Tight and Shale Oil Exploration: A Review of the Global Experience and a Case of West Siberia

Abstract

:1. Introduction

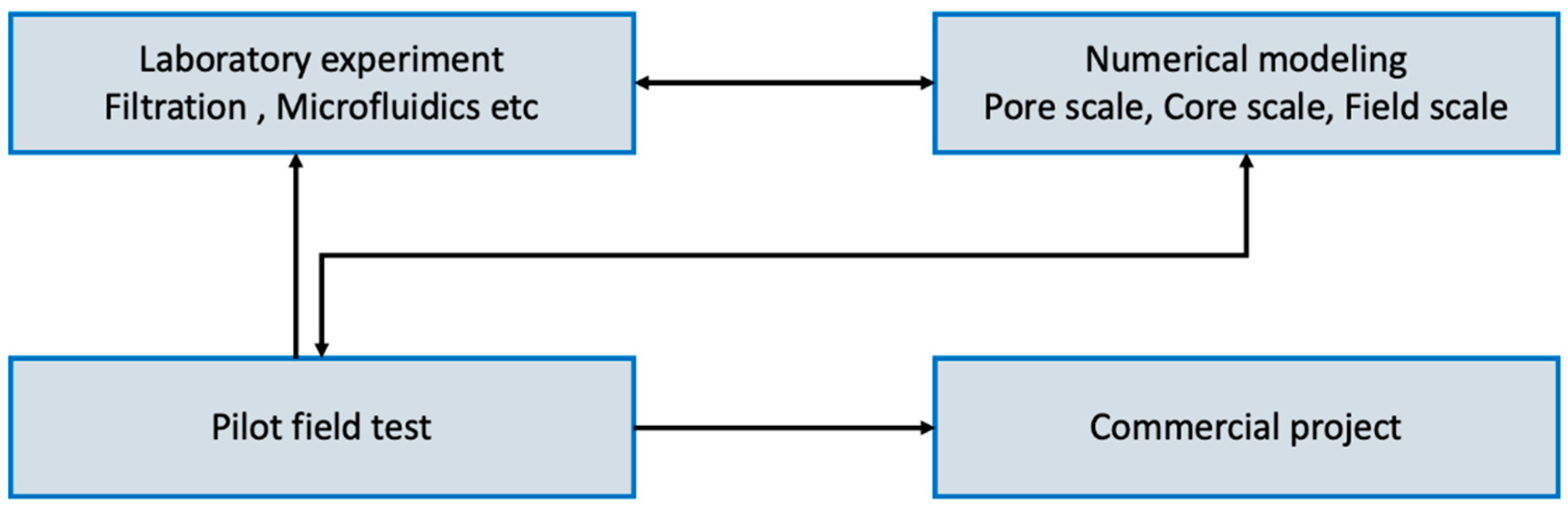

2. Experimental EOR Methods

2.1. Advances in the Thermal Treatment of Shales and Tight Reservoirs

2.1.1. In Situ Combustion and Heating EOR

- The Global Experience:

- Advances in Experimental Studies of ISC on West Siberian Shale and Tight Reservoirs:

2.1.2. Hot-Fluid Injection (HFI)

- The Global Experience:

- Advances in Experimental Studies of HFI on West Siberian Shale and Tight Reservoirs:

2.1.3. State-of-the-Art of the Application of Thermal EOR Methods to West Siberian Shale and Tight Reservoirs

2.2. Gas Treatment of Shale and Tight Reservoirs

- The Global Experience:

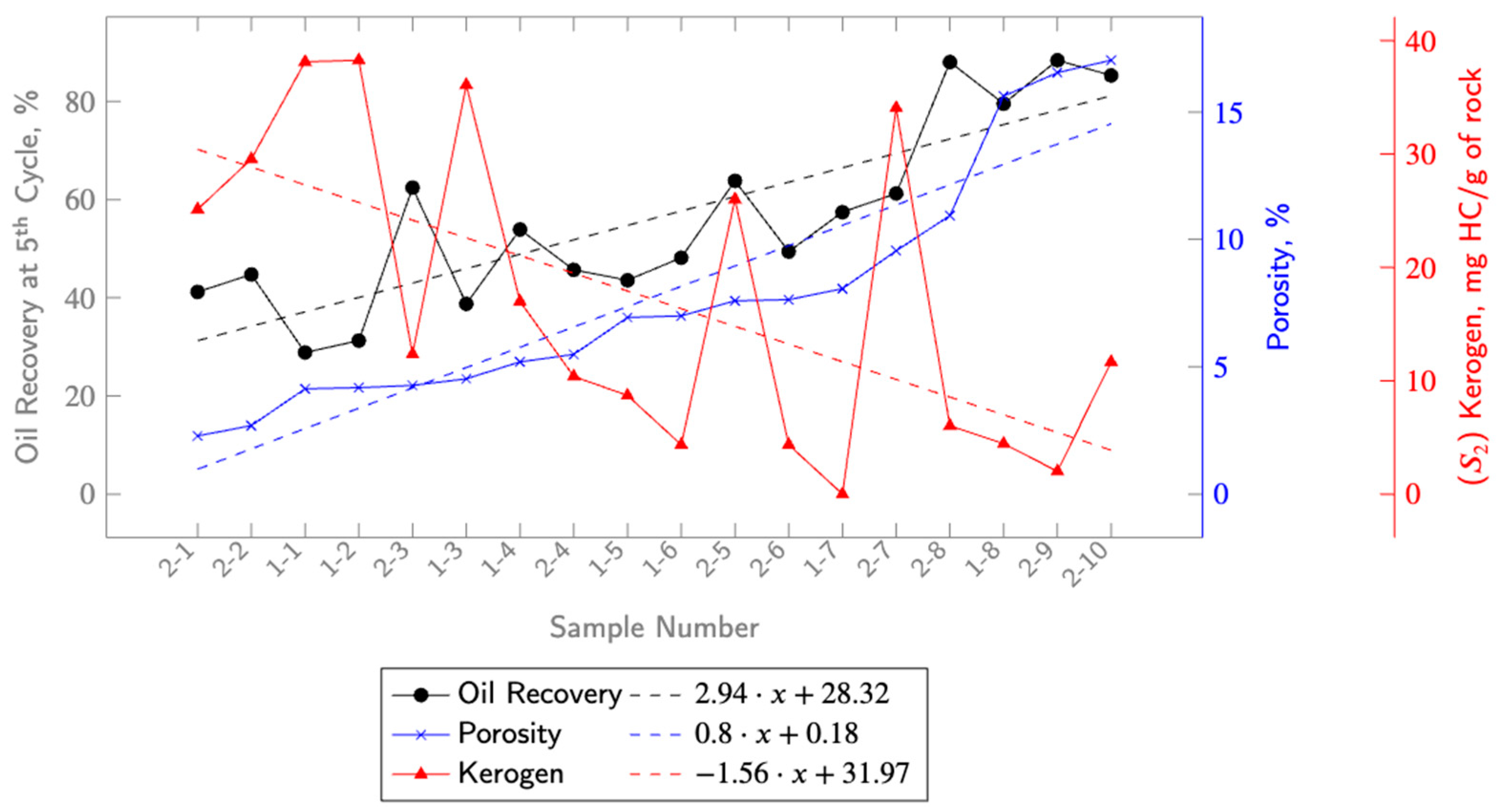

- Advances in Experimental studies of gas injection on West Siberian Shales:

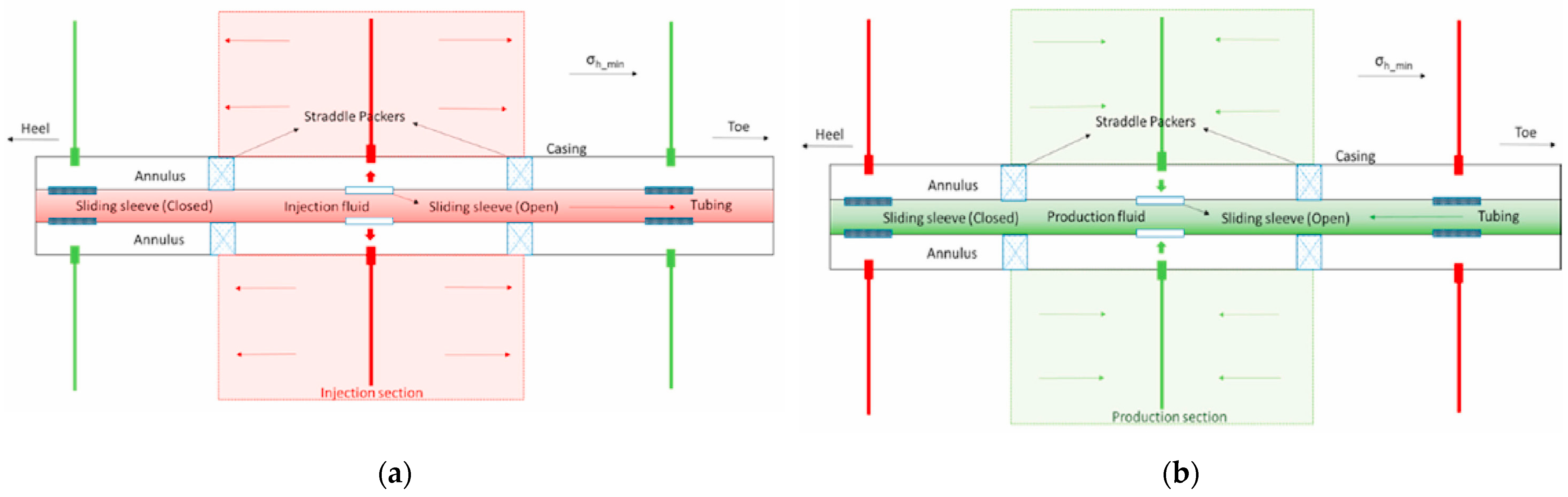

State-of-the-Art of the Application of Gas EOR Methods to West Siberian Shale and Tight Reservoirs

3. Numerical Modeling of Shale and Tight Reservoirs

3.1. Core Reservoir Scale: Hydrodynamic Modeling

3.2. Pore-Scale Digital Rock Physics

3.3. Data-Driven Modeling Approaches

4. Field-Scale Shale and Tight Oil Recovery

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). World Energy Outlook 2023. 2022. Available online: https://www.iea.org/events/world-energy-outlook-2023 (accessed on 17 March 2023).

- Internation Renewable Energy Agency (IRENA). Energy Transition Outlook. 2022. Available online: https://www.irena.org/Energy-Transition/Outlook (accessed on 17 March 2023).

- Owen, N.A.; Inderwildi, O.R.; King, D.A. The status of conventional world oil reserves—Hype or cause for concern? Energy Policy 2010, 38, 4743–4749. [Google Scholar] [CrossRef]

- Fic, J.; Pedersen, P.K. Reservoir characterization of a ‘tight’ oil reservoir, the middle Jurassic Upper Shaunavon Member in the Whitemud and Eastbrook pools, SW Saskatchewan. Mar. Pet. Geol. 2013, 44, 41–59. [Google Scholar] [CrossRef]

- Zhang, X.-S.; Wang, H.-J.; Ma, F.; Sun, X.-C.; Zhang, Y.; Song, Z.-H. Classification and characteristics of tight oil plays. Pet. Sci. 2016, 13, 18–33. [Google Scholar] [CrossRef]

- Yang, S.; Yi, Y.; Lei, Z.; Zhang, Y.; Harris, N.B.; Chen, Z. Improving predictability of stimulated reservoir volume from different geological perspectives. Mar. Pet. Geol. 2018, 95, 219–227. [Google Scholar] [CrossRef]

- Breyer, J.A. Shale Reservoirs—Giant Resources for the 21st Century; American Association of Petroleum Geologists: Tulsa, OK, USA, 2012. [Google Scholar] [CrossRef]

- Burrows, L.C.; Haeri, F.; Cvetic, P.; Sanguinito, S.; Shi, F.; Tapriyal, D.; Goodman, A.L.; Enick, R.M. A Literature Review of CO2, Natural Gas, and Water-Based Fluids for Enhanced Oil Recovery in Unconventional Reservoirs. Energy Fuels 2020, 34, 5331–5380. [Google Scholar] [CrossRef]

- Kalmykov, G.A.; Balushkina, N.S.; Belokhin, V.S.; Bilibin, S.I.; Diyakonova, T.F.; Isakov, T.G. Voids Rocks of the Bazhenov Formation and Saturating Its Fluids. 21 Century Subsoil Use. 2015, pp. 64–71. Available online: https://www.elibrary.ru/item.asp?id=23238487 (accessed on 20 March 2023).

- Boak, J.; Kleinberg, R. Shale Gas, Tight Oil, Shale Oil and Hydraulic Fracturing. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–95. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.; Bai, B. Data analysis for CO2-EOR in shale-oil reservoirs based on a laboratory database. J. Pet. Sci. Eng. 2018, 162, 697–711. [Google Scholar] [CrossRef]

- Vello, K.; Matt, W. CO2-EOR Set for Growth as New CO2 Supplies Emerge. Oil Gas J. 2014, p. 92. Available online: https://www.adv-res.com/pdf/CO2-EOR-set-for-growth-as-new-CO2-supplies-emerge.pdf (accessed on 3 March 2023).

- Hoffman, B.T. Huff-N-Puff Gas Injection Pilot Projects in the Eagle Ford. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Gamadi, T.D.; Sheng, J.; Soliman, M.Y. An Experimental Study of Cyclic Gas Injection to Improve Shale Oil Recovery. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar] [CrossRef]

- Chen, T.; Yang, Z.; Luo, Y.; Lin, W.; Xu, J.; Ding, Y.; Niu, J. Evaluation of Displacement Effects of Different Injection Media in Tight Oil Sandstone by Online Nuclear Magnetic Resonance. Energies 2018, 11, 2836. [Google Scholar] [CrossRef]

- Sheng, J.J. Enhanced oil recovery in shale and tight reservoirs. In Enhanced Oil Recovery in Shale and Tight Reservoirs; Elsevier: Amsterdam, The Netherlands, 2020; p. iii. [Google Scholar] [CrossRef]

- Todd, H.B.; Evans, J.G. Improved Oil Recovery IOR Pilot Projects in the Bakken Formation. In Proceedings of the SPE Low Perm Symposium, Denver, CO, USA, 5–6 May 2016. [Google Scholar] [CrossRef]

- Milad, M.; Junin, R.; Sidek, A.; Imqam, A.; Tarhuni, M. Huff-n-Puff Technology for Enhanced Oil Recovery in Shale/Tight Oil Reservoirs: Progress, Gaps, and Perspectives. Energy Fuels 2021, 35, 17279–17333. [Google Scholar] [CrossRef]

- Yu, Y.; Sheng, J.J. Experimental Investigation of Light Oil Recovery from Fractured Shale Reservoirs by Cyclic Water Injection. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23–26 May 2016. [Google Scholar] [CrossRef]

- Scerbacova, A.; Mukhina, E.; Bakulin, D.; Burukhin, A.; Ivanova, A.; Cheremisin, A.; Spivakova, M.; Ushakova, A.; Cheremisin, A. Water- and Surfactant-Based Huff-n-Puff Injection into Unconventional Liquid Hydrocarbon Reservoirs: Experimental and Modeling Study. Energy Fuels 2023, 37, 11067–11082. [Google Scholar] [CrossRef]

- Kazempour, M.; Kiani, M.; Nguyen, D.; Salehi, M.; Bidhendi, M.M.; Lantz, M. Boosting Oil Recovery in Unconventional Resources Utilizing Wettability Altering Agents: Successful Translation from Laboratory to Field. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar] [CrossRef]

- Zhang, F.; Saputra, I.W.; Parsegov, S.G.; Adel, I.A.; Schechter, D.S. Experimental and Numerical Studies of EOR for the Wolfcamp Formation by Surfactant Enriched Completion Fluids and Multi-Cycle Surfactant Injection. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019. [Google Scholar] [CrossRef]

- Mukhina, E.; Cheremisin, A.; Khakimova, L.; Garipova, A.; Dvoretskaya, E.; Zvada, M.; Kalacheva, D.; Prochukhan, K.; Kasyanenko, A.; Cheremisin, A. Enhanced Oil Recovery Method Selection for Shale Oil Based on Numerical Simulations. ACS Omega 2021, 6, 23731–23741. [Google Scholar] [CrossRef] [PubMed]

- Hemmati-Sarapardeh, A.; Khishvand, M.; Naseri, A.; Mohammadi, A.H. Toward reservoir oil viscosity correlation. Chem. Eng. Sci. 2013, 90, 53–68. [Google Scholar] [CrossRef]

- Mokheimer, E.M.A.; Hamdy, M.; Abubakar, Z.; Shakeel, M.R.; Habib, M.A.; Mahmoud, M. A Comprehensive Review of Thermal Enhanced Oil Recovery: Techniques Evaluation. J. Energy Resour. Technol. 2018, 141, 030801. [Google Scholar] [CrossRef]

- Lewis, J.O. Some Observations Regarding Smith-Dunn Type Compressed Air Process. U.S. Bureau of Mines 1916. 148, Unplublished Internal Documents.

- Crawford, P.M.; Killen, J.C. New Challenges and Directions in Oil Shale Development Technologies. In Oil Shale: A Solution to the Liquid Fuel Dilemma; American Chemical Society: Washington, DC, USA, 2010; pp. 21–60. [Google Scholar] [CrossRef]

- Hascakir, B.; Castanier, L.M.; Kovscek, A.R. In-Situ Combustion Dynamics Visualized with X-Ray Computed Tomography. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar] [CrossRef]

- Morrow, A.W.; Mukhametshina, A.; Aleksandrov, D.; Hascakir, B. Environmental Impact of Bitumen Extraction with Thermal Recovery. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 10–12 June 2014. [Google Scholar] [CrossRef]

- Stosur, J.J. In Situ Combustion Method for Oil Recovery State of the Art and Potential. In The Future Supply of Nature-Made Petroleum and Gas; Elsevier: Amsterdam, The Netherlands, 1977; pp. 611–623. [Google Scholar] [CrossRef]

- Fatemi, S.M.; Kharrat, R.; Vossoughi, S. Investigation of Top-Down In-Situ Combustion Process in Complex Fractured Carbonate Models: Effects of Fractures’ Geometrical Properties. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 15–17 November 2011. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Fan, Z.; Liu, Q. An in situ combustion process for recovering heavy oil using scaled physical model. J. Pet. Explor. Prod. Technol. 2019, 9, 2681–2688. [Google Scholar] [CrossRef]

- Xia, T.; Greaves, M. In Situ Upgrading of Athabasca Tar Sand Bitumen Using Thai. Chem. Eng. Res. Des. 2006, 84, 856–864. [Google Scholar] [CrossRef]

- Greaves, M.; Saghr, A.; Xia, T.; Turtar, A.; Ayasse, C. THAI-New Air Injection Technology for Heavy Oil Recovery and In Situ Upgrading. J. Can. Pet. Technol. 2001, 40. [Google Scholar] [CrossRef]

- Rahnema, H.; Mamora, D.D. Combustion Assisted Gravity Drainage (CAGD) Appears Promising. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar] [CrossRef]

- Guan, W.; Xi, C.; Chen, L.; Muhetar; Gao, C.; Tang, J.; Li, Q. Field control technologies of combustion assisted gravity drainage (CAGD). Pet. Explor. Dev. 2017, 44, 797–804. [Google Scholar] [CrossRef]

- Bagci, S.; Aybak, T. A Laboratory Study of Combustion Override Split-Production Horizontal Well (COSH) Process. J. Can. Pet. Technol. 2000, 39. [Google Scholar] [CrossRef]

- Sun, Y.-H.; Bai, F.-T.; Lü, X.-S.; Li, Q.; Liu, Y.-M.; Guo, M.-Y.; Guo, W.; Liu, B.-C. A Novel Energy-Efficient Pyrolysis Process: Self-pyrolysis of Oil Shale Triggered by Topochemical Heat in a Horizontal Fixed Bed. Sci. Rep. 2015, 5, srep08290. [Google Scholar] [CrossRef]

- Chen, W.; Zhou, Y.; Yu, W.; Yang, L. Experimental Study of Low-Temperature Shale Combustion and Pyrolysis Under Inert and Noninert Environments. SPE Prod. Oper. 2019, 35, 178–187. [Google Scholar] [CrossRef]

- Dubrovay, K.K.; Sheinman, A.B.U. Underground Gasification of Oil Reservoirs. In Combustible Minerals; State Oil Research Institute: Moscow, Russia, 1934; Available online: https://www.geokniga.org/authors/63880 (accessed on 19 February 2023). (In Russian)

- Bondarenko, T.; Cheremisin, A.; Kozlova, E.; Zvereva, I.; Chislov, M.; Myshenkov, M.; Novakowski, V. Experimental investigation of thermal decomposition of Bazhenov formation kerogen: Mechanism and application for thermal enhanced oil recovery. J. Pet. Sci. Eng. 2017, 150, 288–296. [Google Scholar] [CrossRef]

- Gorshkov, M.; Khomyakov, I.S. Thermal Treatment of Reservoir as One of the Powerful Method of Shale Formation Development in Russia. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: London, UK, 2019. [Google Scholar] [CrossRef]

- Mukhametdinova, A.; Mikhailova, P.; Kozlova, E.; Karamov, T.; Baluev, A.; Cheremisin, A. Effect of Thermal Exposure on Oil Shale Saturation and Reservoir Properties. Appl. Sci. 2020, 10, 9065. [Google Scholar] [CrossRef]

- Ponomarev, A.A.; Kadyrov, M.A.; Gafurov, M.R.; Zavatsky, M.D.; Naumenko, V.O.; Nurullina, T.S.; Vaganov, Y.V. Magnetic field impact on geochemistry of soluble organic matter when heat-treating oil shales and search for analogies in nature. Phys. Chem. Earth Parts A/B/C 2023, 129, 103306. [Google Scholar] [CrossRef]

- Kovaleva, L.; Zinnatullin, R.; Musin, A.; Kireev, V.; Karamov, T.; Spasennykh, M. Investigation of Source Rock Heating and Structural Changes in the Electromagnetic Fields Using Experimental and Mathematical Modeling. Minerals 2021, 11, 991. [Google Scholar] [CrossRef]

- Baldwin, R.; Manley, J. Pyrolysis and hydropyrolysis of Kentucky oil shale in supercritical toluene under rapid heating conditions. Fuel Process. Technol. 1988, 17, 201–207. [Google Scholar] [CrossRef]

- Kar, T.; Hascakir, B. In-situ kerogen extraction via combustion and pyrolysis. J. Pet. Sci. Eng. 2017, 154, 502–512. [Google Scholar] [CrossRef]

- Saeed, S.A.; Taura, U.; Al-Wahaibi, Y.; Al-Muntaser, A.A.; Yuan, C.; Varfolomeev, M.A.; Al-Bahry, S.; Joshi, S.; Djimasbe, R.; Suwaid, M.A.; et al. Hydrothermal conversion of oil shale: Synthetic oil generation and micro-scale pore structure change. Fuel 2022, 312, 22786. [Google Scholar] [CrossRef]

- Zhang, Z.; Volkman, J.K.; Greenwood, P.F.; Hu, W.; Qin, J.; Borjigin, T.; Zhai, C.; Liu, W. Flash pyrolysis of kerogens from algal rich oil shales from the Eocene Huadian Formation, NE China. Org. Geochem. 2014, 76, 167–172. [Google Scholar] [CrossRef]

- Kibodeaux, K.R. Evolution of Porosity, Permeability, and Fluid Saturations During Thermal Conversion of Oil Shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar] [CrossRef]

- Gao, Y.; Wan, T.; Dong, Y.; Li, Y. Numerical and experimental investigation of production performance of in-situ conversion of shale oil by air injection. Energy Rep. 2022, 8, 15740–15753. [Google Scholar] [CrossRef]

- Lewan, M.D. Experiments on the Role of Water in Petroleum Formation. Geochim. Cosmochim. Acta 1997, 61, 3691–3723. Available online: https://website.whoi.edu/gfd/wp-content/uploads/sites/14/2018/10/GCARoleofWater_146986.pdf (accessed on 3 March 2023). [CrossRef]

- Sinag, A. Sub- and Supercritical Water Extraction of G\“oyn\”uk Oil Shale. Energy Sources 2004, 26, 885–890. [Google Scholar] [CrossRef]

- Fei, Y.; Marshall, M.; Jackson, W.R.; Qi, Y.; Auxilio, A.R.; Chaffee, A.L.; Gorbaty, M.L.; Daub, G.J.; Cassidy, P.J. Long-Time-Period, Low-Temperature Reactions of Green River Oil Shale. Energy Fuels 2018, 32, 4808–4822. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, S.; Wang, S.; He, L.; Guo, W.; Li, Q.; Deng, S. Subcritical Water Extraction of Huadian Oil Shale at 300 °C. Energy Fuels 2019, 33, 2106–2114. [Google Scholar] [CrossRef]

- Washburn, K.E.; Birdwell, J.E.; Lewan, M.D.; Miller, M. Changes in Porosity and Organic Matter Phase Distribution Monitored by NMR Relaxometry Following Hydrous Pyrolysis Under Uniaxial Confinement. In Unconventional Resources Technology Conference, Denver, Colorado, 12–14 August 2013; Society of Exploration Geophysicists; American Association of Petroleum Geologists; Society of Petroleum Engineers: Tulsa, OK, USA, 2013; pp. 2020–2026. [Google Scholar] [CrossRef]

- Nasyrova, Z.R.; Kayukova, G.P.; Mukhamadyarova, A.N.; Jimasbe, R.; Gareev, B.I.; Vakhin, A.V. Hydrocarbon Composition of Products Formed by Transformation of the Organic Matter of Rocks from Tatarstan Domanik Deposits in Supercritical Water. Pet. Chem. 2022, 62, 199–213. [Google Scholar] [CrossRef]

- Kang, S.; Sun, Y.; Deng, S.; Li, S.; Su, Y.; Guo, W.; Li, J. Extraction of Huadian oil shale in subcritical FeCl2 solution. Fuel Process. Technol. 2020, 211, 106571. [Google Scholar] [CrossRef]

- Kang, S.; Zhang, S.; Wang, Z.; Li, S.; Zhao, F.; Yang, J.; Zhou, L.; Deng, Y.; Sun, G.; Yu, H. Highly efficient catalytic pyrolysis of oil shale by CaCl2 in subcritical water. Energy 2023, 274, 127343. [Google Scholar] [CrossRef]

- Kang, S.; Sun, Y.; Qiao, M.; Li, S.; Deng, S.; Guo, W.; Li, J.; He, W. The enhancement on oil shale extraction of FeCl3 catalyst in subcritical water. Energy 2021, 238, 121763. [Google Scholar] [CrossRef]

- Meng, F.; Yao, C.; Zhang, H.; Zheng, Y.; Di, T.; Li, L. Experimental Investigation on the Pyrolysis Process and Product Distribution Characteristics of Organic-Rich Shale Via Supercritical Water. SSRN Electron. J. 2022, 8, 17–33. [Google Scholar] [CrossRef]

- Popov, E.; Kalmykov, A.; Cheremisin, A.; Bychkov, A.; Bondarenko, T.; Morozov, N.; Karpov, I. Laboratory investigations of hydrous pyrolysis as ternary enhanced oil recovery method for Bazhenov formation. J. Pet. Sci. Eng. 2017, 156, 852–857. [Google Scholar] [CrossRef]

- Stennikov, A.V.; Bugaev, I.A.; Kalmykov, A.G.; Bychkov, A.Y.; Kozlova, E.V.; Kalmykov, G.A. An Experimental Study of the Oil Production from Domanik Formation Rocks Under Hydrothermal Conditions. Mosc. Univ. Geol. Bull. 2018, 73, 60–65. [Google Scholar] [CrossRef]

- Karamov, T.; Leushina, E.; Kozlova, E.; Spasennykh, M. Broad Ion Beam–Scanning Electron Microscopy Characterization of Organic Porosity Evolution During Thermal Treatment of Bazhenov Shale Sample. SPE Reserv. Eval. Eng. 2023, 26, 64–74. [Google Scholar] [CrossRef]

- Turakhanov, A.; Tsyshkova, A.; Mukhina, E.; Popov, E.; Kalacheva, D.; Dvoretskaya, E.; Kasyanenko, A.; Prochukhan, K.; Cheremisin, A. Cyclic Subcritical Water Injection into Bazhenov Oil Shale: Geochemical and Petrophysical Properties Evolution Due to Hydrothermal Exposure. Energies 2021, 14, 4570. [Google Scholar] [CrossRef]

- Bondarenko, T.M.; Mett, D.A.; Nemova, V.D.; Usachev, G.A.; Cheremisin, A.N.; Spasennykh, M.Y. Laboratory investigation of air injection in kerogen-bearing rocks. Part 2. Evaluation of organic matter conversion. Neft. Khozyaystvo—Oil Ind. 2020, 59–61. [Google Scholar] [CrossRef]

- Mikhailova, P.; Leushina, E.; Spasennykh, M.; Morozov, N.; Kozlova, E.; Polyakov, V.; Cheremisin, A. Analysis of Products of Kerogen Thermal Decomposition at Isothermal Conditions in An Open System for the Sample from the Bazhenov Formation. In EAGE/SPE Workshop on Shale Science 2019; European Association of Geoscientists & Engineers: Utrecht, The Netherlands, 2019; pp. 1–5. Available online: https://www.earthdoc.org/content/papers/10.3997/2214-4609.201900482 (accessed on 3 March 2023). [CrossRef]

- Yin, H.; Zhou, J.; Jiang, Y.; Xian, X.; Liu, Q. Physical and structural changes in shale associated with supercritical CO2 exposure. Fuel 2016, 184, 289–303. [Google Scholar] [CrossRef]

- Fu, Q.; Cudjoe, S.; Barati, R.; Tsau, J.-S.; Li, X.; Peltier, K.; Mohrbacher, D.; Baldwin, A.; Nicoud, B.; Bradford, K. Experimental and Numerical Investigation of the Diffusion-Based Huff-n-Puff Gas Injection into Lower Eagle Ford Shale Samples. In Proceedings of the 7th Unconventional Resources Technology Conference, Tulsa, OK, USA, 22–24 July 2019; American Association of Petroleum Geologists: Tulsa, OK, USA, 2019. [Google Scholar] [CrossRef]

- Tran, S.; Yassin, M.R.; Eghbali, S.; Doranehgard, M.H.; Dehghanpour, H. Quantifying Oil-Recovery Mechanisms during Natural-Gas Huff ‘n’ Puff Experiments on Ultratight Core Plugs. SPE J. 2020, 26, 498–514. [Google Scholar] [CrossRef]

- Shabib-Asl, A.; Plaksina, T.; Moradi, B. Evaluation of nanopore confinement during CO2 huff and puff process in liquid-rich shale formations. Comput. Geosci. 2020, 24, 1163–1178. [Google Scholar] [CrossRef]

- Lu, Y.; Zhou, J.; Li, H.; Chen, X.; Tang, J. Different Effect Mechanisms of Supercritical CO2 on the Shale Microscopic Structure. ACS Omega 2020, 5, 22568–22577. [Google Scholar] [CrossRef]

- Luo, X.; Ren, X.; Wang, S. Supercritical CO2-water-shale interactions and their effects on element mobilization and shale pore structure during stimulation. Int. J. Coal Geol. 2019, 202, 109–127. [Google Scholar] [CrossRef]

- Teklu, T.W.; Alharthy, N.; Kazemi, H.; Yin, X.; Graves, R.M. Hydrocarbon and Non-hydrocarbon Gas Miscibility with Light Oil in Shale Reservoirs. In SPE Improved Oil Recovery Symposium; Society of Petroleum Engineers: Houston, TX, USA, 2014. [Google Scholar] [CrossRef]

- Shilov, E.; Dorhjie, D.B.; Mukhina, E.; Zvada, M.; Kasyanenko, A.; Cheremisin, A. Experimental and numerical studies of rich gas Huff-n-Puff injection in tight formation. J. Pet. Sci. Eng. 2021, 208, 109420. [Google Scholar] [CrossRef]

- Li, L.; Sheng, J.J. Experimental study of core size effect on CH4 huff-n-puff enhanced oil recovery in liquid-rich shale reservoirs. J. Nat. Gas Sci. Eng. 2016, 34, 1392–1402. [Google Scholar] [CrossRef]

- Min, B.; Mamoudou, S.; Dang, S.; Tinni, A.; Sondergeld, C.; Rai, C. Comprehensive Experimental Study of Huff-n-Puff Enhanced Oil Recovey in Eagle Ford: Key Parameters and Recovery Mechanism. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020. [Google Scholar] [CrossRef]

- Ozowe, W.; Quintanilla, Z.; Russell, R.; Sharma, M. Experimental Evaluation of Solvents for Improved Oil Recovery in Shale Oil Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Mamoudou, S.; Perez, F.; Tinni, A.; Dang, S.; Sondergeld, C.H.; Rai, C.S.; Devegowda, D. Evaluation of Huff-n-Puff in Shale Using Experiments and Molecular Simulation. In Proceedings of the 8th Unconventional Resources Technology Conference, Tulsa, OK, USA, 7–8 June 2020; American Association of Petroleum Geologists: Tulsa, OK, USA, 2020. [Google Scholar] [CrossRef]

- Alharthy, N.; Teklu, T.W.; Kazemi, H.; Graves, R.M.; Hawthorne, S.B.; Braunberger, J.; Kurtoglu, B. Enhanced Oil Recovery in Liquid–Rich Shale Reservoirs: Laboratory to Field. SPE Reserv. Evaluation Eng. 2017, 21, 137–159. [Google Scholar] [CrossRef]

- Zeng, T.; Miller, C.S.; Mohanty, K.K. Combination of a chemical blend with CO2 huff-n-puff for enhanced oil recovery in oil shales. J. Pet. Sci. Eng. 2020, 194, 107546. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Tan, Q.; Liu, S.; Zhao, H.; Wang, Z. Quantitative study of CO2 huff-n-puff enhanced oil recovery in tight formation using online NMR technology. J. Pet. Sci. Eng. 2022, 216, 110688. [Google Scholar] [CrossRef]

- Ding, M.; Wang, Y.; Liu, D.; Wang, X.; Zhao, H.; Chen, W. Enhancing tight oil recovery using CO2 huff and puff injection: An experimental study of the influencing factors. J. Nat. Gas Sci. Eng. 2021, 90, 103931. [Google Scholar] [CrossRef]

- Askarova, A.; Mukhametdinova, A.; Markovic, S.; Khayrullina, G.; Afanasev, P.; Popov, E.; Mukhina, E. An Overview of Geological CO2 Sequestration in Oil and Gas Reservoirs. Energies 2023, 16, 2821. [Google Scholar] [CrossRef]

- Pan, Y.; Hui, D.; Luo, P.; Zhang, Y.; Zhang, L.; Sun, L. Influences of subcritical and supercritical CO2 treatment on the pore structure characteristics of marine and terrestrial shales. J. CO2 Util. 2018, 28, 152–167. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, K.; Tian, S.; Zhou, L.; Xian, X.; Jiang, Y.; Liu, M.; Cai, J. CO2-water-shale interaction induced shale microstructural alteration. Fuel 2019, 263, 116642. [Google Scholar] [CrossRef]

- Lahann, R.; Mastalerz, M.; Rupp, J.A.; Drobniak, A. Influence of CO2 on New Albany Shale composition and pore structure. Int. J. Coal Geol. 2013, 108, 2–9. [Google Scholar] [CrossRef]

- Zhou, J.; Yin, H.; Tan, J.; Jiang, Y.; Xian, X.; Liu, Q.; Ju, Y. Pore Structural Characterization of Shales Treated by Sub-Critical and Supercritical CO2 Exposure. J. Nanosci. Nanotechnol. 2017, 17, 6603–6613. [Google Scholar] [CrossRef]

- Lyu, Q.; Long, X.; Pg, R.; Tan, J.; Zhou, J.; Wang, Z.; Luo, W. A laboratory study of geomechanical characteristics of black shales after sub-critical/super-critical CO2 + brine saturation. Géoméch. Geophys. Geo-Energy Geo-Resources 2018, 4, 141–156. [Google Scholar] [CrossRef]

- Kutchko, B.; Sanguinito, S.; Natesakhawat, S.; Cvetic, P.; Culp, J.T.; Goodman, A. Quantifying pore scale and matrix interactions of SCCO2 with the Marcellus shale. Fuel 2020, 266, 116928. [Google Scholar] [CrossRef]

- Khosravi, M.H.; Kheirollahi, M.; Liu, B.; Gentzis, T.; Liu, K.; Morta, H.B.; Ostadhassan, M. Physico-chemo-mechanical impact of sc-CO2 on shale formations: The Bakken. Gas Sci. Eng. 2023, 112, 204945. [Google Scholar] [CrossRef]

- Ozotta, O.; Kolawole, O.; Malki, M.L.; Ore, T.; Gentzis, T.; Fowler, H.; Liu, K.; Ostadhassan, M. Nano- to macro-scale structural, mineralogical, and mechanical alterations in a shale reservoir induced by exposure to supercritical CO2. Appl. Energy 2022, 326, 120051. [Google Scholar] [CrossRef]

- Feng, G.; Kang, Y.; Sun, Z.-D.; Wang, X.-C.; Hu, Y.-Q. Effects of supercritical CO2 adsorption on the mechanical characteristics and failure mechanisms of shale. Energy 2019, 173, 870–882. [Google Scholar] [CrossRef]

- Cudjoe, S.E.; Barati, R.; Tsau, J.-S.; Zhang, C.; Nicoud, B.; Bradford, K.; Baldwin, A.; Mohrbacher, D. Assessing the Efficiency of Saturating Shale Oil Cores and Evaluating Hydrocarbon Gas Huff ‘n’ Puff Using Nuclear Magnetic Resonance. SPE Reserv. Evaluation Eng. 2021, 24, 429–439. [Google Scholar] [CrossRef]

- Nguyen, P.; Carey, J.W.; Viswanathan, H.S.; Porter, M. Effectiveness of supercritical-CO2 and N2 huff-and-puff methods of enhanced oil recovery in shale fracture networks using microfluidic experiments. Appl. Energy 2018, 230, 160–174. [Google Scholar] [CrossRef]

- Adel, I.A.; Tovar, F.D.; Zhang, F.; Schechter, D.S. The Impact of MMP on Recovery Factor During CO2—EOR in Unconventional Liquid Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar] [CrossRef]

- Tovar, F.D.; Barrufet, M.A.; Schechter, D.S. Enhanced Oil Recovery in the Wolfcamp Shale by Carbon Dioxide or Nitrogen Injection: An Experimental Investigation. SPE J. 2021, 26, 515–537. [Google Scholar] [CrossRef]

- Yu, Y.; Sheng, J.J. A comparative experimental study of IOR potential in fractured shale reservoirs by cyclic water and nitrogen gas injection. J. Pet. Sci. Eng. 2017, 149, 844–850. [Google Scholar] [CrossRef]

- Kong, B.; Wang, S.; Chen, S. Simulation and Optimization of CO2 Huff-and-Puff Processes in Tight Oil Reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar] [CrossRef]

- Fu, X.; Bonifas, P.; Finley, A.; Lemaster, J.; He, Z.; Venepalli, K. Tight Oil EOR through Inter-Fracture Gas Flooding within a Single Horizontal Well. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar] [CrossRef]

- MacPHAIL, W.F.P.; Shaw, J.C. Well Injection and Production Method and System. 2015. Available online: https://patents.google.com/patent/WO2014124533A1/pt (accessed on 17 July 2023).

- Luo, G.; Ehlig-Economides, C.; Nikolaou, M. Advantage of miscible fluid injection and tight oil production through a single-well alternating production-injection procedure over other single-well EOR methods. J. Pet. Sci. Eng. 2020, 199, 108091. [Google Scholar] [CrossRef]

- Jia, H.; Yuan, C.-D.; Zhang, Y.-C.; Peng, H.; Zhong, D.; Zhao, J.-Z. Recent Progress of High-Pressure Air Injection (HPAI) Process in Light Oil Reservoir: Laboratory Investigation and Field Application. In Proceedings of the SPE Heavy Oil Conference Canada, Calgary, AB, Canada, 12–14 June 2012. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, K.; Liu, C.; Mgijimi, M.B. Geothermal Power Production from Abandoned Oil Reservoirs Using In Situ Combustion Technology. Energies 2019, 12, 4476. [Google Scholar] [CrossRef]

- Sarathi, P.S. In-Situ Combustion Handbook—Principles and Practices; Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 1999. [Google Scholar]

- Aristizábal, J.-J.G.; Vargas, J.-L.G. Modeling segregated insitu combustion processes through a vertical displacement model applied to a colombian field. In CT&F-Ciencia, Tecnología y Futuro; CT&F Ciencia, Tecnología y Futuro: Piedecuesta, Coloumbia, 2005; pp. 111–126. Available online: http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0122-53832005000100009&lng=en&nrm=iso&tlng=en (accessed on 20 February 2023).

- Storey, B.M.; Worden, R.H.; McNamara, D.D. The Geoscience of In-Situ Combustion and High-Pressure Air Injection. Geosciences 2022, 12, 340. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, J.J. Simulation study of huff-n-puff air injection for enhanced oil recovery in shale oil reservoirs. Petroleum 2018, 4, 7–14. [Google Scholar] [CrossRef]

- Kriksunov, L.B.; Macdonald, D.D. Corrosion in Supercritical Water Oxidation Systems: A Phenomenological Analysis. J. Electrochem. Soc. 1995, 142, 4069–4073. [Google Scholar] [CrossRef]

- Marrone, P.A.; Hong, G.T. Corrosion control methods in supercritical water oxidation and gasification processes. J. Supercrit. Fluids 2008, 51, 83–103. [Google Scholar] [CrossRef]

- Anderson, R.; Ratcliffe, I.; Greenwell, H.; Williams, P.; Cliffe, S.; Coveney, P. Clay swelling—A challenge in the oilfield. Earth-Science Rev. 2010, 98, 201–216. [Google Scholar] [CrossRef]

- Zhan, J.; Chen, Z.; Zhang, Y.; Zheng, Z.; Deng, Q. Will the future of shale reservoirs lie in CO2 geological sequestration? Sci. China Technol. Sci. 2020, 63, 1154–1163. [Google Scholar] [CrossRef]

- Li, L.; Su, Y.; Sheng, J.J. Investigation of Gas Penetration Depth During Gas Huff-N-Puff EOR Process in Unconventional Oil Reservoirs. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. [Google Scholar] [CrossRef]

- Song, C.; Yang, D. Experimental and numerical evaluation of CO2 huff-n-puff processes in Bakken formation. Fuel 2017, 190, 145–162. [Google Scholar] [CrossRef]

- Cipolla, C.L.; Lolon, E.P.; Erdle, J.C.; Rubin, B. Reservoir Modeling in Shale-Gas Reservoirs. SPE Reserv. Evaluation Eng. 2010, 13, 638–653. [Google Scholar] [CrossRef]

- Chen, Z.; Liao, X.; Zhao, X.; Dou, X.; Zhu, L. Performance of horizontal wells with fracture networks in shale gas formation. J. Pet. Sci. Eng. 2015, 133, 646–664. [Google Scholar] [CrossRef]

- Janiga, D.; Czarnota, R.; Stopa, J.; Wojnarowski, P. Huff and puff process optimization in micro scale by coupling laboratory experiment and numerical simulation. Fuel 2018, 224, 289–301. [Google Scholar] [CrossRef]

- Zhu, C.; Guo, W.; Sun, Y.; Li, Q.; Deng, S.; Wang, Y.; Cui, G. Reaction mechanism and reservoir simulation study of the high-temperature nitrogen injection in-situ oil shale process: A case study in Songliao Basin, China. Fuel 2022, 316, 123164. [Google Scholar] [CrossRef]

- Shuai, Z.; Xiaoshu, L.; Qiang, L.; Youhong, S. Thermal-fluid coupling analysis of oil shale pyrolysis and displacement by heat-carrying supercritical carbon dioxide. Chem. Eng. J. 2020, 394, 125037. [Google Scholar] [CrossRef]

- Junira, A.; Biancardi, S.; Ganjdanesh, R.; Sepehrnoori, K.; Yu, W.; Ambrose, R. In situ fluid and injection gas compatibility of huff-n-puff gas EOR in a low-permeability shale-sand-carbonate reservoir. J. Pet. Sci. Eng. 2021, 208, 109587. [Google Scholar] [CrossRef]

- Wang, M.; Wang, L.; Zhou, W.; Yu, W. Lean gas Huff and Puff process for Eagle Ford Shale: Methane adsorption and gas trapping effects on EOR. Fuel 2019, 248, 143–151. [Google Scholar] [CrossRef]

- Korobitsyn, D.A.; Yanaev, A.M.; Bochkarev, A.V.; Erofeev, A.A.; Prodan, A.S.; Bukov, O.V.; Migunov, N.M.; Milkov, A.Y. Results of Implementing an Integrated Approach to Modeling, Planning and Conducting of Hydraulic Fracturing on Bazhenov Shale. In Proceedings of the SPE Russian Petroleum Technology Conference, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Erofeev, A.A.; Mitrushkin, D.A.; Meretin, A.S.; Pachezhertsev, A.A.; Karpov, I.A.; Demo, V.O. Simulation of Thermal Recovery Methods for Development of the Bazhenov Formation. In Proceedings of the SPE Russian Petroleum Technology Conference and Exhibition, Moscow, Russia, 24–26 October 2016. [Google Scholar] [CrossRef]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef]

- Ebadi, M.; Orlov, D.; Makhotin, I.; Krutko, V.; Belozerov, B.; Koroteev, D. Strengthening the digital rock physics, using downsampling for sub-resolved pores in tight sandstones. J. Nat. Gas Sci. Eng. 2021, 89, 103869. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Gong, R.; Wang, S. Pore Network Modeling of Oil–Water Flow in Jimsar Shale Oil Reservoir. Front. Earth Sci. 2021, 9. [Google Scholar] [CrossRef]

- Orlov, D.; Ebadi, M.; Muravleva, E.; Volkhonskiy, D.; Erofeev, A.; Savenkov, E.; Balashov, V.; Belozerov, B.; Krutko, V.; Yakimchuk, I.; et al. Different methods of permeability calculation in digital twins of tight sandstones. J. Nat. Gas Sci. Eng. 2021, 87, 103750. [Google Scholar] [CrossRef]

- Zhao, B.; MacMinn, C.W.; Primkulov, B.K.; Chen, Y.; Valocchi, A.J.; Zhao, J.; Kang, Q.; Bruning, K.; McClure, J.E.; Miller, C.T.; et al. Comprehensive comparison of pore-scale models for multiphase flow in porous media. Proc. Natl. Acad. Sci. USA 2019, 116, 13799–13806. [Google Scholar] [CrossRef]

- Soulaine, C.; Creux, P.; Tchelepi, H.A. Micro-continuum Framework for Pore-Scale Multiphase Fluid Transport in Shale Formations. Transp. Porous Media 2018, 127, 85–112. [Google Scholar] [CrossRef]

- Lesinigo, M.; D’angelo, C.; Quarteroni, A. A multiscale Darcy–Brinkman model for fluid flow in fractured porous media. Numer. Math. 2010, 117, 717–752. [Google Scholar] [CrossRef]

- Xie, C.; Raeini, A.Q.; Wang, Y.; Blunt, M.J.; Wang, M. An improved pore-network model including viscous coupling effects using direct simulation by the lattice Boltzmann method. Adv. Water Resour. 2017, 100, 26–34. [Google Scholar] [CrossRef]

- Zhao, J.; Qin, F.; Derome, D.; Kang, Q.; Carmeliet, J. Improved pore network models to simulate single-phase flow in porous media by coupling with lattice Boltzmann method. Adv. Water Resour. 2020, 145, 103738. [Google Scholar] [CrossRef]

- Chen, L.; He, Y.-L.; Kang, Q.; Tao, W.-Q. Coupled numerical approach combining finite volume and lattice Boltzmann methods for multi-scale multi-physicochemical processes. J. Comput. Phys. 2013, 255, 83–105. [Google Scholar] [CrossRef]

- You, J.; Lee, K.J. Experimental Characterization and Pore-Scale Modeling of Iron Precipitation in Shale Reservoirs by Interacting with Hydraulic Fracturing Fluid. Energy Fuels 2022, 36, 12997–13006. [Google Scholar] [CrossRef]

- Dorhjie, D.B.; Yusupov, R.; Krutko, V.; Cheremisin, A. Deviation from Darcy Law in Porous Media Due to Reverse Osmosis: Pore-Scale Approach. Energies 2022, 15, 6656. [Google Scholar] [CrossRef]

- Ebadi, M.; Orlov, D.; Alekseev, V.; Burukhin, A.; Krutko, V.; Koroteev, D. Lift the veil of secrecy in sub-resolved pores by Xe-enhanced computed tomography. Fuel 2022, 328, 125274. [Google Scholar] [CrossRef]

- Akkiraju, R.; Sinha, V.; Xu, A.; Mahmud, J.; Gundecha, P.; Liu, Z.; Liu, X.; Schumacher, J. Characterizing Machine Learning Processes: A Maturity Framework; Springer: Berlin/Heidelberg, Germany, 2020; pp. 17–31. [Google Scholar] [CrossRef]

- Mustafa, A.; Tariq, Z.; Mahmoud, M.; Radwan, A.E.; Abdulraheem, A.; Abouelresh, M.O. Data-driven machine learning approach to predict mineralogy of organic-rich shales: An example from Qusaiba Shale, Rub’ al Khali Basin, Saudi Arabia. Mar. Pet. Geol. 2021, 137, 105495. [Google Scholar] [CrossRef]

- Meshalkin, Y.; Koroteev, D.; Popov, E.; Chekhonin, E.; Popov, Y. Robotized petrophysics: Machine learning and thermal profiling for automated mapping of lithotypes in unconventionals. J. Pet. Sci. Eng. 2018, 167, 944–948. [Google Scholar] [CrossRef]

- Nath, F.; Asish, S.M.; Ganta, D.; Debi, H.R.; Aguirre, G.; Aguirre, E. Artificial Intelligence Model in Predicting Geomechanical Properties for Shale Formation: A Field Case in Permian Basin. Energies 2022, 15, 8752. [Google Scholar] [CrossRef]

- Morozov, A.D.; Popkov, D.O.; Duplyakov, V.M.; Mutalova, R.F.; Osiptsov, A.A.; Vainshtein, A.L.; Burnaev, E.V.; Shel, E.V.; Paderin, G.V. Data-driven model for hydraulic fracturing design optimization: Focus on building digital database and production forecast. J. Pet. Sci. Eng. 2020, 194, 107504. [Google Scholar] [CrossRef]

- Duplyakov, V.; Morozov, A.; Popkov, D.; Shel, E.; Vainshtein, A.; Burnaev, E.; Osiptsov, A.; Paderin, G. Data-driven model for hydraulic fracturing design optimization. Part II: Inverse problem. J. Pet. Sci. Eng. 2022, 208, 109303. [Google Scholar] [CrossRef]

- Syed, F.I.; AlShamsi, A.; Dahaghi, A.K.; Neghabhan, S. Application of ML & AI to model petrophysical and geomechanical properties of shale reservoirs—A systematic literature review. Petroleum 2022, 8, 158–166. [Google Scholar] [CrossRef]

- Belozerov, B.; Bukhanov, N.; Egorov, D.; Zakirov, A.; Osmonalieva, O.; Golitsyna, M.; Reshytko, A.; Semenikhin, A.; Shindin, E.; Lipets, V. Automatic Well Log Analysis Across Priobskoe Field Using Machine Learning Methods. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 15–17 October 2018. [Google Scholar] [CrossRef]

- Tsanda, A.; Bukharev, A.; Budennyy, S.; Andrianova, A. Well Logging Verification Using Machine Learning Algorithms. In Proceedings of the 2018 International Conference on Artificial Intelligence Applications and Innovations (IC-AIAI), Nicosia, Cyprus, 31 October–2 November 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Renata, M.; Morozov, A.D.; Osiptsov, A.A.; Vainshtein, A.L.; Burnaev, E.V.; Shel, E.V.; Paderin, G.V. Machine learning on field data for hydraulic fracturing design optimization. Earth 2019. [Google Scholar] [CrossRef]

- Kazak, A.; Simonov, K.; Kulikov, V. Machine-Learning-Assisted Segmentation of Focused Ion Beam-Scanning Electron Microscopy Images with Artifacts for Improved Void-Space Characterization of Tight Reservoir Rocks. SPE J. 2021, 26, 1739–1758. [Google Scholar] [CrossRef]

- Kang, D.H.; Yang, E.; Yun, T.S. Stokes-Brinkman Flow Simulation Based on 3-D μ-CT Images of Porous Rock Using Grayscale Pore Voxel Permeability. Water Resour. Res. 2019, 55, 4448–4464. [Google Scholar] [CrossRef]

- Jiang, Z.; van Dijke, M.I.J.; Sorbie, K.S.; Couples, G.D. Representation of multiscale heterogeneity via multiscale pore networks. Water Resour. Res. 2013, 49, 5437–5449. [Google Scholar] [CrossRef]

- Carrillo, F.J.; Bourg, I.C.; Soulaine, C. Multiphase flow modeling in multiscale porous media: An open-source micro-continuum approach. J. Comput. Physics X 2020, 8, 100073. [Google Scholar] [CrossRef]

- Guo, B.; Ma, L.; Tchelepi, H.A. Image-based micro-continuum model for gas flow in organic-rich shale rock. Adv. Water Resour. 2018, 122, 70–84. [Google Scholar] [CrossRef]

- Syed, F.I.; Alnaqbi, S.; Muther, T.; Dahaghi, A.K.; Negahban, S. Smart shale gas production performance analysis using machine learning applications. Pet. Res. 2022, 7, 21–31. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, F. Integrating linear and nonlinear forecasting techniques based on grey theory and artificial intelligence to forecast shale gas monthly production in Pennsylvania and Texas of the United States. Energy 2019, 178, 781–803. [Google Scholar] [CrossRef]

- Panja, P.; Velasco, R.; Pathak, M.; Deo, M. Application of artificial intelligence to forecast hydrocarbon production from shales. Petroleum 2018, 4, 75–89. [Google Scholar] [CrossRef]

- Qian, K.-R.; He, Z.-L.; Liu, X.-W.; Chen, Y.-Q. Intelligent prediction and integral analysis of shale oil and gas sweet spots. Pet. Sci. 2018, 15, 744–755. [Google Scholar] [CrossRef]

- Lee, K.; Lim, J.; Yoon, D.; Jung, H. Prediction of Shale-Gas Production at Duvernay Formation Using Deep-Learning Algorithm. SPE J. 2019, 24, 2423–2437. [Google Scholar] [CrossRef]

- Abbas, A.K.; Al-Haideri, N.A.; Bashikh, A.A. Implementing artificial neural networks and support vector machines to predict lost circulation. Egypt. J. Pet. 2019, 28, 339–347. [Google Scholar] [CrossRef]

- Tang, J.; Fan, B.; Xiao, L.; Tian, S.; Zhang, F.; Zhang, L.; Weitz, D. A New Ensemble Machine-Learning Framework for Searching Sweet Spots in Shale Reservoirs. SPE J. 2020, 26, 482–497. [Google Scholar] [CrossRef]

- Hui, G.; Chen, S.; He, Y.; Wang, H.; Gu, F. Machine learning-based production forecast for shale gas in unconventional reservoirs via integration of geological and operational factors. J. Nat. Gas Sci. Eng. 2021, 94, 104045. [Google Scholar] [CrossRef]

- Rahmanifard, H.; Plaksina, T. Application of fast analytical approach and AI optimization techniques to hydraulic fracture stage placement in shale gas reservoirs. J. Nat. Gas Sci. Eng. 2018, 52, 367–378. [Google Scholar] [CrossRef]

- Gazpromneft. Gazpromneft Doubled the Recovery of Bazenov Oil. (Rus.). 2021. Available online: https://www.gazprom-neft.ru/press-center/news/gazprom_neft_udvoila_dobychu_bazhenovskoy_nefti/ (accessed on 20 February 2023).

- Ugryumov, A.; Petrova, D.; Sannikova, I.; Kasyanenko, A.; Khachaturyan, M.; Kolomytsev, A.; Yuschenko, T.; Plotnikov, B.; Karimov, I. Prospectivity Assessment of Bazhenov Formation Using Cutting-edge Integrated Static Model. In Proceedings of the 10th Unconventional Resources Technology Conference, Tulsa, OK, USA, 20–22 June 2022; American Association of Petroleum Geologists: Tulsa, OK, USA, 2022. [Google Scholar] [CrossRef]

- Gazpromneft. Gazpromneft, Lukoil and Tatneft Set Up a Joint Venture to Develop Hard-to-Recover Oil in the Volga-Ural Region. (Rus) Press Release. 2020. Available online: https://www.gazprom-neft.ru/press-center/news/gazprom_neft_lukoyl_i_tatneft_sozdali_sovmestnoe_predpriyatie_dlya_razrabotki_zapasov_trudnoy_nefti_/ (accessed on 20 February 2023).

- Gazpromneft. The joint venture between Gazpromneft and Zarubezhneft Will Ensure the Development of Technologies for the Production of Hard-to-Recover oil in HMAO-Yugra. Press Release. 2020. Available online: https://www.gazprom-neft.ru/press-center/news/sovmestnoe_predpriyatie_gazprom_nefti_i_zarubezhnefti_obespechit_razvitie_tekhnologiy_dobychi_trudno/ (accessed on 20 February 2023).

- Rosneft. Rosneft Annual Report. 2020. Available online: https://www.rosneft.ru/upload/site1/document_file/a_report_2020.pdf (accessed on 20 February 2023).

- Karpov, V.B.; Bakulin, A.A.; Mukhudinov, R.A. Experience in the Development of Hard-to-recover Reserves on the Example of the Sredne-Nazymskoye Field, Challenges and Solutions (Rus.). Geol. Nedropolzovanie 2021, 92–101. [Google Scholar]

- Gu, H.; Cheng, L.; Huang, S.; Du, B.; Hu, C. Prediction of thermophysical properties of saturated steam and wellbore heat losses in concentric dual-tubing steam injection wells. Energy 2014, 75, 419–429. [Google Scholar] [CrossRef]

- Sun, F.; Yao, Y.; Chen, M.; Li, X.; Zhao, L.; Meng, Y.; Sun, Z.; Zhang, T.; Feng, D. Performance analysis of superheated steam injection for heavy oil recovery and modeling of wellbore heat efficiency. Energy 2017, 125, 795–804. [Google Scholar] [CrossRef]

- Nian, Y.-L.; Cheng, W.-L.; Li, T.-T.; Wang, C.-L. Study on the effect of wellbore heat capacity on steam injection well heat loss. Appl. Therm. Eng. 2014, 70, 763–769. [Google Scholar] [CrossRef]

- Marrone, P.A.; Cantwell, S.D.; Dalton, D.W. SCWO System Designs for Waste Treatment: Application to Chemical Weapons Destruction. Ind. Eng. Chem. Res. 2005, 44, 9030–9039. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, F.; Tang, R. Corrosion mechanisms of candidate structural materials for supercritical water-cooled reactor. Front. Energy Power Eng. China 2009, 3, 233–240. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, Y.; Yang, D. Review of oil shale in-situ conversion technology. Appl. Energy 2020, 269, 115121. [Google Scholar] [CrossRef]

- Johnson, R.; Crawford, P.M.; Bunger, J.W. Strategic Significance of America’s Oil Shale Resource. 2004. Available online: https://www.iepm.com/Strat._Significance-Vol._I.pdf (accessed on 20 February 2023).

- Kokorev, V.I.; Darishchev, V.I.; Akhmadeishin, I.A.; Shchekoldin, K.A.; Boksernam, A.A. The Results of the Field Tests and Prospects of Termogas Development of Bazhenov Formation in OJSC RITEK. In Proceedings of the SPE Russian Oil and Gas Exploration & Production Technical Conference and Exhibition, Moscow, Russia, 14–16 October 2014. [Google Scholar] [CrossRef]

- RITEK. Every Drop Is Worth Its Weight in Gold (Rus). Neftyanik RITEKa. 2020, Volume 6. Available online: https://lukoil.ru/FileSystem/9/487632.pdf?ysclid=lc97d59qx2957395562 (accessed on 20 February 2013).

| Method | Description |

|---|---|

| Top-Down ISC | In this method, air or oxygen is injected from the top of the reservoir, and combustion progresses vertically downward [32,33]. |

| Toe-to-Heel Air Injection (THAI) | THAI is a specific implementation of ISC, in which air is injected at the “toe” of a horizontal well, while producing oil from the “heel” of the well. The combustion front moves towards the heel, and the produced oil flows towards the toe of the well. This method is limited to a specific range of reservoir thicknesses and early injection gas (air) breakthrough [34,35]. |

| Combustion-Assisted Gravity Drainage (CAGD) | CAGD combines ISC with gravity drainage. Air or oxygen is injected into the reservoir, and the combustion front heats the oil, reducing its viscosity. Gravity then assists in the drainage and recovery of the mobilized oil [36,37]. |

| Combustion Override, Split production, Horizontal-well (COSH) | COSH is a technique that combines steam injection and ISC. Steam is first injected to heat the reservoir, followed by air or oxygen injection to initiate combustion. The combustion front then overrides the steam chamber, displacing and producing the oil [38]. |

| Formation | Injected Fluid | Max Temperature (°C) |

|---|---|---|

| Kentucky shale [47] | Supercritical toluene | 460 |

| Natih B Formation–Oman [49] | Supercritical water | 400 |

| Domanik formation [58] | Supercritical Water | 374 at 24.6 MPa |

| Huadian oil shale [56] | Subcritical water | 300 |

| Huadian oil shale [59] | Subcritical FeCl2 solution | 350 |

| Huadian oil shale [60] | Subcritical CaCl2 solution | 350 |

| Huadian oil shale [61] | Subcritical FeCl3 solution | 350 |

| Longkou Liangjia [62] | Supercritical water | 425 |

| Method | Reservoir | TOC (wt%) | Kerogen Type | Max Temperature (°C) | Permeability Change | Porosity Change | Reference |

|---|---|---|---|---|---|---|---|

| Air injection | Bazhenov | 8.42–17.42 | II | 446 | - | - | Bondarenko et al. [42] |

| Heating | Bazhenov | - | - | 350 | x8 | - | Gorshkov and Khomyakov [43] |

| Hydrothermal treatment | Bazhenov | 3.91–18.48 | II–III | 300 | - | - | Kovaleva et al. [46] |

| Hydrothermal treatment | Bazhenov | 11 | II | 400 | x77 | x2.4 | Popov et al. [63] |

| Hydrothermal treatment | Domanik and Bazhenov | 6 | - | 300 | - | - | Stennikov et al. [64] |

| Cyclic Hydrothermal treatment | Bazhenov | 1.82–14.11 | II–III | 350 | - | x3 | Turakhanov et al. [66] |

| Method | Advantage | Disadvantage |

|---|---|---|

| In situ combustion | ||

| Hot-fluid Injection |

|

|

| Gas injection |

|

| Investigation | Formation | Method | Findings |

|---|---|---|---|

| Digital rock imaging technique and flow modeling Ebadi et al. [126] | Achimov | 3D digital rock model with binary of only connected pores (single spatial resolution imaging) | Simplified workflow of improving the computation of the permeability of tight reservoirs. |

| Pore-scale absolute permeability of tight oil formation Orlov et al. [128] | Achimov | Direct simulation, LBM 3 & PNM 2 | It is more vital to execute accurate and precise image processing and segmentation than to use complex computation approaches. |

| Digital rock imaging technique and flow modeling Kang et al. [149] | Berea sandstone | 3D digital rock model with binary of only connected pores (double spatial resolution imaging) | A pore segmentation algorithm for dealing with gray-level pore space while preserving pore connection. |

| Multi-scale PNM 2 Jiang et al. [150] | - | Two-scale and three-scale PNM 2 construction from micro-CT measurements from different scales | Network integration with spatial correlation of fine-scale network components leads to considerably different relative permeabilities, as shown by applications to rock CT images, as compared to integration with uniformly distributed (uncorrelated) fine-scale pores. |

| Multi-scale flow modeling Carrillo et al. [151] | - | Micro-continuum model based on modification to the Navier–Stokes equation | A model that only requires a single momentum conservation equation, eliminating the need for multiple meshes, distinct solvers, or complicated interfacial conditions. |

| Multi-scale flow modeling Guo et al. [152] | - | Micro-continuum gas flow model for transport in organic rich shales (NSB 1) | Conventional pressure-dependent apparent permeability may not accurately depict the transport characteristics of organic rich shale. The findings demonstrate that surface diffusion and non-Darcy effects are significant at low gas pressure (1 MPa), but that these processes are insignificant at high pressure (50 MPa). |

| Digital rock imaging technique and flow modeling Wang et al. [116] | Sichuan | Pore-scale flow simulation mode | Pore-scale simulation of gas transport with vigorous incorporation of nano-scale flow mechanisms: gas adsorption, diffusion, and surface diffusion. |

| ML Model | Predicted Parameter | Data Points | Formation | Results |

|---|---|---|---|---|

| NMGM-ARIMA 1 & ARIMA-ANN 2 [154] | Gas production | 60 | - | Both models produced satisfactory results, with the ARIMA-ANN outperforming the NMGM-ARIMA. |

| SVM 3 & ANN 4 [155] | Hydrocarbon production | 144 | Eagle ford, Bakken & Niobrara | It was discovered that RSM and LSSVM had greater oil recovery prediction capabilities than ANN. In addition, LSSVM predicts the gas–oil ratio with the maximum degree of precision. |

| SVM 3 [156] | Sweet spots | - | Shale reservoir in China | It forecasts numerous features for sweet spots in reservoirs, allowing for an objective assessment of shale gas potential. |

| LSTM 5 [157] | Gas production | data from 332 shale gas wells | Durvenay & Montney | The suggested approach can be used with conventional wells; however, because of high density drilling and poor decline curve analysis performance, it is more suitable for unconventional wells. |

| ANN 4 & SVM 3 [158] | Loss circulation | 1120 data points from 385 wells | Iranian origin | Out of all the models tested, the SVM with 18 variables had the highest accuracy (accuracy of 0.92 and 0.91 for training and test model, respectively). |

| SVM 3 & Prevalent classifiers [159] | Sweet spot | Data from 73 wells | - | The maximum agreement rate of 83.37% is produced by XGBoost if the well-log interpreted parameters are omitted from the original data set. During training, GBDT reduces complexity by over 70% compared to SVMs. |

| LR 6 & ANN 4 & Gradient-boosting decision trees & Extra trees [160] | Gas production | Data from 573 horizontal wells | Duvernay | The results show that the major factors that contribute to shale production for the given formation are the total fluid injection, total proppant mass, well TVD, permeability, porosity, gas saturation, number of stages, formation pressure, horizontal length, distance to fault, and formation thickness. |

| GA 7 & DE 8 & PSO 9 [161] | Hydraulic fracturing placement | - | - | By adjusting the control vector corresponding to the number of wellbores, HF spacing, fracture half-length, and numerous HF stages, DE and PSO approaches displayed improved performance and objective function improvement. However, the results of the GA examples revealed that this method was unable to discover the optimal values for the decision variables and became stuck in several local optima, resulting in convergence issues. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorhjie, D.B.; Mukhina, E.; Kasyanenko, A.; Cheremisin, A. Tight and Shale Oil Exploration: A Review of the Global Experience and a Case of West Siberia. Energies 2023, 16, 6475. https://doi.org/10.3390/en16186475

Dorhjie DB, Mukhina E, Kasyanenko A, Cheremisin A. Tight and Shale Oil Exploration: A Review of the Global Experience and a Case of West Siberia. Energies. 2023; 16(18):6475. https://doi.org/10.3390/en16186475

Chicago/Turabian StyleDorhjie, Desmond Batsa, Elena Mukhina, Anton Kasyanenko, and Alexey Cheremisin. 2023. "Tight and Shale Oil Exploration: A Review of the Global Experience and a Case of West Siberia" Energies 16, no. 18: 6475. https://doi.org/10.3390/en16186475

APA StyleDorhjie, D. B., Mukhina, E., Kasyanenko, A., & Cheremisin, A. (2023). Tight and Shale Oil Exploration: A Review of the Global Experience and a Case of West Siberia. Energies, 16(18), 6475. https://doi.org/10.3390/en16186475