Parametric Analysis and Optimization for Thermal Efficiency Improvement in a Turbocharged Diesel Engine with Peak Cylinder Pressure Constraints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Engine Description

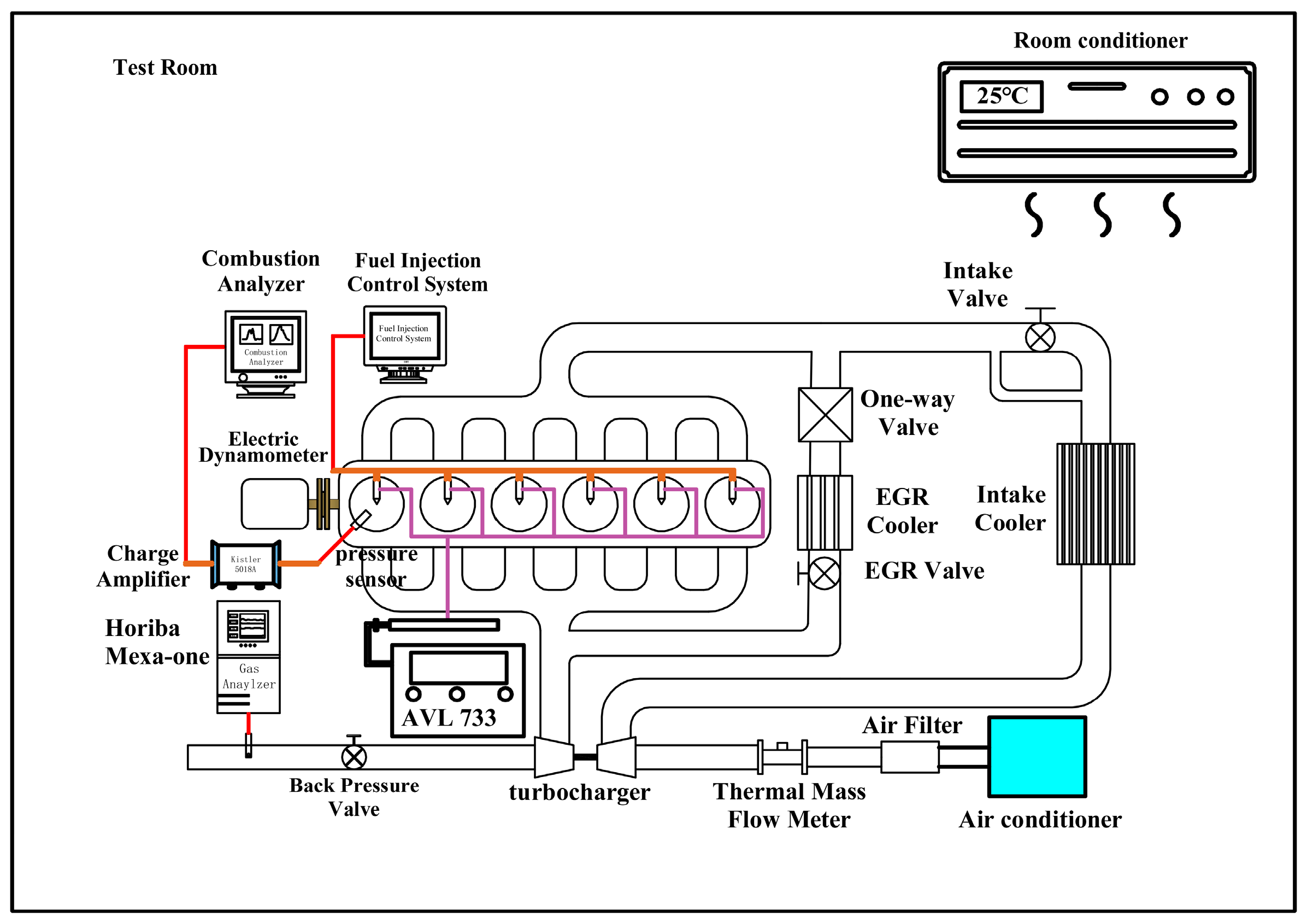

2.2. Experimental Setup and Test Procedure

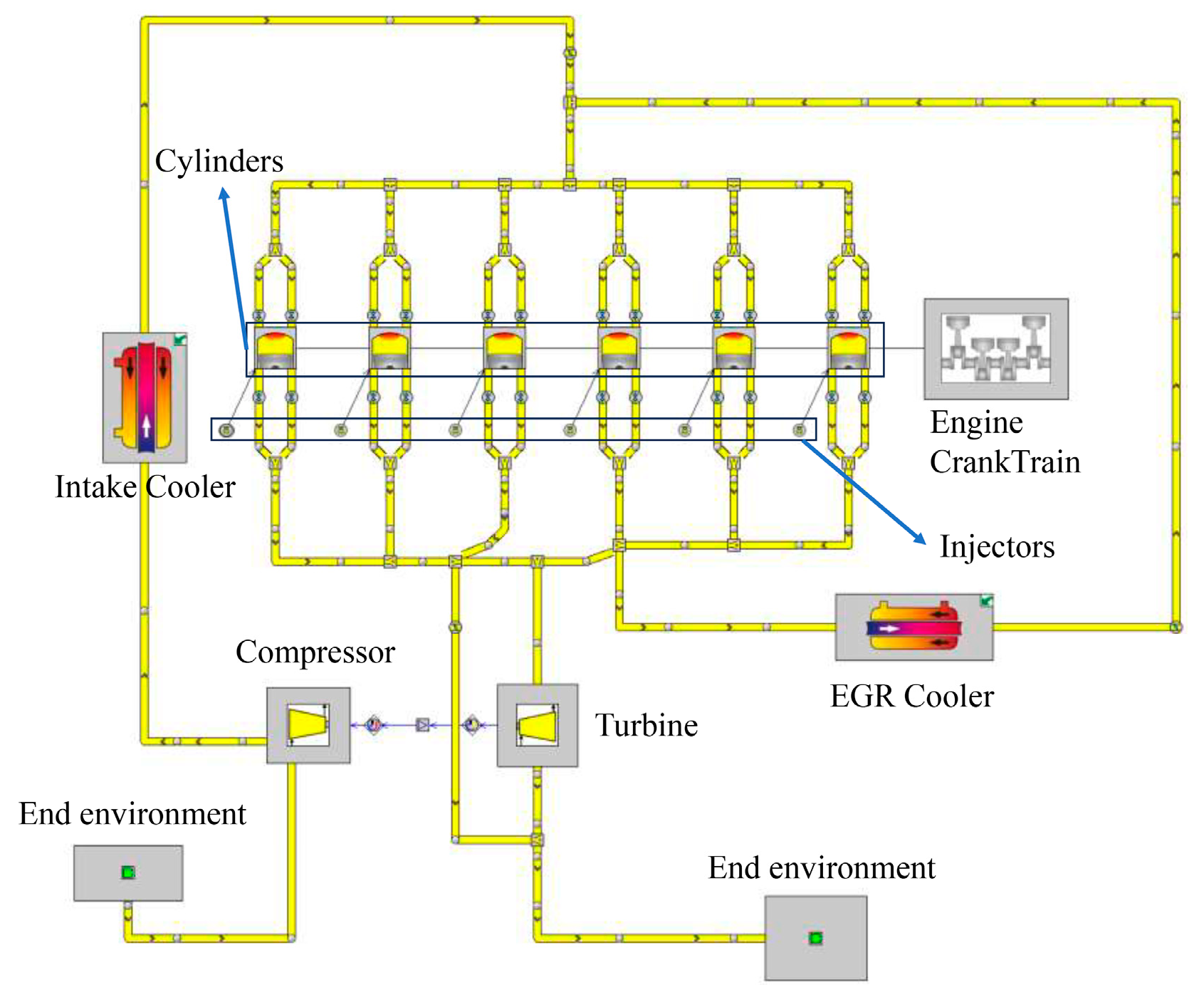

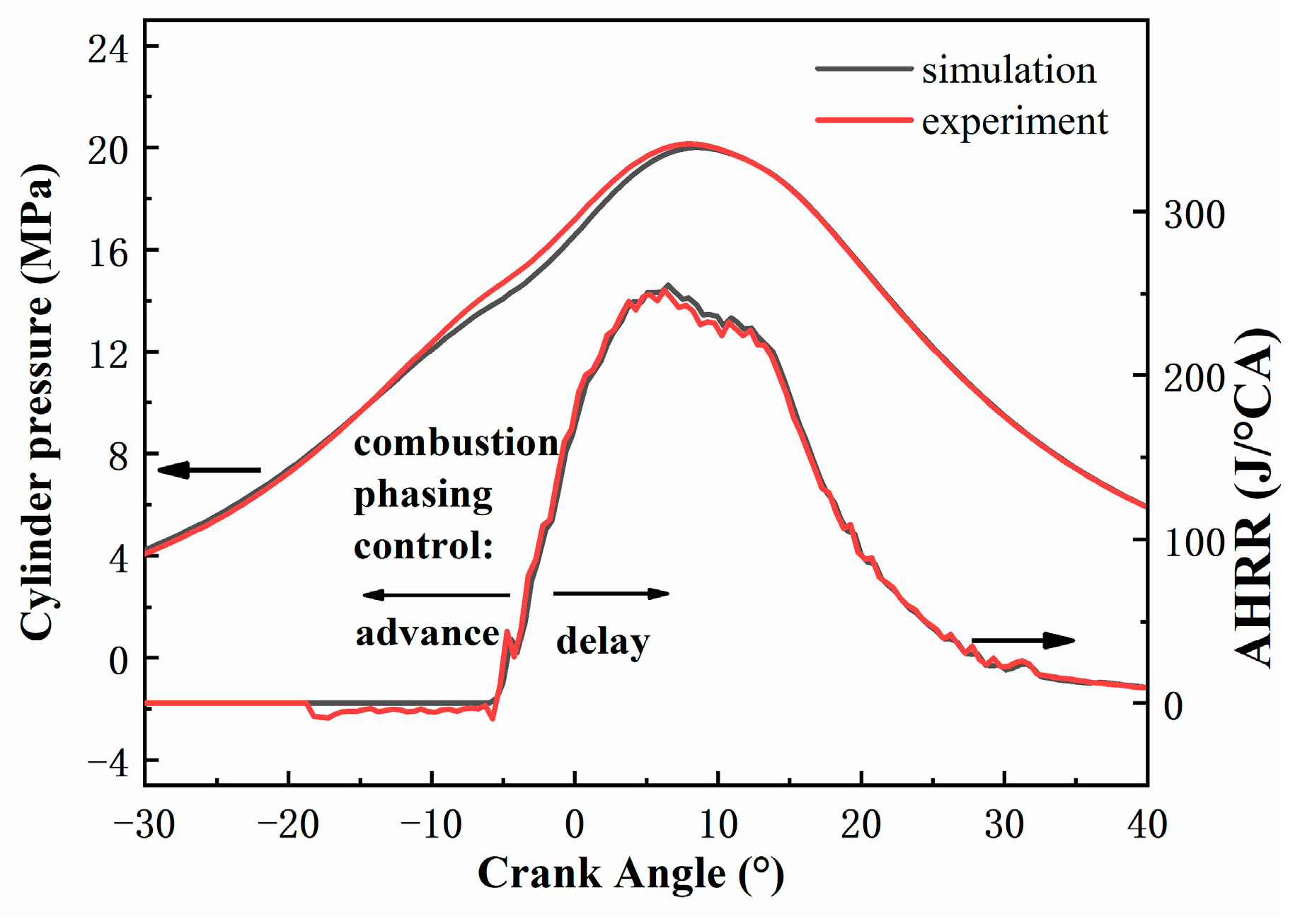

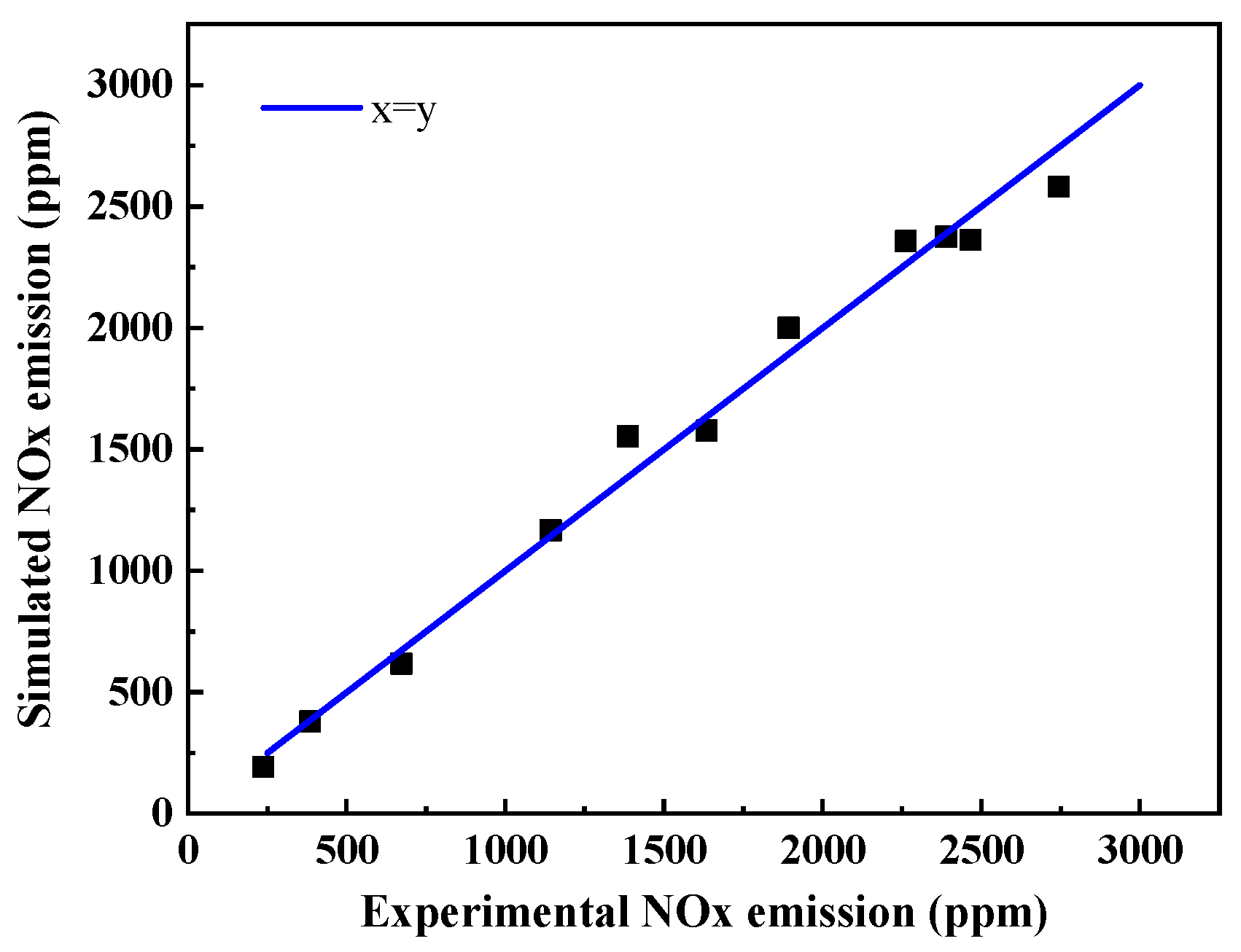

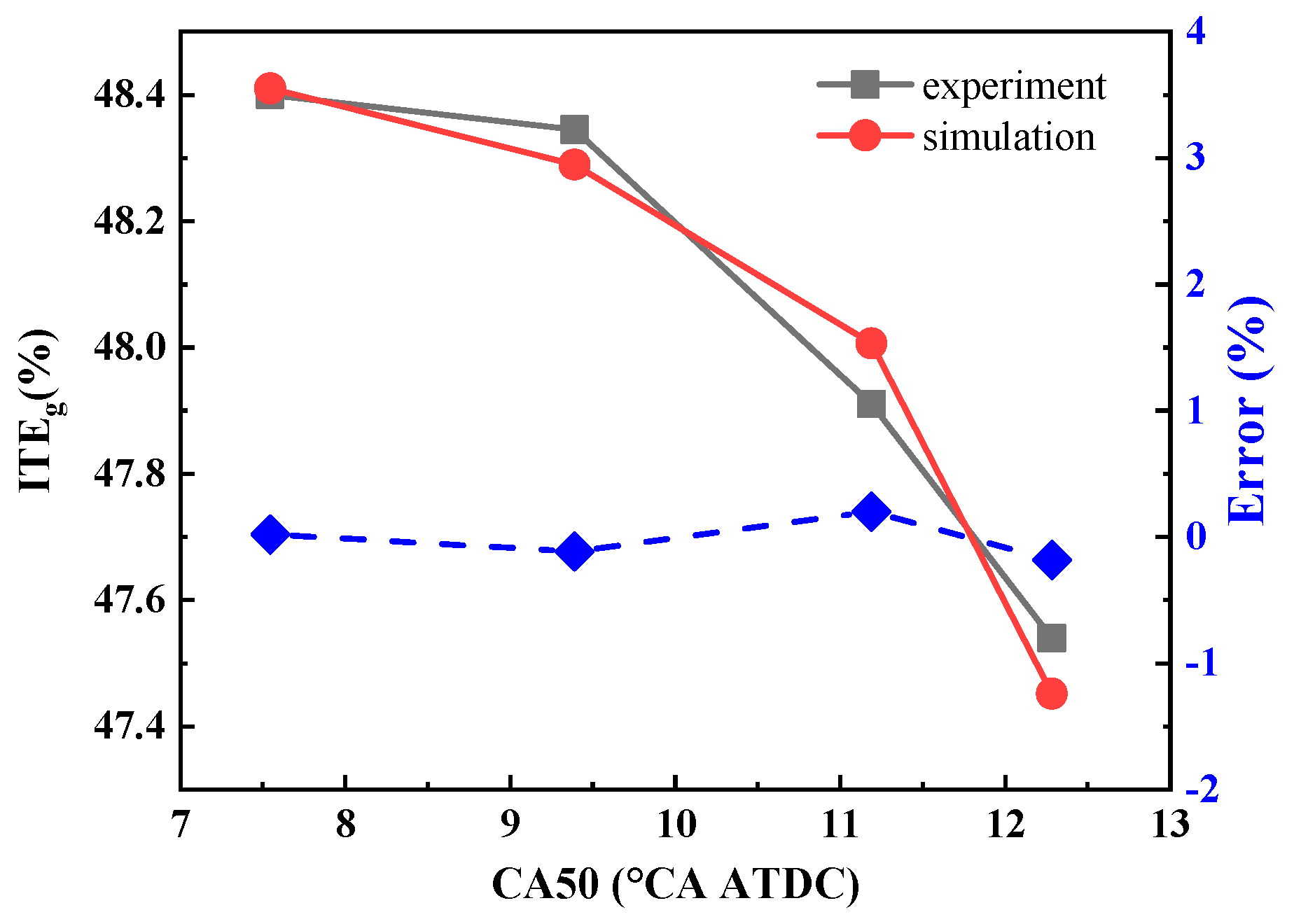

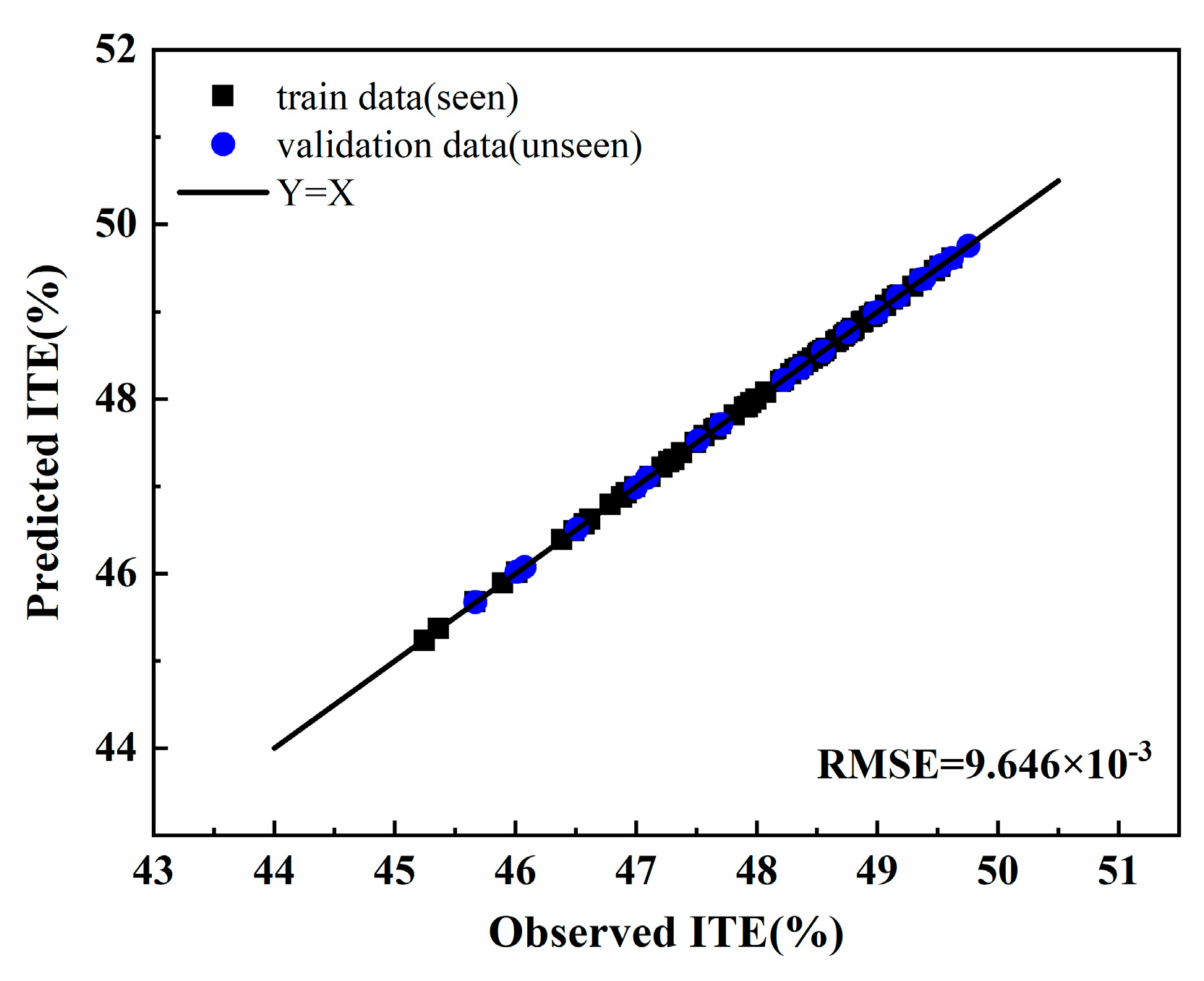

2.3. One-Dimensional Simulation Model Setup and Validation

2.4. Description of Indicators

3. Results and Discussion

3.1. Parametric Analysis

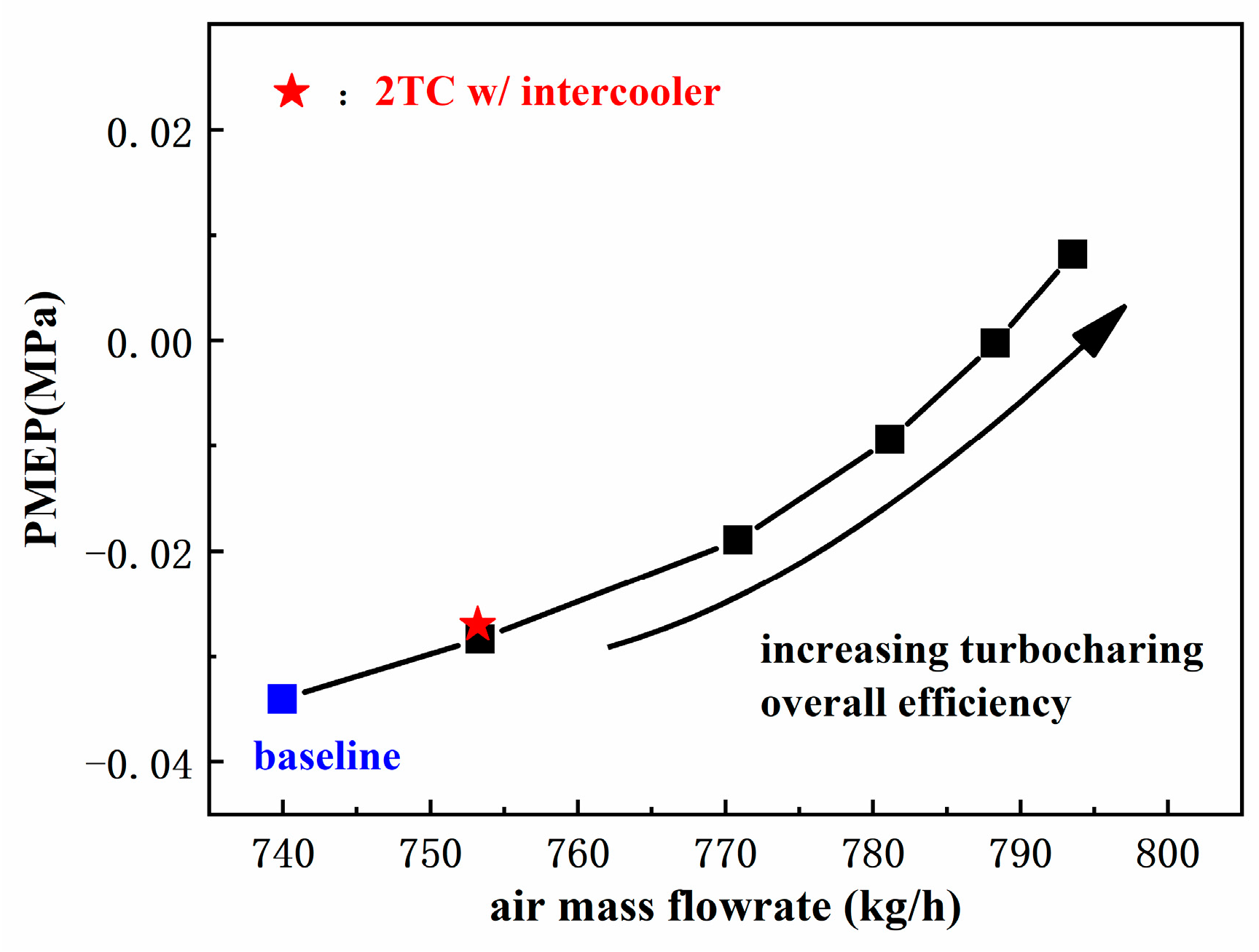

3.1.1. The Effect of Turbocharging Overall Efficiency on Thermal Efficiency

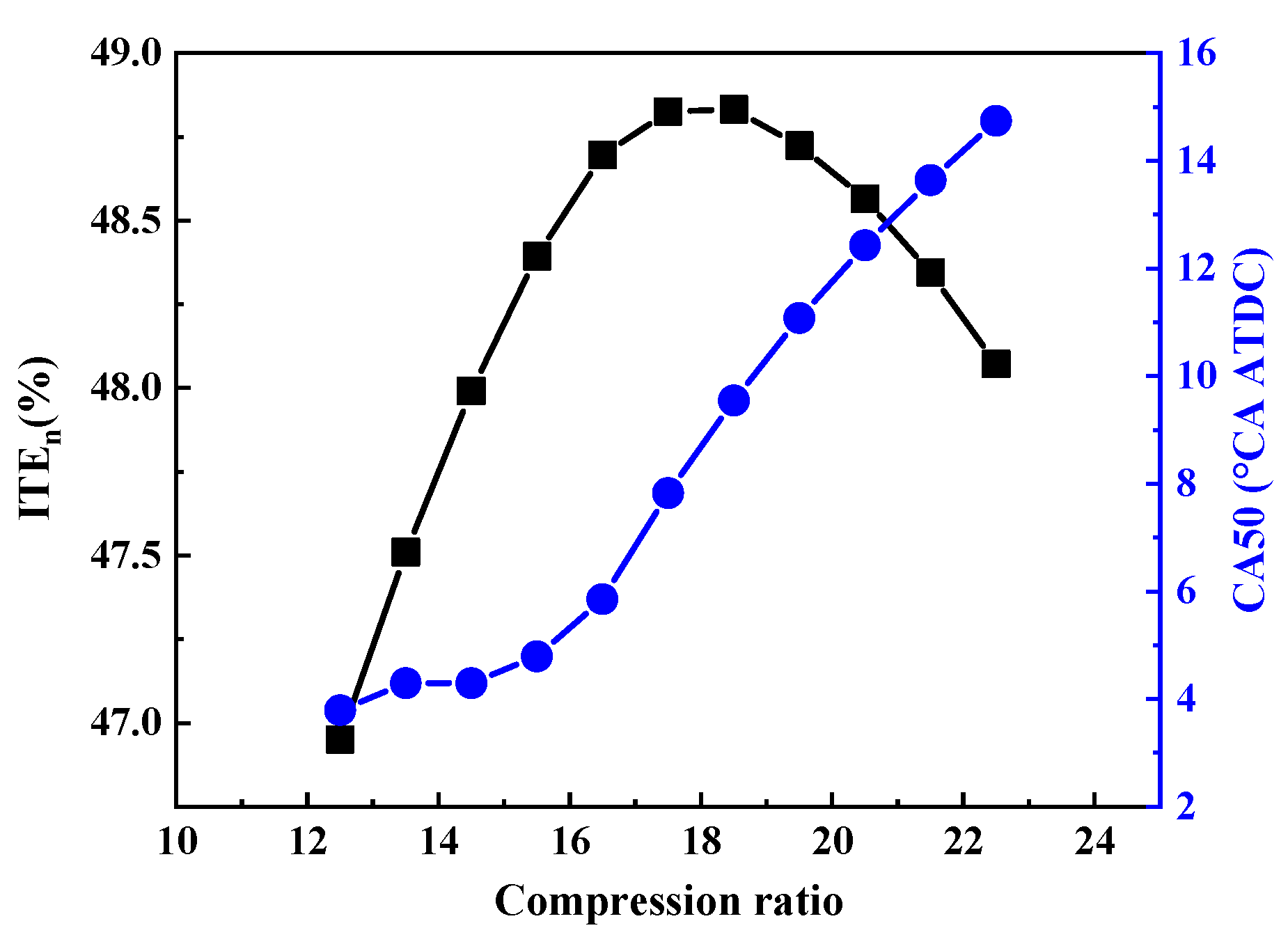

3.1.2. The Effect of CR on Thermal Efficiency

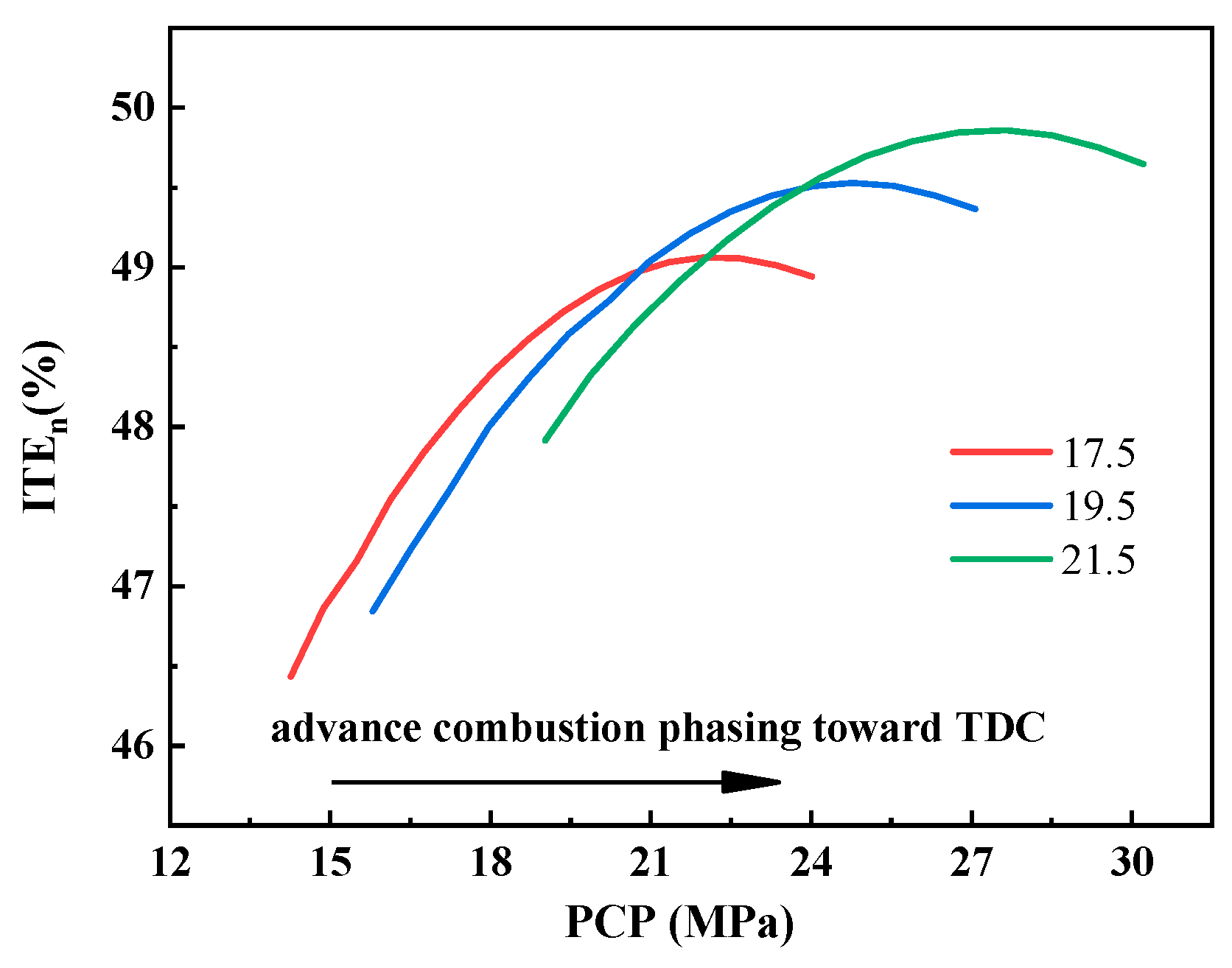

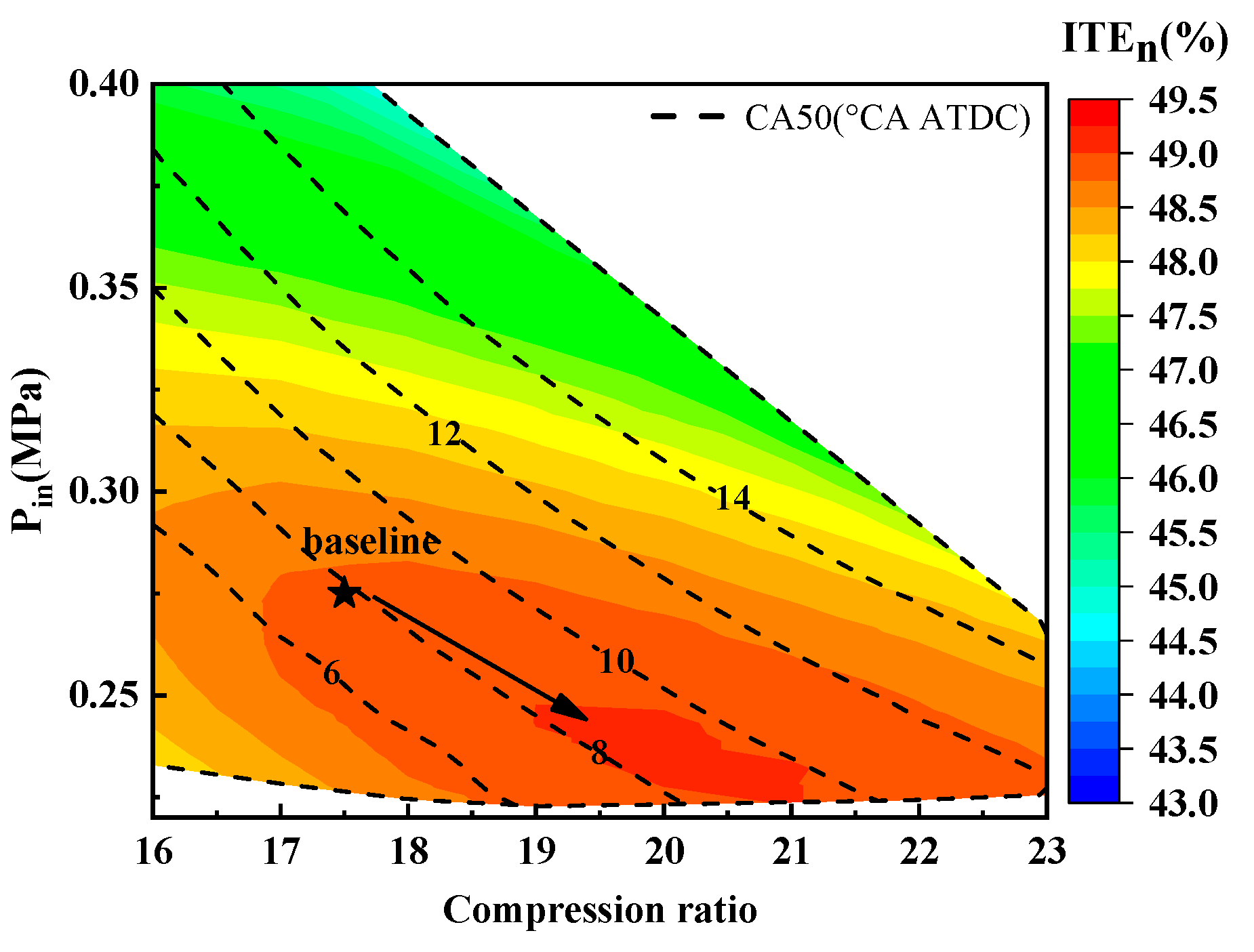

3.1.3. The Combining Effect of Boost Pressure and CR on Thermal Efficiency with PCP Constraint

3.1.4. The Combining Effect of Boost Pressure and EGR Dilution on Thermal Efficiency with a PCP Constraint

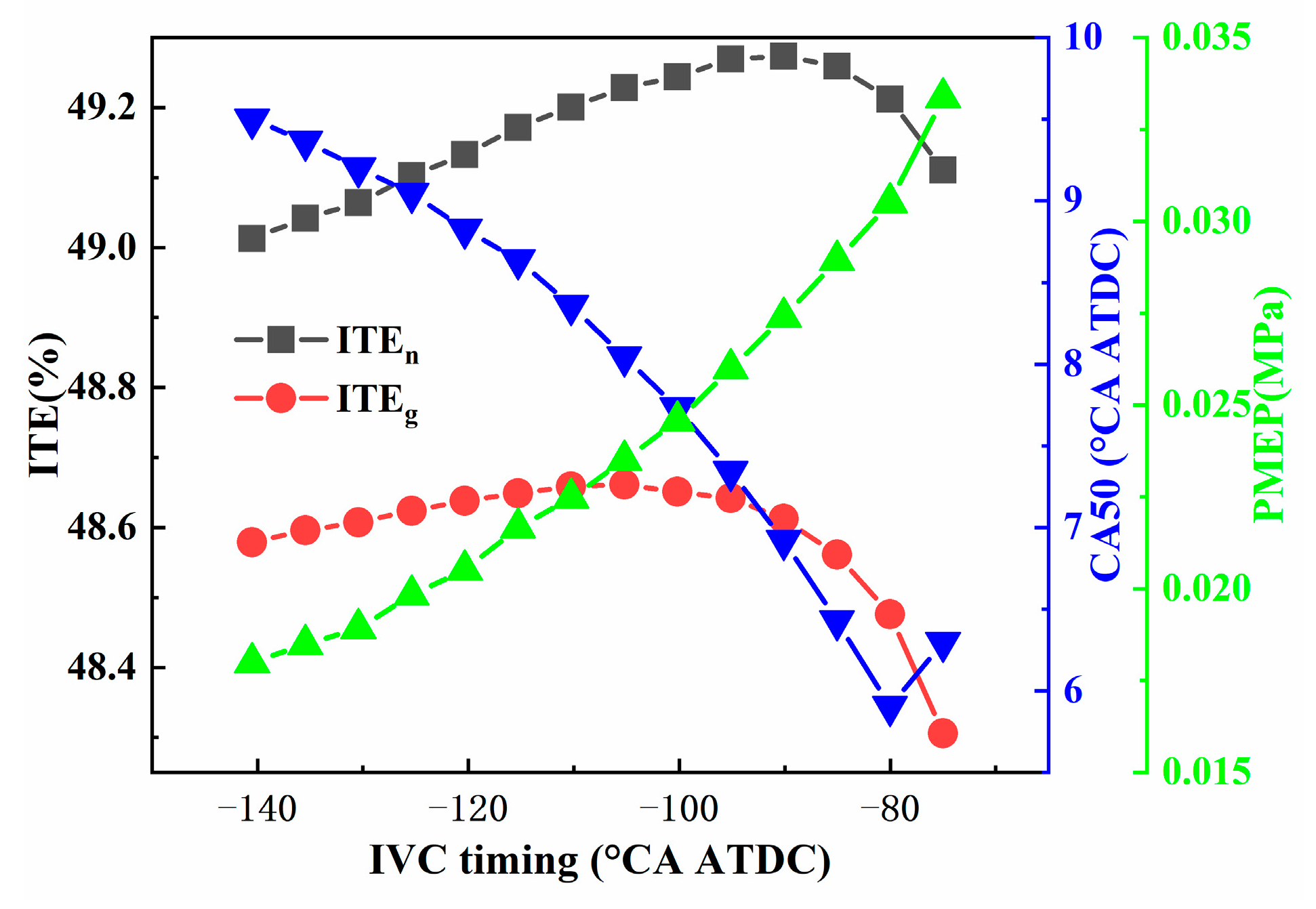

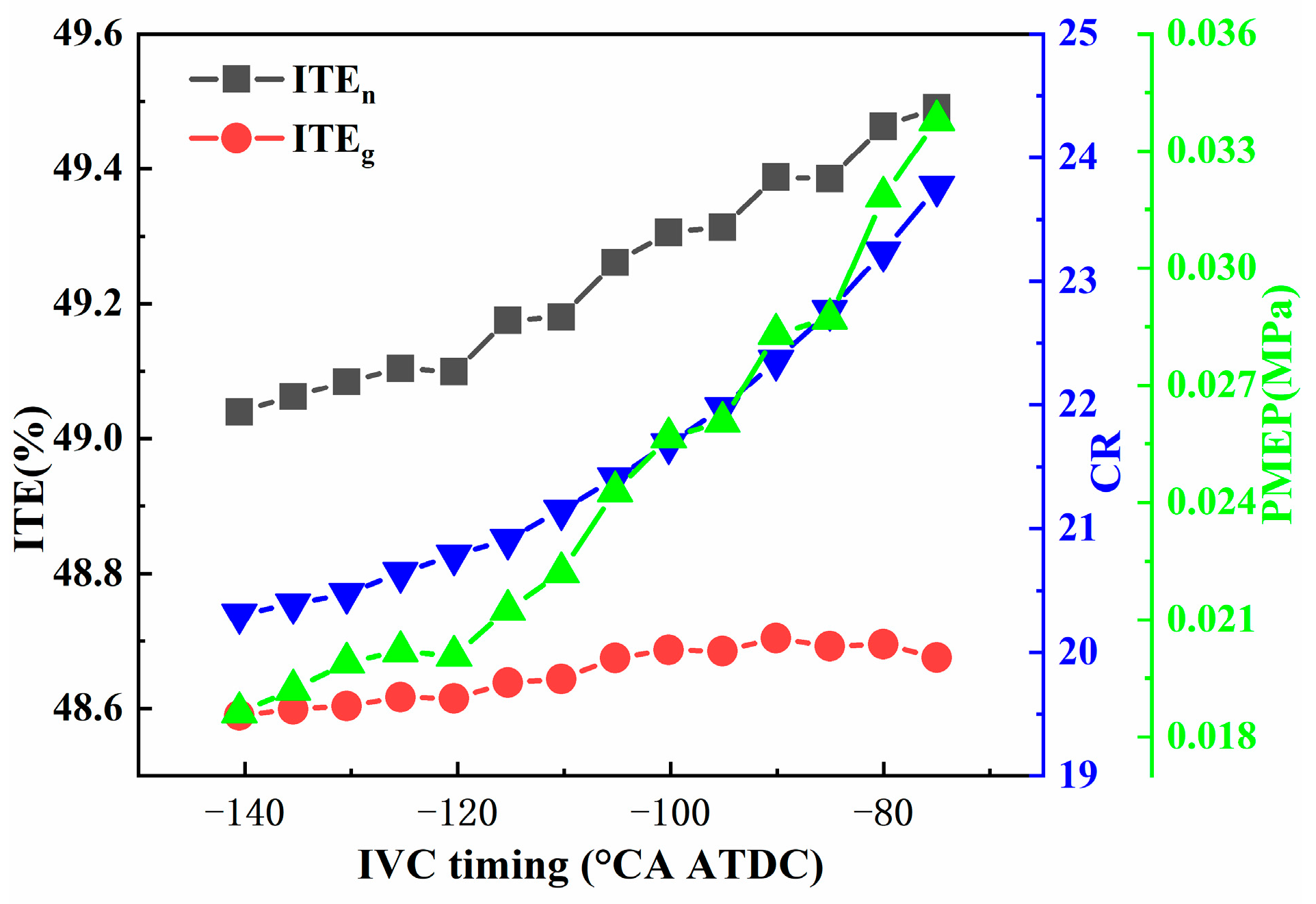

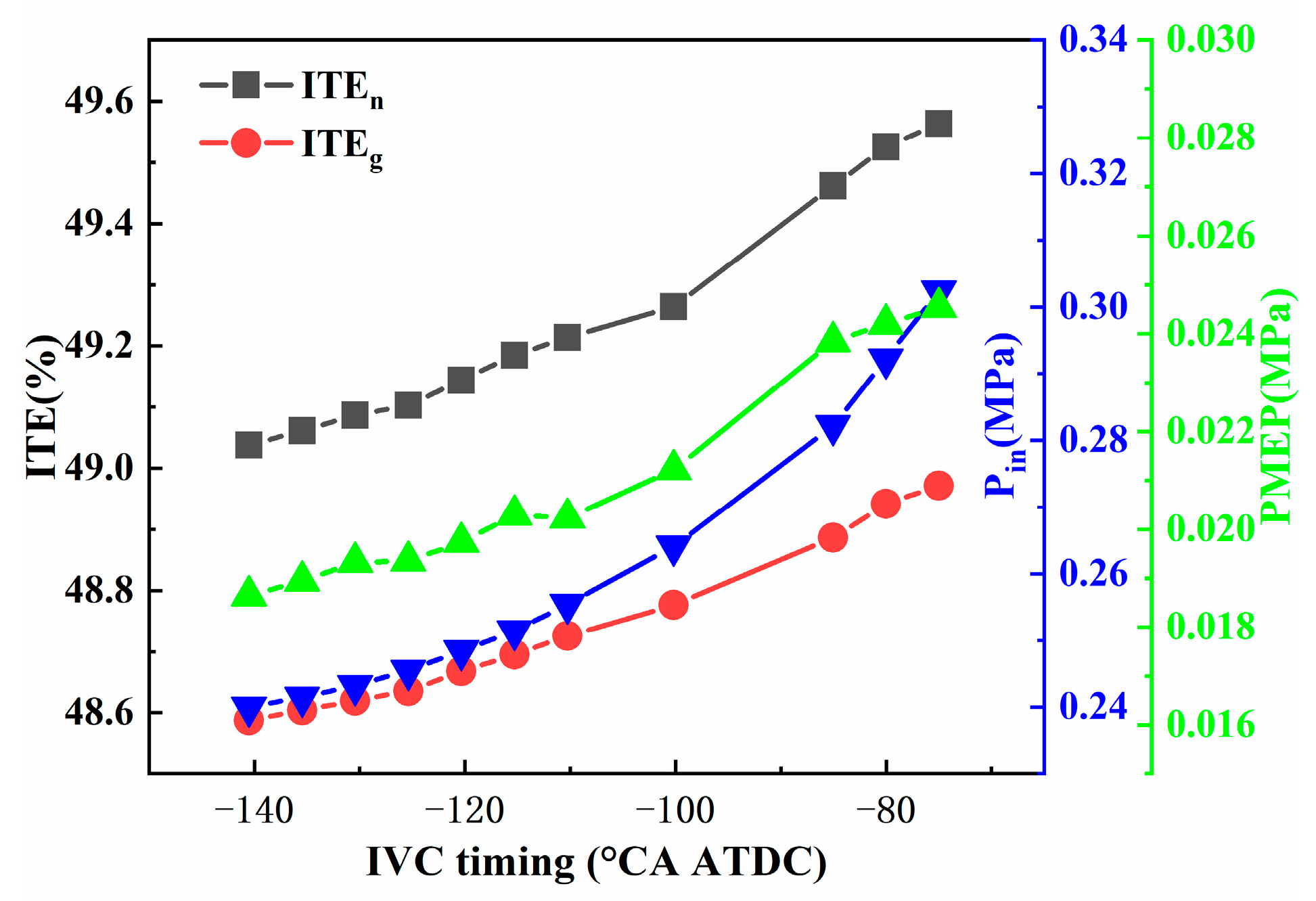

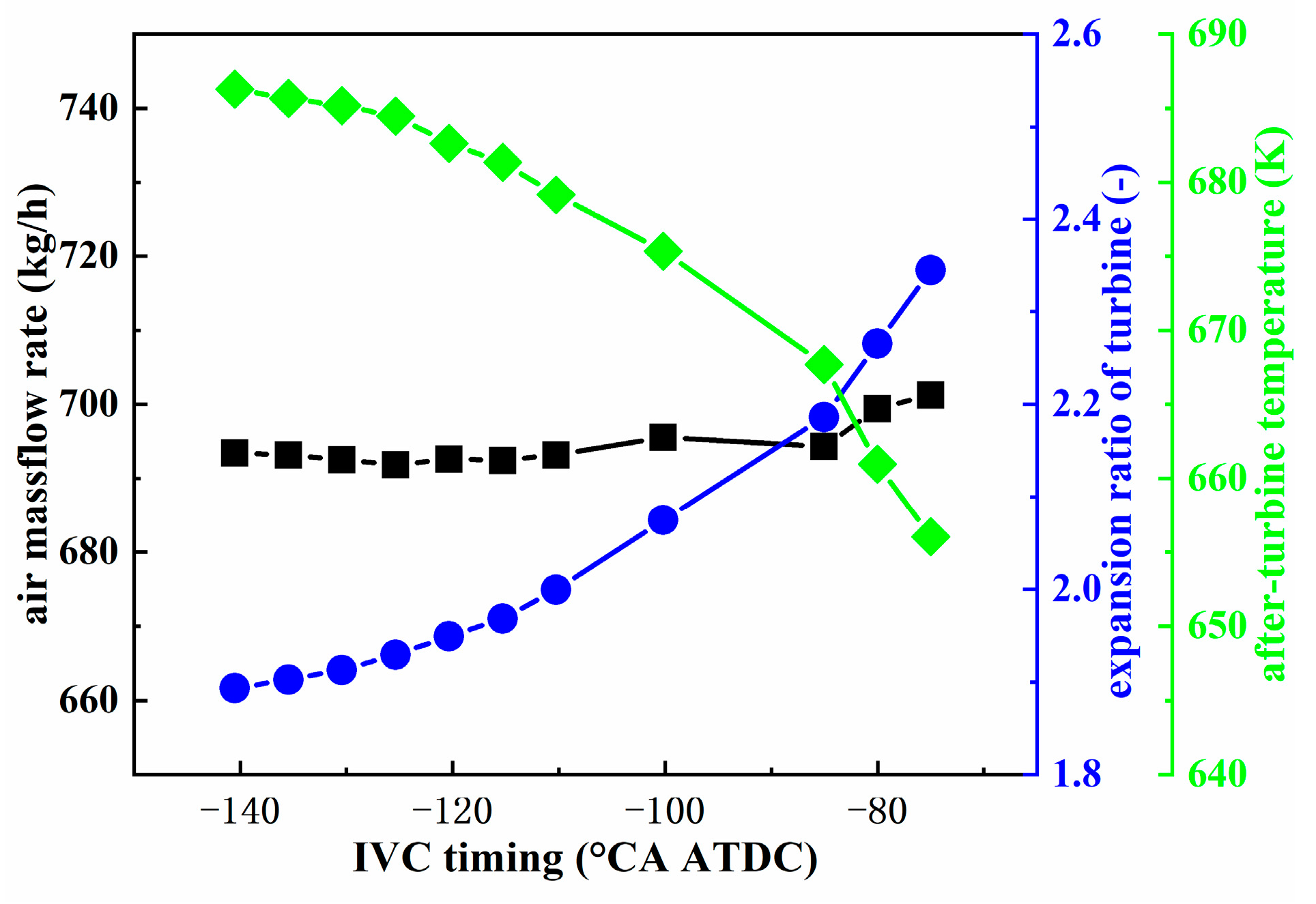

3.1.5. The Combining Effect of Late IVC Timing and CR, Boost Pressure, Combustion Phasing on Thermal Efficiency with PCP Constraint

3.2. Multiple Parameter Optimization for Efficiency Improvement

- The PCP of operation cycle should be below certain limits to avoid engine damage;

- The air–fuel ratio should be above the initial baseline value to guarantee that combustion duration is not affected significantly.

3.3. Thermal Efficiency Improvement Strategy Validation

4. Conclusions

- (1)

- To improve the thermal efficiency at a specific operating point, priority should be put on turbocharger design and matching to ensure high turbocharging overall efficiency at target operating conditions. Alternatively, a 2TC with an intercooler can provide similar effects to increasing the turbocharging overall efficiency. Both the two air systems can increase the air dilution extent and improve pumping work;

- (2)

- Although increasing boost pressure could raise the combustion lean extent to improve ITEg, a high boost pressure also deteriorates PMEP and delays the combustion phasing. There is an optimum value of boost pressure to balance ITEg and PMEP for the highest ITEn;

- (3)

- High turbocharging overall efficiency makes it hard to introduce HP EGR, while high boost pressure increases the maximum HP EGR ratio. EGR dilution by the HP EGR method has a marginal impact on ITEn, but HP EGR with a high boost pressure is beneficial to improve the overall energy efficiency. From the perspective of achieving the highest thermal efficiency, the HP EGR system can be eliminated;

- (4)

- When the PCP is limited, CR, boost pressure, and CA50 compete. By delaying the IVC timing, constraints on CR, boost pressure, and combustion phasing can be mitigated, leading to a higher ITEn. To achieve the highest ITEn under the PCP limits, co-optimization of late IVC timing, high CR, and high boost pressure is needed;

- (5)

- Through co-optimization of multiple parameters, the ITEn increases by 1.56% (absolute) compared with the baseline under a 20 MPa PCP constraint. When the PCP limits increase from 20 MPa to 25 MPa, achieving the highest ITEn requires that the CR increases by about 3.35, the IVC timing delays by about 7 °CA, and the boost pressure only increases by 0.01 MPa. By adopting the thermal efficiency improvement strategy, ITEn is expected to be elevated by 2.42%;

- (6)

- The upgraded engine test results validated the proposed thermal efficiency improvement strategy. Compared with the baseline engine, the brake thermal efficiency and overall energy efficiency were improved by 2.2% and 1.98%, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ATDC | After top death center | ||

| BMEP | Brake mean effective pressure | ||

| CA50 | Crank angle when 50% of the total heat has been released | ||

| CA | Crank angle | ||

| CR | Compression ratio | ||

| EGR | Exhaust gas recirculation | ||

| FMEP | Indicated mean effective pressure | ||

| HP | High pressure | ||

| HRR | Heat release rate | ||

| ITE | Indicated thermal efficiency | ||

| IMEP | Indicated mean effective pressure | ||

| ISFC | Indicated specific fuel consumption | ||

| ISNOx | Indicated specific nitrogen oxide emission | ||

| IVC | Intake valve close | ||

| LP | Low pressure | ||

| LHV | Low heat value | ||

| OEM | Original equipment manufacturer | ||

| PCP | Peak cylinder pressure | ||

| Subscripts | |||

| a | ammonia | d | diesel |

| g | gross | n | net |

| o | overall | in | intake |

References

- IEA. The Future of Trucks: Implications for Energy and the Environment. 2017. Available online: www.iea.org/workshops/the-future-role-of-trucks-for-energy-and-environment.html (accessed on 22 November 2022).

- Mulholland, E.; Teter, J.; Cazzola, P.; McDonald, Z.; Gallachóir, B.P.Ó. The long haul towards decarbonising road freight—A global assessment to 2050. Appl. Energy 2018, 216, 678–693. [Google Scholar] [CrossRef]

- IEA. Energy Technology Perspectives. 2020. Available online: https://www.iea.org/reports/energy-technology-perspectives-2020 (accessed on 12 October 2022).

- Joshi, A. Review of Vehicle Engine Efficiency and Emissions; SAE Technical Paper 2022-01-0540; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- IEA. World Energy Outlook 2022; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/world-energy-outlook-2022 (accessed on 1 August 2023).

- Li, X.; Tan, X.; Wu, R.; Xu, H.; Zhong, Z.; Li, Y.; Zheng, C.; Wang, R.; Qiao, Y. Paths for Carbon Peak and Carbon Neutrality in Transport Sector in China. Engineering 2021, 23, 15–21. [Google Scholar] [CrossRef]

- IEA. Net Zero by 2050-A Roadmap for the Global Energy Sector. 2021. Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 22 November 2022).

- Caton, J.A. Maximum efficiencies for internal combustion engines: Thermodynamic limitations. Int. J. Engine Res. 2017, 19, 1005–1023. [Google Scholar] [CrossRef]

- Stanton, D.W. Systematic Development of Highly Efficient and Clean Engines to Meet Future Commercial Vehicle Greenhouse Gas Regulations. SAE Int. J. Engines 2013, 6, 1395–1480. [Google Scholar] [CrossRef]

- Liu, H.; Ma, J.; Tong, L.; Ma, G.; Zheng, Z.; Yao, M. Investigation on the Potential of High Efficiency for Internal Combustion Engines. Energies 2018, 11, 513. [Google Scholar] [CrossRef]

- Enya, K.; Uchida, N. Enhancing Peak Firing Pressure Limit for Achieving Better Brake Thermal Efficiency of a Diesel Engine; SAE Technical Paper 2019-01-2180; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Benajes, J.; Molina, S.; García, J.M.; Novella, R. Influence of Boost Pressure and Injection Pressure on Combustion Process and Exhaust Emissions in a HD Diesel Engine; SAE Technical Paper 2004-01-1842; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Zhang, Z.; Liu, H.; Yue, Z.; Li, Y.; Liang, H.; Kong, X.; Zhen, Z.; Yao, M. Effects of intake high-pressure compressed air on thermal-work conversion in a stationary diesel engine. Int. J. Green Energy 2022, 173, 338–351. [Google Scholar] [CrossRef]

- Mohr, D.; Shipp, T.; Lu, X. The Thermodynamic Design, Analysis and Test of Cummins’ Supertruck 2 50% Brake Thermal Efficiency Engine System; SAE Technical Paper 2019-01-0247; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Galindo, J.; Serrano, J.; Climent, H.; Varnier, O. Impact of two-stage turbocharging architectures on pumping losses of automotive engines based on an analytical model. Energy Convers. Manag. 2010, 51, 1958–1969. [Google Scholar] [CrossRef]

- Caton, J.A. Combustion phasing for maximum efficiency for conventional and high efficiency engines. Energy Convers. Manag. 2014, 77, 564–576. [Google Scholar] [CrossRef]

- Department of Energy. Annual Merit Review Presentation. Available online: https://www.energy.gov/eere/vehicles/annual-merit-review-presentations (accessed on 22 November 2022).

- Kocher, L. Enabling Technologies for Heavy-Duty Vehicles–Cummins 55BTE. 2018. Available online: https://www.osti.gov/biblio/1474075/ (accessed on 8 March 2023).

- Rakopoulos, C.; Hountalas, D.; Koutroubousis, A.; Zannis, T. Application and Evaluation of a Detailed Friction Model on a DI Diesel Engine with Extremely High Peak Combustion Pressures; SAE Technical Paper 2002-01-0068; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Vojtech, R. Advanced Combustion for Improved Thermal Efficiency in an Advanced on-Road Heavy Duty Diesel Engine; SAE Technical Paper 2018-01-0237; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Heywood, J. Internal Combustion Engine Fundamentals 2E, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2019. [Google Scholar]

- Garcia, E.; Triantopoulos, V.; Boehman, A.; Taylor, M.; Li, J. Impact of Miller Cycle Strategies on Combustion Characteristics, Emissions and Efficiency in Heavy-Duty Diesel Engines; SAE Technical Paper 2020-01-1127; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Yu, X.; Wu, B.; Su, W. Experimental study on the approach for improved brake thermal efficiency on a two-stage turbocharged heavy-duty diesel engine. Fuel 2021, 305, 121523. [Google Scholar] [CrossRef]

- Kitabatake, R.; Minato, A.; Inukai, N.; Shimazaki, N. Simultaneous Improvement of Fuel Consumption and Exhaust Emissions on a Multi-Cylinder Camless Engine. SAE Int. J. Engines 2011, 4, 1225–1234. [Google Scholar] [CrossRef]

- Xing, K.; Huang, H.; Guo, X.; Wang, Y.; Tu, Z.; Li, J. Thermodynamic analysis of improving fuel consumption of natural gas engine by combining Miller cycle with high geometric compression ratio. Energy Convers. Manag. 2022, 254, 115219. [Google Scholar] [CrossRef]

- Zheng, M.; Reader, G.T.; Hawley, J.G. Diesel engine exhaust gas recirculation—A review on advanced and novel concepts. Energy Convers. Manag. 2004, 45, 883–900. [Google Scholar] [CrossRef]

- Mao, B.; Yao, M.; Zheng, Z.; Liu, H. Effects of Dual Loop EGR and Variable Geometry Turbocharger on Performance and Emissions of a Diesel Engine; SAE Technical Paper 2016-01-2340; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Zamboni, G.; Capobianco, M. Influence of high and low pressure EGR and VGT control on in-cylinder pressure diagrams and rate of heat release in an automotive turbocharged diesel engine. Appl. Therm. Eng. 2013, 51, 586–596. [Google Scholar] [CrossRef]

- Zamboni, G.; Capobianco, M. Experimental study on the effects of HP and LP EGR in an automotive turbocharged diesel engine. Appl. Energy 2012, 94, 117–128. [Google Scholar] [CrossRef]

- Xing, K.; Guan, W.; Guo, X.; Wang, Y.; Tu, Z.; Huang, H. Potential of high compression ratio combined with knock suppression strategy for improving thermal efficiency of spark ignition stoichiometric natural gas engine. Energy Convers. Manag. 2023, 276, 116544. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, Z.; Chen, Y.; Huang, H.; Zhu, Z.; Lv, D.; Pan, M.; Guo, X. Study of injection pressure couple with EGR on combustion performance and emissions of natural gas-diesel dual-fuel engine. Fuel 2020, 261, 116409. [Google Scholar] [CrossRef]

- Huang, H.; Li, Z.; Teng, W.; Huang, R.; Liu, Q.; Wang, Y. Effects of EGR rates on combustion and emission characteristics in a diesel engine with n-butanol/PODE3-4/diesel blends. Appl. Therm. Eng. 2019, 146, 212–222. [Google Scholar] [CrossRef]

- Macek, J.; Vitek, O. Determination and Representation of Turbocharger Thermodynamic Efficiencies; SAE Technical Paper 2016-01-1042; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Vijayagopal, R.; Rousseau, A.; Vallet, A. Fuel Consumption and Performance Benefits of Electrified Powertrains for Transit Buses; SAE Technical Paper 2018-01-0321; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Vos, K.R.; Shaver, G.M.; Lu, X.; Allen, C.M.; McCarthy, J.J.; Farrell, L. Improving diesel engine efficiency at high speeds and loads through improved breathing via delayed intake valve closure timing. Int. J. Engine Res. 2019, 20, 194–202. [Google Scholar] [CrossRef]

- Wissink, M.L.; Splitter, D.A.; Dempsey, A.B.; Curran, S.J.; Kaul, B.C.; Szybist, J.P. An assessment of thermodynamic merits for current and potential future engine operating strategies. Int. J. Engine Res. 2017, 18, 155–169. [Google Scholar] [CrossRef]

- Selleri, T.; Melas, A.D.; Joshi, A.; Manara, D.; Perujo, A.; Suarez-Bertoa, R. An Overview of Lean Exhaust deNOx Aftertreatment Technologies and NOx Emission Regulations in the European Union. Catalysts 2021, 11, 404. [Google Scholar] [CrossRef]

- Valera-Medina, A.; Amer-Hatem, F.; Azad, A.K.; Dedoussi, I.C.; de Joannon, M.; Fernandes, R.X.; Glarborg, P.; Hashemi, H.; He, X.; Mashruk, S.; et al. Review on Ammonia as a Potential Fuel: From Synthesis to Economics. Energy Fuels 2021, 35, 6964–7029. [Google Scholar] [CrossRef]

- Caton, J.A. On the importance of specific heats as regards efficiency increases for highly dilute IC engines. Energy Convers. Manag. 2014, 79, 146–160. [Google Scholar] [CrossRef]

- Yao, M.; Zhang, Q.; Liu, H.; Zheng, Z.-Q.; Zhang, P.; Lin, Z.; Lin, T.; Shen, J. Diesel Engine Combustion Control: Medium or Heavy EGR? SAE Technical Paper 2010-01-1125; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Keedwell, A.D.; Dénes, J. Latin Squares and Their Applications, 2nd ed.; Elsevier: Amsterdam, The Netherland, 2015. [Google Scholar]

- Rasmussen, C.E.; Williams, C.K. Gaussian Processes for Machine Learning; The MIT Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Booker, L. Perspectives on Adaptation in Natural and Artificial Systems; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

| OEM | Engine | CR | PCP | Engine Only BTE |

|---|---|---|---|---|

| Cummins | ISX15 | 21.4 | ≥23.8 MPa [18] | 50.6% |

| Volvo | D11 | 23 | 27 MPa | 50.4% |

| Navistar | MaxxForce 13 | - | ≥24 MPa | >51% |

| Engine Type | Inline 6-Cylinder Four Stroke |

|---|---|

| Displacement | 7.7 L |

| Bore | 110 mm |

| Stroke | 135 mm |

| Air system | Waste gate turbocharger |

| Piston material | Aluminum |

| Compression ratio | 17.5 |

| IVC timing | −140.5 °CA ATDC |

| Injection system | Common rail electronic system |

| EGR style | High pressure EGR |

| Parameters | Value |

|---|---|

| Speed | 1200 rpm |

| Load | 1.96 MPa BMEP |

| Injection Pressure | 100 MPa |

| Injection timing | −9 °CA ATDC |

| HP EGR ratio | 0% |

| PCP | 20 MPa |

| Measured Parameters | Apparatus | Range | Accuracy |

|---|---|---|---|

| Speed | Siemens CJ 410 | 0–3000 r/min | ≤±1 r/min |

| Torque | Siemens CJ 410 | 0–2000 Nm | ≤±0.1%FS |

| Fuel consumption | AVL 733 | 0–125 kg/h | ±0.1% |

| Cylinder pressure | Kistler 6125B | 0–25 MPa | ≤±0.3%FSO |

| Air flow rate | Endress + Hauser 65F | 0–2000 kg/h | ±0.15%FS |

| Boost pressure | JIMO pressure sensor | 0–1 MPa | ±0.1%FS |

| Temperature | PT100 | −50–200 °C | ±0.5 °C |

| NOx | Horiba Mexa-one | 0–5000 ppm | ±1.0%FS |

| CO2 (intake) | Horiba Mexa-one | 0–5% | ±1.0%FS |

| CO2 (exhaust) | Horiba Mexa-one | 0–20% | ±1.0%FS |

| Physical Process | Template |

|---|---|

| Combustion | User-imposed combustion profile |

| Turbocharger | CompressorSimple and TurbineSimple |

| NOx formation | EngCylNOx |

| Heat transfer | Hohenberg model |

| Indicators | Experiment | Simulation | Relative Error |

|---|---|---|---|

| Boost pressure | 275 kPa | 275 kPa | 0% |

| Air mass flow rate | 733 kg/h | 739 kg/h | 0.82% |

| PCP | 20.2 MPa | 20 MPa | −0.99% |

| ITEg | 48.40% | 48.41% | 0.02% |

| ITEn | 47.64% | 47.59% | −0.1% |

| PMEP | −0.033 MPa | −0.034 MPa | 3.03% |

| EGR ratio | 0% | 0% | 0% |

| NOx | 2108 ppm | 2158 ppm | 1.89% |

| Parameters | Range |

|---|---|

| CR | 16~24 |

| Pin | 0.2~0.35 MPa |

| IVC timing | −150~−80 °CA ATDC |

| CA50 | −12~0 °CA ATDC |

| PCP (MPa) | CR | IVC Timing (°CA ATDC) | Boost Pressure (kPa) | CA50 (°CA ATDC) | ITEn (%) | EGR (%) | NOx (ppm) |

|---|---|---|---|---|---|---|---|

| 20 (baseline) | 17.5 | −140.5 | 275 | 7.8 | 47.64 | 0 | 2158 |

| 20 | 18.57 | −95.2 | 298 | 8.9 | 49.20 | 1.8 | 2161 |

| 22 | 19.80 | −90.2 | 307 | 8.2 | 49.61 | 2.0 | 2328 |

| 25 | 21.92 | −88.7 | 308 | 7.6 | 50.06 | 2.32 | 2629 |

| Configuration | Origin | Optimized | Tested |

|---|---|---|---|

| Air system | 1TC | 1TC | 2TC with intercooler |

| IVC timing | −140.5 °CA ATDC | −88.7 °CA ATDC | −92 °CA ATDC |

| Geometry CR | 17.5 | 21.92 | 21.5 |

| Effective CR | 16.14 | - | 13.24 |

| PCP limitation | 20 MPa | 25 MPa | 25 MPa |

| HP EGR valve | Close | Full open | Full open |

| Indicators | Baseline Engine (Experiment) | Optimized Engine (25 MPa PCP) | Tested Engine (25 MPa PCP) |

|---|---|---|---|

| Boost pressure | 275 kPa | 308 kPa | 305 kPa |

| Air mass flow rate | 733 kg/h | 762 kg/h | 796 kg/h |

| PCP | 20.2 MPa | 24.9 MPa | 24.9 MPa |

| Combustion efficiency | 99.91% | 100% | 99.94% |

| CA50 | 7.8 °CA ATDC | 7.6 °CA ATDC | 7.2 °CA ATDC |

| EGR | 0% | 2.32% | 0.4% |

| PMEP | −0.033 MPa | 0.006 MPa | −0.003 MPa |

| ITEg | 48.40% | 49.9% | 50.29% |

| ITEn | 47.64% | 50.06% | 50.21% |

| Mechanical efficiency | 93.95% | 93.95% | 93.53% |

| NOx emission | 2108 ppm | 2629 ppm | 2495 ppm |

| BTE | 44.76% | 47.03% | 46.96% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Mao, B.; Yue, Z.; Zheng, Z. Parametric Analysis and Optimization for Thermal Efficiency Improvement in a Turbocharged Diesel Engine with Peak Cylinder Pressure Constraints. Energies 2023, 16, 6478. https://doi.org/10.3390/en16186478

Li L, Mao B, Yue Z, Zheng Z. Parametric Analysis and Optimization for Thermal Efficiency Improvement in a Turbocharged Diesel Engine with Peak Cylinder Pressure Constraints. Energies. 2023; 16(18):6478. https://doi.org/10.3390/en16186478

Chicago/Turabian StyleLi, Linpeng, Bin Mao, Zongyu Yue, and Zunqing Zheng. 2023. "Parametric Analysis and Optimization for Thermal Efficiency Improvement in a Turbocharged Diesel Engine with Peak Cylinder Pressure Constraints" Energies 16, no. 18: 6478. https://doi.org/10.3390/en16186478

APA StyleLi, L., Mao, B., Yue, Z., & Zheng, Z. (2023). Parametric Analysis and Optimization for Thermal Efficiency Improvement in a Turbocharged Diesel Engine with Peak Cylinder Pressure Constraints. Energies, 16(18), 6478. https://doi.org/10.3390/en16186478