Abstract

Some oil wells in the Tahe oilfield have been reported to produce extremely heavy oil due to asphaltene deposition. To enhance the flow of crude oil through the wellbore, engineers adopted the use of light oil from nearby wells to dissolve the heavy crude in the wells’ sections to maximize recovery from the Tahe oilfield. However, this mixing has led to the problem of accelerated asphaltene deposition, which often blocks the wellbore in the process. In this research, the factors that influence the stability of diluted heavy oil, temperature, and mixing ratio on asphaltene deposition characteristics under high pressure are studied using a high-temperature and high-pressure crude oil flow property experimental device based on the differential pressure method. The results under high pressure show that the initial deposition pressure of asphaltene decreases as the experimental temperature increases. With an increase in the mixing light oil ratio, the initial deposition pressure of diluted heavy oil increases, and the deposition trend of asphaltene strengthens. The asphaltene accumulation and deposition will be aggravated by filling quartz sand and pipe diameter changes. The research here is helpful to understand the deposition characteristics of asphaltene during the production of diluted heavy oil. It offers significant guidance in the prevention and control of asphaltene precipitation in heavy oil wells.

1. Introduction

The Tahe oilfield is currently the largest uncompartmentalized marine carbonate oilfield in China. Its reservoir mainly consists of an Ordovician carbonate fractured/caverned karst heavy oil reservoir with an underlying aquifer. The reserves of extra-heavy oil and super-heavy oil (viscosity on the ground ≥50,000 mPa·s) in the oilfield are enormous, but there are problems in production. At present, the oilfield’s mainstream heavy oil production technology is mainly based on mixing heavy oil with light oil to reduce viscosity [1,2,3]. However, this technique causes asphaltene to precipitate in the production process of crude oil and cause deposition in the inner regions of the reservoir that are close to the well perforations, production system, or production equipment while improving the fluidity of heavy oil, causing flow assurance problems [4,5,6]. Given the technical issues, such as an unclear understanding of the deposition characteristics of asphaltene in the process of diluted heavy oil production, it is of great significance for enhancing oil production to study the deposition characteristics of asphaltene in diluted heavy oil [7,8,9].

At present, the methods for studying the deposition characteristics of asphaltene mainly include the microscopic method, capillary microdeposition simulation, the dynamic light scattering method, and so on [10,11,12,13,14,15,16]. But the microscopy methods are less effective under high-temperature and high-pressure experimental conditions. Capillary microdeposition simulation has poor fluidity for heavy oil with high viscosity and is easy to block the capillary channel. The dynamic light scattering method has limitations for Tahe heavy oil and black oil, which cannot be used to study the deposition characteristics of asphaltene in diluted heavy oil wells in the Tahe oilfield. For the purpose of revealing the deposition characteristics of asphaltenes in diluted heavy oil wells located in Tahe oilfield and exploring the influence of experimental temperature, mixing light oil ratio, pipe sand filling, and pipe diameter reduction on asphaltene deposition, an independently developed high-temperature and high-pressure crude oil flow property experimental device is used to simulate the deposition of asphaltene during the heavy oil production process under a high-pressure environment. The measurements are based on the principles of the differential pressure technique, which provides theoretical guidance for efficient production and asphaltene deposition prevention.

2. Materials and Methods

2.1. Materials

The heavy oil is taken from the dead oil of well A in Tahe No. 12 block. The depth, temperature, and reservoir pressure in oil well A are 6500 m, 148.23 °C, and 65.98 MPa, respectively. The light oil used to dilute heavy oil was taken from the light oil production wells also located in the Tahe oilfield. The properties of the oil are presented in Table 1. The CII value was calculated through SARA components of crude oil (CII value > 0.9 implies colloidal instability of crude oil). Based on the colloidal instability index (CII), crude oil with a high resin-aromatic content is less prone to asphaltene risk compared to the one with a low range [17]. The methane gas with 99.9% purity was purchased from Beijing Huatong Gas Chemical Co., Ltd., Beijing, China, Jing Branch.

Table 1.

Properties of the oil sample.

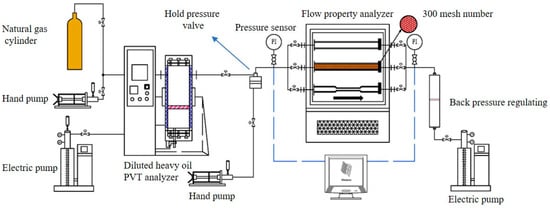

2.2. Experimental Apparatus

The “High temperature and high-pressure crude oil flow property test device” was used to study the deposition characteristics of asphaltene in diluted heavy oil. This device was independently developed by the China University of Petroleum (Beijing, China). The pressure sensors used for the test were produced by Senex Instruments Co., Ltd., Guangzhou, China, with a maximum accuracy of 0.1% F.S., whereas the mesh number of the system filter screen is about 300. The schematic diagram of the experimental setup is shown in Figure 1.

Figure 1.

The schematic diagram of the high-temperature and high-pressure crude oil flow property test device.

The principle of the differential pressure method is based on the Hagen–Poiseuille formula derived when performing steady laminar flow in a circular tube.

ΔP represents the pressure difference at both ends of the pipeline (the pressure difference between the inlet and the outlet pressure in Figure 1), Pa; µ is the viscosity of crude oil, mPa·s; L is the pipe length of the tested part; Q is the rate of the experimental oil (the constant speed and pressure pump ensure the stable flow during the test process), mL/min; and R is the radius of the tested pipe, mm.

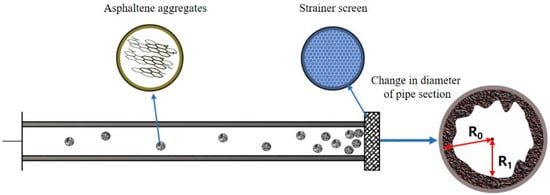

According to the formula, the pressure difference between the two ends of the tested pipeline depends on the crude oil viscosity and radius. The pressure has little effect on the viscosity of the tested oil during the constant temperature and depressurization tests [18]. Therefore, only when asphaltene deposits occur will the flow channel of the filter at the end of the tested pipe be blocked by asphaltene particles, resulting in a reduction of the pipe diameter, which the differential pressure sensor can detect due to a significant increase in pressure drop. A schematic diagram of asphaltene blocking the pipeline is shown in Figure 2.

Figure 2.

The schematic diagram of the asphaltene blocking the pipeline.

2.3. Experimental

2.3.1. The Preparation of Simulated Oil

A specific volume of diluted heavy oil is pumped into the high-temperature and high-pressure PVT analyzer. Then the corresponding volume of natural gas is pumped to replicate the same gas–oil ratio according to the oil well production data. Finally, increase the temperature and pressure to the values corresponding to the reservoir environment. The PVT analyzer cylinder is continuously stirred and rotated for 2 h during the heating and pressure increase process. When the temperature and pressure of the PVT cylinder remain unchanged, the mixture is completely dissolved, and the sample preparation process is completed.

2.3.2. Asphaltene Deposition Test

Simulated oil was prepared according to the reservoir parameters and experimental requirements of well A in Tahe No. 12 block. The high-temperature and high-pressure crude oil flow characteristics test device was used to study the deposition characteristics of asphaltene under high pressure. The constant speed and pressure pump activate the PVT analyzer to inject the sample into the tested pipeline at a rate of 0.10 mL/min. The temperature is kept constant during the test, and the asphaltene deposition process during the decompression process is monitored by controlling the speed of the backpressure pump. The pressure, temperature, volume, and inlet and outlet pressure data of the PVT analyzer are recorded in the meantime at a period of 9 s−1 to analyze the deposition characteristics of asphaltene. Change the experimental temperatures, mix light oil ratios, repeat the simulated oil, and repeat the above experimental steps.

3. Results and Discussion

3.1. Pressure and Temperature Effects on Asphaltene Deposition

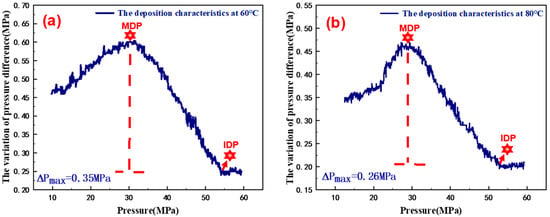

According to the production data and reservoir parameters of well A in block No. 12, the mixing light oil ratio was 1.5, and the simulated oil was tested at 60 °C, 80 °C, 110 °C, and 140 °C, respectively. The high-temperature and high-pressure crude oil flow property test device was used to execute the pump withdrawal operation. The No. 1 pump was set to feed oil at a rate of 0.10 mL/min and pump No. 2 was set at a withdraw rate of 0.15 mL/min. An isothermal depressurization test was then performed to study the deposition characteristics of asphaltene in the diluted heavy oil at different temperatures and high-pressure conditions. The pressure corresponding to the significant increase in differential pressure signal is the initial deposition pressure of asphaltene, or IDP for short, whilst that conforming to the highest point of the differential pressure signal is the maximum deposition pressure of asphaltene, or MDP for short. The difference between the maximum pressure drop and the initial pressure drop is expressed as ΔPmax. The results are shown in Figure 3.

Figure 3.

The deposition characteristics of asphaltene in diluted heavy oil at different temperatures: (a) at 60 °C; (b) at 80 °C; (c) at 110 °C; (d) at 140 °C. (e) Pressure test of simulated asphaltene deposition in diluted heavy oil at different temperatures.

From Figure 3e, it can be concluded by analyzing the variation law of the deposition pressure of asphaltenes in simulated oil at different temperatures: Under the same mixing light oil ratio, as the temperature increases, the initial deposition pressure of asphaltenes decreases and the maximum deposition pressure increases, indicating that the deposition risk range of asphaltene decreases with a temperature rise. Similarly, the difference between the maximum pressure drop at both ends of the pipeline and the initial value of the pressure drop test indirectly characterizes the deposition at different temperatures. The deposition trend of heavy-oil asphaltenes proves that high-temperature conditions are more conducive to the stability of asphaltenes in crude oil.

According to the deposition characteristics of asphaltene in diluted simulated oil at different temperatures in Figure 3, it is found that the differential pressure signal of simulated oil decreases in the late stage of depressurization. The asphaltene aggregation accumulated in the filter is affected by the shearing effect of simulated oil and the local scouring effect around the filter screen, resulting in the “de-aggregation” or dispersion trend of aggregated asphaltenes, which is finally manifested in the reduction of differential pressure. Some researchers define this trend as the “re-dissolution” of asphaltene [19,20]. At the same time, the curve trend in Figure 3 shows that the difficulty of asphaltene “de-aggregation” is related to factors such as temperature, pressure, and asphaltene deposition. The higher the experimental temperature, the more pronounced the breakdown of asphaltene adsorbed to the pipeline and filter. The results of asphaltene deposition characteristics at 140 °C show that the differential pressure signal between 10~20 MPa can be reduced to the initial pressure drop near 60 MPa. This result is consistent with the results of Tokaman’s study of the effect of temperature on the accumulation of asphaltene using a Couette flow device [21].

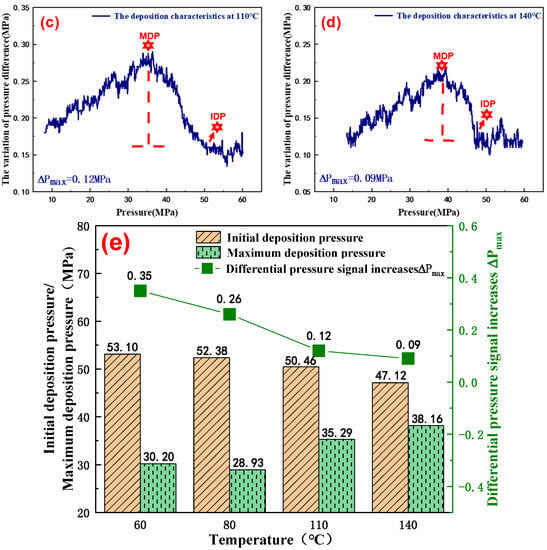

3.2. Mixing Light Oil Ratio Effect on Asphaltene Deposition

The diluted heavy oil in the oilfield is mixed evenly with the heavy crude from well A in Tahe block No.12 at a mass ratio of 0.5, 1.0, 1.5, and 2.0, and the corresponding volume of natural gas is pumped to prepare the simulated oil. The experimental device, feed rate, and withdraw rate of pump used here are the same as those in Section 2.2, “The effect of temperature on the deposition characteristics of asphaltene in diluted heavy oil”. The deposition characteristics of asphaltene in diluted heavy oil at 80 °C at different mixing light oil ratios are studied under isothermal depressurization, and test results are shown in Figure 4.

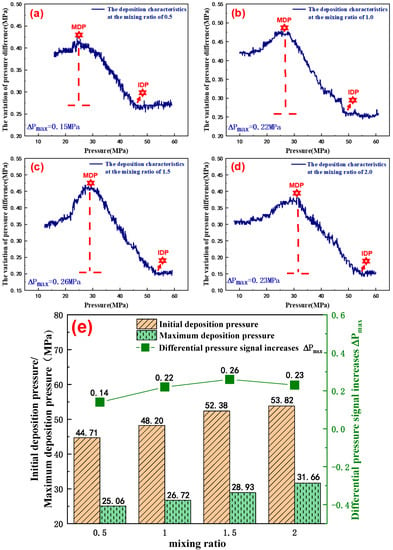

Figure 4.

The deposition characteristics of asphaltene in diluted heavy oil at different mixing light oil ratios: (a) at the mixing ratio of 0.5; (b) at the mixing ratio of 1.0; (c) at the mixing ratio of 1.5; (d) at the mixing ratio of 2.0. (e) Pressure test of simulated asphaltene deposition in diluted heavy oil at different mixing ratio.

From Figure 4e, it is observed that at the same temperature, the addition of light oil has a significant impact on the deposition characteristics of asphaltene in diluted heavy oil at different mixing light oil ratios (0.5, 1.0, 1.5, and 2.0). With the increase in the mixing light oil ratio, the initial deposition pressure of diluted heavy oil shows an increasing trend. This phenomenon implies that in the process of wellbore lifting, an increase in the mixing light oil ratio will easily cause the deposition position of asphaltene to shift to the deep zone of the oil well. At the same time, as the ratio increases from 0.5 to 1.5, the difference between the maximum pressure drop at both ends of the pipeline and the initial value of the pressure drop gradually increases. This increase proves that a high mixing light oil ratio will increase the probability of asphaltene deposition, and asphaltene deposits, hence blockage of the oil well, are more likely to happen. The dilution ratio of heavy oil continued to increase to 2.0, and the increase in pressure difference signal obtained from the simulated oil test did not continue to increase. But considering that the asphaltene components under a mixing ratio of 2.0 are less than those under a ratio of 1.0 in the same volume of simulated oil, it is believed that the amount of asphaltene precipitation per unit volume of heavy oil sample is larger at a mixing ratio of 2.0. It conforms to the characteristic law of the growing deposition tendency of asphaltenes at a high mixing ratio.

The reasons why the increase in mixing ratio causes a more obvious deposition tendency of asphaltene are as follows: The fraction of saturated hydrocarbons in the diluted heavy oil used in the experiments is as high as 75.39%. According to the crude oil colloid theory, colloids wrapped in the outer layer of asphaltene offer a favorable condition to prevent asphaltene precipitation and deposition [22]. A large amount of saturated hydrocarbon in light oil promotes the dissolution and opening of the outer colloid layer of asphaltene particles in heavy oil. Therefore, the probability of aggregation and collision between asphaltene particles increases. On the other hand, light crude contains more light components, and some light components continuously evolve from crude oil during the crude oil production process when the pressure gradually declines, showing a strong extraction effect that reduces the stability of diluted heavy oil and increases the possibility of asphaltene deposition.

3.3. The Effect of Sand Filling and Pipe Diameter Changes on Asphaltene Deposition

According to the mixing light oil ratio of 1.5, setting the test temperature to 80 °C, using crude oil flow properties of high-temperature and high-pressure test devices in conventional piping, quartz sand filling pipe, and variable diameter pipe, and carrying out experiments, respectively, to test the presence of solid particles in the pipe and the impact of pipe diameter changes on the asphaltene deposition simulation oil, the results are shown in Figure 5 and Figure 6.

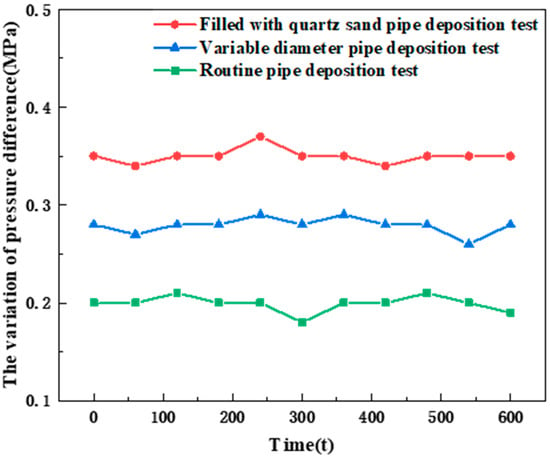

Figure 5.

Initial flow pressure drop test for different types of pipes.

Figure 6.

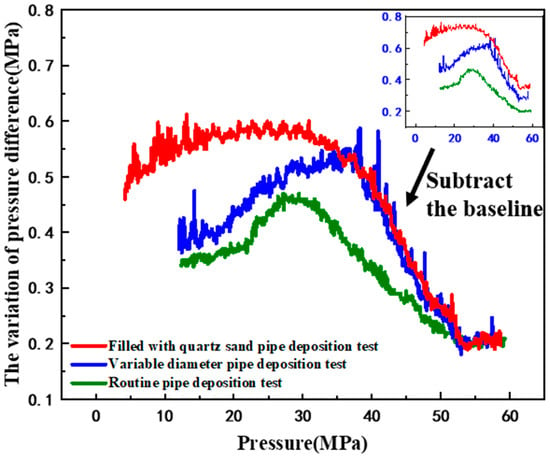

Test of asphaltene deposition characteristics of dilute heavy oil in different pipelines (baseline).

Figure 5 firstly tested the flow pressure drop of conventional pipelines, quartz sand-filled pipelines, and reduced-diameter pipelines with dilute heavy oil at constant temperature (80 °C) and constant pressure (60 MPa). After 10 min of test time, it is not difficult to find that both sand filling and pipe diameter changes caused the increase in flow pressure drop value, but the change in flow pressure drop caused by the change in pipe type can be traced. In the test results in Figure 6, the influence of pipeline change on flow pressure drop can be deducted through baseline operation.

Figure 6 baselines the test results of constant temperature and pressure reduction for three different types of pipelines. It is not difficult to see that the test pressure difference between a sand-filled pipeline and a diameter-changing pipeline is always higher than that of a conventional pipeline, which proves that the presence of solid particles in the pipeline and the diameter-changing of the pipeline will exacerbate the deposition of asphaltene in the pipeline. The analysis of the reasons is as follows: the first is Brownian motion, in which the filling of quartz sand and the changes in pipe diameter aggravate the chaotic motion of particles and the random collision between particles and fluid molecules; the second is turbulence mechanism, in which the change of the pipe causes the expansion of the fluid turbulent layer, and particles are carried together with these eddy currents and then intensify the deposition of asphaltene in the pipeline filter.

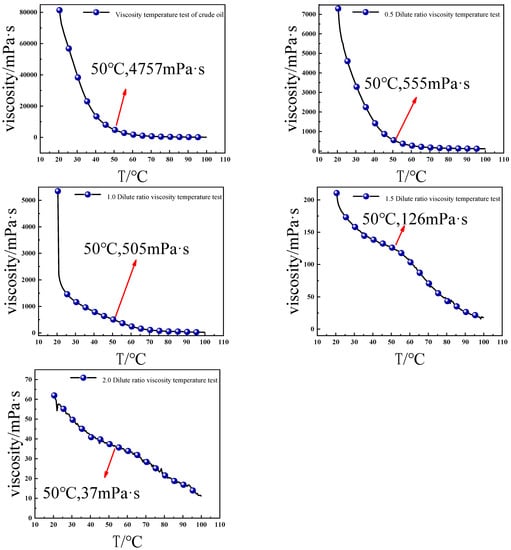

The problem of asphaltene deposition during diluted heavy oil production seriously restricts oil well production. With the aim of lessening the related impacts caused by asphaltene deposition in the crude oil production process, heating devices can be utilized during light oil injection to maintain or even increase the flow temperature of crude oil in the wellbore. The common electric pump power of the Tahe ultra-heavy oil well is about 35~45 Hz, and the maximum depth of pump hanging is about 3000 m. Reasonable mixing light oil ratios should be implemented to reduce the risk of asphaltene deposition in the deep zone of the oil well, on the condition of ensuring the smooth lifting of crude oil. Regarding the dilution ratio of heavy oil, it mainly depends on two aspects: first of all, dilution should achieve the viscosity reduction effect of improving the smooth production of crude oil, which is the main factor affecting the dilution ratio; second, with the increase in dilution ratio, asphaltene deposition and plugging should be reduced while fluidity is ensured. The best dilution ratio of heavy oil and light oil used in this project is about 1.5~2.0. According to Figure A1, the viscosity of heavy oil at the dilution ratio of 1.5 is significantly lower than that of 1.0 and 0.5, while the amount of asphaltene deposited at the dilution ratio of 1.5 is not significantly increased. At the same time, a dilute oil with a low saturated hydrocarbon content and a high aromatic hydrocarbon content should be selected as far as possible to reduce the risk of asphaltene deposition. At the same time, a periodic pipeline cleaning system should be established to guarantee the normal production of oil wells through relevant preventive measures such as injecting asphalt dispersant and shut-in after mixing light oil.

4. Conclusions

- (1)

- With the increase in temperature, the initial deposition pressure of asphaltene decreases, and the deposition risk interval of asphaltene shrinks. At the same time, the deposited asphaltene in diluted heavy oil becomes less. That is to say, high temperatures are conducive to increasing the solubility of asphaltene in crude oil.

- (2)

- The addition of light oil significantly impacts the deposition characteristics of asphaltene in diluted heavy crude. With the increase in the mixing ratio of simulated oil, the initial deposition pressure of diluted heavy oil shows a growing trend, which implies that in the process of wellbore lifting, the increase in the mixing ratio is likely to cause the deposition position of asphaltene to shift to the deep zone of the oil well. At the same time, a high mixing ratio causes a more obvious deposition tendency of asphaltene. Therefore, the production of heavy oil wells should be controlled to an appropriate mixing light oil ratio, which is of great significance to prevent the deposition of asphaltene in the reservoir and near the well.

- (3)

- The deposition of asphaltene in the pipeline is further aggravated by the presence of solid particles in the pipeline and the pipe diameter reduction caused by blockage.

Author Contributions

Conceptualization, Z.Y. and X.W.; investigation, J.Z. and L.L.; data curation X.W., R.X. and W.K.; writing—original draft preparation, Z.Y. and X.W.; writing—review and editing, J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, Research on the law and mechanism of asphaltene precipitation in high temperature and high pressure oil Wells [Project No. 52174047].

Data Availability Statement

Not applicable.

Acknowledgments

Thanks to the Foundation of Sinopec Key Laboratory of Enhanced Oil Recovery for Fractured Vuggy Reservoirs.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Viscosity temperature test of crude oil with different dilution ratios.

References

- Martínez-Palou, R.; Mosqueira, M.d.L.; Zapata-Rendón, B.; Mar-Juárez, E.; Bernal-Huicochea, C.; de la Cruz Clavel-López, J.; Aburto, J. Transportation of heavy and extra-heavy crude oil by pipeline: A review. J. Pet. Sci. Eng. 2011, 75, 274–282. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, W.; Wang, C.; Han, X.; Wang, H.; Zhang, H. Microstructure of Heavy Oil Components and Mechanism of Influence on Viscosity of Heavy Oil. ACS Omega 2023, 8, 10980–10990. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Guo, J.; An, N.; Ren, B.; Li, Y.; Jiang, Q. Study of asphaltene deposition from Tahe crude oil. Pet. Sci. 2013, 10, 134–138. [Google Scholar] [CrossRef]

- Poozesh, A.; Sharifi, M.; Fahimpour, J. Modeling of Asphaltene Deposition Kinetics. Energy Fuels 2020, 34, 9304–9319. [Google Scholar] [CrossRef]

- Schuler, B.; Zhang, Y.; Liu, F.; Pomerantz, A.E.; Andrews, A.B.; Gross, L.; Pauchard, V.; Banerjee, S.; Mullins, O.C. Overview of Asphaltene Nanostructures and Thermodynamic Applications. Energy Fuels 2020, 34, 15082–15105. [Google Scholar] [CrossRef]

- Enayat, S.; Rajan Babu, N.; Kuang, J.; Rezaee, S.; Lu, H.; Tavakkoli, M.; Wang, J.; Vargas, F.M. On the development of experimental methods to determine the rates of asphaltene precipitation, aggregation, and deposition. Fuel 2020, 260, 116250. [Google Scholar] [CrossRef]

- Alhosani, A.; Daraboina, N. Modeling of asphaltene deposition during oil/gas flow in wellbore. Fuel 2020, 280, 118617. [Google Scholar] [CrossRef]

- Eskin, D.; Ratulowski, J.; Akbarzadeh, K.; Pan, S. Modelling asphaltene deposition in turbulent pipeline flows. Can. J. Chem. Eng. 2011, 89, 421–441. [Google Scholar] [CrossRef]

- Vilas Bôas Fávero, C.; Hanpan, A.; Phichphimok, P.; Binabdullah, K.; Fogler, H.S. Mechanistic Investigation of Asphaltene Deposition. Energy Fuels 2016, 30, 8915–8921. [Google Scholar] [CrossRef]

- Schuler, B.; Meyer, G.; Peña, D.; Mullins, O.C.; Gross, L. Unraveling the Molecular Structures of Asphaltenes by Atomic Force Microscopy. J. Am. Chem. Soc. 2015, 137, 9870–9876. [Google Scholar] [CrossRef]

- Yaseen, S.; Mansoori, G.A. Asphaltene aggregation due to waterflooding (A molecular dynamics study). J. Pet. Sci. Eng. 2018, 170, 177–183. [Google Scholar] [CrossRef]

- Boek, E.S.; Wilson, A.D.; Padding, J.T.; Headen, T.F.; Crawshaw, J.P. Multi-scale Simulation and Experimental Studies of Asphaltene Aggregation and Deposition in Capillary Flow. Energy Fuels 2010, 24, 2361–2368. [Google Scholar] [CrossRef]

- Xiong, R.-Y.; Guo, J.-X.; Kiyingi, W.; Xu, H.-X.; Wu, X.-P. The deposition of asphaltenes under high-temperature and high-pressure (HTHP) conditions. Pet. Sci. 2023, 20, 611–618. [Google Scholar] [CrossRef]

- Shojaei, S.A.; Osfouri, S.; Azin, R.; Mousavi Dehghani, S.A. Kinetic modeling of asphaltene nano-aggregates formation using dynamic light scattering technique. J. Pet. Sci. Eng. 2020, 192, 107293. [Google Scholar] [CrossRef]

- Xiong, R.; Guo, J.; Kiyingi, W.; Luo, H.; Li, S. Asphaltene deposition under different injection gases and reservoir conditions. Chem. Eng. Res. Des. 2023, 194, 87–94. [Google Scholar] [CrossRef]

- Paridar, S.; Solaimany Nazar, A.R.; Karimi, Y. Experimental evaluation of asphaltene dispersants performance using dynamic light scattering. J. Pet. Sci. Eng. 2018, 163, 570–575. [Google Scholar] [CrossRef]

- Nguele, R.; Mbouopda Poupi, A.B.; Anombogo, G.A.M.; Alade, O.S.; Saibi, H. Influence of asphaltene structural parameters on solubility. Fuel 2022, 311, 122559. [Google Scholar] [CrossRef]

- Rammay, M.H.; Abdulraheem, A. PVT correlations for Pakistani crude oils using artificial neural network. J. Pet. Explor. Prod. Technol. 2017, 7, 217–233. [Google Scholar] [CrossRef]

- Wiehe, I.A. Asphaltene Solubility and Fluid Compatibility. Energy Fuels 2012, 26, 4004–4016. [Google Scholar] [CrossRef]

- Wang, M.; Hao, Y.; Islam, M.R.; Chen, C.-C. Aggregation thermodynamics for asphaltene precipitation. AIChE J. 2016, 62, 1254–1264. [Google Scholar] [CrossRef]

- Torkaman, M.; Bahrami, M.; Dehghani, M. Influence of Temperature on Aggregation and Stability of Asphaltenes. I. Perikinetic Aggregation. Energy Fuels 2017, 31, 11169–11180. [Google Scholar] [CrossRef]

- Boek, E.S.; Ladva, H.K.; Crawshaw, J.P.; Padding, J.T. Colloidal Asphaltene Deposition and Aggregation in Capillary Flow: Experiments and Mesoscopic Simulation. AIP Conf. Proc. 2008, 1027, 273–275. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).