Laboratory Study on Adhesive Ash Deposition Characteristics of Ammonium Bisulfate in Conditions Simulating an Air Preheater for Hard Coal Combustion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.1.1. Preparation of the Experimental Ash Sample

- (1)

- Collection and characteristics of the fly ash

- (2)

- Mixing of the ABS and the fly ash

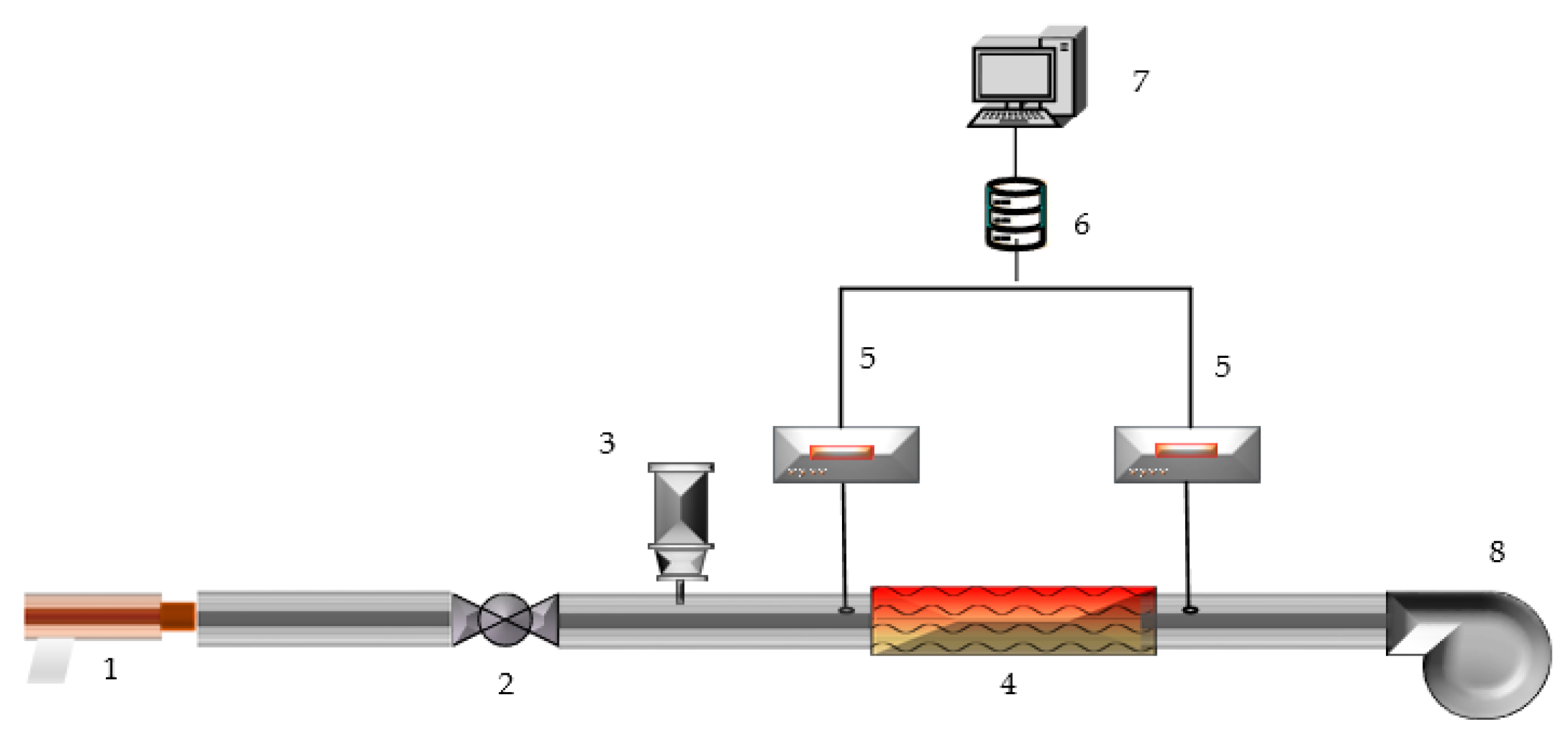

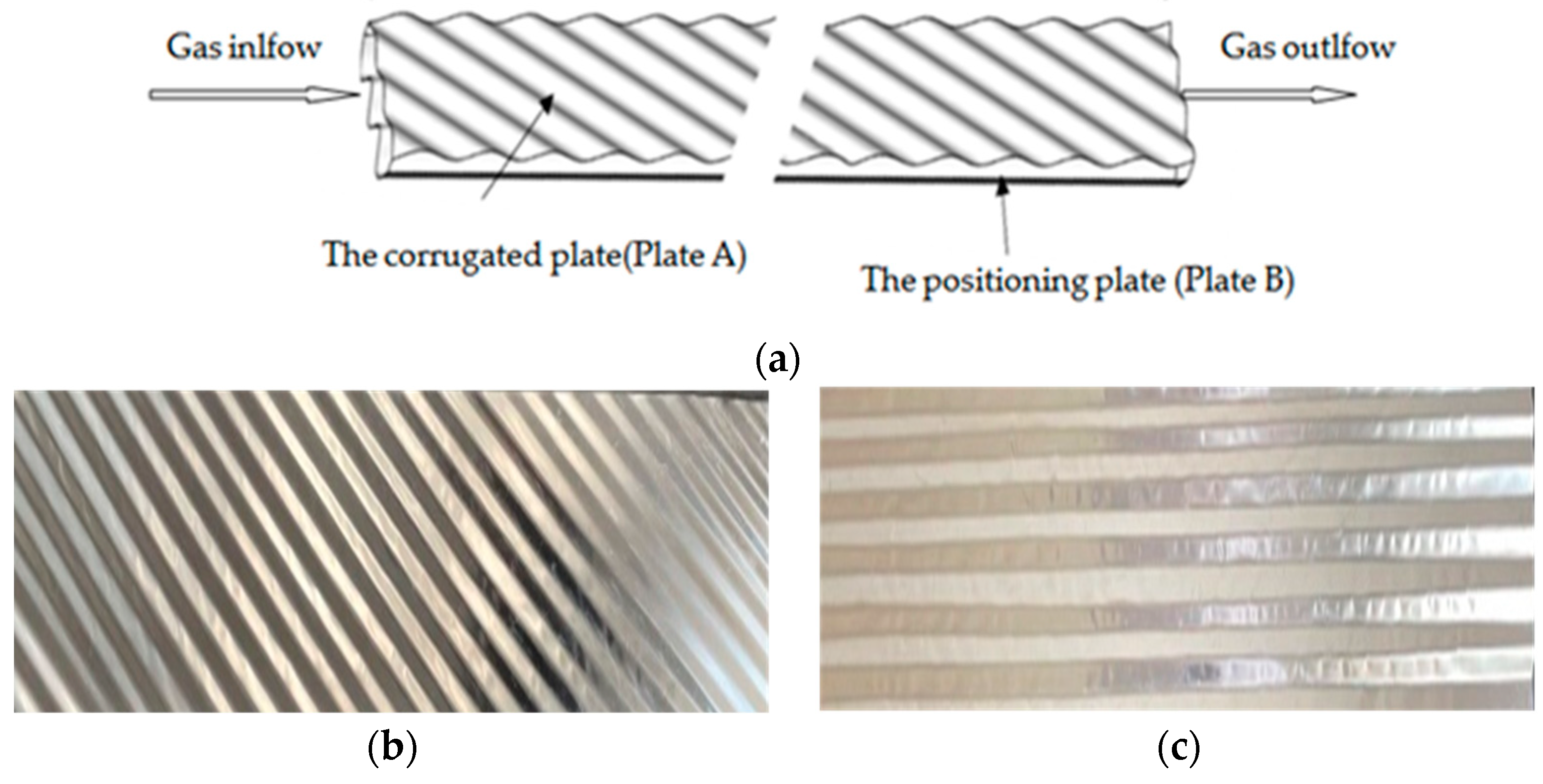

2.1.2. Experimental Devices

- (1)

- A small-sized experimental device simulating the rotary air preheater

- (2)

- Processing devices of the ABS and the fly ash

2.2. Experimental Methods

2.2.1. Experimental Procedure

- (1)

- Pre-heating

- (2)

- Fly ash deposition

- (3)

- Post-heating

- (4)

- Heat dissipation and post-processing

2.2.2. Methods of Data Processing

- (1)

- Ash deposition intensity (O)

- (2)

- ABS adhesion rate (I)

- (3)

- Particle size distribution

3. Results and Discussion

3.1. Effects of the Gas Temperature on the Ash Deposition Characteristics

3.1.1. Effect of the Gas Temperature on the Ash Deposition Intensity

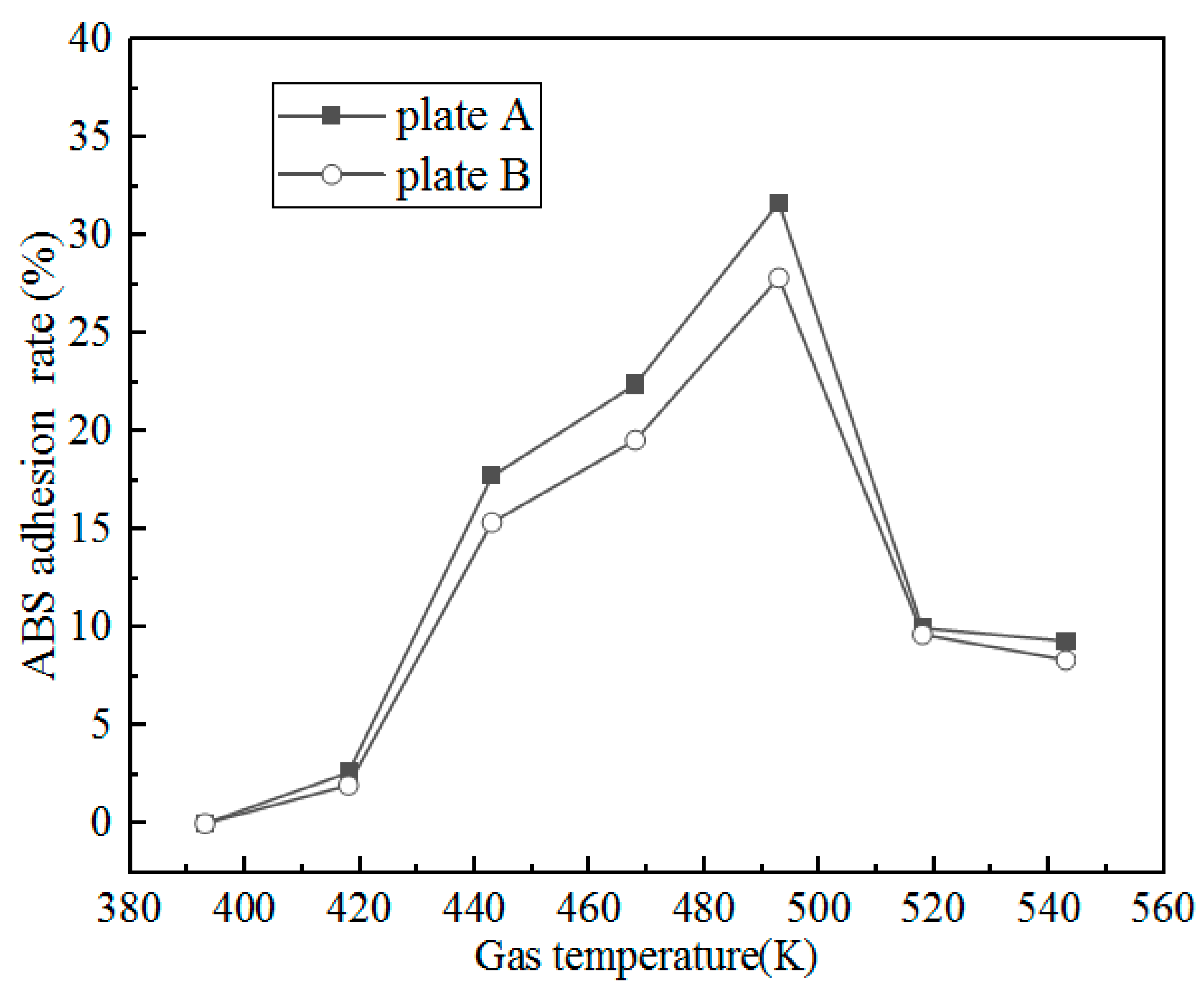

3.1.2. Effects of the Gas Temperature on the ABS Adhesion Rate

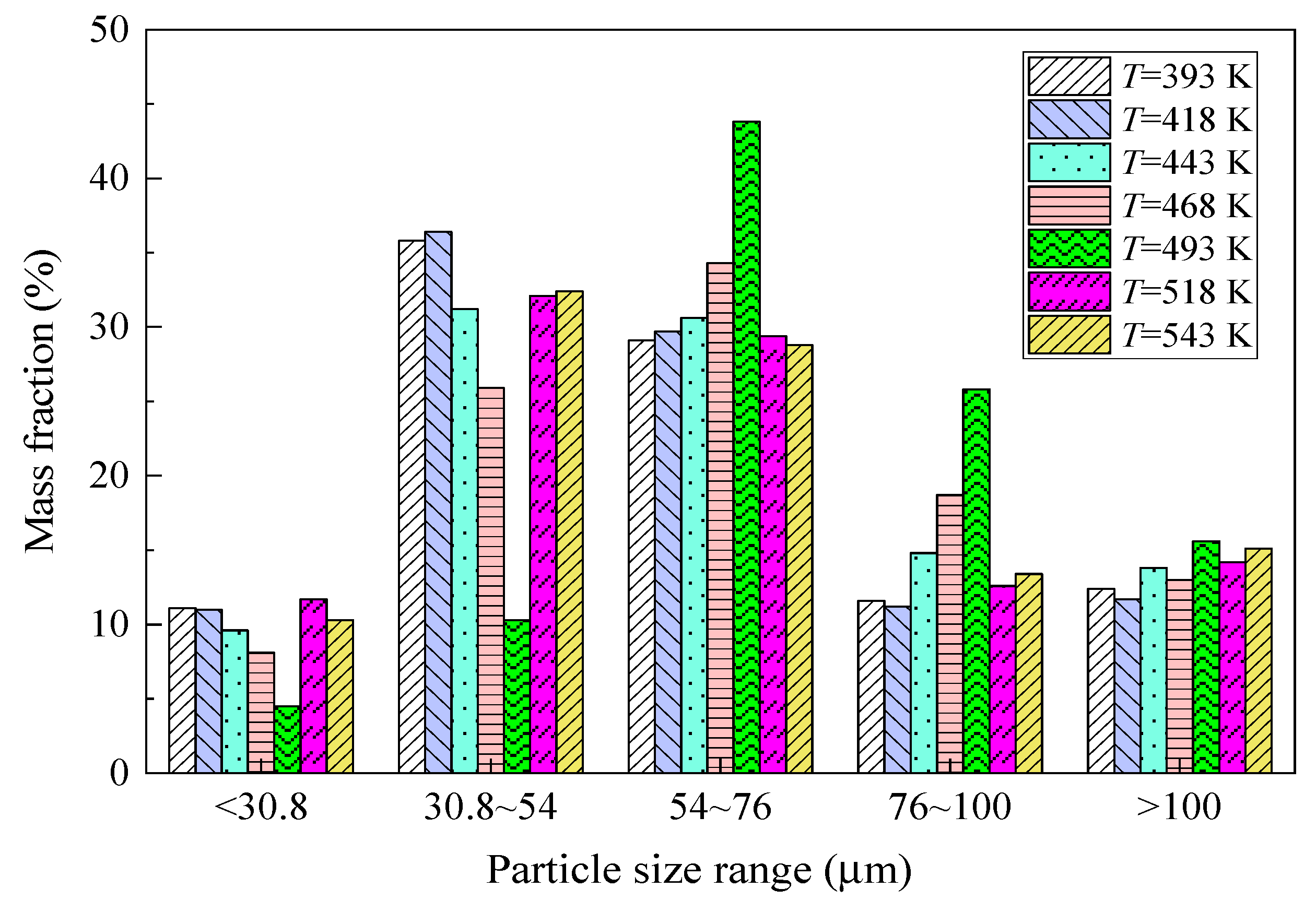

3.1.3. Effects of the Gas Temperature on the Particle Size Distribution of the Ash Deposition

3.2. Effects of the Gas Velocity on the Ash Deposition Characteristics

3.2.1. Effects of the Gas Velocity on the Ash Deposition Intensity

3.2.2. Effects of the Gas Velocity on the ABS Adhesion Rate

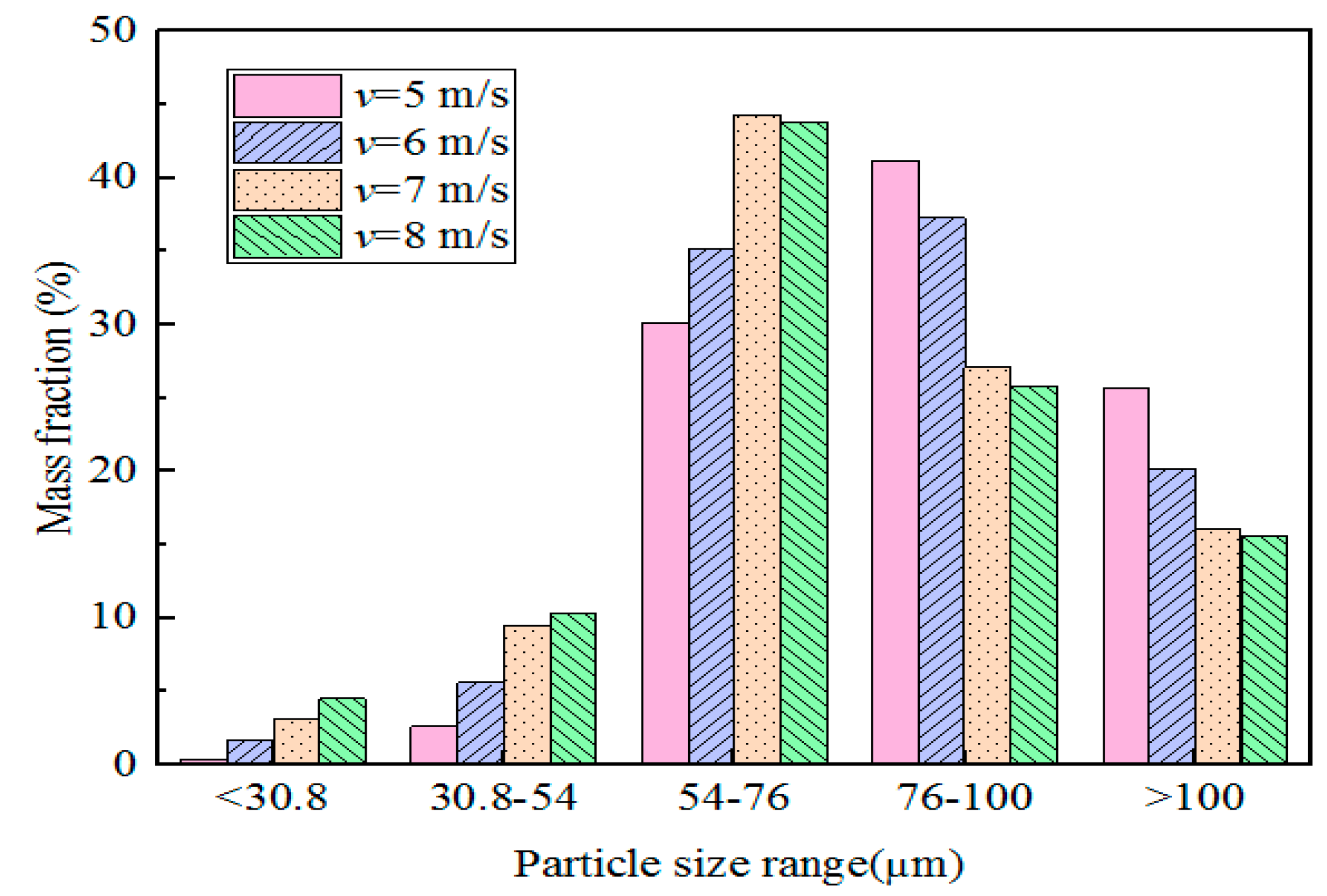

3.2.3. Effects of the Gas Velocity on the Particle Size Distribution of the Ash Deposition

3.3. Effects of the Mass Ratio of the ABS to the Fly Ash (R) on the Ash Deposition Characteristics

3.3.1. Effects of R on the Ash Deposition Intensity

3.3.2. Effects of R on the ABS Adhesion Rate

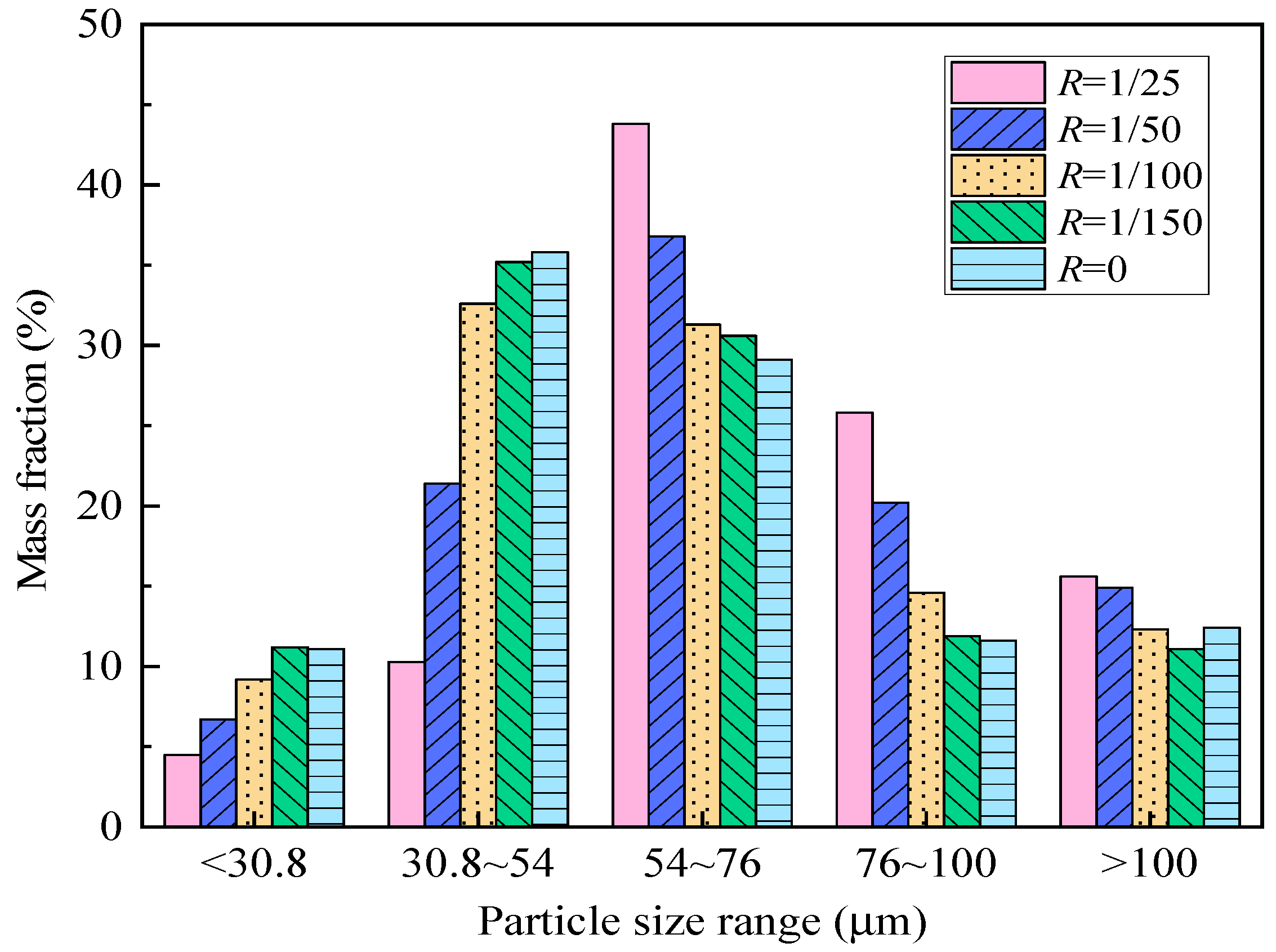

3.3.3. Effects of R on the Particle Size Distribution of the Ash Deposition

3.4. Effects of the Fly Ash Particle Size on the Ash Deposition Characteristics

3.4.1. Effects of the Fly Ash Particle Size on the Ash Deposition Intensity

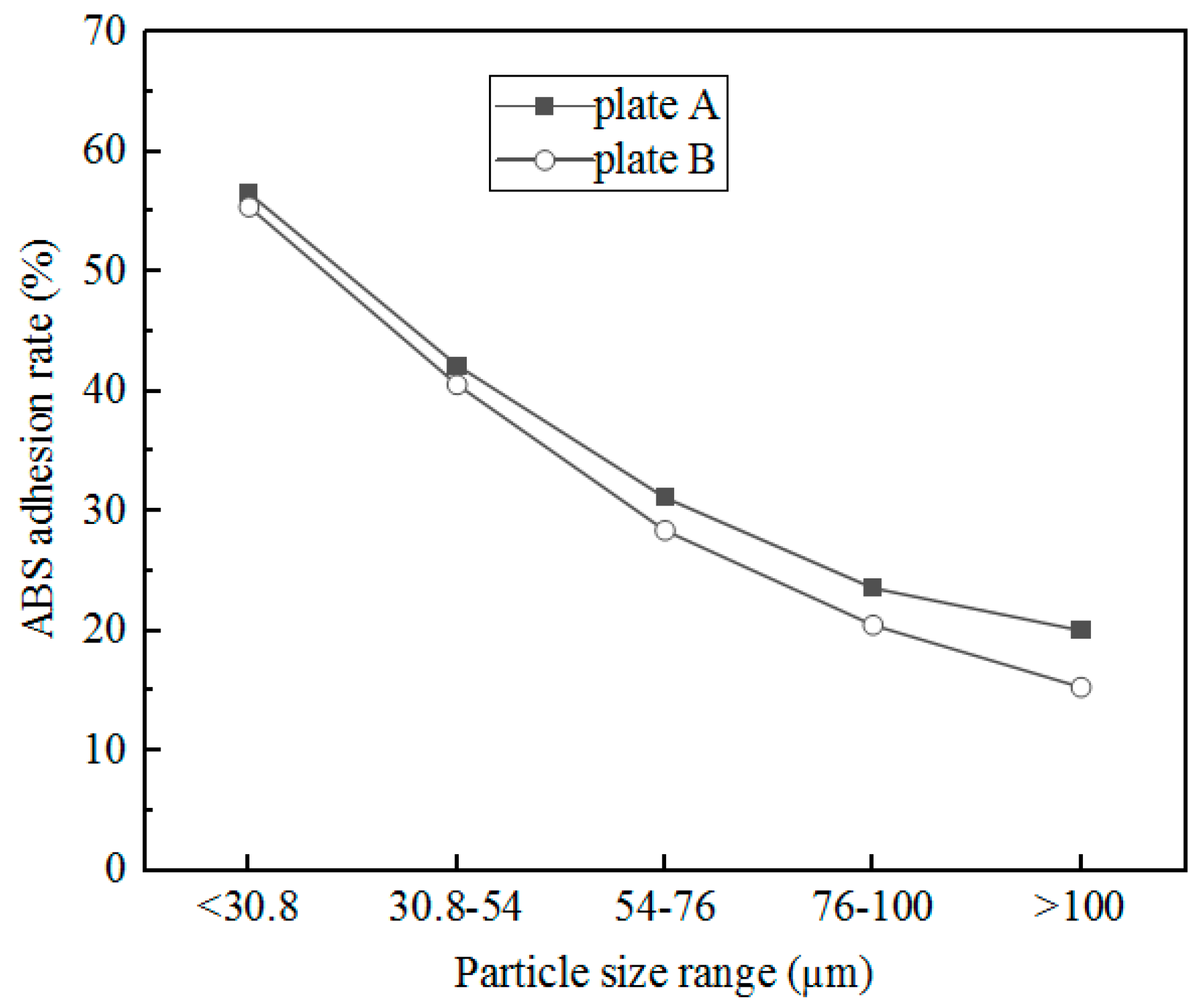

3.4.2. Effects of the Fly Ash Particle Size on the ABS Adhesion Rate

4. Conclusions

- (1)

- The gas temperature is an important factor. When the gas temperature is in the range of 420–493 K, with an increase in the gas temperature, the ABS ash deposition intensity, the ABS adhesion rate, and the mass fraction of the fly ash with the median particle size in the ash deposition all gradually increase. When the gas temperature is 493 K, the ABS adhesion rates of the corrugated plate and the positioning plate both reach their maximum values, which are 31.7% and 27.9%, respectively. When the gas temperature is lower than 420 K or higher than 493 K, the ABS adhesion rate is less than 10%. At the same temperature, the ABS ash deposition intensity of the corrugated plate is 1.3 times that of the positioning plate. Generally, the outlet temperature of the air preheater is lower than 423 K and its intermediate/cold and cold baskets are in the liquefaction temperature zone of ABS. This is the reason that the ABS adhesion ash deposition mainly appears in the intermediate/cold and cold baskets of the air preheater. Therefore, one of the feasible measures is to increase the wall temperature of the intermediate/cold and cold baskets of the air preheater using the steam air heater. The cold air before entering the air preheater is first preheated by the low-pressure bled-steam from the steam turbine in the steam air heater, but the boiler efficiency will decrease to a certain extent due to the increase in exhaust temperature.

- (2)

- The gas velocity is another important factor. With the decrease in the gas velocity, the total ash deposition intensity, the ABS ash deposition intensity, the ABS adhesion rate, and the growth rate of the ABS adhesion rate all increase, and the total ash deposition intensity on the surface of the heat transfer elements can promote the ABS adhesion rate. It is evident that the ABS adhesion ash deposition of the air preheater may tend to be serious due to the decrease in the flue gas velocity when the boiler load is reduced. Hence, the operation parameters of the soot blower need to be adjusted accordingly, including the time, the frequency, and the velocity of the ash blowing.

- (3)

- The ABS content in the fly ash has a great influence on the ABS adhesion rate. With an increase in R, the ABS adhesion rate increases significantly. The greater the ABS adhesion rate, the easier it is for the fly ash particles to agglomerate and the larger the particle size of the ash deposition. Therefore, the amount of ammonia escape from the SCR denitrification facility must be strictly controlled to reduce the formation of the ABS. The constant changes of the boiler load can cause an uneven concentration distribution of NOx in the economizer outlet [21]. Excessive ammonia is usually injected into the SCR denitrification facility for environmental protection [28,29]. As a result, the ammonia escape increases sharply. Therefore, it is recommended to implement an accurate partition ammonia injection strategy to match the NH3 concentration well with the NOx concentration to reduce ammonia escape. Meanwhile, it is an effective method to keep the good activity of the catalyst in the SCR denitrification facility to promote denitration reaction by controlling the suitable flue gas temperature, replacing the catalyst regularly, etc. Additionally, the formation of sulfur trioxide (SO3) can be reduced by means of the desulfurization of raw coal before burning and the low oxygen combustion technology in furnace in order to decrease the generation of ABS.

- (4)

- The particle size of the fly ash also has an obvious effect on the ABS ash deposition intensity and the ABS adhesion rate. With an increase in the particle size, the reduction in the total ash deposition intensity is less than 5%, but the reduction in the ABS ash deposition intensity is nearly 50%, and the ABS adhesion rate decreases significantly. When the fly ash particle size is less than 30.8 μm, the ABS adhesion rate is close to 60%. When the boiler load or the coal quality changes, the particle sizes of the pulverized coal and the fly ash all change. Under the condition of ensuring complete combustion, the larger particle sizes of the pulverized coal can be used. It not only reduces the power consumption for coal pulverization, but also helps to reduce ABS adhesion ash deposition.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Busca, G.; Lietti, L.; Ramis, G.; Berti, F. Chemical and mechanistic aspects of the selective catalytic reduction of NOx by ammonia over oxide catalysts: A review. Appl. Catal. B Environ. 1998, 18, 1–36. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, H.; Chen, Z. Experimental study on the ash deposit thermal conductivity for ammonium bisulfate and fly ash blend with an in situ measurement technology. Fuel 2020, 263, 116575. [Google Scholar] [CrossRef]

- Schreifels, J.J.; Wang, S.; Hao, J. Design and operational considerations for selective catalytic reduction technologies at coal-fired boilers. Front. Energy 2012, 6, 98–105. [Google Scholar] [CrossRef]

- Guo, K.; Ji, J.; Song, W.; Sun, J.; Tang, C.; Dong, L. Conquering ammonium bisulfate poison over low-temperature NH3-SCR catalysts: A critical review. Appl. Catal. B Environ. 2021, 297, 120388. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, M.; Kong, H.; Lyu, J.; Yang, H. Investigation and control technology on excessive ammonia-slipping in coal-fired plants. Energies 2020, 13, 4249. [Google Scholar] [CrossRef]

- Zheng, C.; Wang, Y.; Liu, Y.; Yang, Z.; Qu, R.; Ye, D.; Liang, C.; Liu, S.; Gao, X. Formation, transformation, measurement, and control of SO3 in coal-fired power plants. Fuel 2019, 241, 327–346. [Google Scholar] [CrossRef]

- Orsenigo, C.; Beretta, A.; Forzatti, P.; Svachula, J.; Tronconi, E.; Bregani, F.; Baldacci, A. Theoretical and experimental study of the interaction between NOx reduction and SO2 oxidation over DeNOx-SCR catalysts. Catal. Today 1996, 27, 15–21. [Google Scholar] [CrossRef]

- Qing, M.; Su, S.; Wang, L.; Liu, L.; Xu, K.; He, L.; Jun, X.; Hu, S.; Wang, Y.; Xiang, J. Getting insight into the oxidation of SO2 to SO3 over V2O5-WO3/TiO2 catalysts: Reaction mechanism and effects of NO and NH3. Chem. Eng. J. 2019, 361, 1215–1224. [Google Scholar] [CrossRef]

- Cheng, T.; Luo, L.; Yang, L.; Fan, H.; Wu, H. Formation and emission characteristics of ammonium sulfate aerosols in flue gas downstream of selective catalytic reduction. Energy Fuels 2019, 33, 7861–7868. [Google Scholar] [CrossRef]

- Cheng, T.; Zheng, C.; Yang, L.; Wu, H.; Fan, H. Effect of selective catalytic reduction denitrification on fine particulate matter emission characteristics. Fuel 2019, 238, 18–25. [Google Scholar] [CrossRef]

- Wang, L.; Bu, Y.; Tang, C.; Lv, C.; Chen, X.; Che, D. Study on the formation process of low-temperature ash deposition induced by ammonium bisulfate in pulverized coal-fired boiler. Asia-Pacific J. Chem. Eng. 2020, 15, e2389. [Google Scholar] [CrossRef]

- Si, F.; Romero, C.E.; Yao, Z.; Xu, Z.; Morey, R.L.; Liebowitz, B.N. Inferential sensor for on-line monitoring of ammonium bisulfate formation temperature in coal-fired power plants. Fuel Process. Technol. 2009, 90, 56–66. [Google Scholar] [CrossRef]

- Muzio, L.; Bogseth, S.; Himes, R.; Chien, Y.-C.; Dunn-Rankin, D. Ammonium bisulfate formation and reduced load SCR operation. Fuel 2017, 206, 180–189. [Google Scholar] [CrossRef]

- Bu, Y.; Wang, L.; Chen, X.; Wei, X.; Deng, L.; Che, D. Numerical analysis of ABS deposition and corrosion on a rotary air preheater. Appl. Therm. Eng. 2018, 131, 669–677. [Google Scholar] [CrossRef]

- Luo, M.; Zhao, L.L.; Li, S.Y. Numerical simulation of ash deposition with adhesion of NH4HSO4 in an air preheater. Chin. Soc. Power Eng. 2016, 36, 883–888. [Google Scholar]

- Chen, H.; Pan, P.; Shao, H.; Wang, Y.; Zhao, Q. Corrosion and viscous ash deposition of a rotary air preheater in a coal-fired power plant. Appl. Therm. Eng. 2017, 113, 373–385. [Google Scholar] [CrossRef]

- Yan, L.; Sun, F.; Zheng, P. Research on adhesion mechanism of ash particles and ammonium bisulfate on the metal wall in coal-fired boilers. Fuel 2020, 277, 118021. [Google Scholar] [CrossRef]

- Menasha, J.; Dunn-Rankin, D.; Muzio, L.; Stallings, J. Ammonium bisulfate formation temperature in a bench-scale single-channel air preheater. Fuel 2011, 90, 2445–2453. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, L.; Deng, Y.; Ma, S.-C. Research progress on ammonium bisulfate formation and control in the process of selective catalytic reduction. Environ. Prog. Sustain. Energy 2016, 35, 1664–1672. [Google Scholar] [CrossRef]

- Ma, S.C.; Jin, X.; Sun, Y.X.; Cui, J.W. The formation mechanism of ammonium bisulfate in SCR flue gas denitrification process and control thereof. Therm. Power Gener. 2010, 39, 12–17. [Google Scholar]

- Zhu, B.; Shang, B.; Guo, X.; Wu, C.; Chen, X.; Zhao, L. Study on combustion characteristics and NOx formation in 600 MW coal-fired boiler based on numerical simulation. Energies 2022, 16, 262. [Google Scholar] [CrossRef]

- Ni, Y.; Rong, Y.; Yu, X.; Huang, S.; Xue, X.; Zhou, H. Experimental study on the effects of reheat temperatures on the ammonium bisulfate and ash blend deposition. Fuel 2022, 324, 124719. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, X.; Chu, D.; Sun, F.; Guo, Z. An experimental study of ash accumulation in flue gas. Adv. Powder Technol. 2016, 27, 1473–1480. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, J.; Zhang, K. Investigation of the deposition characteristics of ammonium bisulfate and fly ash blend using an on-line digital image technique: Effect of deposition surface temperature. Fuel Process. Technol. 2018, 179, 359–368. [Google Scholar] [CrossRef]

- Vuthaluru, H.B.; French, D.H. Investigations into the air heater ash deposit formation in large scale pulverized coal fired boiler. Fuel 2015, 140, 27–33. [Google Scholar] [CrossRef]

- Qing, M.; Lei, S.; Kong, F.; Liu, L.; Zhang, W.; Wang, L.; Guo, T.; Su, S.; Hu, S.; Wang, Y.; et al. Analysis of ammonium bisulfate/sulfate generation and deposition characteristics as the by-product of SCR in coal-fired flue gas. Fuel 2022, 313, 122790. [Google Scholar] [CrossRef]

- Liang, D. Experimental Research on the Effects to Flue Ash Particles Characteristics of NH4HSO4 Generating during the Denitrification Process. Master’s Thesis, Shandong University, Jinan, China, 2014. [Google Scholar]

- Zhang, Z.; Song, G.; Chen, C.; Han, Z. Cause analysis of ammonia escape in SCR flue gas denitrification process for 600 MW units. Electr. Power Constr. 2012, 33, 67–70. [Google Scholar]

- Liu, T. Analysis on measurement and control strategy for denitration system of thermal power generating units and its optimization. Zhejiang Electr. Power 2016, 35, 42–44. [Google Scholar]

| Oxides | Mass Fraction (%) |

|---|---|

| SiO2 | 46.41 |

| Al2O3 | 43.23 |

| CaO | 3.64 |

| Fe2O3 | 2.44 |

| TiO2 | 1.00 |

| MgO | 0.62 |

| K2O | 0.28 |

| P2O5 | 0.25 |

| SO3 | 0.24 |

| Na2O | 0.06 |

| MnO2 | 0.02 |

| Plate A of the Heat Transfer Element | Plate B of the Heat Transfer Element | |||||

|---|---|---|---|---|---|---|

| R = 1/25 | R = 0 | R = 1/25 | R = 0 | |||

| Temperature (K) | Total Ash Deposition Intensity (Qtot, A) (g/m2) | ABS Ash Deposition Intensity (QABS, A) (g/m2) | Total Ash Deposition Intensity (Qtot, A) (g/m2) | Total Ash Deposition Intensity (Qtot, B) (g/m2) | ABS Ash Deposition Intensity (QABS, B) (g/m2) | ABS Ash Deposition Intensity (Qtot, B) (g/m2) |

| 393 | 229.5 | 0.0 | 231.5 | 171.0 | 0.0 | 170.5 |

| 418 | 231.0 | 6.0 | 230.5 | 170.5 | 3.5 | 170.5 |

| 443 | 266.0 | 47.0 | 232.5 | 213.0 | 32.5 | 174.0 |

| 468 | 274.5 | 61.5 | 228.5 | 222.5 | 43.5 | 171.0 |

| 493 | 283.5 | 90.0 | 229.0 | 242.0 | 67.5 | 169.5 |

| 518 | 256.0 | 25.5 | 231.0 | 186.5 | 18.0 | 172.5 |

| 543 | 257.5 | 24.0 | 233.0 | 186.5 | 15.5 | 173.5 |

| Plate A of the Heat Transfer Element | Plate B of the Heat Transfer Element | |||

|---|---|---|---|---|

| Gas Velocity (m/s) | Total Ash Deposition Intensity (Qtot, A) (g/m2) | ABS Ash Deposition Intensity (QABS, A) (g/m2) | Total Ash Deposition Intensity (Qtot, B) (g/m2) | ABS Ash Deposition Intensity (QABS, B) (g/m2) |

| 5 | 340.0 | 132.5 | 317.5 | 116.0 |

| 6 | 311.0 | 108.0 | 288.0 | 94.5 |

| 7 | 294.5 | 96.0 | 260.5 | 78.0 |

| 8 | 283.5 | 90.0 | 242.0 | 67.5 |

| Plate A of the Heat Transfer Element | Plate B of the Heat Transfer Element | |||

|---|---|---|---|---|

| Value of R | Total Ash Deposition Intensity (Qtot, A) (g/m2) | ABS Ash Deposition Intensity (QABS, A) (g/m2) | Total Ash Deposition Intensity (Qtot, B) (g/m2) | ABS Ash Deposition Intensity (QABS, B) (g/m2) |

| 1/25 | 283.5 | 90.0 | 242.0 | 67.5 |

| 1/50 | 279.0 | 58.0 | 221.5 | 41.5 |

| 1/100 | 257.0 | 31.5 | 182.0 | 23.0 |

| 1/150 | 236.5 | 14.0 | 174.0 | 6.0 |

| 0 | 229.0 | 0.0 | 169.5 | 0.0 |

| Plate A of the Heat Transfer Element | Plate B of the Heat Transfer Element | |||

|---|---|---|---|---|

| Particle Size Range (μm) | Total Ash Deposition Intensity (Qtot, A) (g/m2) | ABS Ash Deposition Intensity (QABS, A) (g/m2) | Total ash Deposition Intensity (Qtot, B) (g/m2) | ABS Ash Deposition Intensity (QABS, B) (g/m2) |

| <30.8 | 286.5 | 162.0 | 244.5 | 135.5 |

| 30.8–54 | 288.0 | 121.5 | 241.5 | 98.0 |

| 54–76 | 281.0 | 87.5 | 243.0 | 69.0 |

| 76–100 | 282.0 | 66.5 | 239.0 | 49.0 |

| >100 | 279.5 | 56.0 | 238.5 | 36.5 |

| Full particle size | 283.5 | 90.0 | 242.0 | 67.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Ji, X.; Feng, J.; Heng, L.; Zhao, L. Laboratory Study on Adhesive Ash Deposition Characteristics of Ammonium Bisulfate in Conditions Simulating an Air Preheater for Hard Coal Combustion. Energies 2023, 16, 6513. https://doi.org/10.3390/en16186513

Chen X, Ji X, Feng J, Heng L, Zhao L. Laboratory Study on Adhesive Ash Deposition Characteristics of Ammonium Bisulfate in Conditions Simulating an Air Preheater for Hard Coal Combustion. Energies. 2023; 16(18):6513. https://doi.org/10.3390/en16186513

Chicago/Turabian StyleChen, Xiaoqiang, Xinye Ji, Jinjin Feng, Lijun Heng, and Lingling Zhao. 2023. "Laboratory Study on Adhesive Ash Deposition Characteristics of Ammonium Bisulfate in Conditions Simulating an Air Preheater for Hard Coal Combustion" Energies 16, no. 18: 6513. https://doi.org/10.3390/en16186513

APA StyleChen, X., Ji, X., Feng, J., Heng, L., & Zhao, L. (2023). Laboratory Study on Adhesive Ash Deposition Characteristics of Ammonium Bisulfate in Conditions Simulating an Air Preheater for Hard Coal Combustion. Energies, 16(18), 6513. https://doi.org/10.3390/en16186513