Numerical Modeling of Shale Oil Considering the Influence of Micro- and Nanoscale Pore Structures

Abstract

:1. Introduction

2. Microscale Effects in Shale Oil Reservoir

2.1. Stochastic Apparent Permeability Model

2.2. Phase Change Characteristics in Micro- and Nanopores

2.3. Shale Oil Reservoir Two-Phase Flow Mechanism

3. Two-Phase Flow Shale Simulation and Model Validation

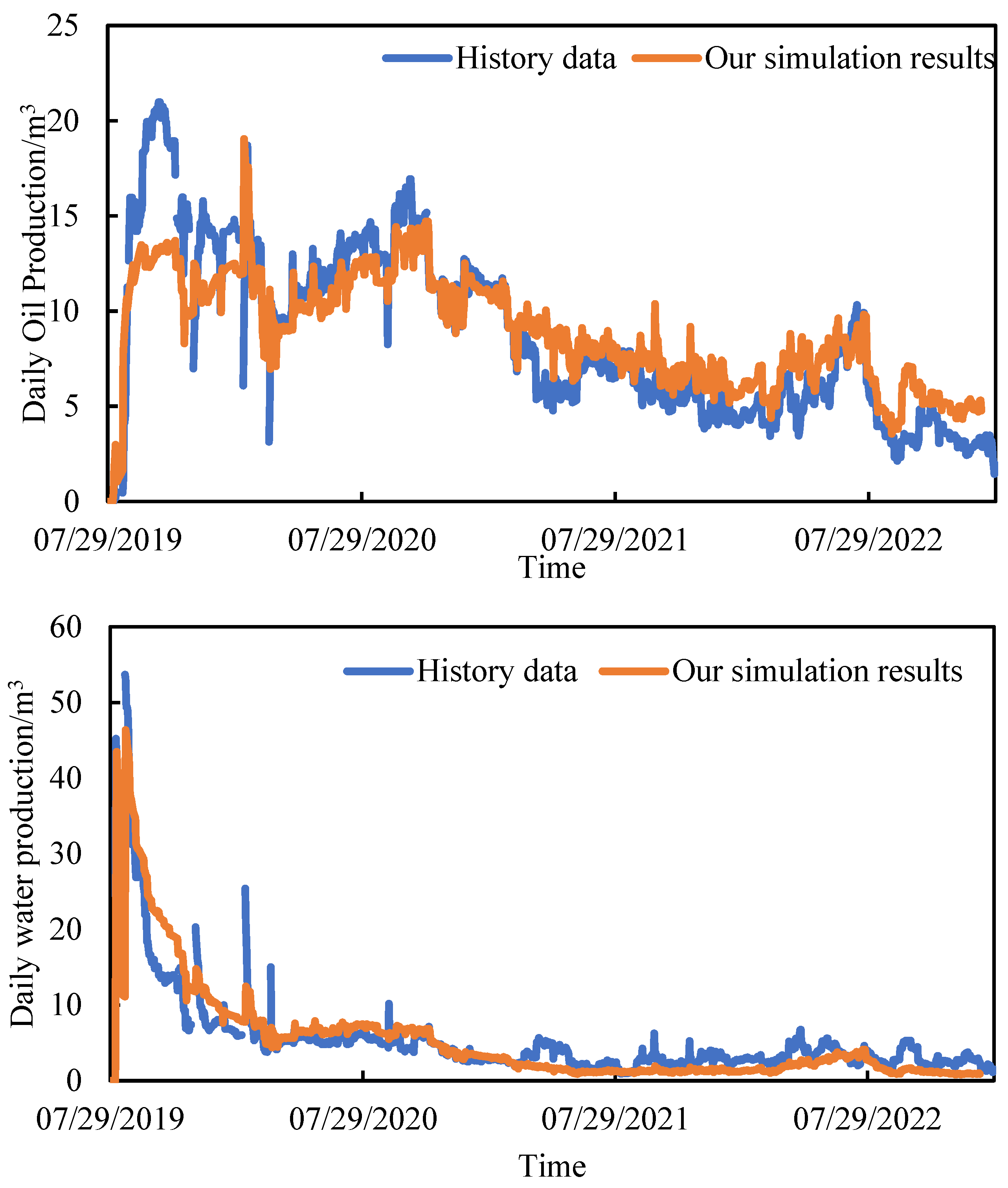

3.1. Model Validation

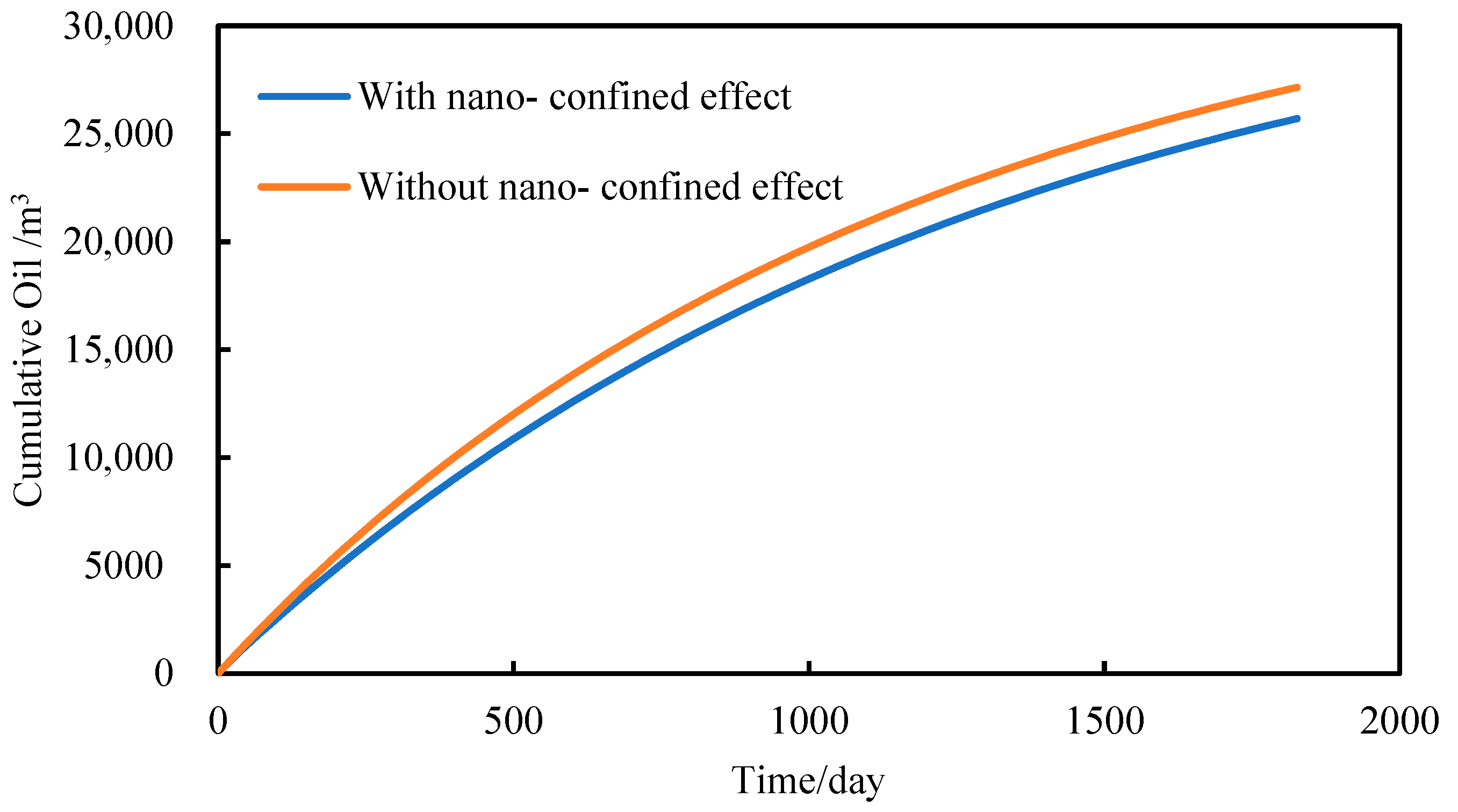

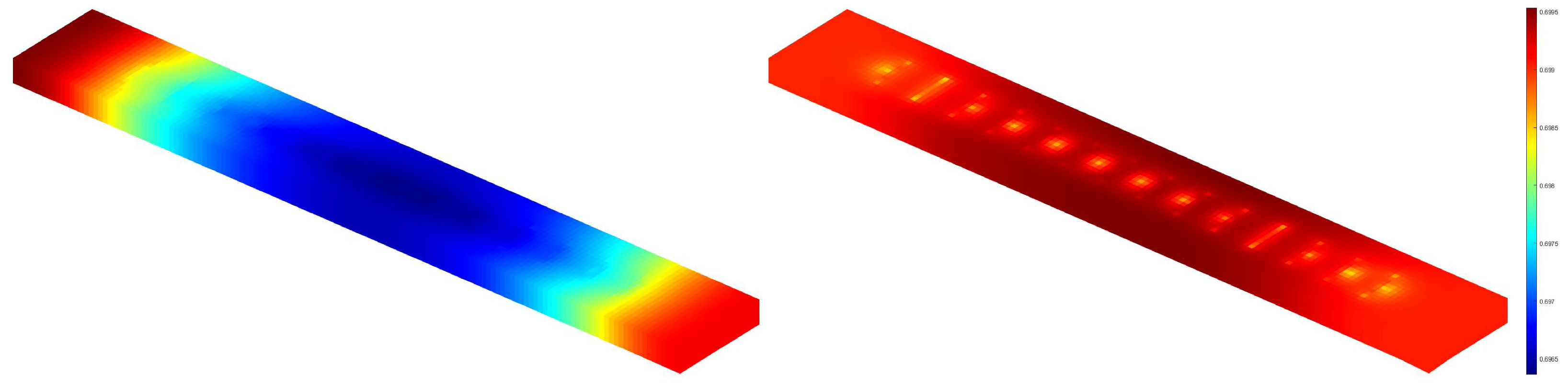

3.2. Influence of Capillary Forces on Reservoirs Considering the Effects of Micro- and Nanoscale Pores

3.3. Influence of Artificial Fractures on Productivity of Fractured Horizontal Wells in Shale Reservoirs

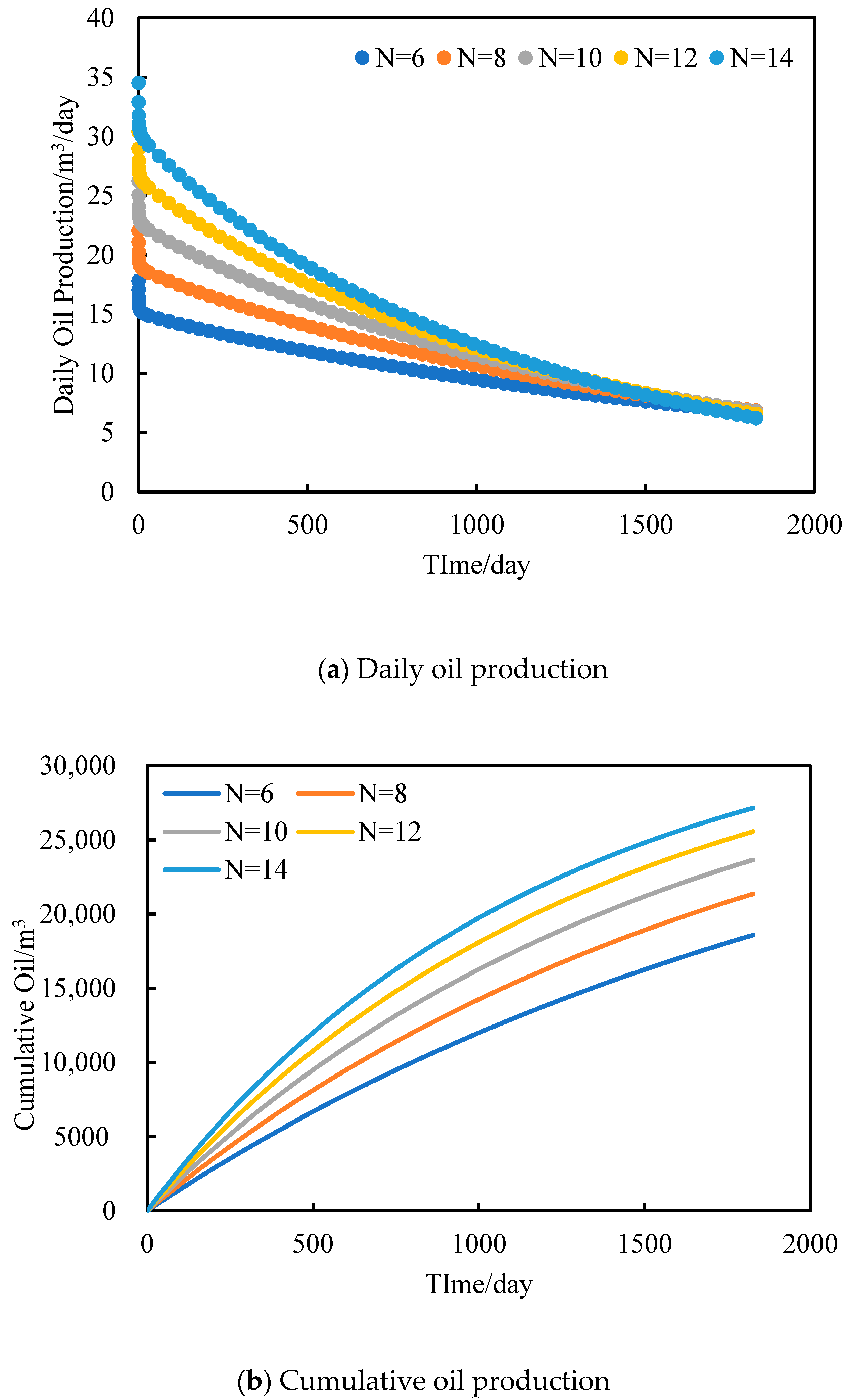

3.3.1. Fracture Number

3.3.2. Fracture Spacing

4. Conclusions

- (1)

- By combining the capillary force model with the thermodynamic state equation and modifying the critical properties of each component, a reaction model can describe the flow mechanism of shale oil in different storage states and flow of dissolved gas, effectively characterizing two-phase flow characteristics of shale oil.

- (2)

- The oil and gas production rates of horizontal wells increase as a function of the enhancement of the vertical flow, and the impact of the vertical flow on shale oil production in a two-phase flow is more significant compared to a single-phase liquid flow. When the bottomhole pressure of the horizontal well is high, the oil and gas production rates are low. However, as the bottomhole pressure decreases, the elastic energy used for oil displacement increases, and more dissolved gas escapes from the crude oil, resulting in an increase in oil and gas production rates, with a greater increase in gas production compared to oil production.

- (3)

- Upon analyzing the dynamic evolution of reservoir pressure fields and permeability fields with and without accounting for capillary forces, it is observed that the cumulative oil yield from shale oil, when considering the influence of micro- and nanoscale pores, is diminished by approximately 6% in comparison to the scenario without such consideration. Under the influence of micro- and nanoscale pores, the reservoir experiences heightened pressure fields and an elevated overall oil saturation distribution. This outcome is attributed to the capillary forces exerted by micro- and nanoscale pores within the shale. These capillary forces contribute to the reduction in the actual bubble point pressure within the oil and gas system. Consequently, the fluid within the reservoir remains in a monophasic liquid state, thus constraining the mobility of oil within the shale and subsequently leading to a reduced flow efficiency.

- (4)

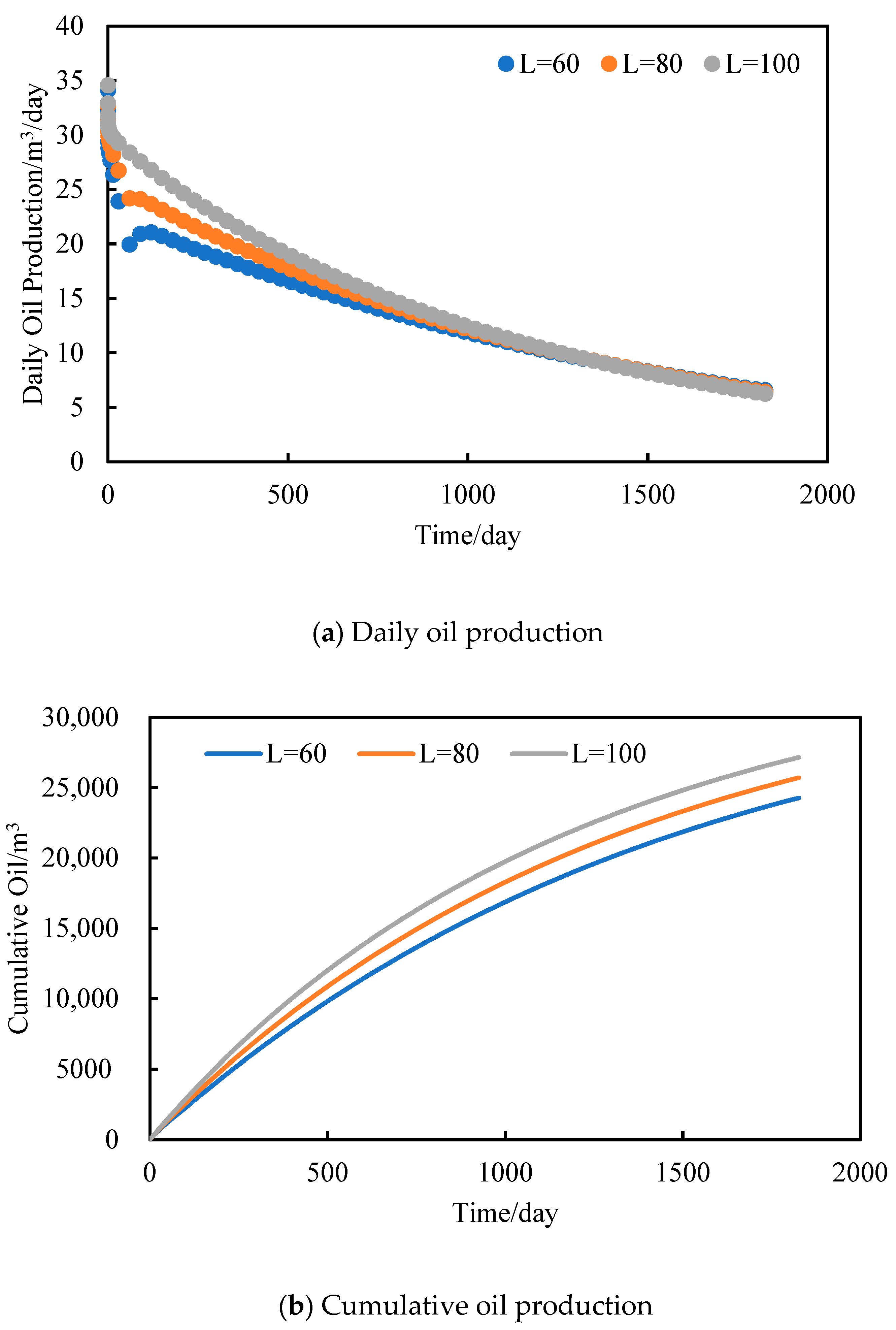

- The number of artificial fractures mainly affects the early stage of horizontal well production. A discernible correlation emerges: an increase in the count of artificial fractures corresponds to a heightened daily oil production and an augmented cumulative oil production. However, with the increase in the number of fractures, the increase in the horizontal well productivity becomes smaller and smaller. Shale gas reservoirs have good production effects after hydraulic fracturing; when the number of fractures is fixed, the greater the fracture spacing, the higher the daily oil production of horizontal wells. This trend is further underscored by the observation that a higher cumulative oil production accompanies a more pronounced fracturing effect.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, D.; Wei, Z.; Liu, R.; Wei, X.; Chen, F.; Liu, Z. Enrichment control factors and explo-ration potential of lacustrine shale oil and gas: A case study of Jurassic in the Fuling area of the Sichuan Basin. Nat. Gas Ind. B 2022, 9, 1–8. [Google Scholar] [CrossRef]

- Ju, W.; Niu, X.B.; Feng, S.B.; You, Y.; Xu, K.; Wang, G.; Xu, H.R. Predicting the present-day in situ stress distribution within the Yanchang Formation Chang 7 shale oil reservoir of Ordos Basin, central China. Pet. Sci. 2020, 17, 912–924. [Google Scholar] [CrossRef]

- Hu, T.; Pang, X.Q.; Jiang, F.J.; Wang, Q.F.; Wu, G.Y.; Liu, X.H.; Jiang, S.; Li, C.R.; Xu, T.W.; Chen, Y.Y. Key factors controlling shale oil enrichment in saline lacustrine rift basin: Implications from two shale oil wells in Dongpu Depression. Bohai Bay Basin. Pet. Sci. 2021, 18, 687–711. [Google Scholar] [CrossRef]

- Tang, Y.; Cao, J.; He, W.J.; Guo, X.G.; Zhao, K.B.; Li, W.W. Discovery of shale oil in alkaline lacustrine basins: The Late Paleozoic Fengcheng Formation, Mahu Sag, Junggar Basin, China. Pet. Sci. 2021, 18, 1281–1293. [Google Scholar] [CrossRef]

- Ambrose, R.J.; Hartman, R.C.; Diaz Campos, M.; Akkutlu, I.Y.; Sondergeld, C. New pore-scale considerations for shale gas in place calculations. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010. SPE-131772-MS. [Google Scholar]

- Wu, H.A.; Chen, J.; Liu, H. Molecular dynamics simulations about adsorption and displacement of methane in carbon nanochannels. J. Phys. Chem. C 2015, 119, 13652–13657. [Google Scholar] [CrossRef]

- Botan, A.; Vermorel, R.; Ulm, F.J.; Pellenq, R.J.M. Molecular simulations of supercritical fluid permeation through disordered microporous carbons. Langmuir 2013, 29, 9985–9990. [Google Scholar] [CrossRef]

- Song, F.; Chen, X. Molecular dynamics study of liquid wall slip. Hydrodyn. Res. Prog. 2012, 27, 80–86. [Google Scholar]

- Wang, S.; Javadpour, F.; Feng, Q. Molecular dynamics simulations of oil transport through inorganic nanopores in shale. Fuel 2016, 171, 74–86. [Google Scholar] [CrossRef]

- Wang, S.; Javadpour, F.; Feng, Q. Fast mass transport of oil and supercritical carbon dioxide through organic nanopores in shale. Fuel 2016, 181, 741–758. [Google Scholar] [CrossRef]

- Wang, S.; Feng, Q.; Javadpour, F.; Xia, T.; Li, Z. Oil adsorption in shale nanopores and its effect on recoverable oil-in-place. Int. J. Coal Geol. 2015, 147–148, 9–24. [Google Scholar] [CrossRef]

- Wang, S.; Feng, Q.; Cha, M.; Lu, S.; Qin, Y.; Xia, T.; Zhang, C. Molecular dynamics simulation of liquid alkane fugacity in shale organic matter pore joints. Pet. Explor. Dev. 2015, 42, 772–778. [Google Scholar] [CrossRef]

- Javadpour, F.; McClure, M.; Naraghi, M.E. Slip-corrected liquid permeability and its effect on hydraulic fracturing and fluid loss in shale. Fuel 2015, 160, 549–559. [Google Scholar] [CrossRef]

- Arora, G.; Sandler, S.I. Nanoporous carbon membranes for separation of nitrogen and oxygen: Insight from molecular simulations. Fluid Phase Equilibria 2007, 259, 3–8. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, X.; Liu, X.; Yang, K.; Zhou, H. Surface Wettability of Basal Surfaces of Clay Minerals: Insights from Molecular Dynamics Simulation. Energy Fuels 2016, 30, 149–160. [Google Scholar] [CrossRef]

- Chang, X.; Xue, Q.; Li, X.; Zhang, J.; Zhu, L.; He, D.; Zheng, H.; Lu, S.; Liu, Z. Inherent wettability of different rock surfaces at nanoscale: A theoretical study. Appl. Surf. Sci. 2018, 434, 73–81. [Google Scholar] [CrossRef]

- Majumder, M.; Chopra, N.; Andrews, R.; Hinds, B. Nanoscale hydrodynamics: Enhanced flow in carbon nanotubes. Nature 2005, 438, 44. [Google Scholar] [CrossRef] [PubMed]

- Whitby, M.; Quirke, N. Fluid flow in carbon nanotubes and nanopipes. Nat. Nanotechnol. 2007, 2, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Falk, K.; Sedlmeier, F.; Joly, L.; Netz, R.R.; Bocquet, L. Ultralow liquid/solid friction in carbon nanotubes: Comprehensive theory for alcohols, alkanes, OMCTS, and water. Langmuir 2012, 8, 14261–14272. [Google Scholar] [CrossRef]

- Wu, K.; Chen, Z.; Li, J.; Li, X.; Xu, J.; Dong, X. Wettability effect on nanoconfined water flow. Proc. Natl. Acad. Sci. USA 2017, 114, 3358–3363. [Google Scholar] [CrossRef]

- Cui, J.; Sang, Q.; Li, Y.; Yin, C.; Li, Y.; Dong, M. Liquid permeability of organic nanopores in shale: Calculation and analysis. Fuel 2017, 15, 426–434. [Google Scholar] [CrossRef]

- Mattia, D.; Calabro, F. Explaining high flow rate of water in carbon nanotubes via solid-liquid molecular intercations. Microfluid Nanofluid 2012, 13, 125–130. [Google Scholar] [CrossRef]

- Qi, Z.; Yuliang, S.; Wendong, W.; Mingjing, L.; Guanglong, S. Apparent permeability for liquid transport in nanopores of shale reservoirs: Coupling flow enhancement and near wall flow. Int. J. Heat Mass Transf. 2017, 115, 224–234. [Google Scholar]

- Xu, J.; Su, Y.; Wang, W.; Wang, H. Stochastic Apparent Permeability Model of Shale Oil Considering Geological Control. In Proceedings of the Unconventional Resources Technology Conference, Virtual, 20–22 July 2020; pp. 2443–2460. [Google Scholar]

- Wang, X.; Li, J.; Jiang, W.; Zhang, H.; Feng, Y.; Yang, Z. Characteristics, current exploration practices, and prospects of continental shale oil in China. Adv. Geo-Energy Res. 2022, 6, 454–459. [Google Scholar] [CrossRef]

- Sharifi, M.; Kelkar, M.; Karkevandi-Talkhooncheh, A. A workflow for flow simulation in shale oil reservoirs: A case study in woodford shale. Adv. Geo-Energy Res. 2021, 5, 365–375. [Google Scholar] [CrossRef]

- Feng, Q.; Xu, S.; Xing, X.; Zhang, W.; Wang, S. Advances and challenges in shale oil development: A critical review. Adv. Geo-Energy Res. 2020, 4, 406–418. [Google Scholar] [CrossRef]

- Su, Y.; Sun, Q.; Wang, W.; Guo, X.; Xu, J.; Li, G.; Pu, X.; Han, W.; Shi, Z. Spontaneous imbibition characteristics of shale oil reservoir under the influence of osmosis. Int. J. Coal Sci. Technol. 2022, 9, 69. [Google Scholar] [CrossRef]

- Bai, L.; Wang, Y.; Zhang, K.; Yang, Y.; Bao, K.; Zhao, J.; Li, X. Spatial variability of soil moisture in a mining subsidence area of northwest China. Int. J. Coal Sci. Technol. 2022, 9, 64. [Google Scholar] [CrossRef]

- Hamanaka, A.; Sasaoka, T.; Shimada, H.; Matsumoto, S. Amelioration of acidic soil using fly ash for mine revegetation in post-mining land. Int. J. Coal Sci. Technol. 2022, 9, 33. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Reservoir thickness/m | 45.72 | TOC/% | 3.00 |

| Length of horizontal section/m | 1188.72 | Initial water saturation/% | 30 |

| Number of fracturing | 14 | Initial oil saturation/% | 70 |

| Hydraulic fracture length/m | 152.4 | Initial gas saturation/% | 0 |

| Matrix porosity | 0.1 | Temperature/°C | 154.00 |

| Permeability/10−3 μm2 | 0.13 | Initial pressures/MPa | 51.71 |

| Composite compressibility/MPa−1 | 0.00018 | Theoretical bubble point pressure/MPa | 27.58 |

| Parameter | Value | Parameter | Value |

| Reservoir thickness/m | 45.72 | fracture widths | 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, Q.; Zhou, X.; Ren, D.; Dong, J.; Xu, M.; Li, R. Numerical Modeling of Shale Oil Considering the Influence of Micro- and Nanoscale Pore Structures. Energies 2023, 16, 6482. https://doi.org/10.3390/en16186482

Ran Q, Zhou X, Ren D, Dong J, Xu M, Li R. Numerical Modeling of Shale Oil Considering the Influence of Micro- and Nanoscale Pore Structures. Energies. 2023; 16(18):6482. https://doi.org/10.3390/en16186482

Chicago/Turabian StyleRan, Qiquan, Xin Zhou, Dianxing Ren, Jiaxin Dong, Mengya Xu, and Ruibo Li. 2023. "Numerical Modeling of Shale Oil Considering the Influence of Micro- and Nanoscale Pore Structures" Energies 16, no. 18: 6482. https://doi.org/10.3390/en16186482

APA StyleRan, Q., Zhou, X., Ren, D., Dong, J., Xu, M., & Li, R. (2023). Numerical Modeling of Shale Oil Considering the Influence of Micro- and Nanoscale Pore Structures. Energies, 16(18), 6482. https://doi.org/10.3390/en16186482