Characterization of the Operation of a BESS with a Photovoltaic System as a Regular Source for the Auxiliary Systems of a High-Voltage Substation in Brazil

Abstract

1. Introduction and Context

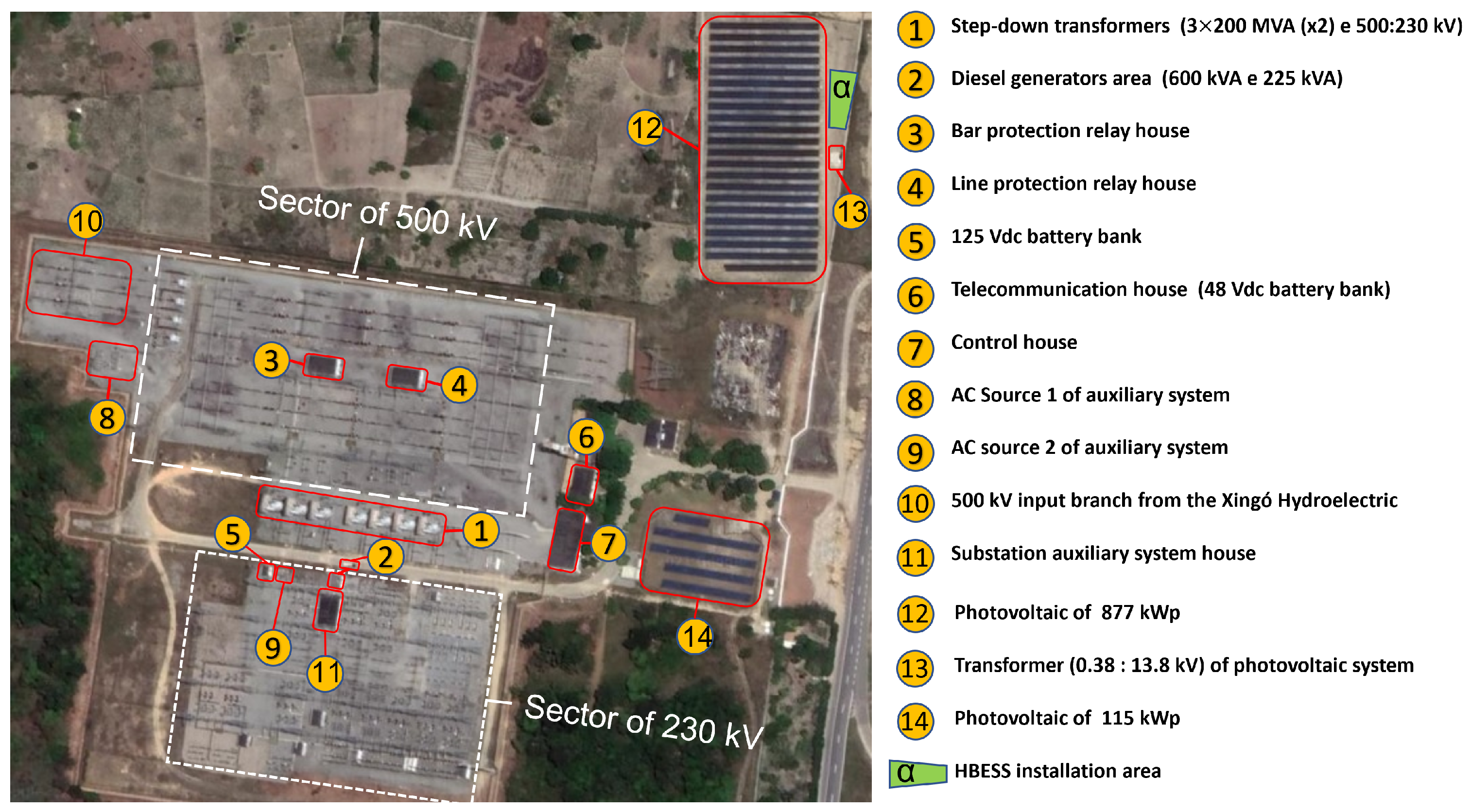

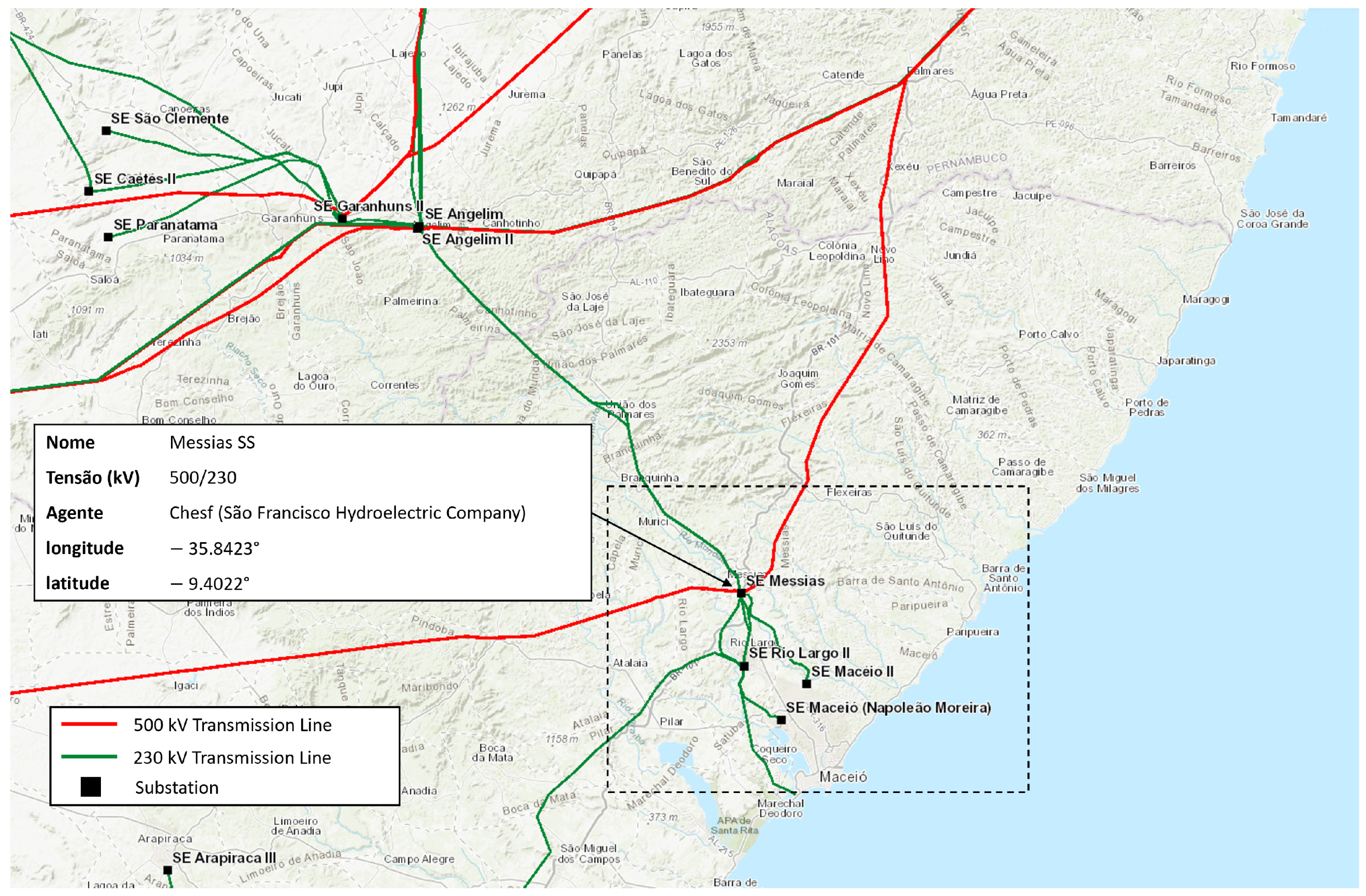

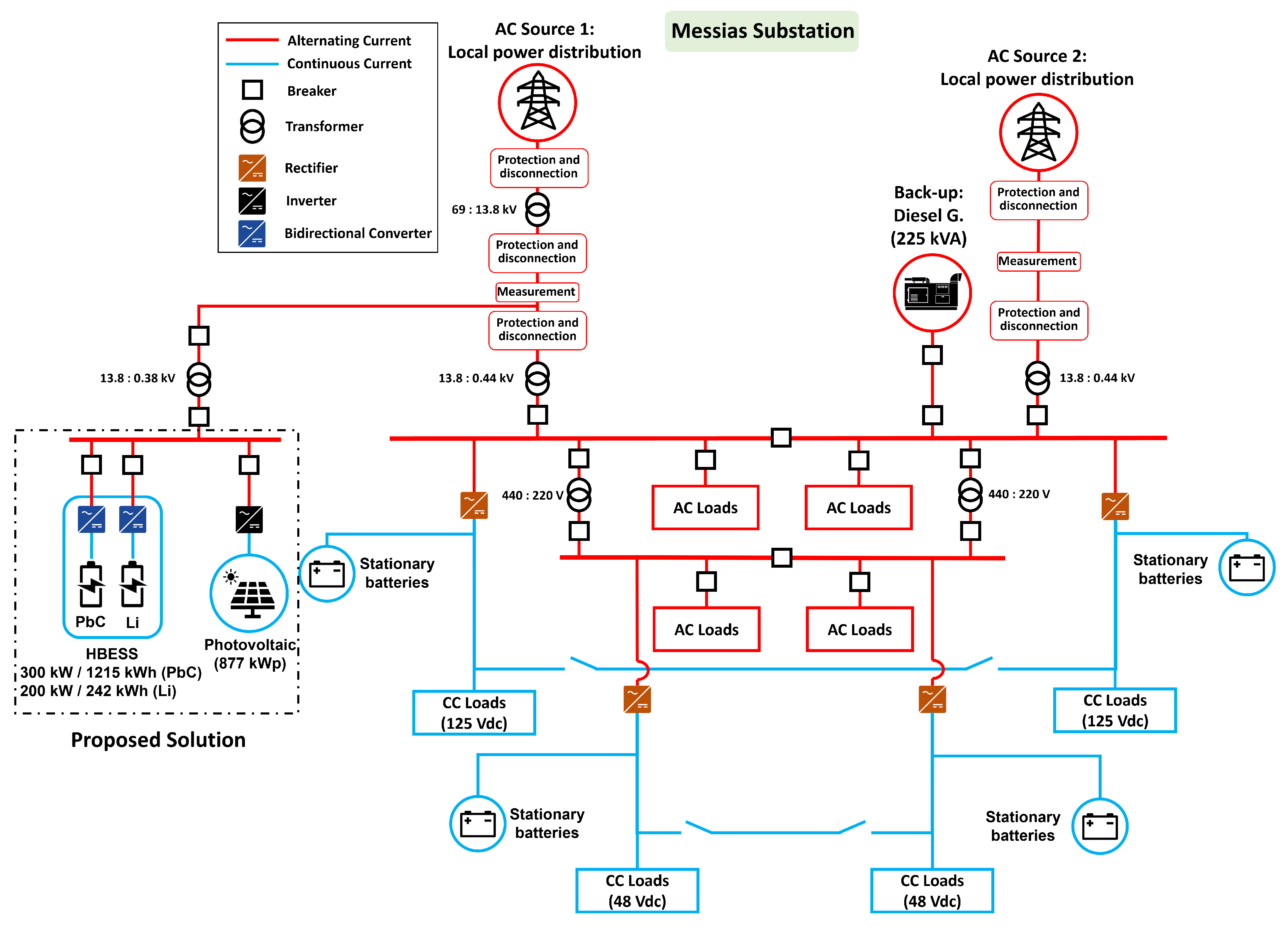

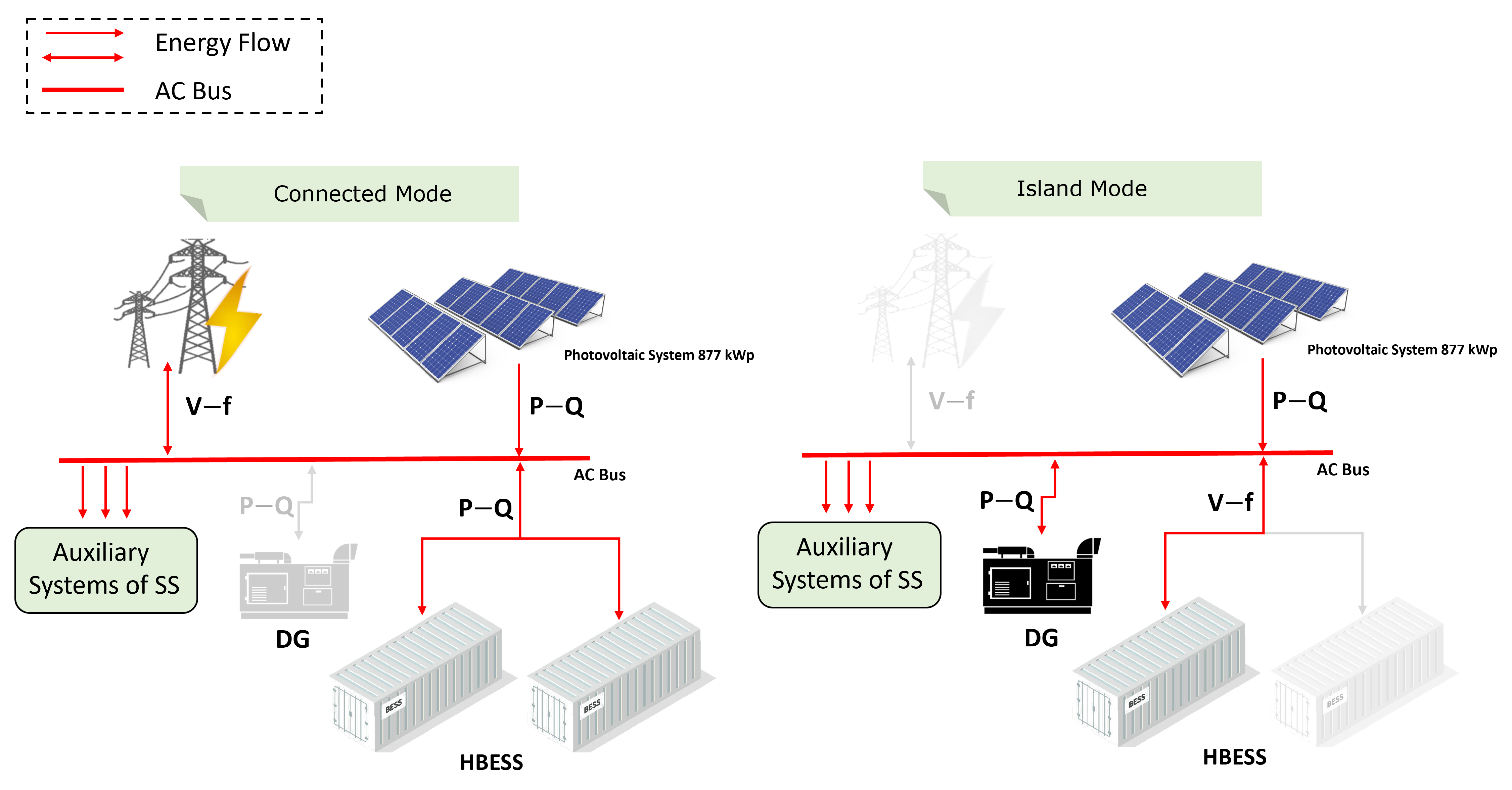

1.1. Messias Substation Description

1.2. Literature Review

1.2.1. Battery Energy Storage System

1.2.2. Hybrid Arrangements of Distributed Energy Resources

1.2.3. Application of Hybrid Arrangements to Electric Power Substations

1.3. Main Contributions

2. Materials and Methods

3. Experimental Tests

3.1. Assumptions Considered during the Tests

- (1)

- The ITEMM microgrid exclusively uses a battery energy storage system with lead-carbon technology (BESS 1). However, the Messias SS microgrid will feature two different technologies (lithium-ion and lead carbon). Therefore, the representation of these systems in the ITEMM microgrid is given in power, in which the 1:3 scale is considered in Table 4;

- (2)

- The tests focused on islanded operation, given the sensitivity of disturbances appearing during the transition and off-grid operation;

- (3)

- To represent the Messias SS load, a second storage system (BESS 2) was used, consuming energy from the microgrid, and configured for 40 kW of maximum active power absorption;

- (4)

- Knowing that the main load of the ITEMM microgrid that represented Messias SS is a small energy storage system (BESS 2) performing recharging, after its State of Charge (SoC), it presents a high level, causing internal resistance of the battery for absorption of energy. For this reason, it was necessary, in some parts of the tests, to discharge the BESS 2 in the main storage system (BESS 1);

- (5)

- Due to the SoC being close to 95% of BESS 2, at times, a 22 kW charging station with an electric vehicle and resistive load (30 kW maximum) was used to complement the power established for the load;

- (6)

- The charging station’s power varies according to the electric vehicle’s (EV) SoC. Thus, it was observed that the active power consumption of the microgrid achieved by this system varies with a negative derivative; that is, the EV charging process starts with high power and reduces as the SoC increases;

- (7)

- The diesel generator was operated on with 20 kVA.

3.2. Test Topology Microgrid

3.3. Physical View of the ITEMM Microgrid

3.4. Experimental Test Plan

- BESS 1 test operating in grid-feeding mode (P–Q): When we operate the microgrid in a connected mode, the main electrical grid is responsible for the stability of the microgrid components, as its main function is to provide the voltage references and frequency for synchronizing distributed generation equipment—in this case, the photovoltaic system and the battery energy storage system. Several applications can be performed with a BESS operating grid connection, such as demand control, reactive control, and power smoothing [40]. The expected result of the test is BESS operating as a follower of the V and f references of the electrical grid and performing its predefined functions in this scenario. Articles [41,42] present details of the grid-feeding mode of operation.

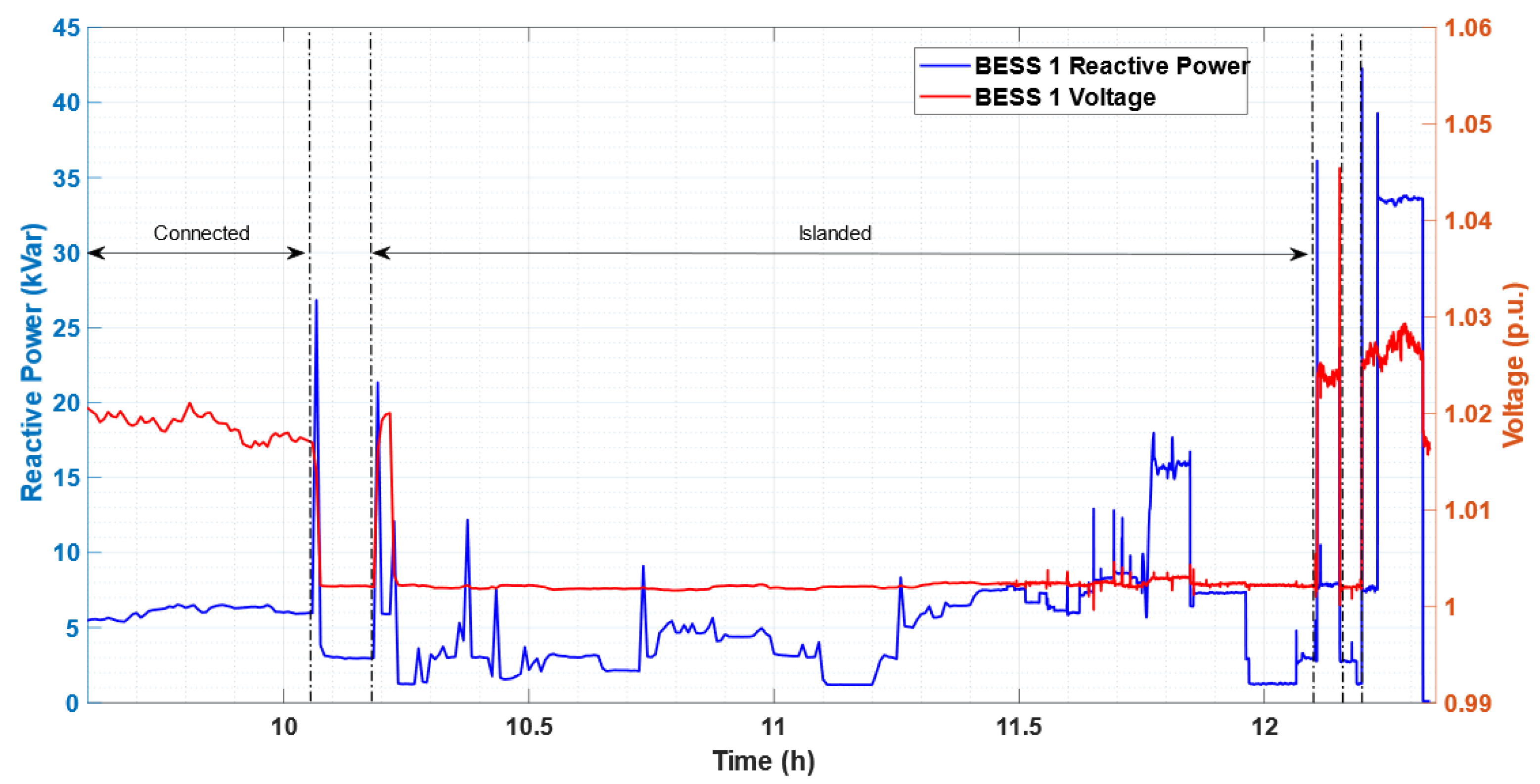

- Test of BESS 1 operating in grid-forming mode (V–f): When the microgrid operation is connected to the main electrical grid, generation and consumption in the microgrid typically have no restrictions on their operations or on the energy levels they can inject or consume from the grid. In the case of islanded operation, there are limitations related to the power and energy levels between the components that compose it. In this sense, after the BESS enters backup mode, the microgrid in islanded operation receives voltage and frequency reference from the PCS. EMS management is needed achieve the optimal energy balance between the microgrid components. In this aspect, the expected result is that the BESS can operate, offering V and f reference for the microgrid, and maintaining the power quality at adequate levels. Articles [41,42] present the details of the grid-forming mode of operation.

- Test of BESS 1 in V–f mode with input from the photovoltaic system: During islanded operation, it is expected that the BESS will be able to mitigate the effects of sudden high active power input into the microgrid. The active power of the PV system influences the microgrid voltage, causing this parameter to rise and fall during high power variations. In addition, when the generation is greater than the load, there are variations in frequency, voltage, and power factor reduction. Thus, adequate microgrid sizing is reinforced to ensure a balance about renewable generation and loads.

- Test of BESS 1 in V–f mode with diesel generator input: In islanded operation, the diesel generator input causes high penetration of active power in the microgrid, influencing the voltage and frequency of the islanded system. The behavior presented is similar to the PV system input in the islanded grid. It is expected in this test that the BESS, after the entry of the diesel generator, will be able to stabilize the voltage through its Volt-Var control and the frequency through its absorption of excess active power.

- Test of BESS 1 connected to islanded transition with load: Unintentional islanding occurs without any predictability, due to main grid failures, equipment failures, and events of the same nature [43,44]. These occurrences make it impossible to implement previous adjustments to the microgrid and its components. Therefore, this type of islanding can result in severe transients to the microgrid and make operation stability in islanded mode difficult. In this sense, the balance between the microgrid’s load and generation and the controls is used to define the operation’s continuity in the microgrid’s islanded mode. It is expected in this test that BESS can carry out the transition and stabilize the microgrid formed due to unintentional islanding.

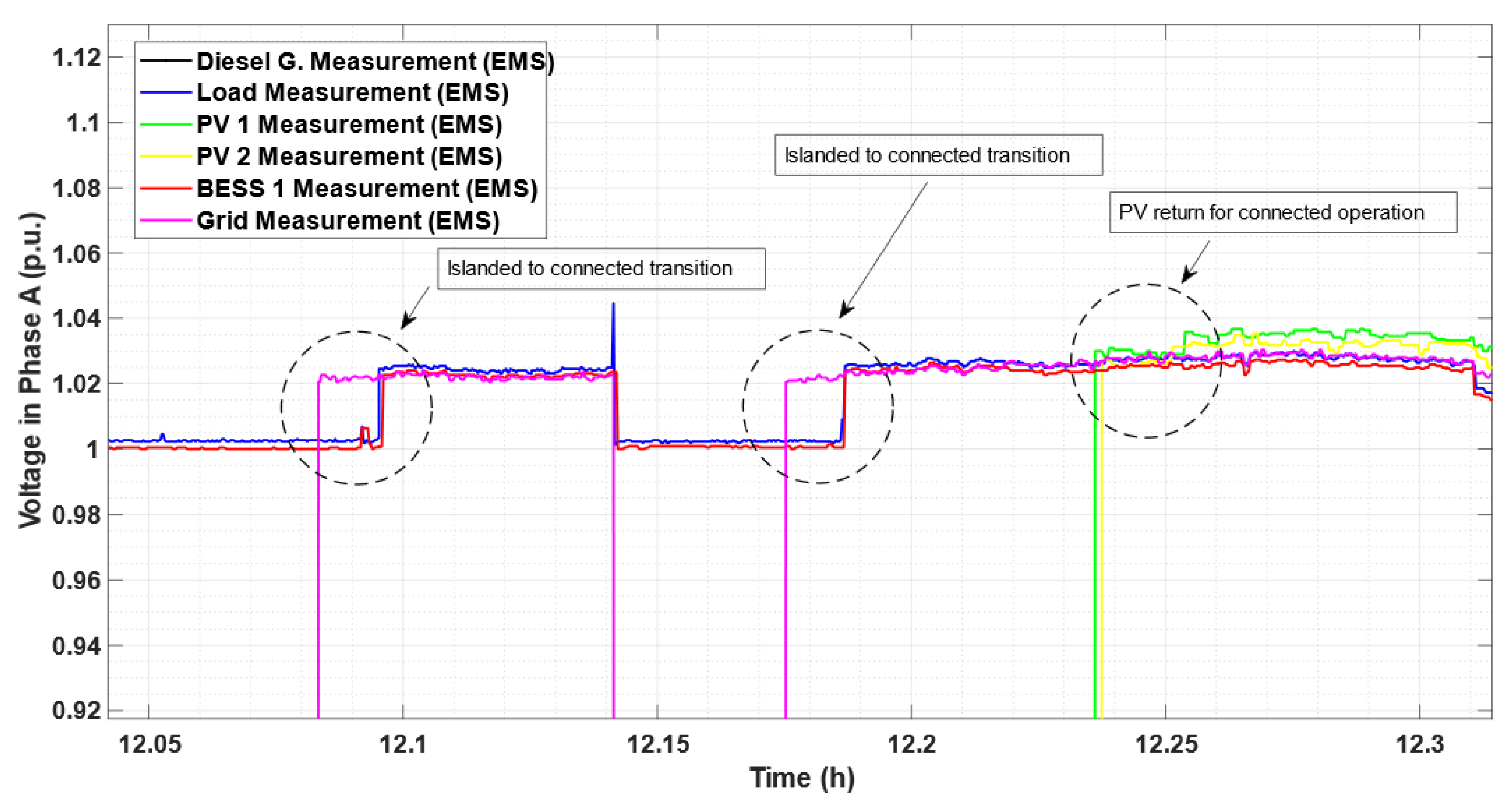

- Test of BESS 1 reconnection with load: The microgrid reconnection, changing from the operation in islanded mode to connecting to the main electrical grid, is a fundamental step in the operation cycle of a microgrid. This is a time when BESS returns voltage and frequency control to the main electrical grid. It is expected in this test that BESS can perform the change from the grid forming operating mode to the grid follower mode and continue performing the P–Q applications predefined in this scenario.

4. Results

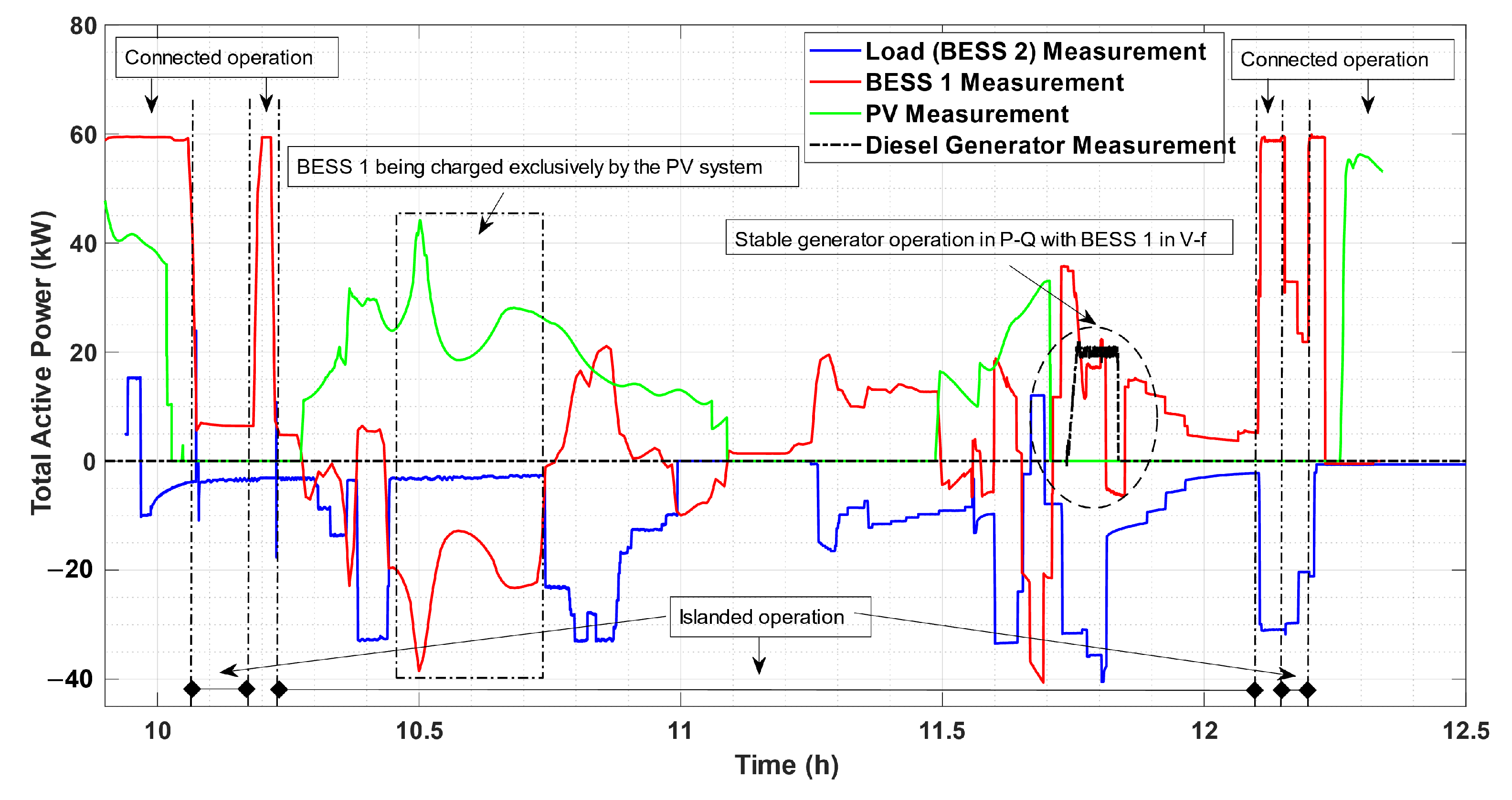

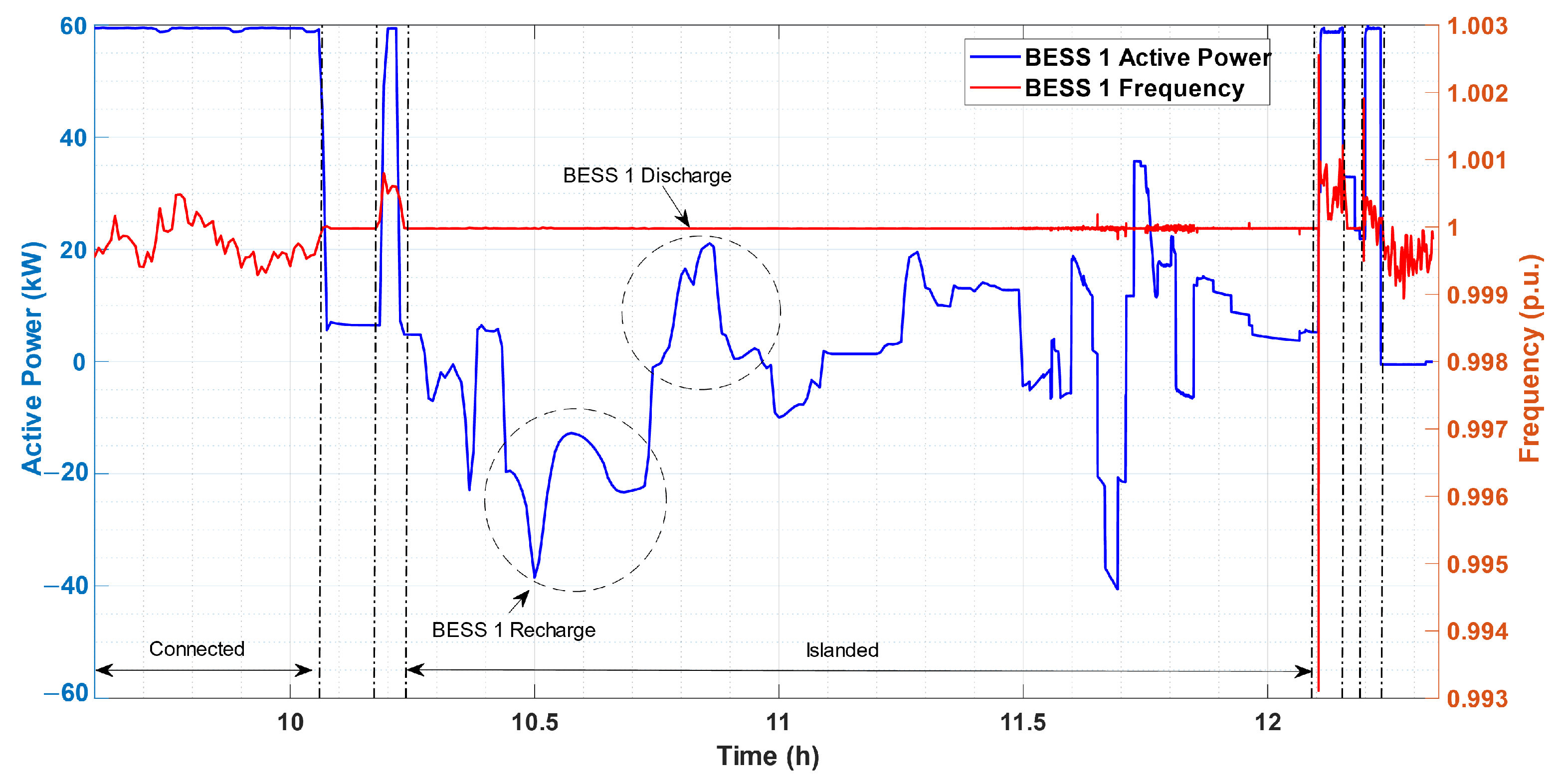

4.1. BESS 1 Operating in Grid-feeding and Grid-Forming Mode

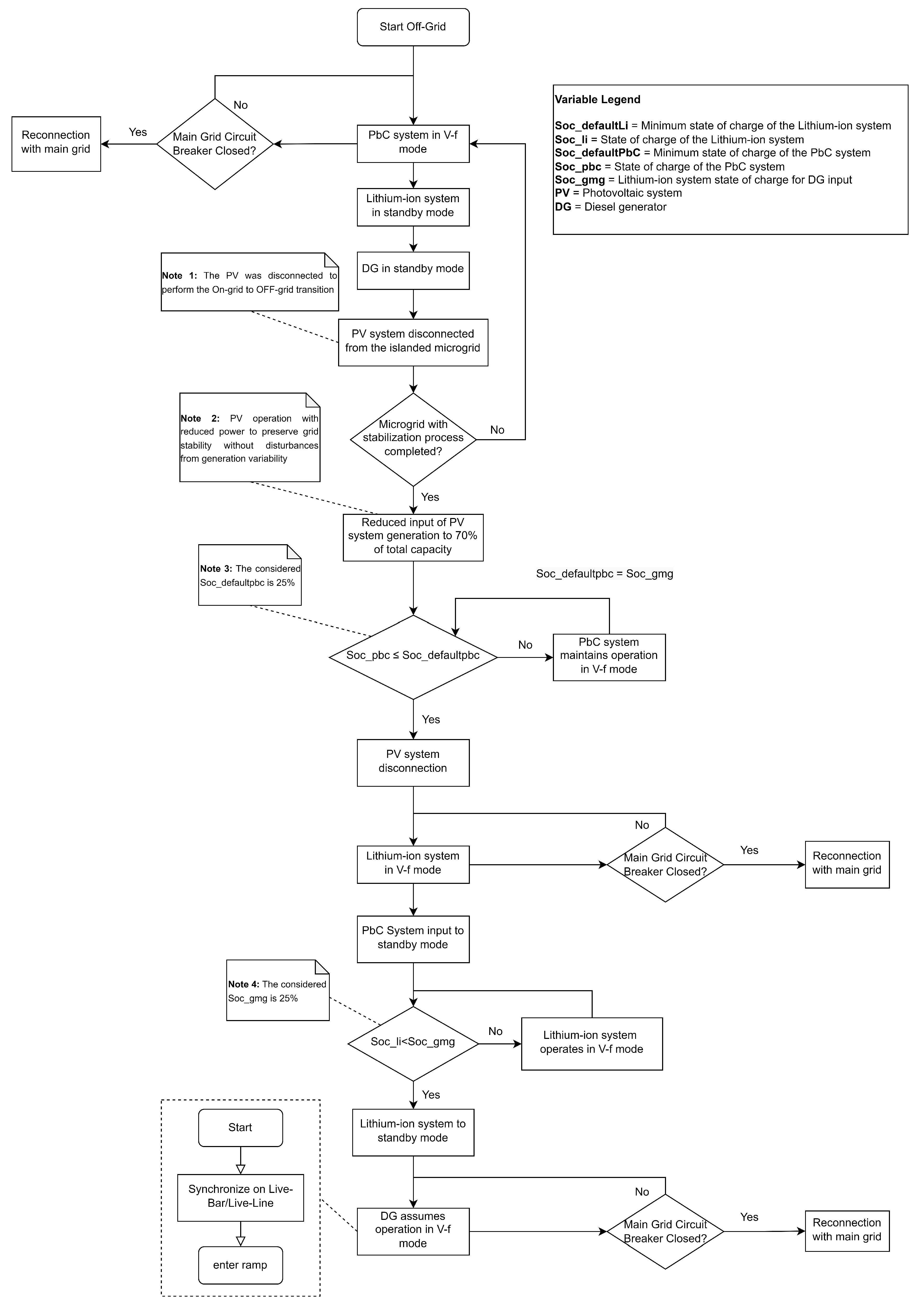

4.2. BESS 1 Operating in Grid-Forming Mode with PV System and Diesel Generator

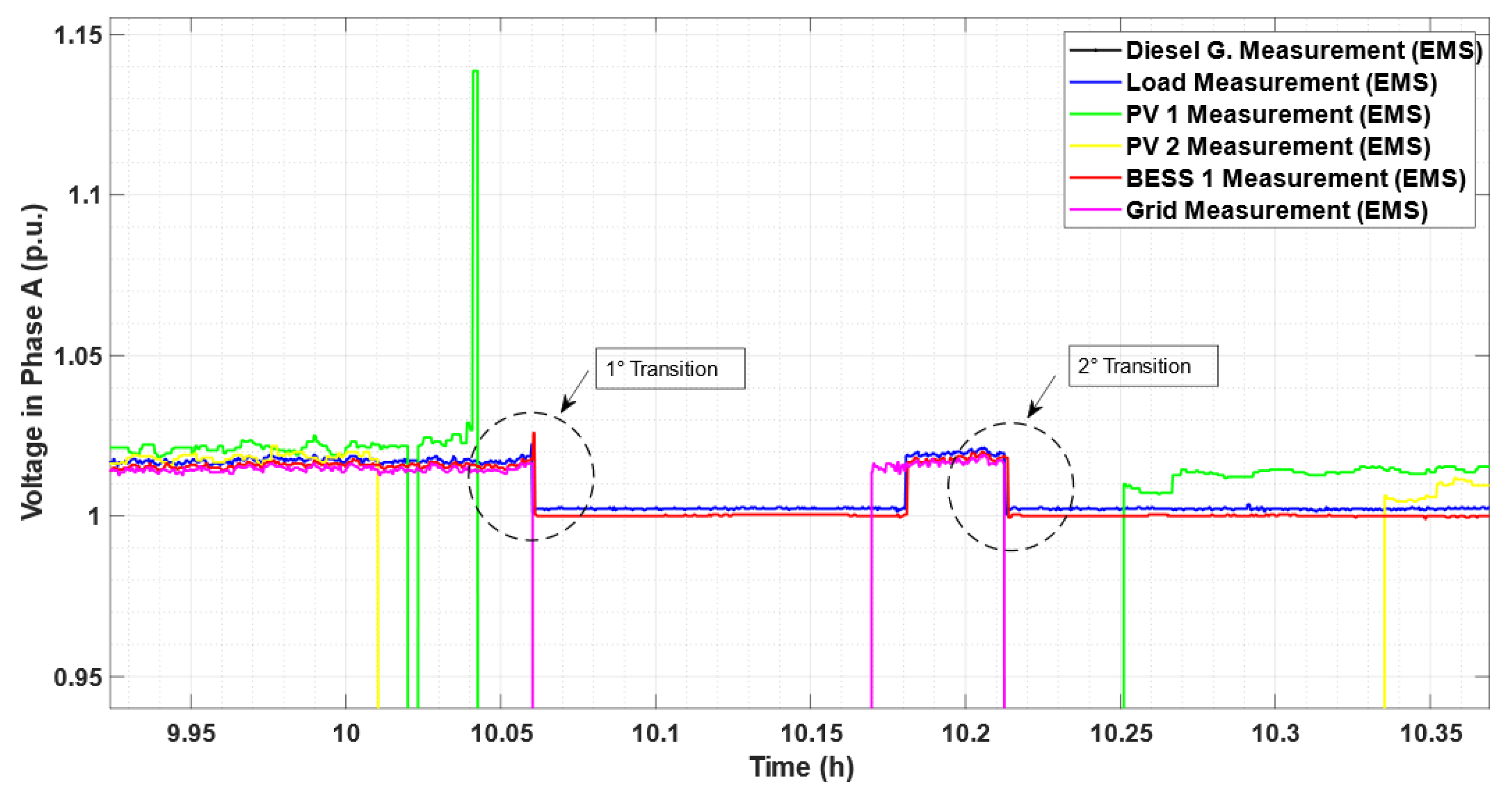

4.3. BESS 1 Operating on Connected to Islanded Transition with Load

4.4. BESS 1 Operating on Reconnection with Load

5. Discussion

- It was observed in operation connected to the grid that the BESS in the grid-feeding mode, acting as P–Q (power injection or absorption), performs all the proposed applications; for example, it is possible to observe in the results of the demand control or reactive control;

- In islanded operation, BESS was visualized as a voltage and frequency reference for the microgrid, in which a significant improvement was observed in the microgrid power quality;

- The results showed BESS acting and maintaining power quality in different scenarios on the same day, leading to grid forming because of sequential unintentional islanding. This type of islanding occurs without any predictability due to faults in the main electrical grid and, in this sense, they are considered very severe for a microgrid;

- It has been proven that, as a grid-forming technique, BESS can recharge through a photovoltaic system without impacting the voltage and frequency quality of the microgrid and the load supply;

- It was shown that BESS, as a grid-forming technique, can maintain power quality levels with the power variation of the photovoltaic system;

- BESS in V–f mode can manage a microgrid with PV inverters operating in parallel, since the power proportions of BESS with the PV system are respected;

- It can be observed that in moments of unavailability of photovoltaic generation, BESS supplied the demand requested by the loads;

- The result showed that BESS could match its power to complement the input of a diesel generator or PV system in islanded operation. In this aspect, the load was supplied with power from the BESS and the generator or PV system;

- It was observed in the islanded operation that the BESS (in V–f mode) could stabilize the voltage and frequency even because of the starting peak of the diesel generator set input;

- It was proved that the BESS (V–f mode) performs the energy balance between generation and load during the entire islanded operation, maintaining the microgrid power quality.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| ANEEL | Brazilian Electricity Regulatory Agency |

| BESS | Battery Energy Storage Systems |

| BMS | Battery Management System |

| BTM | Behind the Meter |

| Chesf | São Francisco Hydroelectric Company |

| DB | Database |

| DC | Direct Current |

| DG | Diesel Generators |

| EMS | Energy Management System |

| ESS | Energy Storage System |

| EV | Electric Vehicle |

| GESDB | Global Energy Storage Database |

| HBESS | Hybrid Battery Energy Storage Systems |

| HVAC | Heating, Ventilating, and Air Conditioning |

| ITEMM | Edson Mororó Moura Institute of Technology |

| NWA | Non-wires |

| ONS | Brazilian National Electric System Operator |

| PCS | Power Conversion System |

| POC | Point of Connection |

| PRODIST | Distribution Procedure |

| PV | Photovoltaic systems |

| Saux | Auxiliary Systems |

| SCADA | Supervisory Control and Data Acquisition System |

| SIN | Brazilian Interconnected System |

| SoC | State of Charge |

| SS | Substation |

| STS | Static Transfer Switch |

| TD | Transmission Distribution |

References

- Brazilian National Electric System Operator (ONS). Chapter 2.6—Minimum Requirements for Substations and Their Equipment. In ONS Network Procedures; ONS: Rio de Janeiro, Brazil, 2021. [Google Scholar]

- Brazilian National Electric System Operator (ONS). Chapter 2.3—Minimum Requirements for Substations and Their Equipment. In ONS Network Procedures; ONS: Rio de Janeiro, Brazil, 2011. [Google Scholar]

- Brazilian Electricity Regulatory Agency (ANEEL). Opening of Public Consultation for Review of Chapters 2.3 and 10.14 of Network Procedures; ANEEL: Brasilia, Brazil, 2019. [Google Scholar]

- Brazilian Energy Research Office (EPE). Geographic Information System of the Brazilian Energy Sector; EPE’: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- Costa, T.; Vasconcelos, A.; Arcanjo, A.; Silva, W.; Pereira, A.; Jatoba, E.; Filho, J.M.; Barreto, E.; Villalva, M.; Marinho, M. Microgrid Sizing for Substation Support of the Electric Power Transmission. In Proceedings of the XV Symposium of Specialists in Planning the Operation and Expansion of Electric Energy Systems (XV SEPOPE), Foz do Iguaçu, Brazil, 15–18 March 2022. [Google Scholar]

- Bortolini, M.; Gamberi, M.; Grazian, A.; Pilati, F. Economic and Environmental bi-objective Design of an Off-grid Photovoltaic–Battery–Diesel Generator Hybrid Energy System. Energy Convers. Manag. 2015, 106, 1024–1038. [Google Scholar] [CrossRef]

- Lawder, M.T.; Suthar, B.; Northrop, P.W.C.; De, S.; Hoff, C.M.; Leitermann, O.; Crow, M.L.; Santhanagopalan, S.; Subramanian, V.R. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- BS EN IEC 62933-1:2018; Electrical Energy Storage (EES) Systems. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2018; p. 69.

- Lemaire, E.; Martin, N.; Norgard, P.; de Jong, E.; de Graaf, R.; Groenewegen, J.; Kolentini, E.; Tselepis, S. European White Book on Grid-Connected Storage; DERlab: Kassel, Germany, 2011. [Google Scholar]

- Rekioua, D. Hybrid Renewable Energy Systems: Optimization and Power Management Control; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Ogunniyi, E.O.; Pienaar, H. Overview of battery energy storage system advancement for renewable (photovoltaic) energy applications. In Proceedings of the 2017 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 4–5 April 2017; pp. 233–239. [Google Scholar] [CrossRef]

- Taibi, E.; Nikolakakis, T.; Gutierrez, L.; Fernandez, C.; Kiviluoma, J.; Lindroos, T.J.; Rissanen, S. Power System Flexibility for the Energy Transition, Part 1: Overview for Policy Makers; International Renewable Energy Agency: Maszar City, United Arab Emirates, 2018. [Google Scholar]

- Guermoui, M.; Melgani, F.; Gairaa, K.; Mekhalfi, M.L. A comprehensive review of hybrid models for solar radiation forecasting. J. Clean. Prod. 2020, 258, 120357. [Google Scholar] [CrossRef]

- Zhang, G. Time series forecasting using a hybrid ARIMA and neural network model. Neurocomputing 2003, 50, 159–175. [Google Scholar] [CrossRef]

- de O. Santos, D.S.; de Mattos Neto, P.S.G.; de Oliveira, J.F.L.; Siqueira, H.V.; Barchi, T.M.; Lima, A.R.; Madeiro, F.; Dantas, D.A.P.; Converti, A.; Pereira, A.C.; et al. Solar Irradiance Forecasting Using Dynamic Ensemble Selection. Appl. Sci. 2022, 12, 3510. [Google Scholar] [CrossRef]

- Sun, W.; Harrison, G.P. Wind-solar complementarity and effective use of distribution network capacity. Appl. Energy 2019, 247, 89–101. [Google Scholar] [CrossRef]

- Silva, L.M.R.; Beluco, A.; Daronco, G. A wind PV diesel hybrid system for energizing a sewage station in Santa Rosa, in southern Brazil. IEEE Lat. Am. Trans. 2020, 18, 773–780. [Google Scholar] [CrossRef]

- Ismail, M.; Moghavvemi, M.; Mahlia, T. Techno-economic analysis of an optimized photovoltaic and diesel generator hybrid power system for remote houses in a tropical climate. Energy Convers. Manag. 2013, 69, 163–173. [Google Scholar] [CrossRef]

- Reddy, Y.; Jithendranath, J.; Chakraborty, A.K.; Guerrero, J.M. Stochastic optimal power flow in islanded DC microgrids with correlated load and solar PV uncertainties. Appl. Energy 2022, 307, 118090. [Google Scholar] [CrossRef]

- Dulău, L.I.; Bică, D. Optimization of generation cost in a microgrid. Procedia Manuf. 2018, 22, 703–708. [Google Scholar] [CrossRef]

- Fotopoulou, M.; Rakopoulos, D.; Petridis, S. Decision Support System for Emergencies in Microgrids. Sensors 2022, 22, 9457. [Google Scholar] [CrossRef] [PubMed]

- Hoff, T.; Shugar, D. The value of grid-support photovoltaics in reducing distribution system losses. IEEE Trans. Energy Convers. 1995, 10, 569–576. [Google Scholar] [CrossRef]

- Al-Ashwal, A. Photovoltaic system for transmission substation application. Renew. Energy 1998, 14, 157–163. [Google Scholar] [CrossRef]

- Kerdphol, T.; Tripathi, R.N.; Hanamoto, T.; Khairudin; Qudaih, Y.; Mitani, Y. ANN based optimized battery energy storage system size and loss analysis for distributed energy storage location in PV-microgrid. In Proceedings of the 2015 IEEE Innovative Smart Grid Technologies—Asia (ISGT ASIA), Bangkok, Thailand, 3–6 November 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Gao, Y.; Xue, F.; Yang, W.; Yang, Q.; Sun, Y.; Sun, Y.; Liang, H.; Li, P. Optimal operation modes of photovoltaic-battery energy storage system based power plants considering typical scenarios. Prot. Control. Mod. Power Syst. 2017, 2, 36. [Google Scholar] [CrossRef]

- Akagi, S.; Yoshizawa, S.; Ito, M.; Fujimoto, Y.; Miyazaki, T.; Hayashi, Y.; Tawa, K.; Hisada, T.; Yano, T. Multipurpose control and planning method for battery energy storage systems in distribution network with photovoltaic plant. Int. J. Electr. Power Energy Syst. 2020, 116, 105485. [Google Scholar] [CrossRef]

- Australian Renewable Energy Agency (ARENA). Co-Location INVESTIGATION: A Study into the Potential for Co-Locating Wind and Solar Farms in Australia; AECOM Australia Pty. Ltd.: Sydney, Australia, 2016. [Google Scholar]

- TenneT. Grid Connection Regulations—High and Extra-High Voltage; TenneT TSO GmbH: Bayreuth, Germany, 2019. [Google Scholar]

- Hydro-Québec. Technical Requirements for the Connection of Generating Stations to the Hydro-Québec Transmission System; Hydro-Québec: Montreal, BC, Canada, 2019. [Google Scholar]

- Energinet. Technical Regulation 3.3.1 for Electrical Energy Storage Facilities; Energinet: Fredericia, Denmark, 2019. [Google Scholar]

- AEMC. Draft Rule Determination—Efficient Management of System Strength on the Power System; Australian Energy Market Commission: Sydney, Australia, 2021. [Google Scholar]

- Australian Energy Market Operator. National Electricity Amendment (Integrating Energy Storage Systems into the NEM) Rule 2021; Rule Determination; Australian Energy Market Commission: Sydney, Australia, 2021. [Google Scholar]

- Ontario Energy Board (OEB). Distribution System Code; OEB: Toronto, ON, Canada, 2022. [Google Scholar]

- Department of Energy (DOE). DOE Global Energy Storage Database; Office of Electricity: Washington, DC, USA, 2016. [Google Scholar]

- São Francisco Hydroelectric Company (CHESF). Call to Receive R&D+I Project Proposal(s): Photovoltaic Mini-generation with Battery Energy Storage as an Autonomous Source of Supply of Auxiliary Services of 230/500 kV Substations with Internal Source Restriction; CHESF: Recife, Brazil, 2020. [Google Scholar]

- Ramos, F.O.; Pinheiro, A.L.; Lima, R.N.; Neto, M.M.B.; Junior, W.A.; Bezerra, L.G.S. A Real Case Analysis of a Battery Energy Storage System for Energy Time Shift, Demand Management, and Reactive Control. In Proceedings of the 2021 IEEE PES Innovative Smart Grid Technologies Conference—Latin America (ISGT Latin America), Lima, Peru, 15–17 September 2021; pp. 1–5. [Google Scholar] [CrossRef]

- IEC TS 62898-1:2017; Microgrids—Part 1: Guidelines for Microgrid Projects Planning and Specification. The International Electrotechnical Commission (IEC): Geneva, Switzerland, 2017.

- IEC TS 62898-2:2018; Microgrids—Part 2: Guidelines for Operation. The International Electrotechnical Commission (IEC): Geneva, Switzerland, 2018.

- IEEE 2030.8; IEEE Standard for the Testing ofMicrogrid Controllers. IEEE Standards Association: Piscataway, NJ, USA, 2018; p. 42.

- Ramos, F.; Pinheiro, A.; Nascimento, R.; de Araujo Silva Junior, W.; Mohamed, M.; Annuk, A.; Marinho, M. Development of Operation Strategy for Battery Energy Storage System into Hybrid AC Microgrids. Sustainability 2022, 14, 13765. [Google Scholar] [CrossRef]

- Rocabert, J.; Luna, A.; Blaabjerg, F.; Rodríguez, P. Control of Power Converters in AC Microgrids. IEEE Trans. Power Electron. 2012, 27, 4734–4749. [Google Scholar] [CrossRef]

- Dantas, N.K.L.; Souza, A.C.M.; Vasconcelos, A.S.M.; Junior, W.d.A.S.; Rissi, G.; Dall’Orto, C.; Maciel, A.M.A.; Castro, J.F.C.; Liu, Y.; Rosas, P. Impact Analysis of a Battery Energy Storage System Connected in Parallel to a Wind Farm. Energies 2022, 15, 4586. [Google Scholar] [CrossRef]

- Ioris, D.; de Godoy, P.T.; Felisberto, K.D.R.; Poloni, P.; de Almeida, A.B.; Marujo, D. Microgrid Operation and Control: From Grid-Connected to Islanded Mode. In Planning and Operation of Active Distribution Networks: Technical, Social and Environmental Aspects; Zambroni de Souza, A.C., Venkatesh, B., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 233–256. [Google Scholar] [CrossRef]

- Ioris, D. Study of Unintentional Islanding in Microgrids Based on Electronic Power Converters. Master’s Thesis, Universidade Estadual do Oeste do Paraná (UNIOESTE), Cascavel, Brazil, 2021. [Google Scholar]

- National Electricity Regulatory Agency (ANEEL). Distribution Procedures (PRODIST) Module 8—Quality of Electric Energy; ANEEL: Brasilia, Brazil, 2021. [Google Scholar]

- Costa, T.S. Development of a Hybrid Battery energy Storage System (HBESS) for Powering Auxiliary Services in a High Voltage Substation. Ph.D. Thesis, UNICAMP Universidade Estadual de Campinas, Campinas, Brazil, 2022. [Google Scholar]

| Equipment | Year | Shutdown (Total Amount) | ||

|---|---|---|---|---|

| SIN | Auxiliary Systems (AC) | |||

| Transmission/Distribution Line | 2017 | 3486 | 0 | 0.00% |

| 2018 | 3033 | 0 | 0.00% | |

| Transformers | 2017 | 824 | 2 | 0.24% |

| 2018 | 601 | 3 | 0.50% | |

| Reactive Control | 2017 | 502 | 11 | 2.19% |

| 2018 | 786 | 18 | 2.29% | |

| Converter/filters | 2017 | 165 | 0 | 0.00% |

| 2018 | 326 | 0 | 0.00% | |

| Buses | 2017 | 132 | 0 | 0.00% |

| 2018 | 116 | 0 | 0.00% | |

| Diesel Generator | 2017 | 2867 | 87 | 3.03% |

| 2018 | 2486 | 70 | 2.82% | |

| Total | 2017 | 7976 | 100 | 1.25% |

| 2018 | 7348 | 91 | 1.24% | |

| Year | Time of Impact | Quantity of Events | Total of Events |

|---|---|---|---|

| 2017 | 00 h 00 min–00 h 20 min | 5 | 11 |

| 00 h 20 min–00 h 40 min | 1 | ||

| 00 h 40 min–00 h 60 min | 1 | ||

| Above 60 min | 4 | ||

| 2018 | 00 h 00 min–00 h 20 min | 4 | 10 |

| 00 h 20 min–00 h 40 min | 2 | ||

| 00 h 40 min–00 h 60 min | - | ||

| Above 60 min | 4 |

| Energy Supplying | Ancillary Services | Support and Infrastructure Services for T&D | Behind-the-Meter (BTM) Services | Renewable and DG Integration |

|---|---|---|---|---|

| Time-shift; Improving electrical capacity. | Voltage regulation; Frequency regulation; Improving electrical reserve; Voltage support; Blackstart. | Investments deferrel; Congestion relief; Transmission support. | Energy quality; Reliability; Time-shift; Demand management. | Time-shift; Frequency regulation; Voltagem support; Improving electrical capacity. |

| Component | Real ITEMM Microgrid | Adapted ITEMM Microgrid | Messias SS Microgrid | Approximate Scale |

|---|---|---|---|---|

| BESS Pb-C | 250 kW | 100 kW | 300 kW | 1:3 |

| BESS Li ion ¹ | 0 kW | 66 kW ¹ | 200 kW | |

| PV Inverter | 252 kW | 36 kW | 100 kW (off-grid) | |

| Diesel | 75 kVA | 75 kVA | 225 kVA | |

| Load | 260 kW | 40 kW | 120 kW (max.) |

| Components of the ITEMM Microgrid | |

|---|---|

| BESS (Battery Energy Storage System) 1 | |

| Technology | Lead carbon |

| Apparent power | 250 kVA |

| Active power | 250 kW |

| Rated energy | 560 kWh |

| Rated voltage (Phase–Phase) | 380 V |

| Active power configuration | positive: discharge, negative: recharge |

| Reactive power configuration | positive: capacitive, negative: inductive |

| BESS (Battery Energy Storage System) 2 | |

| Technology | Lead-carbon |

| Apparent power | 50 kVA |

| Active power | 50 kW |

| Rated energy | 72 kWh |

| Rated voltage (Phase–Phase) | 380 V |

| Active power configuration | positive: discharge, negative: recharge |

| Reactive power configuration | positive: capacitive, negative: inductive |

| Diesel Generator | |

| Apparent power | 75 kVA |

| Rated voltage (Phase–Phase) | 380 V |

| Frequency | 60 Hz |

| Full tank | 60 L |

| Photovoltaic Systems (inverters) | |

| The rated voltage at output AC | 380 V |

| The frequency at output AC | 60 Hz |

| Maximum current at output AC | 53.5 A |

| Active power at output AC | 36 kW |

| Maximum Apparent power AC | 36 kVA |

| Resistive Load | |

| Total rated power | 30 kW |

| Arrangement | 2 × 10 kW/1 × 5 kW/2 × 2 kW/1 × 1 kW |

| Rated voltage (Phase–Phase) | 380 V |

| Charger | |

| Max. power per socket | 22 kW |

| Max. current per socket | 32 A |

| Electric Vehicle | |

| Technology | Lithium ions |

| Total voltage | 400V |

| Energy | 22 kWh |

| Scenario | Test | |

|---|---|---|

| 3 August 2022 | On-grid | Functions P–Q of BESS 1 |

| Transition | Grid (V–f) + BESS 1 (P–Q) + BESS 2 (Load) → off-grid mode | |

| Off-grid | BESS 1 (V–f) + BESS 2 (Load) + PV 1 + “R” Load | |

| Off-grid | BESS 1 (V–f) + BESS 2 (Load) + PV 1 + PV 2 + EV + “R” Load | |

| Off-grid | BESS 1 (V–f) + BESS 2 (Load) + Diesel (20 kW) + “R” Load | |

| Reconnection | BESS 1 (V–f) + BESS 2 (Load) → on-grid mode | |

| Islanded 1 | Islanded 2 | Islanded 3 | PRODIST | ||||

|---|---|---|---|---|---|---|---|

| Voltage (p.u.) | |||||||

| Maximum | 1.002 | Maximum | 1.004 | Maximum | 1.002 | Maximum | 1.050 |

| Medium | 1.002 | Medium | 1.002 | Medium | 1.001 | Reference | 1.000 |

| Minimum | 1.002 | Minimum | 0.999 | Minimum | 1.000 | Minimum | 0.920 |

| Frequency (p.u.) | |||||||

| Maximum | 1.000 | Maximum | 1.000 | Maximum | 1.000 | Maximum | 1.002 |

| Medium | 1.000 | Medium | 1.000 | Medium | 1.000 | Reference | 1.000 |

| Minimum | 1.000 | Minimum | 1.000 | Minimum | 1.000 | Minimum | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Araujo Silva Júnior, W.; Vasconcelos, A.; Arcanjo, A.C.; Costa, T.; Nascimento, R.; Pereira, A.; Jatobá, E.; Filho, J.B.; Barreto, E.; Dias, R.; et al. Characterization of the Operation of a BESS with a Photovoltaic System as a Regular Source for the Auxiliary Systems of a High-Voltage Substation in Brazil. Energies 2023, 16, 1012. https://doi.org/10.3390/en16021012

de Araujo Silva Júnior W, Vasconcelos A, Arcanjo AC, Costa T, Nascimento R, Pereira A, Jatobá E, Filho JB, Barreto E, Dias R, et al. Characterization of the Operation of a BESS with a Photovoltaic System as a Regular Source for the Auxiliary Systems of a High-Voltage Substation in Brazil. Energies. 2023; 16(2):1012. https://doi.org/10.3390/en16021012

Chicago/Turabian Stylede Araujo Silva Júnior, Washington, Andrea Vasconcelos, Ayrlw Carvalho Arcanjo, Tatiane Costa, Rafaela Nascimento, Alex Pereira, Eduardo Jatobá, José Bione Filho, Elisabete Barreto, Roberto Dias, and et al. 2023. "Characterization of the Operation of a BESS with a Photovoltaic System as a Regular Source for the Auxiliary Systems of a High-Voltage Substation in Brazil" Energies 16, no. 2: 1012. https://doi.org/10.3390/en16021012

APA Stylede Araujo Silva Júnior, W., Vasconcelos, A., Arcanjo, A. C., Costa, T., Nascimento, R., Pereira, A., Jatobá, E., Filho, J. B., Barreto, E., Dias, R., & Marinho, M. (2023). Characterization of the Operation of a BESS with a Photovoltaic System as a Regular Source for the Auxiliary Systems of a High-Voltage Substation in Brazil. Energies, 16(2), 1012. https://doi.org/10.3390/en16021012