Legacy Well Leakage Risk Analysis at the Farnsworth Unit Site

Abstract

:1. Introduction

2. Materials and Methods

2.1. NRAP Tools and Integrated Assessment Modeling Approach

- Divide the system into discrete components;

- Develop detailed component models that are validated against lab/field data;

- Develop reduced-order models (ROM) that rapidly reproduce component model predictions;

- Link ROMs via integrated assessment models (IAMs) to predict system performance and risk; calibrate using lab/field data from NRAP and other sources;

- Develop strategic monitoring protocols that allow verification of predicted system performance.

2.2. Reservoir Model of FWU

2.3. Reservoir Model Scenarios

3. Results and Discussion

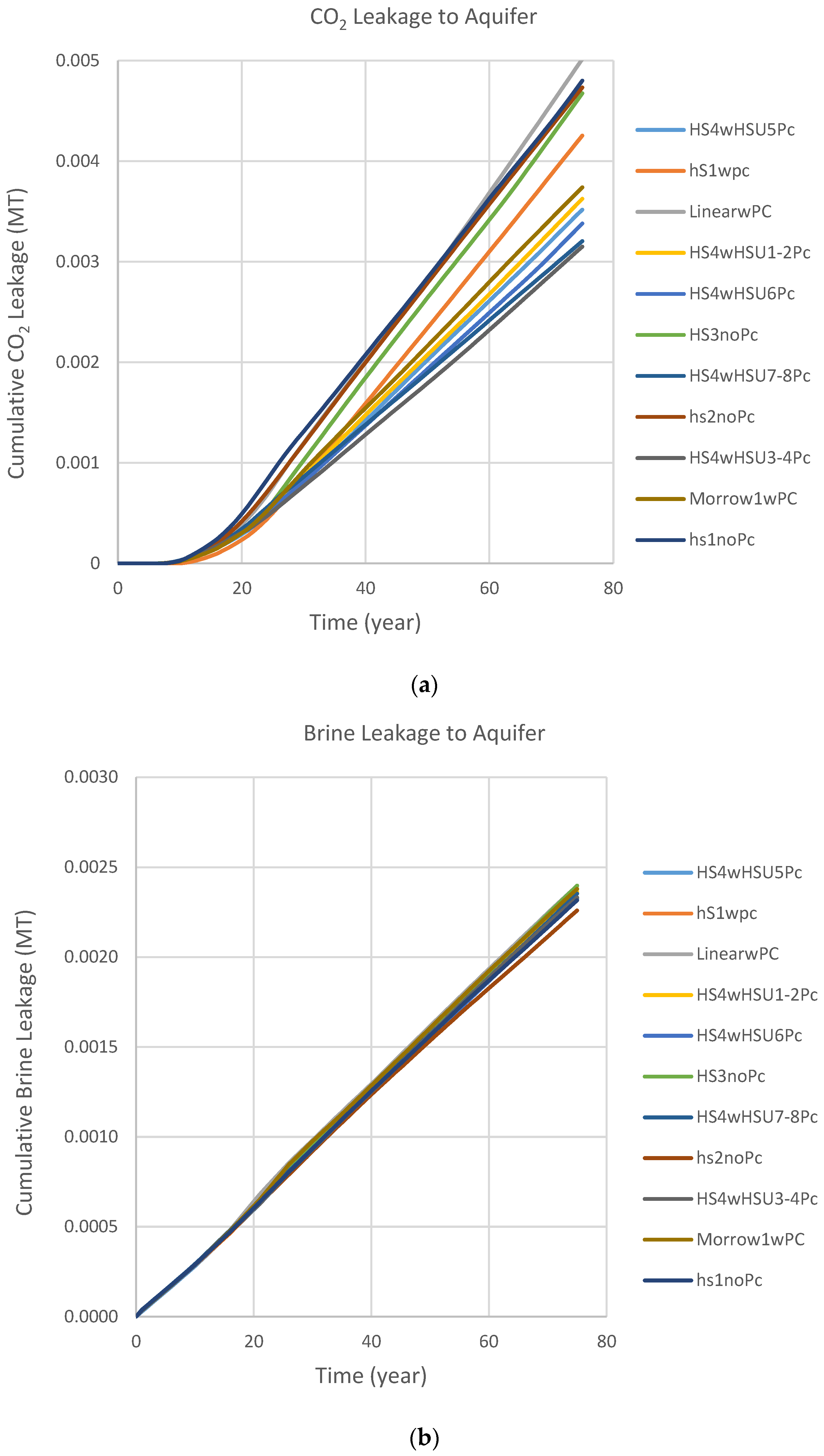

3.1. NRAP-IAM-CS Quantification of CO2 and Brine Leakage

3.2. Impact of Various Wellbore Integrity Distribution on Leakage

3.3. Open Well Leakage Scenario

3.4. Individual Well Leakage Analysis—Open Well Scenario

3.5. Individual Well Leakage Analysis—Cemented Well Scenario

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haszeldine, R.S. Carbon Capture and Storage: How Green Can Black Be? Science 2009, 325, 1647–1652. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Liu, J.; Zhang, Q.; Teng, F.; McLellan, B.C. A critical review on deployment planning and risk analysis of carbon capture, utilization, and storage (CCUS) toward carbon neutrality. Renew. Sustain. Energy Rev. 2022, 167, 112537. [Google Scholar] [CrossRef]

- Balch, R.; McPherson, B.; Grigg, R. Overview of a Large Scale Carbon Capture, Utilization, and Storage Demonstration Project in an Active Oil Field in Texas, USA. Energy Procedia 2017, 114, 5874–5887. [Google Scholar] [CrossRef]

- Balch, R.; McPherson, B.; Will, R.A.; Ampomah, W. Recent Developments in Modeling: Farnsworth Texas, CO2 EOR Carbon Sequestration Project. SSRN Electron. J. 2021, 1–11. [Google Scholar] [CrossRef]

- Balch, R.; McPherson, B. Associated Storage With Enhanced Oil Recovery: A Large-Scale Carbon Capture, Utilization, and Storage Demonstration in Farnsworth, Texas, USA. In Geophysical Monitoring for Geologic Carbon Storage; Huang, L., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2022; pp. 343–360. [Google Scholar] [CrossRef]

- Wilson, E.J.; Friedmann, S.J.; Pollak, M.F. Research for Deployment: Incorporating Risk, Regulation, and Liability for Carbon Capture and Sequestration. Environ. Sci. Technol. 2007, 41, 5945–5952. [Google Scholar] [CrossRef] [PubMed]

- White, S.; Carroll, S.; Chu, S.; Bacon, D.; Pawar, R.; Cumming, L.; Hawkins, J.; Kelley, M.; Demirkanli, I.; Middleton, R.; et al. A risk-based approach to evaluating the Area of Review and leakage risks at CO2 storage sites. Int. J. Greenh. Gas. Control 2020, 93, 102884. [Google Scholar] [CrossRef]

- Xiao, T.; McPherson, B.; Esser, R.; Jia, W.; Dai, Z.; Chu, S.; Pan, F.; Viswanathan, H. Chemical Impacts of Potential CO2 and Brine Leakage on Groundwater Quality with Quantitative Risk Assessment: A Case Study of the Farnsworth Unit. Energies 2020, 13, 6574. [Google Scholar] [CrossRef]

- Carroll, S.A.; Keating, E.; Mansoor, K.; Dai, Z.; Sun, Y.; Trainor-Guitton, W.; Brown, C.; Bacon, D. Key factors for determining groundwater impacts due to leakage from geologic carbon sequestration reservoirs. Int. J. Greenh. Gas. Control 2014, 29, 153–168. [Google Scholar] [CrossRef]

- Onishi, T.; Nguyen, M.C.; Carey, J.W.; Will, B.; Zaluski, W.; Bowen, D.W.; Devault, B.C.; Duguid, A.; Zhou, Q.; Fairweather, S.H.; et al. Potential CO2 and brine leakage through wellbore pathways for geologic CO2 sequestration using the National Risk Assessment Partnership tools: Application to the Big Sky Regional Partnership. Int. J. Greenh. Gas. Control 2019, 81, 44–65. [Google Scholar] [CrossRef]

- Bacon, D.H.; Qafoku, N.P.; Dai, Z.; Keating, E.H.; Brown, C.F. Modeling the impact of carbon dioxide leakage into an unconfined, oxidizing carbonate aquifer. Int. J. Greenh. Gas. Control 2016, 44, 290–299. [Google Scholar] [CrossRef]

- Dilmore, R.; Wyatt, C.; Pawar, R.; Carroll, S.; Oldenburg, C.; Yonkofski, C.; Bacon, D.; King, S.; Lindner, E.; Bachmann, C.; et al. NRAP Phase I Tool Development and Quality Assurance Process; NRAP-TRS-II-021-2016; NRAP Technical Report Series; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, USA, 2016; p. 64.

- Pawar, R.J.; Bromhal, G.S.; Chu, S.; Dilmore, R.M.; Oldenburg, C.M.; Stauffer, P.H.; Zhang, Y.Q.; Guthrie, G.D. The National Risk Assessment Partnership’s integrated assessment model for carbon storage: A tool to support decision making amidst uncertainty. Int. J. Greenh. Gas. Control 2016, 52, 175–189. [Google Scholar] [CrossRef]

- Stauffer, P.H.; Viswanathan, H.S.; Pawar, R.J.; Guthrie, G.D. A system model for geologic sequestration of carbon dioxide. Environ. Sci. Technol. 2009, 43, 565–570. [Google Scholar] [CrossRef] [PubMed]

- GoldSim Technology Group. GoldSim Probabilistic Simulation Environment User’s Guide; Version 11.1.7; GoldSim Technology Group LLC: Issaquah, WA, USA, 2016; Volumes 1 and 2. [Google Scholar]

- Czoski, P. Geologic Characterization of the Morrow B reservoir in Farnsworth Unit, TX Using 3D VSP Seismic, Seismic Attributes, and Well Logs. Master’s Thesis, New Mexico Institute of Mining and Technology, Department of Earth and Environmental Science, Socorro, NM, USA, 2014; p. 102. [Google Scholar]

- Ross-Coss, D.; Ampomah, W.; Balch, R.S.; Cather, M.; Mozely, P.; Rasmussen, L. An Improved Approach for Sandstone Reservoir Characterization. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23–26 May 2016. SPE-180375. [Google Scholar]

- Ampomah, W.; Balch, R.S.; Ross-Coss, D.; Hutton, A.; Cather, M.; Will, R.A. An Integrated Approach for Characterizing a Sandstone Reservoir in the Anadarko Basin. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3 May 2016. [Google Scholar] [CrossRef]

- Ampomah, W.; Balch, R.; Grigg, R.B.; Cather, M.; Gragg, E.; Will, R.A.; White, M.; Moodie, N.; Dai, Z. Performance assessment of CO2-enhanced oil recovery and storage in the Morrow reservoir. Geomech. Geophys. Geo-Energy Geo-Resour. 2017, 3, 245–263. [Google Scholar] [CrossRef]

- Gallagher, S.R. Depositional and Diagenetic Controls on Reservoir Heterogeneity: Upper Morrow Sandstone, Farnsworth Unit, Ochiltree County, Texas. Ph.D. Thesis, New Mexico Institute of Mining and Technology, Socorro, NM, USA, 2014. [Google Scholar]

- Balch, R.; McPherson, B. Integrating Enhanced Oil Recovery and Carbon Capture and Storage Projects: A Case Study at Farnsworth Field, Texas. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23–26 May 2016. [Google Scholar] [CrossRef]

- Moodie, N.; Ampomah, W.; Jia, W.; Heath, J.; McPherson, B. Assignment and calibration of relative permeability by hydrostratigraphic units for multiphase flow analysis, case study: CO2-EOR operations at the Farnsworth Unit, Texas. Int. J. Greenh. Gas. Control 2019, 81, 103–114. [Google Scholar] [CrossRef]

- Moodie, N.; Ampomah, W.; Heath, J.; Jia, W.; McPherson, B. Quantitative analysis of the influence of capillary pressure on geologic carbon storage forecasts case study: CO2-EOR in the Anadarko basin, Texas. Int. J. Greenh. Gas. Control 2021, 109, 103373. [Google Scholar] [CrossRef]

- King, S. Reservoir Reduced-Order Model—Generator (RROM-Gen) Tool User’s Manual; NRAP-TRS-III-0XX-2016; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, USA, 2016.

- Stauffer, P.; Chu, S.; Tauxe, C.; Pawar, R. NRAP Integrated Assessment Model-Carbon Storage (NRAP-IAM-CS) Tool User’s Manual Version: 2016.11-1.1; NRAP-TRS-III-010-2016; NRAP Technical Report Series; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, USA, 2016; p. 64. [CrossRef]

- Carey, J.W. Probability Distributions for Effective Permeability of Potentially Leaking Wells at CO2 Sequestration Sites; NRAPTRS-III-021-2017; NRAP Technical Report Series; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, USA, 2017; p. 28.

- Moodie, N.; Ampomah, W.; Jia, W.; McPherson, B. Relative Permeability: A Critical Parameter in Numerical Simulations of Multiphase Flow in Porous Media. Energies 2021, 14, 2370. [Google Scholar] [CrossRef]

| Distribution Model | Type | Low End (m2) | Midrange (m2) | High End (m2) |

|---|---|---|---|---|

| Alberta | Uniform | 95.4% of wells 10−20 | 4.4% of wells 10−17~10−14 | 0.2% of wells 10−13~10−12 |

| Gulf of Mexico | Uniform | 88% of wells 10−20 | 11.4% of wells 10−17~10−14 | 0.6% of wells 10−13~10−12 |

| FutureGen low flow rate | Log-normal | 90% of wells 10−20 (mean) | 10% of wells 10−17~10−15 (mean) | |

| FutureGen high flow rate | Log-normal | 90% of wells 10−20~10−18 (mean) | 10% of wells 10−15~10−13 (mean) | |

| Cemented Well (hypothetically assume all wells with very high fixed permeability) | 100% of wells 5 × 10−11 | |||

| Open Well (hypothetical) | 100% of wells |

| Injection Period | Injection Fluid |

|---|---|

| 2010–2016 | Unlimited CO2 + recycled CO2 |

| 2016–2024 | 560 MT/day CO2 + recycled CO2 |

| 2024–2026 | 448 MT/day CO2 + recycled CO2 |

| 2026–2028 | 392 MT/day CO2 + recycled CO2 |

| 2028–2030 | 336 MT/day CO2 + recycled CO2 |

| 2030–2035 | Recycled CO2 only |

| 2035–2085 | Post injection monitoring period |

| Base Model |

|

| Linear model |

|

| Morrow1 Model |

|

| Hydrostratigraphic Region 1 Model |

|

| Hydrostratigraphic Region 2 Model |

|

| Hydrostratigraphic Region 3 Model |

|

| Hydrostratigraphic Region 4 Model |

|

| Total Mass of CO2 Injected (tons) | |||

|---|---|---|---|

| Homogeneous Cases | Heterogeneous Cases | ||

| Base Model | 9,496,675 | HS1wPc | 9,240,643 |

| Morrow1 | 9,590,256 | HS1noPc | 8,459,803 |

| Morrow1wPc | 10,256,219 | HS2wPc | 9,202,484 |

| Linear | 9,613,866 | HS2noPc | 8,370,725 |

| LinearwPc | 10,157,328 | HS3wPc | 8,859,159 |

| HS4wHSU1-2Pc | 9,426,994 | HS3noPc | 8,507,114 |

| HS4wHSU3-4Pc | 8,988,384 | HS4wPc | 10,065,672 |

| HS4wHSU5Pc | 8,988,394 | ||

| HS4wHSU6Pc | 9,426,962 | ||

| HS4wHSU7-8Pc | 9,386,476 | ||

| Well # | Relative Distance to Nearby Injection Well | Distance (m) to Nearby Injection Well | Well Coordinate X (m) | Well Coordinate Y (m) | CO2 Leakage (MT) | Brine Leakage (MT) |

|---|---|---|---|---|---|---|

| 7 | close | 367 | 316,988 | 4,014,458 | 0.01005 | 0.3345 |

| 15 | closer | 121 | 319,426 | 4,015,635 | 0.001053 | 0.04434 |

| 11 | closest | 112 | 319,003 | 4,014,425 | 0 | 0.002614 |

| 22 | In the middle of Injection wells | 360 | 319,780 | 4,013,646 | 0 | 0.002459 |

| 31 | far | 775 | 320,905 | 4,013,513 | 0 | 0.002763 |

| 6 | farther | 801 | 317,001 | 4,015,657 | 0 | 0.02046 |

| 2 | farthest | 1310 | 316,534 | 4,016,479 | 0 | 0.0136 |

| X (m) | Y (m) | Well # | Total CO2 Leakage (MT) | Total Brine Leakage (MT) | pH Plume (m3) | TDS Plume (m3) |

|---|---|---|---|---|---|---|

| 319,407.1 | 4,016,070 | 15 | 6.30 × 10−4 | 8.66 × 10−5 | 0 | 0 |

| 316,533.8 | 4,016,479 | 14 | 4.99 × 10−4 | 8.56 × 10−5 | 0 | 0 |

| 316,599.5 | 4,014,454 | 23 | 3.46 × 10−4 | 7.64 × 10−5 | 0 | 0 |

| 316,599.3 | 4,014,061 | 12 | 3.01 × 10−4 | 9.03 × 10−5 | 0 | 0 |

| 317,407.7 | 4,016,870 | 20 | 2.80 × 10−4 | 9.21 × 10−5 | 0 | 0 |

| 317,001.5 | 4,015,657 | 7 | 2.25 × 10−4 | 7.43 × 10−5 | 0 | 0 |

| 316,987.9 | 4,014,458 | 13 | 2.17 × 10−4 | 7.46 × 10−5 | 0 | 0 |

| 318,193.5 | 4,013,648 | 6 | 2.14 × 10−4 | 7.93 × 10−5 | 0 | 0 |

| 318,205.7 | 4,013,242 | 18 | 1.45 × 10−4 | 8.22 × 10−5 | 0 | 0 |

| 319,792.1 | 4,014,438 | 17 | 1.13 × 10−4 | 8.13 × 10−5 | 0 | 0 |

| 319,003.5 | 4,014,425 | 30 | 1.10 × 10−4 | 7.42 × 10−5 | 0 | 0 |

| 319,401 | 4,015,259 | 26 | 1.06 × 10−4 | 8.39 × 10−5 | 0 | 0 |

| 319,799.9 | 4,015,249 | 16 | 1.05 × 10−4 | 8.25 × 10−5 | 0 | 0 |

| 319,397.2 | 4,014,857 | 21 | 1.02 × 10−4 | 7.91 × 10−5 | 0 | 0 |

| 319,425.5 | 4,015,635 | 22 | 7.76 × 10−5 | 7.94 × 10−5 | 0 | 0 |

| 320,211.9 | 4,014,707 | 8 | 7.66 × 10−5 | 7.27 × 10−5 | 0 | 0 |

| 319,792.2 | 4,012,839 | 3 | 7.51 × 10−5 | 7.01 × 10−5 | 0 | 0 |

| 319,446.7 | 4,013,692 | 11 | 6.98 × 10−5 | 7.98 × 10−5 | 0 | 0 |

| 319,009.2 | 4,013,233 | 19 | 6.43 × 10−5 | 7.18 × 10−5 | 0 | 0 |

| 318,617.8 | 4,013,076 | 4 | 4.89 × 10−5 | 6.93 × 10−5 | 0 | 0 |

| 320,170.2 | 4,013,250 | 9 | 4.79 × 10−5 | 7.23 × 10−5 | 0 | 0 |

| 319,780.2 | 4,013,646 | 28 | 4.58 × 10−5 | 6.97 × 10−5 | 0 | 0 |

| 319,001.6 | 4,014,030 | 10 | 2.92 × 10−5 | 6.80 × 10−5 | 0 | 0 |

| 318,602 | 4,013,236 | 29 | 2.56 × 10−5 | 7.01 × 10−5 | 0 | 0 |

| 320,156.9 | 4,012,433 | 24 | 2.39 × 10−5 | 7.05 × 10−5 | 0 | 0 |

| 320,541.3 | 4,014,727 | 1 | 1.99 × 10−5 | 7.00 × 10−5 | 0 | 0 |

| 320,989.5 | 4,015,102 | 27 | 7.53 × 10−6 | 6.83 × 10−5 | 0 | 0 |

| 320,561.2 | 4,013,902 | 5 | 5.38 × 10−6 | 6.76 × 10−5 | 0 | 0 |

| 320,561.5 | 4,014,308 | 31 | 0.00 | 6.71 × 10−5 | 0 | 0 |

| 320,553.4 | 4,013,520 | 25 | 0.00 | 6.71 × 10−5 | 0 | 0 |

| 320,904.7 | 4,013,513 | 2 | 0.00 | 6.71 × 10−5 | 0 | 0 |

| All 31 wells | 4.01 × 10−3 | 2.34 × 10−3 |

| Well # | Relative Distance to Nearby Injection Well | Distance (m) to Nearby Injection Well | Well Coordinate X (m) | Well Coordinate Y (m) | CO2 Leakage (MT) | Brine Leakage (MT) |

|---|---|---|---|---|---|---|

| 7 | close | 367 | 316,988 | 4,014,458 | 2.25 × 10−4 | 7.43 × 10−5 |

| 15 | closer | 121 | 319,426 | 4,015,635 | 6.30 × 10−4 | 8.66 × 10−5 |

| 11 | closest | 112 | 319,003 | 4,014,425 | 6.98 × 10−5 | 7.98 × 10−5 |

| 22 | In the middle of Injection wells | 360 | 319,780 | 4,013,646 | 7.76 × 10−5 | 7.94 × 10−5 |

| 31 | far | 775 | 320,905 | 4,013,513 | 0 | 6.71 × 10−5 |

| 6 | farther | 801 | 317,001 | 4,015,657 | 2.14 × 10−4 | 7.93 × 10−5 |

| 2 | farthest | 1310 | 316,534 | 4,016,479 | 0 | 6.71 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, S.; Viswanathan, H.; Moodie, N. Legacy Well Leakage Risk Analysis at the Farnsworth Unit Site. Energies 2023, 16, 6437. https://doi.org/10.3390/en16186437

Chu S, Viswanathan H, Moodie N. Legacy Well Leakage Risk Analysis at the Farnsworth Unit Site. Energies. 2023; 16(18):6437. https://doi.org/10.3390/en16186437

Chicago/Turabian StyleChu, Shaoping, Hari Viswanathan, and Nathan Moodie. 2023. "Legacy Well Leakage Risk Analysis at the Farnsworth Unit Site" Energies 16, no. 18: 6437. https://doi.org/10.3390/en16186437

APA StyleChu, S., Viswanathan, H., & Moodie, N. (2023). Legacy Well Leakage Risk Analysis at the Farnsworth Unit Site. Energies, 16(18), 6437. https://doi.org/10.3390/en16186437