Operation Mode and Energy Consumption Analysis of a New Energy Tower and Ground Source-Coupled Heat Pump System

Abstract

:1. Introduction

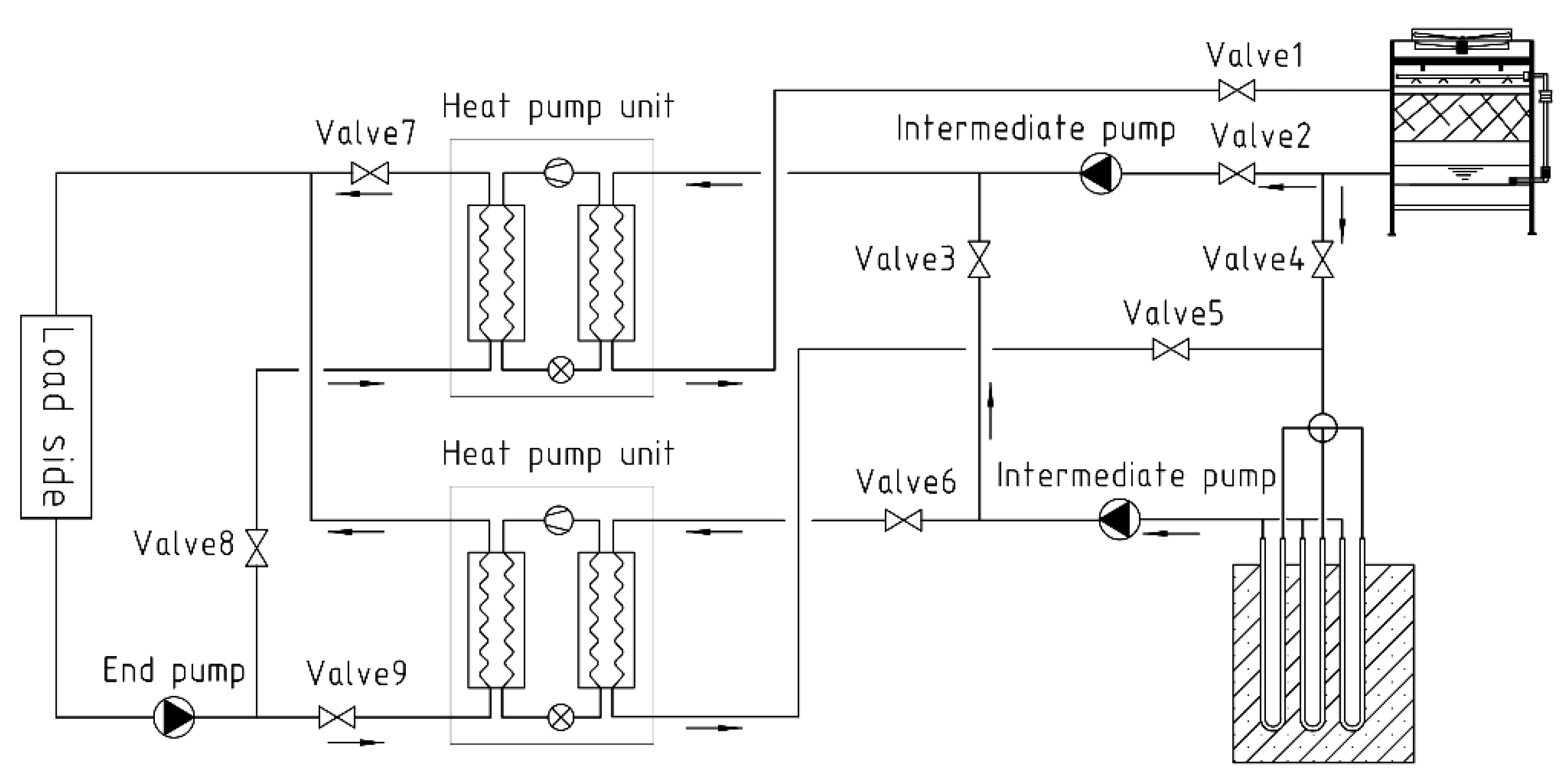

2. New Coupled ET–GSHP System

- (1)

- ET–GSHP series operation mode: When the outdoor air temperature is high, the ETHP efficiency is high, and the independent operation can meet the heat demand of the end. Under the premise of ensuring the water supply temperature, the hot water flowing out of the energy tower is first sent to the soil and then sent to the heat pump unit for heating after being stored in the soil in a buried pipe. At this time, Valve 1, Valve 3, Valve 4, Valve 7, and Valve 8 open and Valve 2, Valve 5, Valve 6, and Valve 9 close. The antifreeze in the pipeline enters the energy tower to absorb the heat in the air and enters the buried pipe. After transferring part of the heat to the soil, it enters the heat pump unit and transfers the heat to the refrigerant in the evaporator of the unit. After the refrigerant absorbs heat in the evaporator, the heat is transferred to the end circulating water on the condenser side by the heat pump, and the heat is transferred to the heat user under the action of the end circulating pump to complete the cycle.

- (2)

- ET–GSHP parallel operation mode: When the outdoor air temperature is low, the ETHP heating efficiency decreases and cannot meet the heat demand at the end alone. Therefore, the GSHP system needs to be enabled for auxiliary heating. At this time, Valve 1, Valve 2, Valve 5, Valve 6, Valve 7, Valve 8, and Valve 9 open and Valve 3 and Valve 4 close. For the energy tower side, the antifreeze in the pipeline directly enters the heat pump unit after absorbing the heat in the air in the energy tower and transmits the heat to the heat user; for the soil source side, the antifreeze in the pipeline enters the buried pipe heat exchange system, absorbs heat from the soil, enters the heat pump unit, and transmits the heat to the heat user.

- (3)

- GSHP separate operation mode: When the outdoor air temperature is too low under extremely cold conditions, or the performance of the ETHP unit is significantly reduced due to snowfall and other reasons, the ETHP unit is closed, and only the GSHP unit is used for terminal heating. At this time, Valve 5, Valve 6, and Valve 9 open and Valve 1, Valve 2, Valve 3, Valve 4, Valve 7, and Valve 8 close. The antifreeze in the pipeline enters the buried pipe heat transfer system, absorbs heat from the soil, enters the heat pump unit, and transfers the heat to the heat user.

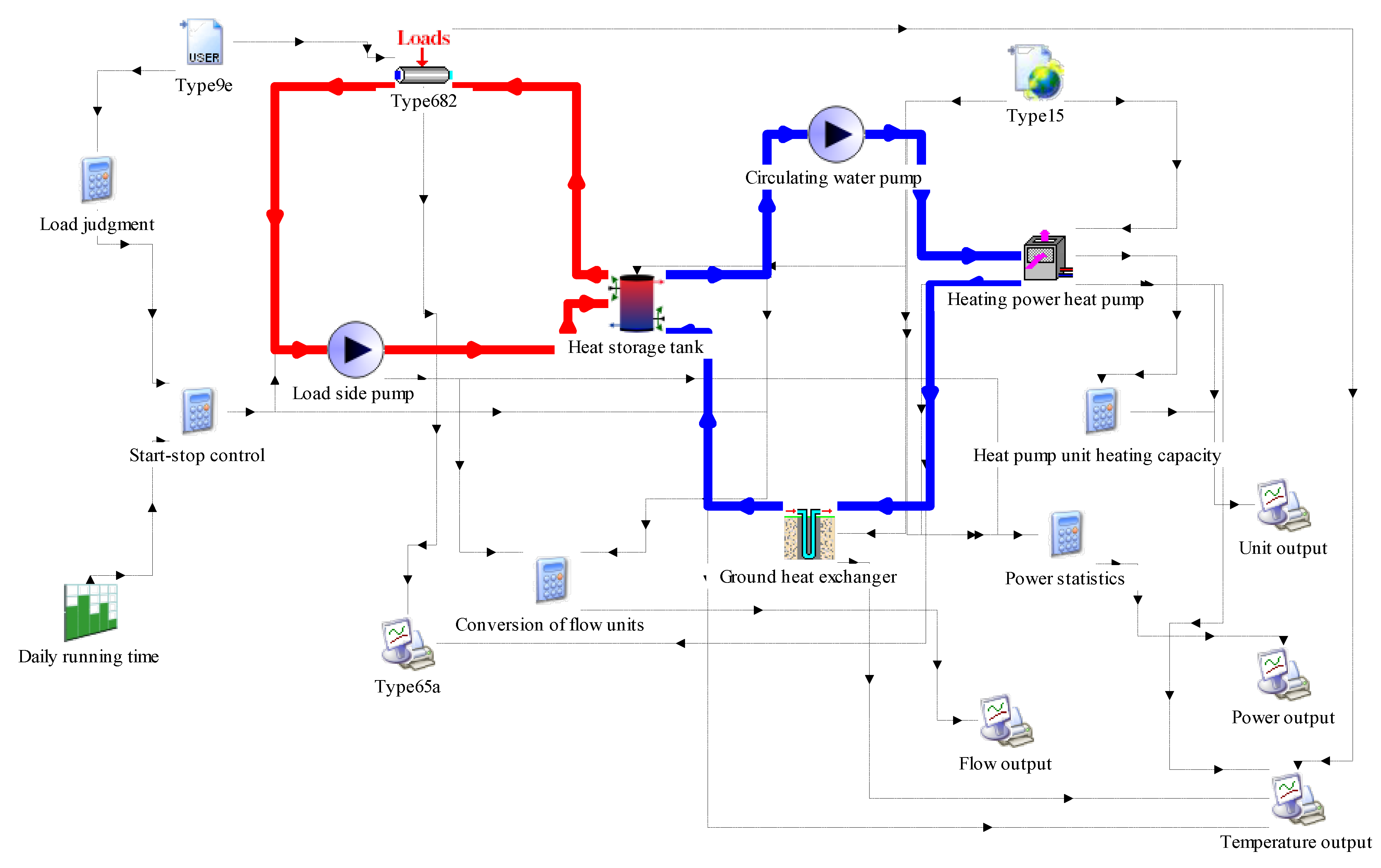

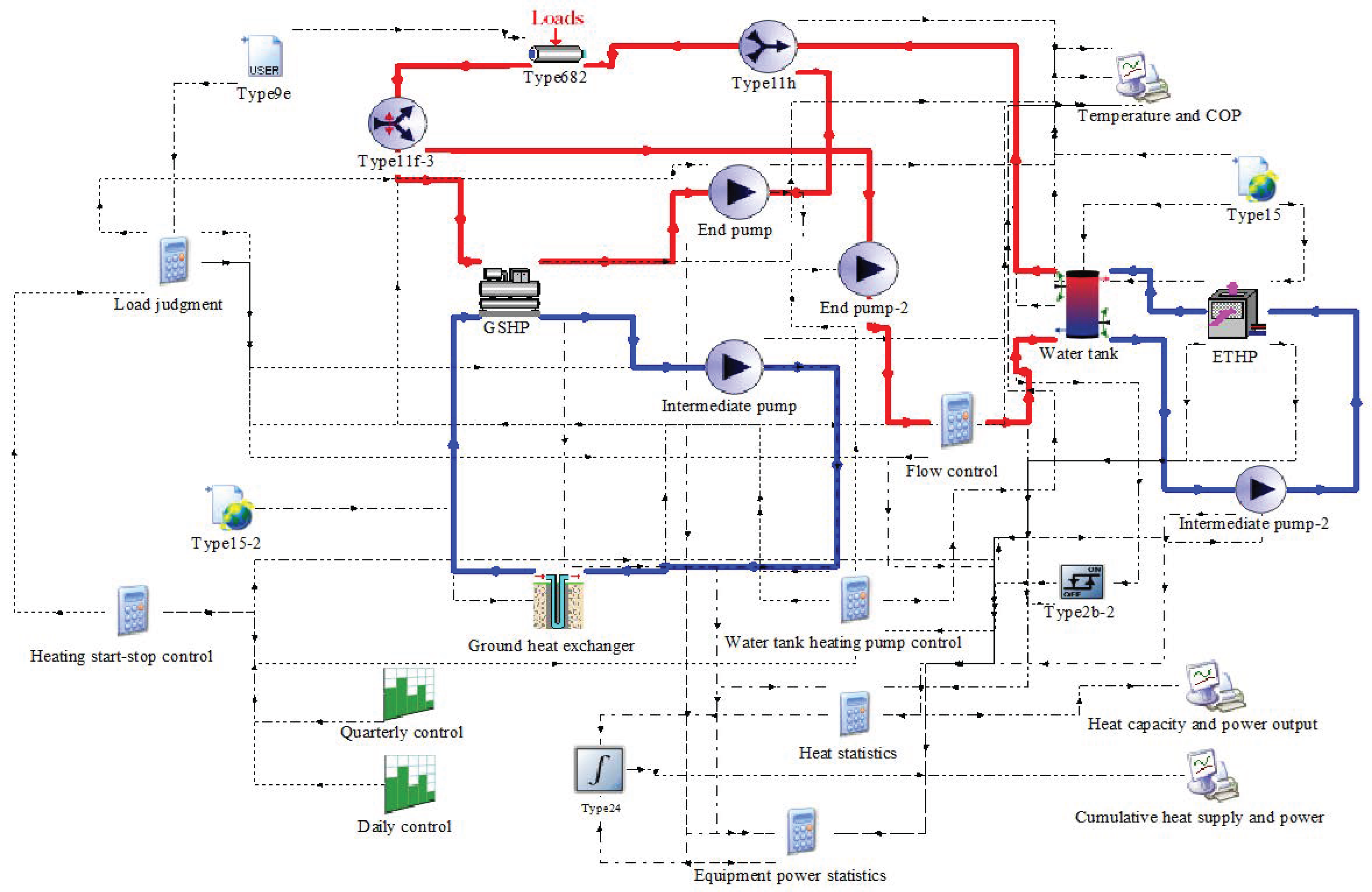

3. Methodology

3.1. Mathematical Modeling of Energy Towers

3.2. Mathematical Modeling of Buried Pipe Systems

4. Numerical Simulation

4.1. Architectural Overview

4.2. System Operation Mode and Simulation Model Construction

5. Results and Discussion

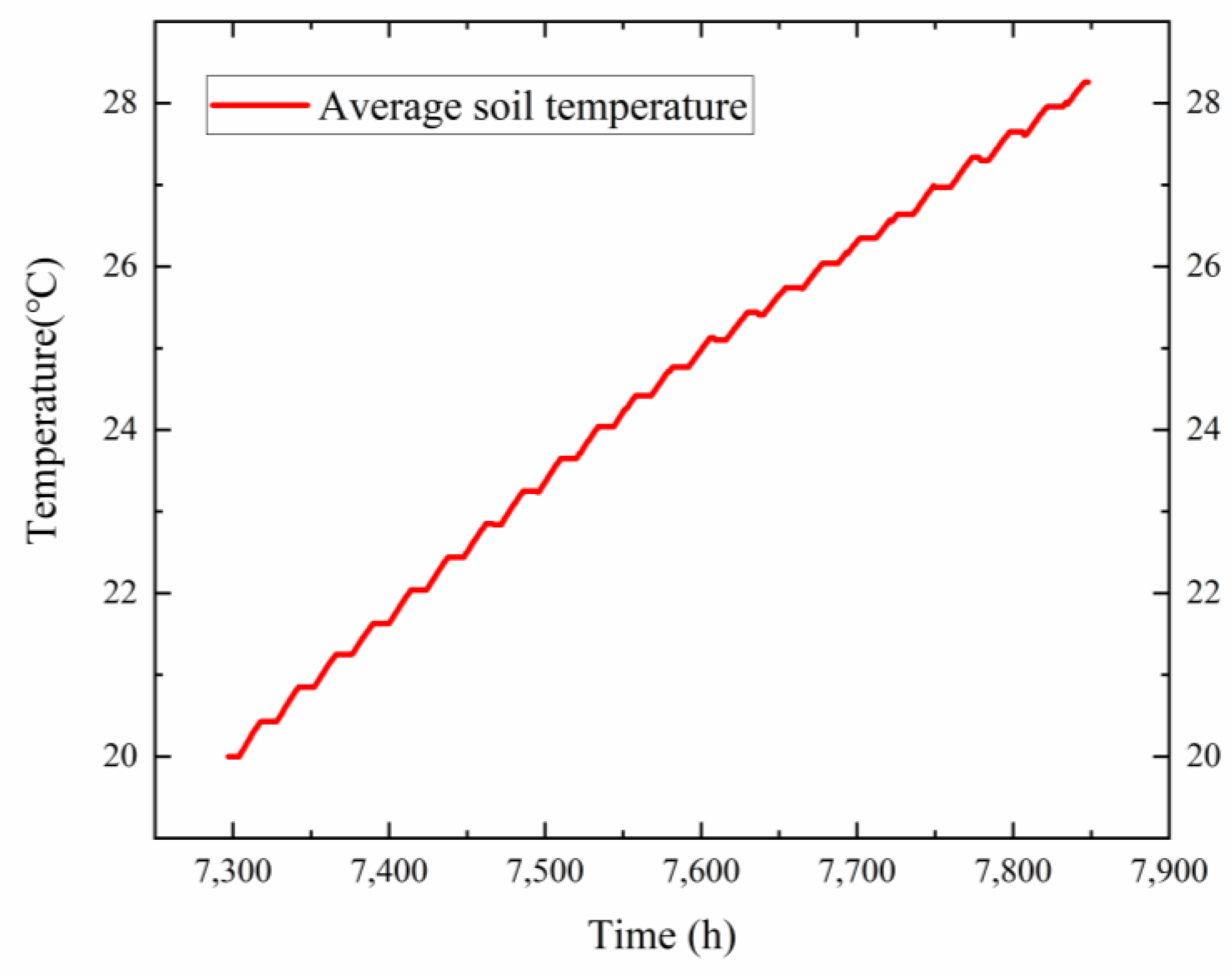

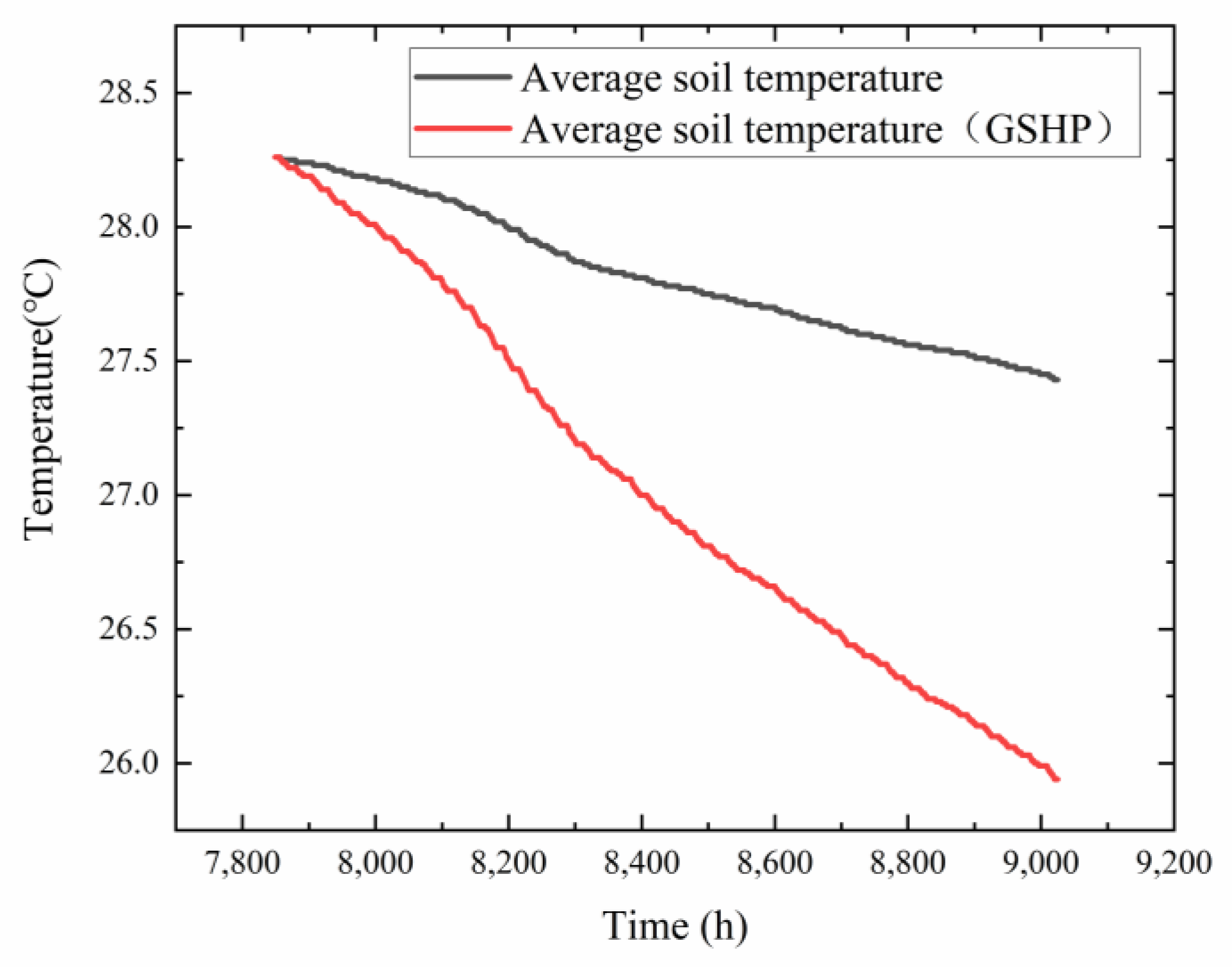

5.1. Analysis of System Cascade Operation and Soil Temperature Variations

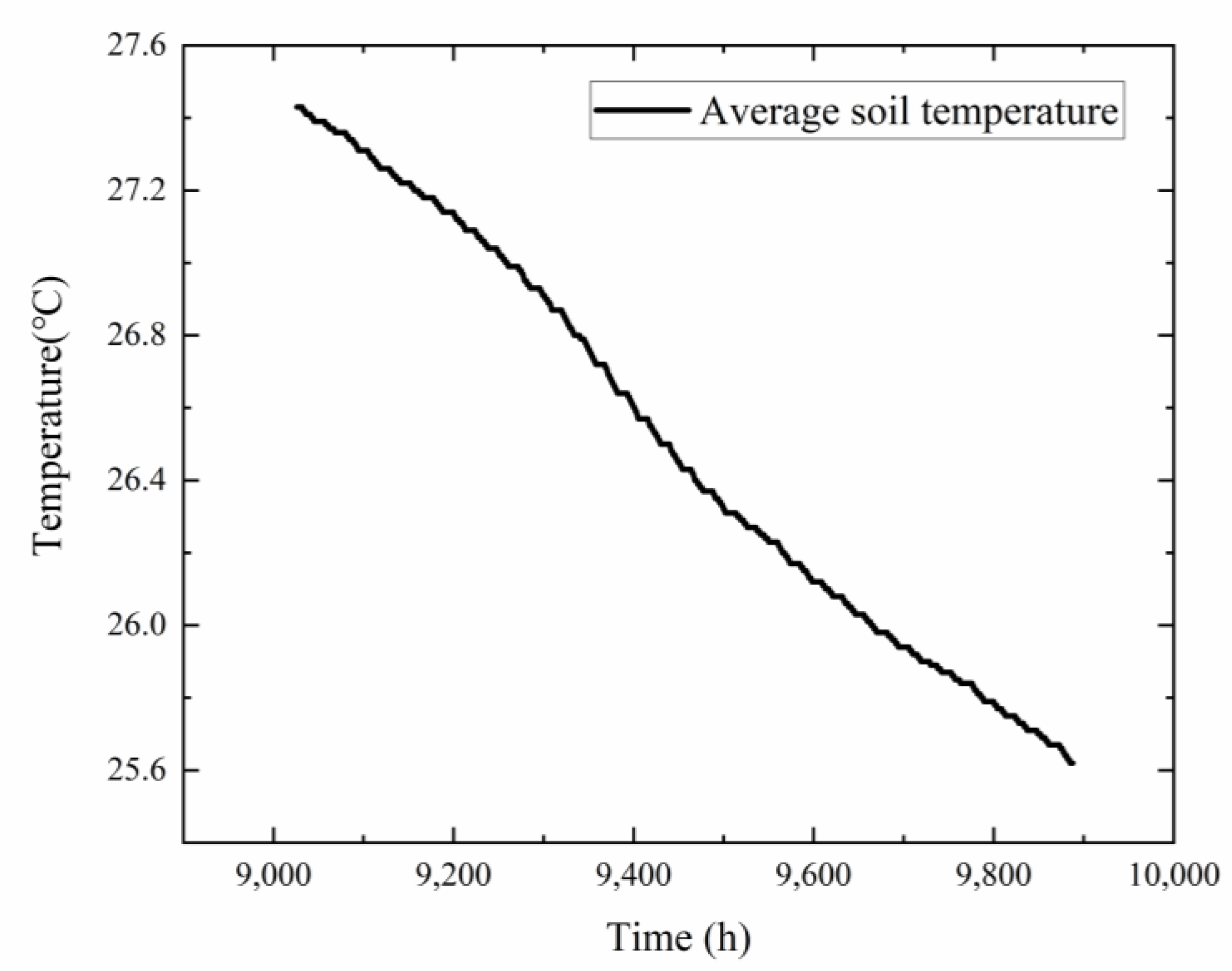

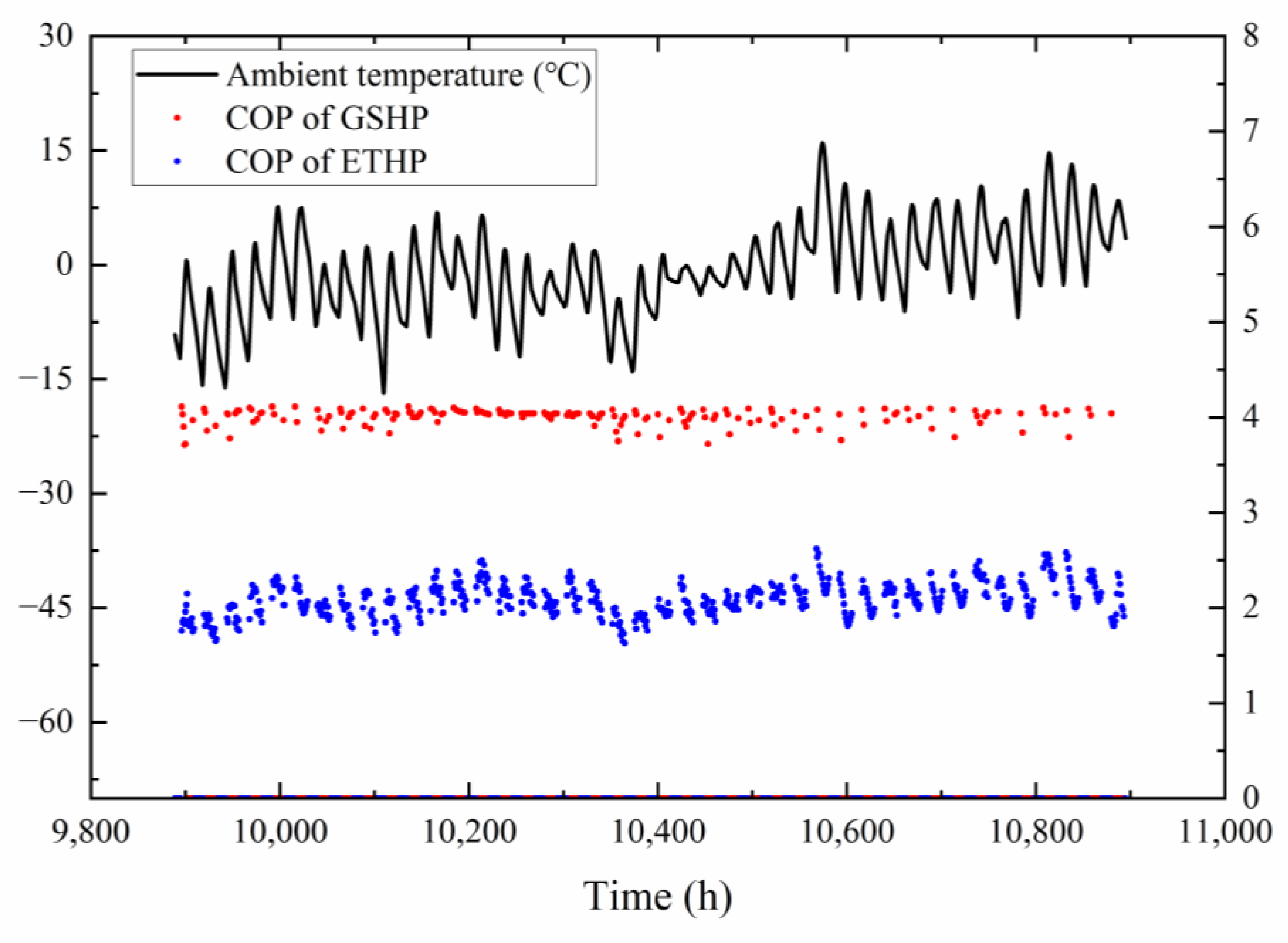

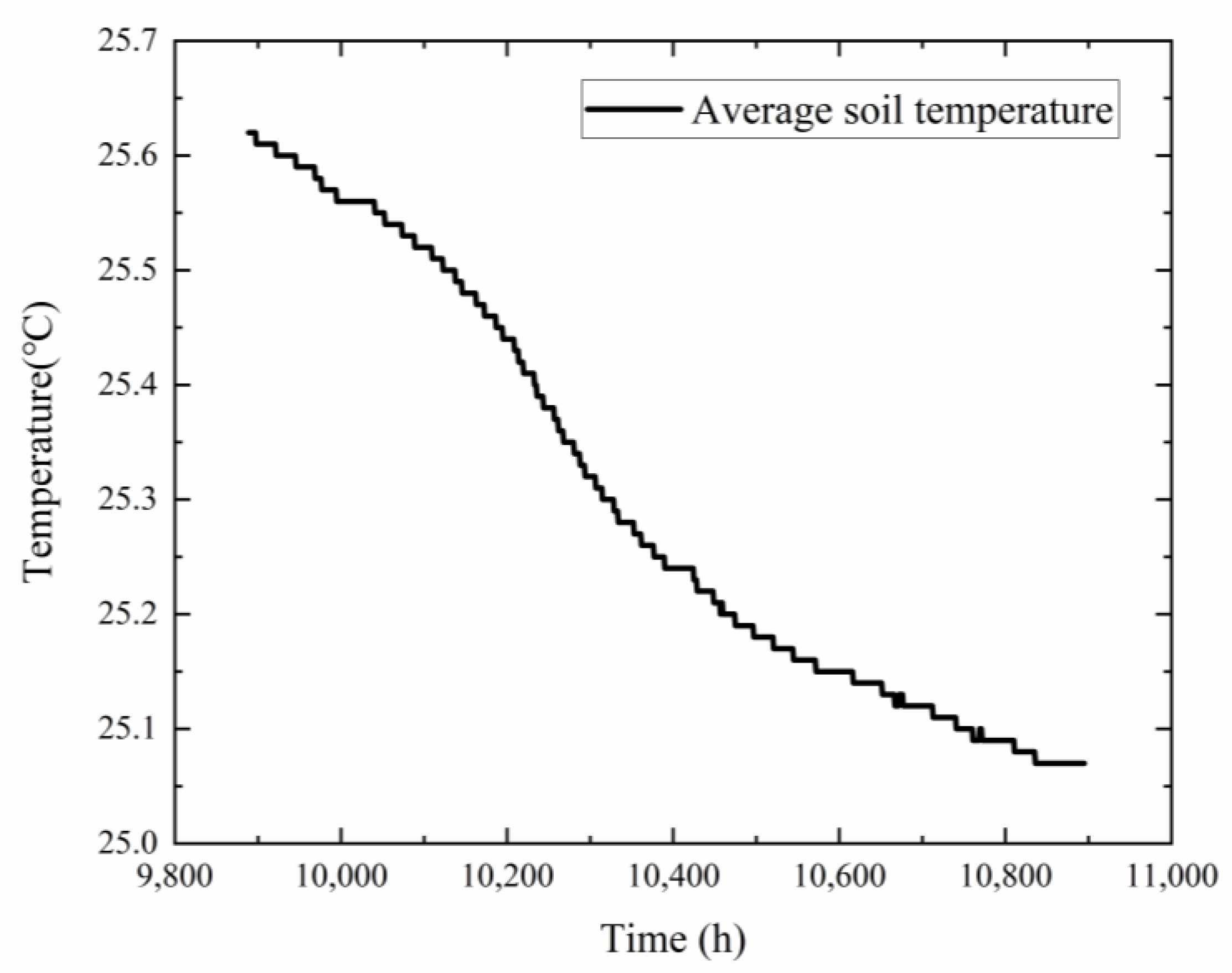

5.2. Analysis of System Parallel Operation and Extreme Cold Condition Operation

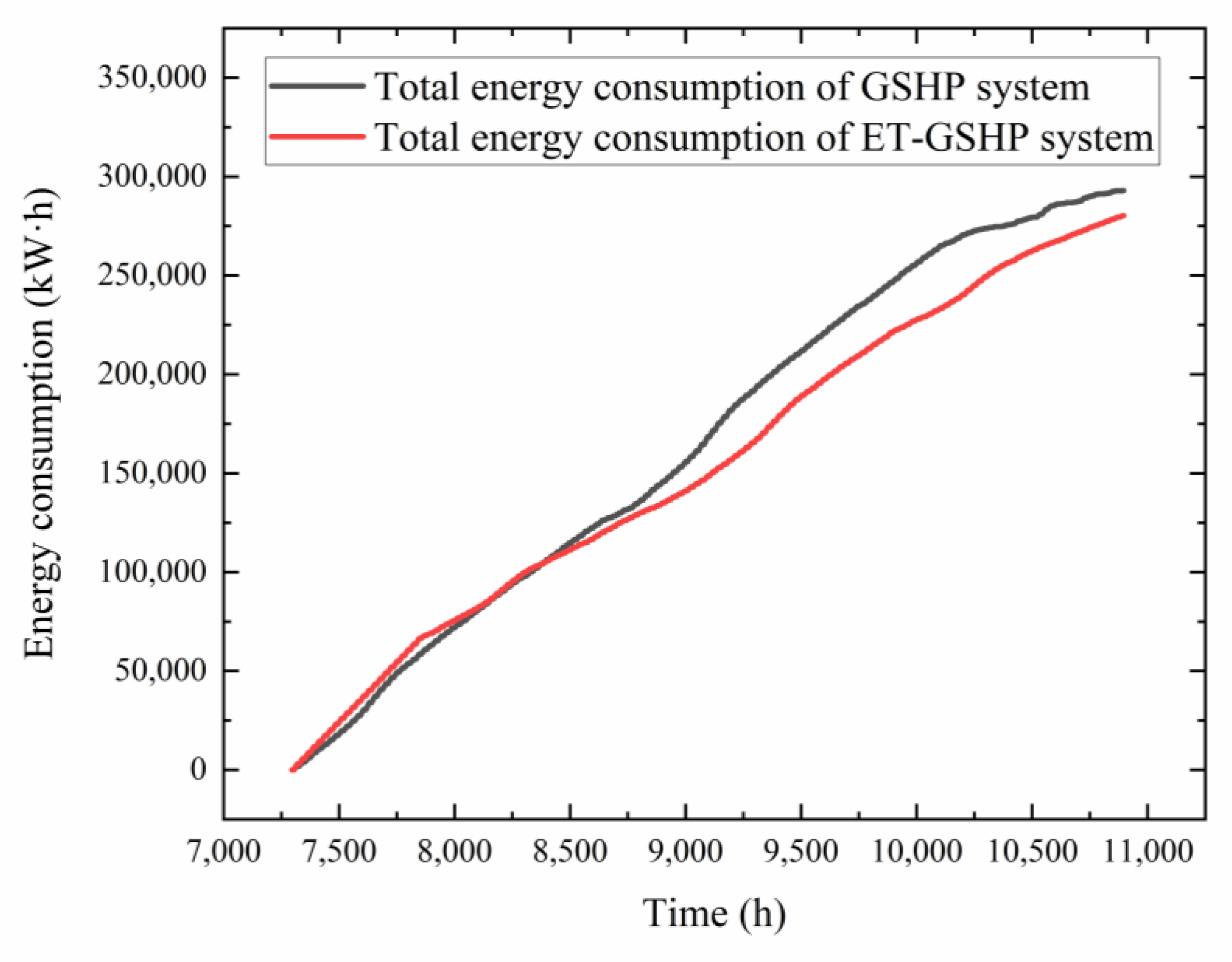

5.3. Analysis of System Energy Consumption

6. Conclusions

- (1)

- The heating season is divided into four operation stages according to the change in outdoor ambient temperature: the first stage is from 1 November to 24 November and uses the series heat storage operation mode; the second stage is from 24 November to 12 January and uses parallel operation and the soil source heat pump to make up for the heat; the third stage is from 12 January to 17 February, during which time the energy tower unit is shut down and the soil source heat pump takes on the heat supply task alone; the fourth stage is from 17 February to 31 March and uses the parallel operation mode. The simulation results showed that the distribution method has high economy and is appropriate for year-round operation. The series period accounts for approximately 15.36% of the entire heating period, the parallel operation period accounts for approximately 60% of the entire heating period, and the ground source alone operation period accounts for approximately 24.64% of the entire heating period.

- (2)

- During the series operation, the soil’s average temperature rose from 20 degrees Celsius to 28 degrees Celsius, considerably enhancing the soil’s ability to store heat. The system’s COP was kept constant between 2.73 and 3.56, with an average COP of 3.03. Due to the drop in outdoor temperature, the COP of the ETHP unit dramatically reduced during the parallel operating time, dropping by roughly 23.3% compared to the series operation period, with an average COP of 3.19 during the first period of the parallel operation. The average soil temperature decreased only 0.83 °C, and the soil still maintained a strong heat transfer capacity. In the second stage, the energy tower heat pump unit’s performance started to improve. Its highest COP was 3.01, its average COP was 2.09, and the system’s average COP was 3.04. The average soil temperature after heating is 25.07 °C, 8.96 °C higher than it would be with a conventional soil source heat pump. This is helpful for preserving the soil heat balance during continuous operation.

- (3)

- The average COP of the system for the whole heating period is 3.315, which shows that it can maintain a high heating capacity throughout. The total energy consumption of the traditional soil source heat pump system for the whole heating season is 292,977.34 kW·h, and the total energy consumption of the coupled system for the whole heating season is 280,266.92 kW·h, which is 4.34% less than the total energy consumption of the traditional soil source heat pump for heat supply, indicating high economy and environmental protection.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| ch | specific heat capacity kJ/(kg·°C) |

| cpa | constant pressure-specific heat capacity of air kJ/(kg·°C) |

| cpg | constant pressure-specific heat capacity of air, kJ/(kg·°C) |

| ma | volume flow rate of air, m3/s |

| mg | volume flow rate of antifreeze, m3/s |

| Ai | total area of the inner surface of the tube, m2 |

| Ao | total area of the outer surface of the tube, m2 |

| hi | heat transfer coefficient of the inner surface of the tube, W/(m2·K) |

| ho | heat transfer coefficient of the outer surface of the tube, W/(m2·K) |

| Taout | air outlet temperature, °C |

| Tain | air inlet temperature, °C |

| Tgout | antifreeze outlet temperature, °C |

| Tgin | antifreeze inlet temperature, °C |

| Qg | antifreeze absorbs heat, W |

| TGHE, out | outlet temperature of GHE, °C |

| TGHE, in | inlet temperature of GHE, °C |

| Tsoil | soil temperature, °C |

| ksoil | thermal conductivity of soil, W/(m3·K) |

| kGHE | thermal conductivity of GHE, W/(m·K) |

| vsoil | volume of soil, m3 |

| LGHE | length of GHE, m |

| cf | specific heat capacity of fluid, J/(kg·°C) |

| mf | mass flow rate of the fluid, kg/s |

| Abbreviations | |

| NTU | number of transfer units |

| COP | coefficient of performance |

| ETHP | energy tower heat pump |

| GHE | ground heat exchanger |

| ET–GSHP | energy tower-coupled ground source heat pump |

| Greek symbols | |

| ρa | density of air, kg/m3 |

| ρg | density of antifreeze, kg/m3 |

| η | efficiency |

| ξ | heat transfer efficiency |

| β | damping coefficient |

References

- Chen, L.; Huang, L.P.; Hua, J.M.; Chen, Z.H.; Wei, L.L.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Dong, L.; Yap, P.S. Green construction for low-carbon cities: A review. Environ. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Altaf, H.; Iftikhar, I. Modeling and multi-objective optimization of time, greenhouse gas emissions, and resources for sustainable construction projects. Sustain. Prod. Consum. 2023, 39, 269–284. [Google Scholar]

- Saba, A.; Fariborz, H. Occupancy and occupant activity drivers of energy consumption in residential buildings. Energy Build. 2021, 250, 111303. [Google Scholar]

- Laaroussi, Y.; Bahrar, M.; El Mankibi, M.; Draoui, A.; Si-Larbi, A. Occupant presence and behavior: A major issue for building energy performance simulation and assessment. Sustain. Cities Soc. 2020, 63, 102420. [Google Scholar] [CrossRef]

- Kumar, K.K.; Roy, C.C.; Deepti, Y.; Ravikant, V.; Swapnamoy, D.; Smriti, J.K.; Karthik Selva Kumar, K.S. Renewable and sustainable clean energy development and impact on social, economic, and environmental health. Energy Nexus 2022, 7, 100118. [Google Scholar]

- Thomas, E.R. Advanced nuclear energy: The safest and most renewable clean energy. Curr. Opin. Chem. Eng. 2023, 39, 100878. [Google Scholar]

- Xu, S.; Ge, J.P. Sustainable development of clean heating in rural northern China: Locally tailored energy options. Sustain. Prod. Consum. 2023, 35, 655–667. [Google Scholar] [CrossRef]

- Liu, Z.J.; Liu, Y.W.; He, B.J.; Xu, W.; Jin, G.Y.; Zhang, X.T. Application and suitability analysis of the key technologies in nearly zero energy buildings in China. Renew. Sustain. Energy Rev. 2019, 101, 329–345. [Google Scholar] [CrossRef]

- Fan, M.Y.; He, G.J.; Zhou, M.G. The winter choke: Coal-Fired heating, air pollution, and mortality in China. J. Health Econ. 2020, 71, 102316. [Google Scholar] [CrossRef]

- Tang, B.J.; Zou, Y.; Yu, B.Y.; Guo, Y.Y.; Zhao, G.P. Clean heating transition in the building sector: The case of Northern China. J. Clean. Prod. 2021, 307, 127206. [Google Scholar] [CrossRef]

- Dong, S.H.; Zhao, H.Y.; Zheng, Y.B.; Ni, L. Carbon reduction analysis of electric heat pumps in carbon neutrality in China. Sustain. Cities Soc. 2023, 97, 104758. [Google Scholar] [CrossRef]

- Yu, M.; Li, S.; Zhang, X.J.; Zhao, Y. Techno-economic analysis of air source heat pump combined with latent thermal energy storage applied for space heating in China. Appl. Therm. Eng. 2021, 185, 116434. [Google Scholar] [CrossRef]

- Jung, Y.J.; Oh, J.W.; Han, U.; Lee, H.S. A comprehensive review of thermal potential and heat utilization for water source heat pump systems. Energy Build. 2022, 266, 112124. [Google Scholar] [CrossRef]

- Song, C.F.; Li, Y.; Rajeh, T.; Ma, L.; Zhao, J.; Li, W.J. Application and development of ground source heat pump technology in China. Prot. Control. Mod. Power Syst. 2021, 6, 17. [Google Scholar] [CrossRef]

- Agnieszka, K.; Paweł, B.; Grzegorz, W. Economic analysis of heat pump exploitation—A case study. Energy 2023, 280, 128184. [Google Scholar]

- Rong, X.Y.; Long, W.G.; Jia, J.K.; Liu, L.H.; Si, P.F.; Shi, L.J.; Yan, J.Y.; Liu, B.R.; Zhao, M.S. Experimental study on a multi-evaporator mutual defrosting system for air source heat pumps. Appl. Energy 2023, 332, 120528. [Google Scholar] [CrossRef]

- Sun, J.M.; Zhao, B.; Gao, D.K.; Xu, L.Z. Heat transfer analysis of evaporator of air source heat pump (ASHP) in case of frost based on chirplet finite element method. Therm. Sci. Eng. Prog. 2021, 26, 101134. [Google Scholar] [CrossRef]

- Huang, S.F.; Yu, H.F.; Zhang, M.X.; Qu, H.S.; Wang, L.B.; Zhang, C.Y.; Yuan, Y.B.; Zhang, X.S. Advances, challenges and outlooks in frost-free air-source heat pumps: A comprehensive review from materials, components to systems. Appl. Therm. Eng. 2023, 234, 121163. [Google Scholar] [CrossRef]

- Yu, S.P.; Su, Y.; Cai, W.H.; Qiu, G.D. Experimental investigation on an air source heat pump system with a novel anti-frosting evaporator. Appl. Therm. Eng. 2023, 221, 119910. [Google Scholar] [CrossRef]

- Jung, Y.J.; Kim, J.B.; Kim, H.J.; Nam, Y.J.; Cho, H.H.; Lee, H.S. Comprehensive multi-criteria evaluation of water source heat pump systems in terms of building type, water source, and water intake distance. Energy Build. 2021, 236, 110765. [Google Scholar] [CrossRef]

- Jang, Y.; Lee, D.C.; Kim, J.Y.; Ham, S.H.; Kim, Y.C. Performance characteristics of a waste-heat recovery water-source heat pump system designed for data centers and residential area in the heating dominated region. J. Build. Eng. 2022, 62, 105416. [Google Scholar] [CrossRef]

- Self, S.J.; Reddy, B.V.; Rosen, M.A. Geothermal heat pump systems: Status review and comparison with other heating options. Appl. Energy 2013, 101, 341–348. [Google Scholar] [CrossRef]

- You, T.; Wang, F. Green ground source heat pump using various low-global-warming-potential refrigerants: Thermal imbalance and long-term performance. Renew. Energy 2023, 210, 159–173. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Q.; Liang, C.M.; Wang, H.Q.; Ma, X.N. An overview of the recent development of the Ground Source Heat Pump (GSHP) system in China. Renew. Energy 2023, 210, 269–279. [Google Scholar] [CrossRef]

- You, T.; Wu, W.; Shi, W.X.; Wang, B.L.; Li, X.T. An overview of the problems and solutions of soil thermal imbalance of ground-coupled heat pumps in cold regions. Appl. Energy 2016, 177, 515–536. [Google Scholar] [CrossRef]

- Xu, L.L.; Pu, L.; Zhang, S.Q.; Li, Y.Z. Hybrid ground source heat pump system for overcoming soil thermal imbalance: A review. Sustain. Energy Technol. Assess. 2021, 44, 101098. [Google Scholar] [CrossRef]

- Bisengimana, E.; Zhou, J.Z.; Binama, M.; Zhao, K.M.; Abbas, S.; Yuan, Y.P. The frosting and soil imbalance performance issues of building heat pumps: An overview. Energy Build. 2022, 273, 112387. [Google Scholar] [CrossRef]

- Li, Y.F.; Bi, Y.H.; Lin, Y.S.; Wang, H.Y.; Sun, R.R. Analysis of the soil heat balance of a solar-ground source absorption heat pump with the soil-based energy storage in the transition season. Energy 2023, 264, 126394. [Google Scholar] [CrossRef]

- Xie, L.Y.; Huang, S.F.; Ye, Y.Y.; Zhang, X.S. Regional suitability of heating tower heat pumps based on technical and economic performance maps. Energy Build. 2021, 245, 111048. [Google Scholar] [CrossRef]

- Liu, M.Z.; Jiang, L.F.; Zhang, H.; Zheng, X.J.; You, S.J.; Wei, S. An exploration on the applicability of heating tower heat pump and air source heat pump systems in different climatic regions. J. Clean. Prod. 2019, 238, 117889. [Google Scholar] [CrossRef]

- Huang, S.F.; Ye, Y.Y.; Han, X.; Zuo, W.D.; Zhang, X.S.; Jiang, L. Performance evaluation of heating tower heat pump systems over the world. Energy Convers. Manag. 2019, 186, 500–515. [Google Scholar] [CrossRef]

- Huang, S.F.; Zuo, W.D.; Lu, H.X.; Liang, C.H.; Zhang, X.S. Performance comparison of a heating tower heat pump and an air-source heat pump: A comprehensive modeling and simulation study. Energy Convers. Manag. 2019, 180, 1039–1054. [Google Scholar] [CrossRef]

- Xie, L.Y.; Zhang, M.X.; Huang, S.F.; Zhao, S.G.; Zhang, X.S. Sensitivity analysis and optimization of design parameters of heating tower heat pump. Energy Convers. Manag. 2022, 258, 115547. [Google Scholar] [CrossRef]

- Zhao, R.; Shi, B.; Zhao, X.H.; Zhang, L.; Xu, W.G.; Yu, Z.K.; Fang, J.M.; Ji, Y.X.; Hu, Y.Y.; Bao, B.G. Study on thermal performance of new finned heat exchange tube bundles in cooling tower. Int. J. Therm. Sci. 2021, 168, 107064. [Google Scholar] [CrossRef]

- Xiao, H.S.; Song, P.Y.; Wang, B.L.; Li, Z.M.; Shi, W.X.; Yang, Z.X.; Li, X.T.; Huang, Y.S.; Liang, Z.H. Experimental investigation of a heat-source tower heat pump with self-regenerator using subcooling heat. Energy Build. 2021, 240, 110858. [Google Scholar] [CrossRef]

- Huang, S.F.; Lu, X.; Zuo, W.D.; Zhang, X.S.; Liang, C.H. Model-based optimal operation of heating tower heat pump systems. Build. Environ. 2019, 160, 106199. [Google Scholar] [CrossRef]

- Shen, X.H.; Li, N.P.; Yongga, A. Simulation Research on the Heating Performance of the Combined System of Solar Energy and Heat-Source Tower Heat Pump in a Hot Summer and Cold Winter Area. Energies 2021, 14, 1816. [Google Scholar] [CrossRef]

- Feng, R.; Liu, Y.; Fang, J.F. Heating performance of solar assisted closed heat source tower heat pump system in winter. Trans. Chin. Soc. Agric. Eng. 2020, 36, 210–217. [Google Scholar]

- Cheng, Y.F. Study on the Operation Performance of Cold Water Phase Change Energy and Closed Heat Source Tower Heat Pump System. Master’s Thesis, Qingdao University, Qingdao, China, 2022. [Google Scholar]

- Qiu, G.D.; Li, K.F.; Cai, W.H.; Yu, S.P. Optimization of an integrated system including a photovoltaic/thermal system and a ground source heat pump system for building energy supply in cold areas. Appl. Energy 2023, 349, 121698. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Zhou, J.; Yang, Y.; Xu, F.; Liu, H.C.; Yan, Y.L. Performance analysis of a novel solar assisted ground source heat pump water heating system with graded thermal energy storage. Energy Convers. Manag. 2023, 288, 117179. [Google Scholar] [CrossRef]

- Emanuele, Z.; Stefano, B.; Stefano, B.; Villiam, B.; Marco, A.; Francesco, T. Sequential coupled numerical simulations of an air/ground-source heat pump: Validation of the model and results of yearly simulations. Energy Build. 2022, 277, 112540. [Google Scholar]

- Guo, H.F.; Zhang, Z.; Chen, X.; Song, Y.L.; Yang, R.M.; Bao, K.X.; Shang, S.W. Study on multi-objective decision-making operation strategy of heat supply tower. Sci. Total Environ. 2023, 859, 160188. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.H.; Liu, Z.Q.; Liang, Y.K.; Peng, G.H.; Wang, W.Y.; Liu, W. Simulation Experiment on Energy Tower Coupled with Buried Pipe System of Ground-source Heat Pump for Cross-season Heat Storage. J. Phys. Conf. Ser. 2021, 2108, 012039. [Google Scholar] [CrossRef]

- Hu, Z.C.; Geng, S.W.; Li, W.F.; Ge, F.H.; Liu, X.Y. Study on soil heat storage performance and operation strategy of new integrated HST-GSHP system in different cold regions. Energy Build. 2022, 256, 111748. [Google Scholar] [CrossRef]

- Braun, J.; Klein, S.; Mitcel, J. Applications of optimal control to chilled water systems without storage. ASHRAE Trans. 1989, 95, 663–675. [Google Scholar]

- Yin, B.Q.; Wu, X.T. Performance Analysis on a Large Scale Borehole GSHP in Tianjin Cultural Centre. In Proceedings of the 2nd International Conference on Energy Engineering and Environmental Protection (EEEP), Sanya, China, 20–22 November 2017. [Google Scholar]

- GB 50736-2012; Design Code for Heating Ventilation and Air Conditioning of Civil Buildings. Ministry of Housing and Urban-Rural Development: Beijing, China, 2012.

- Hellström, G.; Mazzarella, L.; Pahud, D. Duct Ground Storage Model—TRNSYS Version; Technical Report; Department of Mathematical Physics, University of Lund: Lund, Sweden, 1996. [Google Scholar]

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Kummert, M. TRNSYS 16—A Transient System Simulation Program User Manual, Solar Energy Laboratory; University of Wisconsin-Madison: Madison, WI, USA, 2004. [Google Scholar]

- Huang, Y.F.; Ge, F.H.; Hu, Z.C.; Qin, H.; Yang, Y.M.; Zheng, H.Q. Experimental analysis On Application of Heat Source Tower Heat Pump System Under Low Temperature Condition. Acta Energiae Solaris Sin. 2021, 42, 260–266. [Google Scholar]

| Design Parameters | |

|---|---|

| Heating method | Air conditioning and heating |

| Supply and return water temperature/°C | 45/40 |

| Indoor design temperature/°C | 18 |

| Relative humidity/% | 40 |

| Building envelope | 50% energy efficiency design standard for public buildings |

| Per capita area (m2/person) | 8 |

| Room occupancy rate | 0.8 |

| Operation Period | Energy Consumption (kW·h) | |

|---|---|---|

| GSHP | ET–GSHP | |

| 11.1–11.24 | 58,553.16 | 66,449.24 |

| 11.24–1.12 | 99,939.84 | 76,466.16 |

| 1.12–2.17 | 87,919.3 | 78,131.8 |

| 2.17–3.31 | 46,565 | 59,219.7 |

| The whole operation period | 292,977.34 | 280,266.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wu, R.; Yu, H.; Yang, Y.; Zhan, H. Operation Mode and Energy Consumption Analysis of a New Energy Tower and Ground Source-Coupled Heat Pump System. Energies 2023, 16, 6493. https://doi.org/10.3390/en16186493

Zhang Y, Wu R, Yu H, Yang Y, Zhan H. Operation Mode and Energy Consumption Analysis of a New Energy Tower and Ground Source-Coupled Heat Pump System. Energies. 2023; 16(18):6493. https://doi.org/10.3390/en16186493

Chicago/Turabian StyleZhang, Yao, Ronghua Wu, Hao Yu, Yujuan Yang, and Hao Zhan. 2023. "Operation Mode and Energy Consumption Analysis of a New Energy Tower and Ground Source-Coupled Heat Pump System" Energies 16, no. 18: 6493. https://doi.org/10.3390/en16186493

APA StyleZhang, Y., Wu, R., Yu, H., Yang, Y., & Zhan, H. (2023). Operation Mode and Energy Consumption Analysis of a New Energy Tower and Ground Source-Coupled Heat Pump System. Energies, 16(18), 6493. https://doi.org/10.3390/en16186493