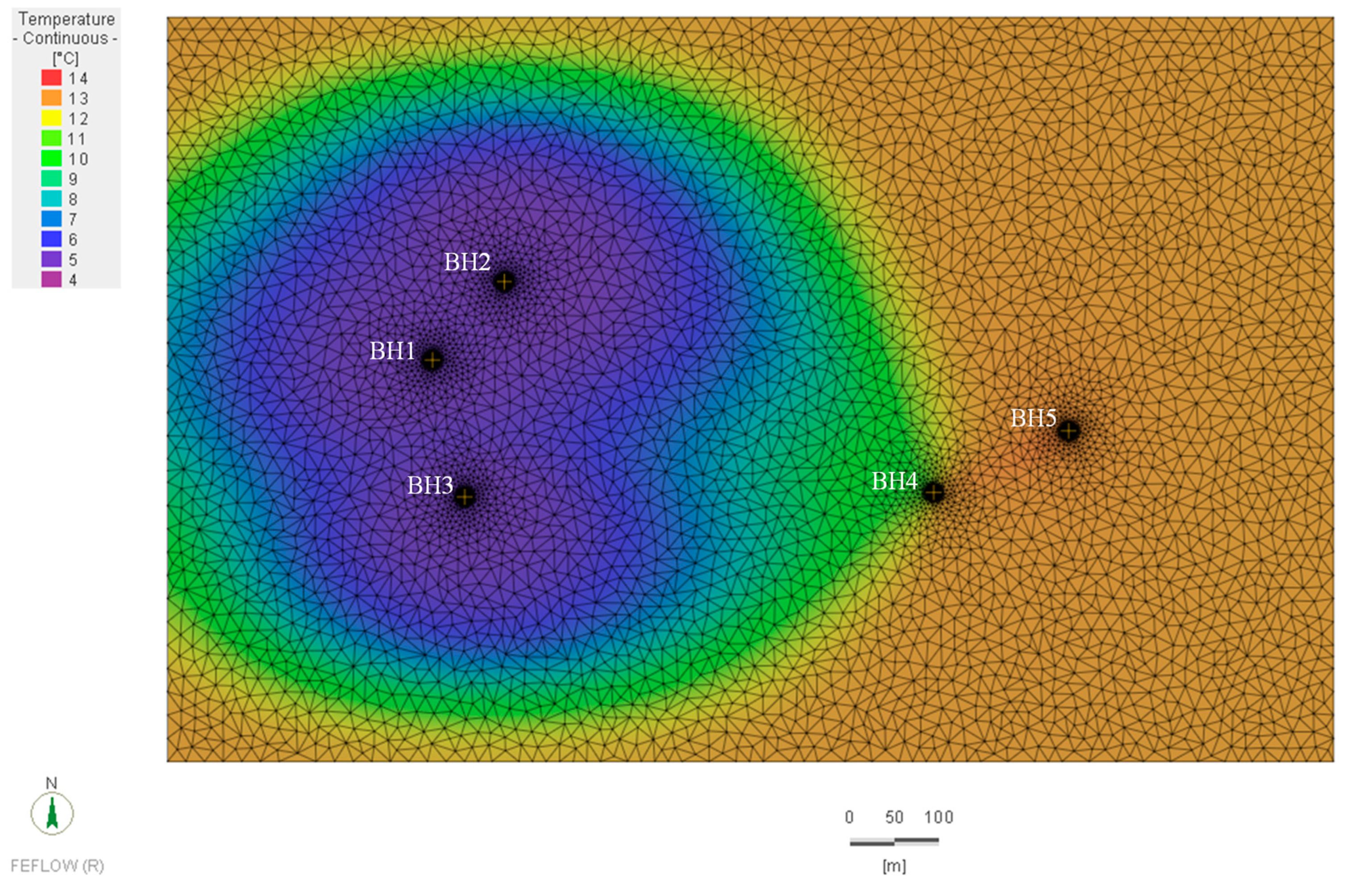

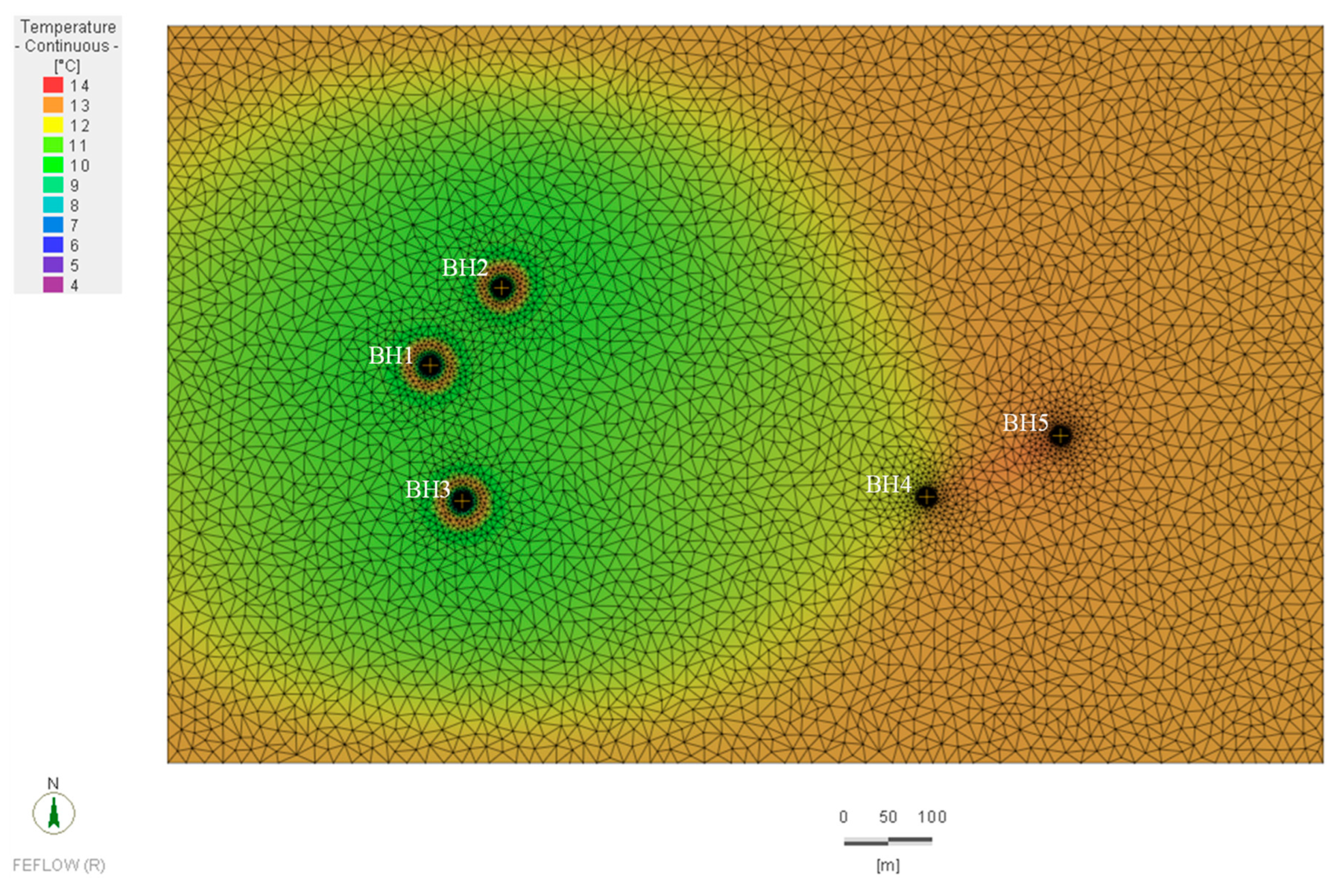

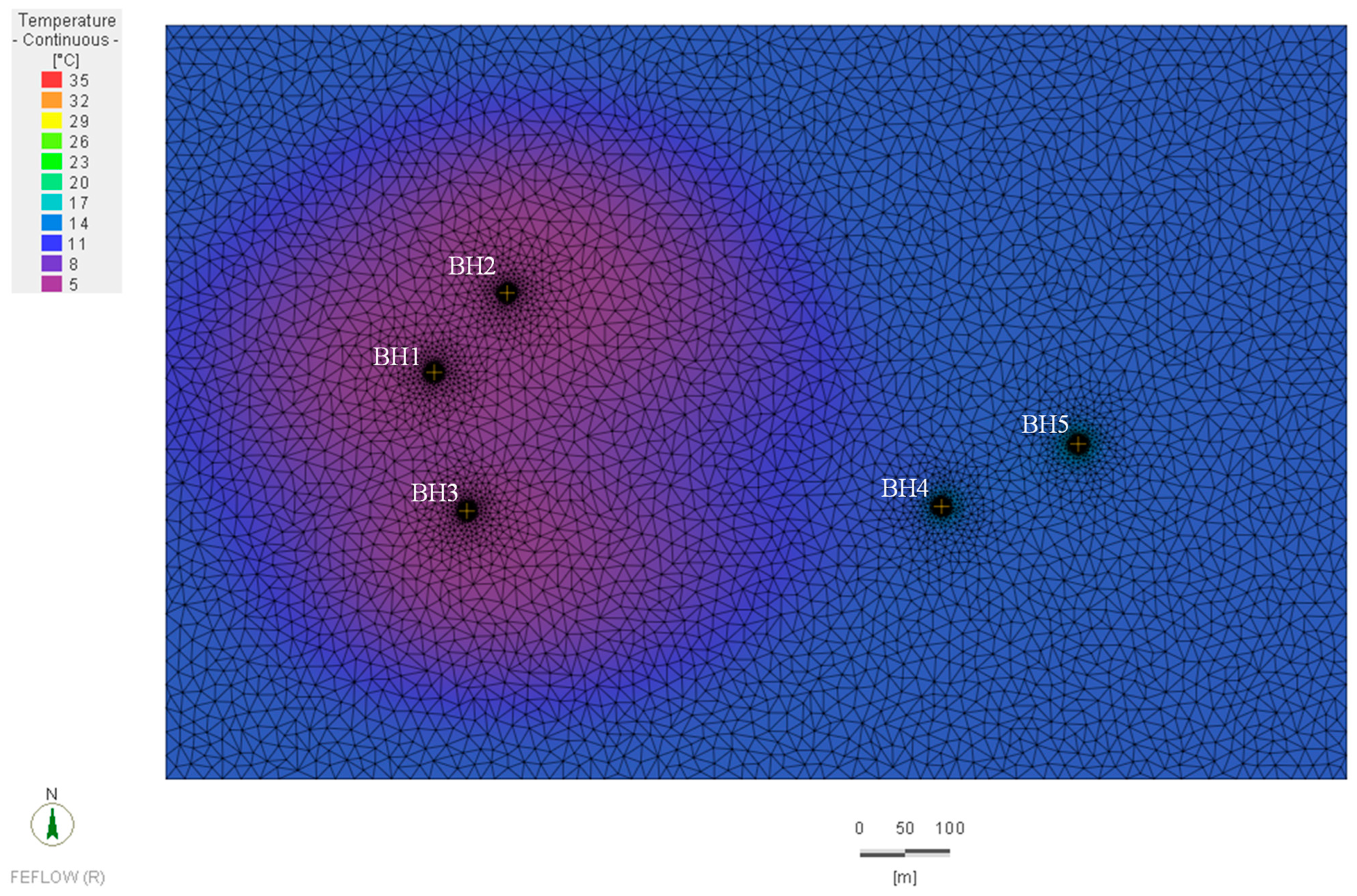

3.5. Thermal Plume Development and Groundwater Flow Impact

4. Conclusions

- Thermal feedback occurs in the CH, HR, and HC operations. The thermal plume reached BH4 in each operation. However, BH5 was not affected by the thermal plume, since it is located 160 m away from BH4.

- It takes around 60, 70 and 65 years to observe a temperature drop of 0.2 °C in the CH, HR, and HC operations, respectively. After 100 years of simulation, the observed temperature in BH4 decreased by 10%, 8%, and 5% in the CH, HR, and HC operations, respectively.

- In the CH, HR, HC and ATES operations, the total thermal energy gained from the groundwater during the heating period is 372, 340, 341, and 515 GWh over 100 years, respectively. During the cooling period, it is approximately 106 and 501 GWh in the HC and ATES operations, respectively.

- The HR operation decreases the thermal impact observed in the abstraction temperature. However, the thermal energy gain from the groundwater in HR operation is lower than CH due to no energy production in the recovery time of two months per year. The HC operation also decreases the thermal impact on the abstraction temperature compared to the CH. The thermal energy gain during the heating period in the HC operation is relatively higher than in the HR operation, but lower than in the CH operation. The thermal energy gain during the heating period is 38% higher in ATES than in CH due to the use of stored thermal energy during the cooling period.

- The thermal energy gain during the cooling period in the ATES operation is approximately fivefold the HC operation. This result can be attributed to two reasons. First, the ATES operation uses the stored cooler water during the heating period, which increases the thermal energy gain by increasing ΔT. Second, the abstraction rate during the cooling period in the ATES operation is 50% higher than in the HC operation because the ATES operation uses three wells to abstract water from the aquifer, whilst the HC operation uses two wells.

- The utilization of an ATES system can lead to a 173% increase in thermal energy gain compared to the actual system operation. However, its feasibility depends on the hydrogeological conditions of the site. On the other hand, implementing an HC system can enhance efficiency by 20% without the need to change the working principle of the system.

- Groundwater flow has a considerable impact on thermal plume development. It disperses the thermal plume in the groundwater flow direction, resulting in greater thermal changes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- D’Agostino, D.; Cuniberti, B.; Bertoldi, P. Energy consumption and efficiency technology measures in European non-residential buildings. Energy Build. 2017, 153, 72–86. [Google Scholar] [CrossRef]

- Russo, S.L.; Taddia, G.; Verda, V. Development of the thermally affected zone (TAZ) around a groundwater heat pump (GWHP) system: A sensitivity analysis. Geothermics 2012, 43, 66–74. [Google Scholar] [CrossRef]

- Blázquez, C.S.; Verda, V.; Nieto, I.M.; Martín, A.F.; González-Aguilera, D. Analysis and optimization of the design parameters of a district groundwater heat pump system in Turin, Italy. Renew. Energy 2020, 149, 374–383. [Google Scholar] [CrossRef]

- Singh, R.M.; Sani, A.K.; Amis, T. An overview of ground-source heat pump technology. In Managing Global Warming: An Interface of Technology and Human Issues; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Casasso, A.; Tosco, T.; Bianco, C.; Bucci, A.; Sethi, R. How Can We Make Pump and Treat Systems More Energetically Sustainable? Water 2019, 12, 67. [Google Scholar] [CrossRef]

- Florides, G.; Kalogirou, S. Ground heat exchangers—A review of systems, models and applications. Renew. Energy 2007, 32, 2461–2478. [Google Scholar] [CrossRef]

- Galgaro, A.; Cultrera, M. Thermal short circuit on groundwater heat pump. Appl. Therm. Eng. 2013, 57, 107–115. [Google Scholar] [CrossRef]

- Banks, D. Thermogeological assessment of open-loop well-doublet schemes: A review and synthesis of analytical approaches. Hydrogeol. J. 2009, 17, 1149–1155. [Google Scholar] [CrossRef]

- Bloemendal, M.; Olsthoorn, T.; Boons, F. How to achieve optimal and sustainable use of the subsurface for Aquifer Thermal Energy Storage. Energy Policy 2014, 66, 104–114. [Google Scholar] [CrossRef]

- Gao, L.; Zhao, J.; An, Q.; Wang, J.; Liu, X. A review on system performance studies of aquifer thermal energy storage. Energy Procedia 2017, 142, 3537–3545. [Google Scholar] [CrossRef]

- Fleuchaus, P.; Schüppler, S.; Godschalk, B.; Bakema, G.; Blum, P. Performance analysis of Aquifer Thermal Energy Storage (ATES). Renew. Energy 2019, 146, 1536–1548. [Google Scholar] [CrossRef]

- Dickinson, J.S.; Buik, N.; Matthews, M.C.; Snijders, A. Aquifer thermal energy storage: Theoretical and operational analysis. 2009, 59, 249–260. Geotechnique 2009, 59, 249–260. [Google Scholar] [CrossRef]

- Bonte, M.; Van Breukelen, B.M.; Stuyfzand, P.J. Environmental impacts of aquifer thermal energy storage investigated by field and laboratory experiments. J. Water Clim. Chang. 2013, 4, 77–89. [Google Scholar] [CrossRef]

- Park, D.; Lee, E.; Kaown, D.; Lee, S.-S.; Lee, K.-K. Determination of optimal well locations and pumping/injection rates for groundwater heat pump system. Geothermics 2021, 92, 102050. [Google Scholar] [CrossRef]

- Halilovic, S.; Böttcher, F.; Kramer, S.C.; Piggott, M.D.; Zosseder, K.; Hamacher, T. Well layout optimization for groundwater heat pump systems using the adjoint approach. Energy Convers. Manag. 2022, 268, 116033. [Google Scholar] [CrossRef]

- Pophillat, W.; Attard, G.; Bayer, P.; Hecht-Méndez, J.; Blum, P. Analytical solutions for predicting thermal plumes of groundwater heat pump systems. Renew. Energy 2020, 147, 2696–2707. [Google Scholar] [CrossRef]

- Russo, S.L.; Civita, M.V. Open-loop groundwater heat pumps development for large buildings: A case study. Geothermics 2009, 38, 335–345. [Google Scholar] [CrossRef]

- Russo, S.L.; Gnavi, L.; Roccia, E.; Taddia, G.; Verda, V. Groundwater Heat Pump (GWHP) system modeling and Thermal Affected Zone (TAZ) prediction reliability: Influence of temporal variations in flow discharge and injection temperature. Geothermics 2014, 51, 103–112. [Google Scholar] [CrossRef]

- Russo, S.L.; Taddia, G.; Baccino, G.; Verda, V. Different design scenarios related to an open loop groundwater heat pump in a large building: Impact on subsurface and primary energy consumption. Energy Build. 2011, 43, 347–357. [Google Scholar] [CrossRef]

- Halilovic, S.; Odersky, L.; Hamacher, T. Integration of groundwater heat pumps into energy system optimization models. Energy 2021, 238, 121607. [Google Scholar] [CrossRef]

- Biglia, A.; Ferrara, M.; Fabrizio, E. On the real performance of groundwater heat pumps: Experimental evidence from a residential district. Appl. Therm. Eng. 2021, 192, 116887. [Google Scholar] [CrossRef]

- Kranz, S.; Bartels, J. Simulation and Data Based Optimisation of an Operating Seasonal Aquifer Thermal Energy Storage. In Proceedings of the World Geothermal Congress 2010, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Halilovic, S.; Böttcher, F.; Zosseder, K.; Hamacher, T. Optimizing the spatial arrangement of groundwater heat pumps and their well locations. Renew. Energy 2023, 217, 119148. [Google Scholar] [CrossRef]

- Boon, D.P.; Butcher, A.; Townsend, B.; Woods, M.A. Geological and Hydrogeological Investigations in the Colchester Northern Gateway Boreholes: February 2020 Survey; British Geological Survey: Nottingham, UK, 2020. [Google Scholar]

- Birks, D.; Coutts, C.A.; Younger, P.L.; Parkin, G. Development of A Groundwater Heating and Cooling Scheme in A Per-Mo-Triassic Sandstone Aquifer in South-West England and Approach to Managing Risks. Geosci. South-West Engl. 2015, 13, 428–436. Available online: http://eprints.gla.ac.uk/116692/ (accessed on 28 July 2022).

- Boon, D.P.; Farr, G.J.; Abesser, C.; Patton, A.M.; James, D.R.; Schofield, D.I.; Tucker, D.G. Groundwater heat pump feasibility in shallow urban aquifers: Experience from Cardiff, UK. Sci. Total. Environ. 2019, 697, 133847. [Google Scholar] [CrossRef]

- Diersch, H.-J.G. FEFLOW: Finite Element Modeling of Flow, Mass and Heat Transport in Porous and Fractured Media; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–996. [Google Scholar] [CrossRef]

- De-wit, E. Pumping Test Factual Report Project Name: Colchester Northern Gateway Heat Network Stage Gate 4 Client; Colchester Amphora Energy: Colchester, UK, 2020. [Google Scholar]

- Park, B.-H.; Bae, G.-O.B.; Lee, K.-K. Importance of thermal dispersivity in designing groundwater heat pump (GWHP) system: Field and numerical study. Renew. Energy 2015, 83, 270–279. [Google Scholar] [CrossRef]

- Allen, D.J.; Brewerton, L.J.; Coleby, L.M.; Gibbs, B.R.; Lewis, M.A.; MacDonald, A.M.; Wagstaff, S.J.; Williams, A.T. The Physical Properties of Major Aquifers in England and Wales; British Geological Survey: Nottingham, UK, 1997. [Google Scholar]

- Busby, J. A modelling study of the variation of thermal conductivity of the English Chalk. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 417–423. [Google Scholar] [CrossRef]

- Cengel, Y.; Afshin, G. Heat and Mass Transfer: Fundamentals and Applications; McGraw Hill: New York, NY, USA, 2014. [Google Scholar]

| Geological Formation | Ground Depth (m) | Horizontal Hydraulic Conductivity (m/s) | Vertical Hydraulic Conductivity (m/s) | Thermal Conductivity of Solid (j/m/s/k) | Thermal Conductivity of Fluid (j/m/s/k) | Porosity | Volumetric Heat Capacity of Solid (MJ/m3/K) | Volumetric Heat Capacity of Fluid (MJ/m3/K) |

|---|---|---|---|---|---|---|---|---|

| Topsoil/Made Ground, Sand and Gravels | 0–6 | 5 × 10−4 | 5 × 10−5 | 1.5 | 0.6 | 0.34 | 2.52 | 4.2 |

| Thames Group | 6–50 | 5.8 × 10−11 | 5.8 × 10−12 | |||||

| Lambeth Group and Thanet Sands | 50–72 | 2 × 10−8 | 2 × 10−9 | |||||

| White Chalk Subgroup * | 72–154 | 1 × 10−6–3.9 × 10−6 | 1 × 10−7–3.9 × 10−7 | 1.87 | ||||

| White Chalk Subgroup ** | 154–185 | 1.96 | ||||||

| White Chalk Subgroup *** | 185–275 | 8 × 10−8–8 × 10−9 | 8 × 10−9–8 × 10−10 | 1.8 | ||||

| Gault Clay | 275–300 | 8.3 × 10−12 | 8.3 × 10−13 | 1.5 |

| Numerical Simulations (Scenarios) | Abbreviation | Heating Period (Months per Year) | Cooling Period (Months per Year) |

|---|---|---|---|

| Continuous heating | CH | 12 | 0 |

| Heating and recovery | HR | 10 | |

| Heating and cooling | HC | 2 | |

| Aquifer thermal energy storage | ATES |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sezer, T.; Sani, A.K.; Singh, R.M.; Cui, L. Numerical Investigation and Optimization of a District-Scale Groundwater Heat Pump System. Energies 2023, 16, 7169. https://doi.org/10.3390/en16207169

Sezer T, Sani AK, Singh RM, Cui L. Numerical Investigation and Optimization of a District-Scale Groundwater Heat Pump System. Energies. 2023; 16(20):7169. https://doi.org/10.3390/en16207169

Chicago/Turabian StyleSezer, Taha, Abubakar Kawuwa Sani, Rao Martand Singh, and Liang Cui. 2023. "Numerical Investigation and Optimization of a District-Scale Groundwater Heat Pump System" Energies 16, no. 20: 7169. https://doi.org/10.3390/en16207169

APA StyleSezer, T., Sani, A. K., Singh, R. M., & Cui, L. (2023). Numerical Investigation and Optimization of a District-Scale Groundwater Heat Pump System. Energies, 16(20), 7169. https://doi.org/10.3390/en16207169