Performance Simulation Model of a Radiation-Enhanced Thermal Diode Tank-Assisted Refrigeration and Air-Conditioning (RTDT-RAC) System: A Novel Cooling System

Abstract

:1. Introduction

2. Performance Simulation Models

2.1. Physical Model

2.2. Modelling of TDT-RAC Cycles

- There is no heat transfer through the RTDT walls;

- The heat generated by the RAC system’s condenser is fully absorbed by the RTDT water;

- The cooling capacity required for the conditioned room is fixed every day;

- The evaporating temperature is set as a constant value at 10 °C;

- In the early morning, the minimum CTDT water temperature is 2 °C higher than the night ambient temperature, whereas the minimum RTDT water temperature is 0.5 °C higher than the night ambient temperature;

- There is no heat loss in processes 3 to 4 (via the expansion valve);

- The temperature distributions within the CTDT and RTDT are uniform;

- Constant ambient conditions are also assumed, such as the ambient temperature, sky temperature, and wind speed;

- The model assumes an ideal heat transfer and neglects any losses or inefficiencies that may occur in practical scenarios;

- A reasonable estimate for the temperature gap between the refrigerant temperature inside the condenser coils and the external (air/water) temperature around the condenser coil can range from 5 to 15 °C. In this model, the condensing temperature is either 15 °C higher than the ambient air temperature or 5 °C higher than the water temperature.

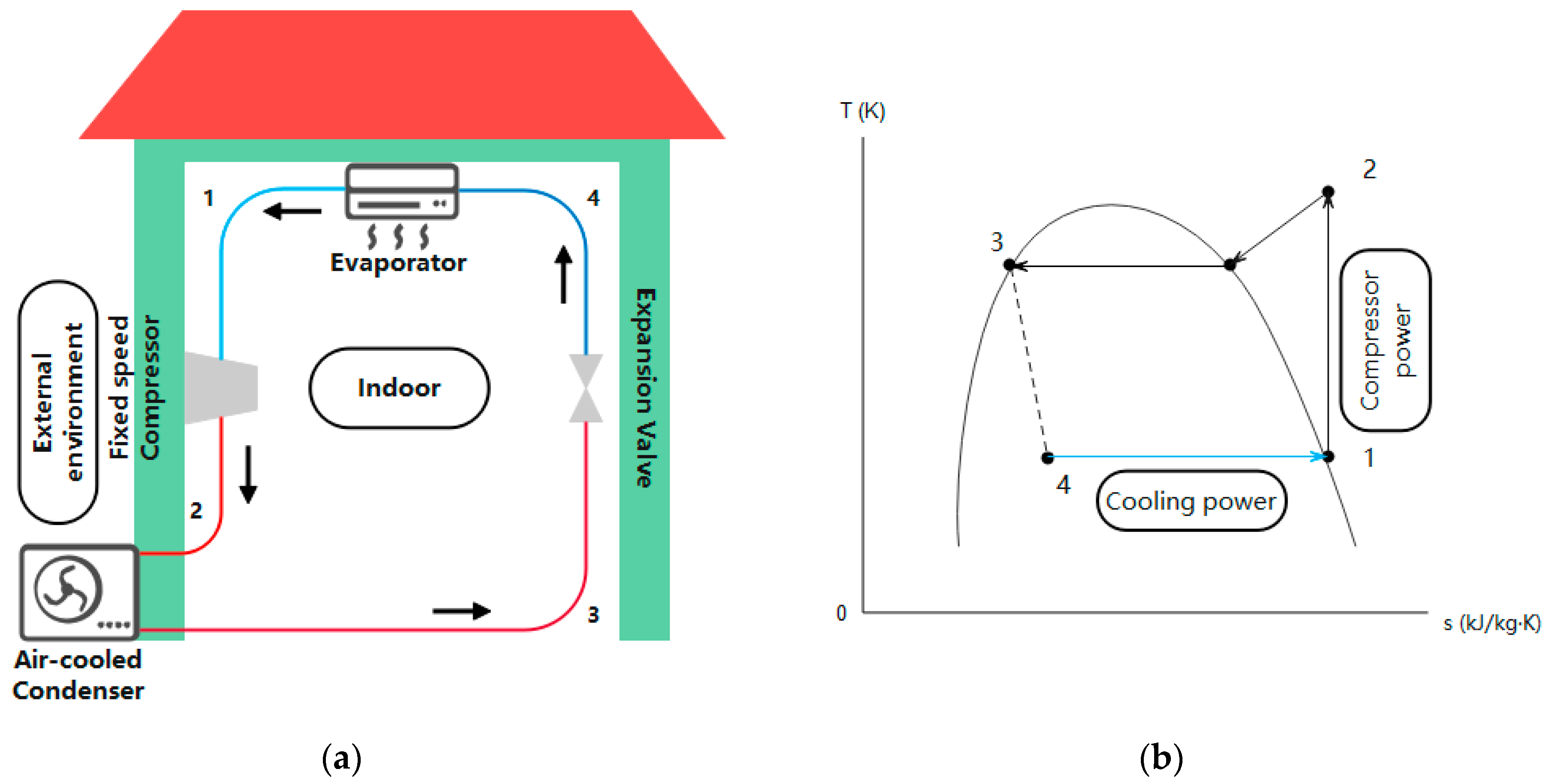

2.2.1. System 1: A Reference Air-Sourced RAC System

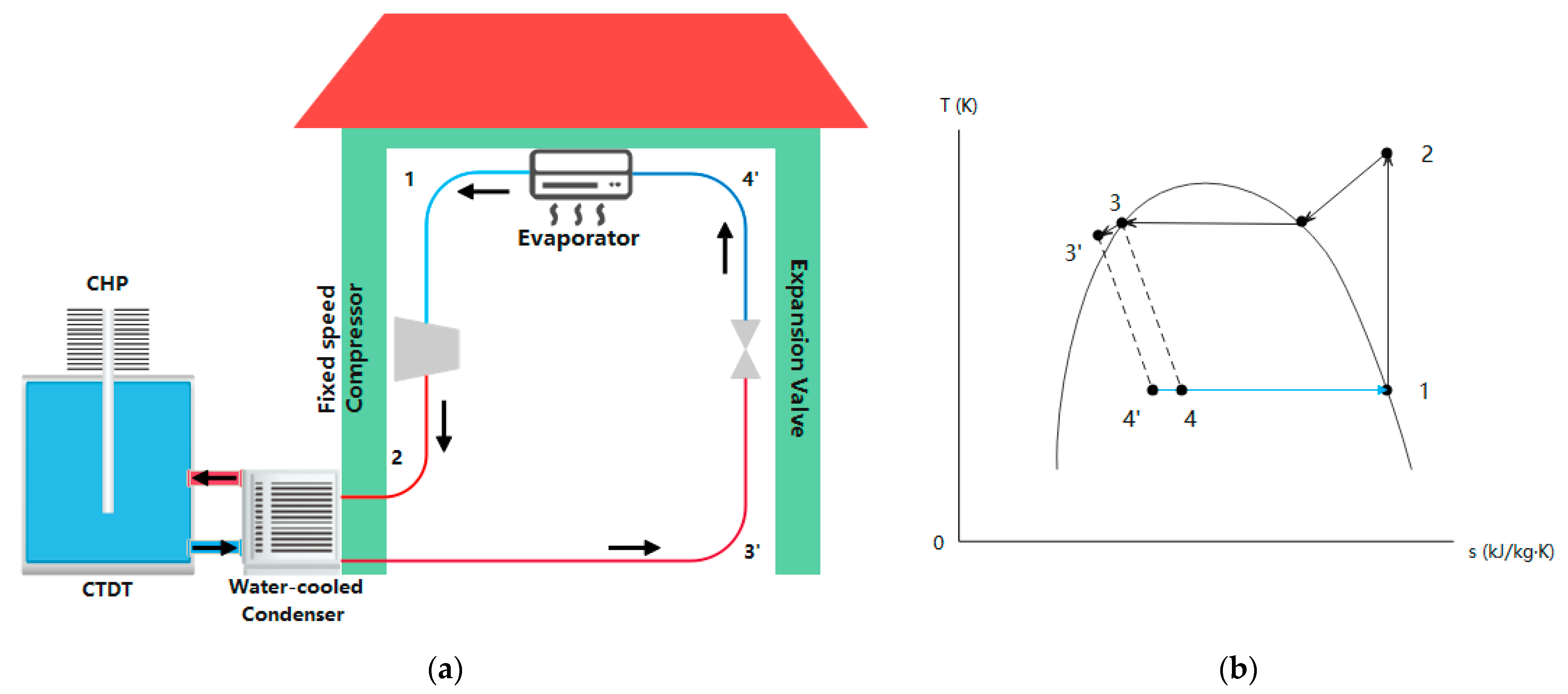

2.2.2. System 2: A Fixed-Speed CTDT-RAC System

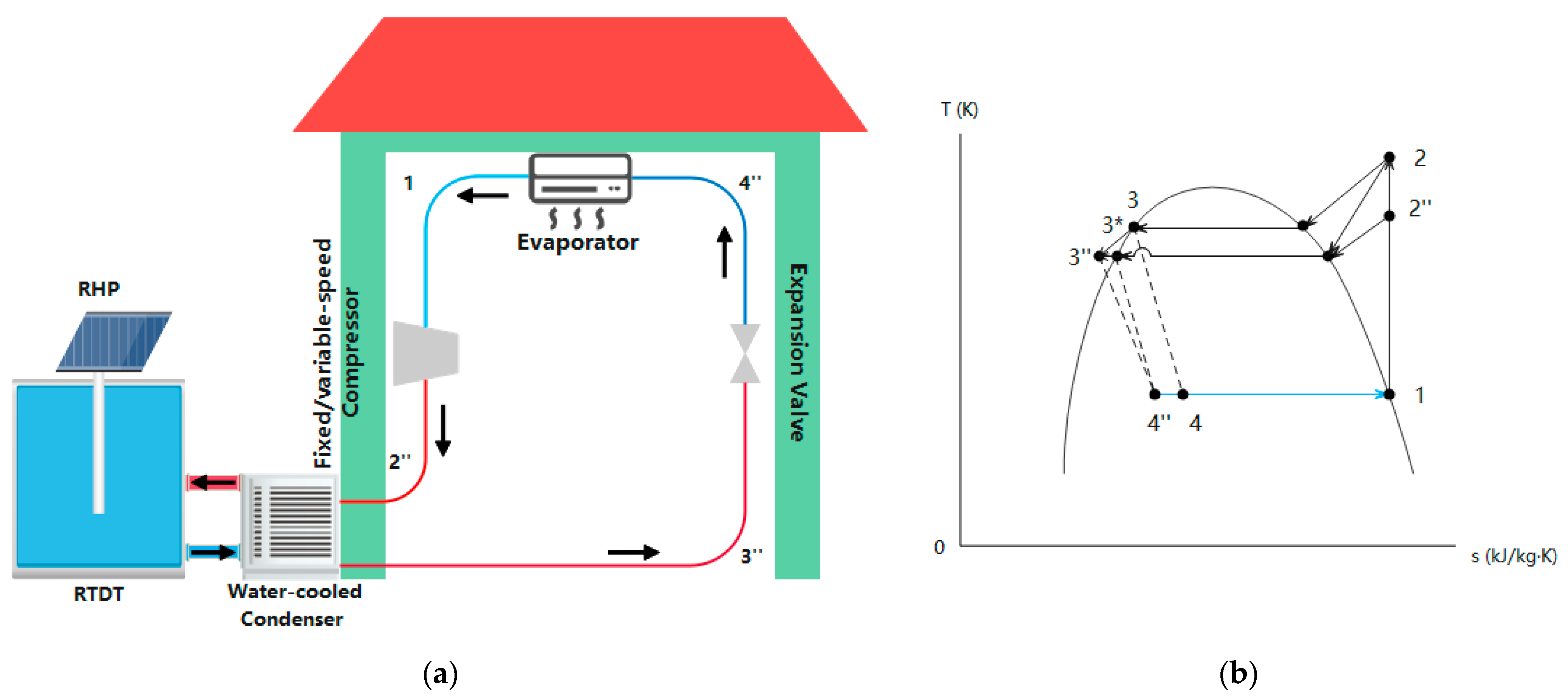

2.2.3. Systems 3 and 4: RTDT-RAC Systems

3. Reference Case

4. Sensitivity Analysis

4.1. Daytime Ambient Temperature

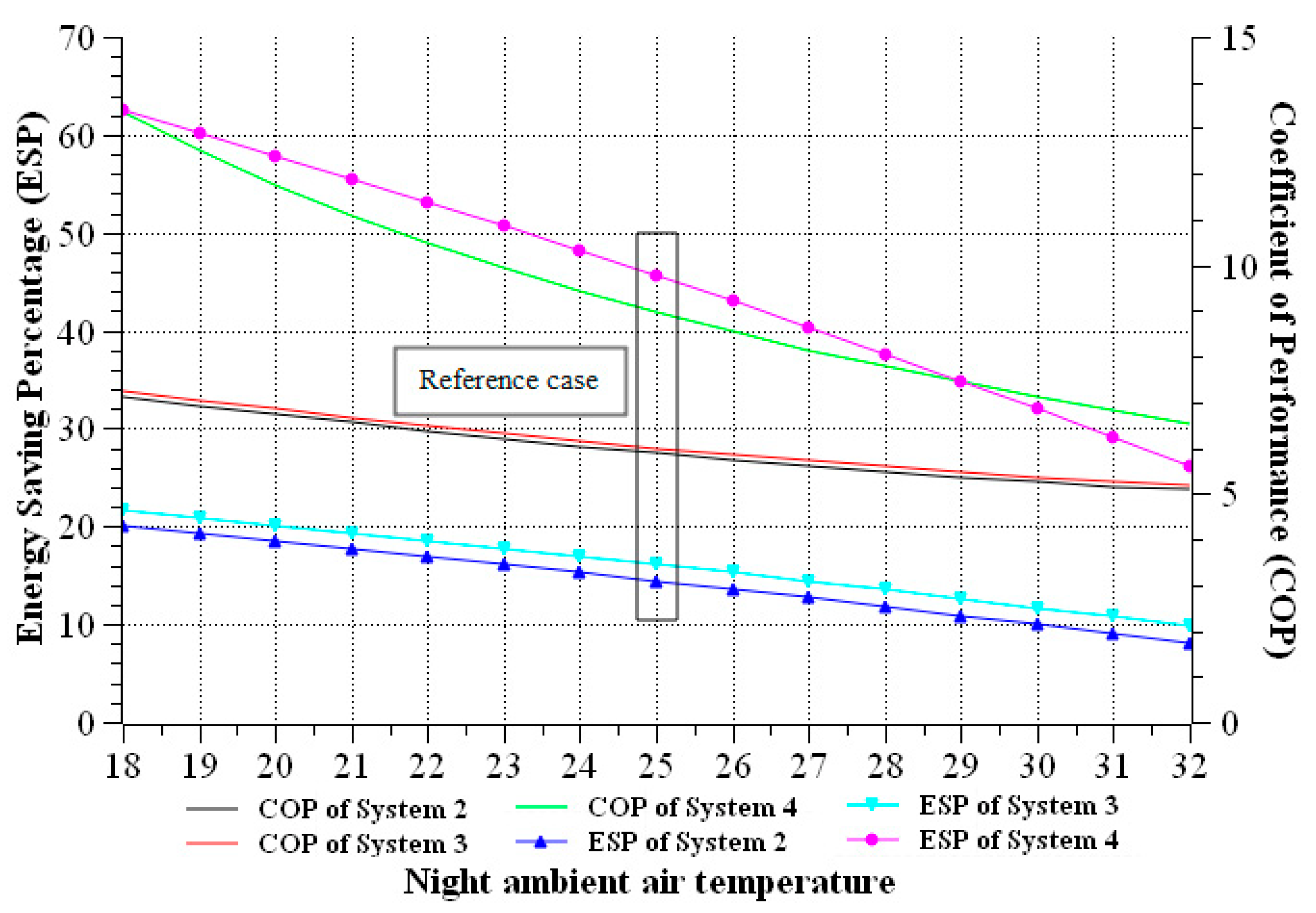

4.2. Night Ambient Temperature

4.3. Tank Size to Cooling Capacity (TS/Qc) Ratio

5. Economic Analysis

6. Conclusions

- In the reference case analysis, the proposed RTDT-RAC system incorporating a variable-speed compressor demonstrated the highest energy efficiency. This configuration achieves optimal energy savings, with potential energy reductions of up to 45.59%. The fixed-speed RTDT-RAC system and the CTDT-RAC system also exhibit notable energy savings, with energy reductions of 16.11% and 14.43%, respectively. These findings prove the superior performance of the RTDT-RAC system compared to that of other systems;

- The day/night ambient temperature difference was identified as a critical factor influencing the system performance. The results indicate that Systems 2–4, equipped with water-sourced condensers, are sensitive to changes in ambient temperatures. A higher day/night ambient temperature difference leads to an improved system performance, which also highlights the need for the careful consideration of compatibility with the prevailing environmental conditions during the system design;

- The impact of the tank size to cooling capacity (TS/Qc) ratio on system performance was investigated. The findings reveal that the ESP and COP curves exhibit similar trends. Increasing the TS/Qc ratio initially leads to rapid improvements in energy savings and COP, but the curves eventually flatten out. An optimal TS/Qc value of 1 m3/kW was found to offer the highest cost-effectiveness and efficiency. Beyond this value, further increases in the ratio result in diminishing returns in terms of ESP and COP enhancement;

- The analysis also identified a threshold TS/Qc value, which is approximately 0.18 m3/kW for the TDT-RAC systems to achieve positive ESPs. Below this threshold value, Systems 2–4 consume more energy than the reference system.

7. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Specific heat capacity (kJ/kg °C) | |

| Es | Saved energy (kJ) |

| h | Specific enthalpy (kJ/kg) |

| Mass flow rate (kg/s) | |

| m | Mass (kg) |

| Heat through to condenser(kJ) | |

| The rate of heat through to the condenser (kW) | |

| Cooling capacity (kW) | |

| Daytime ambient temperature (°C) | |

| Night ambient temperature (°C) | |

| Room temperature (°C) | |

| TS/Qc | Tank size to cooling capacity ratio |

| CTDT water temperature (°C) | |

| RTDT water temperature (°C) | |

| ∆T | Day and night ambient temperature difference (°C) |

| System daily operating time (h or s) | |

| System operating time interval (h or s) | |

| Tank size (m3) | |

| i | Number of time step |

| j | System number |

| Input energy (kJ) | |

| Greek Symbols | |

| Density (kg/m3) | |

| Abbreviations | |

| CHP | Convective heat pipe |

| COP | Coefficient of performance |

| CTDT | Convection thermal diode tank |

| ESP | Energy-saving percentage |

| GSHP | Ground-sourced heat pump |

| HTC | Heat transfer capacity |

| RAC | Refrigeration and air-conditioning |

| RHP | Radiation-enhanced heat pipe |

| RTDT | Radiation-enhanced thermal diode tank |

| TDT | Thermal diode tank |

| TDT-RAC | Thermal diode tank-assisted refrigeration and air-conditioning |

| WSHP | Water-sourced heat pump |

References

- Jahangeer, K.; Tay, A.A.; Islam, R. Numerical investigation of transfer coefficients of an evaporatively-cooled condenser. Appl. Therm. Eng. 2011, 31, 1655–1663. [Google Scholar] [CrossRef]

- Kumbhar, A.; Gulhane, N.; Pandure, S. Effect of Various Parameters on Working Condition of Chiller. Energy Procedia 2017, 109, 479–486. [Google Scholar] [CrossRef]

- Hajidavalloo, E.; Eghtedari, H. Performance improvement of air-cooled refrigeration system by using evaporatively cooled air condenser. Int. J. Refrig. 2010, 33, 982–988. [Google Scholar] [CrossRef]

- Hajidavalloo, E. Application of evaporative cooling on the condenser of window-air-conditioner. Appl. Therm. Eng. 2007, 27, 1937–1943. [Google Scholar] [CrossRef]

- Youbi-Idrissi, M.; Macchi-Tejeda, H.; Fournaison, L.; Guilpart, J. Numerical model of sprayed air cooled condenser coupled to refrigerating system. Energy Convers. Manag. 2007, 48, 1943–1951. [Google Scholar] [CrossRef]

- Yu, F.W.; Chan, K.T. Application of Direct Evaporative Coolers for Improving the Energy Efficiency of Air-Cooled Chillers. J. Sol. Energy Eng. 2005, 127, 430–433. [Google Scholar] [CrossRef]

- Kim, B.-J.; Jo, S.-Y.; Jeong, J.-W. Energy performance enhancement in air-source heat pump with a direct evaporative cooler-applied condenser. Case Stud. Therm. Eng. 2022, 35, 102137. [Google Scholar] [CrossRef]

- Ketwong, W.; Deethayat, T.; Kiatsiriroat, T. Performance enhancement of air conditioner in hot climate by condenser cooling with cool air generated by direct evaporative cooling. Case Stud. Therm. Eng. 2021, 26, 101127. [Google Scholar] [CrossRef]

- Pan, S.; Pei, F.; Wei, Y.; Wang, H.; Liu, J.; Zhang, X.; Li, G.; Gu, Y. Design and experimental study of a novel air conditioning system using evaporative condenser at a subway station in Beijing, China. Sustain. Cities Soc. 2018, 43, 550–562. [Google Scholar] [CrossRef]

- Ruiz, J.; Cutillas, C.; Martínez, P.; Kaiser, A.; Lucas, M. Experimental study on energy performance of a split air-conditioner by using variable thickness evaporative cooling pads coupled to the condenser. Appl. Therm. Eng. 2016, 105, 1041–1050. [Google Scholar] [CrossRef]

- Wang, T.; Sheng, C.; Nnanna, A.A. Experimental investigation of air conditioning system using evaporative cooling condenser. Energy Build. 2014, 81, 435–443. [Google Scholar] [CrossRef]

- Sarntichartsak, P.; Thepa, S. Modeling and experimental study on the performance of an inverter air conditioner using R-410A with evaporatively cooled condenser. Appl. Therm. Eng. 2013, 51, 597–610. [Google Scholar] [CrossRef]

- Spitler, J.D.; Mitchell, M.S. Advances in Ground-Source Heat Pump Systems. Surface Water Heat Pump Systems; Woodhead Publishing: Stillwater, Oklahoma, USA, 2016; Available online: https://www.sciencedirect.com/science/article/abs/pii/B978008100311400008X (accessed on 12 May 2023).

- Kharseh, M.; Al-Khawaja, M.; Suleiman, M.T. Potential of ground source heat pump systems in cooling-dominated environments: Residential buildings. Geothermics 2015, 57, 104–110. [Google Scholar] [CrossRef]

- Morrone, B.; Coppola, G.; Raucci, V. Energy and economic savings using geothermal heat pumps in different climates. Energy Convers. Manag. 2014, 88, 189–198. [Google Scholar] [CrossRef]

- Luo, J.; Rohn, J.; Bayer, M.; Priess, A.; Wilkmann, L.; Xiang, W. Heating and cooling performance analysis of a ground source heat pump system in Southern Germany. Geothermics 2014, 53, 57–66. [Google Scholar] [CrossRef]

- Akrouch, G.A.; Sánchez, M.; Briaud, J.-L. Thermal performance and economic study of an energy piles system under cooling dominated conditions. Renew. Energy 2020, 147, 2736–2747. [Google Scholar] [CrossRef]

- Christodoulides, P.; Aresti, L.; Florides, G. Air-conditioning of a typical house in moderate climates with Ground Source Heat Pumps and cost comparison with Air Source Heat Pumps. Appl. Therm. Eng. 2019, 158, 113772. [Google Scholar] [CrossRef]

- Maddah, S.; Deymi-Dashtebayaz, M.; Maddah, O. 4E analysis of thermal recovery potential of industrial wastewater in heat pumps: An invisible energy resource from the iranian casting industry sector. J. Clean. Prod. 2020, 265, 121824. [Google Scholar] [CrossRef]

- Wei, F.; Wang, B.; Cheng, Z.; Cui, M. Experimental research on vapor-injected water source heat pump using R1234ze(E). Appl. Therm. Eng. 2023, 229, 120595. [Google Scholar] [CrossRef]

- Bruch, A.; Bourdon, D.; Dumas, C.; Blaise, A.; Chouvel-Saye, A. Experimental characterization of a water/rock thermocline cold thermal energy storage for optimization of condenser cooling. J. Energy Storage 2021, 44, 103426. [Google Scholar] [CrossRef]

- López-Zavala, R.; Velázquez-Limón, N.; Ojeda-Benítez, S.; Nakasima-López, M.; Lara, F.; Aguilar-Jiménez, J.; Santillán-Soto, N.; Islas, S. Novel desalination system that uses product water to generate cooling through a barometric ejector-condenser. Energy 2023, 276, 127536. [Google Scholar] [CrossRef]

- Raveendran, P.S.; Sekhar, S.J. Experimental studies on the performance improvement of household refrigerator connected to domestic water system with a water-cooled condenser in tropical regions. Appl. Therm. Eng. 2020, 179, 115684. [Google Scholar] [CrossRef]

- Wang, M.; Hu, E.; Chen, L. Energy-Saving Potential of Thermal Diode Tank Assisted Refrigeration and Air-Conditioning Systems. Energies 2021, 15, 206. [Google Scholar] [CrossRef]

- Wang, M.; Hu, E.; Chen, L. Radiation-enhanced thermal diode tank (RTDT) for refrigeration and air-conditioning (RAC) systems. Int. J. Refrig. 2023, 146, 237–247. [Google Scholar] [CrossRef]

- Cost of a Rainwater Tank—Tankworld Australia. Available online: https://www.tankworld.com.au/cost-of-a-rainwater-tank/ (accessed on 10 August 2023).

- Average Electricity Prices in Australia per kWh—Canstar Blue. Available online: https://www.canstarblue.com.au/electricity/electricity-costs-kwh/ (accessed on 10 August 2023).

| Input | |

| Cooling capacity for the conditioned room (kW) | |

| Troom | Room temperature (°C) |

| Ta | Daytime ambient air temperature (°C) |

| Te | Evaporating temperature (°C) |

| Tnight | Night ambient temperature (°C) |

| Twater_C | CTDT water temperature (°C) |

| Twater_R | RTDT water temperature (°C) |

| ∆t | Time step (hour) |

| tRAC | Total operation time (hour) |

| V | Tank size (m3) |

| CP | Specific heat capacity of water (kJ/kg °C) |

| Density of water (kg/m3) | |

| Outputs | |

| COP | COP for each time step |

| Compressor power | |

| Es | Saved energy |

| Input | |

|---|---|

| Daytime ambient air temperature, Ta (°C) | 40 |

| Conditioned room temperature, Troom (°C) | 22 |

| Evaporating temperature, Te (°C) | 10 |

| Night ambient temperature, Tnight (°C) | 25 |

| CTDT water temperature, Twater_C (°C) | 27 (Tnight + 2 °C) |

| RTDT water temperature, Twater_R (°C) | 25.5 (Tnight + 0.5 °C) |

| Tank size, V (m3) | 10 |

| Water density, ρ (kg/m3) | 1000 |

| RAC system cooling capacity, (kW) | 20 |

| Tank size to cooling capacity (TS/Qc) ratio | 0.5 |

| RAC system daily operation duration, tRAC (hour) | 8 (from 9 am to 17 pm) |

| Systems | COP | Daily Wc (kWh) | Daily Es (kWh) | ESP |

|---|---|---|---|---|

| System 1. Reference air-sourced RAC system | 4.68 | 34.16 | - | - |

| System 2. Fixed-speed CTDT-RAC system | 5.48 | 29.24 | 4.93 | 14.43% |

| System 3. Fixed-speed RTDT-RAC system | 5.59 | 28.66 | 5.5 | 16.11% |

| System 4. Variable-speed RTDT-RAC system | 8.97 | 18.57 | 15.58 | 45.59% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Hu, E.; Chen, L. Performance Simulation Model of a Radiation-Enhanced Thermal Diode Tank-Assisted Refrigeration and Air-Conditioning (RTDT-RAC) System: A Novel Cooling System. Energies 2023, 16, 6506. https://doi.org/10.3390/en16186506

Wang M, Hu E, Chen L. Performance Simulation Model of a Radiation-Enhanced Thermal Diode Tank-Assisted Refrigeration and Air-Conditioning (RTDT-RAC) System: A Novel Cooling System. Energies. 2023; 16(18):6506. https://doi.org/10.3390/en16186506

Chicago/Turabian StyleWang, Mingzhen, Eric Hu, and Lei Chen. 2023. "Performance Simulation Model of a Radiation-Enhanced Thermal Diode Tank-Assisted Refrigeration and Air-Conditioning (RTDT-RAC) System: A Novel Cooling System" Energies 16, no. 18: 6506. https://doi.org/10.3390/en16186506

APA StyleWang, M., Hu, E., & Chen, L. (2023). Performance Simulation Model of a Radiation-Enhanced Thermal Diode Tank-Assisted Refrigeration and Air-Conditioning (RTDT-RAC) System: A Novel Cooling System. Energies, 16(18), 6506. https://doi.org/10.3390/en16186506