Abstract

Woodfuel that is unsustainably sourced and inefficiently used results in negative environmental and health impacts. This study assessed charcoal use and resultant concentrations of indoor air pollutants (IAP) in an urban informal settlement while cooking with a Jikokoa stove (an improved branded charcoal stove) and medium and small-sized artisanal Kenya Ceramic Jikos (KCJs). Fuel stacking was prevalent with charcoal and kerosene being used by 25% of the studied households. Cooking with a Jikokoa stove reduced charcoal consumption by 6.4% and 26% compared to small and medium-sized KCJs, respectively. The small-sized KCJ reduced charcoal consumption by 21% compared to the medium-sized KCJ. The Jikokoa stove reduced concentrations of carbon monoxide (CO) by 10% and 50% and fine particulate matter (PM2.5) by 6% and 77% compared to small-sized and medium-sized KCJs, respectively. The Jikokoa stove reduced carbon dioxide (CO2) concentrations by 15.6% compared to the medium-sized KCJ. The small-sized KCJ reduced CO and PM2.5 concentrations by 45% and 75%, respectively, compared to the medium-sized KCJ. In summary, small-sized KCJs are more effective than medium-sized ones, and Jikokoa stoves more effective than small-sized KCJs, making it the stove of choice. The more efficient charcoal stoves are, the more charcoal consumption and IAP can be reduced, mitigating environmental degradation, climate change and health problems associated with smoke in the kitchen. There is need for participatory research to scale improved stoves and upgrade local practices as they are cheaper and already embedded in the cooking culture.

1. Introduction

Globally, there is an increased demand for bioenergy with close to a third of the global population using charcoal and firewood [1]. This raises concerns about sustainability, especially in charcoal production and use in Sub-Saharan Africa (SSA) countries [1,2,3,4]. According to the Food and Agriculture Organisation (FAO) [4], out of the 53 Metric tons (Mt) of charcoal produced globally, 33.9 Mt or about 64% was produced and utilized in Africa; a very small proportion of charcoal produced in Africa is exported to European countries [5]. Rapid population, urbanisation and economic growth within the continent is set to raise the demand for charcoal [6,7,8,9,10]. In Kenya, for instance, demand for charcoal increased by 82% between 2001 and 2021 [11], and the demand trend is projected to continue [12,13]. Charcoal is strongly favoured by urban households due to its high energy content and the fact that it is less bulky than firewood and, therefore, easier to transport and store. Charcoal also burns with less smoke [9]. Recent studies have shown an increase in charcoal’s popularity among rural households in Africa. In Kenya, for instance, about 46% of urban and 42% of rural households use charcoal with an estimated consumption of about 7 kg and 7.9 kg per week per household, respectively [14]. However, information on charcoal use and the subsequent implications for indoor air pollution is limited compared to that of firewood. This article uniquely and exhaustively presents information on charcoal use practices with different cooking stoves and how they might affect indoor air pollution and climate change.

Long-term exposure to PM2.5 and CO associated with inefficient cooking stoves and fuels is known to have negative health effects, especially on the respiratory system [15,16,17,18,19]. Carbon monoxide is produced from poor or incomplete combustion of carbon-based fuels, such as charcoal burning using an inefficient stove. Coupled with poor ventilation for those cooking in kitchens, the result can be instant death [20]. Particulate matter, especially particles of mass 2.5 μm in aerodynamic diameter (PM2.5), is also of great importance in assessing air quality in cooking places; it poses great danger to those exposed [21]. Close to three billion people, mostly in developing countries, burn biomasses of various kinds for cooking, resulting in 3.8 million premature deaths worldwide [17,21]. A systems approach across the woodfuel value chain and a theory of change for sustainable woodfuel, as discussed by [22], which involves the introduction of cleaner woodfuel production technologies, such as those described by Yang et al. [23] and improved charcoal stoves that reduce fuel consumption and air pollutants, can help reduce pressure on wood extraction and mitigate health and climate change impacts [15,16,24].

Currently, a wide range of technologies is being introduced in Kenya to improve fuel use efficiency while reducing indoor air pollution [24,25]. Despite the high dependence on biomass fuel in countries in Sub-Saharan Africa (SSA), uptake and consistent use of these technologies have remained low compared to other regions [26]. Different social, economic, and cultural factors influence the use and adoption of these technologies [26,27,28,29]. Policy-driven programmes to enhance innovations as well as uptake of improved stoves through Clean Development Mechanisms (CDM) have been rolled out in Kenya to scale up improved cooking stove projects [24]. To enhance a smooth transition to cleaner energies, researchers, such as Gill-Wiehl et al., Schot et al., Williams et al., and Wahlund et al. [27,30,31,32,33], have emphasized the importance of incorporating users into the development of technologies that are people-centred. This is key as users tend to eventually abandon non-people-centred innovations or use them alongside traditional technologies in a practice known as fuel stacking [34], inhibiting the realisation of the intended impacts [34,35,36]. According to a recent report by the Ministry of Energy (MoE) in Kenya, 40%, 3.6%, and 4.6% of urban charcoal users use improved artisanal portable charcoal stoves, branded charcoal stoves such as Jikokoa stoves, and artisanal metallic charcoal stoves, respectively [14]. Among rural charcoal users, 30.8%, 2.8%, and 8.6% use improved artisanal portable charcoal stoves, branded charcoal stoves, and artisanal metallic charcoal stoves, respectively [14].

Most of the charcoal produced in Kenya is consumed in urban areas with households being the major consumers followed by small commercial businesses and institutions [14,37]. The majority of these households are found in middle and low-income settlements within urban areas [37]. Over 60% of the urban population in Kenya is found in informal settlements that are characterized by high poverty levels, joblessness, and poor and overcrowded housing that make living in such areas hard to bear and precarious [38]. Enhancing cleaner and affordable energy access for such communities, alongside reducing the health burdens from household air pollution from 49% to 20% by 2030, will greatly contribute to attainment of the Agenda 2030 for Sustainable Development Goals (SDGs) on health and energy access as well as the country’s Vision 2030 development blueprint.

This study assessed the fuel types used, charcoal use efficiency, and concentration of indoor air pollutants in an urban informal settlement while cooking with charcoal using an improved branded stove (Jikokoa) and artisanal medium and small- sized (KCJ) stoves locally produced and commonly used by local households. This paper contributes to the scarce data on cooking with charcoal in densely populated informal settlements in SSA. It also adds to the knowledge on the quality of charcoal from invasive species, as well as its use and management of its spread. The data further contribute towards policy development on the sustainability of the charcoal sector and discussions about biomass cooking and climate change.

2. Materials and Methods

2.1. Study Area

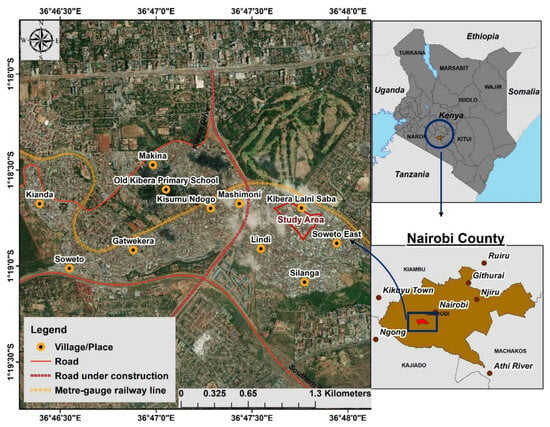

The study was carried out at Laini Saba village, Kibera informal/slum settlement, Kibra constituency, in Nairobi County. The Kibera informal settlement is one of the largest slums in Africa with a population of 120,057 [39]. The settlement sits on a flat ridge plateau located about 5 km southeast of the Nairobi city centre (Figure 1) and covers an area of about 550 acres [40].

Figure 1.

Kibera slum (Source: this study).

2.2. Research Design

This study was conducted to assess Kibera households’ cooking practices, energy mix, fuel use efficiency, and concentrations of CO2, CO, and PM2.5 in cooking areas/kitchen while cooking with an improved branded charcoal stove (Jikokoa) produced by Burn manufacturing in Nairobi, Kenya or a Kenya Ceramic Jiko (KCJ) fabricated locally by artisans in Nairobi. The participatory cooking was conducted by households using the two types of stove and charcoal from Prosopis juliflora carbonized under an improved earth kiln (IEK), traditional earth mound kiln (TEK), and drum kiln (DK) and charcoal from Acacia tortilis carbonized under a TEK in Baringo County [41].

2.3. Selection of the Households and Baseline Survey

The households that participated in this study were sampled from 304 households in the Kibera slum. These households were entered into an online random number generator which selected the first 35 households and gave priority to the first 21 households as the beneficiaries of the improved stove to participate in the study. The remaining 14 households were kept as reserves for replacement of any households unwilling to participate in the study. One household was not willing to participate and was replaced with another household from the reserve. Three households among the twenty-five issued with the Jikokoa were purposively selected to conduct the participatory cooking tests.

2.4. Baseline Survey

To understand common cooking practices, household expenditure on cooking energy, and cooking energy mixes used by the households before the introduction of the improved branded charcoal stove (Jikokoa), a household survey was conducted for the 24 households who received the new stove. The survey was conducted using semi-structured questionnaires that were administered by the researchers to the household representative who participates in cooking for the household and in the presence of a local assistant.

2.5. Participatory Cooking Test

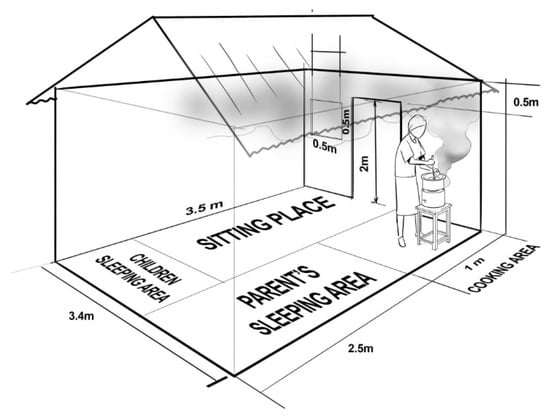

Cooking took place in three different kitchens that generally represent the type of kitchen commonly found in the informal settlement (Figure 2). The main household cook performed the cooking in the presence of the researchers. The food cooked was a meal commonly consumed in most of the households in Kenya which comprises of two dishes that are cooked separately and consecutively: maize (Zea mays) flour vigorously stirred in measured boiling water into a semi-solid consistency, locally known as ugali, and kale (Brassica oleracea), commonly known as sukuma wiki, which was cooked together with tomatoes (Solanum lycopersicum), cooking oil, salt, and onions (Allium cepa). Food preparation involved washing and chopping the kale at a grocery store in the neighbourhood; the tomatoes and onions were prepared by the household cook before commencement of the cooking exercise. The same type of meal and amounts were cooked for lunch and dinner in all households. Cooking lunch took place between 9 a.m. to 12 p.m. and dinner between 3 p.m. to 6 p.m. in all households. The cooking test period was from 15 January 2020 to 24 February 2020.

Figure 2.

Illustration of the kitchens found in Kibera slum (Infographic by Fucha Media, Nairobi).

The amount of ingredients used to cook the meals was enough to feed five people. Ugali was prepared with 1 kg of Pembe-brand maize flour and 2 L of water, while 540 g of sukuma wiki, 240 g of tomatoes, 100 g of cooking oil, 100 g of onions, and 11 g of salt were used for the second dish. This meal is considered sufficient for a standard Kenyan household of five people [42,43]. Since the study aimed to take measurements under normal practices, it was left to the cooks to decide on whether to open or close the doors and windows of the cooking areas/kitchen when cooking the meals.

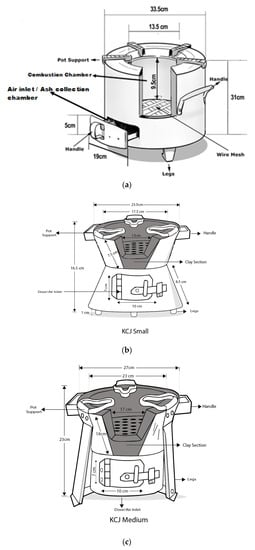

2.5.1. Stoves Used to Cook

Two charcoal stove types were used in the cooking tests: Jikokoa stoves (Figure 3a), a type of modern branded charcoal stove locally produced by Burn manufacturing, which takes in an average of 0.4 kg of charcoal, and Kenya Ceramic Jikos (KCJs), artisanal charcoal stoves commonly used in Kenya. There are two sizes of KCJs that are commonly used by the households in Kibera; a small-sized stove that takes an average of 0.3 kg of charcoal (Figure 3b) and a medium-sized stove that takes an average of 0.54 kg of charcoal (Figure 3c). The cost of purchasing a Jikokoa stove from the supermarket and a medium-sized KCJ and a small-sized KCJ from local traders in Kibera was KES 4500 (USD 45), 350 (USD 3.5), and 250 (USD 2.5), respectively (USD 1 = KES 100). The baseline survey conducted among 24 households showed that 17 households used KCJ stoves, of which 12 used the medium-sized stove and 5 used the small-sized stove. Both stoves were lit outside using Khaki paper and a match and returned to the kitchen after the fuel was well lit and had stopped smoking.

Figure 3.

(a) Jikokoa stove, (b) small-sized KCJ, and (c) medium-sized KCJ (Infographic by Fucha Media, Nairobi).

2.5.2. Fuel Used and Efficiency

During the tests, a composite of charcoal from the same kiln and tree species was weighed as an Initial Pile (IP) and kept separate. All the charcoal used in cooking the meal was picked from the IP and the charcoal remaining after cooking was weighed, recorded, and marked as the Last Pile (LP). When the meal was ready, any burning charcoal remaining on the stove was quenched by putting it in an empty pot, which was then covered with a lid to cut off oxygen to facilitate cooling. After cooling, this charcoal was weighed and marked as the Last Charcoal (LC). The amount of ash produced, too, was weighed and recorded. The Gross Charcoal (GF) used was the weight difference between the IP and the amount of charcoal left in the pile recorded as the LP after cooking (Equation (1)). The weight of the Net Fuel used (NF) for cooking was the difference between the GF and the charcoal from the stove that was cooled after cooking, i.e., the LC (Equation (2)). Time taken for the fuel to be well lit, for water to boil, and to cook the meal were taken and recorded, and these times were used to calculate the time taken to cook the meal and the time taken by the entire cooking process.

2.5.3. Charcoal Burning Period

Time taken for charcoal to burn completely was compared for charcoal from different species and kilns and for the different cooking stoves used. To determine this, tests were conducted using a Jikokoa stove and a small-sized KCJ with charcoal produced using a TEK and IEK, while cooking using A. tortilis charcoal produced under a TEK was conducted using only the small-sized KCJ stove. A predetermined amount of charcoal to be inserted/placed into each stove was used in all the runs, and a pot of water was placed on the stove to mimic the normal cooking practices and reduce atmospheric interference during the process. The charcoal was left to burn to ashes, and the time it took to burn completely was recorded.

2.5.4. Measuring Indoor Air Concentration of Carbon Monoxide, Carbon Dioxide, Fine Particulate Matter, and Flame Temperature

The concentrations of carbon monoxide (CO), carbon dioxide (CO2), and fine particulate matter (PM2.5) were measured 1 h before the start of the cooking exercise, during the actual cooking period, and 1 h after the cooking exercise. This was to help determine the actual concentrations of gases and particles resulting from the cooking activity. The CO concentration was measured at 60 s intervals using an EL-USB-CO carbon monoxide data logger (DATAQ Instruments, 603-746-5524). The CO2 and PM2.5 concentrations were recorded every 1 min using a Telaire7001 Carbon Dioxide and Temperature meter by LASCAR and a PATS+ meter by Berkeley Air Monitoring Group, respectively. The PATS+ PM meter was zeroed following the procedure given in the PATS+ and PICA User Manual_v11 before being implemented (Berkeley Air Monitoring Group). The three portable instruments were set at 1.5 m above and 1 m to the side of the stove position, simulating the position of the cook as described by Njenga et al. [44]. Flame temperature was measured every 10 min throughout the cooking period using a thermocouple.

2.6. Data Management and Analysis

Data from the household survey were entered and analysed using IBM SPSS version 24 while data on fuel use efficiency and concentrations of indoor air pollutants were managed with Microsoft Excel 2016. The same program was used for analyses of descriptive statistics as well as ANOVA and the confidence level was set at 95%. To determine the Emission Factor (EF) of CO and CO2 from burning charcoal on the cooking stoves, the mass balance of carbon was used. In this process, it was assumed that all of the carbon emitted from the burning charcoal, i.e., CO and CO2, was captured in the measurements.

3. Results and Discussions

3.1. Households’ Demographics

Out of the 24 interviewed households, 15 were male-headed households and 9 were female-headed. Household size ranged from one to seven members with an average of four members. Households’ main cooks varied from one household to the other with women and girls being the main cooks for most of the households (Table 1). The reality is that women and girls are the main cooks and, therefore, are disproportionately exposed to health risks associated with emissions from cooking and time expenditure.

Table 1.

Households’ main cooks (Source: this study).

3.2. Stove and Fuel Mix or Stacking

To meet their cooking needs effectively, most households stacked the various stoves and fuels available and affordable to them. This common practice is documented in the literature. Shanker et al. [35] reported stacking of both stoves and fuels as a common household practice to meet cooking needs [20,34]. In our study, the most common stove mix was a charcoal + a kerosene stove, while three households did not stack at all (Table 2). As observed with the stoves, the fuels used by Kibera households were also a mix; they varied across households but aligned to the stove mix used. However, the frequency of use of these stoves/fuels varied with households and stove mix categories; hence, their average percentage contribution to the mix also varied across mix categories (Table 2). Kerosene and charcoal contributed to the cooking energy mix of 83% and 75% of the interviewed households, respectively, though at varying percentages (Table 2). The average frequency of use of the fuel types varied across each mix (Table 3).

Table 2.

Fuel mix used by the households to cook and average % contribution of fuel to the mix (Source: this study).

Table 3.

Fuel frequency of use in the different mixes (Source: this study).

3.3. Cost of the Cooking Fuel

All the households accessed all of the fuel types they used to cook through purchase and paid for them in various units of measure (Table 4).

Table 4.

Units of measure of fuel and cost (Source: this study).

The mix that cost those households surveyed the most was charcoal + kerosene (Table 5). The high cost of this energy mix is due to the high use of these fuels to meet cooking energy needs with kerosene contributing more (Table 2). The monthly cost estimated by households, however, falls short of indicating the unit cost of each fuel and expenditure per meal.

Table 5.

Cost of energy mixes per month (Source: this study).

3.4. Fuel Use Efficiency in Cooking

3.4.1. Burning Period

The type of charcoal and stove used are key determinants of the burning period of the fuel. Improved charcoal stoves burn charcoal for a longer time, thus reducing the need for reloading while cooking. Charcoal from A. tortilis produced under a TEK burned for 25.7% longer in a small-sized KCJ than charcoal from P. juliflora produced under a TEK and 26% longer than charcoal from P. juliflora produced under an IEK. Acacia species tend to have a higher calorific value than P. juliflora. As a result, charcoal producers and users selectively source these indigenous trees for charcoal production as their charcoal is presumed to be of higher quality and, thus, preferred by customers [2]. The Jikokoa stove had a 9.6% longer burning period than the small-sized KCJ while burning charcoal of the same species, kiln, and weight (Table 6). However, the difference was not statistically significant.

Table 6.

Burning period of charcoal with Jikokoa stove and small-sized KCJ (Source: this study).

3.4.2. Charcoal Consumption and Use Efficiency

The calorific value of P. juliflora charcoal produced under TEK, IEK, and DK was 27.1, 27.6, and 27.4 MJ/kg, respectively, while that of A. tortilis produced under TEK was 28.6 MJ/kg [41]. These values are in line with what is reported in other works of the literature such as [45,46,47].

The Jikokoa stove reduced charcoal consumption by 6.4% and 26% compared to the small-sized KCJ and the medium-sized KCJ, respectively, during the cooking period. Reasons for this lower consumption were combined technical advancements such as the Jikokoa stove’s relatively reduced charcoal volume uptake, reduced heat loss, and ability to utilise small-sized burning charcoal that is otherwise discarded as waste from conventional stoves. Use of the small-sized KCJ with a volume of 374 g reduced charcoal use by 21% compared to the medium-sized KCJ with a volume of 538 g of charcoal. On average, the Jikokoa stove had a net fuel savings of 26% compared to 24.2% and 32% for the small-sized KCJ and the medium-sized KCJ, respectively (Table 7). Net fuel saving is an important measure of fuel saving as households cool the fuel left after cooking for another use.

Table 7.

Fuel use efficiency (Source: this study).

Compared with the most commonly used medium-sized KCJ, use of the Jikokoa stove reduced charcoal consumption by 26%, translating to USD 1.5 of savings per week, assuming that three major dishes are cooked per day in an area where charcoal consumption is estimated to be 7 kg per household per week [14]. This is less than the 45% savings previously reported by the stove manufacturer, even though it does not specify the size of KCJ that it used when comparing with the Jikokoa stove [48]. There was a significant difference in net fuel used while cooking using the Jikokoa stove compared to the medium-sized KCJ (p = 0.00068). There was also a significant difference (p = 0.0016) in the fuel used while cooking with the small-sized KCJ compared to the medium-sized KCJ, signifying a great saving on fuel consumption at a cheaper cost (USD 2.5) compared to the savings using a more expensive industrial branded stove (USD 45).

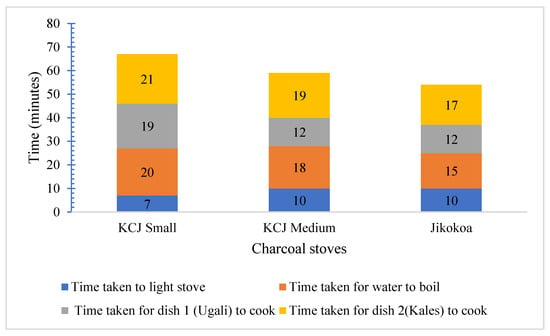

In Kenya, cooking ugali involves boiling water, adding maize flour, and mashing the solid mix until it is well cooked. After ugali is ready, it is removed from the pot and covered to keep it warm. On the same stove, vegetables are then cooked and the two are served together. To cook, stoves first need to be lit. As such, the time consumed in the cooking process included the time for lighting the stoves, the time taken to bring water to boil, and the time taken to cook the two dishes. It took an average of 7 min to light a small-sized KCJ while the Jikokoa and medium-sized KCJ stoves each took 10 min. The Jikokoa stove saved time spent while cooking by 26.7% and 10.2% compared to a small-sized KCJ and a medium-sized KCJ, respectively. During the whole cooking process, which spans from lighting the stove to the completion of cooking the two dishes, Jikokoa, medium-sized KCJ, and small-sized KCJ stoves took 54, 59, and 67 min, respectively. The Jikokoa stove saved 19.4% and 8.5% of the time taken compared to small-sized and medium-sized KCJs, respectively (Figure 4). There was a significant difference (p = 0.0341) in time spent while cooking on the Jikokoa stove compared to the small-sized KCJ.

Figure 4.

Time taken to cook Ugali and Kale include lighting the stove, taking water to boil, cooking Ugali, and cooking Kale.

The flame temperature during cooking varied by charcoal type and stove used (Table 8). Comparing charcoal from the same species, the Jikokoa stove had the highest flame temperature recorded, followed those of the medium-sized KCJ and small-sized KCJ, which had the lowest. The small-sized KCJ took a longer time to cook the meal and recorded substantially lower temperatures compared to Jikokoa and medium-sized KCJ stoves. Based on charcoal types, A. tortilis charcoal recorded higher flame temperatures than P. juliflora charcoal.

Table 8.

Flame temperature (°C) (Source: this study).

3.4.3. Concentration of Pollutants from Cooking with Charcoal and Potential Health and Climate Change Impacts

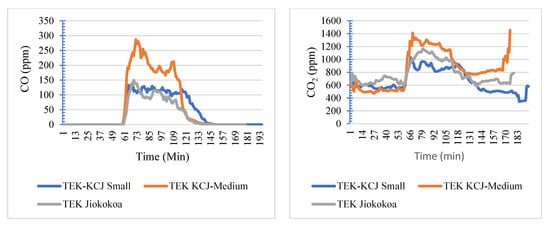

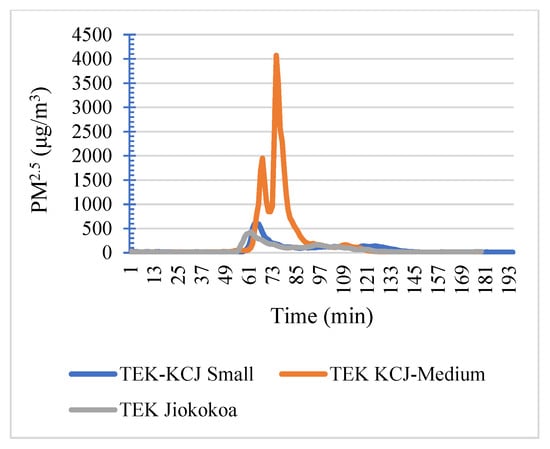

Cooking with P. juliflora charcoal produced under a TEK with the Jikokoa stove reduced CO concentrations by 50% and 9.8% compared to the medium-sized KCJ and the small-sized KCJ, respectively. With about 70.6% of charcoal users cooking with medium-sized KCJs, many households are at risk of exposure to higher CO concentrations, which is a health hazard. Concentrations of PM2.5 while cooking with the Jikokoa stove reduced by 76.6% and 6% compared to concentrations observed while using medium-sized and small-sized KCJs, respectively. CO2 concentration was reduced by 15.6% while cooking with the Jikokoa stove compared to the medium-sized KCJ. Shifting from the medium-sized KCJ to the small-sized KCJ, which takes in lower volumes of charcoal per load, reduced the concentration of CO, CO2, and PM2.5 by 44.6%, 27.9%, and 75%, respectively.

Cooking with the small-sized KCJ using charcoal from P. juliflora carbonized under a IEK and DK reduced concentrations of pollutants (CO, CO2, and PM2.5) by 14.5%, 9.7%, and 90.4%; and 12.6%, 64.8%, and 41.6%, respectively, compared to the Jikokoa stove (Table 9). Cooking with the Jikokoa stove and A. tortilis charcoal produced under a TEK reduced concentrations of CO and CO2 by 13.7% and 20% while PM2.5 concentration increased by 33.7% when compared with cooking using small-sized KCJ. Cooking with the Jikokoa stove while using charcoal from the same tree species and kiln (TEK P. juliflora) recorded 37% and 19% decreases in climate impact compared to cooking with medium and small-sized KCJs, respectively (Table 10). Gases produced during cooking such as CO and CO2 have the potential to trap light in the atmosphere and release it in form of heat, leading to global warming.

Table 9.

Concentration of pollutants generated by different fuels and cooking stove options in Kibera, Kenya (Source: this study).

Table 10.

Climate impact of cooking with charcoal by different stoves in Kibera, Kenya (Source: this study).

The concentration of indoor air pollutants varied during the cooking period with all stoves as illustrated in (Figure 5a–c). Concentrations of CO in the current study were above the WHO-recommended levels of 35 mg/m3, equivalent to 40 ppm at 760 mmHg and 25 °C per 1 h of exposure where exposure to this level should not occur more than once per day with light physical activities [49]. The concentrations were well above the recommended levels by 162%, 190%, and 425% for Jikokoa, small-sized KCJ and medium-sized KCJ stoves, respectively, considering charcoal from the same kiln and species. Recommended concentration levels of particulate matter (PM2.5) by WHO over a 24 h period of exposure is 25 μg/m3 [50]. During the cooking exercise, the concentration levels of PM2.5 were above the WHO-recommended levels of 25 μg/m3 by 585%, 629%, and 2831.2% for Jikokoa, small-sized KCJ and medium-sized KCJ stoves, respectively, while using P. juliflora charcoal produced using a TEK. Indoor air concentrations of CO and PM2.5 in this study were relatively high even when compared to those from firewood [13]. This can be attributed to the poor ventilation and air circulation in Kibera urban slum dwellings. Muindi et al. [51] reported less than 20% of households in Korogocho and Viwandani slum settlements in Nairobi opening doors for ventilation while cooking in the evening and less than 10% were reported opening their windows. In this study, the researcher noted that it was normal practice for cooks to keep their windows closed during the cooking process, thus limiting air circulation and causing accumulation of pollutants in the kitchen/cooking area as cooking continued. Due to limited space in rooms (Figure 2), windows were permanently closed, and the space was utilized for other purposes, such as hanging kitchen utensils or a television set. This poses a great danger to the people in the house during cooking since the same room is used for sitting and sleeping (Figure 2). Average CO2 concentrations were below the WHO’s permissible exposure limit of 5000 ppm averaged over an 8 h workday [50].

Figure 5.

Concentration of indoor air pollutants before, during, and after cooking (TEK-KCJ Small: n = 6, TEK-Jikokoa: n = 6, KCJ-Medium: n = 6) (Source: this study).

Using the Jikokoa stove for cooking reduced the amount of charcoal consumed in cooking a meal, which consequently minimized the need to cut down trees for charcoal making. Trees are carbon sinks that reduce CO2 in the atmosphere, thus mitigating climate change [1]. The Jikokoa stove also emitted less CO2 and CO gases compared to the most commonly used medium-sized KCJ by 15.6% and 50%, respectively. The impact of CO extends beyond the indoor environment; CO is said to contribute to the formation of tropospheric ozone which is another air pollutant with unhealthy effects [17]. Even though CO does not cause climate change directly, its presence affects the abundance of greenhouse gases such as methane and carbon dioxide [52].

3.4.4. Study Limitations

This study was carried out in an urban informal settlement in Kibera, Nairobi, Kenya, which is one type of residential area. The households studied were those that were randomly selected and given the improved Jikokoa stove for free after being trained on its use. The study also considered only one type of improved stove (Jikokoa) but, in the market, there are other available improved stoves with different designs and efficiencies. The study also considered only CO, CO2, and PM2.5 but we are aware that there are other pollutants of concern.

4. Conclusions and Recommendations

The majority of households in Kibera used a mix of fuels to meet their cooking needs. Using a Jikokoa-branded stove and a smaller-sized KCJ reduced the amount of charcoal consumed and this could consequently reduce expenditure on cooking energy and demand for trees to produce charcoal. The study also revealed that using improved stoves reduces the time spent during cooking. Cooking with a Jikokoa stove reduced IAP compared to a medium-sized KCJ stove. Further, cooking with a small-sized KCJ reduced IAP as lesser amounts of charcoal was burned due to the small volume of charcoal that the stoves take in per loading. However, concentration of pollutants from all the stoves were above the WHO-recommended levels. This could be attributed to the limited ventilation in cooking areas as well as pollution produced by burning charcoal and that from outside, although this was not measured. Reducing indoor air pollution and time spent cooking with charcoal would improve women’s and girls’ lives, including the lives of children below school age as they spend a lot of time near the stove while it is in use. Household cooks can use the saved time to engage in other productive activities as well as reduce the time they are exposed to pollutants. Reducing IAP mitigates climate change in the long run.

There is a great need for participatory research while developing cooking stoves for use, especially in developing countries where kitchen settings are different from the laboratories used by innovators while developing and testing new cooking stoves. The impact of ventilation is an example of the kind of local conditions that could not be reproduced in a lab setting. Considering needs and aspirations of users will enhance the performance, acceptability, and adoption of efficient cooking stoves and the speed the development of these technologies. Stove developers should also consider the volume capacity of fuel that stoves can take per loading to minimize it while enhancing stove efficiency. Cooking stoves with chimneys need to be developed for use in densely populated slum areas where there is little air circulation as this would help to reduce the high indoor air pollution noted in this study. Of course, at scale, chimneys increase external air pollution and, thus, spread the pollution burden to neighbours and into the atmosphere, hence the need for growing trees as carbon sinks in urban areas. More fundamentally, even the most efficient stove/fuel combination is unlikely to compensate for the density of living conditions in areas like Kibera. While improving cooking conditions can help, reducing crowding, providing space for air circulation in urban neighbourhoods, planting trees, and providing parks, as well as improving per capita income, are all necessary to improve the health and lives of residents in substantial ways. Repeating studies such as this one in other slum contexts will help provide broader science-based data that can influence bioenergy policy review and development as well as the design of context-appropriate interventions/solutions.

Author Contributions

Conceptualization, M.K., J.K.G. and M.N.; methodology, M.K., J.K.G., M.N. and R.M.; software, M.K., J.K.G. and M.N.; validation, M.K., J.K.G., R.M. and M.N.; formal analysis, M.K. and J.K.G.; investigation, M.K., J.K.G. and M.N.; resources, M.K., J.K.G., R.M. and M.N.; data curation, M.K. and J.K.G.; writing—original draft preparation, M.K., J.K.G. and M.N.; writing—review and editing, M.K., J.K.G., R.M., C.M. and M.N.; visualization, M.K., J.K.G., R.M. and M.N.; supervision, R.M. and M.N.; project administration, M.N.; funding acquisition, M.N. and R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the European Union through the Governing Multifunctional Landscapes (GML) in Sub-Saharan Africa project, implemented by the Center for International Forestry Research (CIFOR) in partnership with World Agroforestry (ICRAF), the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ), the Forest and Farm Facility (FFF), and the Food and Agriculture Organization of the United Nations (FAO). The authors are also grateful for the financial support from the CGIAR programs on Forests, Trees and Agroforestry (FTA) and Water Land and Ecosystems (WLE) and USDA National Institute of Food and Agriculture and Hatch Appropriations under Project #PEN04724 and Accession #1020895.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Authors are grateful to the Kenya Forestry Research Institute (KEFRI) for laboratory analysis of charcoal and wood samples and the residents of Kibera Laini Saba for their participation in the study. Finally, the authors express their gratitude to Cathy Watson of CIFOR-ICRAF for her support in copyediting this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Food and Agriculture Organisation (FAO). Forest Pathways for Green Recovery and Building Inclusive, Resilient and Sustainable Economies. In Brief to The State of the World’s Forests 2022; FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- Chidumayo, E.N.; Gumbo, D.J. The environmental impacts of charcoal production in tropical ecosystems of the world: A synthesis. Energy Sustain. Dev. 2013, 17, 86–94. [Google Scholar] [CrossRef]

- Mensah, K.E.; Damnyag, L.; Kwabena, N.S. Analysis of charcoal production with recent developments in Sub-Sahara Africa: A review. Afric. Geo. Rev. 2022, 41, 35–55. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO). Global Forest Products. Forest Products and Statistics Team. Forestry Policy and Resources Division, Forestry Department. Food and Agriculture Organization of the United Nations. 2019. Available online: https://www.fao.org/forestry/statistics/80570/en/ (accessed on 22 May 2020).

- Haag, V.; Zemke, V.T.; Lewandrowski, T.; Zahnen, J.; Hirschberger, P.; Bick, U.; Koch, G. The European Charcoal Trade. IAWA J. 2020, 41, 463–477. [Google Scholar] [CrossRef]

- Ouedraogo, N.S. Africa energy future: Alternative scenarios and their implications for sustainable development strategies. Energy Pol. 2017, 106, 457–471. [Google Scholar] [CrossRef]

- Amowine, N.; Ma, Z.; Li, M..; Zhou, Z.; Asunka, B.A.; Amowine, J. Energy efficiency improvement assessment in Africa: An integrated dynamic DEA approach. Energies 2019, 12, 3915. [Google Scholar] [CrossRef]

- Ren, H.; Guo, W.; Zhang, Z.; Kisovi, L.M.; Das, P. Population density and spatial patterns of informal settlements in Nairobi, Kenya. Sustainability 2020, 12, 7717. [Google Scholar] [CrossRef]

- Akpalu, W.; Dasmani, I.; Aglobitse, P.B. Demand for cooking fuels in a developing country: To what extent do taste and preferences matter? Energy Pol. 2011, 39, 6525–6531. [Google Scholar] [CrossRef]

- Smith, H.E.; Hudson, M.D.; Schreckenberg, K. Livelihood diversification: The role of charcoal production in southern Malawi. Energy Sustain. Dev. 2017, 36, 22–36. [Google Scholar] [CrossRef]

- FAO 2023. FAOSTAT Statistical Database. [Rome]: Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 3 February 2023).

- Iiyama, M.; Chenevoy, A.; Otieno, E.; Kinyanjui, T.; Ndegwa, G.; Vandenabeele, J.; Njenga, M.; Johnson, O. Achieving Sustainable Charcoal in Kenya: Harnessing the Opportunities for Cross Sectoral Integration; World Agroforestry (ICRAF): Nairobi, Kenya; Stockholm Environment Institute (SEI): Nairobi, Kenya, 2014. [Google Scholar]

- Namaswa, T.; Githiomi, J.; Oduor, N.; Kitheka, E. Sustainable biomass energy production and utilization in sub-Saharan Africa: A case study of Kenya. J. Hortic. For. 2022, 14, 56–67. [Google Scholar]

- Ministry of Energy (MoE); Cleaner Cooking Association of Kenya (CCAK). Kenya Household Cooking Sector Study. Assessment of the Supply and Demand of Cooking Solutions at the Household Level; CCAK and Ministry of Energy: Nairobi, Kenya, 2019.

- Njenga, M.; Larsson, L.; Iiyama, M.; Sundberg, C.; Helander, H.; Röing de Nowina, K.; De Leeuw, J.; Neufeldt, H.; Jamnadass, R. Gasifier as a cleaner cooking system in rural Kenya. J. Clean Prod. 2016, 121, 208–217. [Google Scholar] [CrossRef]

- Branch, A.; Agyei, F.K.; Anai, J.G.; Apecu, S.L.; Bartlett, A.; Brownell, E.; Caravani, M.; Cavanagh, C.J.; Fennell, S.; Langole, S.; et al. From crisis to context: Reviewing the future of sustainable charcoal in Africa. Energy Res. Soc. Sci. 2022, 87, 102457. [Google Scholar] [CrossRef]

- World Health Organisation. World Health Statistics 2018: Monitoring Health for the Sustainable Development Goals (SDGs). 2018. Available online: https://www.who.int/en/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 27 August 2020).

- Qiu, Y.; Yang, F.A.; Lai, W. The impact of indoor air pollution on health outcomes and cognitive abilities: Empirical evidence from China. Popul. Environ. 2019, 40, 388–410. [Google Scholar] [CrossRef]

- Li, S.; Meng, J.; Zheng, H.; Zhang, N.; Huo, J.; Li, Y.; Guan, D. The driving forces behind the change in energy consumption in developing countries. Environ. Res. Lett. 2021, 16, 054002. [Google Scholar] [CrossRef]

- Kim, H.; Kang, K.; Kim, T. Measurement of particulate matter (PM2.5) and health risk assessment of cooking-generated particles in the kitchen and living rooms of apartment houses. Sustainability 2018, 10, 843. [Google Scholar] [CrossRef]

- Bailis, R.; Cowan, A.; Berrueta, V.; Masera, O. Arresting the Killer in the Kitchen: The Promises and Pitfalls of Commercializing Improved Cook stoves. World Dev. 2009, 10, 1694–1705. [Google Scholar] [CrossRef]

- Njenga, M.; Sears, R.R.; Mendum, R. Sustainable woodfuel systems: A theory of change for sub-Saharan Africa. Environ. Res. Comm. 2023, 5, 051003. [Google Scholar] [CrossRef]

- Yang, C.; Wu, H.; Cai, M.; Zhou, Y.; Guo, C.; Han, Y.; Zhang, L. Valorization of Biomass-Derived Polymers to Functional Biochar Materials for Supercapacitor Applications via Pyrolysis: Advances and Perspectives. Polymers 2023, 15, 2741. [Google Scholar] [CrossRef]

- Lambe, F.; Jürisoo, M.; Wanjiru, H.; Senyagwa, J. Bringing Clean, Safe, Affordable Cooking Energy to Households Across Africa: An Agenda for Action; Stockholm Environment Institute: Stockholm, Sweden; Nairobi, Kenya, 2015. [Google Scholar]

- Mahmoud, Y.; Njenga, M.; Sundberg, C.; De Nowina, K.R. Soils, sinks, and smallholder farmers: Examining the benefits of biochar energy transitions in Kenya. Energy Res. Soc. Sci. 2021, 75, 102033. [Google Scholar] [CrossRef]

- Guta, D.; Baumgartner, J.; Jack, D.; Carter, E.; Shen, G.; Orgill-Meyer, J.; Rosenthal, J.; Dickinson, K.; Bailis, R.; Masuda, Y.; et al. A systematic review of household energy transition in low and middle income countries. Energy Res. Soc. Sci. 2022, 86, 102463. [Google Scholar] [CrossRef]

- Gill-Wiehl, A.; Price, T.; Kammen, D.M. What’s in a stove? A review of the user preferences in improved stove designs. Energy Res. Soc. Sci. 2021, 81, 102281. [Google Scholar] [CrossRef]

- Bielecki, C.; Wingenbach, G. Rethinking improved cook stove diffusion programs: A case study of social perceptions and cooking choices in rural Guatemala. Energy Pol. 2014, 66, 350–358. [Google Scholar] [CrossRef]

- Kitheka, E.; Kimiti, J.M.; Oduor, N.; Mutinda, J.W.; Ingutia, C.; Githiomi, J. Factors influencing adoption of biomass energy conservation technologies in selected areas of Kitui County, Kenya. J. Environ. Sci. Eng. 2019, 8, 70–81. [Google Scholar]

- Gill-Wiehl, A.; Sievers, S.; Kammen, D.M. The value of community technology workers for LPG use: A pilot in Shirati, Tanzania. Energy Sustain. Soc. 2022, 12, 5. [Google Scholar] [CrossRef]

- Schot, J.; Kanger, L.; Verbong, G. The roles of users in shaping transitions to new energy systems. Nat. Energy 2016, 1, 16054. [Google Scholar] [CrossRef]

- Williams, N.B.; Quilliam, R.S.; Campbell, B.; Ghatani, R.; Dickie, J. Taboos, toilets and biogas: Socio-technical pathways to acceptance of a sustainable household technology. Energy Res. Soc. Sci. 2022, 86, 102448. [Google Scholar] [CrossRef]

- Wahlund, M.; Palm, J. The role of energy democracy and energy citizenship for participatory energy transitions: A comprehensive review. Energy Res. Soc. Sci. 2022, 87, 102482. [Google Scholar] [CrossRef]

- Energy Sector Management Assistance Program (ESMAP). What Drives the Transition to Modern Energy Cooking Services? A Systematic Review of the Evidence; Technical Report 015/21; World Bank: Washington, DC, USA, 2021. [Google Scholar]

- Shankar, A.V.; Quinn, A.K.; Dickinson, K.L.; Williams, K.N.; Masera, O.; Charron, D.; Jack, D.; Hyman, J.; Pillarisetti, A.; Bailis, R.; et al. Everybody stacks: Lessons from household energy case studies to inform design principles for clean energy transitions. Energy Pol. 2020, 141, 111468. [Google Scholar] [CrossRef]

- Ochieng, C.A.; Zhang, Y.; Nyabwa, J.K.; Otieno, D.I.; Spillane, C. Household perspectives on cook stove and fuel stacking: A qualitative study in urban and rural Kenya. Energy Sustain. Dev. 2020, 59, 151–159. [Google Scholar] [CrossRef]

- Ministry of Environment, Water and Natural Resources (MEWNR), Government of Kenya (GoK). Analysis of Demand and Supply of Wood Products in Kenya; Government of Kenya: Nairobi, Kenya, 2013.

- United Nations Human Settlements Programme (UN-Habitat). UN-Habitat Support to Sustainable Urban Development in Kenya: Addressing Urban Informality. 2016. Available online: https://unhabitat.org/sites/default/files/download-manager-files/UN-Habitat%20SSUDK_%20Report_Vol%204_final.LowRes.pdf (accessed on 27 June 2023).

- Kenya National Bureau of Statistics (KNBS). The 2019 Kenya Population and Housing Census: Population by County and Sub-County, KNBS 2019; Kenya National Bureau of Statistics: Nairobi, Kenya, 2019.

- Bodewes, C. Parish Transformation in Urban Slums: Voices of Kibera, Kenya; Paulines Publications Africa: Nairobi, Kenya, 2005. [Google Scholar]

- Njenga, M.; Kirimi, M.; Koech, G.; Erick Otieno, W.; Muriuki, J.; Sola, P.; Bourne, M.; Siko, I.; Mendum, R. Improvements in Charcoal Production and the Environmental Implications: Potential for the Invasive Prosopis Juliflora in Kenya. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Njenga, M.; Mahmoud, Y.; Mendum, R.; Iiyama, M.; Jamnadass, R.; De Nowina, K.R.; Sundberg, C. Quality of charcoal produced using micro gasification and how the new cook stove works in rural Kenya. Environ. Res. Lett. 2017, 12, 095001. [Google Scholar] [CrossRef]

- Kenya National Bureau of Statistics (KNBS). The Kenya 2009 Population and Housing Census; Population Distribution by Administrative Units; KNBS: Nairobi, Kenya, 2010; Volume 1A.

- Njenga, M.; Karanja, N.; Jamnadass, R.; Kithinji, J.; Sundberg, C.; Jirjis, R. Quality of briquettes produced locally from charcoal dust and sawdust in Kenya. J. Bio. Mater. Biol. 2013, 7, 315–322. [Google Scholar] [CrossRef]

- Oduor, N.M.; Ngugi, W.; Wa Gathui, T. Sustainable Tree Management for Charcoal Production Acacia Species in Kenya; African Centre for Technology Studies (ACTS): Nairobi, Kenya, 2012. [Google Scholar]

- Oduor, N.; Githiomi, J.K. Fuel-wood energy properties of Prosopis juliflora and Prosopis pallida grown in Baringo District, Kenya. Afr. J. Agric. Res. 2013, 8, 2476–2481. [Google Scholar]

- Sirmah, P.; Muisu, F.; Mburu, F.; Dumarçay, S.; Gérardin, P. Evaluation of Prosopis juliflora properties as an alternative to wood shortage in Kenya. Boiset Forêts Trop. 2008, 298, 25–35. [Google Scholar]

- BURN-Manufacturing. Winner Case Study Summary—Case Study; BURN Manufacturing: Nairobi, Kenya, 2015. [Google Scholar]

- World Health Organisation. WHO Guidelines for Indoor Air Quality on Selected Pollutants. 2010. Available online: https://apps.who.int/iris/bitstream/handle/10665/260127 (accessed on 27 August 2020).

- World Health Organisation, Climate and Clean Air Coalition. Air Pollution, Climate and Health. 2016. Available online: https://www.who.int/sustainabledevelopment/AirPollution_Climate_Health_Factsheet.pdf (accessed on 28 August 2020).

- Muindi, K. Household air pollution: Sources and exposure levels to fine particulate matter in Nairobi slums. Toxics 2016, 4, 12. [Google Scholar] [CrossRef]

- Strode, S.A.; Duncan, B.N.; Yegorova, E.A.; Kouatchou, J.; Ziemke, J.R.; Douglass, A.R. Implications of carbon monoxide bias for methane lifetime and atmospheric composition in chemistry climate models. Atmos. Chem. Phys. 2015, 15, 11789–11805. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).