Possibilities of RDF Pyrolysis Products Utilization in the Face of the Energy Crisis

Abstract

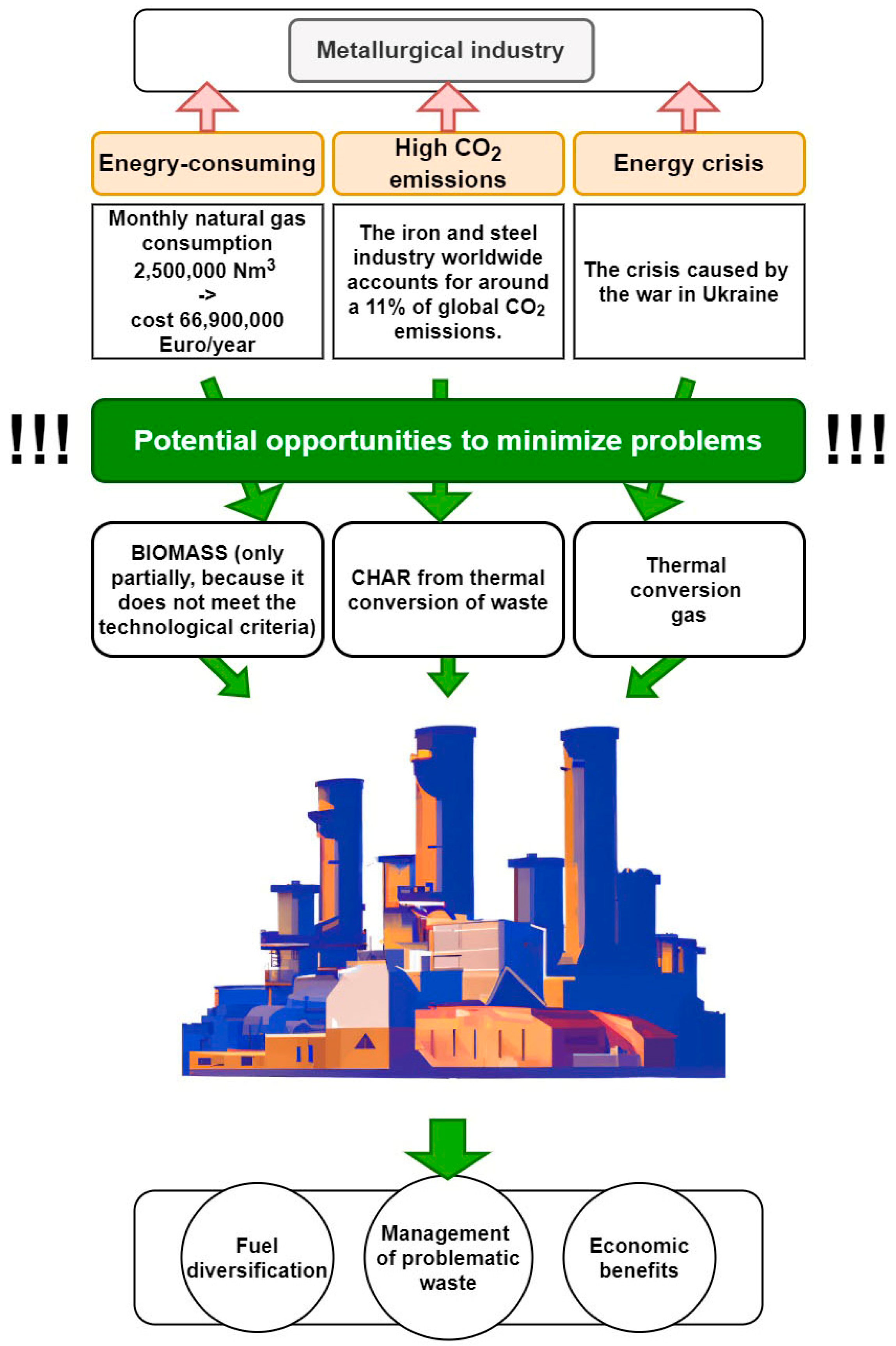

:1. Introduction

2. Theoretical Background

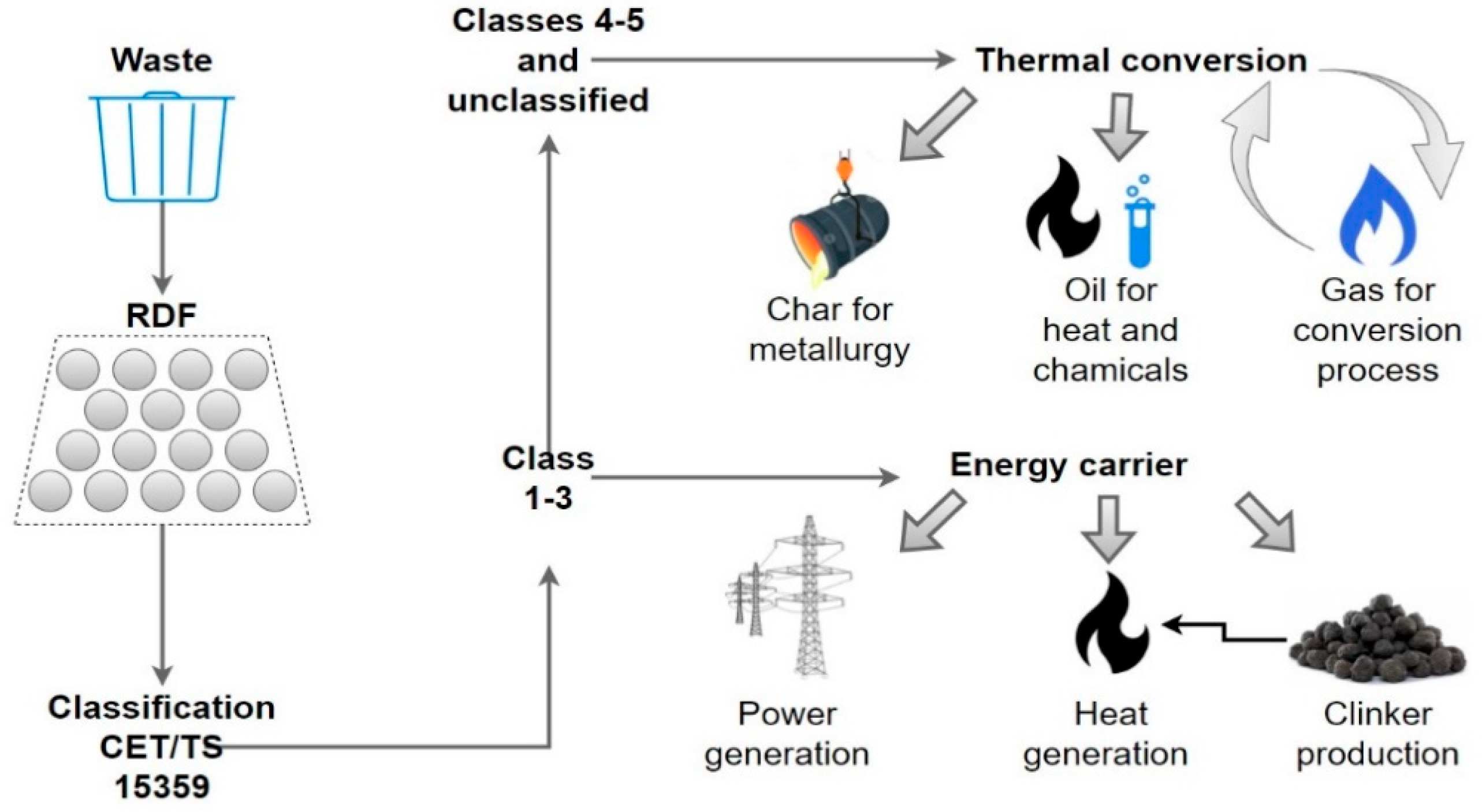

2.1. Energy Potential of RDF

2.2. Legal Background of Energy Recovery from RDF

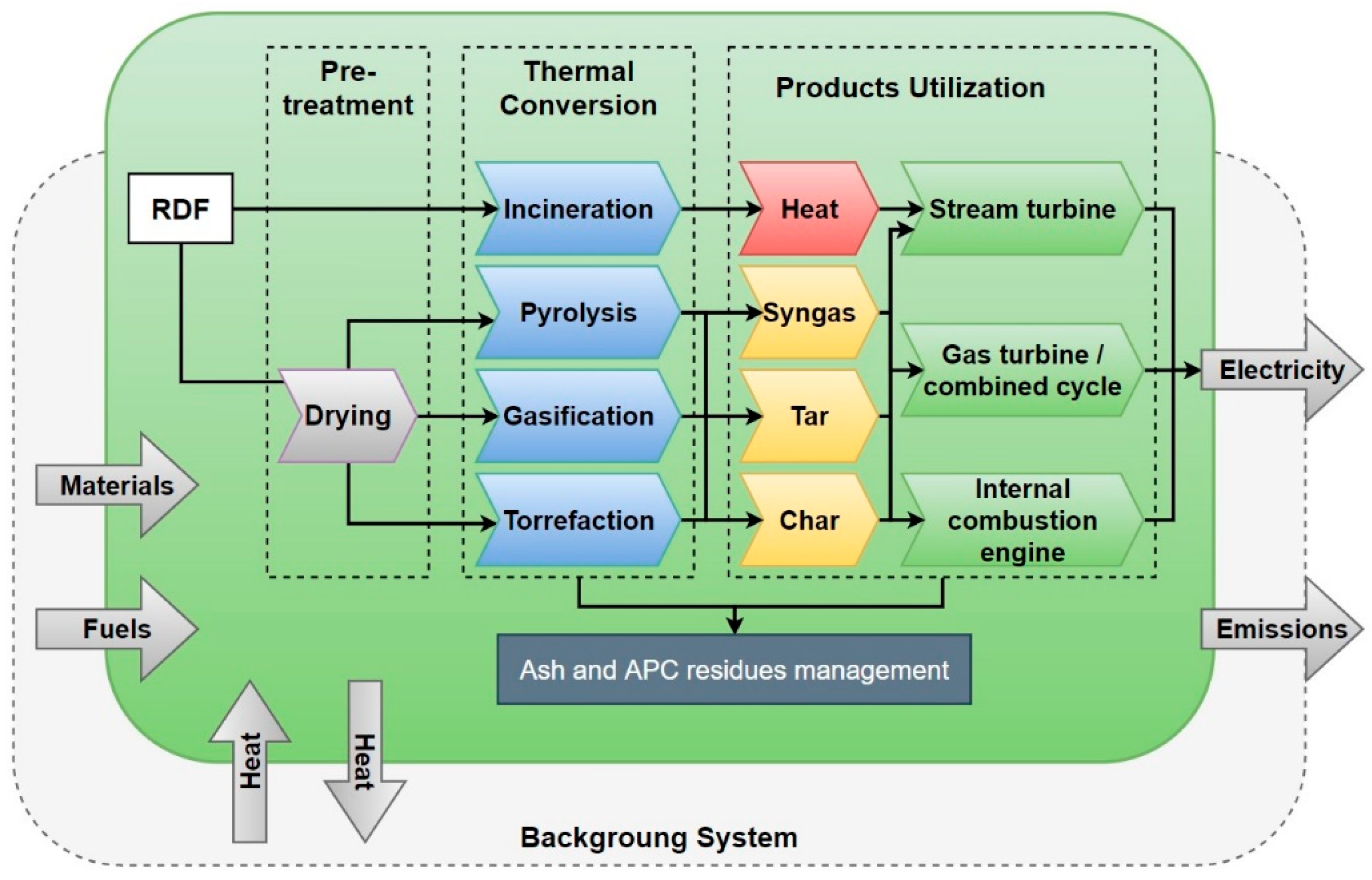

2.3. Processes of Thermal Conversion of Municipal Waste

| PYROLYSIS | |

|---|---|

|  |

|

|

| GASIFICATION | |

|---|---|

|  |

|

|

| TORREFACTION | |

|---|---|

|  |

|

|

| COMBUSTION | |

|---|---|

|  |

|

|

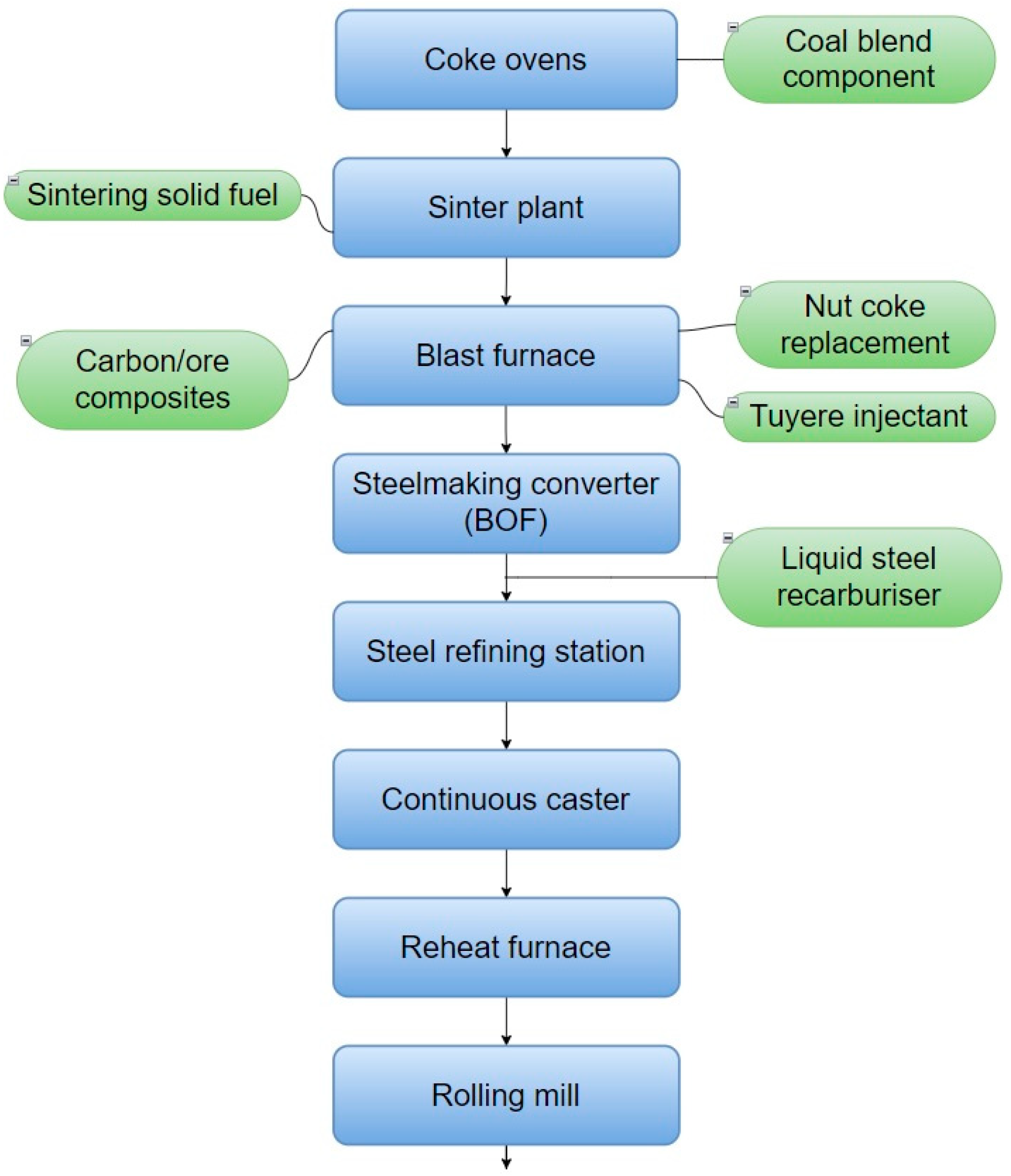

3. Possibilities of Using RDF Pyrolysis Products

- The possibility of managing the surplus RDF;

- The possibility of managing environmentally harmful plastic waste, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) [66], textile and rubber wastes, as well as gaseous products of thermal conversion of these wastes;

- coke ovens;

- sintering processes;

- blast furnace processes;

- carbonization of liquid steel.

4. Analysis of Strengths and Weaknesses of Generating Energy from RDF Pyrolysis Products

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Quek, A.; Balasubramanian, R. Life cycle assessment of energy and energy carriers from waste matter—A review. J. Clean. Prod. 2014, 79, 18–31. [Google Scholar] [CrossRef]

- Singh, A. Managing the uncertainty problems of municipal solid waste disposal. J. Environ. Manag. 2019, 240, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Di Giacomo, G.; Romano, P. Evolution and Prospects in Managing Sewage Sludge Resulting from Municipal Wastewater Purification. Energies 2022, 15, 5633. [Google Scholar] [CrossRef]

- Kundariya, N.; Mohanty, S.S.; Varjani, S.; Hao Ngo, H.; Wong, J.W.C.; Taherzadeh, M.J.; Chang, J.S.; Yong Ng, H.; Kim, S.H.; Bui, X.T. A review on integrated approaches for municipal solid waste for environmental and economical relevance: Monitoring tools, technologies, and strategic innovations. Bioresour. Technol. 2021, 342, 125982. [Google Scholar] [CrossRef]

- Das, A.K.; Islam, M.N.; Billah, M.M.; Sarker, A. COVID-19 and municipal solid waste (MSW) management: A review. Environ. Sci. Pollut. Res. 2021, 28, 28993–29008. [Google Scholar] [CrossRef]

- Ng, K.S.; Phan, A.N. Evaluating the Techno-economic Potential of an Integrated Material Recovery and Waste-to-Hydrogen System. Resour. Conserv. Recycl. 2021, 167, 105392. [Google Scholar] [CrossRef]

- Maj, I.; Matus, K. Aluminosilicate Clay Minerals: Kaolin, Bentonite, and Halloysite as Fuel Additives for Thermal Conversion of Biomass and Waste. Energies 2023, 16, 4359. [Google Scholar] [CrossRef]

- Chand Malav, L.; Yadav, K.K.; Gupta, N.; Kumar, S.; Sharma, G.K.; Krishnan, S.; Rezania, S.; Kamyab, H.; Pham, Q.B.; Yadav, S.; et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. J. Clean. Prod. 2020, 277, 123227. [Google Scholar] [CrossRef]

- Sieradzka, M.; Rajca, P.; Zajemska, M.; Mlonka-Mędrala, A.; Magdziarz, A. Prediction of gaseous products from refuse derived fuel pyrolysis using chemical modelling software—Ansys Chemkin-Pro. J. Clean. Prod. 2020, 248, 119277. [Google Scholar] [CrossRef]

- Rajca, P.; Poskart, A.; Chrubasik, M.; Sajdak, M.; Zajemska, M.; Skibiński, A.; Korombel, A. Technological and economic aspect of Refuse Derived Fuel pyrolysis. Renew. Energy 2020, 161, 482–494. [Google Scholar] [CrossRef]

- Wielgosiński, G. Review of waste thermal treatment technology. New Energy 2011, 1, 55–67. [Google Scholar]

- Xie, Y.; Wang, J.; Cai, X.; Huang, Z. Self-acceleration of cellular flames and laminar flame speed of syngas/air mixtures at elevated pressures. Int. J. Hydrogen Energy 2016, 41, 18250–18258. [Google Scholar] [CrossRef]

- Javed, N.; Muhammad, S.; Iram, S.; Ramay, M.W.; Jaffri, S.B.; Damak, M.; Fekete, G.; Varga, Z.; Székács, A.; Aleksza, L. Analysis of Fuel Alternative Products Obtained by the Pyrolysis of Diverse Types of Plastic Materials Isolated from a Dumpsite Origin in Pakistan. Polymers 2023, 15, 24. [Google Scholar] [CrossRef] [PubMed]

- Sanchis-Sebastiá, M.; Ruuth, E.; Stigsson, L.; Galbe, M.; Wallberg, O. Novel sustainable alternatives for the fashion industry: A method of chemically recycling waste textiles via acid hydrolysis. Waste Manag. 2021, 121, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Rollinson, A.N.; Oladejo, J.M. ‘Patented blunderings’ efficiency awareness, and self-sustainability claims in the pyrolysis energy from waste sector. Resour. Conserv. Recycl. 2019, 141, 233–242. [Google Scholar] [CrossRef]

- Peng, N.; Li, Y.; Liu, Z.; Liu, T.; Gai, C. Emission, distribution and toxicity of polycyclic aromatic hydrocarbons (PAHs) during municipal solid waste (MSW) and coal co-combustion. Sci. Total Environ. 2016, 565, 1201–1207. [Google Scholar] [CrossRef]

- Jouhara, H.; Olabi, A.G. Editorial: Industrial waste heat recovery. Energy 2018, 160, 1–2. [Google Scholar] [CrossRef]

- Sun, Y.; Seetharaman, S.; Liu, Q.; Zhang, Z.; Liu, L.; Wang, X. Integrated biomass gasification using the waste heat from hot slags: Control of syngas and polluting gas releases. Energy 2016, 114, 165–176. [Google Scholar] [CrossRef]

- Perondi, D.; Poletto, P.; Restelatto, D.; Manera, C.; Silva, J.P.; Junges, J.; Collazzo, G.C.; Dettmer, A.; Godinho, M.; Vilela, A.C.F. Steam gasification of poultry litter biochar for bio-syngas production. Process Saf. Environ. Prot. 2017, 109, 478–488. [Google Scholar] [CrossRef]

- Zajemska, M.; Sajdak, M.; Iwaszko, J.; Skrzyniarz, M.; Biniek-Poskart, A.; Skibi, A.; Maroszek. A. The role of calorific waste in transformation of iron and steel industry towards sustainable production. Resour. Conserv. Recycl. 2023, 191, 2022–2024. [Google Scholar] [CrossRef]

- Násner, A.M.L.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Restrepo, J.C.; Venturini, O.J.; Ratner, A. Refuse Derived Fuel (RDF) production and gasification in a pilot plant integrated with an Otto cycle ICE through Aspen plusTM modelling: Thermodynamic and economic viability. Waste Manag. 2017, 69, 187–201. [Google Scholar] [CrossRef] [PubMed]

- Bensidhom, G.; Ben Hassen-Trabelsi, A.; Alper, K.; Sghairoun, M.; Zaafouri, K.; Trabelsi, I. Pyrolysis of Date palm waste in a fixed-bed reactor: Characterization of pyrolytic products. Bioresour. Technol. 2018, 247, 363–369. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.T.; Lee, H.T.; Juch, C.I.; Wan, H.P.; Shim, H.S.; Adams, B.R.; Chen, S.L. Study of syngas co-firing and reburning in a coal fired boiler. Fuel 2004, 83, 1991–2000. [Google Scholar] [CrossRef]

- Malinowski, A.; Chwiałkowski, W. Energy recycling of RDF fraction of municipal solid waste by continuous pyrolysis. Chem. Environ. Biotechnol. 2017, 20, 27–33. [Google Scholar] [CrossRef]

- Gerassimidou, S.; Velis, C.A.; Williams, P.T.; Komilis, D. Characterisation and composition identification of waste-derived fuels obtained from municipal solid waste using thermogravimetry: A review. Waste Manag. Res. 2020, 38, 942–965. [Google Scholar] [CrossRef]

- Rajca, P.; Skibiński, A.; Biniek-Poskart, A.; Zajemska, M. Review of Selected Determinants Affecting Use of Municipal Waste for Energy Purposes. Energies 2022, 15, 57. [Google Scholar] [CrossRef]

- Variny, M.; Varga, A.; Rimár, M.; Janošovský, J.; Kizek, J.; Lukáč, L.; Jablonský, G.; Mierka, O. Advances in biomass co-combustion with fossil fuels in the European context: A review. Processes 2021, 9, 100. [Google Scholar] [CrossRef]

- Rozporządzenie Ministra Gospodarki z dnia 16 lipca 2015 r. w Sprawie Dopuszczania Odpadów do Składowania na Składowiskach, Dz.U. 2015 poz. 1277. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150001277/O/D20151277.pdf (accessed on 15 July 2023).

- Berardi, P.; Almeida, M.F.; de Lopes, M.; Maia Dias, J. Analysis of Portugal’s refuse derived fuel strategy, with particular focus on the northern region. J. Clean. Prod. 2020, 277, 123262. [Google Scholar] [CrossRef]

- Hussain, S.A.; Razi, F.; Hewage, K.; Sadiq, R. The perspective of energy poverty and 1st energy crisis of green transition. Energy 2023, 275, 127487. [Google Scholar] [CrossRef]

- Ochoa-Barragán, R.; Munguía-López, A.d.C.; Ponce-Ortega, J.M. A hybrid machine learning-mathematical programming optimization approach for municipal solid waste management during the pandemic. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Durak, H. Comprehensive Assessment of Thermochemical Processes for Sustainable Waste Management and Resource Recovery. Processes 2023, 11, 2092. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Aboughaly, M.; Ayoub, N. Comparative study of MSW heat treatment processes and electricity generation. J. Energy Inst. 2018, 91, 481–488. [Google Scholar] [CrossRef]

- Zhang, S.; Yi, B.W.; Worrell, E.; Wagner, F.; Crijns-Graus, W.; Purohit, P.; Wada, Y.; Varis, O. Integrated assessment of resource-energy-environment nexus in China’s iron and steel industry. J. Clean. Prod. 2019, 232, 235–249. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Wasielewski, R.; Bałazińska, M. Energy recovery from waste in the aspect of qualificationsof electricity and heat as coming from renewable energysources and to participate in the emissions trading system. Energy Policy J. 2018, 21, 129–142. [Google Scholar]

- Kumar, A.; Agrawal, A. Recent trends in solid waste management status, challenges, and potential for the future Indian cities—A review. Curr. Res. Environ. Sustain. 2020, 2, 100011. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef]

- Chen, D.; Yin, L.; Wang, H.; He, P. Pyrolysis technologies for municipal solid waste: A review. Waste Manag. 2014, 34, 2466–2486. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Oasmaa, A.; Pihkola, H.; Deviatkin, I.; Tenhunen, A.; Mannila, J.; Minkkinen, H.; Pohjakallio, M.; Laine-Ylijoki, J. Pyrolysis of plastic waste: Opportunities and challenges. J. Anal. Appl. Pyrolysis 2020, 152, 104804. [Google Scholar] [CrossRef]

- Primus, A.; Rosik-Dulewska, C. Energy production in low-power cogeneration systems usingthe gasification technology of post-municipal waste.The legal and economic conditions. Energy Policy J. 2017, 20, 79–92. [Google Scholar]

- Sajdak, M.; Muzyka, R.; Gałko, G.; Ksepko, E.; Zajemska, M.; Sobek, S.; Tercki, D. Actual Trends in the Usability of Biochar as a High-Value Product of Biomass Obtained through Pyrolysis. Energies 2023, 16, 355. [Google Scholar] [CrossRef]

- Mousa, E.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass applications in iron and steel industry: An overview of challenges and opportunities. Renew. Sustain. Energy Rev. 2016, 65, 1247–1266. [Google Scholar] [CrossRef]

- Edo, M.; Skoglund, N.; Gao, Q.; Persson, P.E.; Jansson, S. Fate of metals and emissions of organic pollutants from torrefaction of waste wood, MSW, and RDF. Waste Manag. 2017, 68, 646–652. [Google Scholar] [CrossRef] [PubMed]

- Malindzakova, M.; Strąka, M.; Rosova, A.; Kanuchova, M.; Trebuna, P. Modeling the process for incineration of municipal waste. Chem. Ind. 2015, 94, 1260–1264. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y. Key factors influencing the environmental performance of pyrolysis, gasification and incineration Waste-to-Energy technologies. Energy Convers. Manag. 2019, 196, 497–512. [Google Scholar] [CrossRef]

- Korombel, A.; Ławińska, O.; Zajemska, M. Pyrolysis-Based Municipal Solid Waste Management in Poland—SWOT Analysis. Energies 2022, 15, 510. [Google Scholar]

- Zajemska, M.; Rajca, P.; Szwaja, S.; Morel, S. The chemical mechanism of the HCl formation in the pyrolysis process of selected wastes. Przemysł Chem. 2019, 98, 907–910. [Google Scholar]

- Czajczyńska, D.; Anguilano, L.; Ghazal, H.; Krzyżyńska, R.; Reynolds, A.J.; Spencer, N.; Jouhara, H. Potential of pyrolysis processes in the waste management sector. Therm. Sci. Eng. Prog. 2017, 3, 171–197. [Google Scholar] [CrossRef]

- Skrzyniarz, M. Directions of plastic waste management in the era of COVID-19. Mater. Econ. Logist. J. 2021, 08, 25–31. [Google Scholar] [CrossRef]

- Piechocki, J.; Sołowiej, P.; Neugebauer, M. Gasification of waste miomass from agricultural production. Agric. Eng. 2010, 5, 219–224. [Google Scholar]

- Białowiec, A.; Pulka, J.; Stępień, P.; Manczarski, P.; Gołaszewski, J. The RDF/SRF torrefaction: An effect of temperature on characterization of the product—Carbonized Refuse Derived Fuel. Waste Manag. 2017, 70, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Nobre, C.; Vilarinho, C.; Alves, O.; Mendes, B.; Gonçalves, M. Upgrading of refuse derived fuel through torrefaction and carbonization: Evaluation of RDF char fuel properties. Energy 2019, 181, 66–76. [Google Scholar] [CrossRef]

- Nobre, C.; Alves, O.; Longo, A.; Vilarinho, C.; Gonçalves, M. Torrefaction and carbonization of refuse derived fuel: Char characterization and evaluation of gaseous and liquid emissions. Bioresour. Technol. 2019, 285, 121325. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Liao, Y.; Chen, Y.; Ma, X. Insight into the gas pollutants emission of rural solid waste during the gasification-combustion process: Influencing factors and mechanisms. Fuel 2024, 355, 129510. [Google Scholar] [CrossRef]

- Mentes, D.; Nagy, G.; Szabó, T.J.; Hornyák-Mester, E.; Fiser, B.; Viskolcz, B.; Póliska, C. Combustion behaviour of plastic waste—A case study of PP, HDPE, PET, and mixed PES-EL. J. Clean. Prod. 2023, 402, 136850. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Z.; Zhang, Y.; Guo, T.; Li, Y.; Hopke, P.K.; Li, X. Volatility distribution of primary organic aerosol emissions from household crop waste combustion in China. Environ. Pollut. 2023, 323, 121353. [Google Scholar] [CrossRef]

- Jagodzińska, K.; Zaini, I.N.; Svanberg, R.; Yang, W.; Jönsson, P.G. Pyrolysis of excavated waste from landfill mining: Characterisation of the process products. J. Clean. Prod. 2021, 279, 123541. [Google Scholar] [CrossRef]

- Kijo-Kleczkowska, A.; Gnatowski, A. Recycling of PlasticWaste, with Particular Emphasis on Thermal Methods—Review. Energies 2022, 15, 2114. [Google Scholar] [CrossRef]

- Gałko, G.; Mazur, I.; Rejdak, M.; Jagustyn, B.; Hrabak, J.; Ouadi, M.; Jahangiri, H.; Sajdak, M. Evaluation of alternative refuse-derived fuel use as a valuable resource in various valorised applications. Energy 2023, 263, 125920. [Google Scholar] [CrossRef]

- Simshauser, P. The 2022 energy crisis: Fuel poverty and the impact of policy interventions in Australia’s National Electricity Market. Energy Econ. 2023, 121, 106660. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Masláni, A.; Hlína, M.; Fathi, J.; Mates, T.; Pohorelý, M.; Meers, E.; Syc, M.; Jeremiás, M. Thermal plasma assisted pyrolysis and gasification of RDF by utilizing sequestered CO2 as gasifying agent. J. CO2 Util. 2022, 66, 102275. [Google Scholar] [CrossRef]

- Ooi, T.C.; Thompson, D.; Anderson, D.R.; Fisher, R.; Fray, T.; Zandi, M. The effect of charcoal combustion on iron-ore sintering performance and emission of persistent organic pollutants. Combust. Flame 2011, 158, 979–987. [Google Scholar] [CrossRef]

- Zajemska, M.; Magdziarz, A.; Iwaszko, J.; Skrzyniarz, M.; Poskart, A. Numerical and experimental analysis of pyrolysis process of RDF containing a high percentage of plastic waste. Fuel 2022, 320, 123981. [Google Scholar] [CrossRef]

- Smoliński, A.; Wojtacha-Rychter, K.; Król, M.; Magdziarczyk, M.; Polański, J.; Howaniec, N. Co-gasification of refuse-derived fuels and bituminous coal with oxygen/steam blend to hydrogen rich gas. Energy 2022, 254, 124210. [Google Scholar] [CrossRef]

- Gałko, G.; Rejdak, M.; Tercki, D.; Bogacka, M.; Sajdak, M. Evaluation of the applicability of polymeric materials to BTEX and fine product transformation by catalytic and non-catalytic pyrolysis as a part of the closed loop material economy. J. Anal. Appl. Pyrolysis 2021, 154, 105017. [Google Scholar] [CrossRef]

- Szwaja, S.; Zajemska, M.; Szwaja, M.; Maroszek, A. Integration of waste biomass thermal processing technology with a metallurgical furnace to improve its efficiency and economic benefit. Clean Technol. Environ. Policy 2023, 25, 577–587. [Google Scholar] [CrossRef]

- Manyà, J.J.; García-Ceballos, F.; Azuara, M.; Latorre, N.; Royo, C. Pyrolysis and char reactivity of a poor-quality refuse-derived fuel (RDF) from municipal solid waste. Fuel Process. Technol. 2015, 140, 276–284. [Google Scholar] [CrossRef]

- Chavando, J.A.M.; de Matos, E.C.J.; Silva, V.B.; Tarelho, L.A.C.; Cardoso, J.S. Pyrolysis characteristics of RDF and HPDE blends with biomass. Int. J. Hydrogen Energy 2022, 47, 19901–19915. [Google Scholar] [CrossRef]

- Zaini, I.N.; García López, C.; Pretz, T.; Yang, W.; Jönsson, P.G. Characterization of pyrolysis products of high-ash excavated-waste and its char gasification reactivity and kinetics under a steam atmosphere. Waste Manag. 2019, 97, 149–163. [Google Scholar] [CrossRef]

- Czajczyńska, D.; Krzyżyńska, R.; Jouhara, H.; Spencer, N. Use of pyrolytic gas from waste tire as a fuel: A review. Energy 2017, 134, 1121–1131. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Haghighi, M.N.; Yeganeh, H.; McDonald, A.G. Evaluation of pyrolysis process parameters on polypropylene degradation products. J. Anal. Appl. Pyrolysis 2014, 109, 272–277. [Google Scholar] [CrossRef]

- Veses, A.; Sanahuja-Parejo, O.; Callén, M.S.; Murillo, R.; García, T. A combined two-stage process of pyrolysis and catalytic cracking of municipal solid waste for the production of syngas and solid refuse-derived fuels. Waste Manag. 2020, 101, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.S.; Chang, Y.; Poon, C.S.; Lee, D.J. Slow pyrolysis of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef]

- Pressley, P.N.; Aziz, T.N.; Decarolis, J.F.; Barlaz, M.A.; He, F.; Li, F.; Damgaard, A. Municipal solid waste conversion to transportation fuels: A life-cycle estimation of global warming potential and energy consumption. J. Clean. Prod. 2014, 70, 145–153. [Google Scholar] [CrossRef]

- Czajczyńska, D.; Nannou, T.; Anguilano, L.; Krzyzyńska, R.; Ghazal, H.; Spencer, N.; Jouhara, H. Potentials of pyrolysis processes in the waste management sector. Energy Procedia 2017, 123, 387–394. [Google Scholar] [CrossRef]

- Ouadi, M.; Jaeger, N.; Greenhalf, C.; Santos, J.; Conti, R.; Hornung, A. Thermo-Catalytic Reforming of municipal solid waste. Waste Manag. 2017, 68, 198–206. [Google Scholar] [CrossRef]

- Zhang, H.L. Pyrolysis Properties of Municipal Organic Wastes and Study on the Improvement Effects of Biochar on Soil; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Fombu, A.H.; Ochonogor, A.E. Design and Construction of a Semi-batch Pyrolysis Reactor for the Production of Biofuel. IOP Conf. Ser. Earth Environ. Sci. 2021, 730, 012041. [Google Scholar] [CrossRef]

- Ślefarski, R.; Jójka, J.; Czyżewski, P.; Gołębiewski, M.; Jankowski, R.; Markowski, J.; Magdziarz, A. Experimental and Numerical-Driven Prediction of Automotive Shredder Residue Pyrolysis Pathways toward Gaseous Products. Energies 2021, 14, 1779. [Google Scholar] [CrossRef]

- Xue, Y.; Zhou, S.; Brown, R.C.; Kelkar, A.; Bai, X. Fast pyrolysis of biomass and waste plastic in a fluidized bed reactor. Fuel 2015, 156, 40–46. [Google Scholar] [CrossRef]

- Eke, J.; Onwudili, J.A.; Bridgwater, A.V. Influence of Moisture Contents on the Fast Pyrolysis of Trommel Fines in a Bubbling Fluidized Bed Reactor. Waste Biomass Valorization 2019, 11, 3711–3722. [Google Scholar] [CrossRef]

- Fan, Z.; Friedmann, S.J. Low-carbon production of iron and steel: Technology options, economic assessment, and policy. Joule 2021, 5, 829–862. [Google Scholar] [CrossRef]

- Li, Z.; Hanaoka, T. Plant-level mitigation strategies could enable carbon neutrality by 2060 and reduce non-CO2 emissions in China’s iron and steel sector. One Earth 2022, 5, 932–943. [Google Scholar] [CrossRef]

- Khanna, R.; Li, K.; Wang, Z.; Sun, M.; Zhang, J.; Mukherjee, P.S. Biochars in Iron and Steel Industries; Elsevier: Amsterdam, The Netherlands, 2019; Volume 2017, pp. 429–446. [Google Scholar]

- Griffin, P.W.; Hammond, G.P. The prospects for ‘green steel’ making in a net-zero economy: A UK perspective. Glob. Transit. 2021, 3, 72–86. [Google Scholar] [CrossRef]

- Somers, J.; Moya, J. Decarbonisation of industrial heat: The iron and steel sector. Ee-IpOrg 2020, 4. Available online: https://setis.ec.europa.eu/decarbonisation-industrial-heat-iron-and-steel-sector_en (accessed on 15 July 2023).

- Zhang, S.; Worrell, E.; Crijns-Graus, W.; Wagner, F.; Cofala, J. Co-benefits of energy efficiency improvement and air pollution abatement in the Chinese iron and steel industry. Energy 2014, 78, 333–345. [Google Scholar] [CrossRef]

- Bailera, M.; Lisbona, P.; Peña, B.; Romeo, L.M. A review on CO2 mitigation in the Iron and Steel industry through Power to X processes. J. CO2 Util. 2021, 46, 101456. [Google Scholar] [CrossRef]

- Shukla, I. Potential of renewable agricultural wastes in the smart and sustainable steelmaking process. J. Clean. Prod. 2022, 370, 133422. [Google Scholar] [CrossRef]

- Mallett, A.; Pal, P. Green transformation in the iron and steel industry in India: Rethinking patterns of innovation. Energy Strategy Rev. 2022, 44, 100968. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, S.; Peng, T.; Ou, X. A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew. Sustain. Energy Rev. 2021, 143, 110846. [Google Scholar] [CrossRef]

- Lukáč, L.; Kizek, J.; Jablonský, G.; Karakash, Y. Defining the Mathematical Dependencies of NOx and CO Emission Generation after Biomass Combustion in Low-Power Boiler. Civ. Environ. Eng. Rep. 2019, 29, 153–163. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Y.; Li, H.; Tao, Y.; De Clercq, D. Quantitative analysis of the precise energy conservation and emission reduction path in China’s iron and steel industry. J. Environ. Manag. 2019, 246, 717–729. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Zhang, Q.; Xu, L.; Tian, S.; Wang, P. Future CO2 emission trends and radical decarbonization path of iron and steel industry in China. J. Clean. Prod. 2021, 326, 129354. [Google Scholar] [CrossRef]

- Rousset, P.; Figueiredo, C.; De Souza, M.; Quirino, W. Pressure effect on the quality of eucalyptus wood charcoal for the steel industry: A statistical analysis approach. Fuel Process. Technol. 2011, 92, 1890–1897. [Google Scholar] [CrossRef]

- Chan, W.P.; Veksha, A.; Lei, J.; Oh, W.-D.; Dou, X.; Giannis, A.; Lisak, G.; Lim, T.T. A novel real-time monitoring and control system for waste-to-energy gasification process employing differential temperature profiling of a downdraft gasifier. J. Environ. Manag. 2019, 234, 65–74. [Google Scholar] [CrossRef]

- Li, F.; He, X.; Shoemaker, C.A.; Wang, C.H. Experimental and numerical study of biomass catalytic pyrolysis using Ni2P-loaded zeolite: Product distribution, characterization and overall benefit. Energy Convers. Manag. 2020, 208, 112581. [Google Scholar] [CrossRef]

- Liu, Y.; Xue, L.; Ma, J.; Peng, C.; Bai, F.; Li, Y.; Zhao, J. Three-dimensional numerical simulation, energy efficiency and economic benefit estimation of oil shale in situ pyrolysis process. Geoenergy Sci. Eng. 2023, 227, 211804. [Google Scholar] [CrossRef]

- Škrbić, S.; Ašonja, A.; Prodanović, R.; Ristić, V.; Stevanović, G.; Vulić, M.; Janković, Z.; Radosavac, A.; Igić, S. Analysis of plant-production-obtained biomass in function of sustainable energy. Sustainability 2020, 12, 5486. [Google Scholar] [CrossRef]

| PAHs | Process Temperature | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 500 °C | 600 °C | 700 °C | 800 °C | 900 °C | ||||||

| Type of thermally converted fuel | ||||||||||

| MSW | MSW/Coal | MSW | MSW/Coal | MSW | MSW/Coal | MSW | MSW/Coal | MSW | MSW/Coal | |

| 2-ring | 57.3 | 21.3 | 184.0 | 41.2 | 288.1 | 44.4 | 43.42 | 22.73 | 400.0 | 25.2 |

| 3-ring | 671.8 | 67.26 | 1221.6 | 108.1 | 4283.7 | 257.9 | 5619.3 | 285.2 | 3078.9 | 884.5 |

| 4-ring | 225.5 | 5.30 | 783.8 | 9.6 | 4040.6 | 15.2 | 1110.2 | 9.2 | 2002.3 | 1132.5 |

| 5-ring | 14.4 | 0.52 | 98.9 | 0.2 | 835.4 | 4.9 | 100.1 | 0.1 | 235.8 | 70.9 |

| 6-ring | 3.36 | 0.06 | 30.6 | 0.0 | 201.2 | 2.0 | 0.4 | 0.1 | 119.1 | 37.5 |

| Sum | 972.4 | 94.60 | 2319.0 | 159.2 | 9649.1 | 324.5 | 6873.4 | 317.5 | 5836.2 | 2150.8 |

| Parameters | Units | Acceptable Limits Values |

|---|---|---|

| Total moisture content | % | ≤18.0 |

| Total sulfur content (operating condition) | % | ≤0.5 |

| Chlorine content (dry state) | % | ≤0.7 |

| LHV (operating condition) | GJ/Mg | ≥20.0 |

| Strengths | Weaknesses |

|---|---|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrzyniarz, M.; Sajdak, M.; Zajemska, M.; Biniek-Poskart, A.; Iwaszko, J.; Skibiński, A. Possibilities of RDF Pyrolysis Products Utilization in the Face of the Energy Crisis. Energies 2023, 16, 6695. https://doi.org/10.3390/en16186695

Skrzyniarz M, Sajdak M, Zajemska M, Biniek-Poskart A, Iwaszko J, Skibiński A. Possibilities of RDF Pyrolysis Products Utilization in the Face of the Energy Crisis. Energies. 2023; 16(18):6695. https://doi.org/10.3390/en16186695

Chicago/Turabian StyleSkrzyniarz, Magdalena, Marcin Sajdak, Monika Zajemska, Anna Biniek-Poskart, Józef Iwaszko, and Andrzej Skibiński. 2023. "Possibilities of RDF Pyrolysis Products Utilization in the Face of the Energy Crisis" Energies 16, no. 18: 6695. https://doi.org/10.3390/en16186695

APA StyleSkrzyniarz, M., Sajdak, M., Zajemska, M., Biniek-Poskart, A., Iwaszko, J., & Skibiński, A. (2023). Possibilities of RDF Pyrolysis Products Utilization in the Face of the Energy Crisis. Energies, 16(18), 6695. https://doi.org/10.3390/en16186695