1. Introduction

Digital twin technologies have gained popularity among researchers since they were proposed in 2003 by Grieves [

1]. After two decades of development, digital twins have undergone intensive development in various fields, such as industry [

2,

3], construction [

4,

5], communication [

6], and power grids [

7]. For example, Tao et al. summarized the state-of-the-art of digital twins in industrial applications in [

2], including product design, production, and health management.

Because digital twins provide a variety of powerful functionalities, they are enabling technologies for various purposes. For instance, they can be used in power generation systems, such as power plants, including fossil fuel power, nuclear and renewable energy power plants [

8], solar PV plants [

9], hydro generators using finite element simulation [

10], and distributed generation systems [

11]. In addition, digital twins have been applied to wind turbines for fault prediction [

12] and an offshore wind turbine with an output prediction model [

13]. In [

14], a digital twin high-frequency generator with self-excitation was developed using MATLAB 2021/Simulink. However, most of the aforementioned research studies only provide conceptual designs or algorithms without detailed hardware and software descriptions and they lack physical-twin twinning.

The digital twin technologies can be potentially used in the verification of the new algorithms design for the energy sector, such as multi-objective optimization for a solar hybrid steam power plant [

15], failure prevention in microgrid systems [

16], deep recognition networks of capacitor voltage transformers [

17], and solar power forecasting [

18], etc. If the algorithms can be validated on a real-time data monitoring platform with physical twins, they could greatly improve the reliability and validity of the algorithms.

Digital twins have also been used in diesel generators [

19], which focused on backup and emergency power supply systems. After years of development, diesel generators have realized many ways of combining with other energy sources. Not only the diesel generator system, but also the wind–diesel hybrid system has helped to maximize the contribution of wind resources in local power generation [

20]. In this paper, we also investigate the diesel generator. However, we focus on the design and implementation of the entire system and its use purposes.

With the development of the Internet-of-Things (IoTs), networked control, and data-driven modeling technologies as well as digital twins can be developed in a more complex form and used for advanced applications. These factors can be potentially addressed if the digital twin applications are built on the foundations of a scalable and interoperable framework that can drive a digital twin application across the project lifecycle: from ideation to theoretical deep dive to proof of concept to large-scale experiment to real-world deployment at scale [

21]. This paper uses advanced digital twin technologies, the IoTs, networked control, and data-driven modeling to construct a diesel generator digital twin platform, which aims to realize various applications, such as three-dimensional (3D) visualized real-time modeling, monitoring and simulation.

2. Motivation and Contribution

Diesel engine generator systems are crucial in providing power in stationary power-generation units such as distributed remote site power systems [

22,

23] and ships’ power systems [

24,

25]. Because they are a key infrastructure, the understanding of diesel engine generator systems is vital for use and maintenance purposes. This paper explores a web-based digital twin generator platform with the following features and functionalities:

(1) Online access to the physical diesel generator system and its digital twin; users can use a web browser to remotely access developed experimental resources and perform 3D visual experimental operations.

(2) Through the combination of mechanism and data-driven, a mathematical model of the generator system is established, and the mathematical model is combined with the 3D model to build a digital twin. They are linked with each other through the network data link to realize the high reproducibility of physical systems through digital twins.

(3) The algorithm-driven method is used to realize the comprehensive and real-time online monitoring and display of generator parameters, and the 3D animation display of the digital twin is driven in real time by the parameters of the actual generator.

(4) According to the needs of teaching and scientific research, remote experiments and virtual simulation experiments can be developed based on the digital twin system, including load experiments and excitation experiments. The digital twin platform can also be used as a scientific research platform for parameter identification and fault diagnosis for more in-depth scientific research.

Based on the features and functionalities, the novelties of the proposed digital twin generator system are summarized as follows.

A five-layer architecture for network based digital twin systems is proposed in this paper. As a general framework, the sophisticated architecture can not only be used for the diesel generator systems proposed in this paper, but it can also be applied to many other digital twin systems.

In terms of the mathematical modeling and real-time code generation, two roadmaps are provided for users to quickly implement their digital twin systems.

The digital twin mathematical model can be built in a Simulink environment and the block diagrams can be converted into a real-time simulation program using a modified Simulink Coder.

As an alternative, the user can also design and quickly implement the mathematical model using M2PLink, which is a fully web-based system developed to replace conventional commercial modeling software like MATLAB/Simulink.

A web-based real monitoring interface with various widgets such as dynamical charts, oscilloscopes and number inputs is implemented in this paper. In order to enhance the sense of presence, 3D animations which are synchronized with the real-time simulation are also provided in the user interface.

Generally, this paper provides a general web-based framework for digital twin applications, from design, modeling, implementation, real-time monitoring and 3D visualization.

3. Architecture

In this section, the overall architecture of the digital twin diesel generator system is introduced. The digital twin diesel generator is constructed as an online platform; thus, users (a student, a teacher, or a researcher) can access the digital twin system via a mainstream web browser, such as Google Chrome, Microsoft Edge, or Mozilla Firefox.

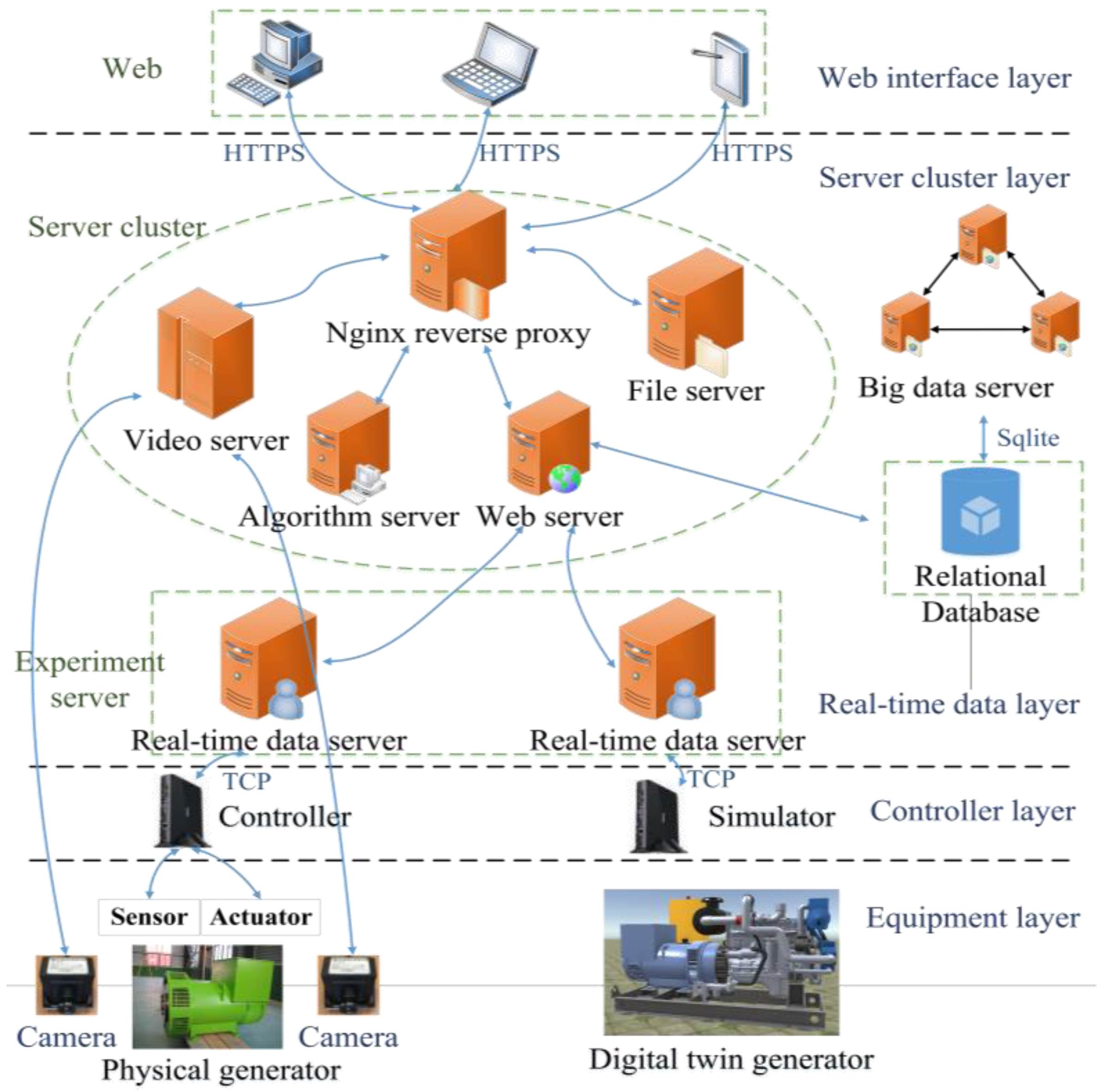

Using a multi-layer high-performance network architecture, we can construct the networked digital twin generator platform as shown in

Figure 1, which includes a web interface layer, server cluster layer, real-time data layer, controller layer, and equipment layer. Both physical and digital twin generator systems can be connected to the system through this architecture. Through this architecture, users can log into the corresponding URL with a browser and remotely access the system’s resources, operating the physical generator and its digital twin. Any operation that can be performed on physical equipment, including the design and generation of algorithms, the execution of algorithms, the configuration of the monitoring interface, and remote data monitoring (real-time images and real-time 3D visualization), can be realized in the form of online experimentation.

3.1. Web Interface Layer

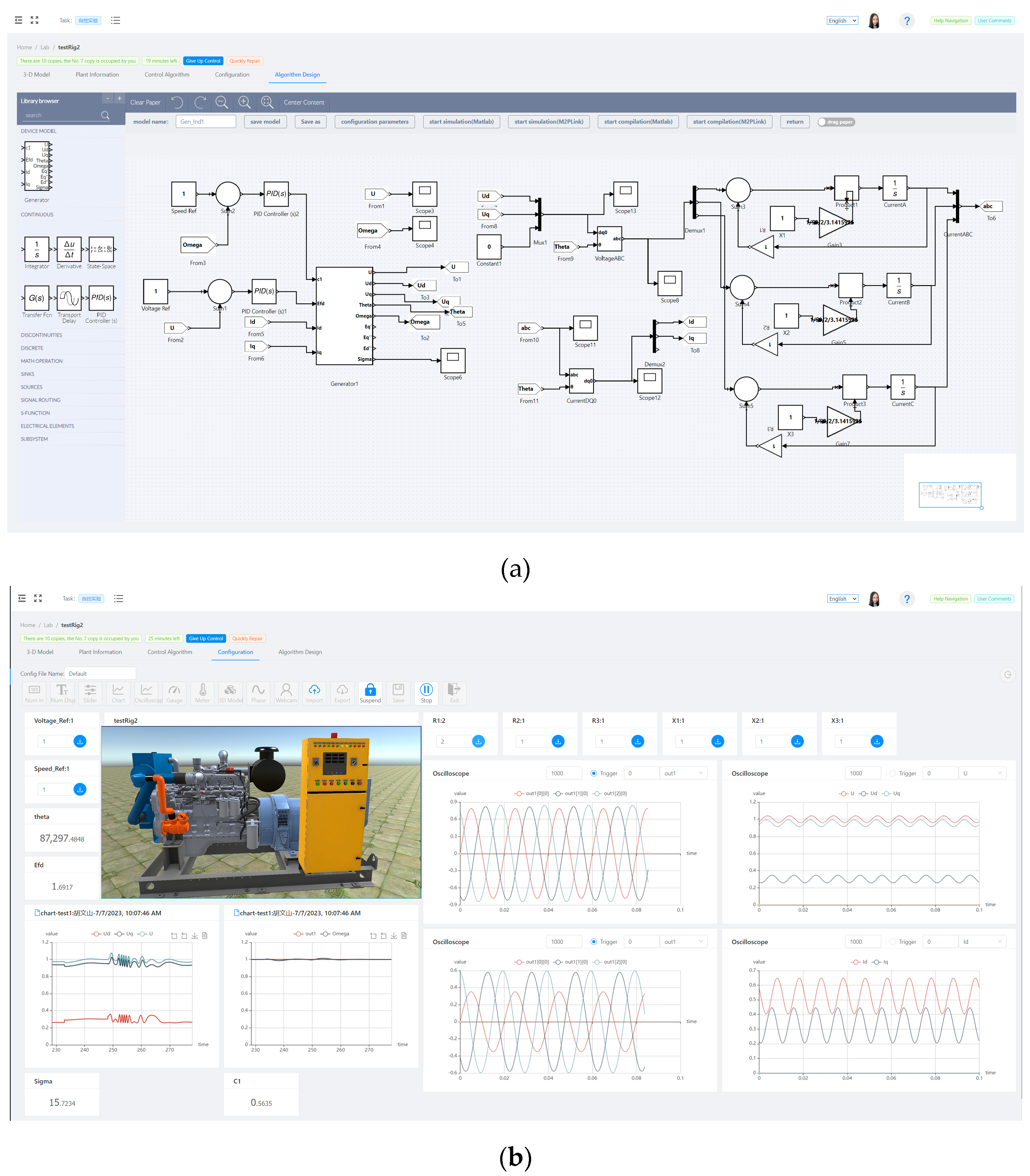

The web interface is developed using HTML5 technology, which can realize plug-in-free access. The frontend provides the interface of the system, including the system management interface, status monitoring interface, curve display interface, digital twin display interface, and algorithm design interface. Some of the interfaces are shown in

Figure 2. After logging into the system, users can remotely operate the physical generator system and the corresponding digital twin system through the frontend interface. The system interface adopts a user-friendly graphical visualization, which supports the design, generation, upload, and execution of monitoring algorithms, the configuration of the monitoring interface, remote data monitoring, such as remote real-time image and real-time 3D visualization, as well as other functions.

3.2. Server Cluster Layer

The server cluster layer provides data support services for the frontend and adopts the data processing mode of separating dynamic and static data. Static data such as user data are stored in a relational database, and real-time dynamic data are stored in a real-time database or big data platform. The server cluster layer provides a series of application services for the platform, including data communication services and algorithm design services. It mainly includes the following types of servers.

Web server: stores frontend code that is developed using the REACT framework with many open-source modules such as Joint.js, Echart.js, and Three.js.

File server: stores static files, including configuration files and control algorithms.

Algorithm server: receives the configuration of the control algorithm designed by the frontend user in the form of a block diagram, and converts the block diagram of the control algorithm into executable control code; diagrams and converts the block diagram of the control algorithm into executable control code.

Video server: collects the monitoring data streams of the camera, converts the format, and pushes it to the frontend in real time.

Big data server: stores real-time data from system operation, including system experimental data and operation data of user behaviors.

Relational database server: stores static data, including system configuration, user login information, and equipment information.

Nginx reverse proxy server: serves as the entry point of the system, integrating various services and publishing them on a unified website.

3.3. Real-Time Data Layer

The real-time data layer is deployed with an experiment server, which is connected to the controller through the TCP protocol and the web interface layer through the WebSocket protocol. The experiment server is a bridge interface between the web interface and the physical and virtual devices; on the one hand, it uploads real-time data from the equipment layer to the frontend; on the other hand, it receives the control commands (e.g., algorithm downloading, parameter tuning) from the web interface layer and transmits them down to the equipment layer for execution.

3.4. Controller Layer

The controller layer includes physical and virtual controllers (otherwise called simulators), both developed in embedded systems that can run control programs generated by the algorithm servers. The physical controller drives the physical generator through hardware interfaces (such as AD, DA, and PWM) to achieve remote control. The virtual controller runs a mathematical model of the generator to simulate the operation of the generator. The physical and virtual controllers use the same data interface and use the network interface to communicate with the experiment server in real time.

3.5. Equipment Layer

The equipment layer includes the physical and digital twin of the generator. For the physical equipment, various sensors (voltage, current, temperature, flow, vibration, etc.) and actuators (excitation, speed regulation, etc.) are installed and connected to the controller through a hardware interface.

The digital twin of the generator is presented in the form of a virtual replica, and the operating state of the physical equipment can be simulated through a mathematical model and a 3D model, to achieve the effect of combining virtual and real equipment. The system architecture can not only be used to build a digital twin of the generator system, but is also highly scalable. Other physical systems and digital twin systems can also be connected to this platform with the same structure to achieve unified management. The system is also customizable, and all or part of the functions can be deployed for different functional requirements. It is a lightweight service that can be deployed in a single laptop.

4. Design and Implementation of Digital Twin

Based on the five-layer architecture, the digital twin of the diesel generator can be designed and implemented. The mathematical model of the generator system can be built using both Simulink and M2Plink [

26], and then implemented into the proposed architecture, through which the users can operate the digital twin system using a web-based interface through networks.

4.1. Mathematical Modeling of Diesel Generator

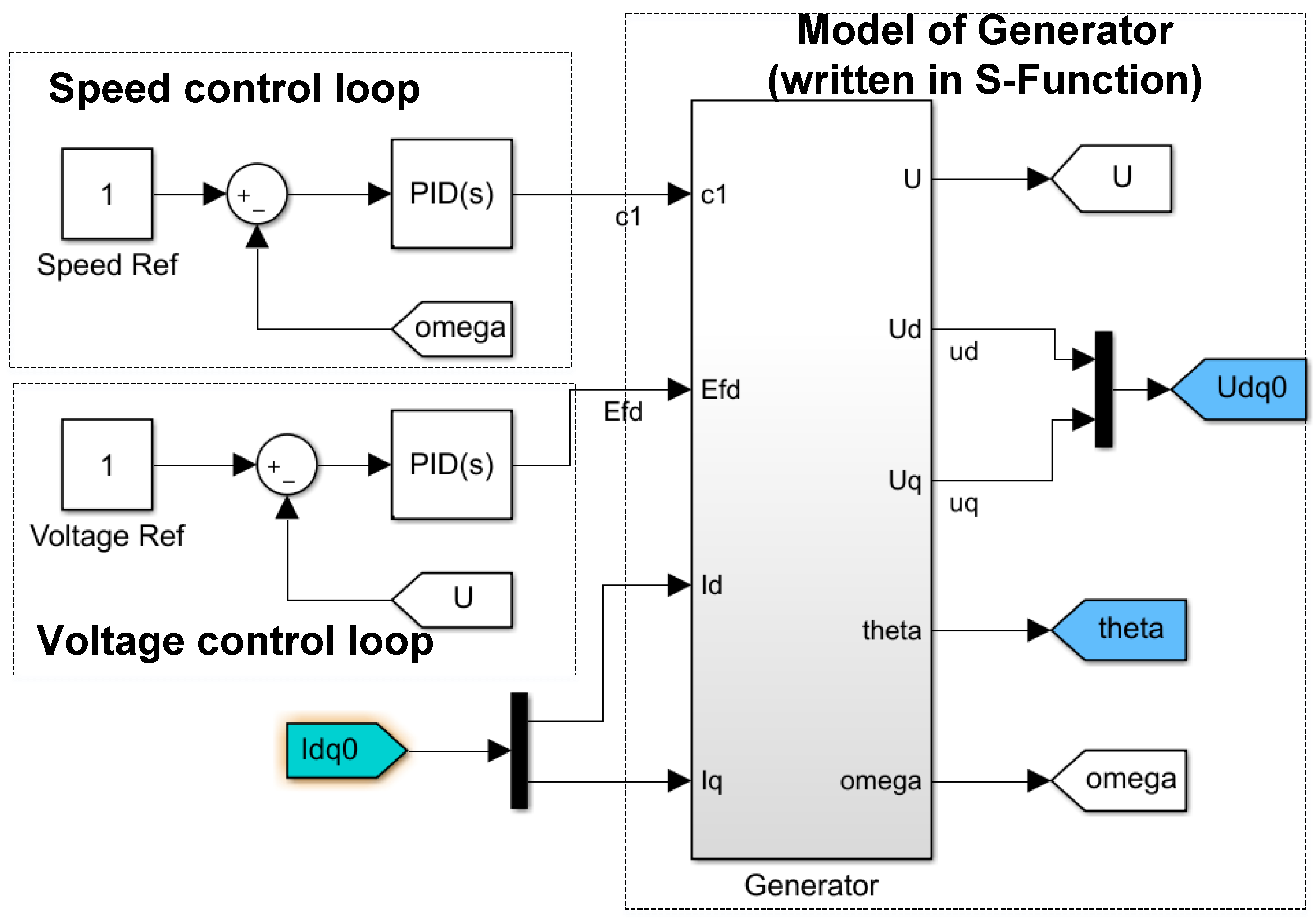

On the basis of the digital twin architecture, a mathematical model of the generator system is established, and the structure of the model is shown in

Figure 3. The mathematical model includes three parts: the diesel generator, the control system, and the electrical loads.

Generation system model: The diesel power generation system model includes a diesel engine, generator, and electrical loads.

The control system includes excitation control and speed control. In this case, simple PI strategies are implemented into the base control loops, and various control algorithms can be used in real time.

The load part adopts the electronic load to establish the steady-state mathematical model of the electronic load. The dynamic mathematical model of the switching load is also constructed. The three phase loads are built independently and by adjusting the load parameters in real time, both the balanced and the unbalanced load can be emulated.

As shown in

Figure 3, the mathematical model built using Simulink can be converted into executable codes using a Simulink Coder. The original Simulink Coder is modified, as the communication interface between the real-time simulator and servers is added to the framework [

27]. The generated real-time simulation codes with network communication capacities are downloaded and executed inside the real-time simulators. During the real-time simulation, the dynamical 3D model in the frontend and the real-time simulation implemented in the backend are synchronized through the network connections, by which 3D visualization is also provided for the users.

4.1.1. Mathematical Model for the Generator

The synchronous generator is modeled on the d-q (direct-quadrant) axis. It is described on the per unit (p. u.) basis. Some insignificant issues are ignored for the sake of simplicity.

- (1)

The effect of magnetic saturation of the core is ignored and the permeability coefficient is constant.

- (2)

The motor magnetic circuit and windings are completely symmetrical.

- (3)

The effects of the harmonic magnetic potential, harmonic flux and the corresponding harmonic electric potential are ignored.

The mathematical model of the electromagnetic transient process of the diesel generator includes the stator voltage balance equation and the rotor winding electromagnetic transient equation of the synchronous generator. As the rotor of the generator is rigidly connected with the diesel crankshaft, then all the processes in the diesel cause the changing distribution of the magnetic flux in the air gap and, therefore, the spectral composition of the output current and voltage of the synchronous generator [

28]. The simplifications made by the synchronous generator model are: (1) ignoring the stator winding transient; and (2) considering only the influence of the positive sequence component on the generator transient process and omitting the zero-axis magnetic chain voltage equation in the Pike equation.

The generator model is described as follows:

where

c1 is the input torque from the diesel engine,

Ef is the input excitation voltage,

Id and

Iq are the d-axis and q-axis input currents,

Ud and

Uq are the d-axis and q-axis output voltages,

U is the stator winding terminal voltage,

ω is the electrical speed,

θ is the electrical angle,

Ed″ is the d-axis transient potential,

Eq′ is the q-axis transient potential, and

Eq″ is the q-axis transient potential. Apart from the variables, the basic parameters of the generators such as the winding resistance, winding reactance, open-circuit constants, and inertial constant are listed in

Table 1.

4.1.2. Speed and Voltage Control

Various control strategies can be applied for the speed and voltage regulation of generator systems. The most straightforward and most commonly applied method in practical industrial applications is the proportional-integral (PI) control strategy, which mainly aims to improve the steady state performance of the control system. PI control is widely used in industrial control, automation control, robot control and other fields, especially in motor control and power system stability analysis with many contributions. For example, [

29] presents the design and implementation of a PI-controller on a 10 kVA STATCOM prototype with simulation and experimental verification. The PI controllers for the speed and voltage loop can be described as

where

PU and

IU are the PI parameters for the voltage loop,

Pω and

Iω are the PI parameters for the speed loop,

Ur is the reference voltage,

U is the actual voltage,

ωr is the reference electrical speed, and

ω is the actual electrical speed.

There are two feedback control loops in the generator control system. For the voltage loop, the difference between the reference voltage Ur and actual voltage U is calculated as Uerr using (9). Based on Uerr, the excitation voltage Ef can be obtained by the PI control algorithm (10) and applied into the excitation circuit. Through the adjustment of the excitation, the voltage U can be properly regulated to follow the reference voltage Ur. The speed loop utilizes a similar principle. In this case, the PI controller in (11) and (12) adjusts the diesel engine torque c1, by which the generator speed ω can be regulated to follow the reference speed ωr.

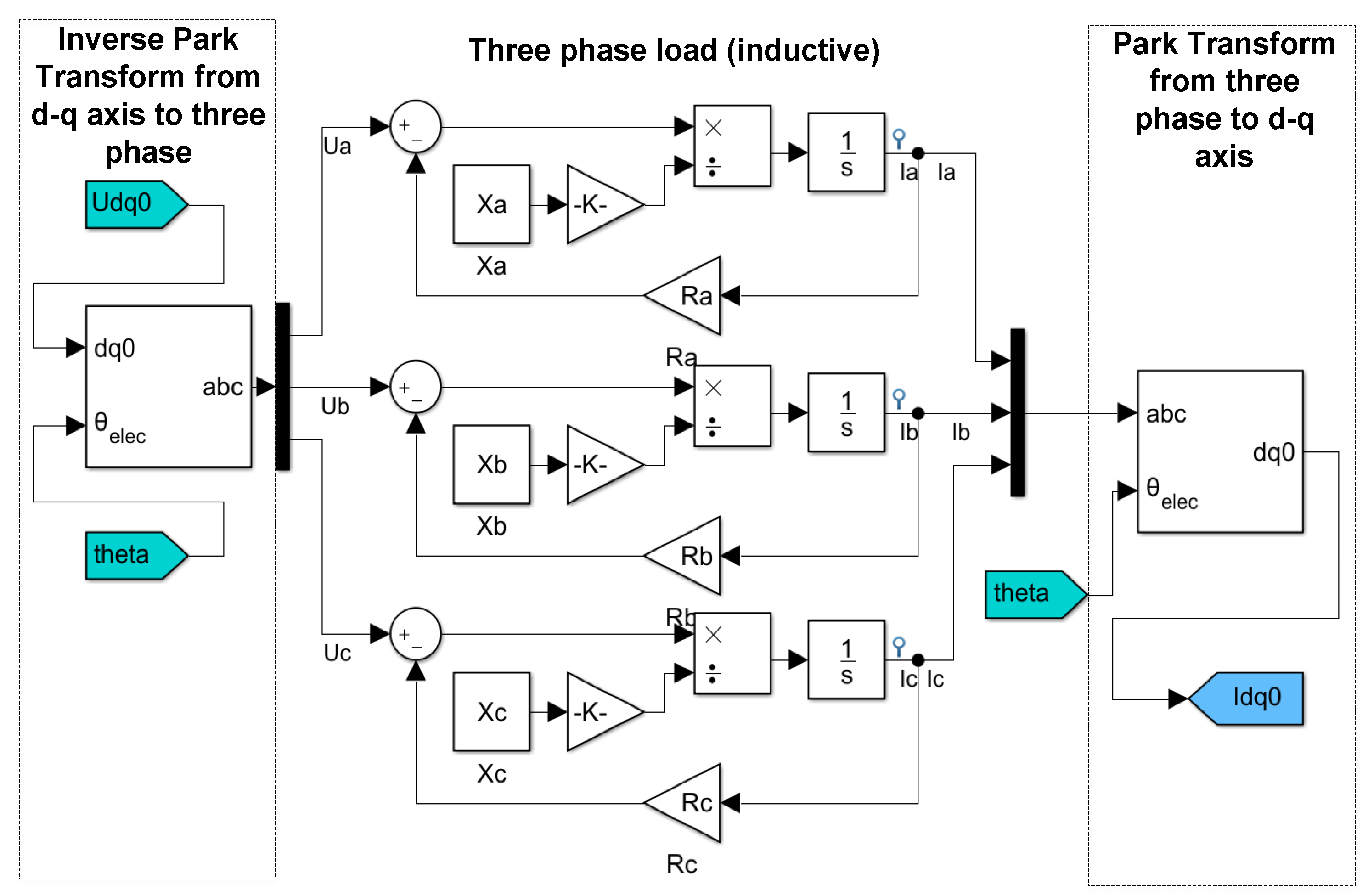

4.1.3. Electrical Loads

For the sake of simplicity, only the linear loads are modeled in this case. Using the Park transform, we convert the d-q voltages and currents into three phases. The loads on the three phases are modeled separately using transfer functions. The loads can be resistive, inductive and capacitive depending on the forms of the corresponding differential equations. By adjusting the parameters in the differential functions, the three-phase load can be changed in real time and the unbalanced loads can also be simulated by applying an unbalanced load to the generator system.

4.2. Implementation of the Mathematical Model

4.2.1. Implementation with MATLAB/Simulink

Mechanism-based modeling can be implemented using MATLAB/Simulink, in which the modeling of mechanical parts can be abstracted into transfer functions and differential equations, which are completed using the control system toolbox. The mathematical model of the generator is created using customized S-Functions in which the differential Equations (1)–(8) are written in C codes. The control systems and the load are built using the blocks provided by Simulink, which is shown in

Figure 4.

Figure 5 shows an example of the block diagram for inductive loads. As the inputs, the d-q axis voltages from the generators are converted into the three phases and applied to the three separate loads. The three-phase current responses are obtained and converted into the d-q axis as the output.

Rx and

Xx are the resistance and inductive impedance of the load for each phase, respectively.

As indicated in

Figure 4 and

Figure 5, the outputs of the generator model are exactly the input of the electrical load and vice versa. By putting the two parts together, the full model of the generator digital twin is created. After the model is built, the MATLAB coder is used to convert the simulation program into a real-time simulation program and run it out of the MATLAB/Simulink environment. The original Simulink Coder is modified and extra codes for communications between the controller layer and real time data layer are added into the original Simulink Coder framework [

27], therefore the generated codes are able to communicate with the experiment servers in real time.

The generated executable codes can be uploaded into the private control algorithm list in the web interface, with which the user can conduct online experiments on the digital twin. By customizing the monitoring interface such as in

Figure 2b, the users are able to monitor all the signals in the digital twin using various widgets such as charts and oscilloscopes, and also adjust the parameters, such as the control parameters and loads, in real time.

4.2.2. Implementation Using M2Plink

Although MATLAB/Simulink has many advantages in mathematical modeling, it is commercial software with substantial costs. As an alternative solution, M2Plink, which is a core part of the M2PLab [

26] system, has been developed to replace Simulink. It allows users to build the graphical algorithm block diagram by connecting the blocks provided in the interface.

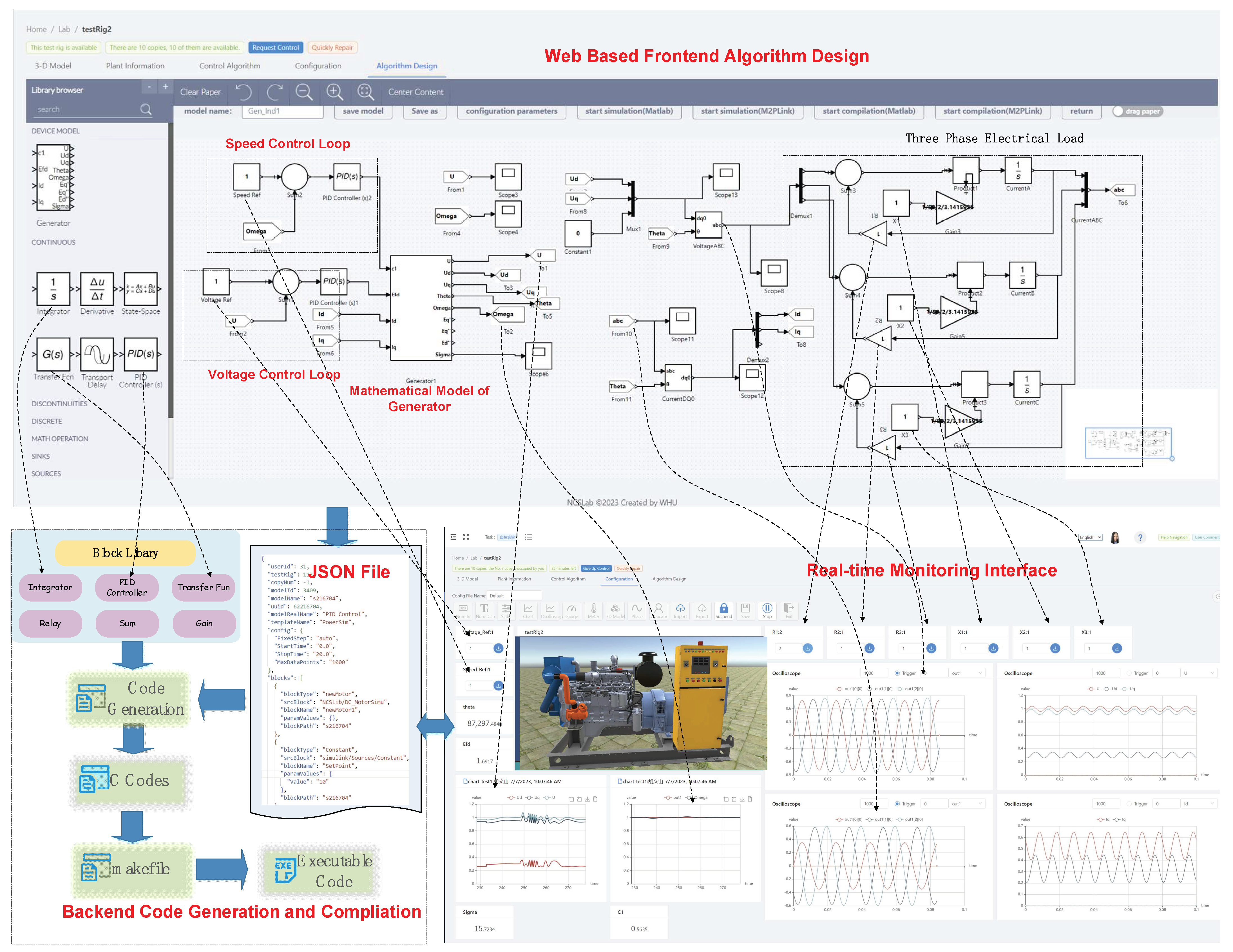

Figure 6 shows the road map of the building and implementation of the digital twin for the diesel generator using M2PLink. There are two parts in M2PLink, one is the frontend algorithm design interface, and the other is the backend simulation and code generation engine.

The algorithm design interface is designed based on the Joint.js framework which is a community-driven diagramming library that helps developers to create flowchart applications. The M2PLink algorithm design interface provides various control module blocks similar to Simulink. Apart from the normal blocks such as Integrator, PID Controller and Transfer Functions, a block named Generator which represents the diesel generator mathematical model is provided for the users. Based on the given blocks, the users are able to create the mathematical models of the digital twins by dragging the blocks into the workplace and connecting these blocks.

The top part of

Figure 6 shows a typical model for a generator system, in which both the speed control and excitation loop are placed on the right-hand side to regulate the generator speed and voltage. An inductive three-phase electrical load is placed on the right side and its impendence parameters can be modified in real time.

After the block diagram is created, both the blocks and connections are described in JSON (JavaScript Object Notation) format. Therefore, the whole block diagram can be packaged and sent to the backend in a JSON file where the diagram is analyzed and parsed into excitable codes.

- 2.

Code Generation Engine on the Backend

The entire information on the algorithm block diagram is packaged as data in JSON format and sent to the backend when the algorithm block diagram is required to be compiled. The backend code generation engine parses the blocks and their connections one by one and corresponding real-time digital twin codes in C language can be generated. Each block in the frontend has the corresponding logic code module in the backend, and the parameter values from frontend blocks are also passed to backend logic code modules. Using different C compilers and makefiles, the codes can be compiled for multiple platforms such as PC Windows, PC Linux, and Raspberry PI.

4.3. 3D Visualization for Diesel Generator Digital Twin

Apart from the various widgets, 3D visualization of the generator system shown in

Figure 7 is also provided for the users as shown in the monitoring interface.

As the digital driving engine of the digital twin system, the real-time simulation program is dynamically linked with the 3D model at the web interface of the user through the network data link, which achieves a high degree of reproduction of physical equipment. Users are able to watch the 3D replicas from different angles, which could enhance their sense of presence, even though they are operating on digital twins.

4.4. Web-Based Real-Time Monitoring Interface for Diesel Generator Digital Twin

The executable codes generated by Simulink or M2PLink are stored in the users’ private control algorithm list. These algorithms can be downloaded to the controllers in the device layer where the real-time simulation for the digital twin can be implemented.

Once the real-time simulation is executed in the controller, the network communication between the simulation and frontend web-based monitoring interface can be established via the experiment servers. A web-based configuration interface is developed and various widgets, such as dynamical charts, oscilloscopes and number inputs, are provided for users to build their customized monitoring interface as shown in

Figure 6. All the signals inside the digital twin block diagram, such as the generator velocity, three-phase voltages and current, can be monitored and all the parameters, such as the PI controller parameters and electrical load parameters, can be tuned in real time. The bottom right part of

Figure 6 shows an example of the monitoring interface, in which four oscilloscopes are placed to show the three-phase voltage, d-q axis voltage, three-phase current and d-q axis current and two dynamical charts are placed to display the nominal voltage and generator rotation speed. Several number inputs are placed to allow the users to tune the three-phase load impedances and PI parameters for both the closed-loop speed control and voltage control.

4.5. Data-Driven Modeling and Identification

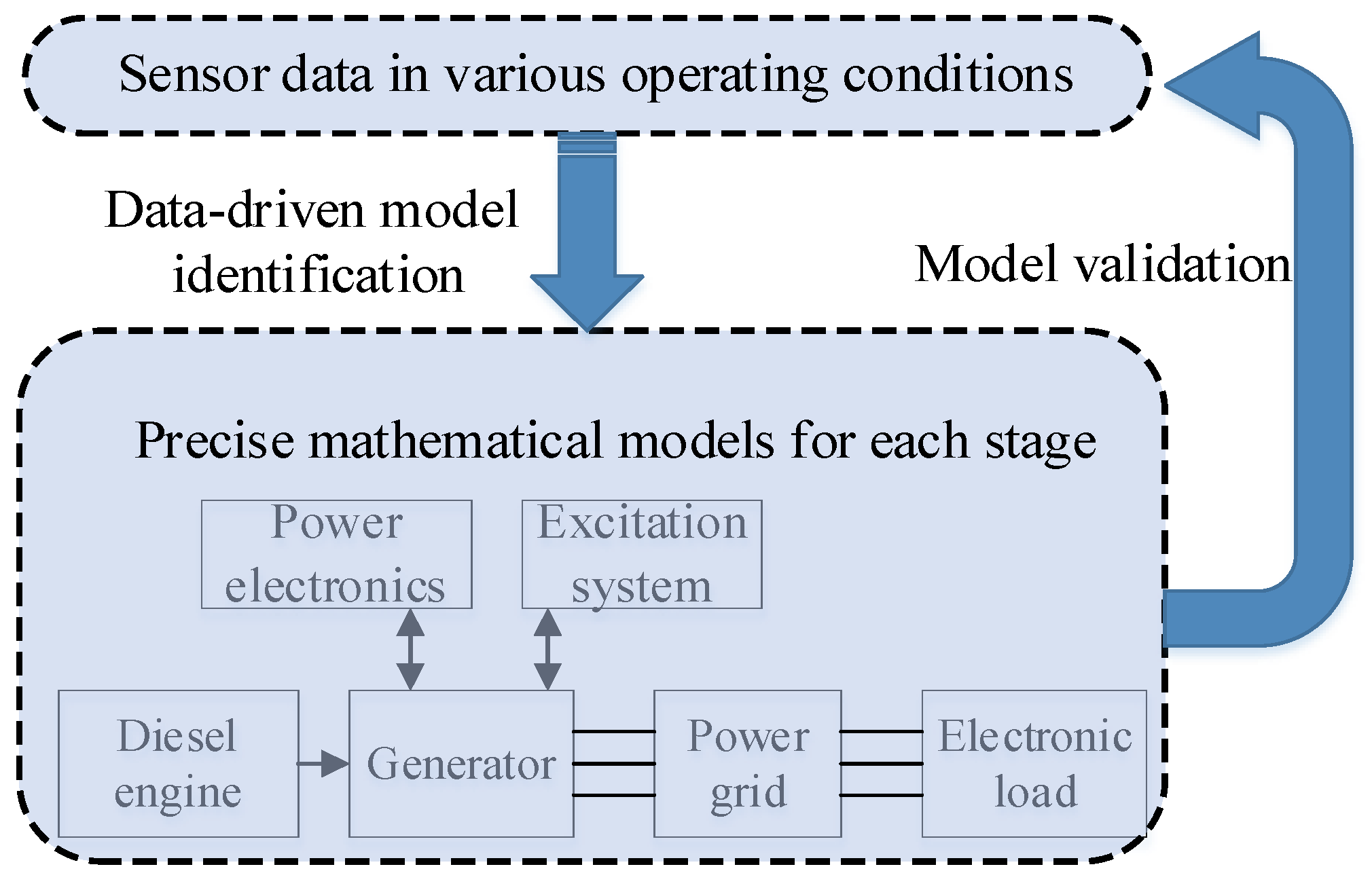

Mechanism-based modeling is idealized and may not fully reflect the dynamic characteristics of the system. For time-varying parts, data-driven modeling is adopted, as shown in

Figure 8. The overall system architecture is based on the mechanism model; however, based on massive operating data, some internal parameters of the system are obtained by system identification. The system operation data are collected from the physical diesel generator system, on which a large number of sensors is installed. In this way, the physical quantities of each link on the physical system can be collected.

The data-driven modeling and identification process is as follows: (1) designing modeling experiments and letting the system run under various working conditions; (2) collecting data under different working conditions; (3) using big data analysis methods to establish mathematical models of each link, and identifying the parameters of the model.

For the identified model, it is necessary to verify the actual data. If the model can reflect the dynamic characteristics of the actual data, the model can be accepted; otherwise, the experiment should be redesigned for new identification, which is an iterative process. As more data become available after running the model, the model will become increasingly accurate. The data-driven model can partially or completely replace the mechanism model, making the mathematical model more accurate, which can reflect the dynamic characteristics of the diesel generator system more accurately.

5. Potential Use

5.1. Comprehensive Experimentation with the Web Interface

The digital twin diesel generator system can be accessed remotely online because the physical and digital twin generators are deployed as network resources. Users can use a browser, log in to the corresponding URL anytime, anywhere, and operate remote physical and digital twin systems to carry out corresponding experiments. Everything that can be done in local experiments, including the design of monitoring algorithms, the generation of monitoring algorithms, the upload of monitoring algorithms, the execution of monitoring algorithms, the configuration of the monitoring interface, and remote data monitoring, can be carried out by the designed online experiments.

5.2. Digital Twin-Assisted Real-Time Online Monitoring of Diesel Generator

The algorithm-driven method is adopted to realize comprehensive, real-time online monitoring and display of generator parameters. Different types of parameters can be monitored, including three-phase voltage, current, active power, reactive power, frequency, power factor, apparent power, speed, water temperature, oil temperature, oil pressure, motor status, bearing vibration and others. Software-defined support is provided for the online selection and setting of monitoring parameters, and parameters are displayed in a variety of configuration formats, including curve charts, line charts, and pie charts. At the same time, the 3D animation display of the digital twin is driven in real time by the parameters of the actual generator.

5.3. Digital Twin for Research and Education

Through the combination of mechanism- and data-driven methods, an accurate mathematical model of the generator system is established. On the basis of the mathematical model, a digital twin of the generator system is constructed together with the 3D model. In the digital twin system of the generator, the real-time simulation of the 3D model and the mathematical model is linked through the network data link to achieve a high degree of reproduction of the physical system. Any experiment that needs to be performed on a physical system can be initially verified on the digital twin using 3D visualization, which saves time and money and avoids possible dangers to the users or the physical equipment. According to the needs of teaching and scientific research, remote experiments and virtual simulation experiments on the digital twin system, including load experiments and excitation experiments, can be conducted. These experimental projects can be completed in the form of remote experiments, operating physical generator equipment, or virtual experiments on 3D visualized digital twins.

6. Conclusions

In this paper, a digital twin diesel generator system, which plays an important role in stationary power-generation units such as distributed remote site power systems and ships’ power systems, was proposed considering teaching, learning and research purposes. The following work has been accomplished in the paper.

A five-layer architecture, namely, the web interface layer–server cluster layer–real-time data layer–controller layer–equipment layer, is outlined, and each of the layers is discussed in detail; this forms a general framework for digital twin implementation.

Two roadmaps are provided to design, build and implement the digital twin systems. The users are able to use either most commonly used MATLAB/Simulink or MP2Link which is a web-based system to replace commercial modeling software.

A web-based real-time monitoring interface with various widgets including 3D visualization is also introduced in the paper.

The mathematical model, data-driven modeling and identifications, and development of teaching tasks are discussed to detail the potential use of the digital twin diesel generator system.

Generally, the proposed system can be used for comprehensive experiments with web accessibility, which provides cost-effective and safe experiments for research and educational purposes.

In the future, the digital twin diesel generator system will be applied to more experiments, and more usage and feedback data will be collected for further analysis and improvement. Our future research work will focus on the real-time fault identification of diesel generator systems under different working conditions, which is rarely considered in this paper.

Further, future research direction will also consider the economic evaluation of digital twin diesel power generation systems and the possibility of investment [

30]; this work will consider the introduction of option value [

31] and a new class of optimization models for identifying the optimal investment strategy [

32], which will have the potential to further expand the capacity of this work in terms of innovation and business value. This is because better economic efficiency can expand the scope of application of the system and promote the value of the new technology.

Author Contributions

Conceptualization, X.D., J.H., N.L. and W.H.; methodology, X.D.; software, W.H.; validation, X.D., W.H. and Z.L.; writing—original draft preparation, X.D.; writing—review and editing, J.H., N.L., W.H. and Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the National Natural Science Foundation of China under Grant 62073247 and National Science and Technology Major Project under Grant No. HT-J2019-I-0012-0012.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication—A Whitepaper by Dr. Michael Grieves. White Paper, March 2014, pp. 1–7. Available online: https://www.researchgate.net/publication/275211047_Digital_Twin_Manufacturing_Excellence_through_Virtual_Factory_Replication (accessed on 2 June 2023).

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Hu, W.; Liu, G.-P.; Guan, S.; Feng, X. Toward a Web-Based Digital Twin Thermal Power Plant. IEEE Trans. Ind. Inform. 2021, 18, 1716–1725. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Nguyen, H.X.; Trestian, R.; To, D.; Tatipamula, M. Digital Twin for 5G and Beyond. IEEE Commun. Mag. 2021, 59, 10–15. [Google Scholar] [CrossRef]

- Digital twin and its application to power grid online analysis. CSEE J. Power Energy Syst. 2019, 5, 391–398. [CrossRef]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Yalçin, T.; Paradell Solà, P.; Stefanidou-Voziki, P.; Domínguez-García, J.L.; Demirdelen, T. Exploiting Digitalization of Solar PV Plants Using Machine Learning: Digital Twin Concept for Operation. Energies 2023, 16, 5044. [Google Scholar] [CrossRef]

- Moussa, C.; Ai-Haddad, K.; Kedjar, B.; Merkhouf, A. Insights into digital twin based on finite element simulation of a large hydro generator. In Proceedings of the 44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 553–558. [Google Scholar] [CrossRef]

- Bulatov, Y.N.; Kryukov, A.V.; Korotkova, K.E. Digital Twin of the Distributed Generation Plant. IOP Conf. Ser. Mater. Sci. Eng. 2020, 976, 012024. [Google Scholar] [CrossRef]

- Ma, J.; Yuan, Y.; Chen, P. A fault prediction framework for Doubly-fed induction generator under time-varying operating conditions driven by digital twin. IET Electr. Power Appl. 2022, 17, 499–521. [Google Scholar] [CrossRef]

- Kim, C.; Dinh, M.-C.; Sung, H.-J.; Kim, K.-H.; Choi, J.-H.; Graber, L.; Yu, I.-K.; Park, M. Design, Implementation, and Evaluation of an Output Prediction Model of the 10 MW Floating Offshore Wind Turbine for a Digital Twin. Energies 2022, 15, 6329. [Google Scholar] [CrossRef]

- Murashov, I.; Zverev, S.; Smorodinov, V.; Grachev, S. Development of digital twin of high frequency generator with self-excitation in Simulink. IOP Conf. Ser. Mater. Sci. Eng. 2019, 643, 012078. [Google Scholar] [CrossRef]

- Beyralvand, D.; Yaghoubi, M. 4E analysis and multi-objective optimisation for a solar hybrid steam power plant using ABC algorithm: A case study in Iran. Int. J. Power Energy Convers. 2021, 12, 44. [Google Scholar] [CrossRef]

- Belkacemi, R.; Zarrabian, S. Real-time intelligent control and cascading failure prevention in microgrid systems based on neural network algorithm: An experimental approach. Int. J. Power Energy Convers. 2016, 7, 292. [Google Scholar] [CrossRef]

- Wu, J.; Li, S.; Chang, Z.; Chen, M.; Xiong, X.; Duan, Z. A deep recognition network of capacitor voltage transformer based on dilated convolution and Bi-LSTM. Int. J. Power Energy Convers. 2022, 13, 131. [Google Scholar] [CrossRef]

- Majumder, I.; Bisoi, R.; Nayak, N.; Hannoon, N. Solar power forecasting using robust kernel extreme learning machine and decomposition methods. Int. J. Power Energy Convers. 2020, 11, 260. [Google Scholar] [CrossRef]

- Isaev, A.V.; Nefed’Ev, A.I.; Isaev, I.A. Digital Twin Technologies for Diesel Generator Sets in Backup and Emergency Power Supply Systems. In Proceedings of the 2022 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 16–20 May 2022; pp. 1079–1084. [Google Scholar] [CrossRef]

- Haruni, A.M.O.; Gargoom, A.; Haque, M.E.; Negnevitsky, M. Voltage and frequency stabilisation of wind-diesel hybrid remote area power systems. In Proceedings of the 2009 Australasian Universities Power Engineering Conference AUPEC, Adelaide, SA, Australia, 27–30 September 2009; pp. 1–6. [Google Scholar]

- Gourisetti, S.N.G.; Bhadra, S.; Sebastian-Cardenas, D.J.; Touhiduzzaman, M.; Ahmed, O. A Theoretical Open Architecture Framework and Technology Stack for Digital Twins in Energy Sector Applications. Energies 2023, 16, 4853. [Google Scholar] [CrossRef]

- Sakamoto, O. An example of a diesel generator model with fluctuating engine torque for transient analysis using XTAP. J. Int. Counc. Electr. Eng. 2016, 6, 31–35. [Google Scholar] [CrossRef][Green Version]

- Benhamed, S.; Ibrahim, H.; Belmokhtar, K.; Hosni, H.; Ilinca, A.; Rousse, D.; Chandra, A.; Ramdenee, D. Dynamic modeling of diesel generator based on electrical and mechanical aspects. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Jia, J.; Dong, H. Research on ship power plant simulation system based on LabVIEW and MATLAB mixed programming. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 December 2017; Volume 2018, pp. 72–75. [Google Scholar] [CrossRef]

- Meng, J.; Lan, H.; Lin, T.; Liu, F. Robust L2 Control Design for Controllable Phase Compounding Excitation System of Marine Diesel Engine Generator. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012; pp. 12–15. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, G.-P.; Hu, W.; Lei, Z. M2PLab: A Pocket Laboratory with Unified and Flexible Framework Applied in Engineering Education. IEEE Trans. Ind. Electron. 2023, 1–10. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Hu, W.; Liu, G.-P. Controller Effect in Online Laboratories—An Overview. IEEE Trans. Learn. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- Gasparjan, A.; Terebkov, A.; Zhiravetska, A. Monitoring of electro-mechanical system diesel-synchronous generator. In Proceedings of the 2015 IEEE 5th International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Riga, Latvia, 11–13 May 2015; pp. 103–108. [Google Scholar] [CrossRef]

- Moharana, J.; Sengupta, M.; Sengupta, A. Design and implementation of a PI-controller on a 10 kVA STATCOM prototype. Int. J. Power Energy Convers. 2015, 6, 85. [Google Scholar] [CrossRef]

- Giannelos, S.; Konstantelos, I.; Strbac, G. Investment Model for Cost-effective Integration of Solar PV Capacity under Uncertainty using a Portfolio of Energy Storage and Soft Open Points. In Proceedings of the 2019 IEEE Milan PowerTech, Milan, Italy, 23–27 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Konstantelos, I.; Giannelos, S.; Strbac, G. Strategic Valuation of Smart Grid Technology Options in Distribution Networks. IEEE Trans. Power Syst. 2017, 32, 1293–1303. [Google Scholar] [CrossRef]

- Giannelos, S.; Konstantelos, I.; Strbac, G. Option Value of Demand-Side Response Schemes Under Decision-Dependent Uncertainty. IEEE Trans. Power Syst. 2018, 33, 5103–5113. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).