Proposal for Repairable Silicon Solar Panels: Proof of Concept

Abstract

:1. Introduction

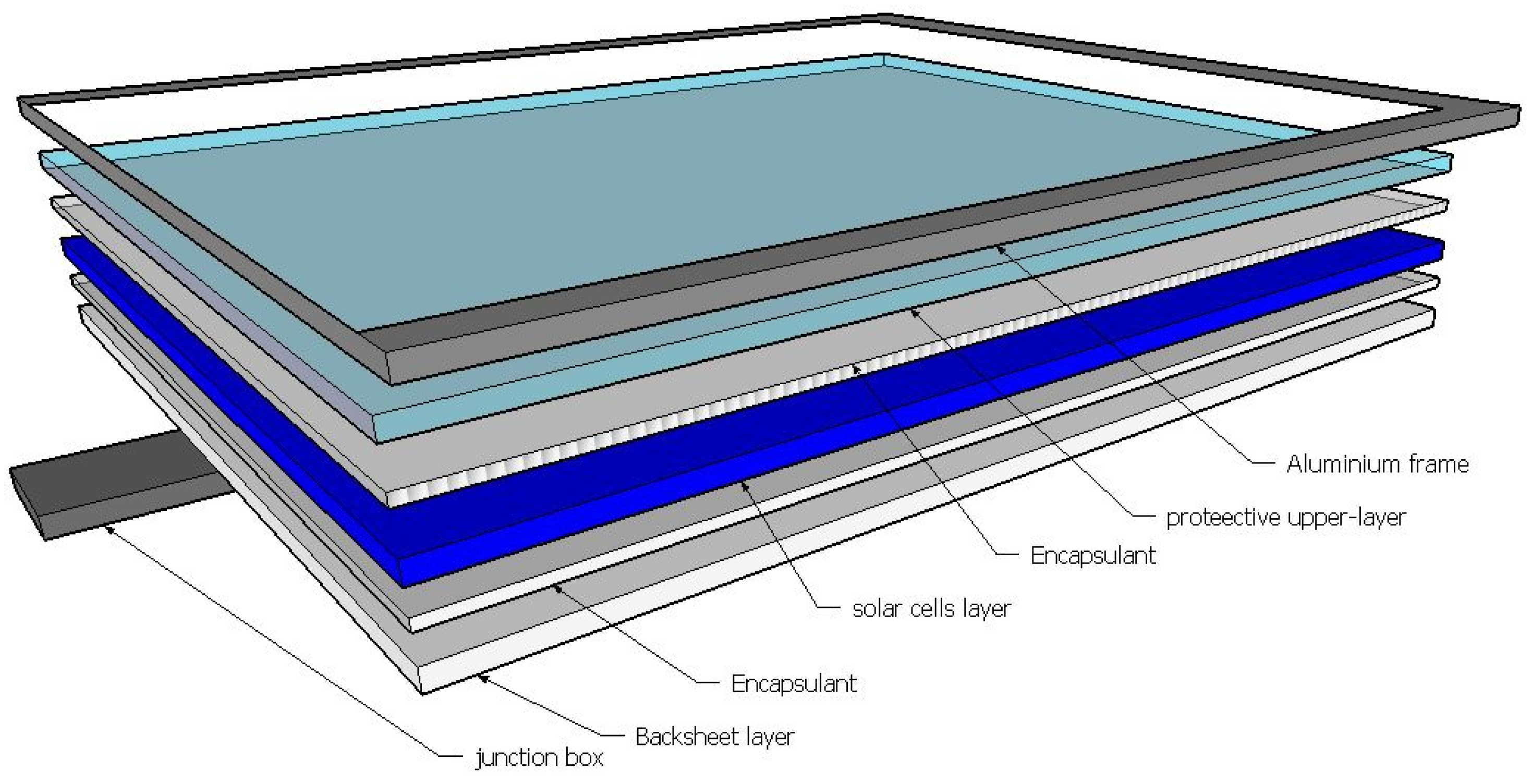

2. Traditional Solar Panels Construction

3. Implementation of the Proposed Repairable Solar Module

3.1. Module Preparation

- Cell sorting: after testing and classifying the cells based on their analogous electrical properties, a copper strip is bonded to the front surface (negative part) of each cell.

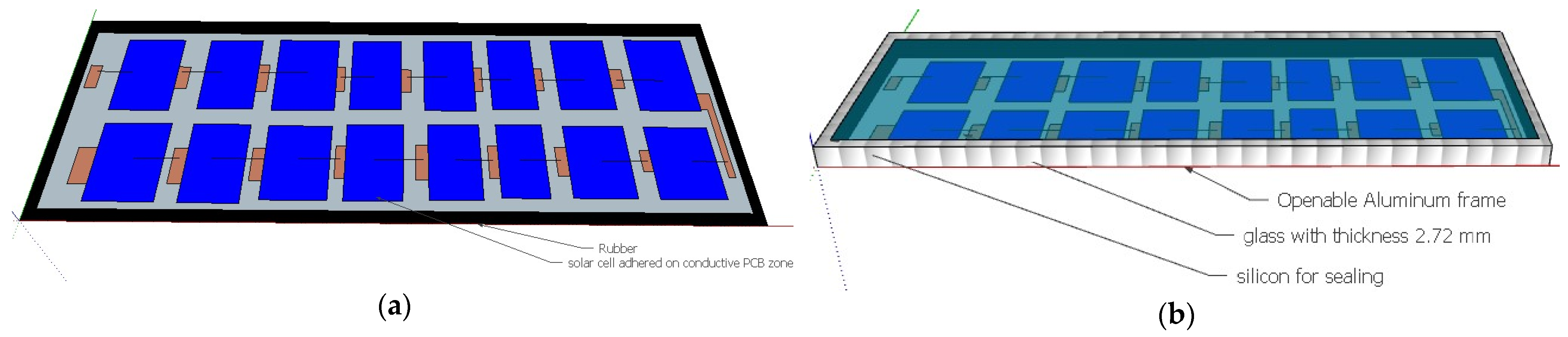

- Substrate preparation: The preparation of the substrate for the proposed module structure comprises two primary steps. The initial step involves substrate cleaning, which eliminates any impurities or debris that might impact the current flow performance. The second step is to divide the PCB into equal conductive zones; each conductive zone is electrically separated from the other zones and is specified to one solar cell, to which it is adhered using conductive silver epoxy, as is shown in Figure 3a. This step is crucial to guarantee the proper series connection of the solar cells and eliminate any short-circuiting risk.

- Cell adherence to the substrate: Following substrate preparation, the subsequent step involves firmly adhering the solar cells to the PCB substrate. Both the cell and substrate surfaces undergo thorough cleaning to eliminate any oils or contaminants. Subsequently, 1 gm of silver conductive epoxy is extruded onto the back of each cell. Within a 5 min timeframe, the cells are meticulously positioned over the designated conductive zones on the substrate. The epoxy is then left to cure for one hour, ensuring secure attachment. This process is iterated for each cell in each zone until all the cells are successfully affixed to the substrate.

- Soldering cell front: the tabbing wire on the opposite side of each cell within a specific zone is soldered to the conductive part of the neighboring zone, effectively connecting the cells in series.

- Visual examination: the circuit is visually checked to ensure that the circuit has been connected correctly.

- Assembly: the assembly involves stacking a set of materials consisting of an aluminum frame, rubber sheets, glass, the substrate with the solar cells, and epoxy.

- Encapsulation: To complete the assembly of the module, the surface edges are cleaned, and the output leads are attached. Strips of rubber are then adhered to the substrate edges using epoxy and left for one hour to cure. Finally, the two plates (glass and printed board) are placed within the openable aluminum frame.

- Final assembly: the final step is to seal all the edges of the module and the gaps between the glass and aluminum frame with silicon resin to ensure that the panel is protected from humidity, as is depicted in Figure 3b.

- Final inspection: After the fabrication process, the module is visually inspected to check for any defects or damage that might have occurred during the process. This examination is crucial as it ensures the quality of the module and verifies that it is well sealed and that it will protect the solar panel from short circuits.

- Repairability check: if any fault occurs in the module, one can easily remove the silicon resin and open the aluminum frame to deal with the fault.

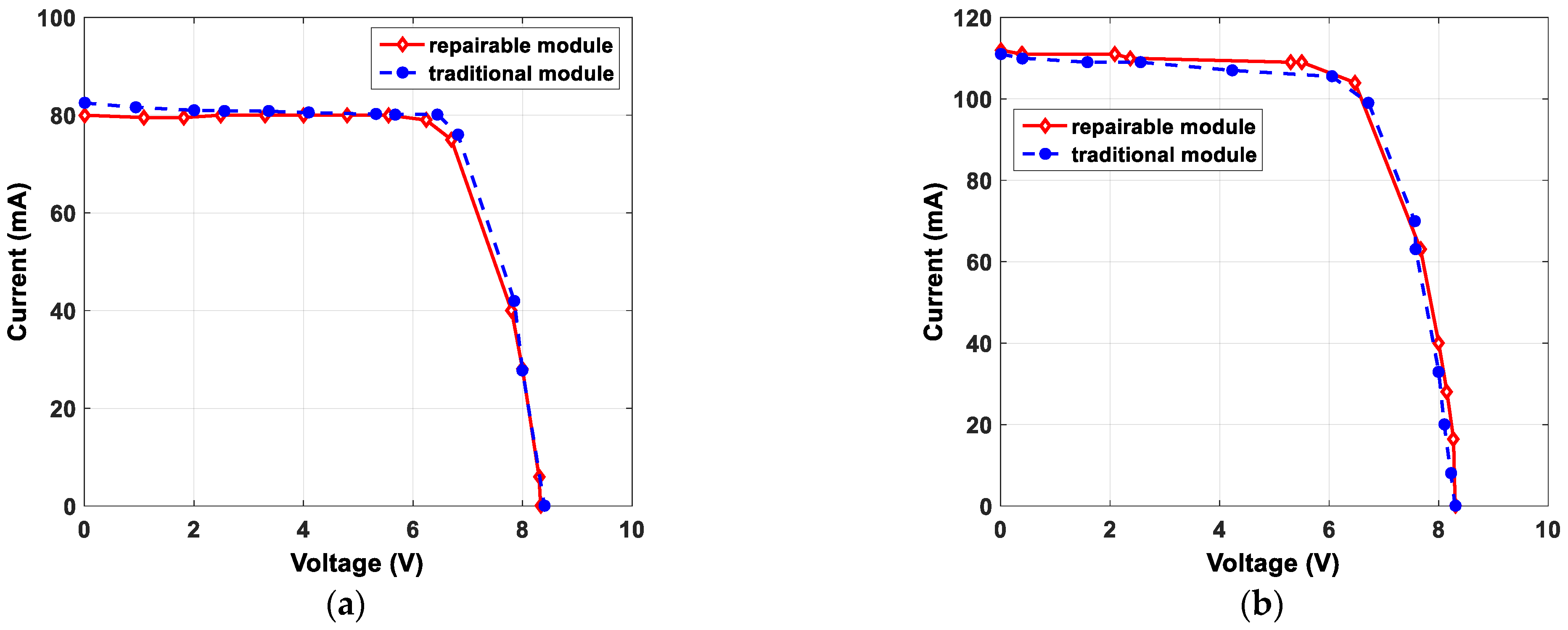

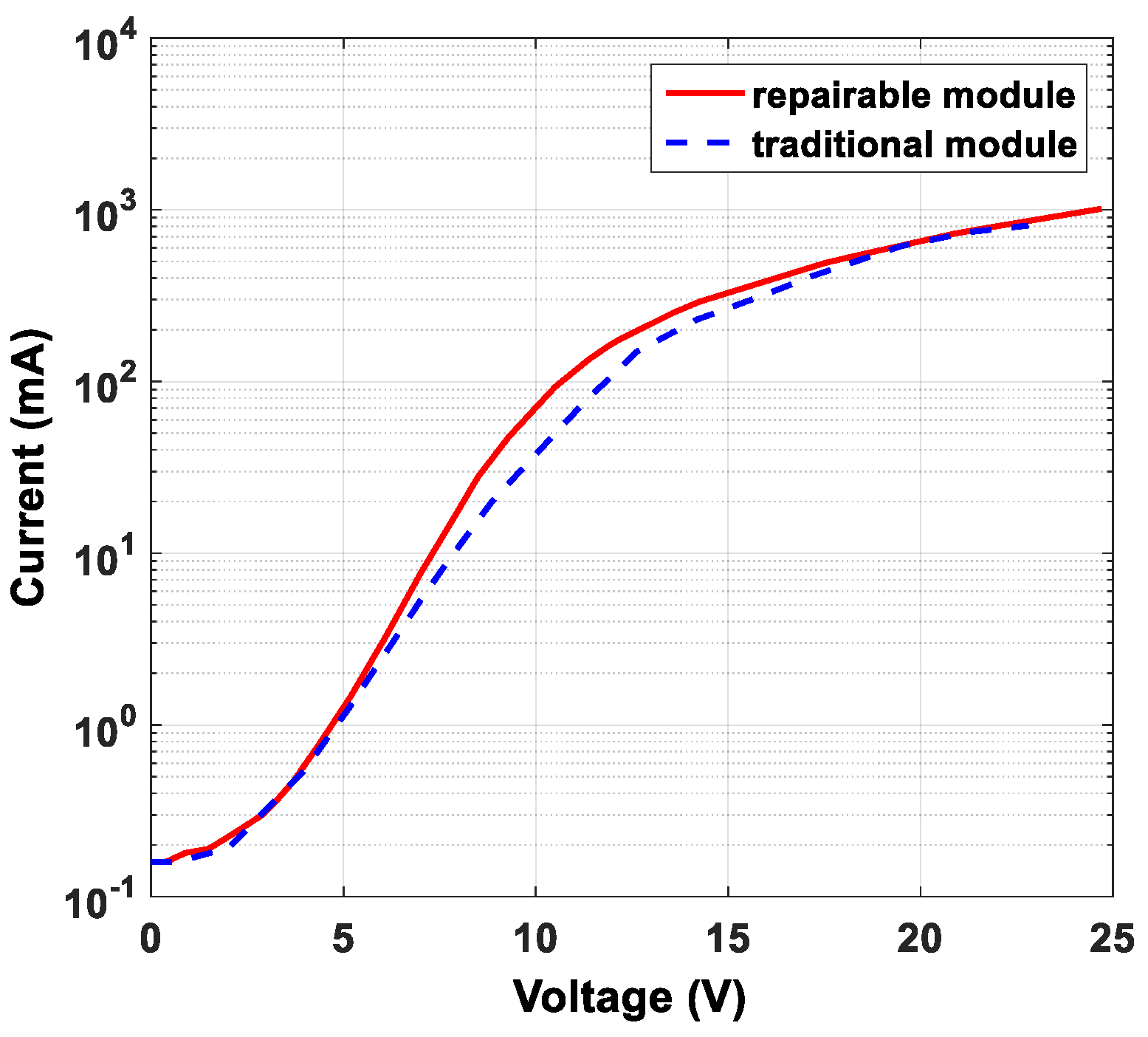

3.2. Electrical Performance Test

4. Numerical Thermal Analysis

- Thermal models are established in one dimension (1D).

- Negligible thermal capacitances are assumed.

- The PV cell temperature is assumed to be uniform as it has a higher thermal conductivity value than the other layers.

- The temperature of the ground (on the back of the PV module) is assumed to be the same as the air temperature (Tg = Ta).

- The transmission (), reflection ), and absorption () coefficients for the repairable and traditional modules (independent of temperature) are shown in Table 2.

- There is almost no internal reflection within the layers of the PV module.

- The emissivity of the glass remains constant, regardless of temperature and wavelength, and its value is 0.91 [12].

- The top surface of the PV module is exposed solely to the sky, while the underside is exposed solely to the ground.

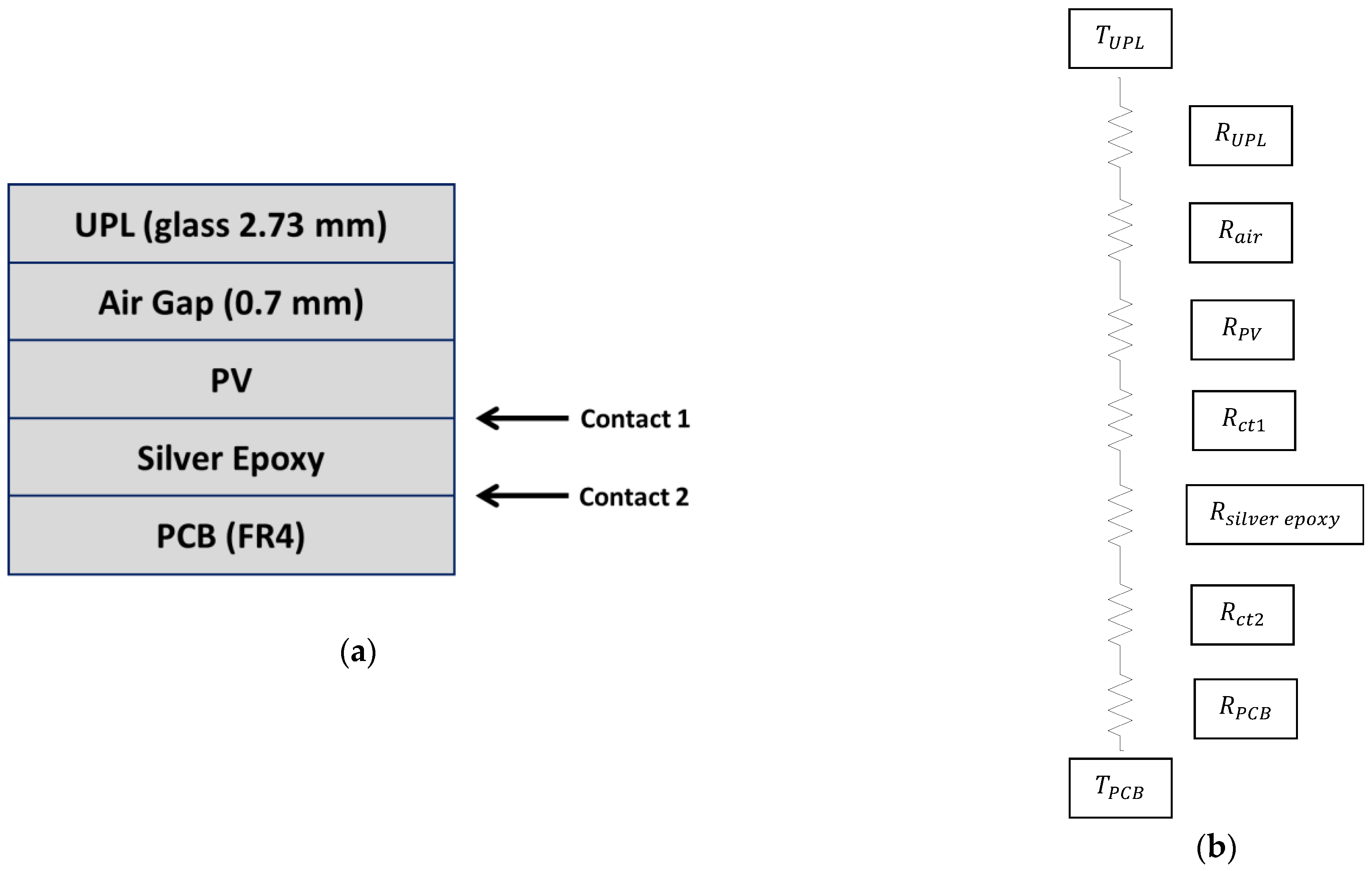

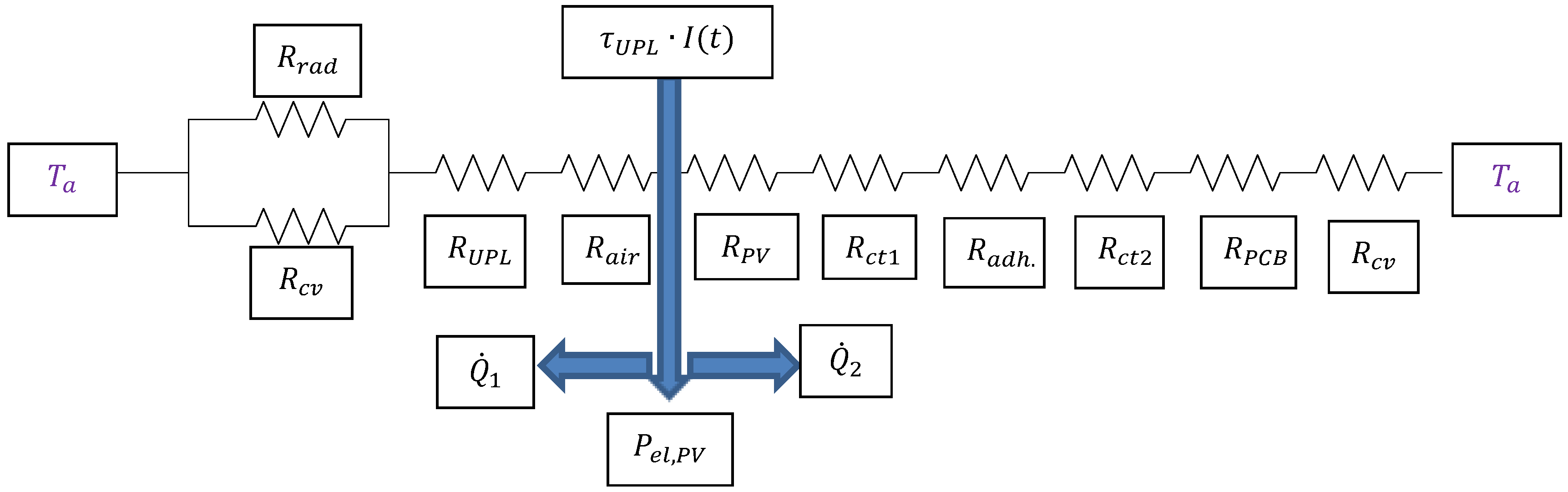

4.1. Repairable PV Module

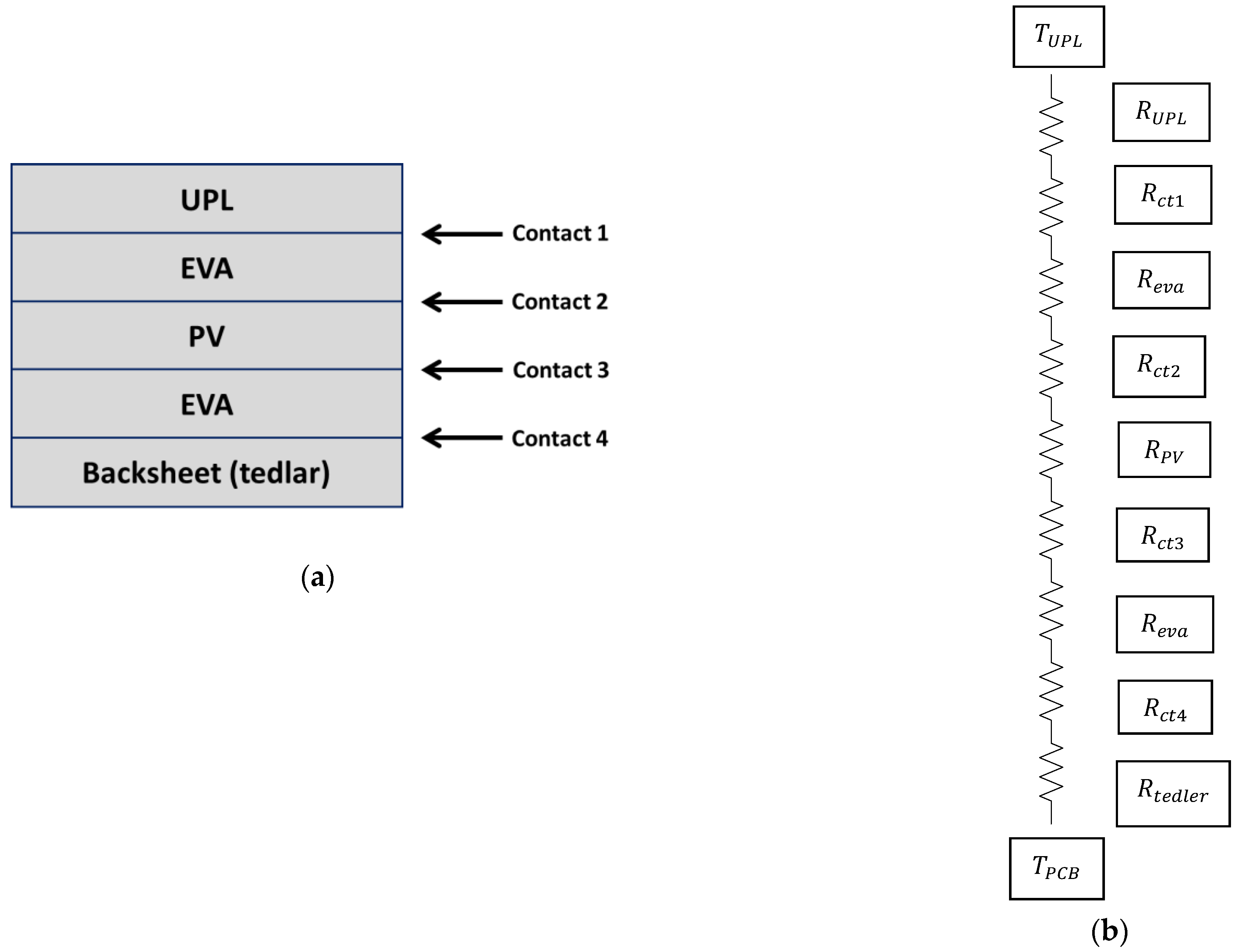

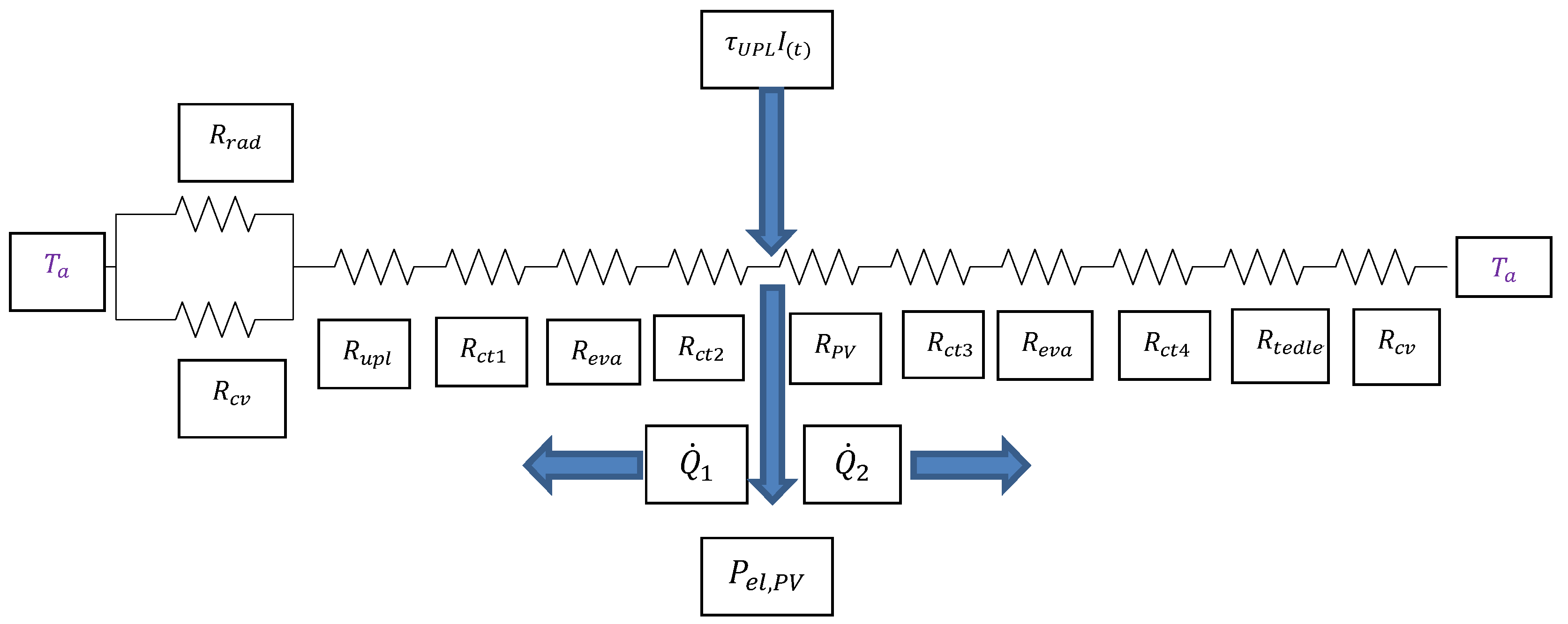

4.2. Traditional PV Module

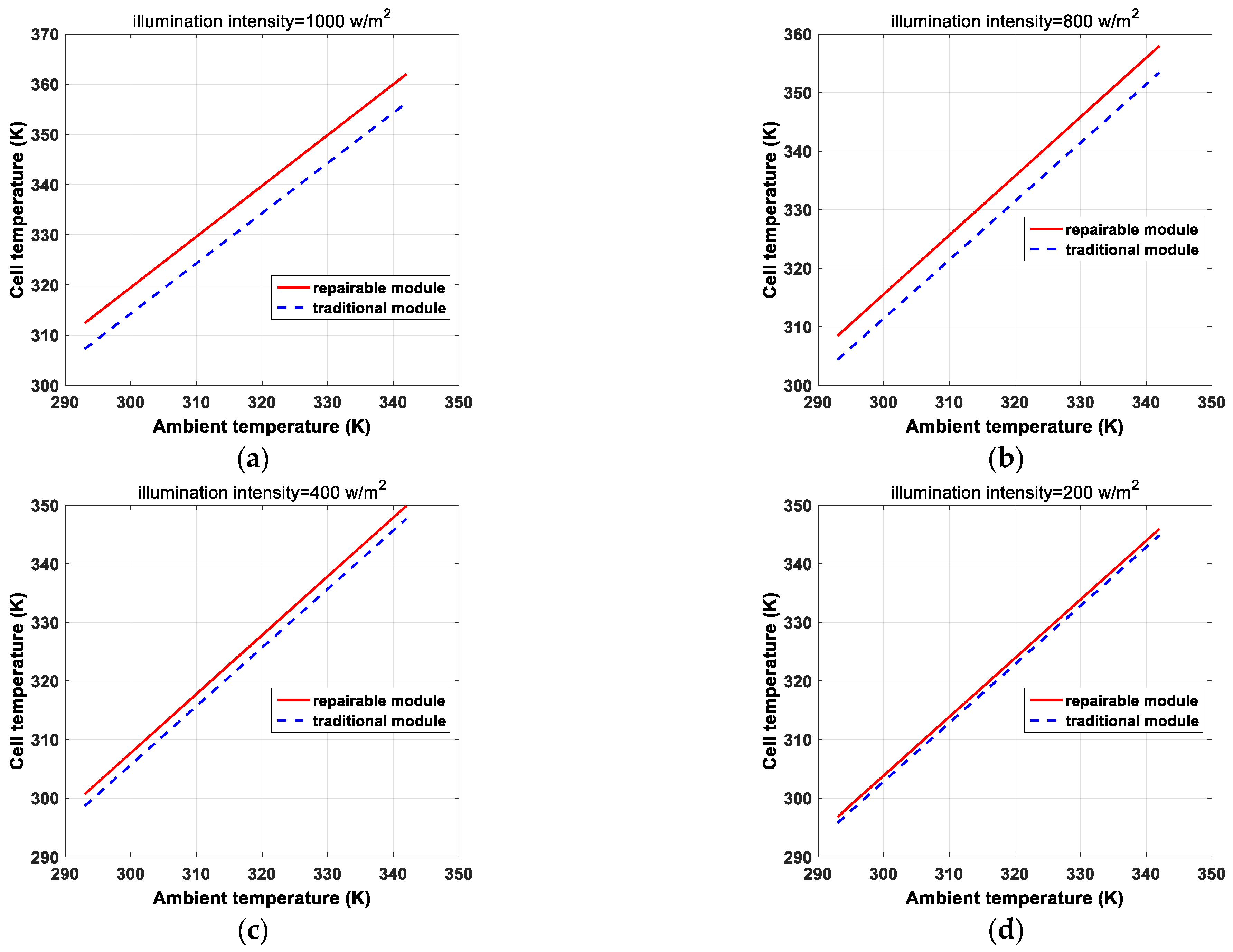

4.3. Numerical Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, V.; Pandey, A.S.; Sinha, S.K. Grid integration and power quality issues of wind and solar energy system: A review. In Proceedings of the 2016 International Conference on Emerging Trends in Electrical Electronics & Sustainable Energy Systems (ICETEESES), Sultanpur, India, 11–12 March 2016; pp. 71–80. [Google Scholar]

- Irena, I.P. End-of-Life Management: Solar Photovoltaic Panels; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Parida, B.; Iniyan, S.; Goic, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Spinelli, P.; Lenzmann, F.; Weeber, A.; Polman, A. Effect of EVA encapsulation on antireflection properties of Mie nanoscatterers for c-Si solar cells. IEEE J. Photovolt. 2015, 5, 559–564. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef] [PubMed]

- Zekry, A.; Shaker, A.; Salem, M. Solar cells and arrays: Principles, analysis, and design. In Advances in Renewable Energies and Power Technologies; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–56. [Google Scholar]

- El-Shazly, A.A.; Zekry, A.; El-Koosy, M.A.; Farid, M.S. Three flat plates terrestrial (3FPT) module fabrication and testing. Renew. Energy 2001, 23, 509–523. [Google Scholar] [CrossRef]

- Tsuno, Y.; Hishikawa, Y.; Kurokawa, K. Translation equations for temperature and irradiance of the IV curves of various PV cells and modules. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conference, Waikoloa, HI, USA, 7–12 May 2006; Volume 2, pp. 2246–2249. [Google Scholar]

- Pantic, L.S.; Pavlović, T.M.; Milosavljević, D.D.; Radonjic, I.S.; Radovic, M.K.; Sazhko, G. The assessment of different models to predict solar module temperature, output power and efficiency for Nis, Serbia. Energy 2016, 109, 38–48. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Mirmira, S.R.; Marotta, E.E.; Fletcher, L.S. Thermal contact conductance of adhesives for microelectronic systems. J. Thermophys. Heat Transf. 1997, 11, 141–145. [Google Scholar] [CrossRef]

- Hammami, M.; Torretti, S.; Grimaccia, F.; Grandi, G. Thermal and performance analysis of a photovoltaic module with an integrated energy storage system. Appl. Sci. 2017, 7, 1107. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Karellas, S.; Braimakis, K.; Stanciu, C.; Badescu, V. Exergy analysis of solar thermal collectors and processes. Prog. Energy Combust. Sci. 2016, 56, 106–137. [Google Scholar] [CrossRef]

- Sarhaddi, F.; Farahat, S.; Ajam, H.; Behzadmehr, A. Exergetic performance evaluation of a solar photovoltaic (PV) array. Aust. J. Basic Appl. Sci. 2010, 4, 502–519. [Google Scholar]

- Watmuff, J.H.; Charters, W.W.S.; Proctor, D. Solar and wind induced external coefficients-solar collectors. Coop. Mediterr. Pour L’energie Sol. 1977, 56. [Google Scholar]

- Evans, D.L. Simplified method for predicting photovoltaic array output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Lupu, A.G.; Hristoforou, E.; Tcaciuc, G.D.; Popescu, A. Theoretical Model for Photovoltaic Panel Thermal Analysis. Bull. Polytech. Inst. Iași. Mach. Constr. Sect. 2022, 68, 79–88. [Google Scholar] [CrossRef]

| No. | Module Parts | Candidate Materials |

|---|---|---|

| 1 | Head cover | Glass (2.73 mm) |

| 2 | Substrate | Printed board (FR4) |

| 3 | Adhesives and sealant | Silver conductive epoxy Epoxy Tin Silicon |

| 4 | Other parts | Soldering wires Aluminum Rubber |

| Layer Material | S (mm) | K (W/m.K) | ||||

|---|---|---|---|---|---|---|

| Modified PV Module | Glass | 2.73 | 1.8 | 0.1 | 0.88 | 0.02 |

| Air | 0.7 | 0.025 | 0.1 | 0.88 | 0.02 | |

| Silicon | 0.4 | 150 | - | - | 1 | |

| Silver epoxy | 0.2 | 1.5 | - | - | - | |

| PCB (FR4) | 1.5 | 0.25 | - | - | - | |

| Traditional PV Module | Glass | 2.73 | 1.8 | 0.1 | 0.88 | 0.02 |

| EVA | 0.4 | 0.35 | - | 0.97 | 0.03 | |

| Silicon | 0.4 | 150 | - | - | 1 | |

| Backsheet | 0.3 | 0.3 | - | - | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Fayome, E.; Zekry, A.H.; Abdelhamed, M.A.; EL-Shazly, A.; Abouelatta, M.; Shaker, A.; Saeed, A. Proposal for Repairable Silicon Solar Panels: Proof of Concept. Energies 2023, 16, 6492. https://doi.org/10.3390/en16186492

El-Fayome E, Zekry AH, Abdelhamed MA, EL-Shazly A, Abouelatta M, Shaker A, Saeed A. Proposal for Repairable Silicon Solar Panels: Proof of Concept. Energies. 2023; 16(18):6492. https://doi.org/10.3390/en16186492

Chicago/Turabian StyleEl-Fayome, Ehab, Abdel Halim Zekry, Mohamed A. Abdelhamed, Ahmed EL-Shazly, Mohamed Abouelatta, Ahmed Shaker, and Ahmed Saeed. 2023. "Proposal for Repairable Silicon Solar Panels: Proof of Concept" Energies 16, no. 18: 6492. https://doi.org/10.3390/en16186492

APA StyleEl-Fayome, E., Zekry, A. H., Abdelhamed, M. A., EL-Shazly, A., Abouelatta, M., Shaker, A., & Saeed, A. (2023). Proposal for Repairable Silicon Solar Panels: Proof of Concept. Energies, 16(18), 6492. https://doi.org/10.3390/en16186492