Monitoring and Preventing Failures of Transmission Pipelines at Oil and Natural Gas Plants

Abstract

1. Introduction

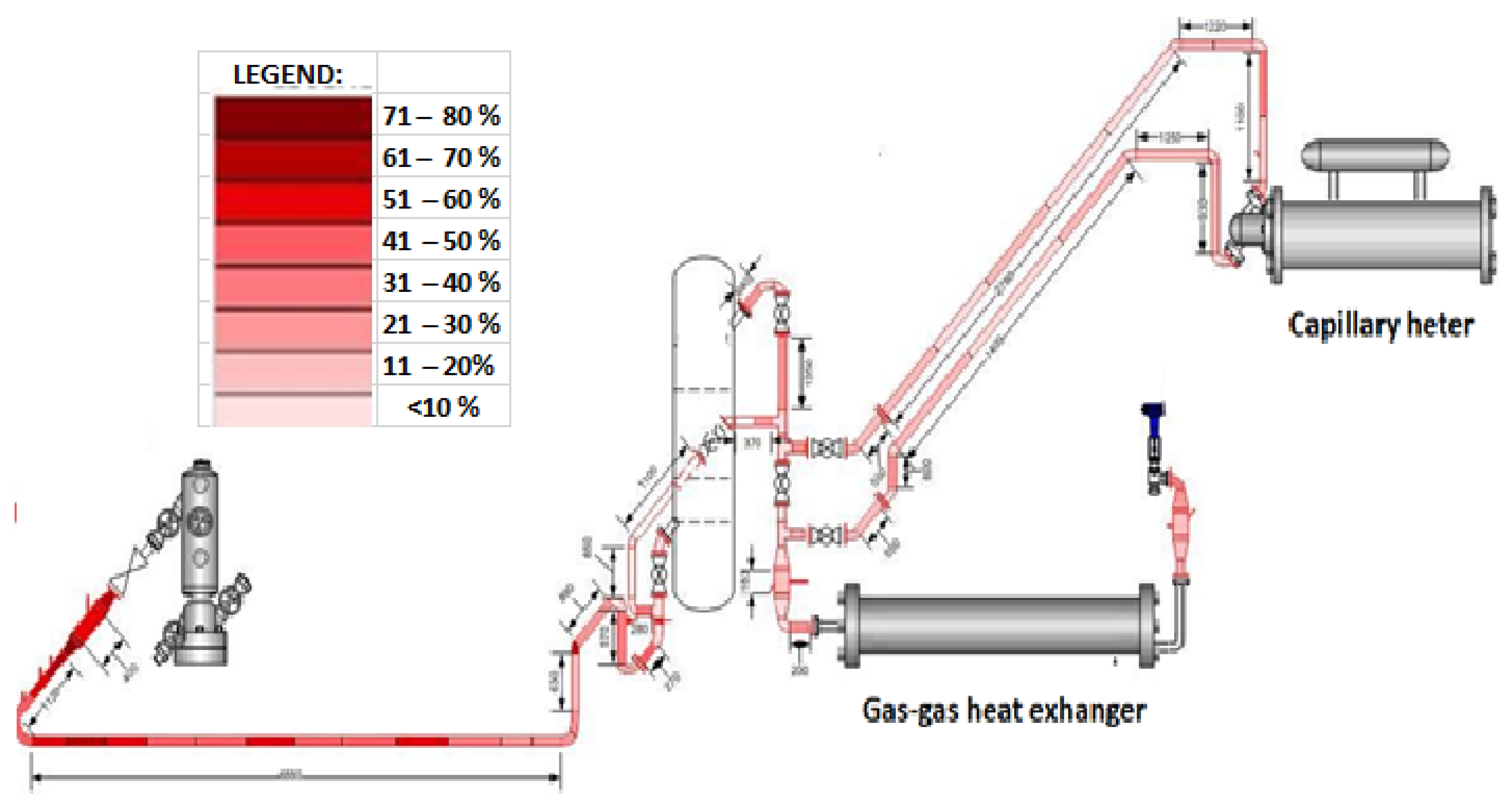

2. Monitoring and Prevention of Pipeline Failures—Research Activities and New Approaches

3. Inhibitors Used for Corrosion Protection

4. Materials and Research Methods

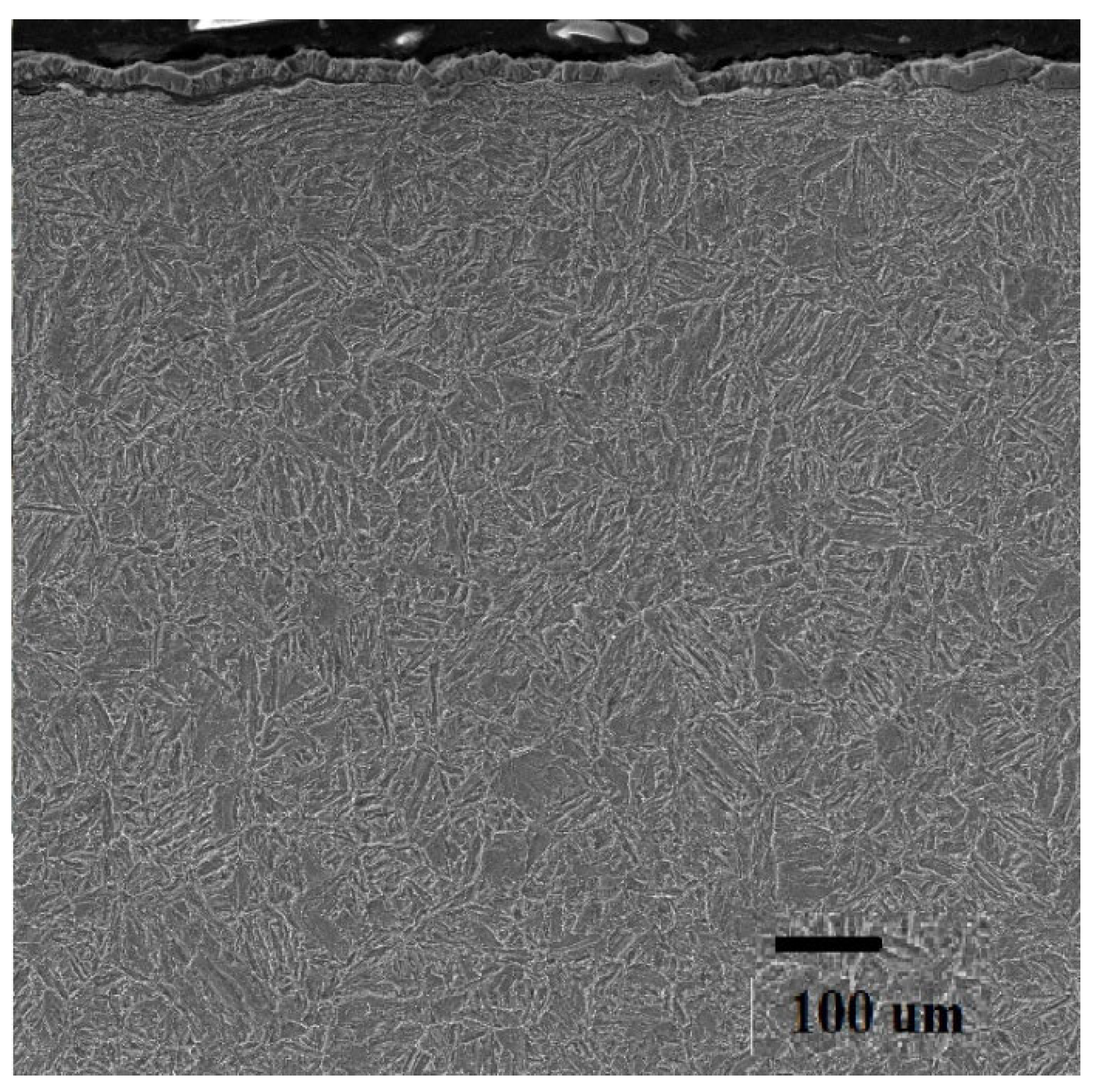

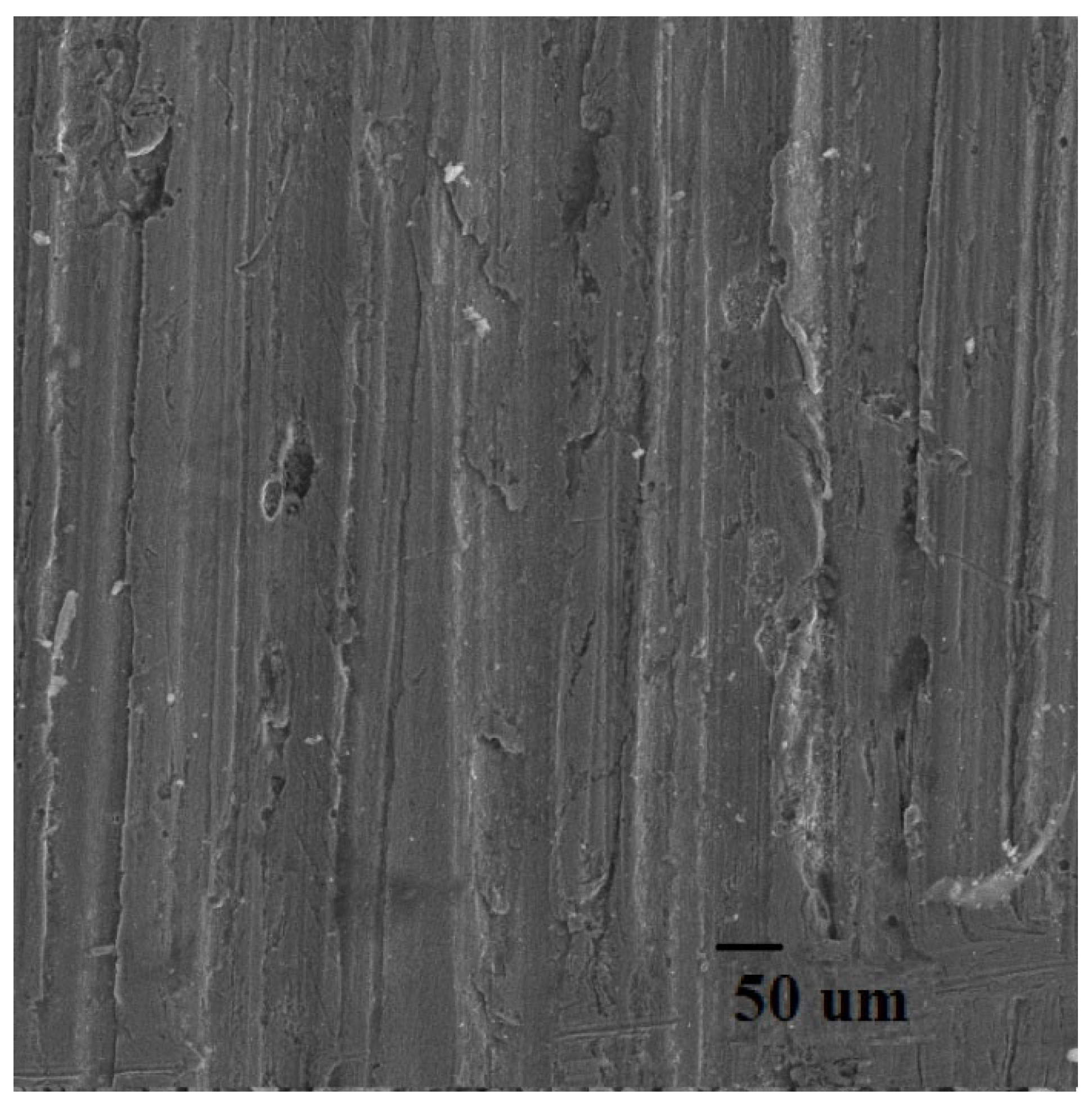

- SEM-EDS scanning microscope photographs of the sample surface were taken.

- Analysis of the chemical composition on the surface of the sample was performed using an X-ray microanalyzer.

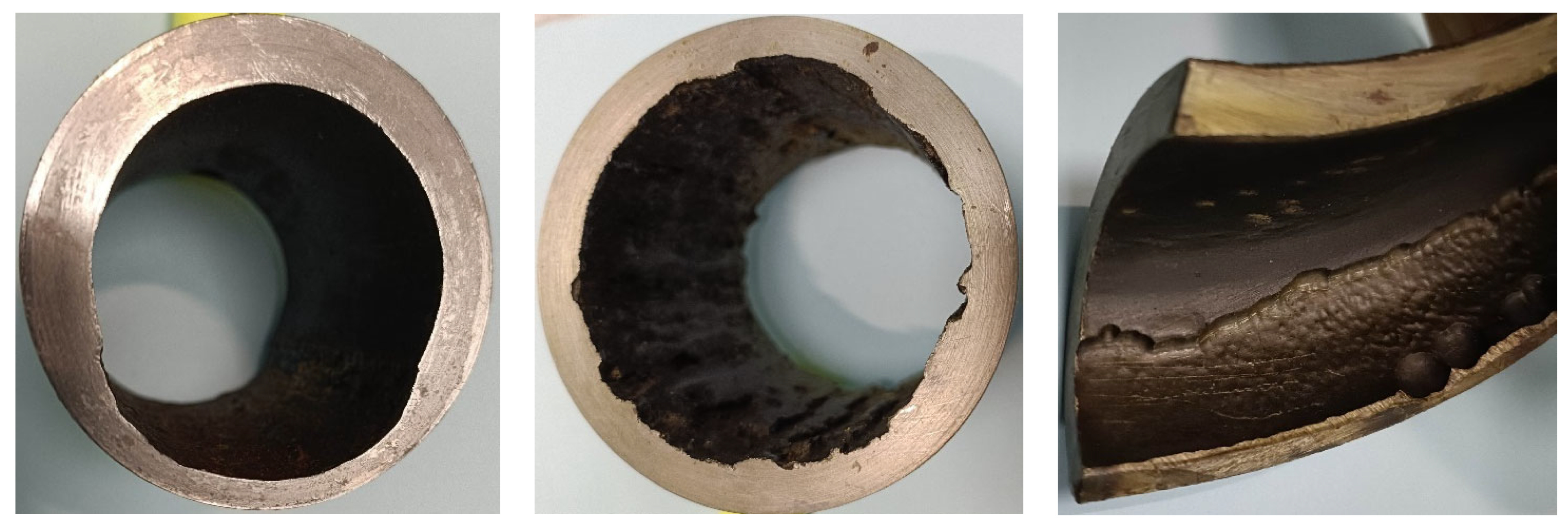

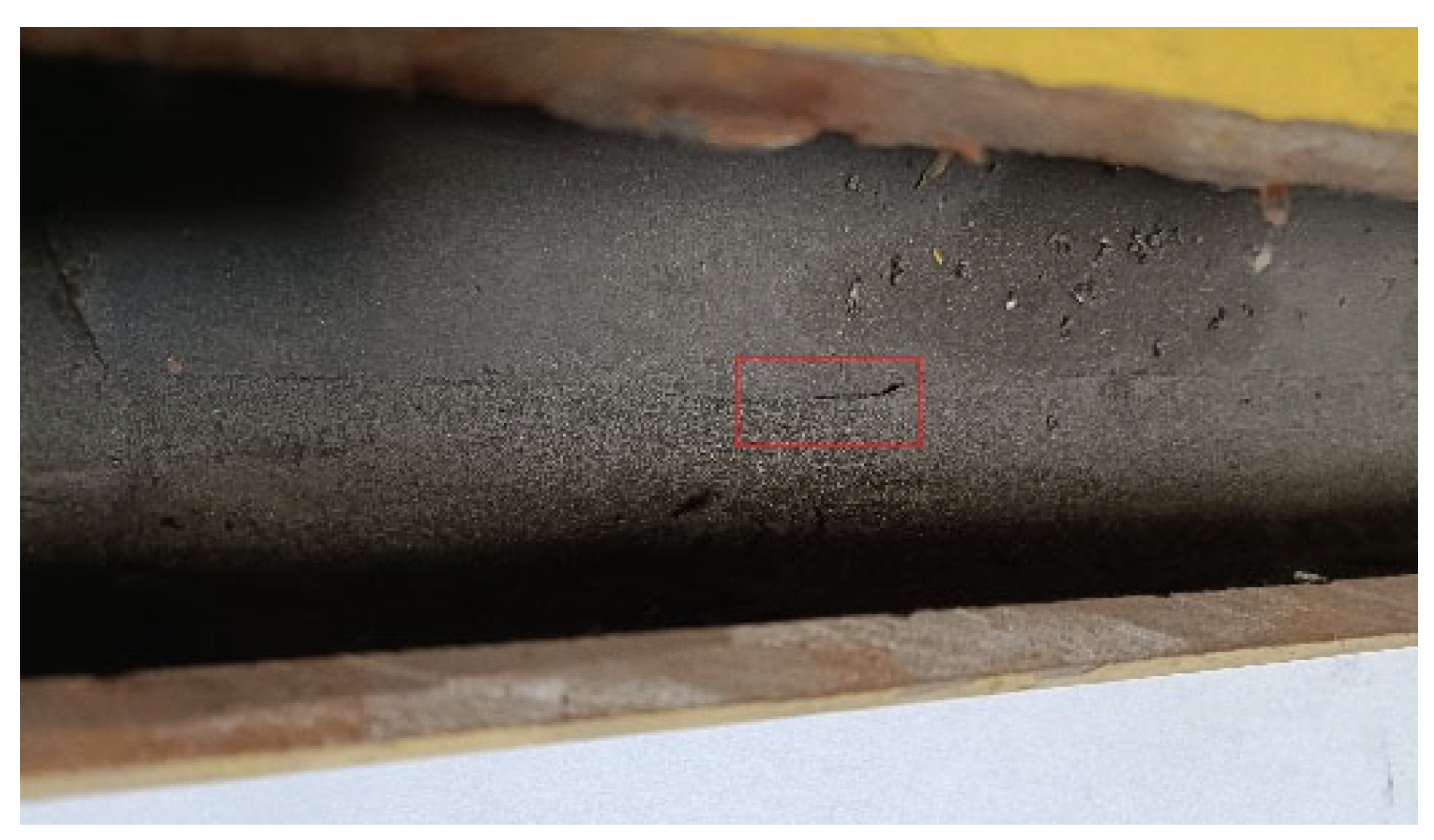

- Transverse metallographic micro-sections were taken from the test specimens (Figure 1) to study the micro-structure of the corrosion scale and the substrate.

- –

- concentration of dissolved oxygen and other oxidants,

- –

- degree of mineralization (mainly the concentration of chlorides and sulphates),

- –

- pH value and the concentration of aggressive CO2 associated with it,

- –

- water alkalinity,

- –

- content of Ca2+ and Mg2+ ions implying water hardness.

5. Results and Discussion

6. Analysis of the Obtained Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, R.; Zhang, H.; Yang, R.; Chen, W.; Chen, G. Nondestructive Testing for Corrosion Evaluation of Metal under Coating. J. Sens. 2021, 2021, 6640406. [Google Scholar] [CrossRef]

- May, Z.; Alam, M.K.; Nayan, N.A. Recent Advances in Nondestructive Method and Assessment of Corrosion Undercoating in Carbon–Steel Pipelines. Sensors 2022, 22, 6654. [Google Scholar] [CrossRef] [PubMed]

- Honarvar, F.; Varvani-Farahani, A. A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef]

- Al-Moubaraki, A.H.; Obot, I.B. Corrosion challenges in petroleum refinery operations: Sources, mechanisms, mitigation, and future outlook. J. Saudi Chem. Soc. 2021, 25, 101370. [Google Scholar] [CrossRef]

- Vankov, Y.; Rumyantsev, A.; Ziganshin, S.; Politova, T.; Minyazev, R.; Zagretdinov, A. Assessment of the Condition of Pipelines Using Convolutional Neural Networks. Energies 2020, 13, 618. [Google Scholar] [CrossRef]

- Ma, Q.; Tian, G.; Zeng, Y.; Li, R.; Song, H.; Wang, Z.; Gao, B.; Zeng, K. Pipeline In-Line Inspection Method, Instrumentation and Data Management. Sensors 2021, 21, 3862. [Google Scholar] [CrossRef] [PubMed]

- Melo, C.; Dann, M.R.; Hugo, R.J.; Janeta, A. Optimal locations for non-destructive inspections to verify direct assessment of internally corroded pipelines. Upstream Oil Gas Technol. 2020, 5, 100008. [Google Scholar] [CrossRef]

- Kremieniewski, M. Improving the Efficiency of Oil Recovery in Research and Development. Energies 2022, 15, 4488. [Google Scholar] [CrossRef]

- Khomenko, A.; Karpenko, O.; Koricho, E.G.; Haq, M.; Cloud, G.L.; Udpa, L. Quantitative comparison of optical transmission scanning with conventional techniques for NDE of impact damage in GFRP composites. Compos. Part B Eng. 2017, 123, 92–104. [Google Scholar] [CrossRef]

- Wronkowicz, A.; Dragan, K.; Lis, K. Assessment of uncertainty in damage evaluation by ultrasonic testing of composite structures. Compos. Struct. 2018, 203, 71–84. [Google Scholar] [CrossRef]

- Yang, J.-S.; Zhao, P.; Cao, Y.-P.; Zhao, X.; Li, Y.; Zhang, D.-J. A New Type of Ultrasonic Wall Thickness Measurement System Applied in Natural-gas Pipeline. In Proceedings of the 2021 IEEE Far East NDT New Technology & Application Forum (FENDT), Kunming, China, 14–17 December 2021. [Google Scholar] [CrossRef]

- Mazzinghi, A.; Freni, A.; Capineri, L. A microwave non-destructive testing method for controlling polymeric coating of metal layers in industrial products. NDT E Int. 2019, 102, 207–217. [Google Scholar] [CrossRef]

- Sedaghati, A.; Honarvar, F.; Sinclair, A.N. Lamb wave-based experimental and numerical studies for detection and sizing of corrosion damage in metallic plates. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 2107–2120. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity Measurements and Analysis for Metal Additive Manufacturing Process Control. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 494–528. [Google Scholar] [CrossRef] [PubMed]

- Yadav, N.; Oswald-Tranta, B.; Gürocak, M.; Galic, A.; Adam, R.; Schledjewski, R. In-line and off-line NDT defect monitoring for thermoplastic automated tape layup. NDT E Int. 2023, 137, 102839. [Google Scholar] [CrossRef]

- Bhargava Reddy, M.S.; Ponnamma, D.; Sadasivuni, K.K.; Aich, S.; Kailasa, S.; Parangusan, H.; Ibrahim, M.; Eldeib, S.; Shehata, O.; Ismail, M.; et al. Sensors in advancing the capabilities of corrosion detection: A review. Sensors Actuators A Phys. 2021, 332, 113086. [Google Scholar] [CrossRef]

- Xu, X.; Fan, Z.; Chen, X.; Cheng, J.; Bu, Y. Ultrasonic Phased Array Imaging Approach Using Omni-Directional Velocity Correction for Quantitative Evaluation of Delamination in Composite Structure. Sensors 2023, 23, 1777. [Google Scholar] [CrossRef]

- Camacho, J.; Svilainis, L.; Álvarez-Arenas, T.G. Ultrasonic Imaging and Sensors. Sensors 2022, 22, 7911. [Google Scholar] [CrossRef]

- Guorong, S.; Ce, B.; Yan, L.; Yang, L.; Jing, Y.; Lei, Z.; Cunfu, H. Guided Wave Focusing Imaging Detection of Pipelines by Piezoelectric Sensor Array. J. Sens. 2022, 2022, 4731341. [Google Scholar] [CrossRef]

- Wright, R.F.; Lu, P.; Devkota, J.; Lu, F.; Ziomek-Moroz, M.; Ohodnicki, P.R. Corrosion sensors for structural health monitoring of oil and natural gas infrastructure: A Review. Sensors 2019, 19, 3964. [Google Scholar] [CrossRef]

- Zhong, S. Progress in terahertz nondestructive testing: A review. Front. Mech. Eng. 2019, 14, 273–281. [Google Scholar] [CrossRef]

- Bajgholi, M.E.; Rousseau, G.; Ginzel, E.; Thibault, D.; Viens, M. Total focusing method applied to probability of detection. Int. J. Adv. Manuf. Technol. 2023, 126, 3637–3647. [Google Scholar] [CrossRef]

- Caminero, M.A.; García-Moreno, I.; Rodríguez, G.P.; Chacón, J.M. Internal damage evaluation of composite structures using phased array ultrasonic technique: Impact damage assessment in CFRP and 3D printed reinforced composites. Compos. Part B Eng. 2019, 165, 131–142. [Google Scholar] [CrossRef]

- Ono, K. A Comprehensive Report on Ultrasonic Attenuation of Engineering Materials, Including Metals, Ceramics, Polymers, Fiber-Reinforced Composites, Wood, and Rocks. Appl. Sci. 2020, 10, 2230. [Google Scholar] [CrossRef]

- Choudhary, S.; Vishwakarma, M.; Dwivedi, S.K. Evaluation and Prevention of Hydrogen Embrittlement by NDT Methods: A Review. Mater. Proc. 2021, 6, 18. [Google Scholar] [CrossRef]

- Luo, Z.; Zhang, S.; Jin, S.; Liu, Z.; Lin, L. Heterogeneous ultrasonic time-of-flight distribution in multidirectional CFRP corner and its implementation into total focusing method imaging. Compos. Struct. 2022, 294, 115789. [Google Scholar] [CrossRef]

- Poorhaydari, K. A Comprehensive Examination of High-Temperature Hydrogen Attack—A Review of over a Century of Investigations. J. Mater. Eng. Perform. 2021, 30, 7875–7908. [Google Scholar] [CrossRef]

- Yan, H.; Zhao, P.; Xiao, C.; Zhang, D.; Jiao, S.; Pan, H.; Wu, X. Design and Kinematic Characteristic Analysis of a Spiral Robot for Oil and Gas Pipeline Inspections. Actuators 2023, 12, 240. [Google Scholar] [CrossRef]

- Bęben, D. Badania skuteczności działania wybranych inhibitorów korozji stosowanych okresowo w przemyśle wydobywczym. Artic. Ochr. Przed Korozją 2019, 11, 376–381. [Google Scholar]

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef]

- Duan, J.; Li, C.; Jin, J. Modal Analysis of Tubing Considering the Effect of Fluid–Structure Interaction. Energies 2022, 15, 670. [Google Scholar] [CrossRef]

- Mazur, R.; Stefanek, P.; Orlikowski, J. Corrosion monitoring as a factor increasing the safety vof hydrotechnical infrastructure. Pol. Acad. Sci. 2022, LXVIII, 197–209. [Google Scholar] [CrossRef]

- Valdez, B.; Schorr, M.; Zlatev, R.; Carrillo, M.; Stoytcheva, M.; Alvarez, L.; Eliezer, A.; Rosas, N. Corrosion Control in Industry. In Environmental and Industrial Corrosion—Practical and Theoretical Aspects; InTech: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Bęben, D. The Influence of Temperature on Degradation of Oil and Gas Tubing Made of L80-1 Steel. Energies 2021, 14, 6855. [Google Scholar] [CrossRef]

- Bęben, D. Ochrona chemiczna metali przed korozją na przykładzie wybranych kopalń gazu ziemnego. Artic. Ochr. Przed Korozją 2014, 57, 478–481. [Google Scholar]

- Khan, A.; Qurashi, A.; Badeghaish, W.; Noui-Mehidi, M.N.; Aziz, M.A. Frontiers and Challenges in Electrochemical Corrosion Monitoring; Surface and Downhole Applications. Sensors 2020, 20, 6583. [Google Scholar] [CrossRef]

- Garcia-Arriaga, V.; Alvarez-Ramirez, J.; Amaya, M.; Sosa, E. H2S and O2 influence on the corrosion of carbon steel immersed in a solution containing 3 M diethanolamine. Corros. Sci. 2010, 52, 2268–2279. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B. External corrosion of oil and gas pipelines: A review of failure mechanisms and predictive preventions. J. Nat. Gas Sci. Eng. 2022, 100, 104467. [Google Scholar] [CrossRef]

- Khalid, H.U.; Ismail, M.C.; Nosbi, N. Permeation Damage of Polymer Liner in Oil and Gas Pipelines: A Review. Polymers 2020, 12, 2307. [Google Scholar] [CrossRef] [PubMed]

- Agnieszka, S. Korozja rur wydobywczych odwiertów gazowych z zawartością CO2. Nafta-Gaz 2011, 6, 395–400. [Google Scholar]

- Pessu, F.; Barker, R.; Chang, F.; Chen, T.; Neville, A. Iron sulphide formation and interaction with corrosion inhibitor in H2S-containing environments. J. Pet. Sci. Eng. 2021, 207, 109152. [Google Scholar] [CrossRef]

- Liu, M.; Du, C.; Liu, Z.; Wang, L.; Zhong, R.; Cheng, X.; Ao, J.; Duan, T.; Zhu, Y.; Li, X. A review on pitting corrosion and environmentally assisted cracking on duplex stainless steel. Microstructures 2023, 3, 2023020. [Google Scholar] [CrossRef]

- Bhandari, J.; Khan, F.; Abbassi, R.; Garaniya, V.; Ojeda, R. Modelling of pitting corrosion in marine and offshore steel structures—A technical review. J. Loss Prev. Process Ind. 2015, 37, 39–62. [Google Scholar] [CrossRef]

- Lopez, A.B.; Sousa, J.P.; Pragana, J.P.M.; Bragança, I.M.F.; Santos, T.G.; Silva, C.M.A. In Situ Ultrasonic Testing for Wire Arc Additive Manufacturing Applications. Machines 2022, 10, 1069. [Google Scholar] [CrossRef]

- Marzorati, S.; Verotta, L.; Trasatti, S.P. Green Corrosion Inhibitors from Natural Sources and Biomass Wastes. Molecules 2018, 24, 48. [Google Scholar] [CrossRef]

- Bęben, D. Wpływ pH roztworu na korozję wybranych gatunków stali. Artic. Ochr. Przed Korozją 2016, 7, 260–263. [Google Scholar]

- Kuznetsov, Y.I.; Redkina, G.V. Thin Protective Coatings on Metals Formed by Organic Corrosion Inhibitors in Neutral Media. Coatings 2022, 12, 149. [Google Scholar] [CrossRef]

- Hughes, A.E.; Winkler, D.A.; Carr, J.; Lee, P.D.; Yang, Y.S.; Laleh, M.; Tan, M.Y. Corrosion Inhibition, Inhibitor Environments, and the Role of Machine Learning. Corros. Mater. Degrad. 2022, 3, 672–693. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Z.; Taylor, B.; Dong, H. Matching pipeline In-line inspection data for corrosion characterization. NDT E Int. 2019, 101, 44–52. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.Y.; Frangopol, D.M. Optimum maintenance of deteriorated steel bridges using corrosion resistant steel based on system reliability and life-cycle cost. Eng. Struct. 2021, 243, 112633. [Google Scholar] [CrossRef]

- Thompson, N.G.; Yunovich, M.; Dunmire, D. Cost of Corrosion and Corrosion Maintenance Strategies. Corros. Rev. 2007, 25, 247–262. [Google Scholar] [CrossRef]

- Al-Qurashi, O.S.; Wazzan, N. Molecular and periodic DFT calculations of the corrosion protection of Fe(110) by individual components of Aerva lanata flower as a green corrosion inhibitor. J. Saudi Chem. Soc. 2022, 26, 101566. [Google Scholar] [CrossRef]

- Stachowicz, A. Zabezpieczenie antykorozyjne instalacji napowierzchniowej i uzbrojenia wgłębnego odwiertów przeznaczonych do zatłaczania cieczy odpadowych i wody złożowej. Nafta-Gaz 2016, 72, 939–944. [Google Scholar] [CrossRef]

- Yang, H.M. Role of Organic and Eco-Friendly Inhibitors on the Corrosion Mitigation of Steel in Acidic Environments-A State-of-Art Review. Molecules 2021, 26, 3473. [Google Scholar] [CrossRef]

- Bharatiya, U.; Gal, P.; Agrawal, A.; Shah, M.; Sircar, A. Effect of Corrosion on Crude Oil and Natural Gas Pipeline with Emphasis on Prevention by Ecofriendly Corrosion Inhibitors: A Comprehensive Review. J. Bio. Tribo. Corros. 2019, 5, 35. [Google Scholar] [CrossRef]

- Argyropoulos, V.; Boyatzis, S.C.; Giannoulaki, M.; Guilminot, E.; Zacharopoulou, A. Organic Green Corrosion Inhibitors Derived from Natural and/or Biological Sources for Conservation of Metals Cultural Heritage. In Microorganisms in the Deterioration and Preservation of Cultural Heritage; Joseph, E., Ed.; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Kolawole, F.O.; Kolawole, S.K.; Agunsoye, J.O.; Adebisi, J.A.; Bello, S.A.; Hassan, S.B. Mitigation of Corrosion Problems in API 5L Steel Pipeline—A Review. J. Mater. Environ. Sci. 2018, 9, 2397–2410. [Google Scholar]

- Behrsing, T.; Deacon, G.B.; Junk, P.C. 1—The chemistry of rare earth metals, compounds, and corrosion inhibitors. In Woodhead Publishing Series in Metals and Surface Engineering, Rare Earth-Based Corrosion Inhibitors; Forsyth, M., Hinton, B., Eds.; Woodhead Publishing: Sawston, UK, 2014; pp. 1–37. [Google Scholar] [CrossRef]

- Zhang, X.; Zevenbergen, J.; Benedictus, T. Corrosion Studies on Casing Steel in CO2 Storage Environments. Energy Procedia 2013, 37, 5816–5822. [Google Scholar] [CrossRef][Green Version]

- Eliyan, F.F.; Alfantazi, A. Influence of temperature on the corrosion behavior of API-X100 pipeline steel in 1-bar CO2-HCO3− solutions: An electrochemical study. Mater. Chem. Phys. 2013, 140, 508–515. [Google Scholar] [CrossRef]

- Jakubowski, M. Influence of pitting corrosion on fatigue and corrosion fatigue of ship structures Part I Pitting corrosion of ship structures. Pol. Marit. Res. 2014, 21, 62–69. [Google Scholar] [CrossRef]

- Li, D.; Liu, Q.; Wang, W.; Jin, L.; Xiao, H. Corrosion Behavior of AISI 316L Stainless Steel Used as Inner Lining of Bimetallic Pipe in a Seawater Environment. Materials 2021, 14, 1539. [Google Scholar] [CrossRef]

- Yang, X.; Hao, T.; Sun, Q.; Zhang, Z.; Lin, Y. The Corrosion Behavior of X100 Pipeline Steel in a Sodium Chloride Solution Containing Magnesium and Calcium. Materials 2023, 16, 5258. [Google Scholar] [CrossRef]

- Azzouni, D.; Haldhar, R.; Salim, R.; Ech-chihbi, E.; Mrani, S.A.; Rais, Z.; Azam, M.; Kim, S.C.; Taleb, M. Adsorption treatment residues as novel ecological corrosion inhibitors applied to mild steel in a molar hydrochloric acid medium: Experimental studies and surface characterization. Mater. Today Commun. 2023, 35, 106181. [Google Scholar] [CrossRef]

- Usarek, Z.; Warnke, K. Inspection of gas pipelines using magnetic flux Leakage technology. Adv. Mater. Sci. 2017, 17, 37–45. [Google Scholar] [CrossRef]

- Songa, Q.H.; Zhanga, Y.F.; Lib, Q.; Lib, Q.X.; Jua, C.; Wanga, Z.L.; Lia, J.J. Corrosion electrochemical behavior of arc sprayed Al coatings. Dig. J. Nanomater. Biostruct. 2022, 17, 825–837. [Google Scholar] [CrossRef]

- Tait, W.S. Chapter 27—Controlling Corrosion of Chemical Processing Equipment. In Handbook of Environmental Degradation of Materials, 3rd ed.; Kutz, M., Ed.; William Andrew Publishing: New York, NY, USA, 2018; pp. 583–600. [Google Scholar] [CrossRef]

- He, Y. Corrosion Monitoring. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Awuku, B.; Huang, Y.; Yodo, N. Predicting Natural Gas Pipeline Failures Caused by Natural Forces: An Artificial Intelligence Classification Approach. Appl. Sci. 2023, 13, 4322. [Google Scholar] [CrossRef]

- Galvão, T.L.P.; Ferreira, I.; Kuznetsova, A.; Novell-Leruth, G.; Song, C.; Feiler, C.; Lamaka, S.V.; Rocha, C.; Maia, F.; Zheludkevich, M.L.; et al. CORDATA: An open data management web application to select corrosion inhibitors. NPJ Mater. Degrad. 2022, 6, 48. [Google Scholar] [CrossRef]

| Designation of the Well | Unit | I-1 |

|---|---|---|

| pH | 5.3 | |

| Density (20 °C) | g/cm3 | 1.043 |

| Dissolved substances | mg/dm3 | 728 |

| Undissolved substances | mg/dm3 | 70 |

| Roasting residue | mg/dm3 | 32 |

| Chlorides | mg/dm3 | 269 |

| Iron | mg/dm3 | 6.2 |

| Mercury | mg/dm3 | 47.5 |

| Calcium | mg/dm3 | 62.5 |

| Magnesium | mg/dm3 | 12.2 |

| Aluminium | mg/dm3 | 1.3 |

| Zinc | mg/dm3 | 14.9 |

| Sodium | mg/dm3 | 105.6 |

| Manganese | mg/dm3 | 0.8 |

| Bar | mg/dm3 | 6.7 |

| Potassium | mg/dm3 | 95.3 |

| Matte | mg/dm3 | 0.6 |

| Copper | mg/dm3 | 0.6 |

| Nickel | mg/dm3 | 0.3 |

| Molybdenum | mg/dm3 | 1.7 |

| Strontium | mg/dm3 | 0.9 |

| Tin | mg/dm3 | 0.5 |

| Lead | mg/dm3 | 0.5 |

| Carbonates | mg/dm3 | n.s. |

| Bicarbonates | mg/dm3 | 610 |

| Sulfates | mg/dm3 | <20 |

| Element % Weight | Native Steel (1) | Pipe Arc | ||

|---|---|---|---|---|

| Part (2) | Boundary Section (3) | Corroded (4) | ||

| Fe | 99.00 | 22.32 | 6.19 | 20.74 |

| O | 0.00 | 25.26 | 24.18 | 21.38 |

| C | 0.096 | 25.19 | 11.83 | 39.53 |

| Mn | 0.43 | 0.08 | 0.00 | 0.05 |

| Si | 0.23 | 0.63 | 0.06 | 0.44 |

| Ca | 0.00 | 0.11 | 0.19 | 0.43 |

| Hg | 0.00 | 16.74 | 33.69 | 7.46 |

| Al | 0.02 | 0.82 | 0.79 | 0.31 |

| S | 0.004 | 6.24 | 14.15 | 5.47 |

| Mg | 0.00 | 0.11 | 0.10 | 0.05 |

| P | 0.016 | 0.12 | 0.00 | 0.02 |

| Cr | 0.034 | 2.35 | 5.54 | 0.39 |

| Cu | 0.02 | 0.04 | 3.29 | 3.74 |

| Parameter | Unit | Normal Conditions | Actual Conditions |

|---|---|---|---|

| Volume | mol/cm3 | 22,669 | 154.7 |

| Density | kg/dm3 | 0.8365 | 0.9585 |

| Compressibility factor | - | 0.9981 | 0.9499 |

| Viscosity | cP | 0.0117 | 0.0183 |

| Thermal conductivity | W/m C | 30.69 | 52.31 |

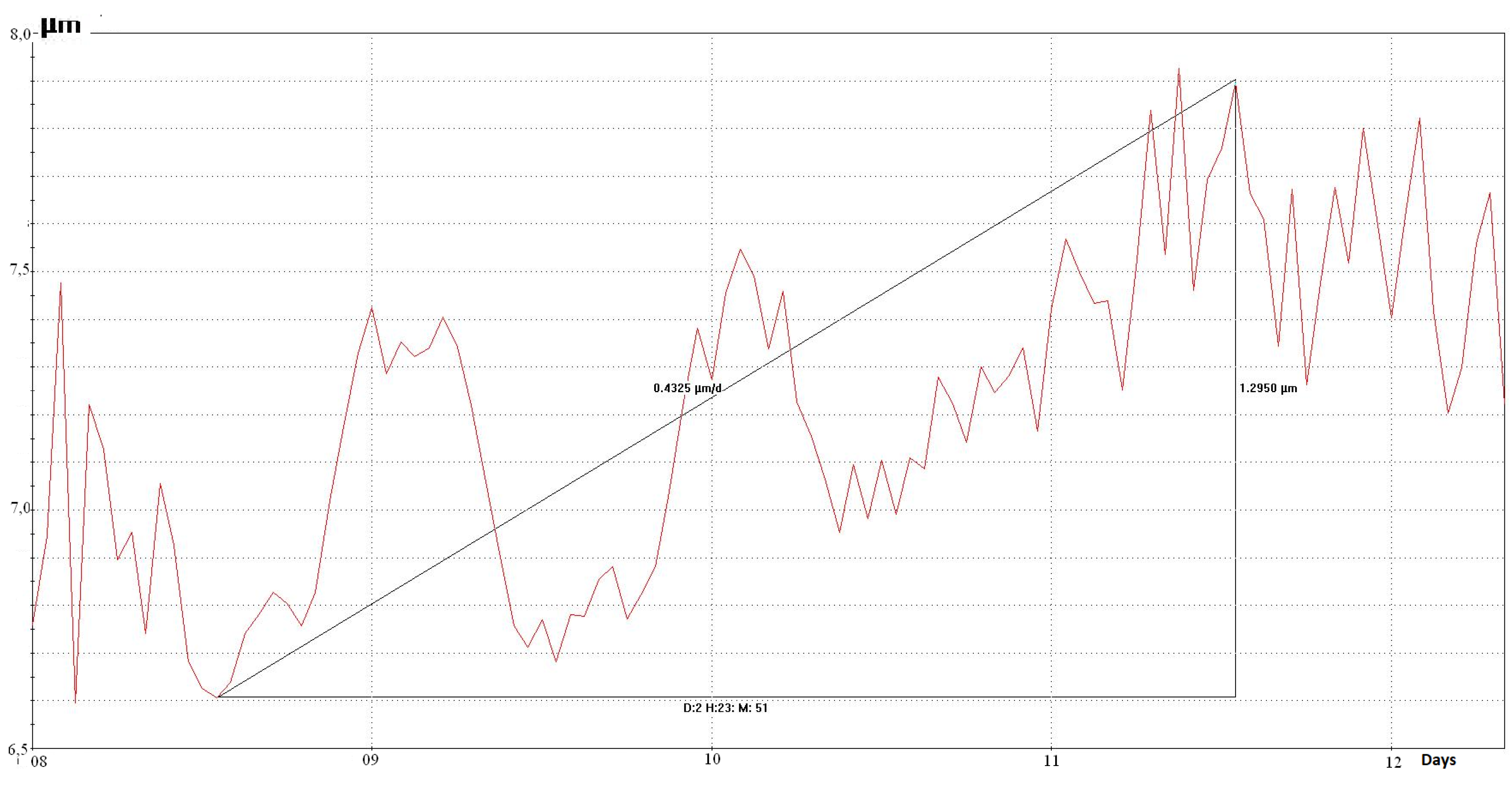

| Measurements | Readings |

|---|---|

| Background measurement without inhibitor [µm/year] | 157.8 |

| Inhibitor quantity [l/h] | 0.5 |

| Average probe reading during the inhibitor test [µm/year] | 8.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bęben, D.; Steliga, T. Monitoring and Preventing Failures of Transmission Pipelines at Oil and Natural Gas Plants. Energies 2023, 16, 6640. https://doi.org/10.3390/en16186640

Bęben D, Steliga T. Monitoring and Preventing Failures of Transmission Pipelines at Oil and Natural Gas Plants. Energies. 2023; 16(18):6640. https://doi.org/10.3390/en16186640

Chicago/Turabian StyleBęben, Dariusz, and Teresa Steliga. 2023. "Monitoring and Preventing Failures of Transmission Pipelines at Oil and Natural Gas Plants" Energies 16, no. 18: 6640. https://doi.org/10.3390/en16186640

APA StyleBęben, D., & Steliga, T. (2023). Monitoring and Preventing Failures of Transmission Pipelines at Oil and Natural Gas Plants. Energies, 16(18), 6640. https://doi.org/10.3390/en16186640