1. Introduction

Despite the tremendous development and widespread implementation of green technologies and the gradual transition to renewable energy, the consumption of hydrocarbon (HC) fuels is currently increasing [

1]. According to various estimates, the demand for oil, in particular, is projected to grow until at least 2040, after which only a gradual, slow decline is likely due to the increasing share of alternative energy [

2]. The growing demand for hydrocarbons and simultaneous depletion of conventional oil and gas fields forces oil companies to develop fields in difficult mining and geological conditions or to move to deep and ultra-deep drilling horizons. In addition to increasing the cost of drilling, this causes certain related fundamental challenges. The bottomhole temperature (BHT) increases with increasing depth of the well. In some fields, the BHT of deep wells exceeds 250 °C. High BHT imposes increased requirements on the thermal stability of drilling fluids used for drilling wells. Therefore, the development of drilling fluid formulations applicable at high BHT is a very urgent task, which is dealt with by a large number of researchers [

3,

4,

5,

6]. As a rule, clay–polymer-based and hydrocarbon-based drilling fluids are used for drilling. However, the main disadvantage of traditional polymer-based and hydrocarbon-based drilling fluids is their low thermal stability due to degradation of the polymers and emulsifiers used in their formulations. In practice, this means that after the operation of such drilling fluids in the well for several hours at high BHT (above 90 °C), they completely or partially lose their initial functional characteristics. To overcome this problem, high-temperature polymer modifications, based on polyacrylamides, sulfonic acid copolymers, amphoteric polymers (PEX), etc., are being developed [

7,

8].

Another direction in the field of temperature stabilization of drilling fluids is the use of nanoparticles (NPs) [

9]. Obviously, NPs are not susceptible to thermal degradation, and are stable in environmental conditions. A large number of studies have been carried out recently in this area. These studies are mainly focused on the stabilization of water-based drilling fluids by NPs. Thus, Al-Malkli et al. [

10] studied the effect of sepiolite NP additives on the functional characteristics of water-based bentonite drilling fluid at high temperatures, ranging from 50 to 180 °C, and elevated pressures. The drilling fluid with sepiolite additive showed a generally higher stability of rheological properties over a wide range of temperatures and pressures. However, at temperatures above 120 °C, the rheological parameters, such as plastic viscosity and yield stress, decreased sharply. This indicates irreversible destruction of the drilling fluid due to thermal degradation. Moreover, according to the authors, the considered nano-additives turned out to be ineffective at low pressure and low temperature. The effect of temperature on the rheological properties of water-based bentonite drilling fluid, modified by Fe

2O

3 NPs with an average size of about 30 nm, was investigated in [

11]. The temperature ranged from 25 to 85 °C. The concentration of NPs was about 1%. It was shown that the addition of NPs increased the yield stress and plastic viscosity by 45–200% and 20–105%, respectively. The plastic viscosity and yield stress of all the solutions decreased with the increase in temperature. However, for the solutions containing Fe

2O

3 NPs, this decrease was much less. The authors [

12] investigated the effect of adding 40 nm silicon and graphite NPs to a water-based complex clay–polymer drilling fluid with bentonite, barite, and starch additives. The temperature varied within the range of 25 to 85 °C. It was shown that the drilling fluid, modified by the NPs, better retained its rheological properties at high temperatures.

A systematic experimental study of the temperature dependence of the viscosity of drilling fluids, modified by NPs of different size and composition, was performed in our recent work [

13]. It was shown that the addition of NPs significantly influences the temperature dependence of the viscosity of clay and clay–polymer dispersions. It was found that the effect of NPs on the viscosity of drilling fluids decreased with increasing temperature. Thus, while at room temperature, the addition of 3 wt.% of NPs increased the viscosity of clay slurry by about eight times, and at a temperature of 80 °C, this increase was about three times. Moreover, it was found that the addition of NPs makes the viscosity of the drilling fluid less sensitive to temperature changes. For example, for a drilling fluid with 3 wt% of 10 nm silicon oxide NPs, increasing the temperature from 25 to 80 °C caused an increase in the effective viscosity by about 2.5 times, whereas, for the base drilling fluid, the increase in viscosity, caused by a similar increase in temperature, was about ten times. In addition, it has been shown that the size of NPs also affects the temperature dependence of the viscosity of drilling fluids. In general, a decrease in NP size leads to an increase in the temperature dependence of drilling fluid viscosity. Therefore, when increasing temperature from 25 to 55 °C, the viscosity of mortar slurry with 150 nm aluminum oxide NPs increased by 1.4 times, and, with 50 nm particles, it increased by 1.7 times. Moreover, it was shown that NPs of different composition at close average sizes and the same concentration have a different effect on the temperature dependence of the viscosity of clay and clay–polymer suspensions. In this respect, solutions with aluminum oxide particles are the most sensitive to temperature.

Recently, to modify the thermal properties of drilling fluids, carbon nanotube additives have also been investigated. For this purpose, mainly multi-walled carbon nanotubes (MWCNTs) are used. Thus, Ahmad et al. [

14] attempted to improve the properties of a water-based bentonite drilling fluid using carbon nanotubes of different modifications. In this study, the temperature varied from 25 to 85 °C. It was demonstrated that the addition of 0.25 wt.% of polymer and the same amount of nanotubes improved the rheological properties of the drilling fluid. With increasing temperature, plastic viscosity decreased and yield stress increased, indicating the thermal degradation of the drilling fluid. The authors of the study [

15] investigated the effect of MWCNT concentration on a drilling fluid also based on water. In this study, the temperature varied from 25 to 180 °C. It was shown that the fluids were viscoplastic non-Newtonian at all pressures and temperatures. The addition of MWCNTs led to an increase in drilling fluid viscosity with increasing concentration. A non-monotonic dependence of the effective viscosity of the fluid on temperature was established for the basic and modified drilling fluids. At temperatures above 120 °C, the effective viscosity of the drilling fluid decreased sharply. This may indicate fluid thinning down due to thermal degradation. Increasing the concentration of nanotubes made the dependence of viscosity on temperature more monotonic. The research goal of work [

16] was to improve the properties of water-based drilling fluids using a novel nanocomposite based on MWCNTs and polyethylene glycol. In this study, a relatively small temperature variation range (from 30 to 40 °C) was considered. It was shown that the addition of a relatively small amount of nanocomposite (1 wt.%) to the drilling fluid led to a significant improvement in the rheological performance. However, while analyzing the temperature dependence of the rheological characteristics, it was found that even this very insignificant change in temperature has led to a significant change in the rheological characteristics. While increasing the temperature from 30 to 40 °C, the plastic viscosity of the drilling fluid has decreased almost twofold, and the yield stress increased almost six times. This indicates a very strong loss of colloidal stability of the fluid. Ahmad et al. [

17] evaluated the effect of CNT additives on the thermal stability of polymer solutions. They showed that, at a nanotube concentration of 2 vol.%, the rheological characteristics of the solution remained stable up to 150 °C. It was also found that the introduction of CNTs reduced filtration loss and fostered a reduction in the hydration of clayey rocks.

Nanocellulose is also widely used to stabilize the rheological properties of drilling fluids. A comprehensive study of using nanocellulose in various forms for these purposes was carried out in [

18], where it was used to modify water-based bentonite drilling fluid. As a result, the advantage of nano-structured cellulose was demonstrated, specifically in the form of NPs. In this study, the temperature varied from 25 to 80 °C. It was shown that the nanocellulose-modified solutions had better rheological characteristics and higher thermal stability.

There have also been recent studies using boron nitride-based nanomaterials as additives to improve the performance of oil-based drilling fluids (OBDF). For example, in [

19], the authors developed a hybrid invert-emulsion drilling fluid based on graphene nanoplates and boron nitride nanoparticles. An extensive and comprehensive experimental investigation was conducted to study and quantify the effect of these nanomaterials on all functional properties of oil-based drilling fluid at different temperatures (25–125 °C). The developed hybrid nanodrilling fluid demonstrated improved rheological properties (it increased the plastic viscosity and yield stress by 17% and 36%, respectively, with the introduction of 0.2 ppb nanomaterials) and filtration characteristics (the maximum reduction in filtrate losses was 60% at a concentration of 0.6 ppb). It was also shown that the high thermal stability, uniform dispersion, and large surface area of nanomaterials significantly improved the performance of OBDF at all temperatures considered.

The authors of [

20] studied the thermal and rheological behavior of two-dimensional nanostructures of oxidized hexagonal boron nitride dispersed directly in xanthan gum and obtained similar results on the influence of these nanoparticles on the properties of the drilling fluid. The results of thermal conductivity measurements showed that the drilling fluid prepared with 6 wt % nano-additives had a thermal conductivity value 7% higher than the sample without nanoparticles. A rheological study of the nanofluids showed that the viscosity values of all samples increased with increasing concentration of boron nitride nanoparticles, and suspensions with higher concentrations exhibited yield stress, whereas suspensions with lower concentrations were shear thinning fluids. Thus, the work showed that these systems may have advantages for use in deeper fields due to their increased thermal conductivity and viscosity.

Thermal degradation of drilling fluids refers to changes in their properties caused by exposure to high temperatures. When drilling fluids are exposed to heat, they can undergo various processes of degradation and compositional changes, which can negatively affect their efficiency and productivity. High temperatures can lead to changes in the physicochemical properties of fluids, such as viscosity, rheological characteristics, and electrostatic and emulsion stability, as well as to changes in the chemical composition of the drilling fluid. This may require adjustment of the solution composition or the use of stabilizing additives. That is why it is necessary to select drilling fluid formulations that will be stable over a wide temperature range and, at the same time, maintain all other functional characteristics for the quality of the drilling process. For this purpose, this work proposes modification of drilling fluids with nanomaterials, which, as shown, meet these requirements.

The literature review has shown that most of the studies on the modification of the high-temperature properties of drilling fluids using various nanomaterials were performed for water-based drilling fluids, whereas, from the practical standpoint, the most promising fluids for drilling in difficult conditions are hydrocarbon-based drilling fluids, which are invert emulsions. There is very little data on the effect of NP and, especially, carbon nanotube additives on the thermal stability of hydrocarbon-based drilling emulsions, and there are no works at all on thermal stabilization of drilling fluids by means of single-walled carbon nanotubes (SWCNTs). At the same time, SWCNTs, as additives for the modification of various properties of drilling fluids, are much more effective compared to other nanomaterials. Thus, this research area looks very promising.

The aim of the present work was to carry out a comparative experimental analysis of the effectiveness of additives of silicon oxide NPs, SWCNTs, and MWCNTs on colloidal stability during the thermal degradation of hydrocarbon-based drilling fluids. Such a comprehensive and systematic study of high-temperature stability for hydrocarbon-based drilling fluids has been performed for the first time.

2. Drilling Fluid Preparation Technique and Experimental Facility for Studying Their Thermal Degradation

Emulsions are unstable thermodynamic dispersed systems consisting of two or more mutually insoluble liquids stabilized by chemical reagents. Proper selection of reagents influences the stability, as well as the rheological, filtration, and antifriction parameters of emulsion drilling fluids.

Hydrocarbon-based drilling fluid is a water-in-oil invert emulsion, i.e., an emulsion in which water (W) is dispersed into tiny droplets, while the HC liquid is a dispersion medium. In this work, we investigated emulsions whose HC/W ratio was 65/35. This ratio was chosen based on the fact that the emulsion loses stability with the increase in the water concentration. In addition, the increase in oil content leads to an increase in the cost of the drilling fluid. Therefore, the chosen ratio is optimal.

The composition of the reagents that were used when preparing the drilling emulsion is described below.

REBASE PC-230 low-viscosity base oils (produced by OOO NPO REASIB, Tomsk, Russia) were used as the base hydrocarbon fluid (64.9 vol.%). REBASE PC-230 base oil with viscosity of 3.9 cP and density of 850 kg/m3 (hereinafter referred to as Oil-1) was used as a base HC fluid in solutions modified by spherical NPs. REBASE low-viscosity oil with viscosity of 3.3 cP and density of 815 kg/m3 (Oil-2) was used as a base HC fluid when preparing drilling fluids with carbon nanotubes (CNTs). This oil is a mixture of synthetic hydrocarbons of narrow fractional composition characterized by low kinematic viscosity, low content of aromatic substances, high flash-point, and low congelation temperature. This oil is used as an HC base in the preparation technology of heat-resistant invert emulsion drilling fluids. Due to highly-stable viscous properties, RS-230 allows preparing invert drilling fluids with a so-called flat rheological flow profile; flat rheology invert drilling fluids provide high technical and technological drilling performance in difficult geological conditions, especially in the case of a narrow regulation range of equivalent circulation density (ECD). They also prevent the loss of stability when drilling in shale rocks, as well as drilling fluid absorption due to hydraulic fractures of weakly cemented formations.

Calcium chloride (CaCl2) brine (30 vol.%) reduces interface surface tension. By increasing the concentration of electrolytes in the aqueous phase, the rate of positive adsorption at the interface increases. Electrolyte ions cause dehydration of the hydrophilic groups of surfactants forming the adsorption layer, which promotes their convergence and more compact arrangement at the interface, reducing the size of molecule landing pad and increasing the condensation of the adsorption layer, which strengthens the protective film of globules. The charges of electrolyte ions attract opposite charges of ionic surfactants and contribute to the formation of a stronger and more condensed adsorption shell.

The non-ionogenic REBASE PC-510 emulsifier (2 vol.%) was used to stabilize the emulsion. The PS-510 emulsifier is a solution of compound ethers of higher unsaturated fatty acids based on mineral oils with the addition of high molecular weight organic compounds. PS-510 is designed as the main emulsifier when preparing heat-resistant invert emulsion drilling fluids.

The ABR hydrophobizer (0.4 vol.%) is used as a co-emulsifier of invert emulsion solutions and as a wetting agent for the solid phase of hydrocarbon-based drilling fluids. ABR is a surfactant that reduces surface tension at the oil/solid interface. It is used for hydrophobization of barite, marble, colmatant, drilled cuttings, and drilling tools. ABR stabilizes the solution in the case of stratum water inflow. In the case of solid phase development and emulsion weighting, the hydrophobizer envelops particles and prevents them from wetting with water and, as a consequence, from aggregating and settling. ABR also serves to reduce the filtration rate.

Organophilic clay (0.8 vol.%) is a structure-forming agent representing montmorillonite clay powder treated with amines with a certain length of HC radical, forming complex aggregates on the surface, which give the clay powder hydrophobic properties and the ability to swell in HC media. Organophilic clays are used as a structure-forming and wall-building component of oil-based solutions intended for use at high temperatures. They form structured solutions if their concentration in the solution exceeds 5 wt.%. Bitumen solutions, structured with organophilic clay, have a high retention capacity with respect to the weighting agent, and remain stable.

Oil-soluble polymer NRP-20M (0.5 vol.%) is a 20 wt.% solution of polyisobutylene in I-20A industrial oil. The introduction of NRP into the emulsion allows increasing the thermal stability of the solution due to the fact that polyisobutylene molecules, being in the interfacial layer, contribute to increasing the density of protective shells on water droplets and contribute to increasing the aggregative stability of the emulsion. Moreover, by thickening the dispersion medium of emulsion drilling fluid, polyisobutylene increases the structural and rheological properties of the solution, reduces its filtration, and increases the viscosity of the filtrate, which has a favorable effect on the preservation of porosity and permeability properties of the productive formation.

Micro calcite was used as LCM (lost circulation material) (4.4 vol.%). It is a fine-dispersed product of the carbonate group, which is produced by the mechanical grinding of marble. The following grades of calcium carbonate (CaCO3) having different average particle sizes were used: MK-100, with an average particle size of 32 μm, MK-60—23 μm, and MK-10—10 μm.

Hydrophobic nanosized silicon oxide (SiO

2) particles were used to modify the drilling emulsion; they are fumed silica, treated with polydimethylsiloxane and/or cetyltrimethylammonium chloride. Silicon dioxide powder has high chemical resistance to many reagents and is characterized by high adsorption properties. The mass fraction of the main substance (SiO

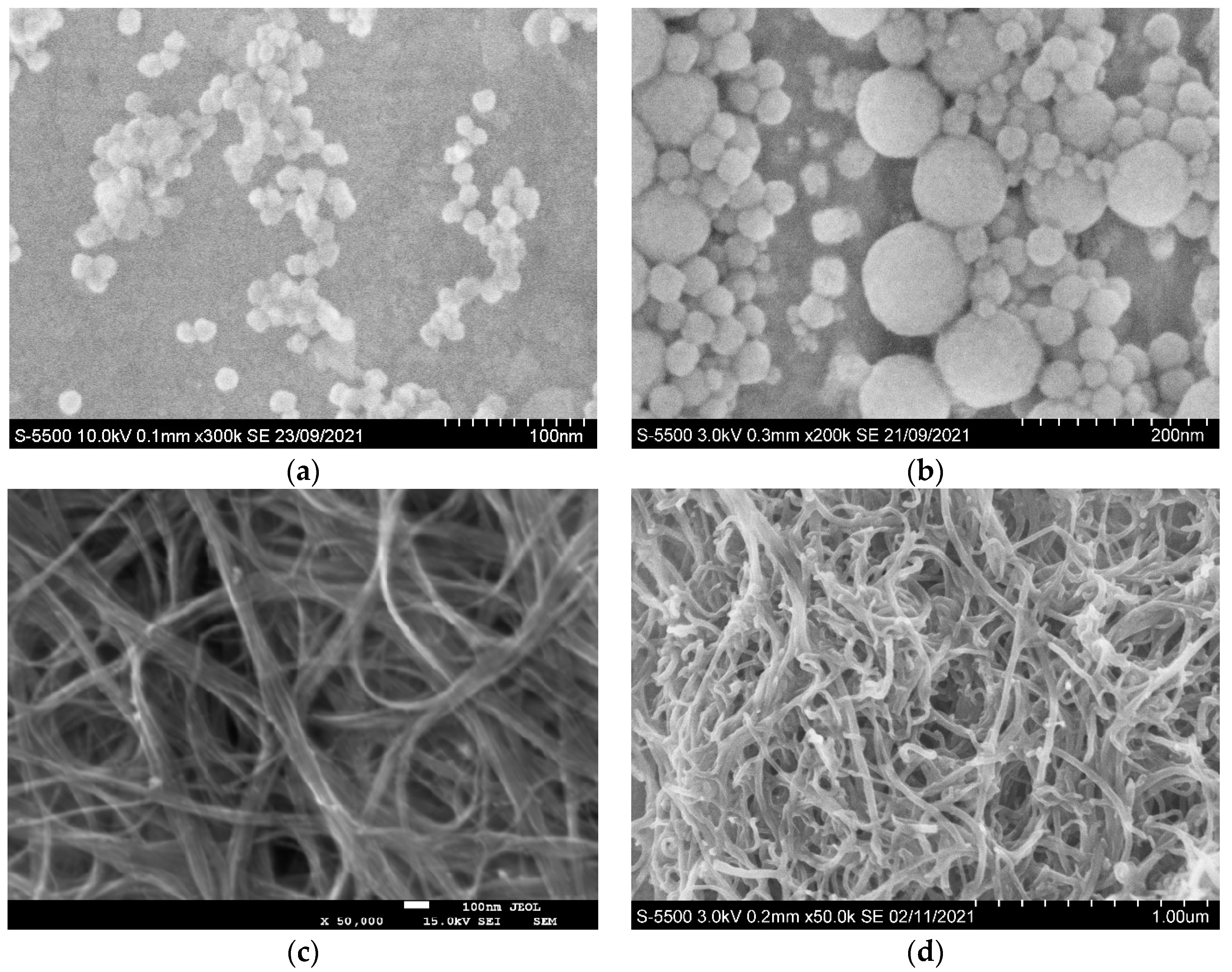

2), in terms of the calcined substance, is not less than 99.6%. The average size of the NPs ranged from 18 to 70 nm. The weight fraction of NPs was set to 0.25, 0.5, 1, and 2 wt.%. Electron photographs of SiO

2 NPs are shown in

Figure 1a. Electron microscopy was performed using a JSM-7001F scanning microscope (JEOL, Japan) and an S-5500 super-resolution scanning electron microscope (Hitachi, Japan). Electron microscopic examination was carried out using a base fluid pre-evaporation technique.

SWCNTs and MWCNTs were used to modify the drilling emulsions. TUBALL

tm; powder (OOO OCSiAl.ru, Novosibirsk, Russia) was used as SWCNTs [

21]. This material is a loose black powder. The average diameter of the SWCNTs was 1.6 ± 0.4 nm, and the specific surface area, according to the BET method, was 510 m

2/g. On the evidence from atomic force microscopy data, the length of the SWCNTs exceeded 4 µm, and their average and bulk densities were 1.8 and 0.1 g/cm

3. Moreover, to improve the thermal stability of the drilling fluid, the effect of MWCNT additives, namely, Taunit-MD, produced by Nanotech Center (Tambov, Russia), was investigated [

22]. The inner diameter of these MWCNTs was 5–15 nm, and the outer diameter was 8–30 nm. The specific surface area was higher than 270 m

2, and the length exceeded 5 μm. The number of carbon layers amounted to 30–40. The electron photographs of the MWCNTs are shown in

Figure 1b. The weight fraction of nanotubes in the solutions was set equal to 0.1, 0.25, and 0.5 wt.%. Methodological experiments have shown that using higher concentrations of MWCNTs for the modification of drilling fluids is impractical due to a very significant increase in viscosity.

The methodology for preparing drilling fluids with NPs and nanotubes was slightly different. NPs were introduced into the HC phase. This was performed to avoid the fragmentation of the dispersed phase into nanoglobules after addition of CaCl2 brine. To break the NP conglomerates, the solution was subjected to intensive ultrasonic treatment after their addition to the HC medium. Ultrasonic treatment was carried out by the Volna UZTA-0.4/22-OM ultrasonic device. The treatment was performed for 30 min at maximum performance.

When preparing nanotube-containing solutions, highly concentrated aqueous calcium chloride brine with a density of 1.1 g/cm3 was prepared first, and nanotubes were introduced into the aqueous phase and also treated by ultrasound. The ultrasonic treatment was carried out for 60 min at maximum performance, providing water cooling to prevent the dispersion from heating.

The dispersions, prepared according to the above technology, were used further for preparing emulsions. Emulsions were prepared using the coarse-droplet crushing technique, whose essence consists in drop-by-drop introduction of components in the course of simultaneous intensive mechanical dispergation by means of a high-speed stirrer. When preparing drilling fluid, HC base, emulsifier, hydrophobizer, oil-soluble polymer, microcolmatants, and calcium chloride brine were introduced sequentially. Intensive mixing was carried out using the Hamilton Beach triple-spindle mixer for 30 min at 20,000 rpm.

To evaluate the effect of nano-additives on the thermal stability of the drilling fluid, a comprehensive study of the hydrodynamic properties of the obtained emulsions was carried out. The colloidal stability of the drilling fluid was investigated in the course of thermal aging.

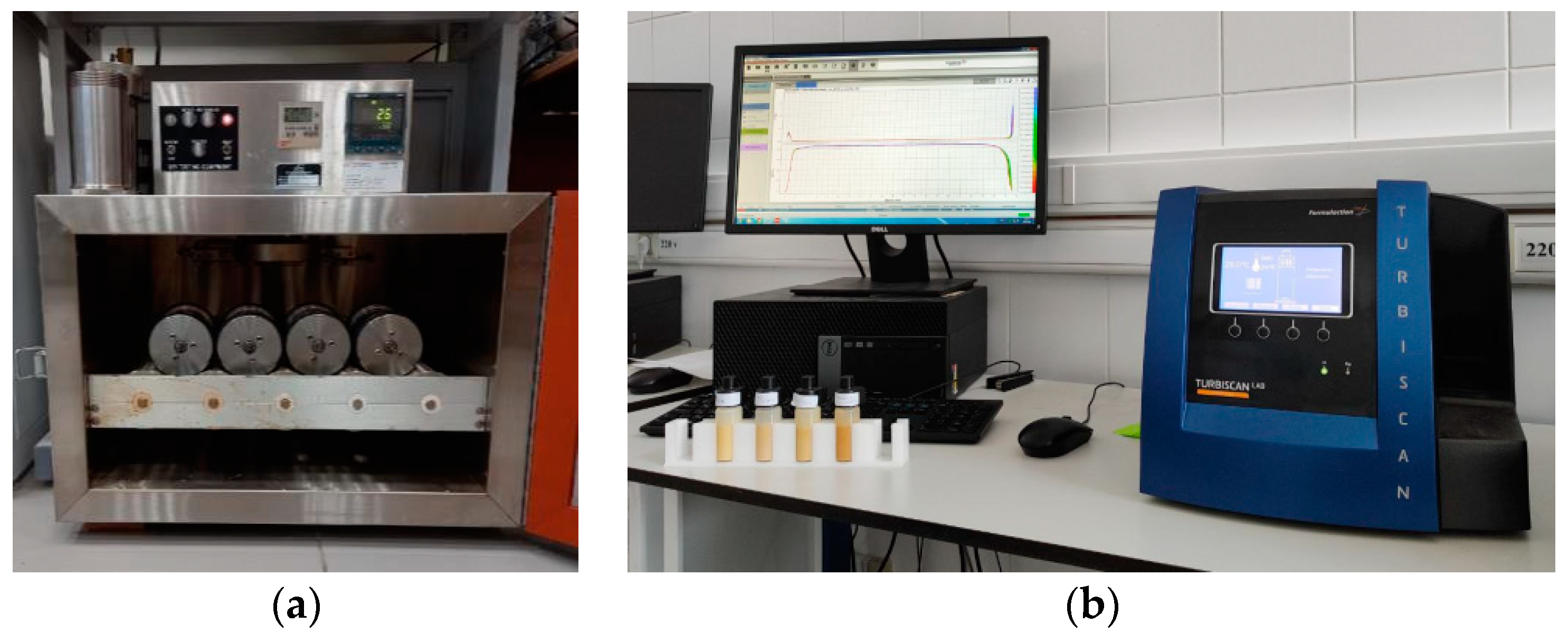

Thermal aging of drilling fluids was investigated using the OFITE roller oven (U.S. Patent No. 4,677,843), which allowed us to determine the temperature effect on drilling fluids circulating through the borehole (

Figure 2a). Pressurizing drilling fluid in containers clearly demonstrates the effect of heat on viscosity, as well as the behavior of various additives at elevated temperatures. The aging was performed in conditions ranging from static to dynamic, and from ambient to elevated temperatures. Thermal aging cells inside the oven were continuously rotated to simulate drilling fluid circulation. The operating temperatures ranged from 38 to 232 °C. The temperature was monitored by an electronic semiconductor thermostat. The temperature varied from 30 to 150 °C, and the thermal aging time varied from 2 to 16 h.

Colloidal stability of emulsions was monitored using the Turbiscan LAB colloidal stability analyzer (

Figure 2b), which allowed the analysis of the long-term stability of drilling fluid samples, as well as the calculation of the average particle/droplet size and volume fraction in the case of simple destabilization mechanisms. The measurement error did not exceed 0.1%.

3. Results of the Study of Thermal Stability of Drilling Fluids with Nano-Additives

One of the most important requirements for any emulsion is its tolerance to coalescence. For the drilling emulsion, this requirement is of fundamental importance. The rate of the destabilization processes increases when the drilling fluid is heated. When drilling wells, drilling fluid often has to operate at very high temperatures; therefore, the thermal stability problem is given great consideration. There are many different ways to stabilize the emulsion. The ability of fine particles to stabilize emulsions has been known for more than a hundred years. For example, the Pickering effect [

23] is well-known. However, disperse systems, stabilized by NPs, have been intensively studied only in the last ten years. Currently, stabilization technologies of direct (oil-in-water) emulsions are being actively investigated due to their promising application in the pharmaceutical, cosmetic, food, and oil and gas industries [

24,

25,

26]. Works are known in which the effect of MWCNTs on the stabilization of emulsions were studied [

27,

28]. It follows from these works that it is possible to reduce the droplet size in the emulsion several times by reducing the surface tension by adding MWCNTs. Drilling emulsions are much more complex colloidal systems; however, at present, no studies on the effect of CNTs on drilling fluids stability are available.

At the same time, there are practically no studies on the thermal stabilization of invert drilling emulsions by NPs, and there are even fewer studies on thermal stabilization through the use of carbon nanotubes. In this respect, the present work investigates the effect of nanosized silicon oxide and MWCNT additives on the stability of drilling fluids in the thermal stabilization process.

For this purpose, the measurement series of colloidal stability of drilling emulsions was carried out using Turbiscan LAB colloidal stability analyzer. The operation principle of Turbiscan LAB is based on the Multiple Light Scattering (MLS) method. The 20 mL sample to be analyzed was carefully placed in a cylindrical glass vial so that the meniscus was clearly visible. A near-infrared (880 nm) laser diode was used as the radiation source. Two synchronous optical sensors were used to measure the intensity of the radiation that passed through the sample (transmission detector, measuring 180° of the incident beam) and the radiation scattered by the sample in the opposite direction (backscatter detector, measuring 45° from the incident beam). The Turbiscan LAB scanned the sample along the vial height (up to 55 mm), recording transmission (T) and backscatter (BS) signals at every 40 µm. The transmission signal T was used when analyzing transparent or translucent samples, and the backscatter signal BS was used when analyzing translucent and opaque samples (concentrated dispersed systems). Measurements of repeated profiles at different time points t allows characterizing the changes occurring in the sample under study. The Turbiscan LAB uses a Turbiscan Stability Index (TSI) to quantitatively compare the stability of multiple samples. The TSI is calculated as the difference in the backscattering profiles of radiation at neighboring time points, averaged over the height of the vial. The lower this parameter, the more stable the emulsion is. In the beginning, the effect of the nano-additive concentration was investigated. To analyze the effect of nano-additives on the high-temperature stability of drilling emulsions, transmission and backscatter profiles were plotted for tested samples before and after 8 h thermal aging tests at 150 °C.

Figure 3 shows the test results for the solution with 18 nm silicon oxide NPs. The changes in the samples over time are clearly visible from the backscatter profile. The emulsion without the addition of NPs demonstrates the most striking example. It can be seen that, after thermal aging, the segregation of the emulsion occurs almost up to half of the vial height, whereas the addition of NPs causes the backscattering profile to become more homogeneous, and the addition of 2 wt.% makes the emulsion stable and unchanged over time for a much longer period, indicating an enhancement in the colloidal stability of the emulsion.

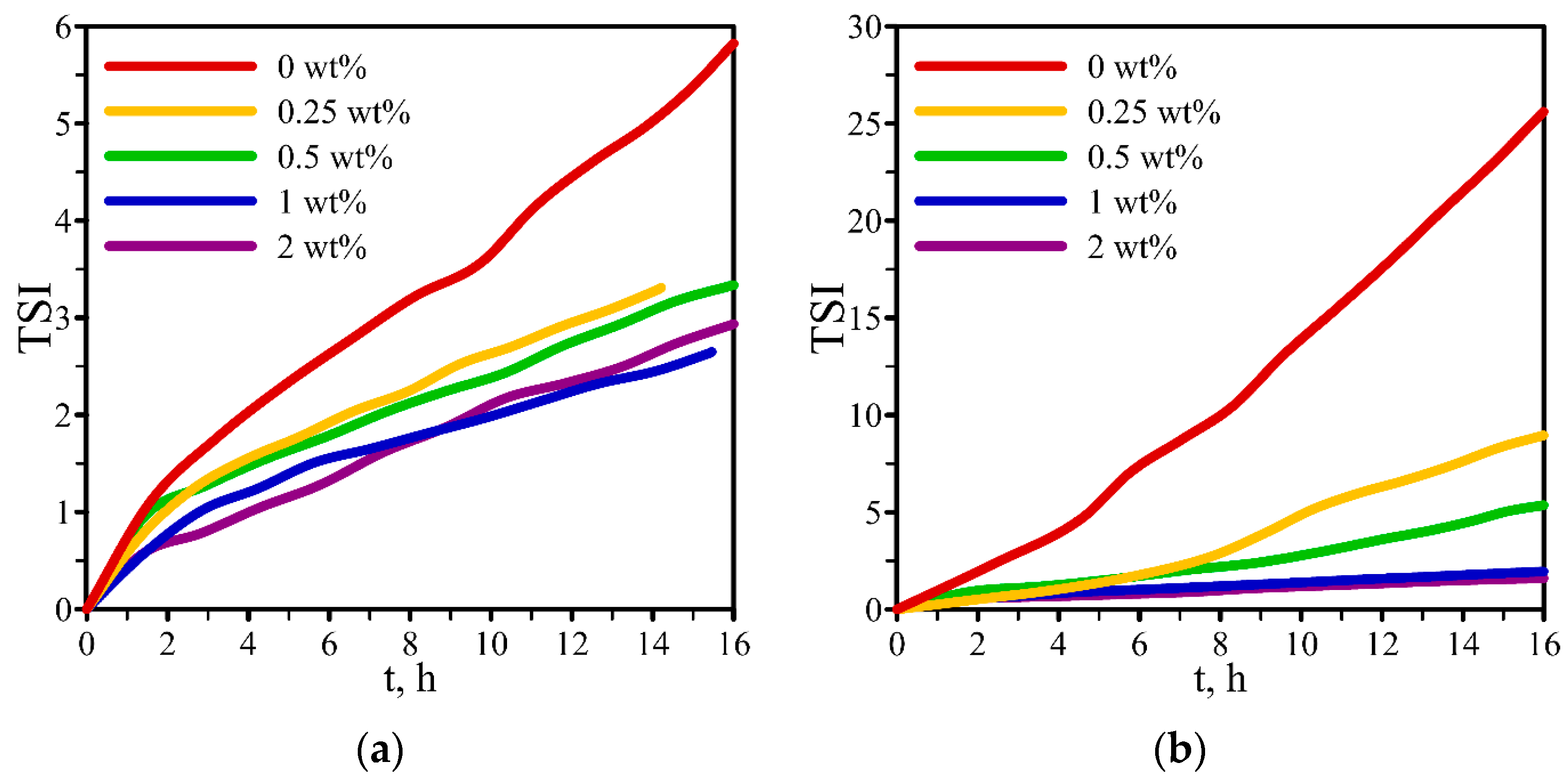

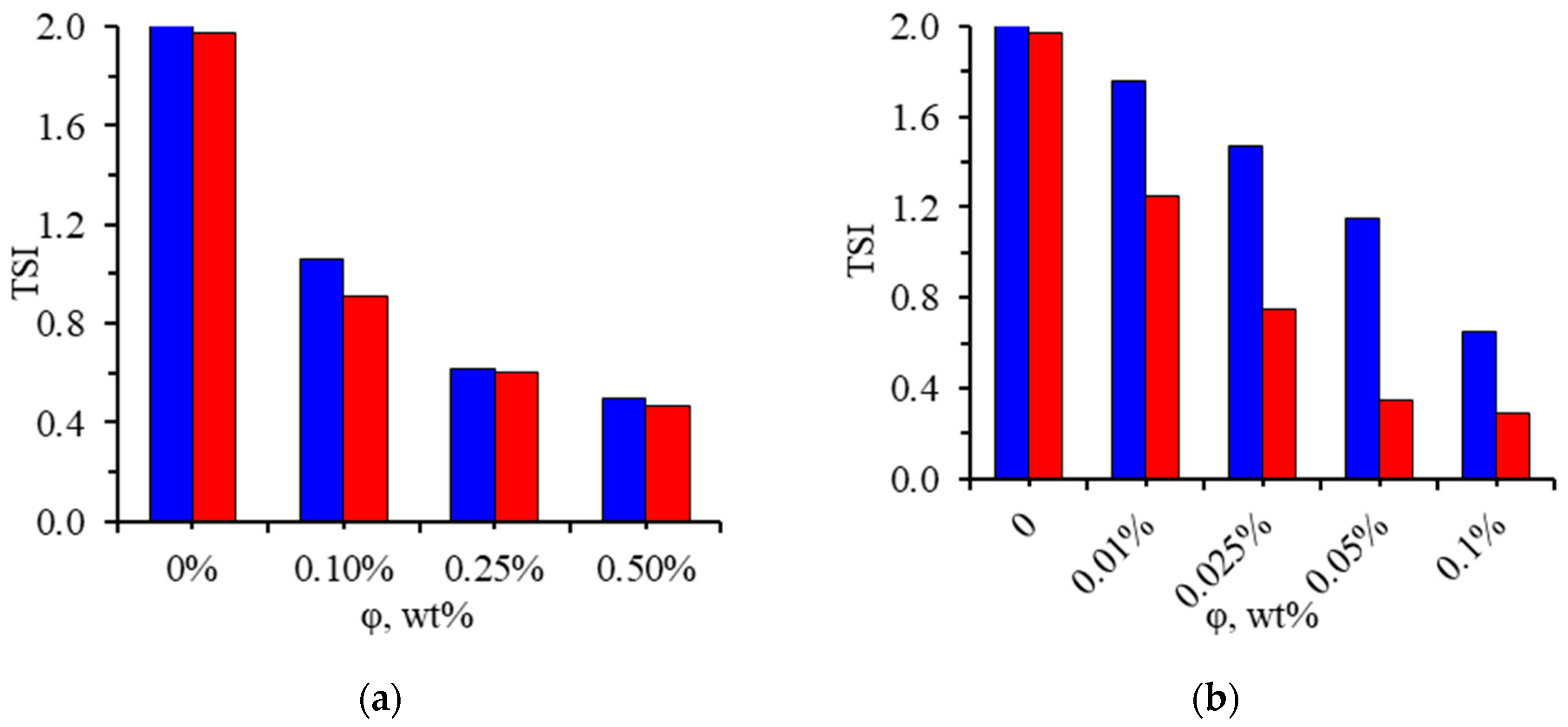

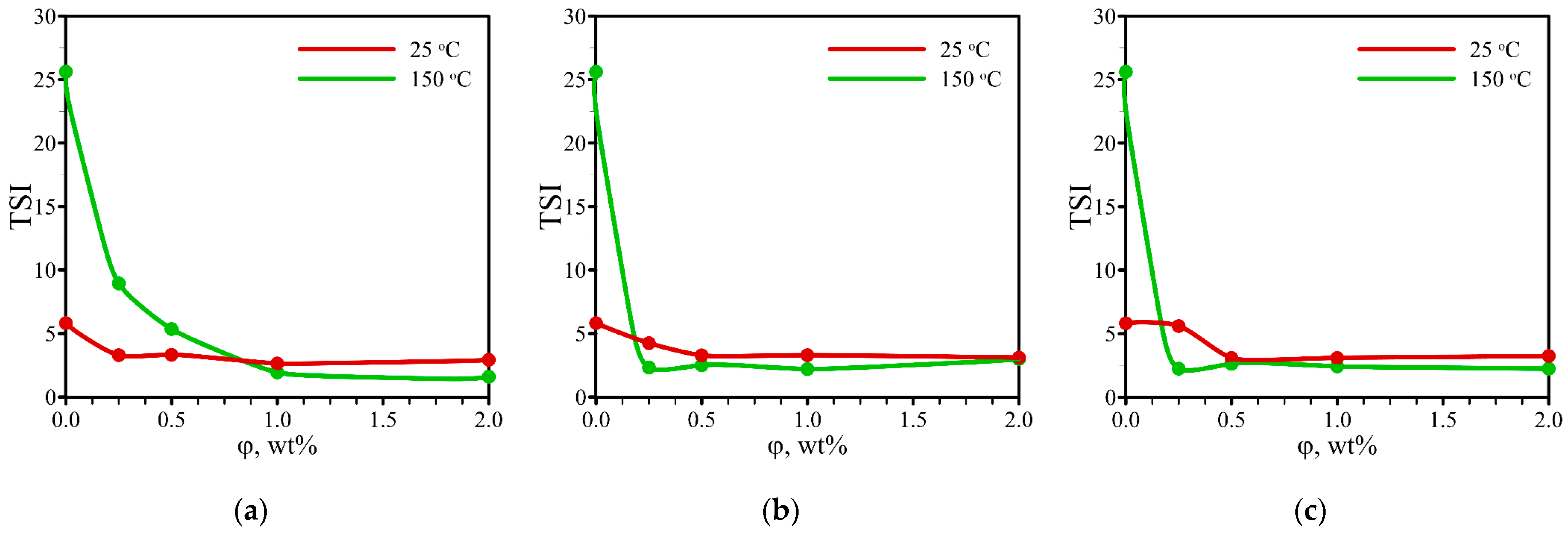

Quantitative comparison of the results on the effect of different NP concentrations on the thermal stability of drilling fluids is shown in

Figure 4. The study of the effect of NP concentration on the colloidal stability of drilling fluids has shown that the colloidal stability of the basic drilling fluid before the thermal aging test has improved significantly after adding NPs, even at a minimum concentration of 0.25 wt.% (see

Figure 4). Compared to the base fluid, the TSI has decreased 2.7 times. Solutions not subjected to thermal aging weakly depend on NP concentration. Further increase in the NP concentration has no significant effect on the stabilization of drilling emulsions at room temperature.

After being kept in the oven at high temperature during the thermal aging test, the base drilling fluid was significantly destabilized. This is clearly visible from both the backscattering and transmission profiles (

Figure 3 (left) and the TSI, measured 16 h after fluid preparation (see

Figure 4b). However, the addition of NPs significantly enhances the colloidal stability of the drilling emulsion after thermal aging. Therefore, after adding 0.25 wt.% of NPs, the TSI of the emulsion after thermal aging had decreased by 2.9 times. A further increase in the concentration of NPs enhanced the stability of the samples, and, at a NP concentration of 2 wt.%, achieved a 16-fold decrease in TSI compared to the basic solution. It has also been shown that, at higher concentrations of NPs (more than 0.5 wt.%), the samples were even more stable than before the thermal aging test. However, increasing the concentration over 1 wt.% is unreasonable, because, in this case, the effect of enhancement is insignificant, and there is no need to increase the optimal cost of drilling fluid.

Similar studies were carried out for drilling fluids modified by carbon nanotubes.

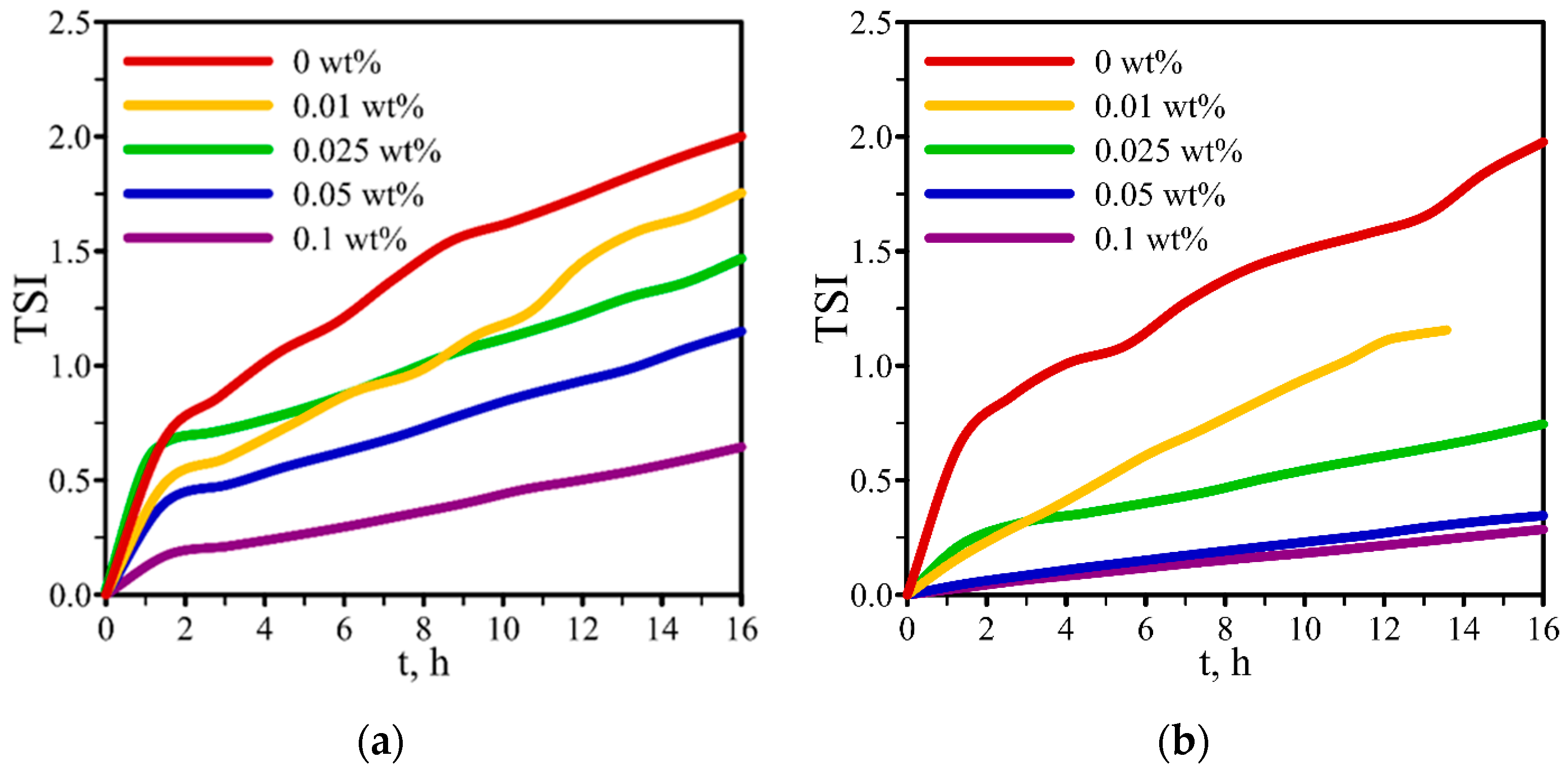

Figure 5 shows the time history of the TSI for drilling emulsion with MWCNT additives before and after thermal aging. In this case, the lower viscosity Oil-2 was used to prepare the CNT-containing drilling fluids, which are more stable in the initial state compared to the above-discussed solutions. After 16 h of observation, the TSI of the base fluid did not exceed 2, while, for the Oil-2-based drilling fluid, the TSI was about 5. Nevertheless, the addition of CNTs to this drilling fluid prior to thermal aging test further stabilizes it. Unlike in the previous case, the TSI decreased monotonically with increasing NT concentration (see

Figure 5a). At the concentration of MWCNTs of 0.5 wt.%, the rate of destabilization of the emulsion decreased about four times.

Figure 5b shows the destabilization rate of emulsions with CNTs for 16 h of observation, pre-aged at 150 °C for 8 h. In this case, the HC base for the drilling fluid was chosen to be optimal. As can be seen, in this case, thermal aging practically did not affect colloidal stability of the studied emulsion. Nevertheless, adding CNTs to a greater extent contributed to its stabilization. Therefore, it was demonstrated that the addition of MWCNTs significantly improves the stability of drilling fluid, both in the initial state and after being subjected to thermal aging.

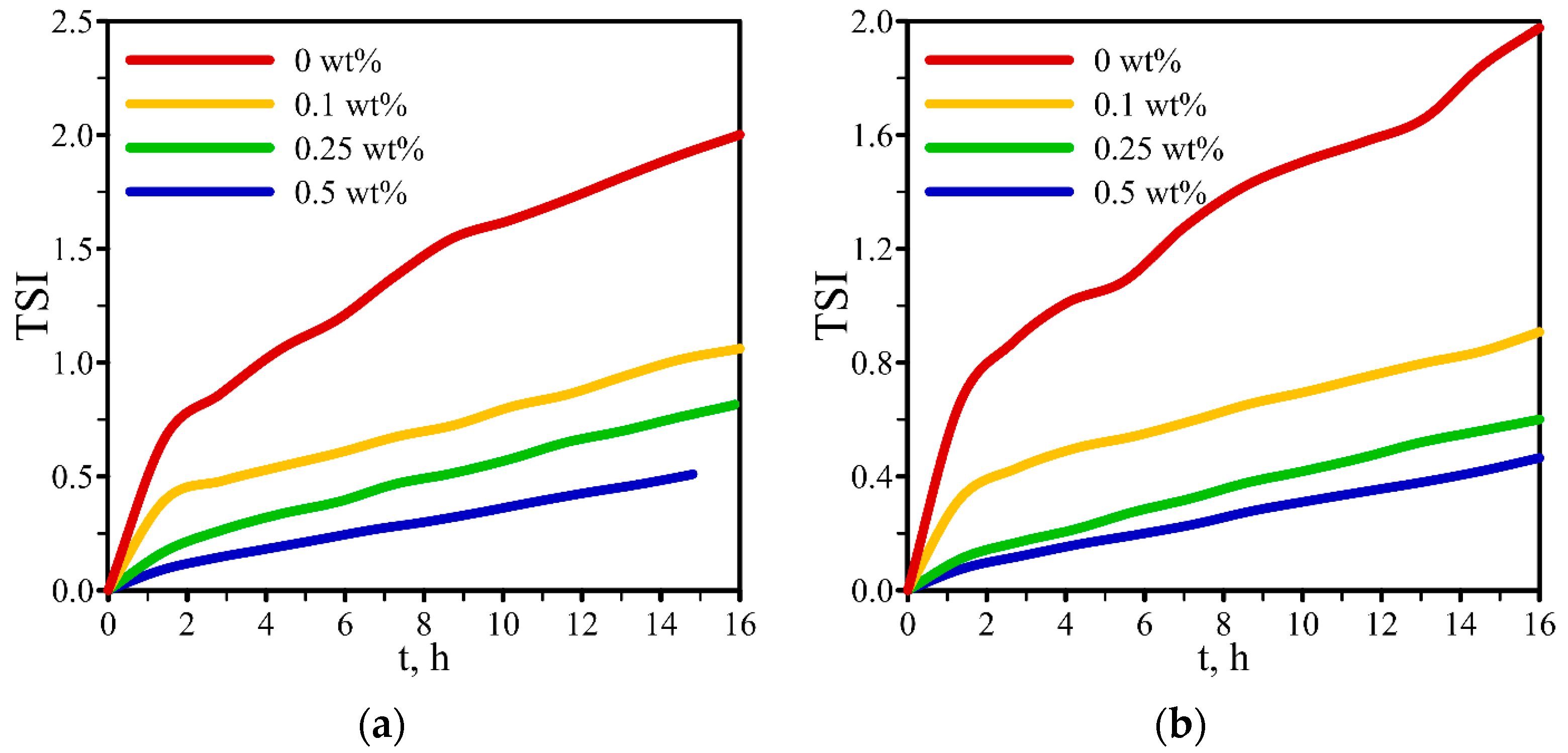

Generally, similar effects are manifested by SWCNT additives.

Figure 6 shows the destabilization kinetics of drilling fluids with SWCNTs before and after thermal aging depending on the concentration of SWCNTs. It was shown that the TSI decreases monotonically with increasing SWCNT concentration. SWCNTs enhance the stability of hydrocarbon-based drilling fluids more effectively. Therefore, the addition of 0.1 wt.% of SWCNTs reduces the TSI by 3.1 times. The analysis of the effect of the SWCNT on the destabilization kinetics of the solutions subjected to thermal aging (see

Figure 6b and

Figure 7b) has shown that their addition effectively enhances the colloidal stability of the emulsion. Thus, the addition of 0.1 wt.% of SWCNTs reduces the TSI by almost six times compared to that of the base solution. In our opinion, the main reason for this effect of CNTs on the stability of drilling emulsions is the formation of nanotube network, which, like polymer molecules, forms a developed structure inside the liquid that limits the mobility of water droplets and solid particles in the oil, thereby contributing to greater colloidal stability. Thus, it was found that the addition of CNTs significantly reduces the destabilization kinetics of hydrocarbon-based drilling fluids, both in the initial state and in the thermal degradation process.

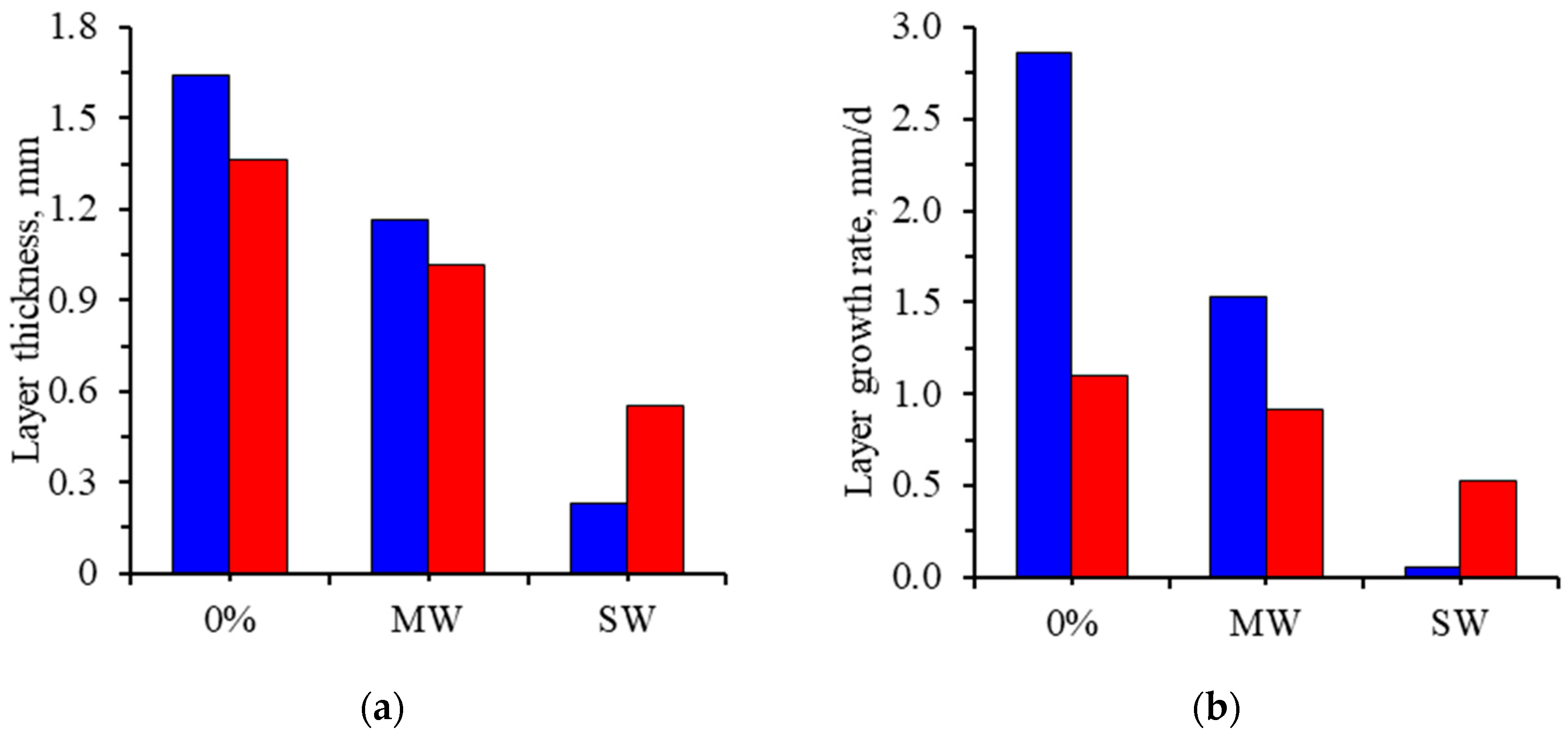

Due to coalescence processes, the droplets increase in size, and the emulsion begins to gradually segregate. As a result, after a while, a thin layer of lighter weight mineral oil is formed at the surface of the drilling fluid cell.

Figure 8 shows the thickness (a) and growth rate (b) of the segregated layer of drilling fluids with SWCNTs and MWCNTs (0.1 wt.%) before and after 8 h exposure at 150 °C. As is obvious, the addition of nanotubes, especially SWCNTs, significantly reduces the segregation rate compared to the base drilling fluid.

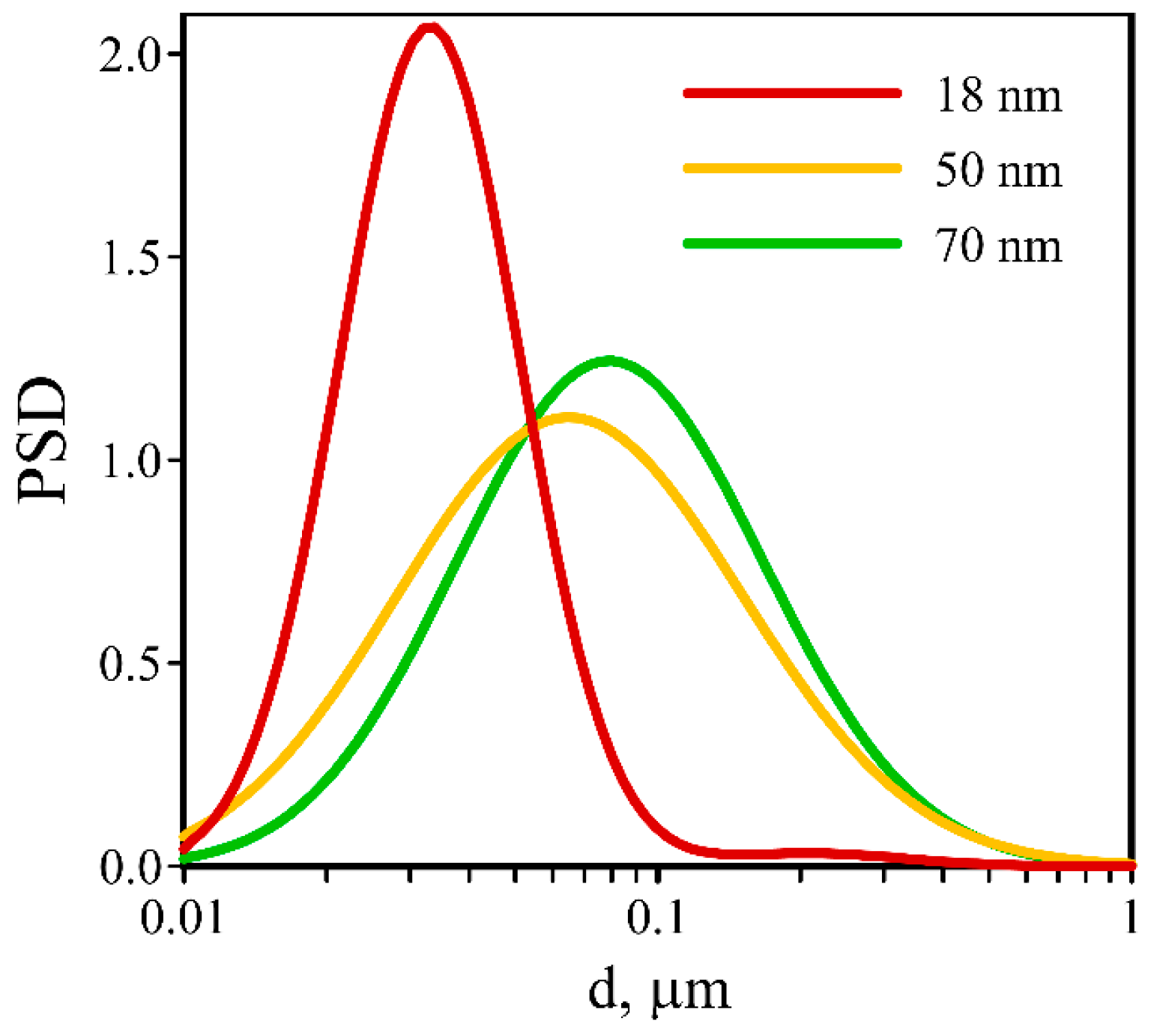

Next, the effect of the NP size on the colloidal stability of hydrocarbon-based drilling fluids containing SiO

2 additive was analyzed directly in the thermal aging process. For this purpose, NP additives of three different average particle sizes, namely 18, 50, and 70 nm, were considered. Such a study was performed for the first time. The NP size distributions are shown in

Figure 9. The particle size distributions directly in the liquid were measured using an acoustic and electroacoustic analyzer DT1202. The acoustic method is based on the measurement of the attenuation degree of the ultrasonic signal, and is used for determining particle size, including in opaque and concentrated media.

Determining the size of nanoparticles in a suspension is a very important task [

29,

30] since the properties of the suspension depend significantly on the size of the nanoparticles. In this work, the average size of the nanoparticles was determined directly in the liquid, which is fundamentally important. The DT-1200 series acoustic and electroacoustic analyzer for characterizing dispersions is designed for characterizing dispersions in a wide range of particle concentrations (0.1 ÷ 60 vol.%) and measuring average particle sizes, dynamic viscosity, and specific electrical conductivity of various dispersions. The acoustic sensor of the device measures the ultrasonic attenuation coefficient (0 ÷ 20 ± 0.01 dB cm

−1 MHz

−1) in a wide dynamic frequency range (from 1 to 100 MHz), as well as the speed of sound, the values of which are subsequently used to determine the average particle size, dynamic viscosity, and specific electrical conductivity of the dispersions under study.

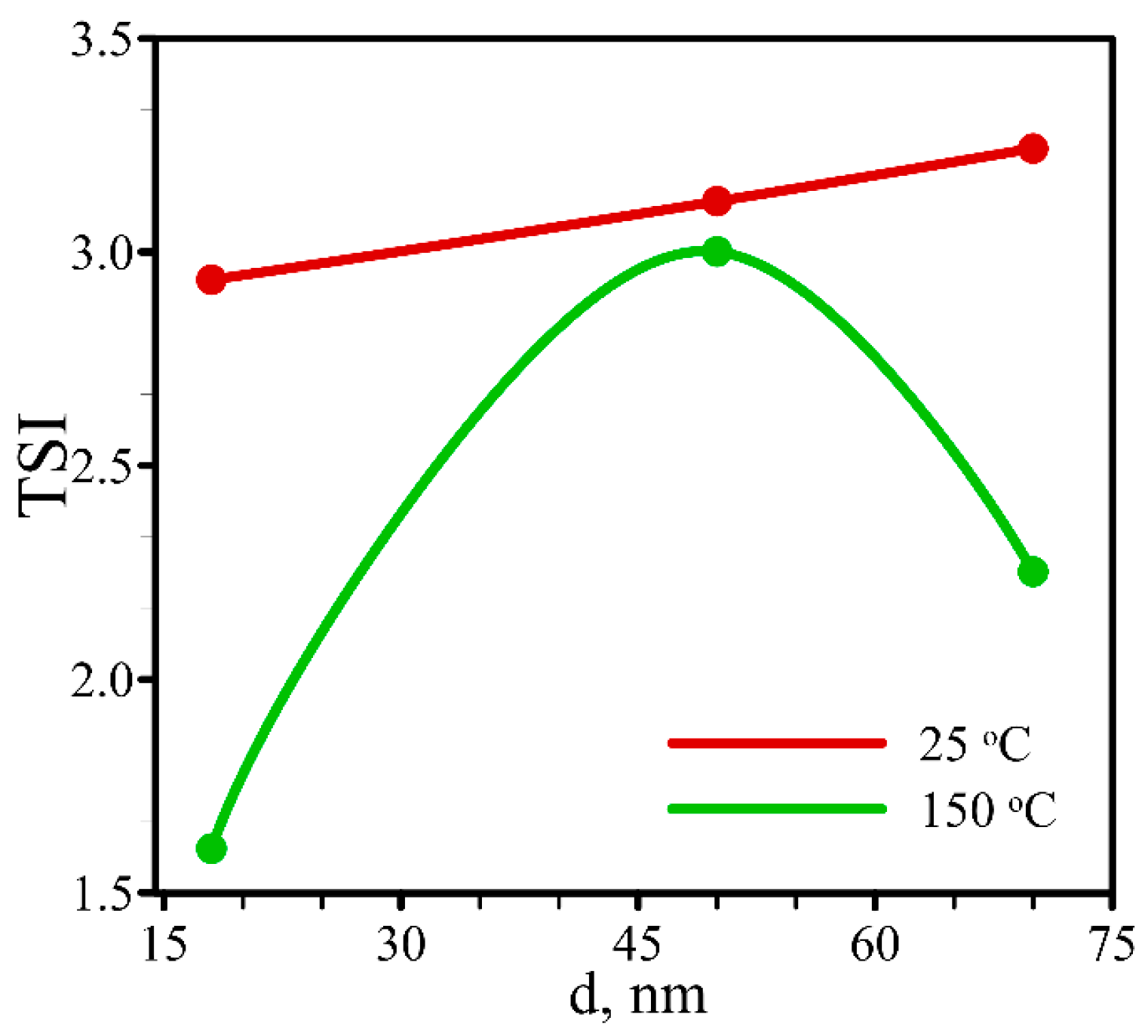

For drilling emulsions with 50 and 70 nm NPs, studies were performed similar to those described above for 18 nm NPs. For samples with larger NPs, a significant improvement in colloidal stability of drilling emulsions, not subjected to thermal aging, was observed already at minimal concentrations (0.25 wt.%). Dependences of the resulting TSI on the concentration of NPs of different sizes, obtained for 16 h of observation, are shown in

Figure 10. Data analysis shows that, for the solutions not subjected to thermal aging, the TSI monotonically decreases with the decreasing size of NPs (see

Figure 11). Reduction in NP size from 70 to 18 nm resulted in enhancement of the colloidal stability of the initial solution by about 12%.

Significantly, a greater influence of coarse-sized NPs was observed in the solutions after their thermal aging test. It was found that, for all NP concentrations, the TSI, measured after 16 h, was lower after the exposure of the solutions to high temperature, comparing to that at room temperature (see

Figure 10 and

Figure 11). This is very important for practical applications, since, usually, standard additives, used to maintain the thermal stability of drilling fluids, keep the drilling emulsions stable in the best case, while NPs improve it.

These results are clearly demonstrated in the graphs, showing the effect of NP size on the TSI (see

Figure 10). It can be seen that the most significant influence on the colloidal stability of drilling emulsions is exerted by 18 nm NPs, i.e., the smallest of all considered sizes. Moreover, this influence is the most significant both before and after thermal aging tests. It is seen that with the increase in the size of the particles, the stability of fluid samples, not subjected to thermal aging, varies within 12%. Therefore, although all the NPs reduce the TSI after 8 h thermal treatment of the solutions at 150 °C, it is most appropriate to use particles with the smallest size. Thus, it is shown that, as the NP size decreases, the stability of hydrocarbon-based drilling fluids to thermal degradation generally increases.

Next, the effect of temperature on the colloidal stability of drilling emulsions with NPs and nanotubes was analyzed for the first time. The main difference from the thermal aging tests of drilling fluids was that, in this case, the change in stability of the fluid samples was studied in static conditions, i.e., without fluid circulation (as was the case of in the thermal aging cells, which were continuously rotating throughout the measurement). The colloidal stability of the drilling fluid in a static state, depending on temperature change, is a very important indicator in the case of forced cessation of drilling, which may occur in case of an emergency or the need to seal the well. In this context, to avoid complications when resuming circulation, the drilling fluid should be maximally stable for a long period at different temperatures (the average temperature gradient is 3 °C per every 100 m). This is important, because if the so-called segregation behavior of the drilling fluid occurs, the hydrostatic pressure will change abruptly over the well depth, which may lead to spontaneous uncontrolled flow of reservoir fluid into the well, creating a risk of drilling fluid release, and, consequently, its loss, as well reservoir fracturing, etc., which is a serious violation of drilling technology.

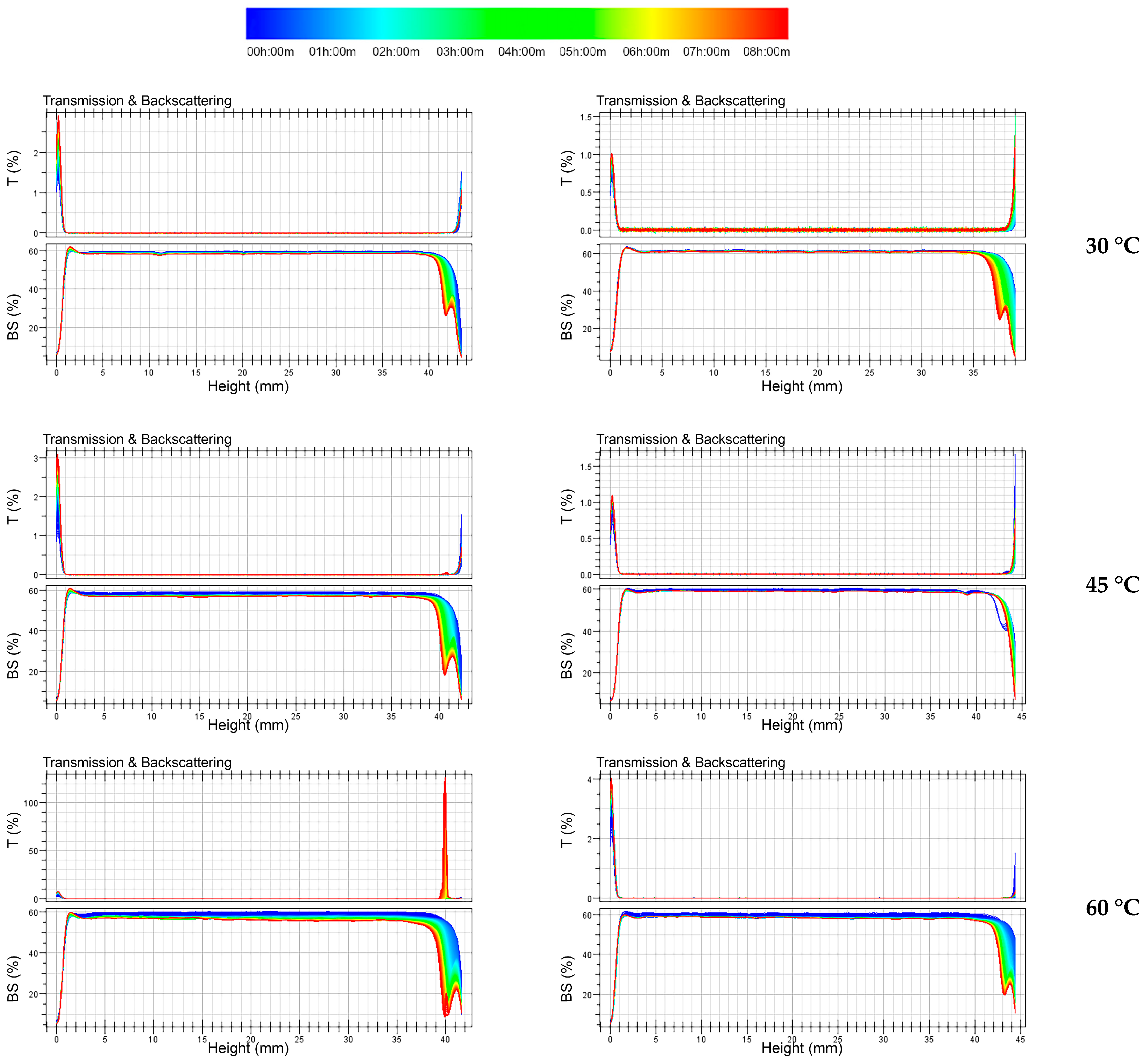

For this test, a drilling fluid sample containing 50 nm NPs at concentration of 2 wt.% was compared with the base fluid without NP additive. The temperature varied from 30 to 60 °C. The destabilization evolution of the samples was investigated for 8 h.

The transmission and backscattering profiles clearly show the positive effect of NPs on the stability of uncirculated drilling fluids with increasing temperature (see

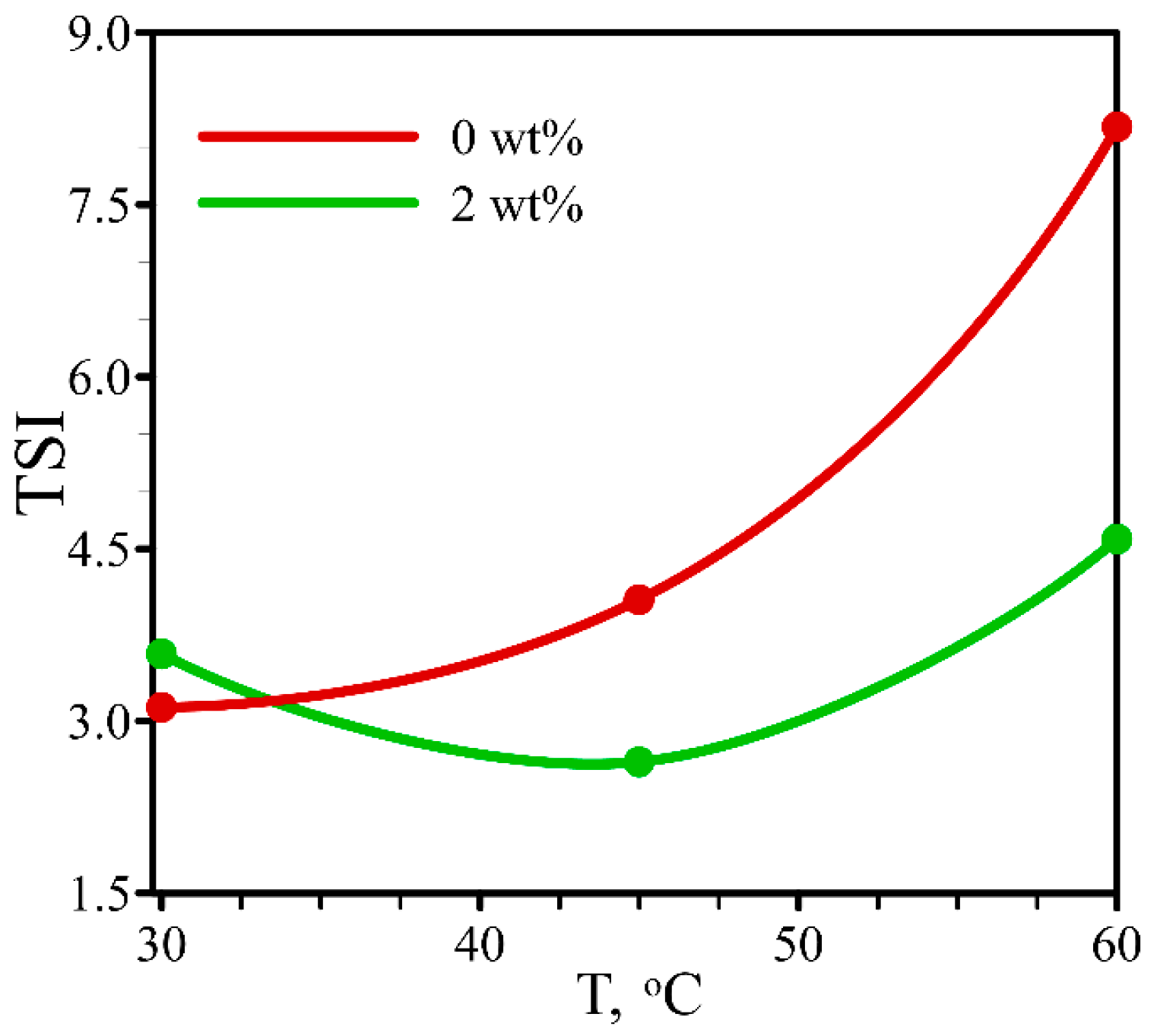

Figure 12). At all temperatures considered, with the addition of NPs into the emulsions, the profiles became more homogeneous, indicating an enhancement of colloidal stability.

Figure 13 demonstrates that the colloidal stability decreases with increasing temperature for all the samples considered. With an increase in temperature by 30 °C, the TSI for the basic solution increased almost three times. However, the addition of NPs stabilizes the solutions. Moreover, the higher the temperature, the stronger the effect of NPs on the TSI. This is clearly seen in

Figure 13. Thus, for a solution at 45 °C, the NPs reduce the TSI by a factor of 1.5, and, for a solution at 60 °C, by a factor of 1.8.

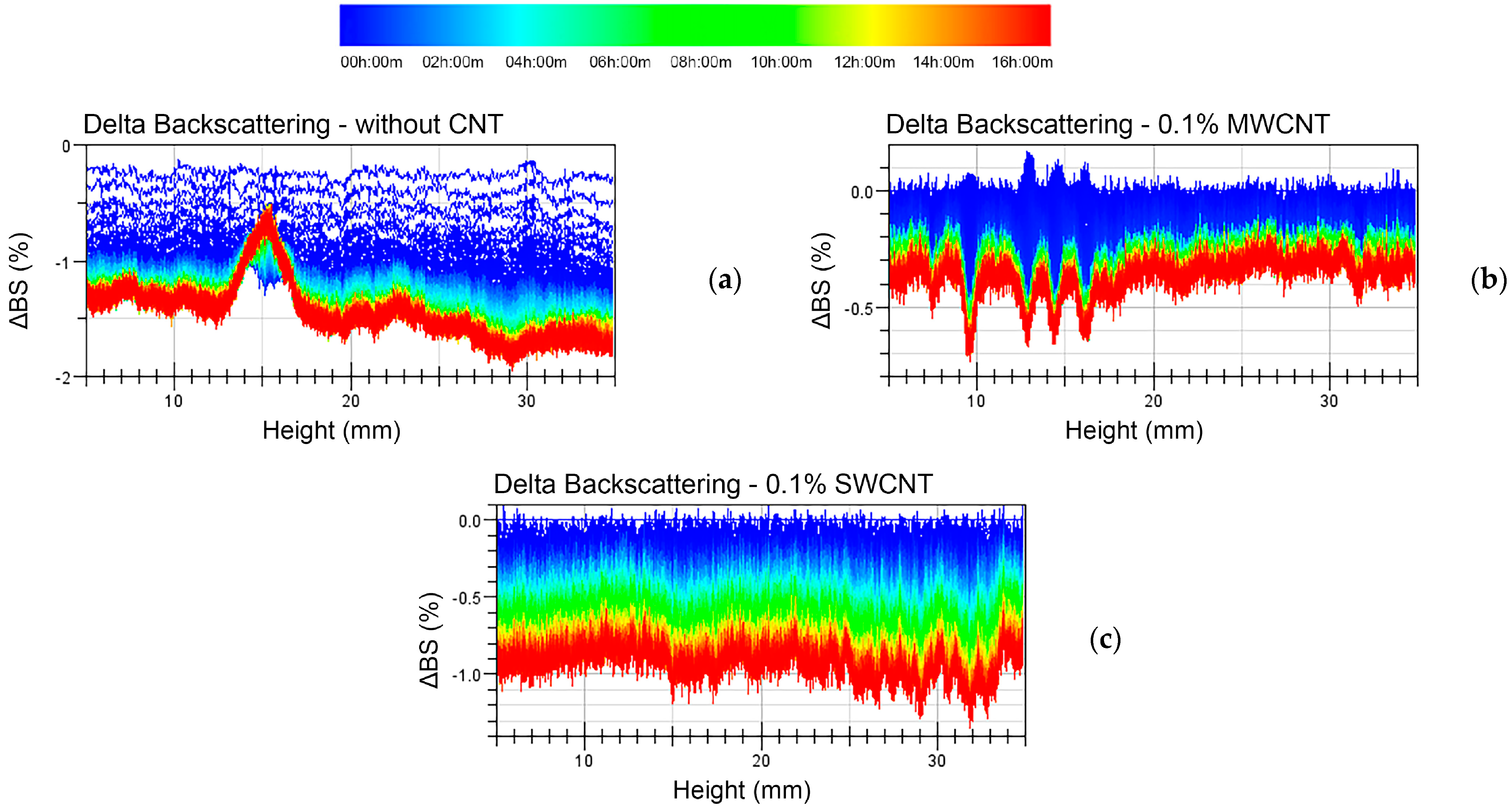

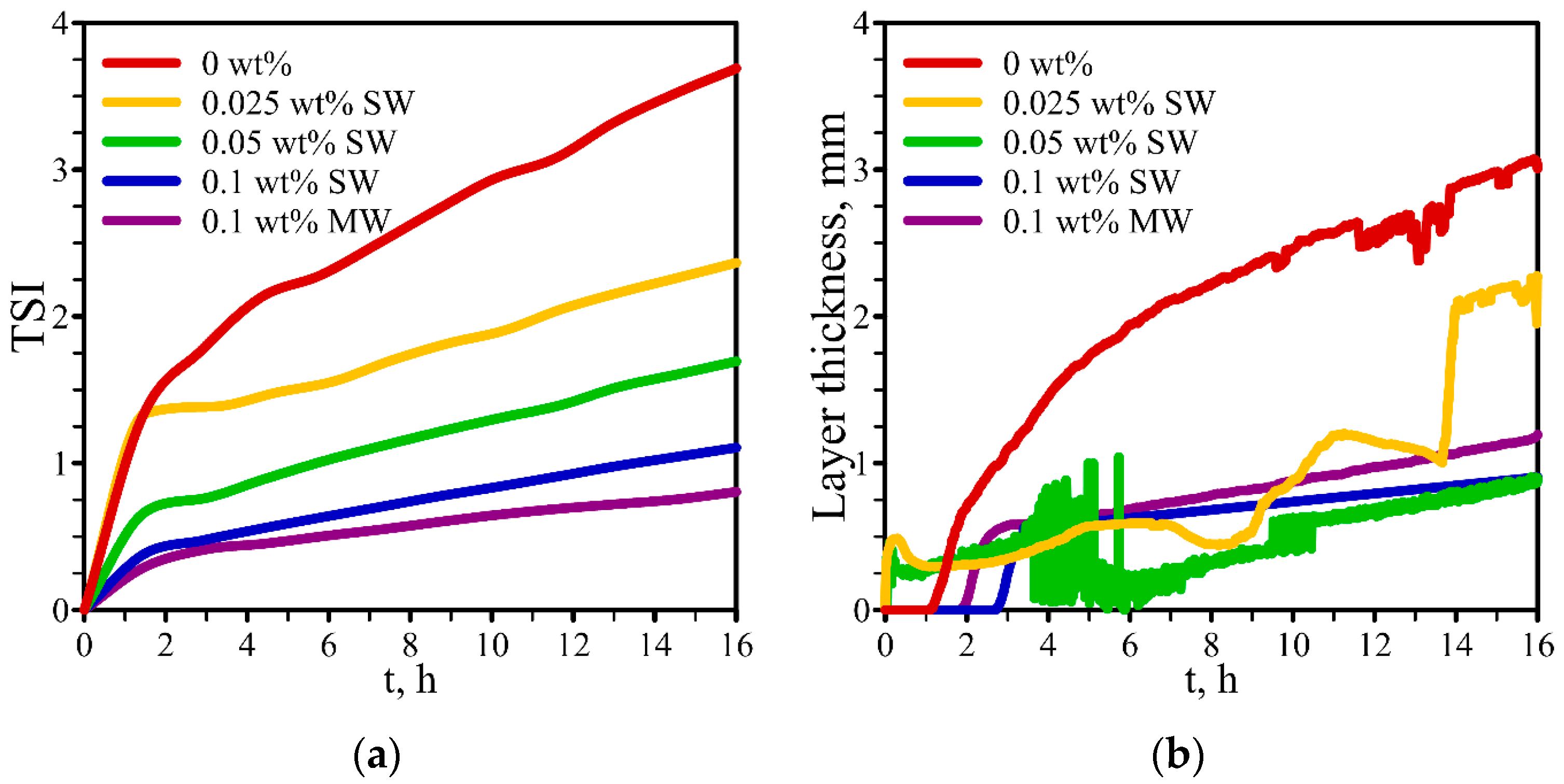

A similar study on the effect of temperature on destabilization kinetics was carried out for drilling fluids with additives of SWCNTs and MWCNTs. The main results of this study are presented in

Figure 14 and

Figure 15. The evolution of the increment of the relative radiation backscattering for drilling fluid samples, held at 60 °C for 16 h, is shown in

Figure 14. Such a change in backscattering indicates the droplet coalescence processes occurring in the fluid volumes. At the same time, the intensity of this destabilization process in solutions with nanotubes is several times lower.

This statement is proved by the destabilization kinetics of drilling fluids with CNTs directly in the process of their exposure at high temperature, shown in

Figure 15a. Increasing temperature significantly destabilizes drilling emulsions. While comparing similar results obtained at room temperature, shown in

Figure 5 and

Figure 6, it can be noted that the destabilization rate of the drilling fluids at 60 °C increases by a factor of about 1.8 for all samples. The addition of nanotubes decreases the destabilization rate both at room and high temperatures. With increasing temperature, the effect of CNT addition increases slightly. Therefore, at 30 °C, the addition of 0.1 wt.% of SWCNTs reduces the TSI by 3.1 times, while, at 60 °C, it reduces by 3.4 times. The addition of MWCNTs gives quite similar results.

Figure 15b shows the thickness of this segregation layer at the surface of the drilling fluid over time when aging the fluid at 60 °C. For the base drilling fluid without additives, this layer starts growing after about one and a half hours of exposure to the set temperature, and it reaches about 3 mm after 16 h of observation. For drilling fluids, modified by 0.1 wt.% of MWCNTs, this layer appears after about two hours, and, for the drilling fluid with SWCNTs at the same concentration, the effect is achieved after three hours, while the layer thickness reaches 1 mm. At the same time, the growth rate of the segregation layer for drilling fluids, modified by nanotubes, is also significantly lower than that for the basic solution. This all indicates a significant stabilization of the drilling fluid samples when adding nanotubes. With increasing nanotube concentration, the stabilizing effect enhances.

In the end, it is necessary to discuss the possible mechanisms of the influence of nanotubes on the processes of colloidal stability of drilling emulsions. As the results of this work showed, with the introduction of nanotubes, the colloidal stability of the emulsion increased significantly. Nanotubes have interfacial wettability and are embedded in the interface between the aqueous and hydrocarbon phases, thereby preventing droplet coalescence. In addition, there are works that studied the effect of multi-walled nanotubes on the size of emulsion droplets [

28]. It has been shown that, with the MWCNT additives, by reducing surface tension, it is possible to reduce the size of the droplets in the emulsion by several times. Reducing the size of emulsion droplets can contribute to the emulsion stabilization process. Another important circumstance that contributes to the stabilization of emulsions using nanotube additives is the fact that their addition significantly increases the viscosity of liquids and changes their rheology [

31]. The addition of nanotubes significantly increases the yield strength of liquids. This indicates that, in emulsions with nanotubes, structure formation processes associated with tube percolation processes occur more intensively. As the length of the tubes increases, the concentration at which percolation occurs, decreases. Nanotubes inside a liquid, like polymer molecules, form a stable network-like structure, which impedes the movement of droplets, thereby preventing their coalescence. We are confident that this is not a complete list of the mechanisms of the influence of nanotube additives on the colloidal stability of drilling emulsions, and this issue requires further research.

In addition to increasing the thermal stability of drilling fluids when adding nanomaterials, one more important fact should be noted. The addition of nanoparticles and carbon nanotubes changes the thermophysical characteristics of the medium. In particular, it increases the coefficient of thermal conductivity and increases heat transfer. It should be noted that the problem of enhancing the thermal conductivity coefficient of fluids using nanotubes is not a new issue. This technology has been widely investigated as a method of enhancing heat transfer using nanofluids. Several dozens of studies, described in review articles, have been carried out in this area [

31,

32,

33,

34]. It has been shown that, indeed, adding nanotubes can enhance the thermal conductivity of fluids by tens of percent. Similar effects are observed when adding MWCNTs to drilling fluids. However, while enhancing thermal conductivity of the heat transfer fluid is beneficial, enhancing that of the drilling fluids is not so unambiguous. On the one hand, it is a beneficial factor, because it contributes to more effective cooling of the drilling bit; on the other hand, it can have a negative impact on thawing rate while drilling in permafrost conditions. Therefore, studying the effect of MWCNT additives on the thermal conductivity of drilling fluids requires a deeper understanding.