Forecasting Strength Parameters of Hardened Geopolymer Slurries Applied to Seal Casing Columns in Boreholes

Abstract

1. Introduction

1.1. Additives Modifying the Technological Properties of Fresh and Hardened Cement Slurries

- Fly ash from hard coal combustion;

- Ground granulated blast furnace slag.

- Portland clinker (K) in the range of 20–64%;

- Ground granulated blast furnace slag (S) 18–49%;

- Silica fly ash (V) 18–49%;

- Reduction in the content of clinker phases susceptible to corrosion, i.e., tricalcium aluminate C3A in the cement composition, which is related to the reduction in the share of clinker in the cement composition in favor of ash;

- Reduction in Ca(OH)2 content in the hardened cement slurry matrix;

- Change in the microstructure of the hardened cement slurry as a result of the fly ash pozzolanic reaction;

- Tightening of the structure by pozzolanic reaction products and non-hydrated fly ash particles.

1.2. Study Objectives

2. Materials and Methods

2.1. Materials

2.2. Methods

- PN–EN 197–1. Cement. Part 1. Composition, requirements, and compliance criteria for common cements, 2012 (after amendment) [46];

- PN–EN ISO 10426–1. Oil and gas industry. Cements and materials for cementing holes. Part 1. Specification, 2010 [47];

- PN–EN ISO 10426–2. Oil and gas industry. Cements and materials for cementing holes. Part 2: Testing of drilling cements, 2006 [48].

2.3. Experimental Procedures

3. Results and Discussion

3.1. Flexural Strength

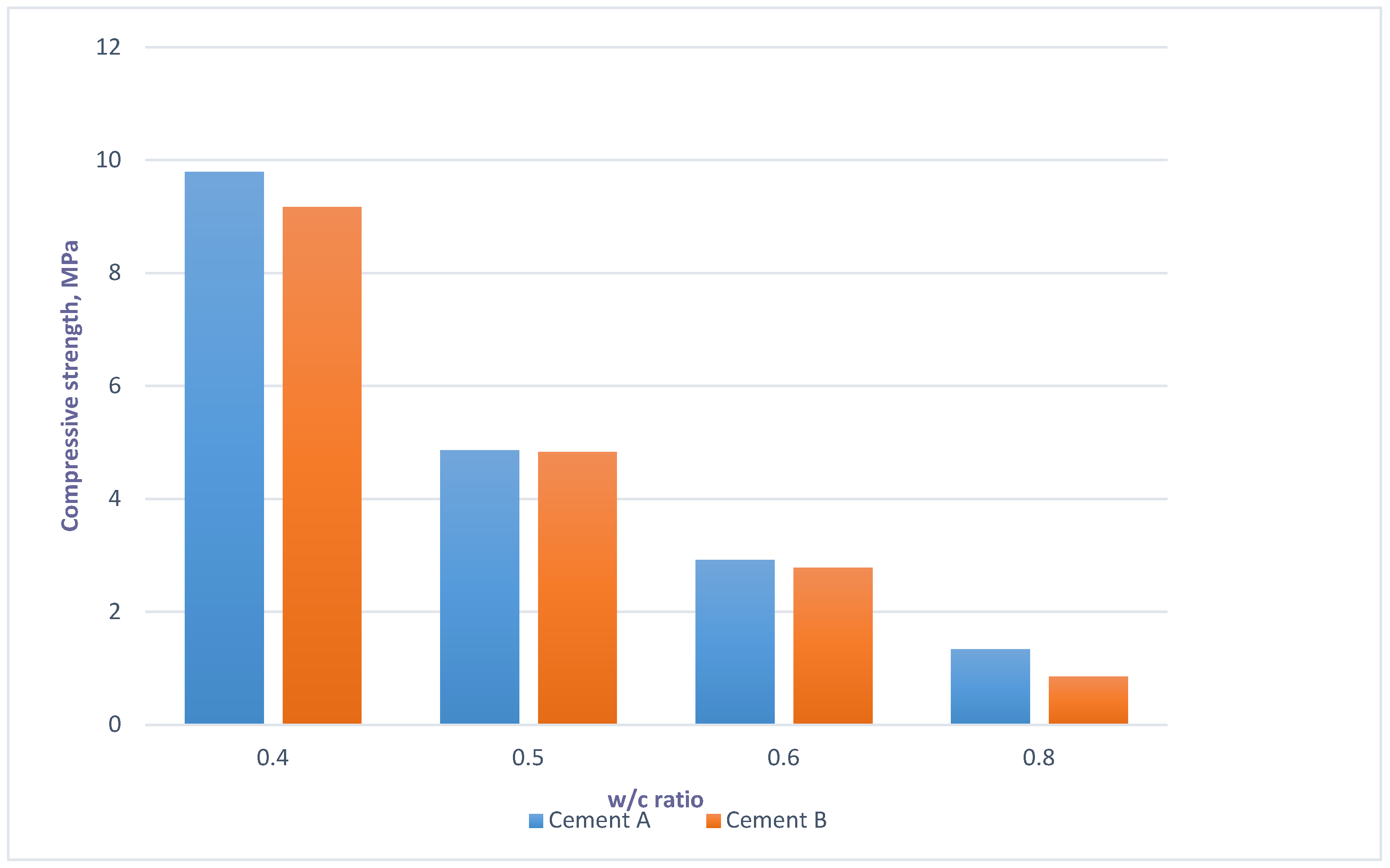

3.2. Compressive Strength

3.3. Statistical Elaboration of Strength Parameters of Hardened Slurries

- linear modely = a × x + b

- logarithmic modely = a + b × ln(x)

- exponential modely = a × exp(b × x)

- x—sample maturation time, [days];

- y—mechanical strength, [MPa].

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aadnoy, B.S.; Cooper, I.; Miska, S.Z.; Mitchell, R.F. Advanced Drilling and Well Technology; Society of Petroleum Engineers: Richardson, TX, USA, 2009. [Google Scholar]

- Habrat, S.; Raczkowski, J.; Zawada, S. Technika i Technologia Cementowań w Wiertnictwie; Wydawnictwa Geologiczne: Warszawa, Poland, 1980. [Google Scholar]

- Kapeluszna, E.; Kotwica, Ł.; Nocuń-Wczelik, W. Comparison of the effect of ground waste expanded perlite and silica fume on the hydration of cements with various tricalcium aluminate content—Comprehensive analysis. Constr. Build. Mater. 2021, 303, 124434. [Google Scholar] [CrossRef]

- Nelson, E.B. Well Cementing; Schlumberger Educational Service: Houston, TX, USA, 1990. [Google Scholar]

- Bensted, J.; Smith, J.R. Cementy wiertnicze. Część 5: Zastosowanie popiołów lotnych w pracach cementacyjnych. Cem. Wap. Bet. Styczeń—Luty 2008. Available online: http://bc.pollub.pl/Content/13293/beton.pdf (accessed on 28 May 2023).

- Bensted, J. Cementy wiertnicze. Część 2: Stosowanie cementów wiertniczych do cementowania odwiertów. Cem. Wap. Bet. Marzec—Kwiecień 2004, 9, 61–72. [Google Scholar]

- Różycka, A.; Kotwica, Ł. Waste originating from the cleaning of flue gases from the combustion of industrial wastes as a lime partial replacement in autoclaved aerated concrete. Mater. Dok. Elektron.—Czas. Elektron. 2022, 15, 2576. [Google Scholar] [CrossRef] [PubMed]

- Gonet, A.; Knez, D.; Macuda, J.; Stryczek, S. Selected Issues of Wellbore Hydraulics and Cementing; Knez, D., Ed.; AGH University of Science and Technology Press: Kraków, Poland, 2017. [Google Scholar]

- Kremieniewski, M.; Rzepka, M.; Stryczek, S.; Wiśniowski, R. Comparison of gas migration test and building structural strength of slurry in the aspect of limiting gas invasion. AGH Drill. Oil Gas 2016, 33, 595–608. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Wiśniowski, R.; Stryczek, S.; Orłowicz, G. Possibilities of Limiting Migration of Natural Gas in Bore-holes in the Context of Laboratory Studies. Energies 2021, 14, 4251. [Google Scholar] [CrossRef]

- Stryczek, S.; Gonet, A.; Kremieniewski, M. Special Cement Slurries for Strengthening Salt Rock Mass. Energies 2022, 15, 6087. [Google Scholar] [CrossRef]

- Kremieniewski, M. Wpływ wybranych dodatków lekkich na zmianę parametrów technologicznych zaczynu. Nafta-Gaz 2022, 78, 426–434. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Kędzierski, M.; Rzepka, M. Poprawa oczyszczenia przestrzeni pierścieniowej otworu wiertniczego przed zabiegiem cementowania. Pr. Nauk. Inst. Naft. I Gazu 2018, 220, 1–171. [Google Scholar]

- Kremieniewski, M.; Kędzierski, M.; Błaż, S. Increasing the Efficiency of Sealing the Borehole in Terms of Spacer Pumping Time. Energies 2021, 14, 6702. [Google Scholar] [CrossRef]

- Kremieniewski, M. Korelacja Skuteczności Działania Środków Dyspergujących o Różnym Mechanizmie Upłynniania; Nafta-Gaz: Hünenber, Switzerland, 2020; pp. 816–826. [Google Scholar]

- Kremieniewski, M. Hybrid Washer Fluid for Primary Cementing. Energies 2021, 14, 1295. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Błaż, S.; Stryczek, S.; Wiśniowski, R.; Gonet, A. Effect of Cleaning the Annular Space on the Adhesion of the Cement Sheath to the Rock. Energies 2021, 14, 5187. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Wiśniowski, R.; Stryczek, S.; Łopata, P. Comparison of Efficient Ways of Mud Cake Removal from Casing Surface with Traditional and New Agents. Energies 2021, 14, 3653. [Google Scholar] [CrossRef]

- Kremieniewski, M. Zaczyny o obniżonej gęstości stosowane w warunkach występowania komplikacji w otworze wiertniczym. Nafta-Gaz 2021, 11, 736–743. [Google Scholar] [CrossRef]

- Gonet, A.; Stryczek, S.; Kremieniewski, M. Modern Methods of Strengthening and Sealing Salt Mines. Energies 2022, 15, 5303. [Google Scholar]

- Kremieniewski, M. Recipe of Lightweight Slurry with High Early Strength of the Resultant Cement Sheath. Energies 2020, 13, 1583. [Google Scholar] [CrossRef]

- Neville, A.M. Właściwości Betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2012. [Google Scholar]

- Łączny, M.; Majka, G.; Cempa-Balewicz, M. Badanie wpływu przetworzonych w procesie karbonatyzacji lotnych popiołów fluidalnych na własności wytrzymałościowe zaprawy cementowej. Cem. Wapno Beton 2016, 21, 265–273. [Google Scholar]

- Suppiah, R.R.; Rahman, S.H.A.; Irawan, S.; Shafiq, N. Development of New Formulation of Geopolymer Cement for Oil Well Cementing. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 12 November 2016. [Google Scholar] [CrossRef]

- Ridha, S.; Yerikania, U. New Nano-Geopolymer Cement System Improves Wellbore Integrity Upon Acidizing Job: Experimental Findings. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Bali, Indonesia, 20 October 2015. [Google Scholar] [CrossRef]

- Suppiah, R.R.; Rahman, S.H.A.; Shafiq, N.; Irawan, S. Uniaxial compressive strength of geopolymer cement for oil well cement. J. Pet. Explor. Prod. Technol. 2020, 10, 67–70. [Google Scholar] [CrossRef]

- Deja, J. Trwałość Zapraw i Betonów Żużlowo—Alkalicznych; Prace Komisji Nauk Ceramicznych; Wydawnictwo Naukowe "Akapit”: Kraków, Poland, 2004; Volume 83. [Google Scholar]

- Giergiczny, Z.; Pużaka, T.; Sokołowski, M. Poradnik Pt.: Cementy w Ofercie Handlowej Górażdże Cement S.A.; Rodzaje Właściwości Zastos: Chorula, Poland, 2000. [Google Scholar]

- Giergiczny, Z. Popiół Lotny w Składzie Cementu i Betonu; Monografia; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2013. [Google Scholar]

- Małolepszy, J. Hydratacja i Własności spoiwa Żużlowo-Alkalicznego; Zeszyty Naukowe AGH nr 53; Wydawnictwa AGH: Kraków, Poland, 1989. [Google Scholar]

- Stryczek, S.; Małolepszy, J.; Gonet, A.; Wiśniowski, R.; Kotwica Ł Złotkowski, A.; Ziaja, J. Popioły z fluidalnego spalania węgla brunatnego, jako dodatek do zaczynów uszczelniających. In Monografia Pod Redakcją Stryczka S.; Wydawnictwa AGH: Kraków, Poland, 2013. [Google Scholar]

- Stryczek, S.; Małolepszy, J.; Gonet, A.; Wiśniowski, R.; Kotwica, Ł. Wpływ dodatków mineralnych na kształtowanie się właściwości technologicznych zaczynów uszczelniających stosowanych w wiertnictwie i geoinżynierii. In Monografia pod Redakcją Stryczka S.; Wydawnictwo S.C.M.R.: Kraków, Poland, 2011. [Google Scholar]

- Kurdowski, W. Chemia Cementu i Betonu; Wydawnictwo Naukowe PWN Warszawa: Warszawa, Poland, 2010. [Google Scholar]

- Stryczek, S.; Gonet, A.; Wiśniowski, R. Wpływ wybranego dodatku mineralnego na własności technologiczne zaczynów cementowych. Zesz. Nauk. Akad. Górniczo-Hut. Im. Stanisława Staszica. Wiert. Naft. Gaz 2005, 22, 333–341. [Google Scholar]

- Stryczek, S.; Brylicki, W.; Wiśniowski, R. Zaczyny uszczelniające nowej generacji o wysokiej trwałości. Wiert. Naft. Gaz 2006, 23, 451–458. [Google Scholar]

- Stryczek, S.; Wiśniowski, R.; Uliasz-Misiak, B.; Złotkowski, A.; Kotwica, Ł.; Rzepka, M.; Kremieniewski, M. Studia Nad Doborem Zaczynów Uszczelniających w Warunkach Wierceń w Basenie Pomorskim; Wydawnictwo AGH: Kraków, Poland, 2016; ISBN 978-83-7464-877-6. [Google Scholar]

- Wiśniowski, R.; Skrzypaszek, K.; Toczek, P. Vom Berg and Hahn–Eyring Drilling Fluid Rheological Models. Energies 2022, 15, 5583. [Google Scholar] [CrossRef]

- Stryczek, S.; Gonet, A.; Czapik, P. Kształtowanie właściwości technologicznych zaczynów uszczelniających za pomocą pyłów cementowych. Wiert. Naft. Gaz 2009, 26, 345–354. [Google Scholar]

- Formela, M.; Stryczek, S. Popioły fluidalne ze spalania węgla brunatnego, jako dodatek do zaczynów uszczelniających wykorzystywanych podczas prac wypełniania pustek w górotworze. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią Pol. Akad. Nauk. 2017, 97, 117–134. [Google Scholar]

- Stryczek, S.; Wiśniowski, R.; Gonet, A. Influence of Mineral Additives on the Technological Properties of Sealing Slurries for Geoengineering Works. Acta Montan. Slovaca Ročník 2006, 1, 204–207. [Google Scholar]

- Wiśniowski, R.; Skrzypaszek, K.; Małachowski, T. Selection of a Suitable Rheological Model for Drilling Fluid Using Applied Numerical Methods. Energies 2020, 13, 3192. [Google Scholar] [CrossRef]

- Suppiah, R.R.; Nermoggan, P.; Shafiq, N. Experimental investigation of the effects of temperature on the morphological characteristics of geopolymer binders. J. Pet. Explor. Prod. Technol. 2022, 12, 3303–3310. [Google Scholar] [CrossRef]

- Alanqari, K.; Al-Yami, A.; Wagle, V. Preparation of a Synthetic Geopolymer Cement Utilizing Saudi Arabian Volcanic Ash for a Sustainable Development: Method, Preparation and Applications. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21 February 2022. [Google Scholar] [CrossRef]

- Mohamed, C.N.; Ranjith, P.G.; Sanjayan, J. Mechanical Properties of Geopolymer Cement in Brine: Its Suitability as Well Cement for Geological Sequestration of Carbon Dioxide (CO2). In Proceedings of the ISRM Regional Symposium—7th Asian Rock Mechanics Symposium, Seoul, Republic of Korea, 15 October 2012. [Google Scholar]

- Sugumaran, M. Study on Effect of Low Calcium Fly Ash on Geopolymer Cement for Oil Well Cementing. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Bali, Indonesia, 20 October 2015. [Google Scholar] [CrossRef]

- PN–EN 197–1; Cement. Part 1. Composition, Requirements, and Compliance Crite-Ria For Common Cements (after Amendment). ISO: Geneva, Switzerland, 2012.

- PN–EN ISO 10426–1; Oil and Gas Industry. Cements and Materials for Cementing Holes. Part 1. Specification. ISO: Geneva, Switzerland, 2010.

- PN–EN ISO 10426–2; Oil and Gas Industry. Cements and Materials for Cementing Holes. Part 2: Testing of Drilling Cements. ISO: Geneva, Switzerland, 2006.

| Component | Portland Cement CEM I 32.5R | Silica Ash * | Ground Granulated Blast Furnace Slag ** |

|---|---|---|---|

| SiO2 | 21.7 | 47.52 | 39.70 |

| Al2O3 | 5.00 | 30.64 | 8.15 |

| Fe2O3 | 2.27 | 7.32 | 0.82 |

| CaO | 64.7 | 3.35 | 42.90 |

| MgO | 2.20 | 2.15 | 5.97 |

| SO3 | 3.00 | 1.44 | 1.97 |

| The Main Ingredients of the Recipes | Cement CEM V/A According to the PN-EN Standard 197–1 | CEM V/A Cement Prepared According to Formula A | CEM V/A Cement Prepared According to Recipe B |

|---|---|---|---|

| Clinker content, % by weight | 40–60 | 53.0 | 45.0 |

| Slag content (S), % by weight | 18–30 | 25.0 | 21.0 |

| Silica ash content (V), % by weight | 18–30 | 18.0 | 30.0 |

| Set time regulator, % by weight | 0–5 | 5.0 | 5.0 |

| Density, kg/m3 | Sedimentation, % | Fluidity, mm | Relative Viscosity, s | Filtration, mL/s | |||||

|---|---|---|---|---|---|---|---|---|---|

| Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B |

| 1870 | 1840 | 0.0 | 0.0 | 115 | 95 | - | - | 60/15 | 33/10 |

| 1810 | 1730 | 0.0 | 0.0 | 130 | 125 | - | - | 86/32 | 71/22 |

| 1700 | 1650 | 0.0 | 0.64 | 205 | 165 | 28.96 | 36.37 | 104/23 | 100/26 |

| 1530 | 1540 | 2.78 | 5.0 | 245 | 115 | 21.67 | 17.83 | 138.24 | 150/35 |

| 1480 | 1440 | 12.12 | 14.6 | >260 | >260 | 12.97 | 13.64 | 164/26 | 174/33 |

| 1390 | 1360 | 16.89 | 19.4 | >260 | >260 | 9.99 | 11.56 | 178/19 | 198/33 |

| Start of Cement Setting, Hour/Minute | Start of Cement Setting, Hour/Minute | Setting Time, Hour/Minute | |||

|---|---|---|---|---|---|

| Cement A | Cement B | Cement A | Cement B | Cement A | Cement B |

| 4:44 | 4:58 | 7:14 | 7:58 | 2:30 | 3:00 |

| 5:12 | 6:40 | 8:12 | 10:50 | 3:00 | 4:10 |

| 6:18 | 7:19 | 10:28 | 12:49 | 4:10 | 5:30 |

| 12:16 | 13:34 | 20:16 | 22:54 | 8:00 | 9:20 |

| 19:59 | 21:38 | 32:39 | 35:28 | 12:40 | 14:50 |

| 25:13 | 27:47 | 43:23 | 47:47 | 18:10 | 20:00 |

| Rheological Model Type | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bingham | Oswald de Waele | Casson | ||||||

| Plastic Viscosity. Pa·s | Yield Limit. Pa | Correlation Coefficient. - | Consistency Factor. Pa·sn | Exponent. - | Correlation Coefficient. - | Plastic Viscosity. Pa·s | Yield Limit. Pa | Correlation Coefficient. - |

| 0.1878 | 30.1511 | 0.9252 | 5.4882 | 0.5299 | 0.9863 | 0.1443 | 11.4248 | 0.9468 |

| 0.0951 | 10.3443 | 0.9849 | 2.4033 | 0.5257 | 0.9913 | 0.0680 | 4.3147 | 0.9941 |

| 0.0802 | 8.1247 | 0.9852 | 1.9619 | 0.5237 | 0.9904 | 0.0588 | 3.2458 | 0.9949 |

| 0.0165 | 3.1323 | 0.9884 | 1.2755 | 0.3514 | 0.9420 | 0.0092 | 1.8420 | 0.9754 |

| 0.0132 | 1.4979 | 0.9880 | 0.4881 | 0.4512 | 0.9378 | 0.0080 | 0.8107 | 0.9849 |

| 0.0072 | 1.0656 | 0.9539 | 0.2484 | 0.4858 | 0.9924 | 0.0052 | 0.4398 | 0.9722 |

| Rheological Model Type | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bingham | Oswald de Waele | Casson | ||||||

| Plastic Viscosity. Pa·s | Yield limit. Pa | Correlation Coefficient. - | Consistency Factor. Pa·sn | Exponent. - | Correlation Coefficient. - | Plastic Viscosity. Pa·s | Yield Limit. Pa | Correlation Coefficient. - |

| 0.2065 | 32.1488 | 0.9235 | 6.2071 | 0.5213 | 0.9884 | 0.1596 | 12.0115 | 0.9454 |

| 0.1143 | 16.0715 | 0.9630 | 3.9503 | 0.4864 | 0.9966 | 0.0814 | 6.8714 | 0.9811 |

| 0.0660 | 9.0184 | 0.9855 | 2.5733 | 0.4610 | 0.9836 | 0.0423 | 4.5109 | 0.9957 |

| 0.0205 | 2.1667 | 0.9934 | 0.7932 | 0.4343 | 0.9408 | 0.0129 | 1.1281 | 0.9959 |

| 0.0102 | 1.3864 | 0.9914 | 0.5764 | 0.3810 | 0.9303 | 0.0059 | 0.8000 | 0.9938 |

| 0.0079 | 0.7660 | 0.9878 | 0.2555 | 0.4590 | 0.9450 | 0.0053 | 0.3552 | 0.9931 |

| w/c | Flexural Strength. MPa | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 day | 2 days | 7 days | 14 days | 21 days | 28 days | |||||||

| Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | |

| 0.4 | <1.29 | <1.29 | 3.68 | 3.29 | 6.77 | 5.65 | 7.94 | 6.39 | 9.37 | 8.79 | 9.94 | 9.18 |

| 0.5 | <1.29 | <1.29 | 2.12 | 1.98 | 4.15 | 4.10 | 5.87 | 5.21 | 7.19 | 6.64 | 8.03 | 7.01 |

| 0.6 | <1.29 | <1.29 | <1.29 | <1.29 | 3.17 | 2.43 | 3.93 | 3.75 | 5.12 | 4.41 | 5.38 | 4.67 |

| 0.8 | - | - | <1.29 | <1.29 | 1.41 | <1.29 | 1.87 | 1.83 | 2.46 | 2.29 | 2.89 | 2.47 |

| 1.0 | - | - | - | - | <1.29 | <1.29 | <1.29 | <1.29 | <1.29 | <1.29 | 1.57 | <1.29 |

| 1.2 | - | - | - | - | <1.29 | <1.29 | <1.29 | <1.29 | <1.29 | <1.29 | <1.29 | <1.29 |

| w/c | Compressive Strength. MPa | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 day | 2 days | 7 days | 14 days | 21 days | 28 days | |||||||

| Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | Cement A | Cement B | |

| 0.4 | 3.51 | 2.92 | 9.79 | 9.17 | 22.01 | 20.07 | 32.78 | 27.89 | 39.17 | 33.99 | 42.36 | 35.67 |

| 0.5 | 1.87 | 1.25 | 4.86 | 4.83 | 11.11 | 10.42 | 17.01 | 15.34 | 22.99 | 19.65 | 25.12 | 21.18 |

| 0.6 | 0.94 | 0.83 | 2.92 | 2.78 | 6.81 | 6.24 | 10.01 | 9.65 | 14.24 | 12.92 | 15.55 | 13.55 |

| 0.8 | - | 1.34 | 0.86 | 3.39 | 2.72 | 4.53 | 3.97 | 6.46 | 5.23 | 7.89 | 6.90 | |

| 1.0 | - | 1.71 | 1.41 | 2.97 | 2.74 | 2.78 | 2.51 | 4.14 | 3.23 | |||

| 1.2 | - | 1.39 | 0.85 | 1.94 | 1.41 | 2.38 | 1.71 | 2.86 | 2.48 | |||

| LINEAR MODEL y = a × x + b | ||||||

|---|---|---|---|---|---|---|

| Type of Cement Slurry | w/c | Regression Equation Coefficient | Correlation Coefficient r, [-] | Factor R2, [-] | Fisher–Snedecor Coefficient F, [-] | |

| a | b | |||||

| Cement slurry recipe A | 0.4 | 0.2244 | 4.3082 | 0.9430 | 0.8893 | 24.1060 |

| 0.5 | 0.2536 | 2.1122 | 0.9797 | 0.9599 | 71.7953 | |

| 0.6 | 0.1250 | 2.1350 | 0.9725 | 0.9459 | 34.9361 | |

| 0.8 | 0.0718 | 0.9000 | 0.9983 | 0.9965 | 571.1264 | |

| Cement slurry recipe B | 0.4 | 0.2234 | 3.4421 | 0.9672 | 0.9355 | 43.5372 |

| 0.5 | 0.1879 | 2.2811 | 0.9617 | 0.9249 | 36.9384 | |

| 0.6 | 0.1054 | 1.9700 | 0.9516 | 0.9055 | 19.1587 | |

| 0.8 | 0.0457 | 1.2367 | 0.9695 | 0.9400 | 15.6735 | |

| LOGARITHMIC MODEL y = a + b·ln(x) | ||||||

|---|---|---|---|---|---|---|

| Type of Cement Slurry | w/c | Regression Equation Coefficient | Correlation Coefficient r, [-] | Factor R2, [-] | Fisher–Snedecor Coefficient F, [-] | |

| a | b | |||||

| Cement slurry recipe A | 0.4 | 2.0502 | 5.4229 | 0.9970 | 0.9940 | 3112.4804 |

| 0.5 | −0.0731 | 5.7660 | 0.9746 | 0.9499 | 198.3691 | |

| 0.6 | −0.9098 | 4.3964 | 0.9882 | 0.9776 | 829.7789 | |

| 0.8 | −0.7455 | 2.4391 | 0.9790 | 0.9584 | 375.3474 | |

| Cement slurry recipe B | 0.4 | 1.4761 | 5.1208 | 0.9697 | 0.9404 | 262.7923 |

| 0.5 | 0.5017 | 4.4317 | 0.9920 | 0.9840 | 792.2141 | |

| 0.6 | −0.7192 | 3.8098 | 0.9934 | 0.9869 | 1554.5960 | |

| 0.8 | −0.6198 | 2.1579 | 0.9888 | 0.9778 | 1517.1351 | |

| EXPONENTIAL MODEL y = a·exp(b·x) | ||||||

|---|---|---|---|---|---|---|

| Type of Cement Slurry | w/c | Regression Equation Coefficient | Correlation Coefficient r, [-] | Factor R2, [-] | Fisher–Snedecor Coefficient F, [-] | |

| a | b | |||||

| Cement slurry recipe A | 0.4 | 4.9360 | 0.0273 | 0.9091 | 0.8266 | 106.4780 |

| 0.5 | 3.0499 | 0.0399 | 0.9416 | 0.8866 | 86.7829 | |

| 0.6 | 2.6045 | 0.0277 | 0.9508 | 0.9041 | 202.0713 | |

| 0.8 | 1.1736 | 0.0330 | 0.9913 | 0.9827 | 903.6949 | |

| Cement slurry recipe B | 0.4 | 4.0752 | 0.0313 | 0.9411 | 0.8857 | 136.3506 |

| 0.5 | 2.9149 | 0.0341 | 0.9223 | 0.8506 | 83.3380 | |

| 0.6 | 2.3718 | 0.0261 | 0.9232 | 0.8524 | 136.9600 | |

| 0.8 | 1.4226 | 0.0204 | 0.9586 | 0.9189 | 415.3929 | |

| LINEAR MODEL y = a·x + b | ||||||

|---|---|---|---|---|---|---|

| Type of Cement Slurry | w/c | Regression Equation Coefficient | Correlation Coefficient r, [-] | Factor R2, [-] | Fisher–Snedecor Coefficient F, [-] | |

| a | b | |||||

| Cement slurry recipe A | 0.4 | 1.4047 | 7.8456 | 0.9569 | 0.9156 | 43.3882 |

| 0.5 | 0.8594 | 3.3711 | 0.9788 | 0.9580 | 91.2240 | |

| 0.6 | 0.5367 | 1.8813 | 0.9800 | 0.9604 | 97.0610 | |

| 0.8 | 0.2434 | 1.2167 | 0.9924 | 0.9848 | 194.7949 | |

| 1.0 | 0.1069 | 1.0300 | 0.9700 | 0.9410 | 31.8842 | |

| 1.2 | 0.0693 | 0.9300 | 0.9990 | 0.9980 | 1000.9574 | |

| Cement slurry recipe B | 0.4 | 1.1700 | 7.3828 | 0.9465 | 0.8958 | 34.3880 |

| 0.5 | 0.7160 | 3.4008 | 0.9645 | 0.9303 | 53.3948 | |

| 0.6 | 0.4713 | 1.9272 | 0.9691 | 0.9392 | 61.8059 | |

| 0.8 | 0.2195 | 0.7748 | 0.9922 | 0.9845 | 190.7455 | |

| 1.0 | 0.0813 | 1.0500 | 0.9548 | 0.9117 | 20.6388 | |

| 1.2 | 0.0741 | 0.3150 | 0.9863 | 0.9728 | 71.5054 | |

| LOGARITHMIC MODEL y = a + b·ln(x) | ||||||

|---|---|---|---|---|---|---|

| Type of Cement Slurry | w/c | Regression Equation Coefficient | Correlation Coefficient r, [-] | Factor R2, [-] | Fisher–Snedecor Coefficient F, [-] | |

| a | b | |||||

| Cement slurry recipe A | 0.4 | 1.9919 | 27.1983 | 0.9945 | 0.9890 | 716.6913 |

| 0.5 | 0.3002 | 16.0342 | 0.9803 | 0.9610 | 179.1859 | |

| 0.6 | −0.0007 | 9.9719 | 0.9773 | 0.9552 | 150.3351 | |

| 0.8 | −0.7439 | 5.3993 | 0.9631 | 0.9275 | 106.8569 | |

| 1.0 | −1.4291 | 3.6374 | 0.9540 | 0.9101 | 135.9283 | |

| 1.2 | −0.6763 | 2.3684 | 0.9866 | 0.9734 | 622.3449 | |

| Cement slurry recipe B | 0.4 | 2.2483 | 22.9610 | 0.9970 | 0.9940 | 1379.236 |

| 0.5 | 0.5526 | 13.7020 | 0.9909 | 0.9818 | 407.3334 | |

| 0.6 | 0.1373 | 8.9193 | 0.9845 | 0.9692 | 227.5012 | |

| 0.8 | −1.0060 | 4.8818 | 0.9654 | 0.9320 | 100.3627 | |

| 1.0 | −0.9903 | 2.9095 | 0.9874 | 0.9749 | 587.4224 | |

| 1.2 | −1.3432 | 2.4834 | 0.9544 | 0.9110 | 94.60491 | |

| EXPONENTIAL MODEL y = a·exp(b·x) | ||||||

|---|---|---|---|---|---|---|

| Type of Cement Slurry | w/c | Regression Equation Coefficient | Correlation Coefficient r, [-] | Factor R2, [-] | Fisher–Snedecor Coefficient F, [-] | |

| a | b | |||||

| Cement slurry recipe A | 0.4 | 1.9919 | 27.1984 | 0.8954 | 0.8017 | 374.3244 |

| 0.5 | 0.3001 | 16.0342 | 0.9235 | 0.8529 | 749.2554 | |

| 0.6 | −0.0007 | 9.9719 | 0.9261 | 0.8577 | 589.4292 | |

| 0.8 | 2.1589 | 0.0480 | 0.9662 | 0.9335 | 116.6963 | |

| 1.0 | 1.4572 | 0.0370 | 0.9686 | 0.9381 | 197.9869 | |

| 1.2 | 1.1887 | 0.0319 | 0.9910 | 0.9820 | 922.2521 | |

| Cement slurry recipe B | 0.4 | 11.6613 | 0.0441 | 0.8842 | 0.7818 | 35.82672 |

| 0.5 | 6.1084 | 0.0483 | 0.9049 | 0.8188 | 39.09004 | |

| 0.6 | 3.7669 | 0.0499 | 0.9079 | 0.8243 | 38.25687 | |

| 0.8 | 1.6797 | 0.0518 | 0.9648 | 0.9308 | 98.66027 | |

| 1.0 | 1.3932 | 0.0312 | 0.9286 | 0.8624 | 106.3110 | |

| 1.2 | 0.6658 | 0.0468 | 0.9903 | 0.9807 | 439.9509 | |

| Type of Cement Slurry | w/c | Mathematical Model Type | |||||

|---|---|---|---|---|---|---|---|

| Linear | Logarithmic | Exponential | |||||

| Correlation Coefficient r, [-] | Factor R2, [-] | Correlation Coefficient r, [-] | Factor R2, [-] | Correlation Coefficient r, [-] | Factor R2, [-] | ||

| Cement slurry recipe A | 0.4 | 0.9430 | 0.8893 | 0.9970 | 0.9940 | 0.9091 | 0.8266 |

| 0.5 | 0.9797 | 0.9599 | 0.9746 | 0.9499 | 0.9416 | 0.8866 | |

| 0.6 | 0.9725 | 0.9459 | 0.9882 | 0.9776 | 0.9508 | 0.9041 | |

| 0.8 | 0.9983 | 0.9965 | 0.9790 | 0.9584 | 0.9913 | 0.9827 | |

| Cement slurry recipe B | 0.4 | 0.9672 | 0.9355 | 0.9697 | 0.9404 | 0.9411 | 0.8857 |

| 0.5 | 0.9617 | 0.9249 | 0.9920 | 0.9840 | 0.9223 | 0.8506 | |

| 0.6 | 0.9516 | 0.9055 | 0.9934 | 0.9869 | 0.9232 | 0.8524 | |

| 0.8 | 0.9695 | 0.9400 | 0.9888 | 0.9778 | 0.9586 | 0.9189 | |

| Type of Cement Slurry | w/c | Mathematical Model Type | |||||

|---|---|---|---|---|---|---|---|

| Linear | Logarithmic | Exponential | |||||

| Correlation Coefficient r, [-] | Factor R2, [-] | Correlation Coefficient r, [-] | Factor R2, [-] | Correlation Coefficient r, [-] | Factor R2, [-] | ||

| Cement slurry recipe A | 0.4 | 0.9569 | 0.9156 | 0.9945 | 0.9890 | 0.8954 | 0.8017 |

| 0.5 | 0.9788 | 0.9580 | 0.9803 | 0.9610 | 0.9235 | 0.8529 | |

| 0.6 | 0.9800 | 0.9604 | 0.9773 | 0.9552 | 0.9261 | 0.8577 | |

| 0.8 | 0.9924 | 0.9848 | 0.9631 | 0.9275 | 0.9662 | 0.9335 | |

| 1.0 | 0.9700 | 0.9410 | 0.9540 | 0.9101 | 0.9686 | 0.9381 | |

| 1.2 | 0.9990 | 0.9980 | 0.9866 | 0.9734 | 0.9910 | 0.9820 | |

| Cement slurry recipe B | 0.4 | 0.9465 | 0.8958 | 0.9970 | 0.9940 | 0.8842 | 0.7818 |

| 0.5 | 0.9645 | 0.9303 | 0.9909 | 0.9818 | 0.9049 | 0.8188 | |

| 0.6 | 0.9691 | 0.9392 | 0.9845 | 0.9692 | 0.9079 | 0.8243 | |

| 0.8 | 0.9922 | 0.9845 | 0.9654 | 0.9320 | 0.9648 | 0.9308 | |

| 1.0 | 0.9548 | 0.9117 | 0.9874 | 0.9749 | 0.9286 | 0.8624 | |

| 1.2 | 0.9863 | 0.9728 | 0.9544 | 0.9110 | 0.9903 | 0.9807 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stryczek, S.; Gonet, A.; Kremieniewski, M.; Kowalski, T. Forecasting Strength Parameters of Hardened Geopolymer Slurries Applied to Seal Casing Columns in Boreholes. Energies 2023, 16, 4458. https://doi.org/10.3390/en16114458

Stryczek S, Gonet A, Kremieniewski M, Kowalski T. Forecasting Strength Parameters of Hardened Geopolymer Slurries Applied to Seal Casing Columns in Boreholes. Energies. 2023; 16(11):4458. https://doi.org/10.3390/en16114458

Chicago/Turabian StyleStryczek, Stanisław, Andrzej Gonet, Marcin Kremieniewski, and Tomasz Kowalski. 2023. "Forecasting Strength Parameters of Hardened Geopolymer Slurries Applied to Seal Casing Columns in Boreholes" Energies 16, no. 11: 4458. https://doi.org/10.3390/en16114458

APA StyleStryczek, S., Gonet, A., Kremieniewski, M., & Kowalski, T. (2023). Forecasting Strength Parameters of Hardened Geopolymer Slurries Applied to Seal Casing Columns in Boreholes. Energies, 16(11), 4458. https://doi.org/10.3390/en16114458