Review of High-Power-Density and Fault-Tolerant Design of Propulsion Motors for Electric Aircraft

Abstract

:1. Introduction

2. Propulsion Motors

- High power and torque density for lightweight propulsion systems;

- High efficiency to ensure efficient use of electrical energy during flight;

- High reliability, reducing the incidence of failures in motor operation;

- High fault tolerance to maintain safe operation after partial motor failure.

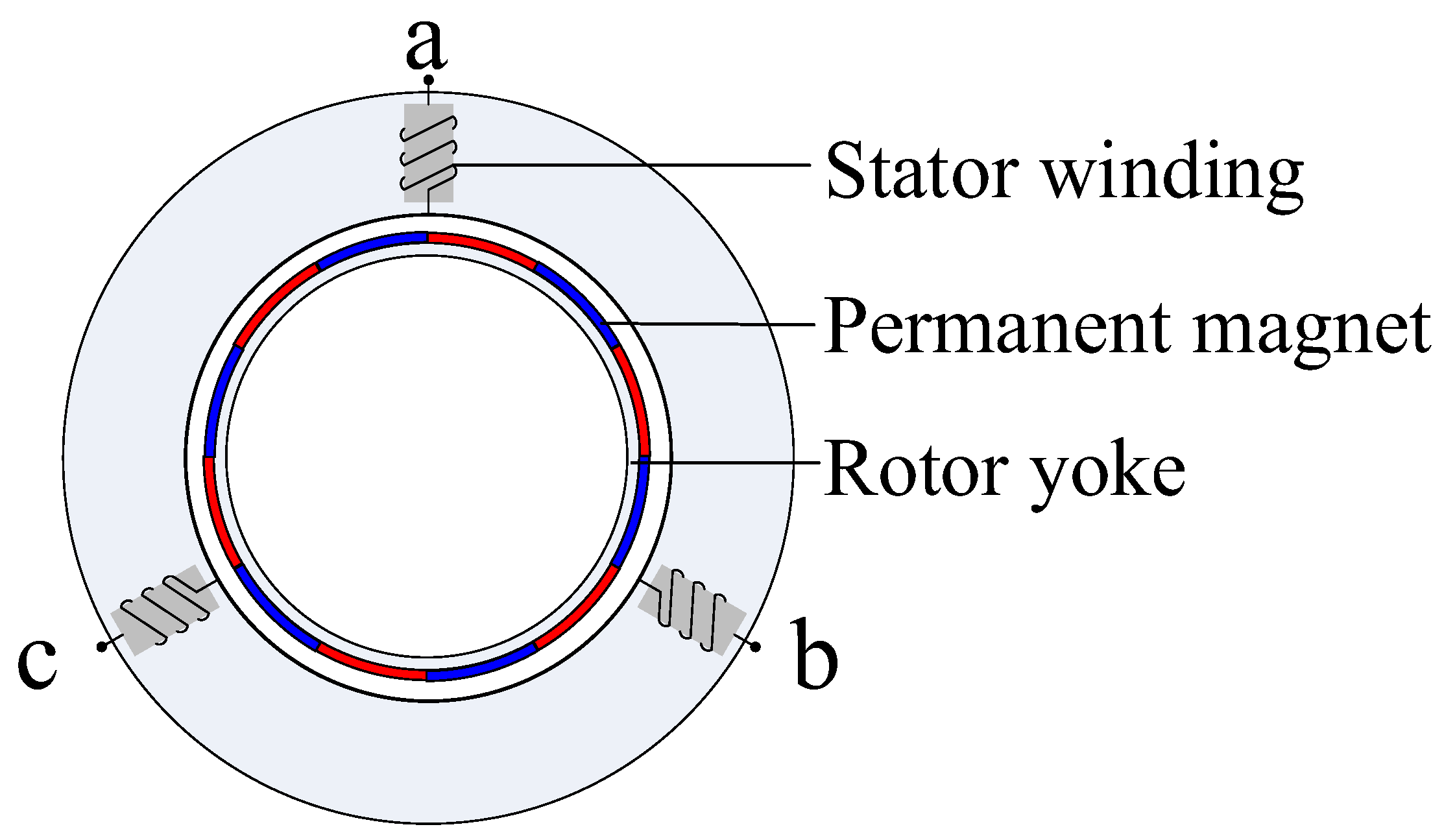

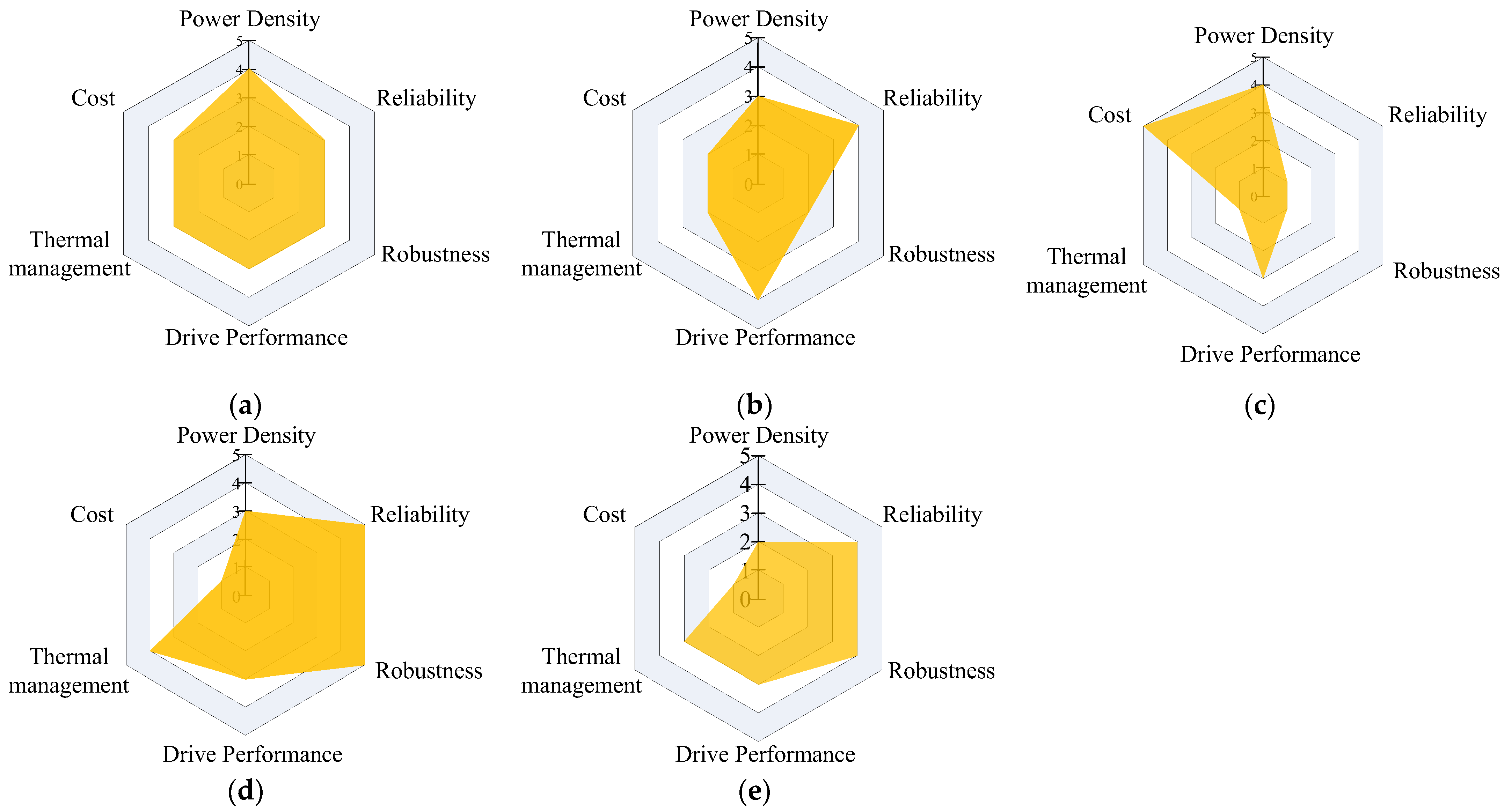

2.1. Permanent Magnet Synchronous Motor (PMSM)

2.2. Wound-Field Synchronous Motor (WFSM)

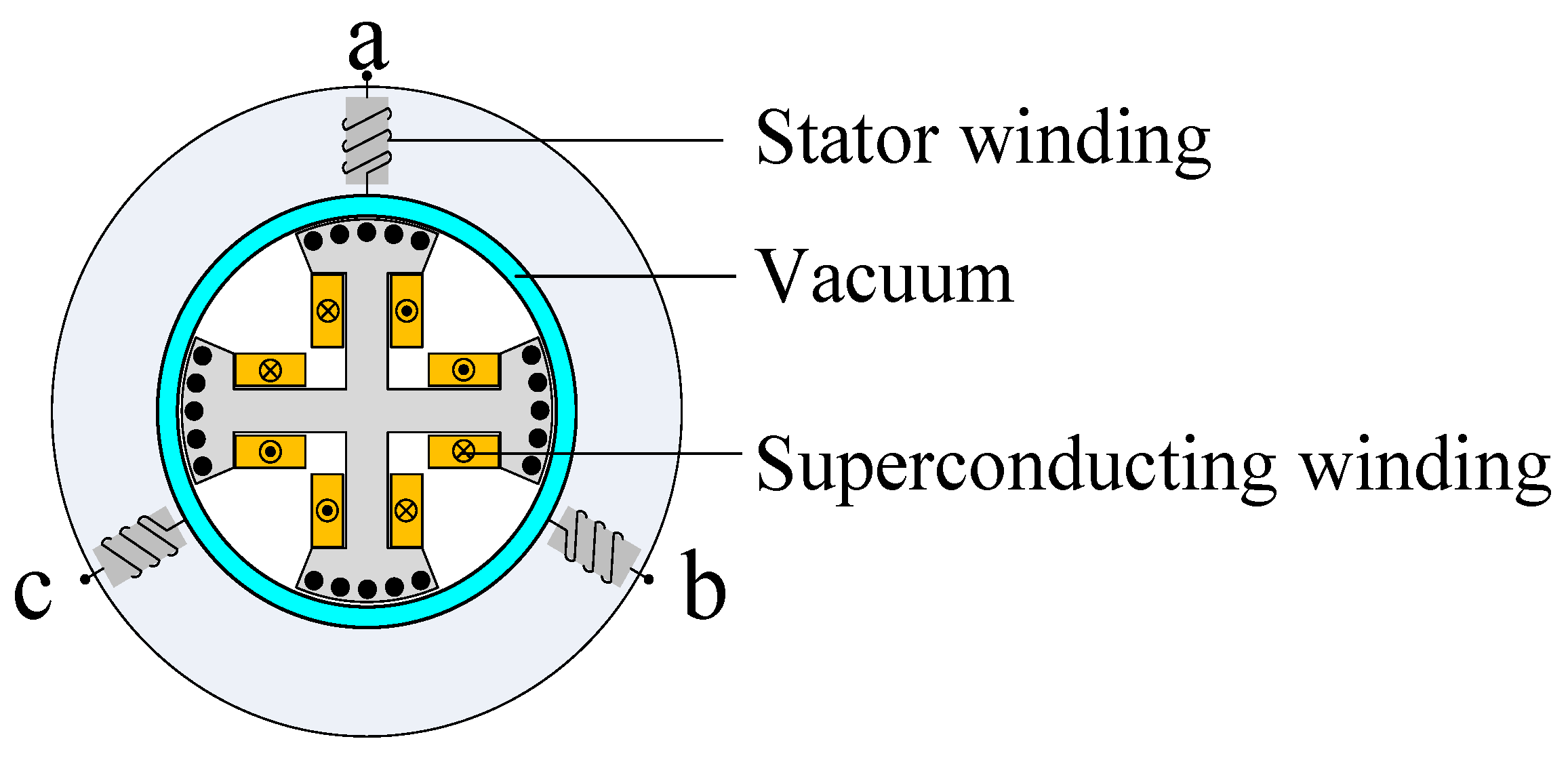

2.3. High-Temperature Superconducting Motor (HTSM)

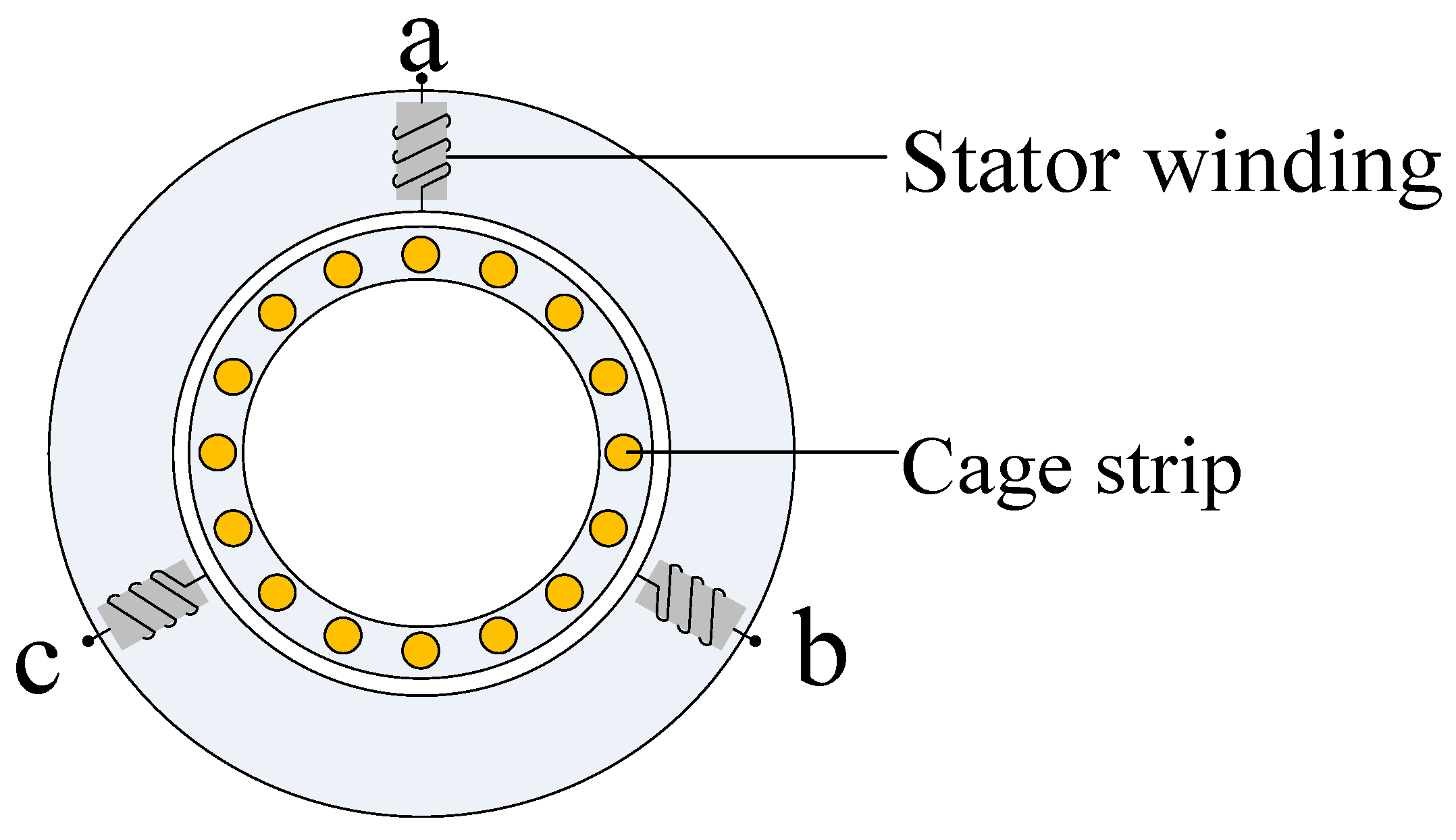

2.4. Induction Motor (IM)

2.5. Switched Reluctance Motor (SRM)

3. High-Power-Density Design

- Boosting the electromagnetic load;

- Boosting the rotational speed;

- Boosting the output power.

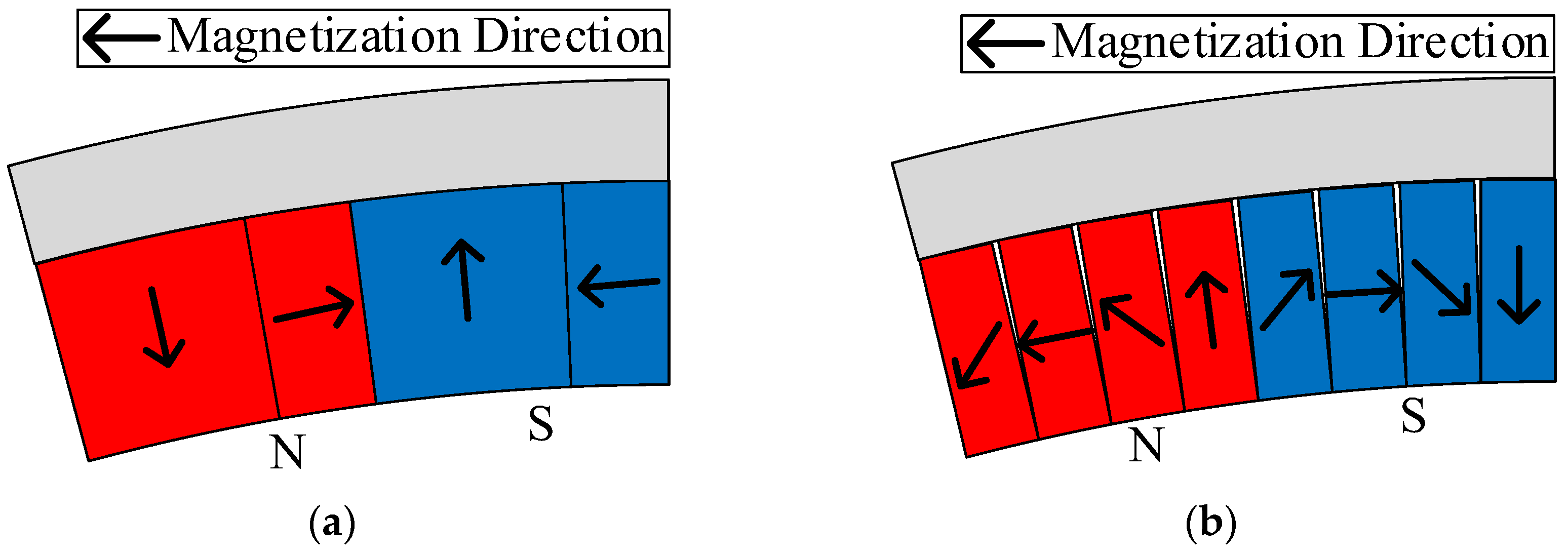

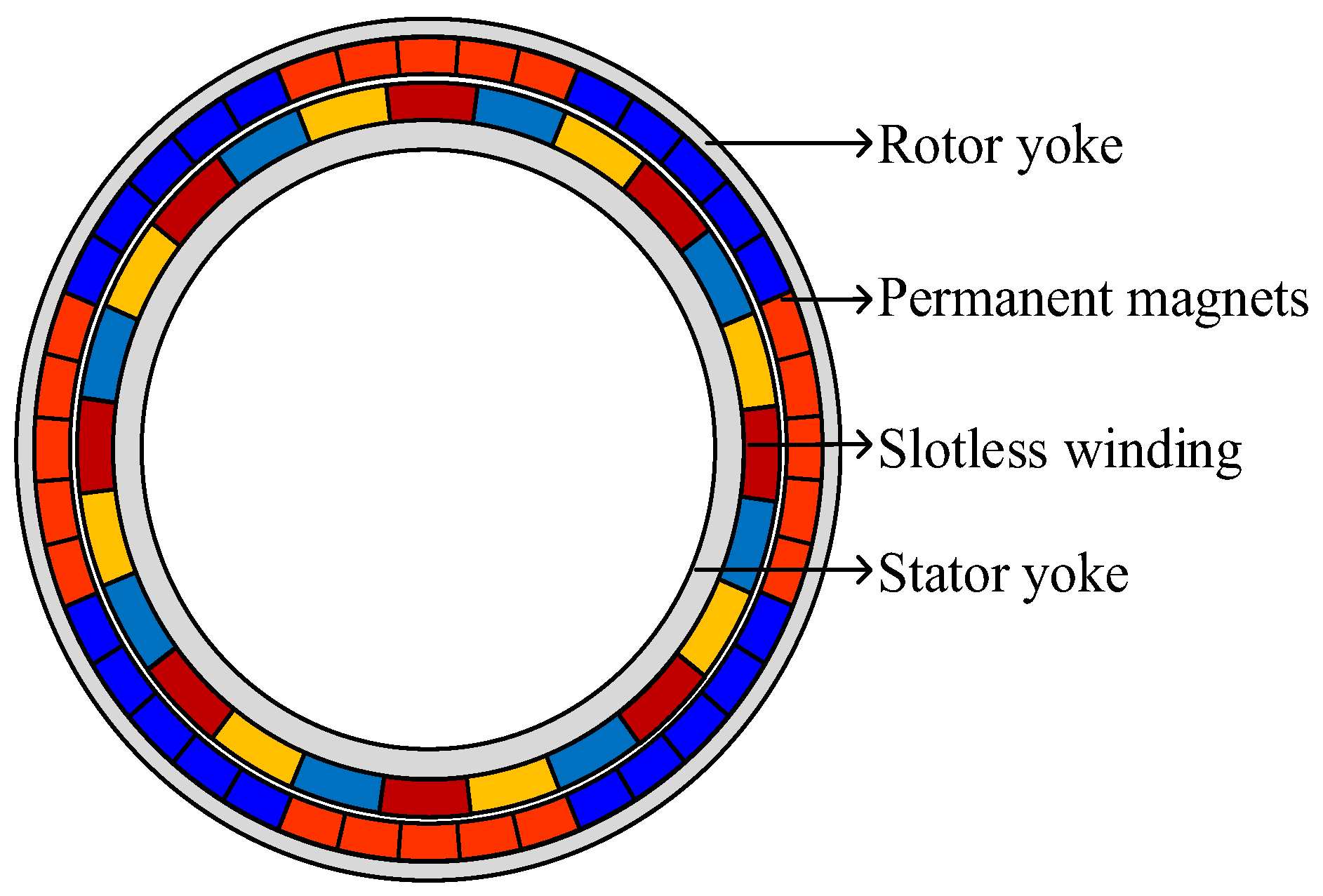

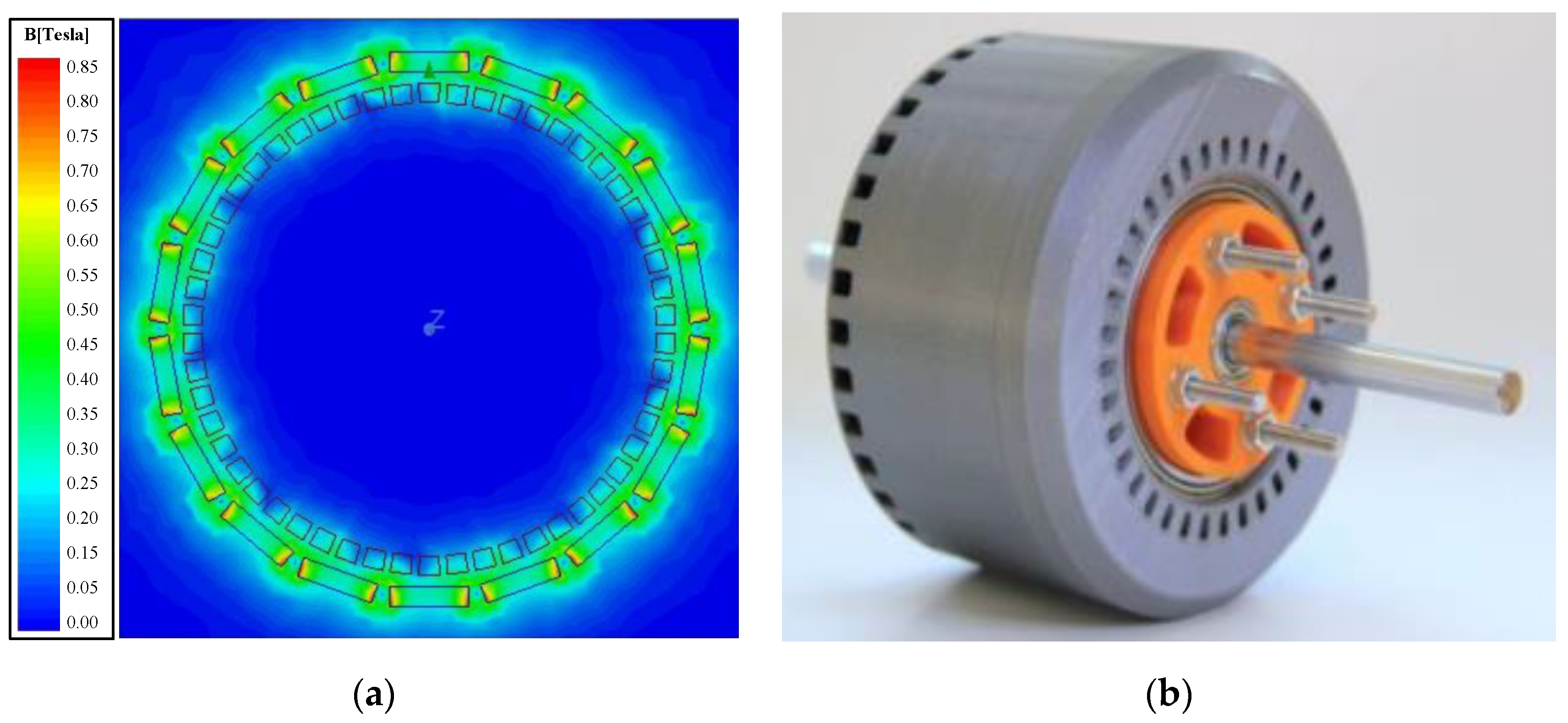

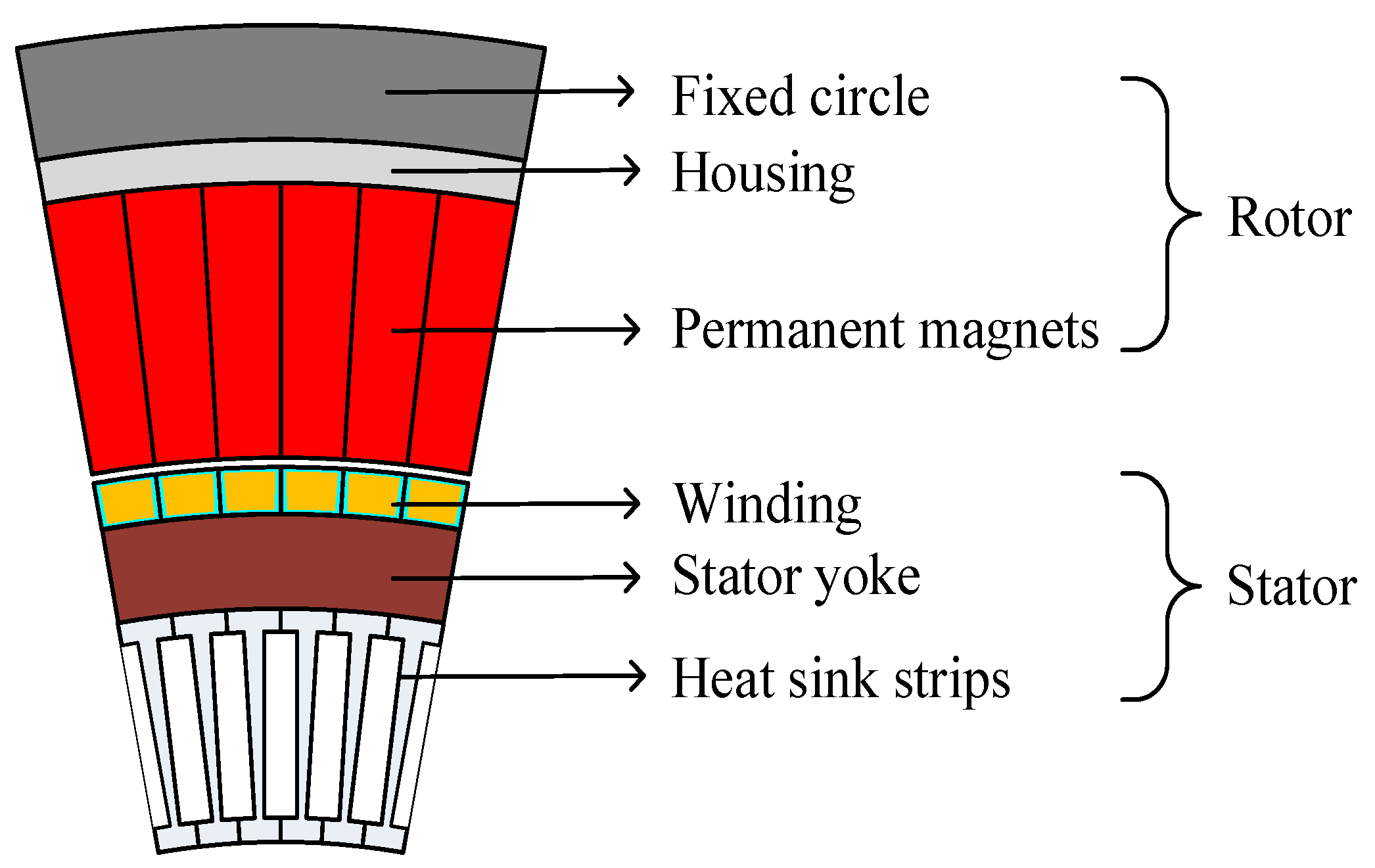

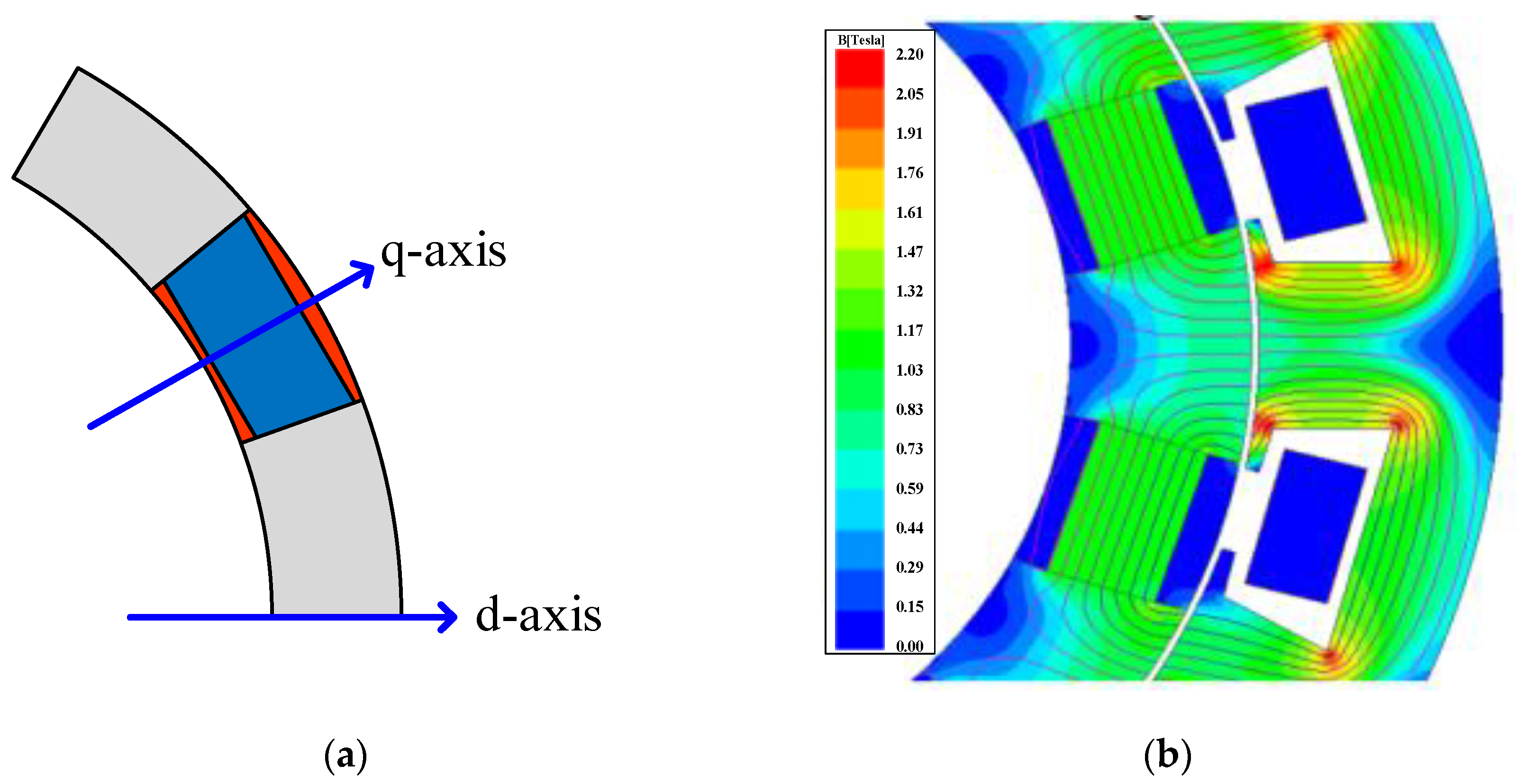

3.1. High Electromagnetic Load

- Single-sided magnetization characteristics: increase the air-gap magnetic density while weakening the rotor yoke magnetic density, ideally removing the rotor yoke and effectively reducing the weight of the motor.

- Improve the sinusoidality of the air-gap density: improve the sinusoidality of the counter potential and reduce torque pulsation and harmonic loss.

- Improve the fundamental amplitude of the air-gap density: higher output torque and power under the same electrical load.

3.2. High Speed

- Much smaller size than low- and medium-speed motors at the same output power;

- Low rotational inertia and high dynamic response capability;

- Direct drive of the load, eliminating the need for traditional mechanical gearing, improving mechanical reliability and reducing transmission noise.

3.3. High Power

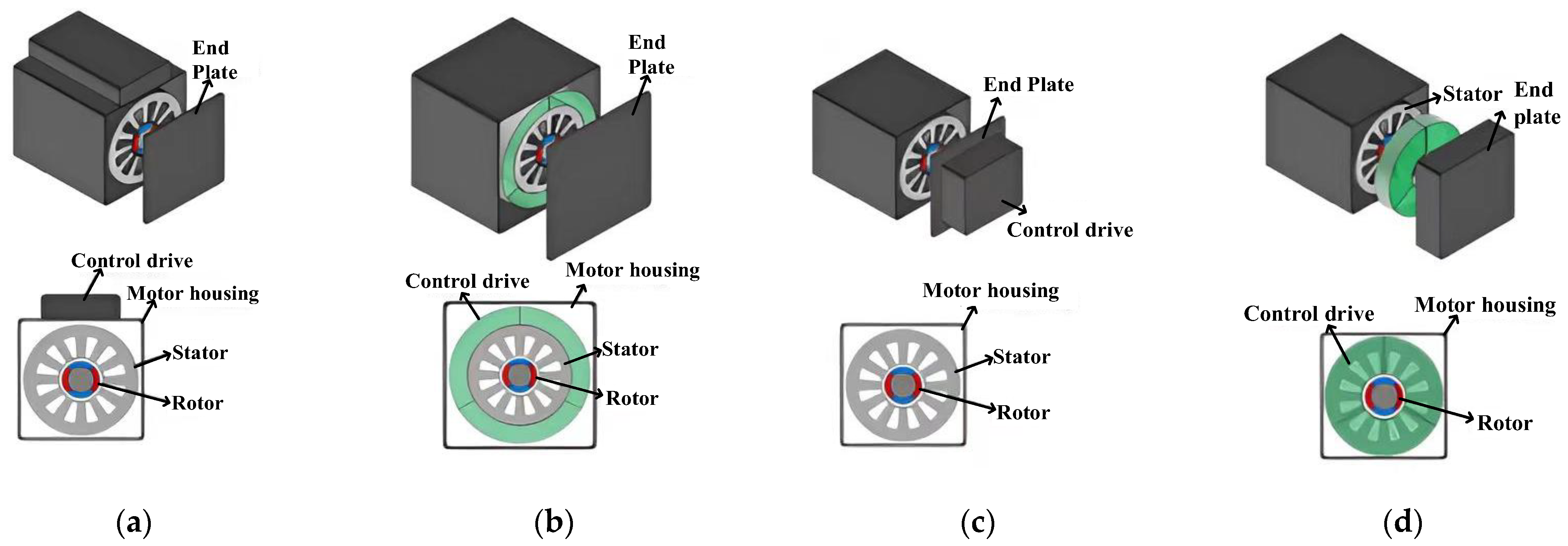

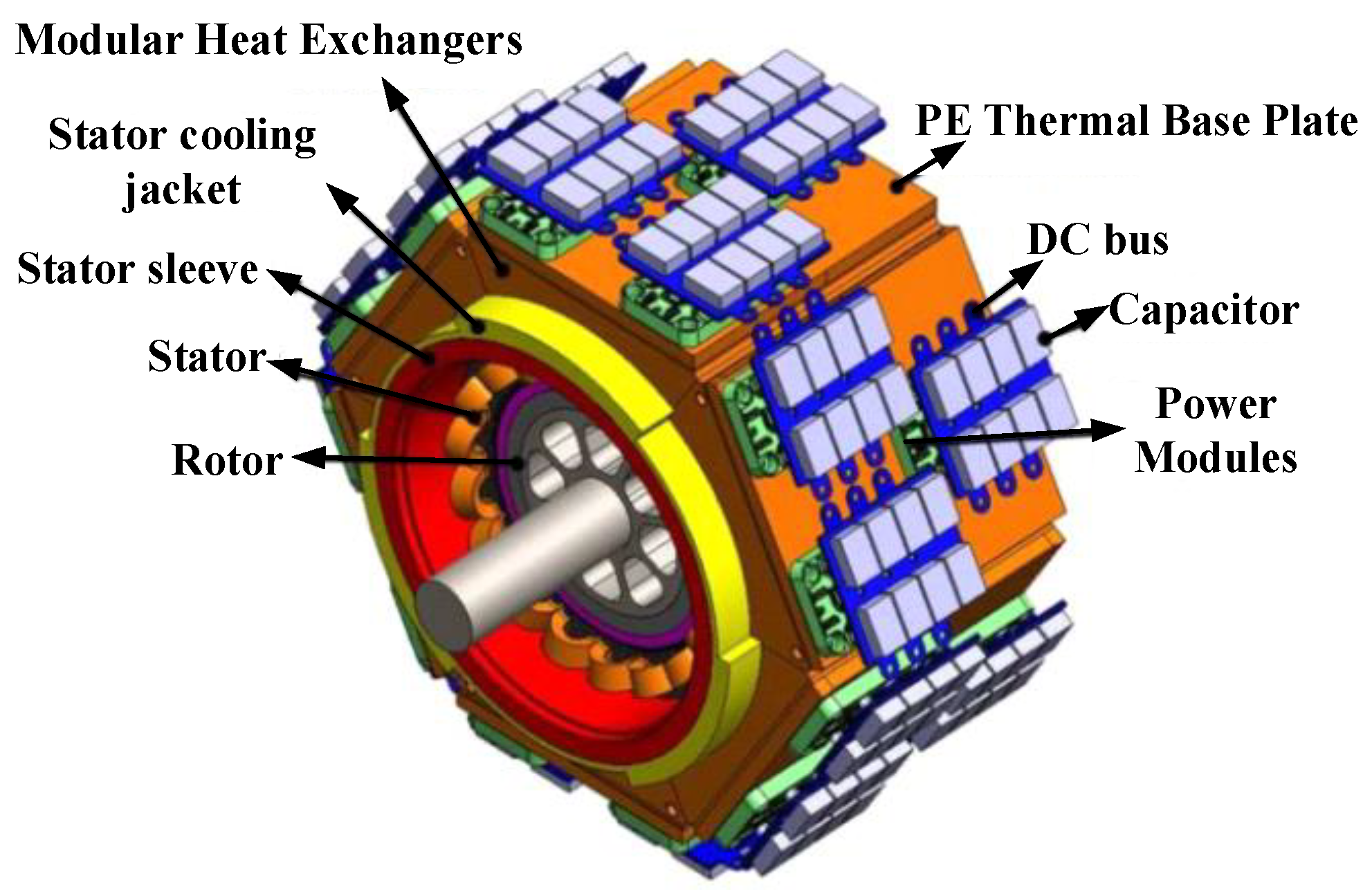

3.4. High Integration Degree

- Reduction of system volume: about 10–20%;

- Reduction of manufacturing costs: about 30–40%;

- Improving system power density;

- Improving system electromagnetic compatibility;

- Improving system efficiency;

- Improve high-temperature operation capability.

4. Fault-Tolerant Design

- (1)

- Fail-safe phase: When a fault occurs, the motor system is able to cut off the fault in time and inhibit the spread of the fault so as to reduce the impact of the faulty parts on the healthy parts.

- (2)

- Fault-tolerant operation stage: This ensures that the motor system still has partial or full output capability after a failure, thus maintaining the safe operation of the propulsion system.

- (1)

- Redundant design: Redundant phase windings, winding units, stator and rotor, and even the whole motor are set up to cut off the faulty part when a fault occurs, and a certain fault-tolerant algorithm is used to keep the healthy part working so as to maintain the safe operation of the motor.

- (2)

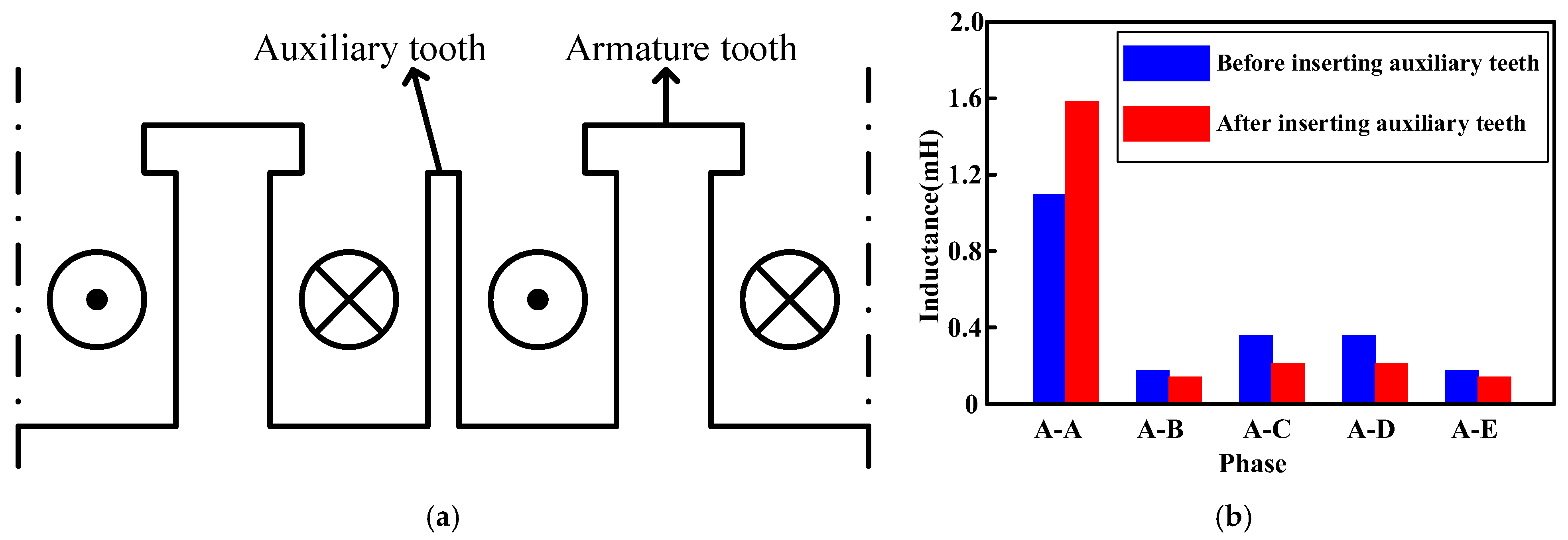

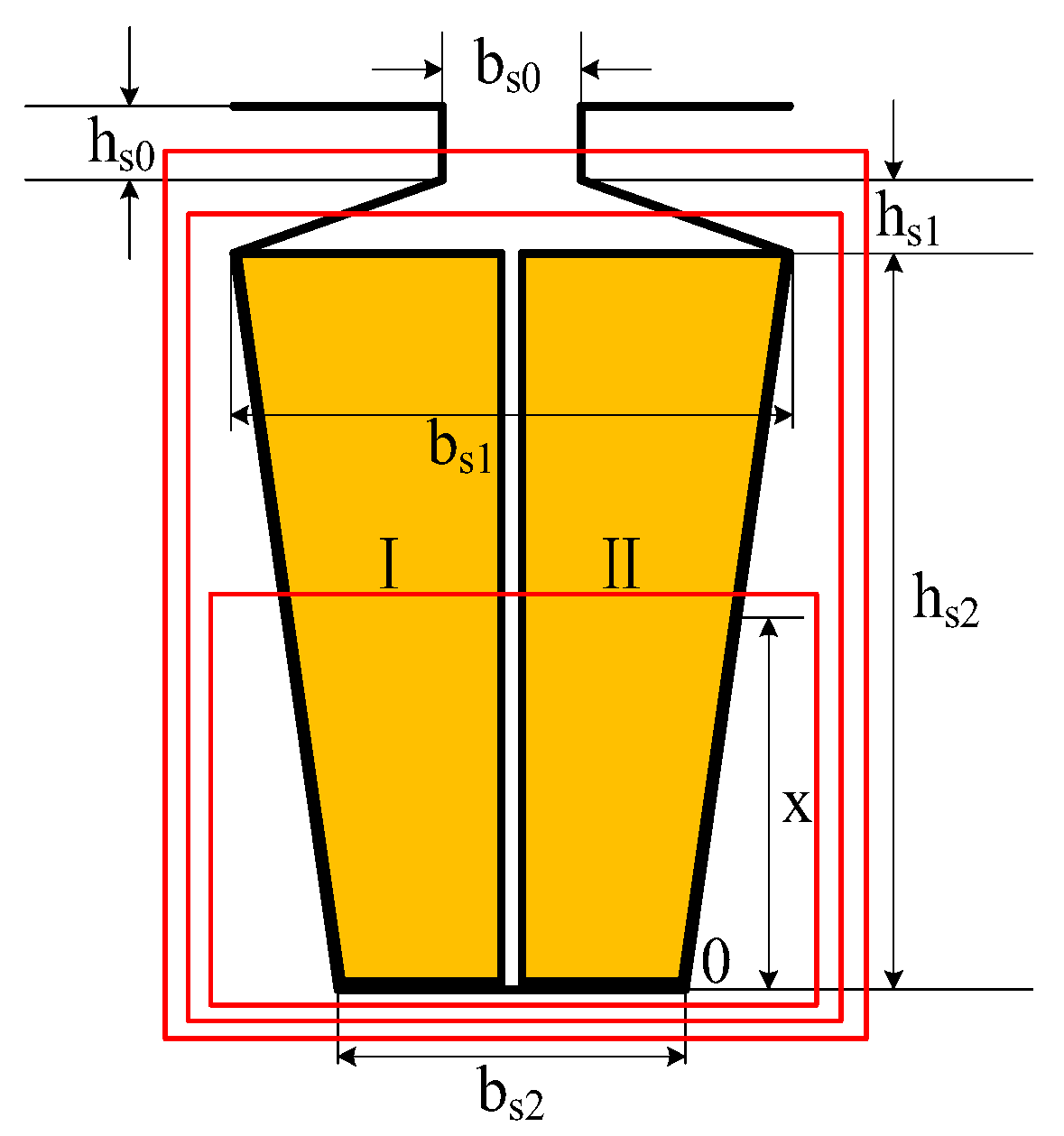

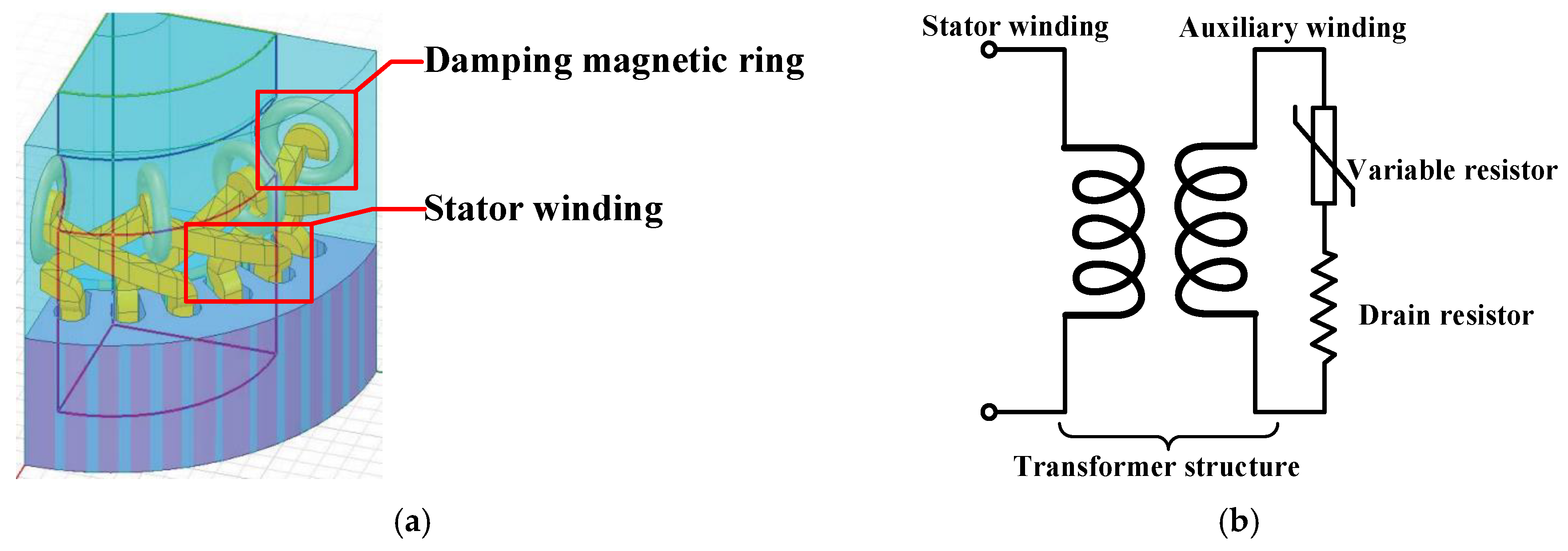

- Fault-tolerant design: The winding form and stator teeth are optimized to improve the self-inductance and reduce the mutual inductance, so as to limit the short-circuit current and prevent the spread of short-circuit faults.

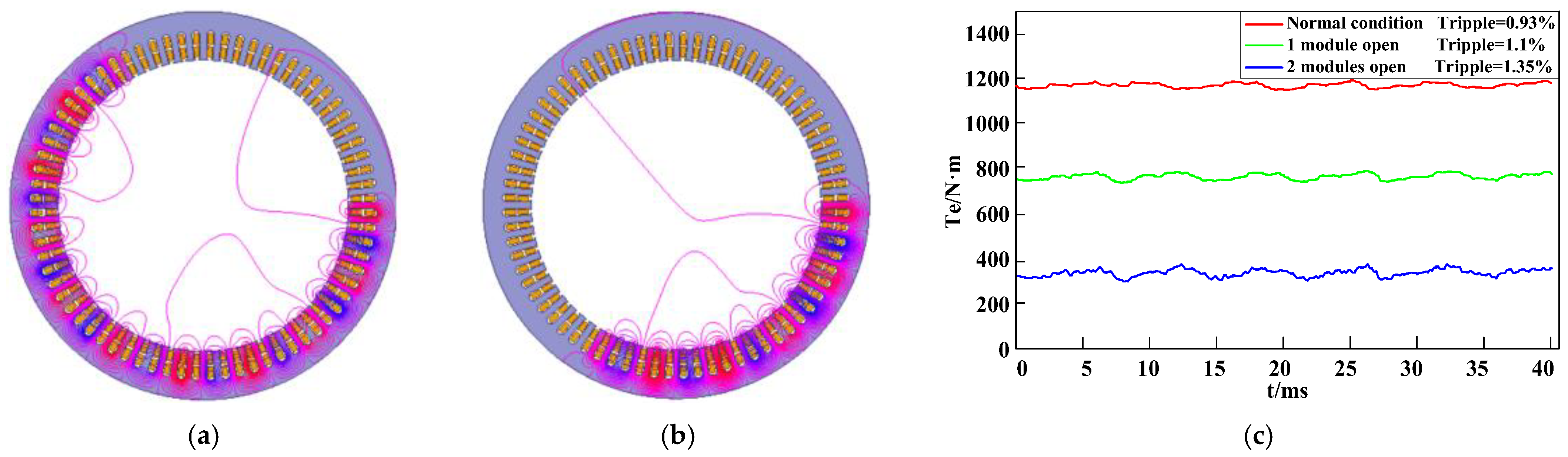

4.1. Redundant Design

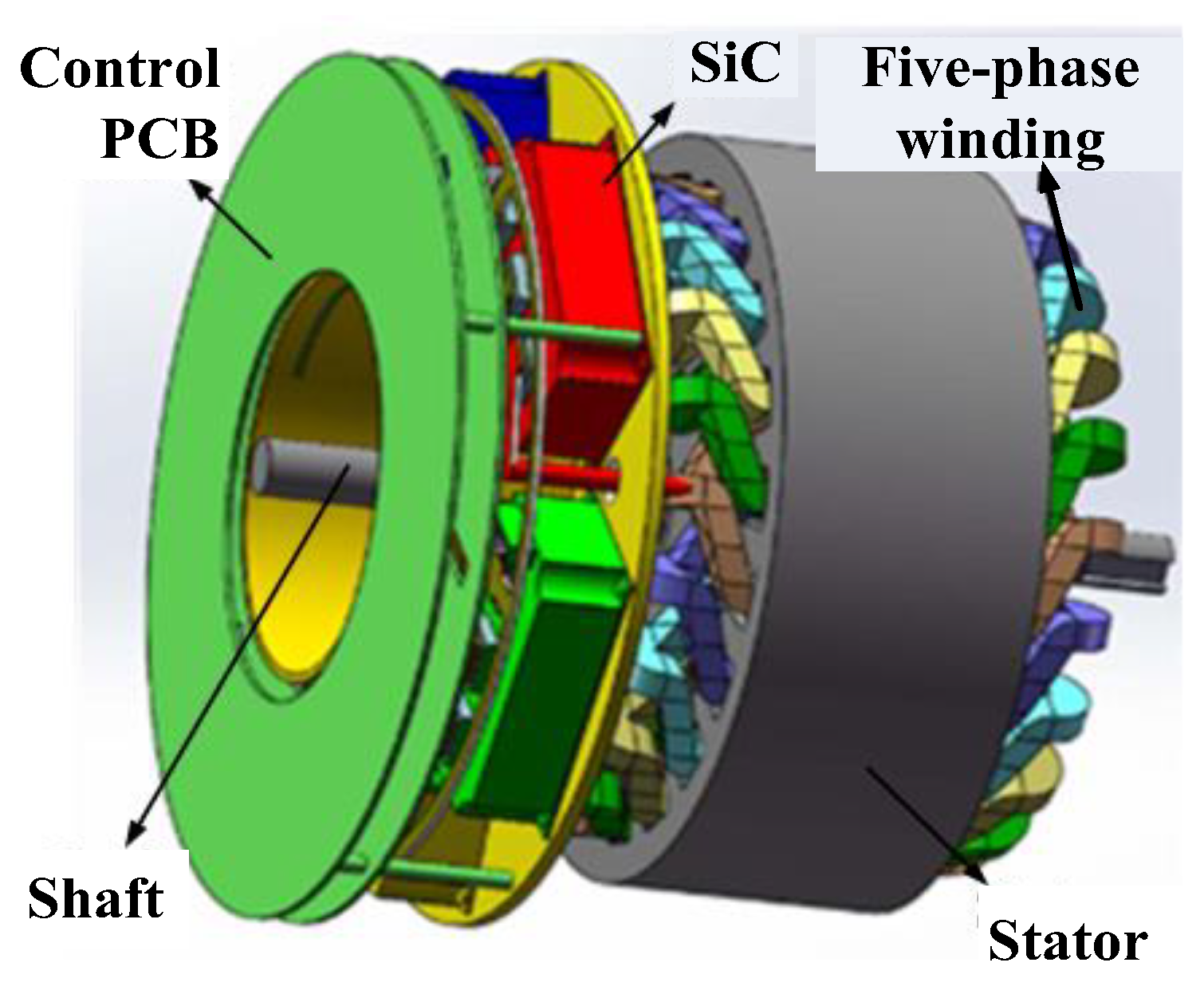

4.1.1. Multi-Phase Motors

- High fault tolerance performance: When a fault occurs in phase m (m ≤ (N-3)) of the N-phase motor, only the power supply to that phase needs to be cut off; then, the corresponding fault-tolerant operation algorithm is used to adjust the amplitude and phase of the healthy 0 phase winding current to reconstruct the circular rotating magnetic field, thus ensuring safe operation of the motor.

- Low-voltage and high-power operation: Under a certain output power and rated current, the rated voltage of the motor decreases with the number of phases, which has obvious advantages in applications where the voltage level is limited.

- High degree of control freedom: The phase voltage is often used as the control object in motor control. Thus, the increase in the number of phases will result in the control volume growing geometrically; the degree of control freedom is significantly increased, so there is more room for algorithm design.

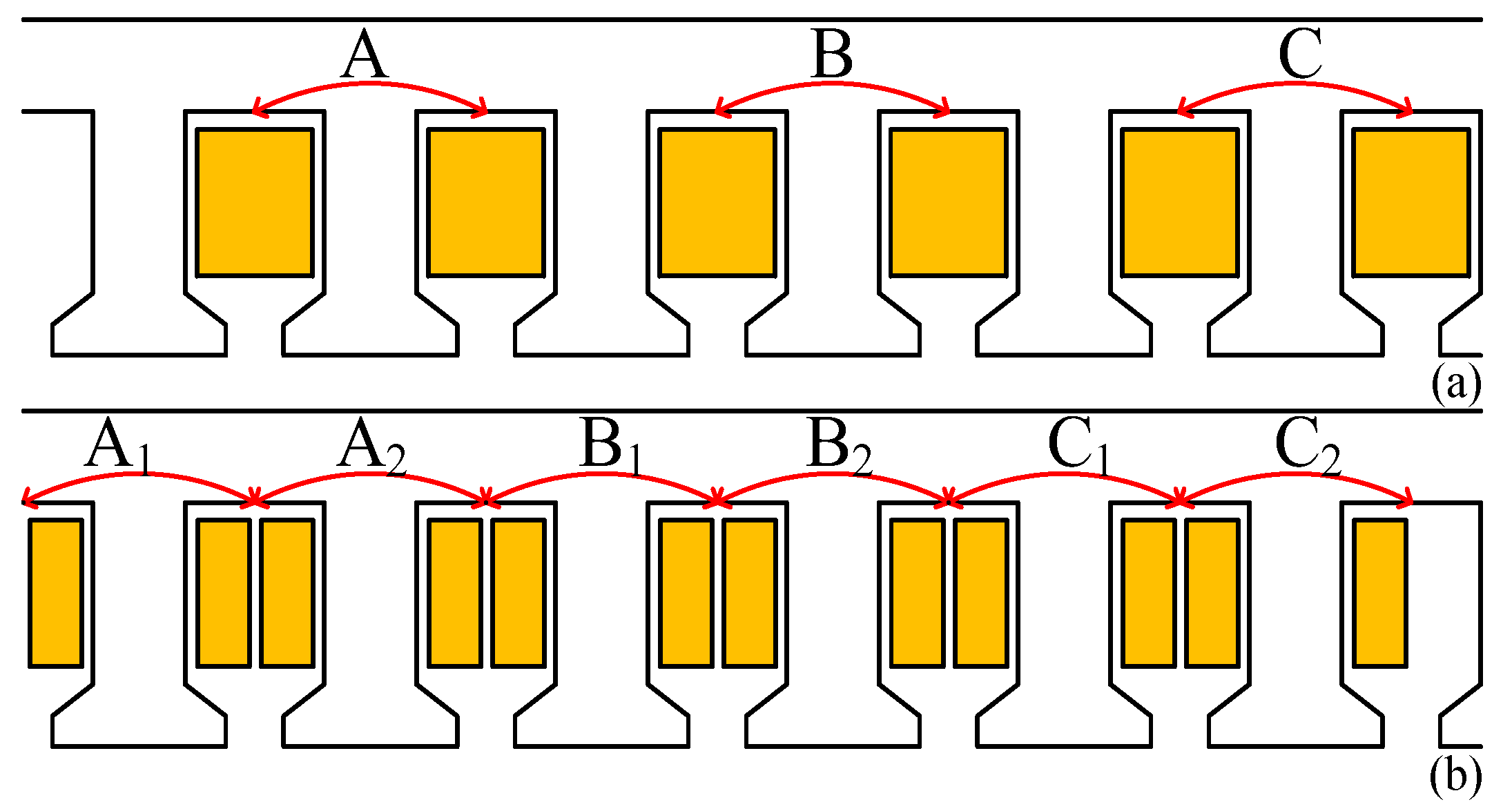

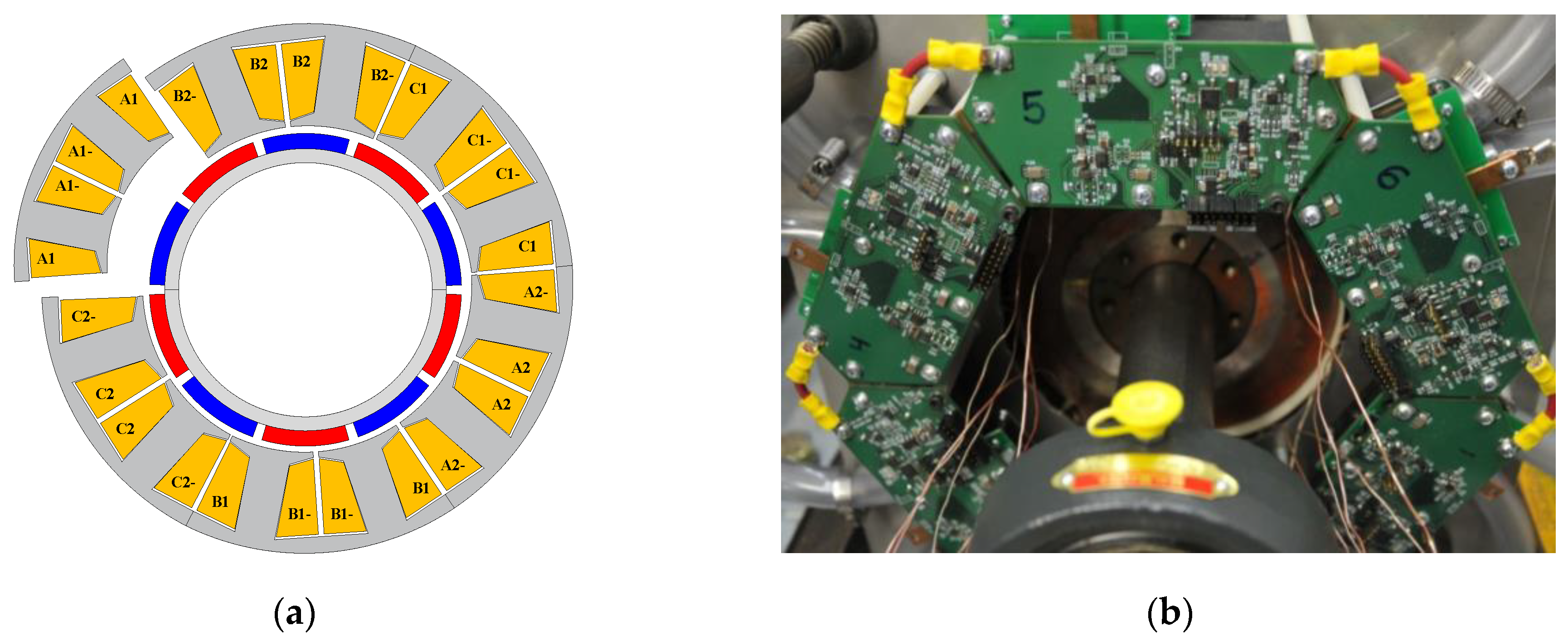

4.1.2. N×3-Phase Design

4.1.3. Open-Winding Structure

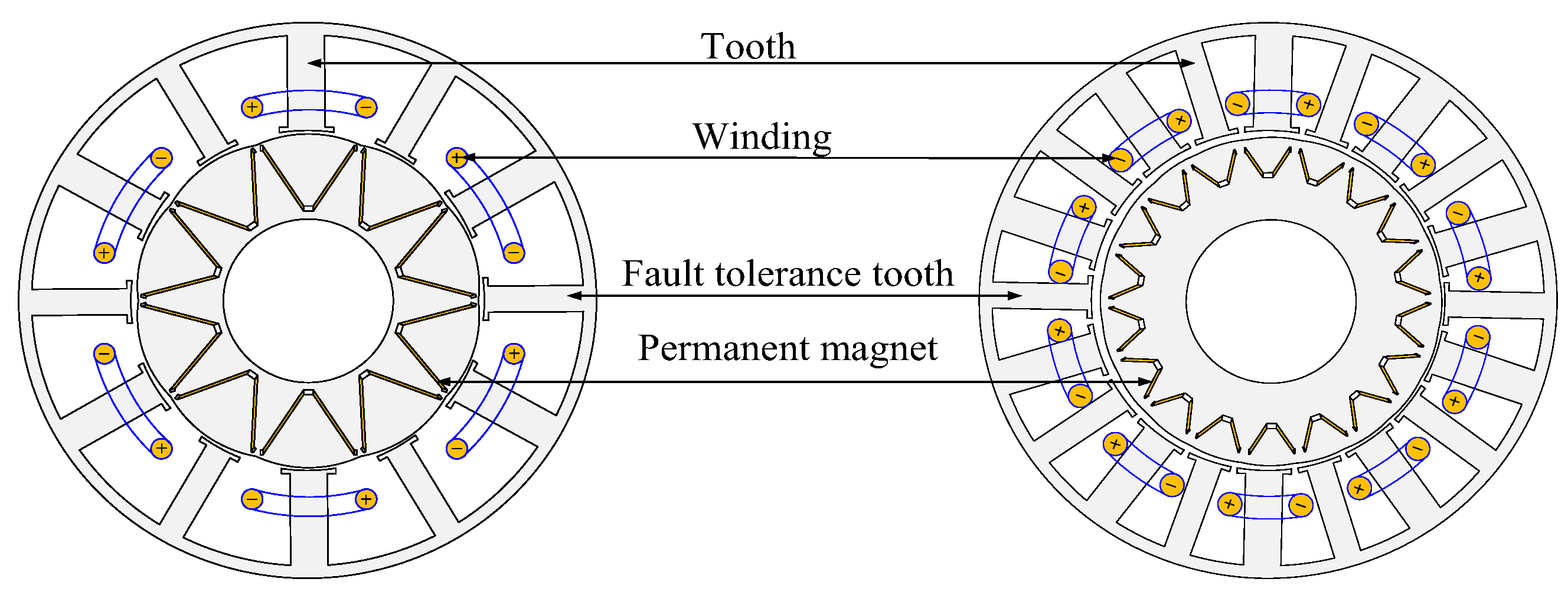

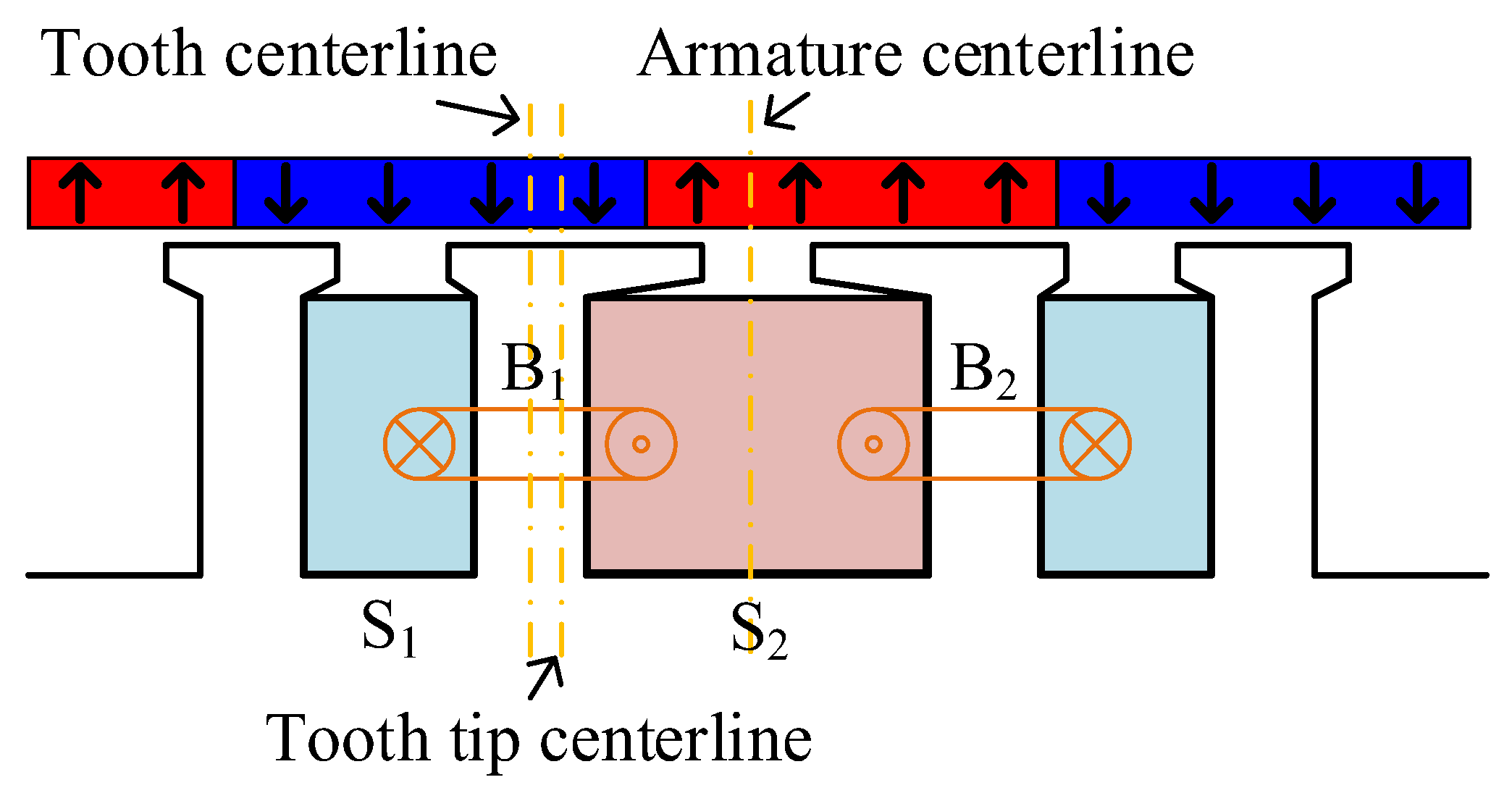

4.2. Design to Enhance Fault Tolerance

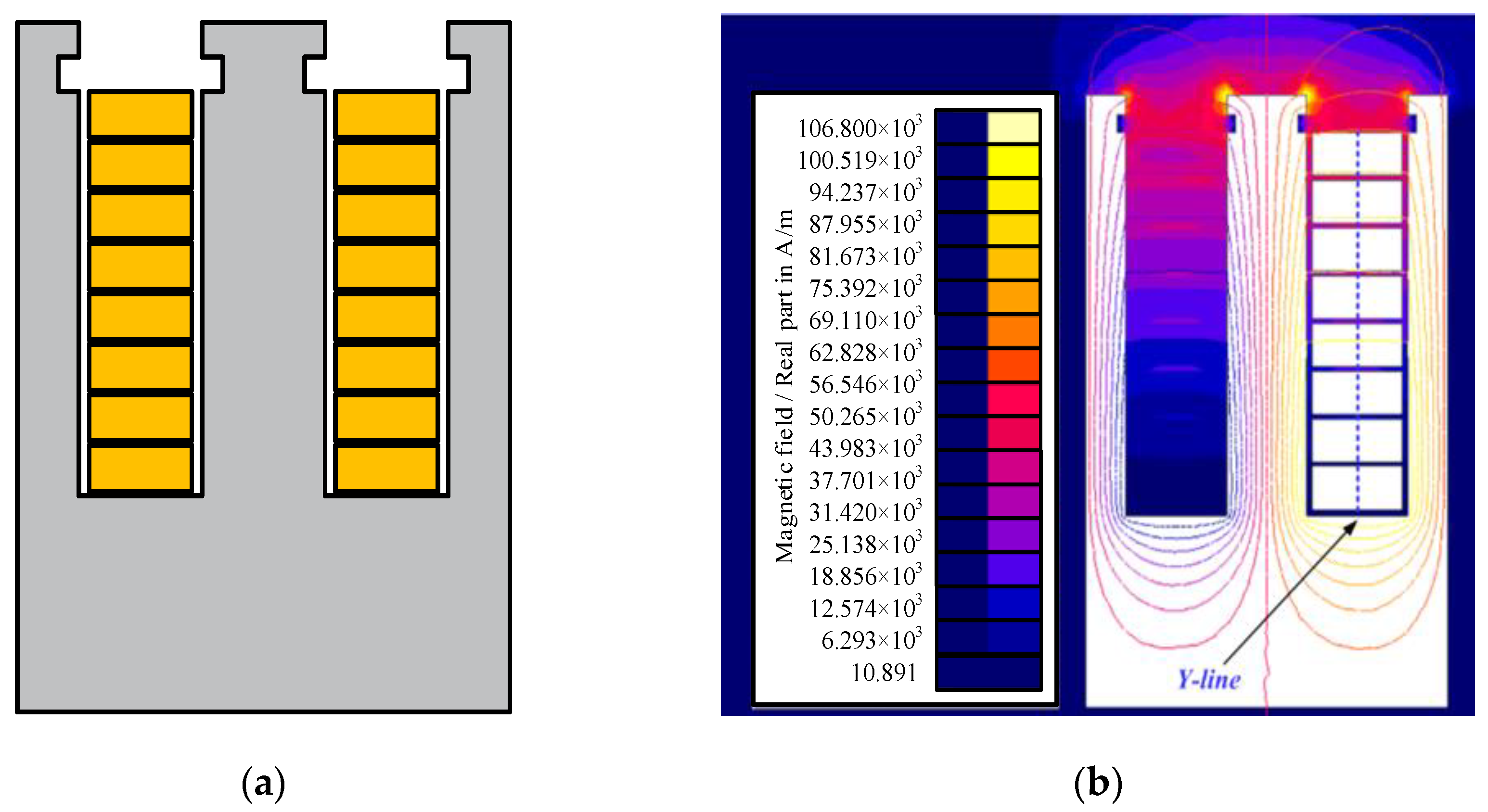

4.2.1. Enhanced Magnetic Isolation Capability

4.2.2. Enhanced Short-Circuit Current-Limiting Capability

5. Conclusions and Outlook

Funding

Conflicts of Interest

References

- Xiangwan, D.; Zhou, D.; Chao, Q.; Wen, Z.; Huhe, T.; Liu, Q. The Concept of Low-Carbon Development. In Overview of Low-Carbon Development; Springer: Singapore, 2019. [Google Scholar]

- Cheng, J.; Shuxiao, L.; Zheng, W.; Zhanhong, C. The Characteristic Differences between Ecological Culture and Low-carbon Tourism Cognition under the Vision of Carbon Neutrality. J. Resour. Ecol. 2022, 13, 936–945. [Google Scholar]

- Air Transport Action Group—Facts and Figures. Available online: https://www.atag.org/facts-figures.html (accessed on 17 September 2020).

- Milos, L.; Giangrande, P.; Hebala, A.; Nuzzo, S.; Galea, M. Review, Challenges, and Future Developments of Electric Taxiing Systems. IEEE Trans. Transp. Electrif. 2019, 5, 1441–1457. [Google Scholar]

- Ashkan, B.; Ghassemi, M. Components of Electrical Power Systems in More and All-Electric Aircraft: A Review. IEEE Trans. Transp. Electrif. 2022, 8, 4037–4053. [Google Scholar]

- Hall, D.L.; Chin, J.C.; Anderson, A.D.; Thompson, J.T.; Smith, A.D.; Edwards, R.; Duffy, K.P. Development of a Maxwell X-57 High Lift Motor Reference Design. In Proceedings of the 2019 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Indianapolis, IN, USA, 19–22 August 2019; pp. 1–24. [Google Scholar]

- Whurr, J.R.; Hart, J. A Rolls-Royce Perspective on Concepts and Technologies for Future Green Propulsion Systems; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Lin, Y.W. The Development and Challenges of More Electric Aircraft. In Highlights in Science, Engineering and Technology; Darcy & Roy Press: Hillsboro, OR, USA, 2022. [Google Scholar]

- Shuli, W.; Zhang, S.; Ma, S. An Energy Efficiency Optimization Method for Fixed Pitch Propeller Electric Aircraft Propulsion Systems. IEEE Access 2019, 7, 159986–159993. [Google Scholar]

- Kristiansen, N.J.; Leandro, M.; Suul, J.A.; Molinas, M. High-Power Machines and Starter-Generator Topologies for More Electric Aircraft: A Technology Outlook. IEEE Access 2020, 8, 130104–130123. [Google Scholar]

- William, W.P.; Sirimanna, T.S.; Bozhko, S.V.; Haran, K.S. Electric/Hybrid-Electric Aircraft Propulsion Systems. Proc. IEEE 2021, 109, 1115–1127. [Google Scholar]

- Ralph, J.; Bowman, C.L.; Jankovsky, A.L.; Dyson, R.W.; Felder, J.L. Overview of NASA Electrified Aircraft Propulsion Research for Large Subsonic Transports. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Commercial Aircraft Propulsion and Energy Systems Research: Reducing Global Carbon Emissions; National Academies Press: Washington, DC, USA, 2017.

- Christopher, C.; Hansman, R.J. Safety Considerations in Emerging Electric Aircraft Architectures. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Ehab, S.; Abdalmagid, M.; Pietrini, G.; Sa’adeh, N.-M.; Callegaro, A.D.; Goldstein, C.; Emadi, A. Review of Electric Machines in More-/Hybrid-/Turbo-Electric Aircraft. IEEE Trans. Transp. Electrif. 2021, 7, 2976–3005. [Google Scholar]

- El-Refaie, A.M.; Osama, M. High specific power electrical machines: A system perspective. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; pp. 1–6. [Google Scholar]

- Xiaolong, Z.; Bowman, C.L.; O’Connell, T.C.; Haran, K.S. Large electric machines for aircraft electric propulsion. IET Electr. Power Appl. 2018, 12, 767–779. [Google Scholar]

- Nagel, N.J. Actuation Challenges in the More Electric Aircraft: Overcoming Hurdles in the Electrification of Actuation Systems. IEEE Electrif. Mag. 2017, 5, 38–45. [Google Scholar] [CrossRef]

- Wenping, C.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of Electric Motor Technologies Used for More Electric Aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar] [CrossRef]

- Hebala, A.; Nuzzo, S.; Connor, P.H.; Gerada, C.; Galea, M. On the Fault Tolerance and PM Demagnetisation of a High-Performance Aircraft Propulsion Motor. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 2338–2343. [Google Scholar]

- Dexter, J.; Brown, G.V. Power Requirements Determined for High-Power-Density Electric Motors for Electric Aircraft Propulsion; NASA: New York, NY, USA, 2005.

- Aldo, B.; Cavagnino, A.; Tenconi, A.; Vaschetto, S.; di Torino, P. The safety critical electric machines and drives in the more electric aircraft: A survey. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 2587–2594. [Google Scholar]

- Airbus. The E-Fan X Puts Its Aerodynamic Design to the Test. Available online: https://www.airbus.com/en/newsroom/stories/2020-02-the-e-fan-x-puts-its-aerodynamic-design-to-the-test (accessed on 4 February 2020).

- Clarke, S.; Redifer, M.; Papathakis, K.; Samuel, A.; Foster, T. X-57 power and command system design. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; pp. 393–400. [Google Scholar] [CrossRef]

- Marrufo, M.A.; Kloesel, K.J. X-57 70kW Permanent Magnet Synchronous Cruise Motor Finite Element Electromagnetic Modeling. 2019. Available online: https://ntrs.nasa.gov/api/citations/20190033258/downloads/20190033258.pdf (accessed on 17 September 2023).

- Hallez, R.F.; Colanaeli, C.; Cuenca, J.; De Ryck, L. Impact of Electric Propulsion on Aircraft Noise—All-Electric Light Aircrafts Case Study. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Cincinnati, OH, USA, 12–14 July 2018; pp. 1–17. [Google Scholar]

- Shu-Mei, C.; Sun, P.; Kuang, Z.; Zhao, T. A thermal-electromagnetic coupled motor design flow for electric aircraft propeller drive application. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–6. [Google Scholar]

- Anghel, C. Modeling and Simulation of a Power Generation System with a High Power Generator; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Sivasubramaniam, H.K.; Kalsi, S.S.; Arndt, T.; Karmaker, H.; Badcock, R.A.; Buckley, B.B.; Haugan, T.J.; Izumi, M.; Loder, D.; Bray, J.; et al. High power density superconducting rotating machines—Development status and technology roadmap. Supercond. Sci. Technol. 2017, 30, 123002. [Google Scholar]

- High-Efficiency Megawatt Motor (HEMM). Available online: https://www1.grc.nasa.gov/aeronautics/eap/technology/hemm/ (accessed on 20 December 2022).

- Mona, G.; Barzkar, A.; Saghafi, M.H. All-Electric NASA N3-X Aircraft Electric Power Systems. IEEE Trans. Transp. Electrif. 2022, 8, 4091–4104. [Google Scholar]

- Dong, T.; Gao, Y.; Nakamura, T. High Fault-Tolerance Dual-Rotor Synchronous Machine with Hybrid Excitation Field Generated by Halbach Permanent Magnets and High Temperature Superconducting Magnets. IEEE Trans. Appl. Supercond. 2023, 33, 5202105. [Google Scholar] [CrossRef]

- Benzaquen, J.; He, J.; Mirafzal, B. Toward more electric powertrains in aircraft: Technical challenges and advancements. CES Trans. Electr. Mach. Syst. 2021, 5, 177–193. [Google Scholar] [CrossRef]

- van der Geest, M.; Polinder, H.; Ferreira, J.A.; Zeilstra, D. Machine selection and initial design of an aerospace starter/generator. In Proceedings of the 2013 International Electric Machines & Drives Conference, Chicago, IL, USA, 12–15 May 2013; pp. 196–203. [Google Scholar]

- Elbuluk, M.E.; Kankam, M.D. Potential starter/generator technology for future aerospace application. IEEE Aerosp. Electron. Syst. Mag. 1996, 11, 17–24. [Google Scholar] [CrossRef]

- Feifei, B.; Liu, H.; Huang, W.; Hu, Y.; Degano, M.; Gerada, C.; Rajashekara, K. Induction-Machine-Based Starter/Generator Systems: Techniques, Developments, and Advances. IEEE Ind. Electron. Mag. 2020, 14, 4–19. [Google Scholar]

- Ohio State University Induction Machine. Available online: https://www1.grc.nasa.gov/aeronautics/eap/technology/electric-machines/induction-machine/ (accessed on 21 August 2021).

- Stawinski, G. Fuel Pump Motor-Drive Systems for More Electric Aircraft; ProQuest Dissertations Publishing: Ann Arbor, MI, USA, 2010. [Google Scholar]

- Irudaya, R.E.F.; Appadurai, M.; Rani, E.F.I.; Jenish, I. Finite-element design and analysis of switched reluctance motor for automobile applications. Multiscale Multidiscip. Model. Exp. Des. 2022, 5, 269–277. [Google Scholar]

- Marcin, B.; Sehab, R.; Whidborne, J.F.; Krebs, G.; Luk, P.C.-K. Fault-tolerant switched reluctance motor propulsion system for eVTOLs. J. Phys. Conf. Ser. 2023, 2526, 012065. [Google Scholar]

- Anderson, A.D.; Renner, N.J.; Wang, Y.; Agrawal, S.; Sirimanna, S.; Lee, D.; Banerjee, A.; Haran, K.; Starr, M.J.; Felder, J.L. System Weight Comparison of Electric Machine Topologies for Electric Aircraft Propulsion. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Cincinnati, OH, USA, 12–14 July 2018; pp. 1–16. [Google Scholar]

- Ali, E.; Ehsani, M. Electrical System Architectures for Future Aircraft; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Shaopeng, W.; Zhou, J.C.; Zhang, X.; Yu, J. Design and Research on High Power Density Motor of Integrated Motor Drive System for Electric Vehicles. Energies 2022, 15, 3542. [Google Scholar]

- Prasad, A.I.; Toulabi, M.S.; Filizadeh, S.; Gole, A. Performance Enhancement of a SynRM and PMaSynRM Using a Cartesian Coordinates-Based Rotor Design Optimization. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 1429–1434. [Google Scholar]

- Jian-Xin, S.; Cai, S.; Hao, H.; Jin, M.-J. Comprehensive parameter design for transversally laminated synchronous reluctance machines. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–9. [Google Scholar]

- Wu, R.; Xu, Q.; Li, Q.; Chen, L. Reducing cogging torque and suppressing torque ripple in PMASynRM for EV/HEV applications. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar]

- Bharatiraja, C.; Deepak, M.; Jagadeesh, D. Finite Element Analysis of Permanent Magnet Less Motors For Electric Vehicle Application. In Proceedings of the 2023 Fifth International Conference on Electrical, Computer and Communication Technologies (ICECCT), Erode, India, 22–24 February 2023; pp. 1–6. [Google Scholar]

- Masato, I.; Suto, T.; Takahashi, A.; Hara, T.; Iwano, R. Development of a High Power Density In-Wheel Motor using Halbach Array Magnets. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 355–360. [Google Scholar]

- Michael, G.; Xu, Z.; Tighe, C.; Hamiti, T.; Gerada, C.; Pickering, S.J. Development of an aircraft wheel actuator for green taxiing. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 2492–2498. [Google Scholar]

- Reza, I.; Alinejad-Beromi, Y.; Yaghobi, H.; Asgharpour-Alamdari, H. Design of Slotless BLDC Motor for Eliminating Cogging Torque; Scienceline: Erzurum, Turkey, 2014. [Google Scholar]

- Zaixin, S.; Liu, C.; Feng, K.; Zhao, H.; Yu, J. Field Prediction and Validation of a Slotless Segmented-Halbach Permanent Magnet Synchronous Machine for More Electric Aircraft. IEEE Trans. Transp. Electrif. 2020, 6, 1577–1591. [Google Scholar]

- Hobbs, K. Ironless, Axial Flux, Electric BLDC Motor for Aircraft Electric Propulsion. Undergraduate Thesis, University of Arkansas, Fayetteville, AR, USA, 2021. [Google Scholar]

- Zhuoran, Z.; Geng, W.; Liu, Y.; Wang, C. Feasibility of a new ironless-stator axial flux permanent magnet machine for aircraft electric propulsion application. CES Trans. Electr. Mach. Syst. 2019, 3, 30–38. [Google Scholar]

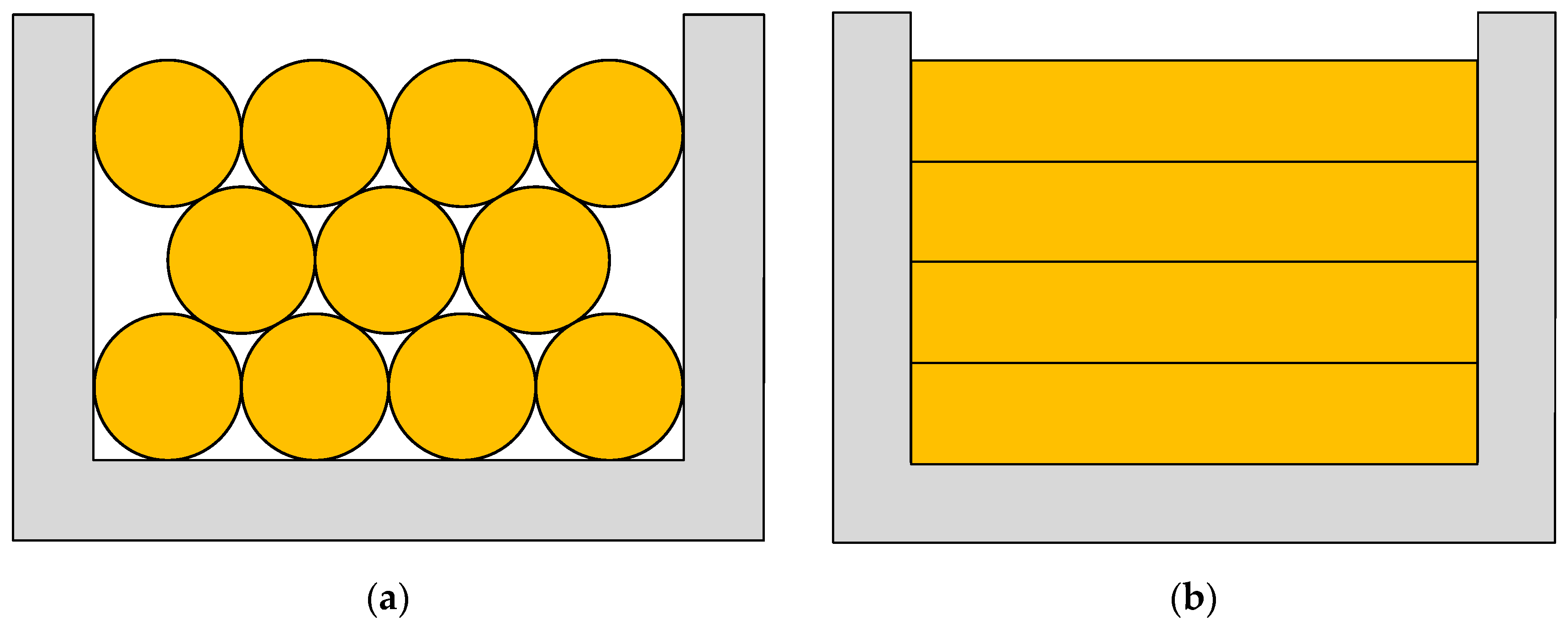

- Marco, V.; Zorzi, A.; Mazzucchelli, M. Torque/volume increase in Permanent Magnet Synchronous Motors by fill factor enhancement. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 309–313. [Google Scholar]

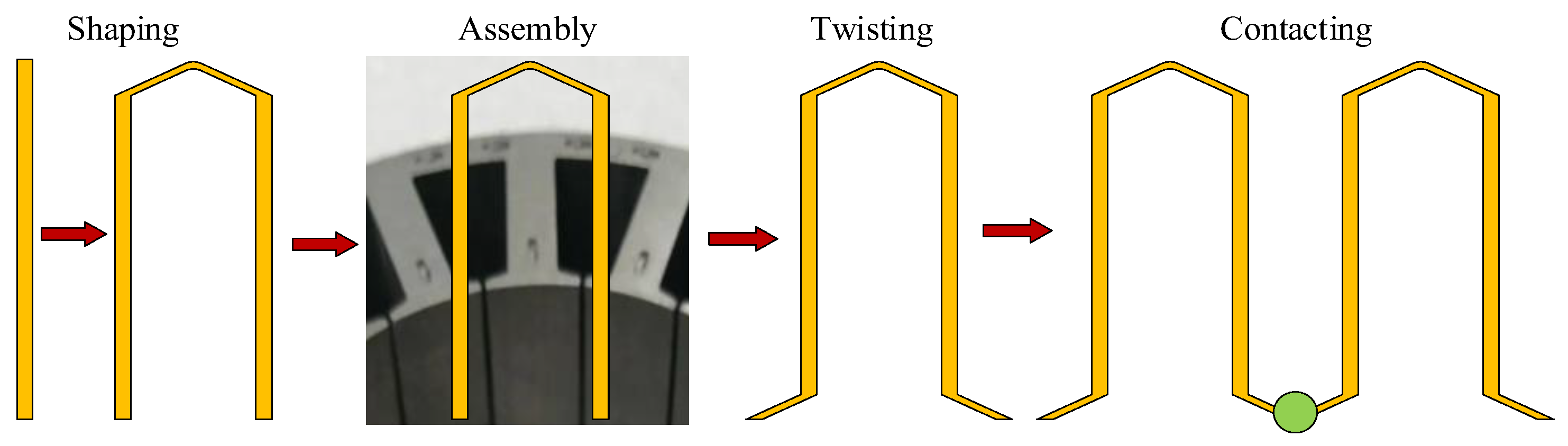

- Tobias, G.; Seefried, J.; Franke, J. Challenges in the manufacturing of hairpin windings and application opportunities of infrared lasers for the contacting process. In Proceedings of the 2017 7th International Electric Drives Production Conference (EDPC), Würzburg, Germany, 5–6 December 2017; pp. 1–7. [Google Scholar]

- Shi, Y.; Ju, Y.; Yang, M. Application of Hair-Pin Winding in Low-Speed High-Torque Permanent Magnet Machines Used in Near Space. Small Spec. Electr. Mach. 2022, 50, 29–32. [Google Scholar]

- Faizul, M.; Rahman, K.M.; Son, Y.; Savagian, P.J.M. Electric Motor Design of General Motors’ Chevrolet Bolt Electric Vehicle. SAE Int. J. Altern. Powertrains 2016, 5, 286–293. [Google Scholar]

- Nimmana, R.L.S.; Chiba, A. Design of High Power Density Motor for EV Applications. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Republic of Korea, 7–10 October 2018; pp. 104–108. [Google Scholar]

- Arzillo, A.; Braglia, P.; Nuzzo, S.; Barater, D.; Franceschini, G.; Gerada, D.; Gerada, C. Challenges and Future opportunities of Hairpin Technologies. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 277–282. [Google Scholar]

- Chuan, L.; Xu, Z.; Gerada, D.; Li, J.; Gerada, C.; Chong, Y.C.; Popescu, M.; Goss, J.E.; Staton, D.A.; Zhang, H. Experimental Investigation on Oil Spray Cooling with Hairpin Windings. IEEE Trans. Ind. Electron. 2020, 67, 7343–7353. [Google Scholar]

- Ahmed, S.; Ibrahim, M.N.F.; Sergeant, P. Mitigation of High-Frequency Eddy Current Losses in Hairpin Winding Machines. Machines 2022, 10, 328. [Google Scholar]

- Takashi, I.; Tanaka, Y.; Homma, H. Motor Stator with Thick Rectangular Wire Lap Winding for HEVs. IEEE Trans. Ind. Appl. 2014, 51, 2917–2923. [Google Scholar]

- Qiping, S.; Zhou, Z.-J.; Li, S.; Liao, X.; Wang, T.; He, X.; Zhang, J. Design and Analysis of the High-Speed Permanent Magnet Motors: A Review on the State of the Art. Machines 2022, 10, 549. [Google Scholar]

- Andy, Y.; Yi, X.; Martin, J.M.; Chen, Y.; Haran, K.S. A high-speed, high-frequency, air-core PM machine for aircraft application. In Proceedings of the 2016 IEEE Power and Energy Conference at Illinois (PECI), Urbana, IL, USA, 19–20 February 2016; pp. 1–4. [Google Scholar]

- Rasul, H.; Vahid, S.; El-Refaie, A.M. A Novel Design for a High Specific Power Interior Permanent Magnet Machine for Aerospace Applications. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 1735–1742. [Google Scholar]

- Mesut, U.; Keysan, O. Multi-physics design optimisation of a GaN-based integrated modular motor drive system. J. Eng. 2019, 2019, 3900–3905. [Google Scholar]

- Hao, C.; Wang, J.; Zhang, Z.; Zhou, L. A Review of Integrated Modular Motor Drive for Medium-Voltage Motors. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021; pp. 1–6. [Google Scholar]

- Lee, W.; Li, S.; Han, D.; Sarlioglu, B.; Minav, T.A.; Pietola, M. A Review of Integrated Motor Drive and Wide-Bandgap Power Electronics for High-Performance Electro-Hydrostatic Actuators. IEEE Trans. Transp. Electrif. 2018, 4, 684–693. [Google Scholar] [CrossRef]

- James, A.S.; Zeng, H.; Bobba, D.; Jahns, T.M.; Sarlioglu, B. Design and Testing of a Modular High-Speed Permanent-Magnet Machine for Aerospace Propulsion. In Proceedings of the 2021 IEEE International Electric Machines & Drives Conference (IEMDC), Hartford, CT, USA, 17–20 May 2021; pp. 1–8. [Google Scholar]

- Shaopeng, W.; Tian, C.; Zhao, W.; Zhou, J.C.; Zhang, X. Design and Analysis of an Integrated Modular Motor Drive for More Electric Aircraft. IEEE Trans. Transp. Electrif. 2020, 6, 1412–1420. [Google Scholar]

- Woongkul, L.; Choi, G. A Comprehensive Review of Fault-Tolerant AC Machine Drive Topologies: Inverter, Control, and Electric Machine. In Proceedings of the 2021 IEEE 13th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Dallas, TX, USA, 22–25 August 2021; Volume 1, pp. 269–275. [Google Scholar]

- Jiaxuan, H.; Zheng, P.; Sui, Y.; Zheng, J.; Yin, Z.; Cheng, L. Third Harmonic Current Injection in Different Operating Stages of Five-Phase PMSM With Hybrid Single/Double Layer Fractional-Slot Concentrated Winding. IEEE Access 2021, 9, 15670–15685. [Google Scholar]

- Del Pizzo, A.; di Noia, L.P.; Di Tommaso, A.O.; Miceli, R.; Rizzo, R. Comparison between 3-ph and 6-ph PMSM drives for the electric propulsion of unmanned aerial vehicles. In Proceedings of the 2021 IEEE 15th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Florence, Italy, 14–16 July 2021; pp. 1–5. [Google Scholar]

- Li, Z.; Fan, Y.; Lorenz, R.D.; Nied, A.; Cheng, M. Design and Comparison of Three-Phase and Five-Phase FTFSCW-IPM Motor Open-End Winding Drive Systems for Electric Vehicles Applications. IEEE Trans. Veh. Technol. 2018, 67, 385–396. [Google Scholar]

- Tao, T.; Zhao, W.X.; Cheng, M.; Wang, Z. Review on fault-tolerant control of multi-phase machines and their key technologies. Proc. CSEE 2019, 39, 315–326. (In Chinese) [Google Scholar]

- Yu, W.; Chenggao, Z.; Wenjuan, H. Overview of Fault-tolerant Technologies of Permanent Magnet Brushless Machine and Its Control System. Proceeding CSEE 2022, 42, 351–372. (In Chinese) [Google Scholar]

- Bingyi, Z.; Gan, B.; Li, Q. Analysis of a Fault-Tolerant Module-Combined Stator Permanent Magnet Synchronous Machine. IEEE Access 2020, 8, 70438–70452. [Google Scholar]

- Hao, Z.; Swanke, J.A.; Jahns, T.M.; Sarlioglu, B. Modular Modeling and Distributed Control of Permanent-Magnet Modular Motor Drives (MMDs) for Electric Aircraft Propulsion. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 4598–4605. [Google Scholar]

- Mellor, P.H.; Yon, J.M.; Baker, J.L.; North, D.; Booker, J.D. Electromagnetic and thermal coupling within a fault-tolerant aircraft propulsion motor. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–7. [Google Scholar]

- Adam, S.; Jahns, T.M. Hardware integration for an integrated modular motor drive including distributed control. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 4881–4887. [Google Scholar]

- Yi, S.; Zheng, P.; Yin, Z.; Wang, M.; Wang, C. Open-Circuit Fault-Tolerant Control of Five-Phase PM Machine Based on Reconfiguring Maximum Round Magnetomotive Force. IEEE Trans. Ind. Electron. 2019, 66, 48–59. [Google Scholar]

- Ahmed, A.W.; Mayer, J.S.; Greifelt, A.; Gerling, D. Novel Inherently Fault Tolerant Permanent Magnet Synchronous Machine (PMSM) With Multiphase Windings. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 42–47. [Google Scholar]

- Yi, S.; Yin, Z.; Cheng, L.; Zheng, P.; Tang, D.; Chen, C.; Wang, C. Multiphase Modular Fault-Tolerant Permanent-Magnet Machine with Hybrid Single/Double-Layer Fractional-Slot Concentrated Winding. IEEE Trans. Magn. 2019, 55, 1–6. [Google Scholar]

- Swanke, J.A.; Zeng, H.; Jahns, T.M. Modular Fault-Tolerant Machine Design with Improved Electromagnetic Isolation for Urban Air Mobility (UAM) Aircraft. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 4570–4577. [Google Scholar]

- Baoping, G.; Zhang, B.; Li, Q.; Guihong, F.; Li, G. Research on Operation of Low-Speed and High-Torque Module Combined Stator Permanent Magnetic Fault-Tolerant Motor with Unequal Span Winding. IEEE Access 2020, 8, 166824–166838. [Google Scholar]

- Zheng, R.; Wang, K.; Li, J.; Zhang, G.; Kong, J. Permanent Magnet Machine with Stator Tooth Offset to Improve Fault-Tolerant Capability. In Proceedings of the 2020 IEEE 9th International Power Electronics and Motion Control Conference (IPEMC2020-ECCE Asia), Nanjing, China, 29 November–2 December 2020; pp. 1957–1961. [Google Scholar]

- Yingying, X.; Zhang, B.; Feng, G. Analysis of Unwinding Stator Module Combined Permanent Magnet Synchronous Machine. IEEE Access 2020, 8, 191901–191909. [Google Scholar]

- Yanwu, X.; Zhang, Z.; Jiang, Y.; Huang, J.; Jiang, W. Numerical Analysis of Turn-to-Turn Short Circuit Current Mitigation for Concentrated Winding Permanent Magnet Machines with Series and Parallel Connected Windings. IEEE Trans. Ind. Electron. 2020, 67, 9101–9111. [Google Scholar]

- Sui, Y. Research on Key Technologies of Five-phase Fault-Tolerant Permanent-magnet Synchronous Machine for Pure Electric Vehicles. Ph.D. Dissertation, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Karamanis, E.K.; Kladas, A.G. Short Circuit Current reduction in PMSM by introducing End Winding Magnetic Circuits. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; Volume 1, pp. 332–337. [Google Scholar]

| Winding Structure | LAA (mH) | MAB (mH) | MAC (mH) | MAD (mH) | MAE (mH) |

|---|---|---|---|---|---|

| Single layer | 3.47 | 0.04 | 0.05 | 0.05 | 0.04 |

| Double layer | 2.25 | 0.02 | 0.15 | 0.15 | 0.02 |

| Hybrid | 3.14 | 0 | 0.01 | 0.01 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, C.; Zhang, C.; Li, L. Review of High-Power-Density and Fault-Tolerant Design of Propulsion Motors for Electric Aircraft. Energies 2023, 16, 7015. https://doi.org/10.3390/en16197015

Wang Y, Zhang C, Zhang C, Li L. Review of High-Power-Density and Fault-Tolerant Design of Propulsion Motors for Electric Aircraft. Energies. 2023; 16(19):7015. https://doi.org/10.3390/en16197015

Chicago/Turabian StyleWang, Yingnan, Chengming Zhang, Chaoyu Zhang, and Liyi Li. 2023. "Review of High-Power-Density and Fault-Tolerant Design of Propulsion Motors for Electric Aircraft" Energies 16, no. 19: 7015. https://doi.org/10.3390/en16197015

APA StyleWang, Y., Zhang, C., Zhang, C., & Li, L. (2023). Review of High-Power-Density and Fault-Tolerant Design of Propulsion Motors for Electric Aircraft. Energies, 16(19), 7015. https://doi.org/10.3390/en16197015