The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier

Abstract

1. Introduction

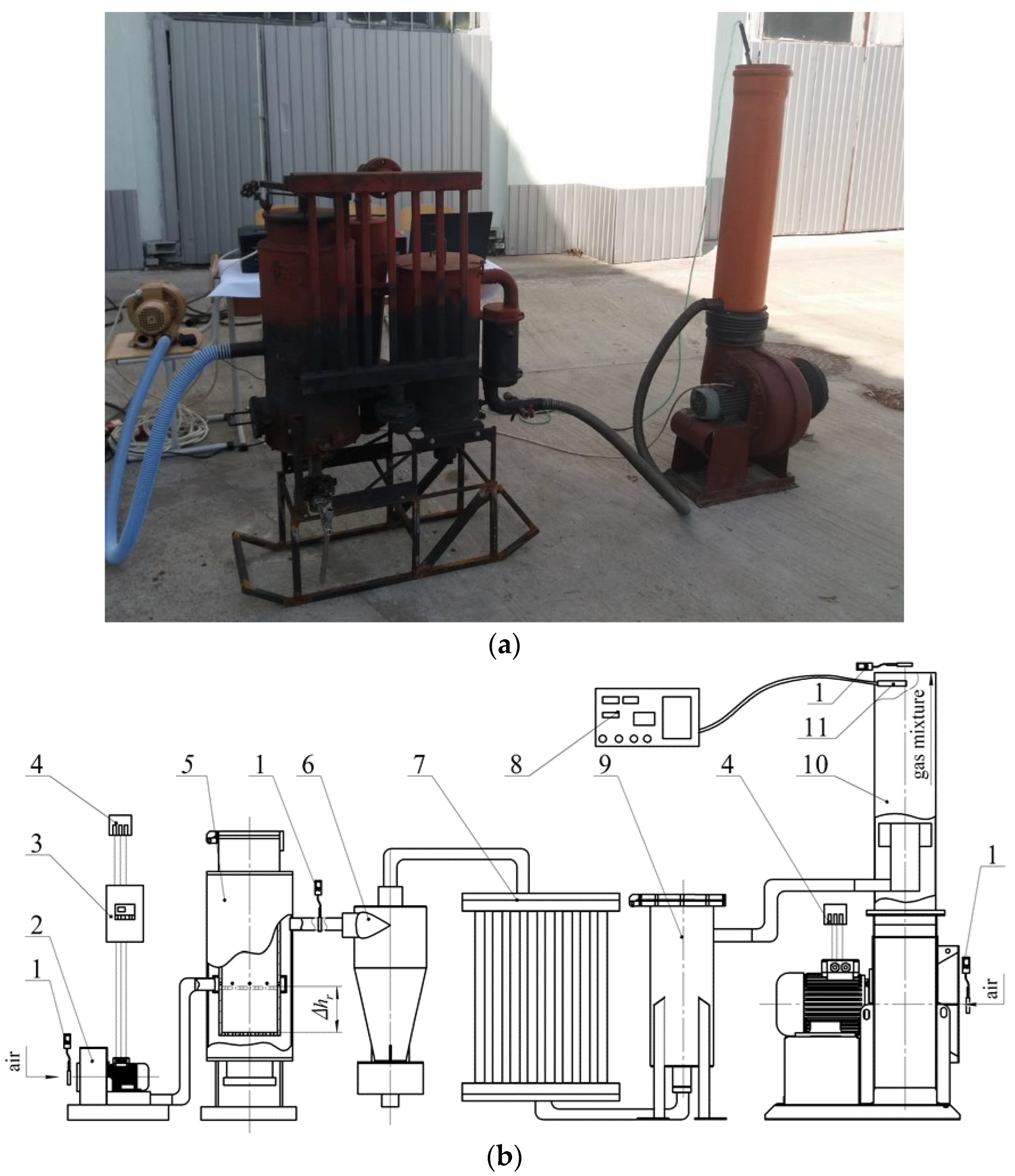

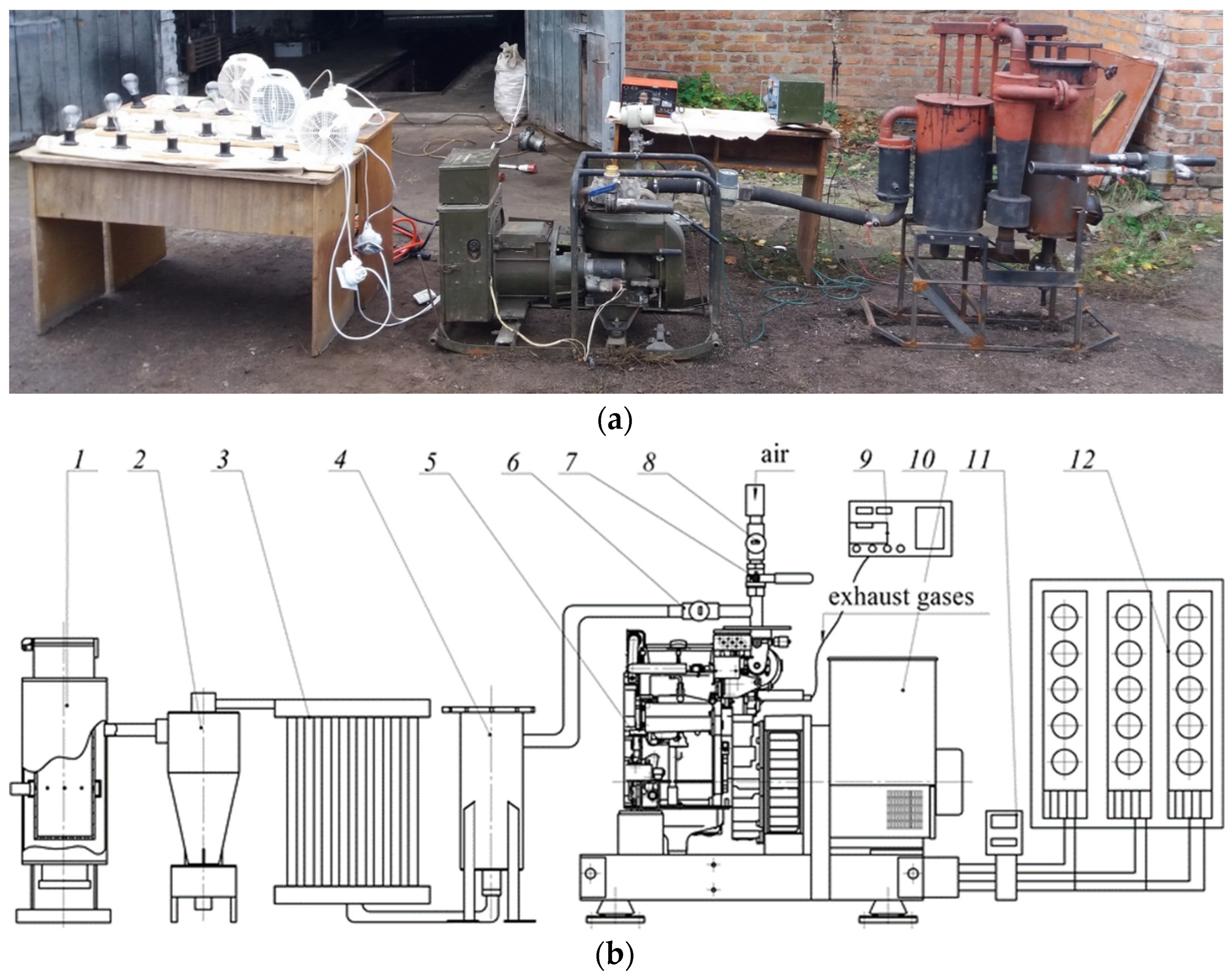

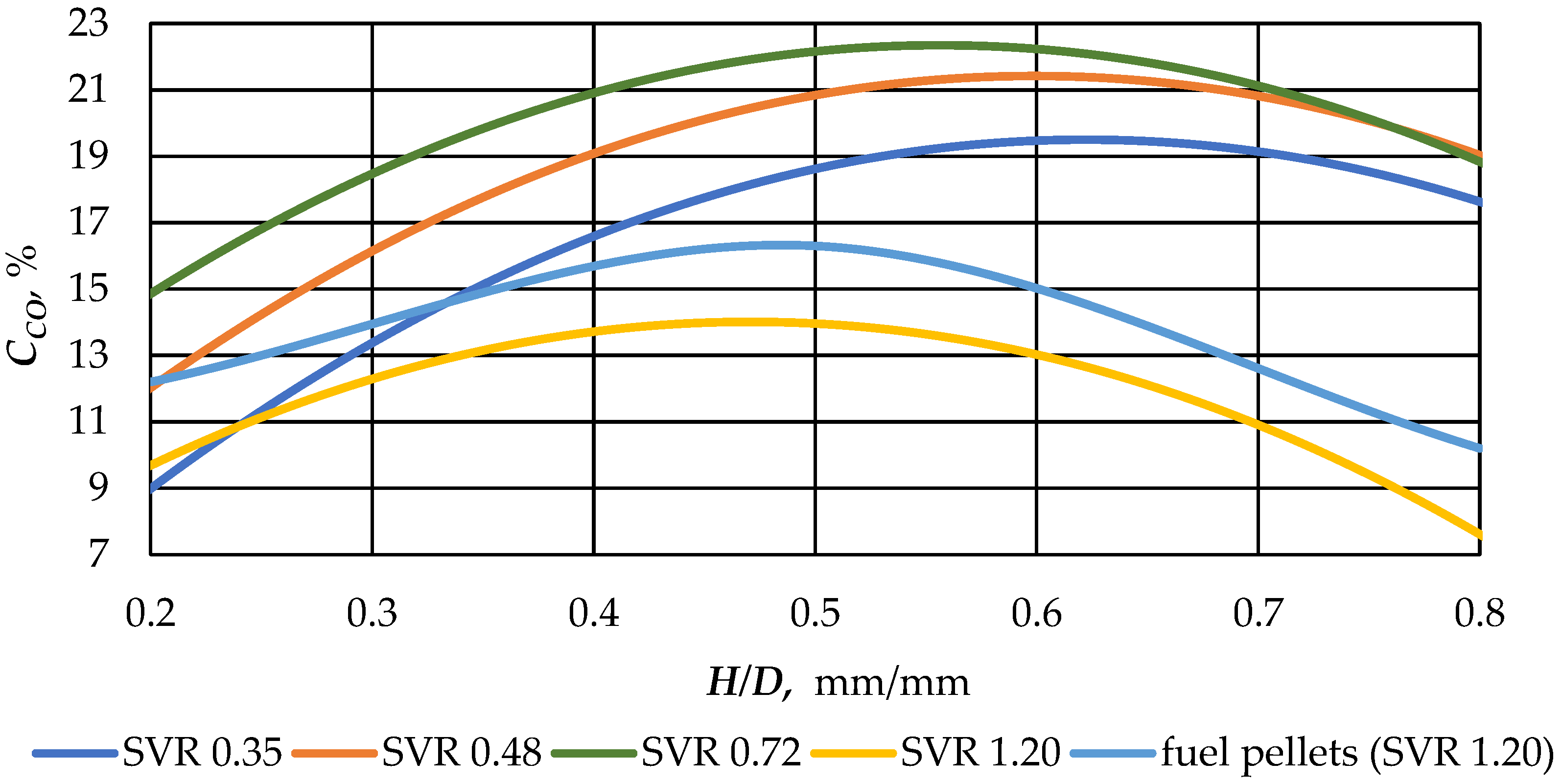

2. Materials and Methods

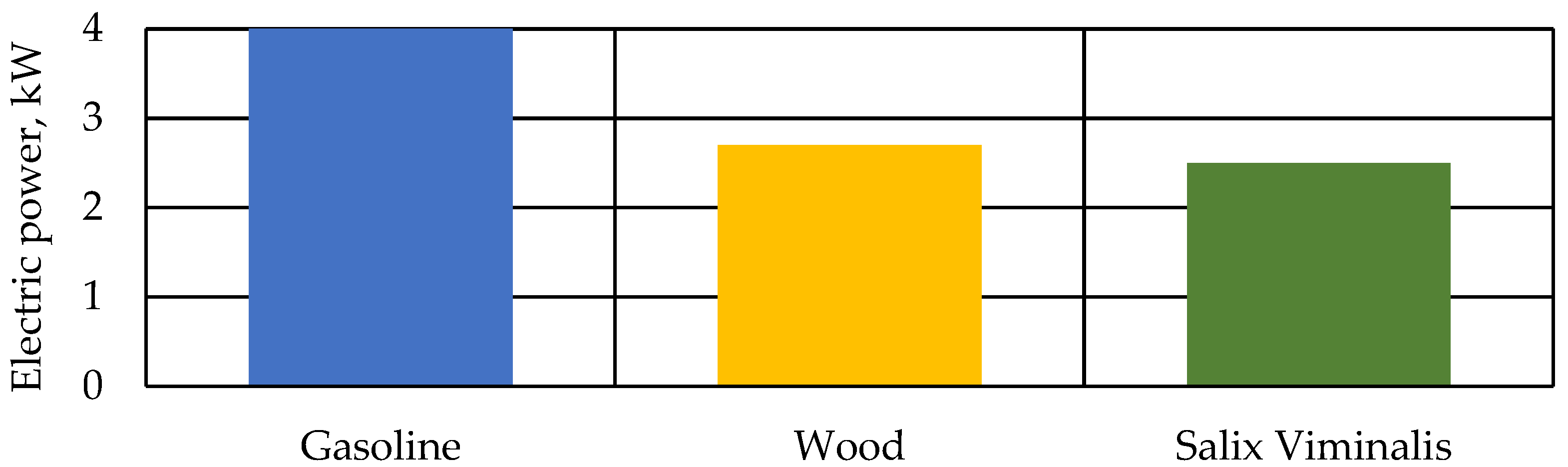

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kucher, O.; Glowacki, S.; Andreitseva, I.; Dibrova, A.; Muzychenko, A.; Szeląg-Sikora, A.; Szparaga, A.; Kocira, S. Energy Potential of Biogas Production in Ukraine. Energies 2022, 15, 1710. [Google Scholar] [CrossRef]

- Golub, G.A.; Kukharets, S.M.; Yarosh, Y.D.; Kukharets, V.V. Integrated use of bioenergy conversion technologies in agroecosystems. INMATEH Agric. Eng. 2017, 51, 93–100. [Google Scholar]

- Mathur, S.; Waswani, H.; Singh, D.; Ranjan, R. Alternative Fuels for Agriculture Sustainability: Carbon Footprint and Economic Feasibility. AgriEngineering 2022, 4, 993–1015. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Kuboń, M.; Tryhuba, I.; Komarnitskyi, S.; Tabor, S.; Kwaśniewski, D.; Mudryk, K.; Faichuk, O.; Hohol, T. Taxonomy and Stakeholder Risk Management in Integrated Projects of the European Green Deal. Energies 2022, 15, 2015. [Google Scholar] [CrossRef]

- Johansson, R.; Meyer, S.; Whistance, J.; Thompson, W.; Debnath, D. Greenhouse gas emission reduction and cost from the United States biofuels mandate. Renew. Sustain. Energy Rev. 2020, 119, 109513. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Cotana, F.; Nicolini, A.; Coccia, V.; Petrozzi, A.; Formica, A.; Bertini, A. Characterization of Various Biomass Feedstock Suitable for Small-Scale Energy Plants as Preliminary Activity of Biocheaper Project. Sustainability 2020, 12, 6678. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil Kumar, P.; Jeevanantham, S.; Karishma, S.; Vo, D.N. Recent advances and sustainable development of biofuels production from lignocellulosic biomass. Bioresour. Technol. 2022, 344, 126203. [Google Scholar] [CrossRef]

- Golub, G.; Skydan, O.; Kukharets, V.; Yarosh, Y.; Kukharets, S. The estimation of energetically self-sufficient agroecosystem’s model. J. Cent. Eur. Agric. 2020, 21, 168–175. [Google Scholar] [CrossRef]

- Golub, G.; Chuba, V.; Lutak, V.; Yarosh, Y.; Kukharets, S. Researching of indicators of agroecosystem without external energy supply. J. Cent. Eur. Agric. 2021, 22, 397–407. [Google Scholar] [CrossRef]

- Kukharets, S.; Hutsol, T.; Glowacki, S.; Sukmaniuk, O.; Rozkosz, A.; Tkach, O. Concept of biohydrogen production by agricultural enterprises. Agric. Eng. 2021, 25, 63–72. [Google Scholar] [CrossRef]

- Umakanth, A.V.; Datta, A.; Reddy, B.S.; Bardhan, S. Chapter 3—Biomass feedstocks for advanced biofuels: Sustainability and supply chain management. In Advanced Biofuel Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 39–72. [Google Scholar] [CrossRef]

- Vaish, S.; Kaur, G.; Sharma, N.K.; Gakkhar, N. Estimation for Potential of Agricultural Biomass Sources as Projections of Bio-Briquettes in Indian Context. Sustainability 2022, 14, 5077. [Google Scholar] [CrossRef]

- Petlickaitė, R.; Jasinskas, A.; Mieldažys, R.; Romaneckas, K.; Praspaliauskas, M.; Balandaitė, J. Investigation of Pressed Solid Biofuel Produced from Multi-Crop Biomass. Sustainability 2022, 14, 799. [Google Scholar] [CrossRef]

- Verdade, L.M.; Piña, C.I.; Rosalino, L.M. Biofuels and biodiversity: Challenges and opportunities. Environ. Dev. 2015, 15, 64–78. [Google Scholar] [CrossRef]

- Hunt, N.D.; Gower, S.T.; Nadelhoffer, K.; Lajtha, K.; Townsend, K.; Brye, K.R. Validation of an agroecosystem process model (AGRO-BGC) on annual and perennial bioenergy feedstocks. Ecol. Model. 2016, 321, 23–34. [Google Scholar] [CrossRef]

- Kurowska, K.; Marks-Bielska, R.; Bielski, S.; Kryszk, H.; Jasinskas, A. Food Security in the Context of Liquid Biofuels Production. Energies 2020, 13, 6247. [Google Scholar] [CrossRef]

- Gomiero, T. Large-scale biofuels production: A possible threat to soil conservation and environmental services. Appl. Soil Ecol. 2018, 123, 729–736. [Google Scholar] [CrossRef]

- Ahamer, G. Why Biomass Fuels Are Principally Not Carbon Neutral. Energies 2022, 15, 9619. [Google Scholar] [CrossRef]

- Mockshell, J.; Villarino, M.E. Agroecological intensification: Potential and limitations to achieving food security and sustainability. Encycl. Food Secur. Sustain. 2019, 3, 64–70. [Google Scholar] [CrossRef]

- Kazemi, H.; Klug, H.; Kamkar, B. New services and roles of biodiversity in modern agroecosystems: A review. Ecol. Indic. 2018, 93, 1126–1135. [Google Scholar] [CrossRef]

- Jasinskas, A.; Šiaudinis, G.; Martinkus, M.; Karčauskienė, D.; Repšienė, R.; Pedišius, N.; Vonžodas, T. Evaluation of common osier (Salix viminalis L.) and black poplar (Populus nigra L.) biomass productivity and determination of chemical and energetic properties of chopped plants produced for biofuel. Balt. For. 2017, 23, 666–672. [Google Scholar]

- Dimitriou, I.; Mola-Yudego, B. Poplar and willow plantations on agricultural land in Sweden: Area, yield, groundwater quality and soil organic carbon. For. Ecol. Manag. 2017, 383, 99–107. [Google Scholar] [CrossRef]

- Alian, S.; Maclean, A. Assessing Site Availability of Aspen and Northern Hardwoods for Potential Feedstock Development in Michigan: A Case Study. Land 2015, 4, 413–435. [Google Scholar] [CrossRef]

- Lutter, R.; Stål, G.; Arnesson Ceder, L.; Lim, H.; Padari, A.; Tullus, H.; Nordin, A.; Lundmark, T. Climate Benefit of Different Tree Species on Former Agricultural Land in Northern Europe. Forests 2021, 12, 1810. [Google Scholar] [CrossRef]

- Nilsson, D.; Rosenqvist, H. Profitability of Crop Cultivation in Small Arable Fields When Taking Economic Values of Ecosystem Services into Account. Sustainability 2021, 13, 13354. [Google Scholar] [CrossRef]

- Ochieng, R.; Gebremedhin, A.; Sarker, S. Integration of Waste to Bioenergy Conversion Systems: A Critical Review. Energies 2022, 15, 2697. [Google Scholar] [CrossRef]

- Tropea, A. Biofuels Production and Processing Technology. Fermentation 2022, 8, 319. [Google Scholar] [CrossRef]

- Baba, T.; Nomura, H.; Srean, P.; Than, T.; Ito, K. Effects of Mechanization and Investments on the Technical Efficiency of Cassava Farms in Cambodia. Agriculture 2022, 12, 441. [Google Scholar] [CrossRef]

- Banerjee, N.; Sukichandran, P.; Chaudhari, P.; Thakur, A.K.; Kumar, R. Energy analysis and feasibility studies for algal biomass and biofuels. Mater. Today Proc. 2022, 57, 1448–1454. [Google Scholar] [CrossRef]

- Gao, J.; Jebrane, M.; Terziev, N.; Daniel, G. Evaluation of Wood Quality Traits in Salix viminalis Useful for Biofuels: Characterization and Method Development. Forests 2021, 12, 1048. [Google Scholar] [CrossRef]

- Abreu, M.; Silva, L.; Ribeiro, B.; Ferreira, A.; Alves, L.; Paixão, S.M.; Gouveia, L.; Moura, P.; Carvalheiro, F.; Duarte, L.C.; et al. Low Indirect Land Use Change (ILUC) Energy Crops to Bioenergy and Biofuels—A Review. Energies 2022, 15, 4348. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Załuski, D.; Olba-Zięty, E. Willow Biomass as Energy Feedstock: The Effect of Habitat, Genotype and Harvest Rotation on Thermophysical Properties and Elemental Composition. Energies 2020, 13, 4130. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Musiał, D. Computational and Experimental Studies of Selected Types of Biomass Combustion in a Domestic Boiler. Materials 2022, 15, 4826. [Google Scholar] [CrossRef]

- Jasinskas, A.; Streikus, D.; Šarauskis, E.; Palšauskas, M.; Venslauskas, K. Energy Evaluation and Greenhouse Gas Emissions of Reed Plant Pelletizing and Utilization as Solid Biofuel. Energies 2020, 13, 1516. [Google Scholar] [CrossRef]

- Romanowska-Duda, Z.; Szufa, S.; Grzesik, M.; Piotrowski, K.; Janas, R. The Promotive Effect of Cyanobacteria and Chlorella sp. Foliar Biofertilization on Growth and Metabolic Activities of Willow (Salix viminalis L.) Plants as Feedstock Production, Solid Biofuel and Biochar as C Carrier for Fertilizers via Torrefaction Process. Energies 2021, 14, 5262. [Google Scholar] [CrossRef]

- Golub, G.; Kukharets, S.; Skydan, O.; Yarosh, Y.; Chuba, V.; Golub, V. The Optimization of the Gasifier Recovery Zone Height When Working on Straw Pellets. Int. J. Renew. Energy Res. 2020, 10, 529–536. [Google Scholar]

- Greinert, A.; Mrówczyńska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef]

- Pan, P.; Zhang, M.; Xu, G.; Chen, H.; Song, X.; Liu, T. Thermodynamic and Economic Analyses of a New Waste-to-Energy System Incorporated with a Biomass-Fired Power Plant. Energies 2020, 13, 4345. [Google Scholar] [CrossRef]

- Patra, T.K.; Sheth, P.N. Biomass Gasification Models for Downdraft Gasifier: A State-of-the-art Review. Renew. Sustain. Energy Rev. 2015, 50, 583–593. [Google Scholar] [CrossRef]

- Golub, G.; Kukharets, S.; Yarosh, Y.; Chuba, V. Method for Optimization of the Gasifier Recovery Zone Height. J. Sustain. Dev. Energy Water Environ. Syst. 2019, 7, 493–505. [Google Scholar] [CrossRef]

- Nunes, L.J.R. Biomass gasification as an industrial process with effective proof-of-concept: A comprehensive review on tech-nologies, processes and future developments. Results Eng. 2022, 14, 100408. [Google Scholar] [CrossRef]

- Anukam, A.; Mamphweli, S.; Reddy, R.; Meyer, E.; Okoh, O. Pre-processing of Sugarcane Bagasse for Gasification in a Downdraft Biomass Gasifier System: A Comprehensive Review. Renew. Sustain. Energy Rev. 2016, 66, 775–801. [Google Scholar] [CrossRef]

- Sarker, S.; Nielsen, H.K. Assessing the gasification potential of five woodchips species by employing a lab-scale fixed-bed downdraft reactor. Energy Convers. Manag. 2015, 103, 801–813. [Google Scholar] [CrossRef]

- Hai, I.U.; Sher, F.; Yaqoob, A.; Liu, H. Assessment of biomass energy potential for SRC willow woodchips in a pilot scale bubbling fluidized bed gasifier. Fuel 2019, 258, 116143. [Google Scholar] [CrossRef]

- Valin, S.; Ravel, S.; Pons de Vincent, P.; Thiery, S.; Miller, H.; Defoort, F.; Grateau, M. Fluidised Bed Gasification of Diverse Biomass Feedstocks and Blends—An Overall Performance Study. Energies 2020, 13, 3706. [Google Scholar] [CrossRef]

- Thomasson, T.; Kiviranta, K.; Tapani, A.; Tähtinen, M. Flexibility from Combined Heat and Power: A Techno-Economic Study for Fully Renewable Åland Islands. Energies 2021, 14, 6423. [Google Scholar] [CrossRef]

- Allesina, G.; Pedrazzi, S. Barriers to Success: A Technical Review on the Limits and Possible Future Roles of Small Scale Gasifiers. Energies 2021, 14, 6711. [Google Scholar] [CrossRef]

- Petrillo, A.; Travaglioni, V.; Di Fraia, S.; Vanoli, L.; Cirillo, D.; La Villetta, M. Experimental study and Life Cycle Assessment of biomass small-scale trigeneration plant. J. Clean. Prod. 2021, 326, 129234. [Google Scholar] [CrossRef]

- Golub, G.; Kukharets, S.; Tsyvenkova, N.; Yarosh, Y.; Chuba, V. Experimental study into the influence of straw content in fuel on parameters of generator gas. East. Eur. J. Enterp. Technol. 2018, 5, 76–86. [Google Scholar] [CrossRef]

- Jia, J.; Xu, L.; Abudula, A.; Sun, B. Effects of operating parameters on performance of a downdraft gasifier in steady and transient state. Energy Convers. Manag. 2018, 155, 138–146. [Google Scholar] [CrossRef]

- Maneerung, T.; Li, X.; Li, C.; Dai, Y.; Wang, C.-H. Integrated downdraft gasification with power generation system and gasification bottom ash reutilization for clean waste-to-energy and resource recovery system. J. Clean. Prod. 2018, 188, 69–79. [Google Scholar] [CrossRef]

- Yarosh, Y.; Golub, G.; Kukharets, S.; Chuba, V. Experimental study of wood gas-operated power plant operation. Eng. Rural. Dev. Proc. 2019, 18, 1337–1343. [Google Scholar] [CrossRef]

- Kukharets, S.; Sukmaniuk, O.; Yarosh, Y.; Kovalchuk, V. Investigational study of environmental performance of power generator operating on generator gas. Eng. Rural. Dev. Proc. 2021, 20, 444–450. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. A semi-empirical approach towards predicting producer gas composition in biomass gasification. Bioresour. Technol. 2019, 272, 535–544. [Google Scholar] [CrossRef] [PubMed]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modlinski, N.; Marczak-Grzesik, M.; Sobek, S.; Adrian, Ł.; Dzikuc, M. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy 2023, 263, 125918. [Google Scholar] [CrossRef]

- Piersa, P.; Unyay, H.; Szufa, S.; Lewandowska, W.; Modrzewski, R.; Ślężak, R.; Ledakowicz, S. An Extensive Review and Comparison of Modern Biomass Torrefaction Reactors vs. Biomass Pyrolysis—Part 1. Energies 2022, 15, 2227. [Google Scholar] [CrossRef]

| The Reduction Zone Height H, mm | The Reduction Zone Diameter D, mm | H/D, mm/mm |

|---|---|---|

| 40 | 200 | 0.2 |

| 100 | 200 | 0.5 |

| 160 | 200 | 0.8 |

| Fraction | No. | Average Sizes, mm | Average Area of a Full Surface S, mm2 | Average Volume V, mm3 | SVR, S/V mm−1 | ||

|---|---|---|---|---|---|---|---|

| Length | Width | Thickness | |||||

| Large | 1 | 40 | 15 | 12 | 2520 | 7200 | 0.35 |

| Medium | 2 | 30 | 12 | 8 | 1392 | 2880 | 0.48 |

| Small | 3 | 20 | 9 | 5 | 650 | 900 | 0.72 |

| Very small | 4 | 10 | 4 | 4 | 192 | 160 | 1.20 |

| Fuel pellets | 5 | 10 | 4 (diameter) | 192 | 160 | 1.20 | |

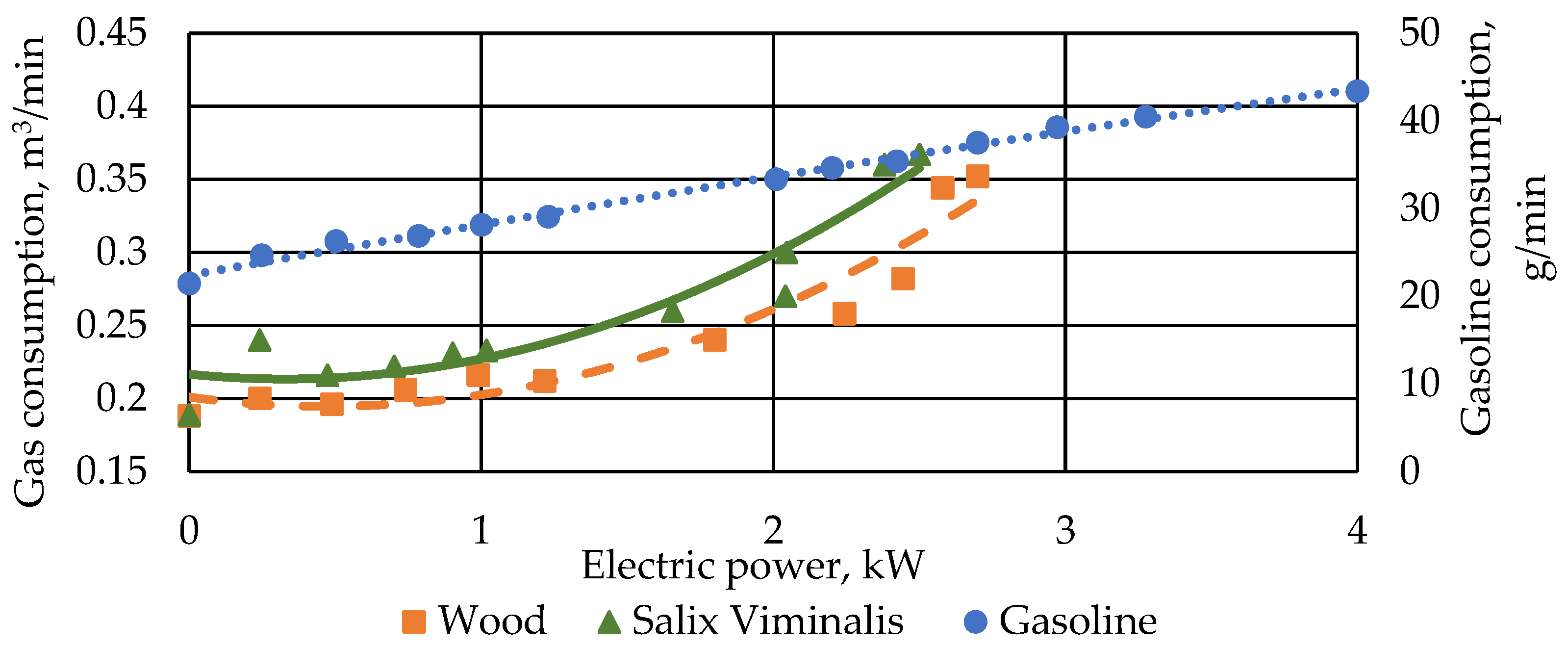

| Fuel | Empirical Equation | The Number of the Equation | Confidence Level (R2) |

|---|---|---|---|

| Gasoline | Q1 = 5.35N + 22.72 | (3) | 0.99 |

| Gas from the hardwood biomass | Q2 = 0.029N2 − 0.027N + 0.20 | (4) | 0.91 |

| Gas from the biomass of the fast-growing willow Salix Viminalis | Q2 = 0.031N2 − 0.020N + 0.22 | (5) | 0.90 |

| where Q1—gasoline consumption, g/min; Q2—gas consumption, m3/min; and N—electric power, kW | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukharets, S.; Jasinskas, A.; Golub, G.; Sukmaniuk, O.; Hutsol, T.; Mudryk, K.; Čėsna, J.; Glowacki, S.; Horetska, I. The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier. Energies 2023, 16, 578. https://doi.org/10.3390/en16020578

Kukharets S, Jasinskas A, Golub G, Sukmaniuk O, Hutsol T, Mudryk K, Čėsna J, Glowacki S, Horetska I. The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier. Energies. 2023; 16(2):578. https://doi.org/10.3390/en16020578

Chicago/Turabian StyleKukharets, Savelii, Algirdas Jasinskas, Gennadii Golub, Olena Sukmaniuk, Taras Hutsol, Krzysztof Mudryk, Jonas Čėsna, Szymon Glowacki, and Iryna Horetska. 2023. "The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier" Energies 16, no. 2: 578. https://doi.org/10.3390/en16020578

APA StyleKukharets, S., Jasinskas, A., Golub, G., Sukmaniuk, O., Hutsol, T., Mudryk, K., Čėsna, J., Glowacki, S., & Horetska, I. (2023). The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier. Energies, 16(2), 578. https://doi.org/10.3390/en16020578