Abstract

The global interest in nearly zero-energy buildings (NZEBs) has led to their establishment as mandatory building objectives in Europe for all new constructions starting in 2021. The principles outlined in the Energy Performance of Building Directive (EPBD) emphasize the significance of reducing energy demand through various energy efficiency measures to achieve NZEB status. Among these measures, the utilization of high-performance glazing systems plays a crucial role in ensuring natural light, ventilation, favorable solar gain, aesthetics, and positive psychological effects in buildings, while maintaining high energy performance and thermal comfort without burdening the budget or harming the environment. The use of increasingly larger glazing areas makes this topic of great relevance. Nevertheless, numerous studies frequently overlook certain crucial aspects of glazing systems in their assessments. This review study aims to assess different glazing solutions based on four critical perspectives called “EThCE”: Energy performance, thermal comfort, cost-effectiveness, and environmental impact, considering their interrelationships. Furthermore, the importance of adopting a comprehensive approach for selecting the optimal glazing solution for NZEBs is discussed. Additionally, the relationship between glazing systems and climate change is taken into account. Ultimately, the authors propose a comprehensive approach, including all the influential factors, to assist designers and homeowners in making informed decisions regarding glazing system selection for new NZEBs or NZEB retrofits in different situations.

1. Introduction

The building sector was responsible for 132 EJ of energy consumption in 2021, or 30% of total global final energy consumption [1]. In the European Union (EU), the building sector accounts for roughly 40% of overall energy consumption and 36% of greenhouse gas (GHG) emissions [2]. The energy inefficiency of buildings, particularly older and historical structures, has been a topic of discussion due to the strain it places on energy resources, predominantly fossil fuels [3,4]. In addition, most of these buildings suffer from thermal discomfort that affects their occupants’ well-being and/or productivity [3]. In the case of the European Union (EU), it is estimated that a 5–6% reduction in total energy consumption and carbon dioxide emissions could be achieved by renovating existing buildings [2]. Therefore, the EU considers building energy efficiency a key action [5]. In line with the Paris Agreement goals, the Energy Performance of Building Directive (EPBD), revised in 2021, indicates that EU members should achieve a minimum 55% reduction in greenhouse gas (GHG) emissions by 2030 (compared with 1990 levels) and reach climate neutrality by 2050. To reach this goal, nearly zero-energy buildings (NZEBs) have become the mandatory building target in Europe for all new buildings since 2021 [6,7,8,9,10].

Among the various components that make up a building’s facade, a lot of attention has been paid to the window and glazing systems in recent years. Windows provide natural light, natural ventilation, favorable solar gain (in cold regions in the winter), aesthetics, and positive psychological impacts, making their use in buildings inevitable [11,12,13]. However, windows are among the most energy-inefficient parts of a building’s envelope, particularly due to their weakness in terms of thermal transmittance (U-value) [14]. Such factors can impact the performance of buildings, influencing aspects such as thermal comfort and energy consumption [15]. Different studies have presented varying estimates for the proportion of energy loss in buildings attributed to inefficient windows, with figures ranging from 20% to 60%. This variation is influenced by factors such as climate conditions, as well as the age, type, and size of the buildings [3,16]. This huge amount of energy loss is generally attributed either to a high U-value (leading to an increase in heating demand), a high g-value (increase in solar gains and cooling needs), or to a combination of both [17]. The U-values of windows are normally much higher than those of other elements, such as walls and horizontal elements. In fact, in the newest building codes introduced by most of the EU members, the U-value of windows is allowed to be four to six times the U-value of the opaque elements [11]. In addition, a high g-value for window glazing can allow a large portion of solar radiation to enter the building, resulting in an increase in cooling demands [3,15,16,18,19,20]. It was estimated that heat transfer through windows is responsible for about 1.5% of Australia’s energy consumption [21]. Curcija et al. [22] mentioned that, in the United States (US), windows in commercial buildings were assumed to use about 1.5% of the total energy consumption in 2011. This is equivalent to the amount of energy consumed by more than 8 million US households. In the literature review conducted by Ohlsson et al. [23], it was mentioned that for a typical “Passive House”, the total heat loss during the heating period is about 40 kWh·m−2·y−1, where 25 kWh·m−2·y−1 is lost through the windows, 8 kWh·m−2·y−1 associated with air renovation, and the remainder through the roof, walls, and ground.

The glazing component holds paramount importance within a window system since it often constitutes the largest proportion of the window area, resulting in its significant influence on the U-value of the entire window. Consequently, the glazing part exerts a substantial impact on the thermal properties of the window as a whole [24,25]. Therefore, the wise selection of window glazing is one of the most effective strategies to decrease energy consumption, facilitating the attainment of sustainable and low- or nearly zero-energy buildings [4,15,18,23,26]. However, selecting a glazing system for a building is not an easy task since many factors should be taken into consideration, including its thermal/optical properties (e.g., U-value, g-value, visible transmittance, etc.), the type of building, the window to wall ratio (WWR), window orientation, climate [27], and, more importantly, the possible impacts of the glazing system on the performance of the building. The fact that the aforementioned factors are interrelated further complicates the choice of glazing systems.

Looking to improve the thermal/optical properties of glazing systems, a wide range of solutions have been investigated by researchers [24]. These include multiple glazing, low-E and solar coatings and films [28], PV glazing [29], phase change materials (PCM) integrated glazing [25,30], water-flow glazing [31], aerogel glazing, vacuum glazing, ventilated glazing, smart glazing [32], etc., and a combination of these technologies [33]. Many of the aforementioned technologies are commercially available, while some of them are still under study. In addition, efforts have been made to optimize each of the mentioned solutions (e.g., optimizing the cavity thickness, adjusting the percentage of the filling gas in the cavity, investigating the positioning of the low-E coatings or films, etc.) [3,28]. Moreover, there have been numerous studies investigating the relationship between the performance of glazing systems and their outdoor/indoor boundary conditions, size, orientation, etc.

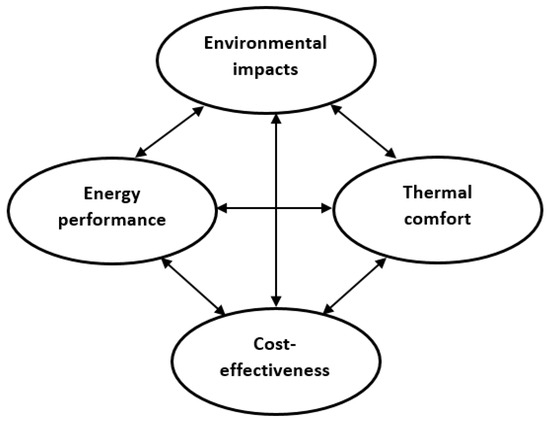

Y. Elaouzy and A. El Fadar [27] argued that investigating the performance of passive techniques (such as glazing systems upgrading) from one of the energy, economic, and environmental (3E) perspectives is insufficient since several factors from each criterion have a critical influence on the performance of the system [27]. Besides considering the 3E perspective, there is also the need to examine how glazing systems affect thermal comfort within buildings [34,35]. However, the literature review showed that numerous studies frequently overlook certain crucial aspects of glazing systems’ performance in their assessments. As a novel contribution of this study, in the pursuit of achieving nearly zero-energy buildings (NZEBs) with both healthy and comfortable indoor environments, the authors are extending beyond the 3E perspective and aim to establish a new set of glazing system evaluation criteria, henceforth referred to as “EThCE”, taking into account energy performance, thermal comfort, cost-effectiveness, and environmental impact, as well as their interrelationships. Ultimately, the authors propose a comprehensive approach, including all the influential factors, to assist designers and homeowners in making informed decisions regarding glazing system selection for new NZEBs or NZEB retrofits in different situations. The main questions that are going to be addressed in this study are as follows:

- What are the main aspects that should be considered when selecting a glazing system for a building? Furthermore, how are those aspects related to each other?

- How can a comprehensive approach help with making the right selection of glazing systems towards achieving nearly zero-energy buildings (NZEBs), as mandated by regulations in numerous countries worldwide?

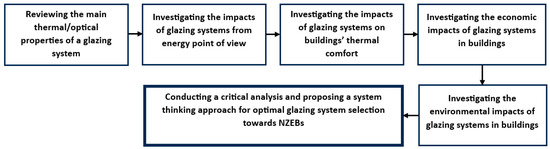

Figure 1 illustrates the flow chart of the current study.

Figure 1.

Flow chart of the current study.

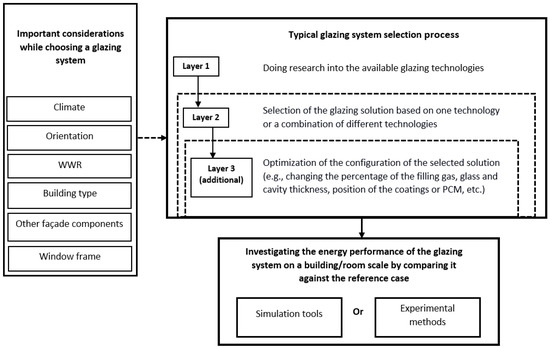

Figure 2 shows the methodology and concept framework of this review study.

Figure 2.

Concept framework of this review study.

2. Glazing Systems’ Main Properties

Many research studies have been conducted to investigate which features of windows have made them energy inefficient and how they could be improved. The studies have mostly focused on the thermal and optical properties of window systems, including the thermal transmittance (U-value) and the g-value (also known as the solar heat gain coefficient (SHGC), total solar energy transmittance (TSET), and solar factor) [36,37,38,39,40,41]. The first step in improving a window’s thermal and optical parameters is to evaluate them as accurately as possible [42].

The ASHRAE Handbook—Fundamentals (ASHRAE 2021) [43] introduced the following equation for energy flows in a steady-state condition for a window system:

where represents the energy flow in (W); is the thermal transmittance (U-value), in (); is the projected area of the window, in (); is the outside air temperature, in (K); is the inside air temperature, in (K); is the g-value; E is the total incident radiation, in (); is the air leakage, in (); is the air density, in (); and represents the specific heat of air, in (. The first term of the equation is related to the heat transfer caused by indoor/outdoor temperature differences; the second term represents the heat transferred inwards because of solar radiation, and the last term is related to the energy transfer due to air leakage through the window. As far as air leakage is concerned, a maximum of 0.0003 (), for curtain walls and storefront fenestration and 0.0001 (), for most other products, would be acceptable. Nowadays, since most manufactured fenestration products meet these limits [43], energy transfer due to air leakage is likely to be considerably less than that of the first two terms in Equation (1). For this reason, as stated by Villalba et al. [44], the energy flow through a window in a steady-state condition may be simplified as the following equation:

Figure 3, reproduced from [45], illustrates the heat transfer and daylight through a double-glazing unit considering the outdoor and indoor environments.

Figure 3.

Schematic view of a double-glazing unit with detailed heat and daylight occurrences. Reproduced from [45].

In general, for assessing the energy performance of windows, the most influential factors affecting the cooling and heating energy consumption of buildings have been found to be the U-value and the g-value [41,46,47,48] and may be followed by other factors such as visible transmittance and air leakage [43,46,49]. Therefore, exact knowledge of the U-value and the g-value of windows (as the most influential parameters) seems essential. In addition, since the glazing part of a window system often constitutes the largest proportion of the window area, this study focuses only on the U-value and g-value of the glazing part.

It should be considered that determining the U-value and g-value of multiple glazing systems, especially complex systems, is not an easy task. These values are not material constants and can be affected by the boundary conditions of the glazing systems [50]. As stated by Simões et al. [11] and Moghaddam et al. [12], three main methods may be employed to accurately determine the U-value and g-value of a glazing system: Numerical methods (or simulation tools), laboratory tests with boundary conditions close to the operational ones, and in situ tests. When considering the use of numerical methods, these should be validated against a reliable experimental method. Otherwise, there is a risk of under- or over-estimation of the results. By developing reliable in situ methods that consider real operational conditions, U-values and g-values could be evaluated more accurately, faster, and at a relatively cheap cost in the future [11].

Figure 4 gives a general idea of the U-values and g-values of some of the commercially available glazing systems investigated by [25,51]. It is noteworthy to mention that currently, there is a wide range of products on the market with different U-values and g-values depending on the number and thickness of panes, type, and positioning of coatings, type and percentage of filling gases, etc. More information regarding the thermal/optical properties of a variety of generic fenestration products can be found in [43].

Figure 4.

U-value and g-value of some of the commercially available glazing systems [25,51].

3. Energy Performance Evaluation of Glazing Systems

In many developing countries, single-glazing units are in use, even though the U-value of this type of glazing is almost two times that of the worst-performing double-glazing units. In spite of being in developed countries, many houses still rely on single-glazing systems. Research regarding commercial buildings’ energy retrofitting in the UK revealed that replacing single-glazing units with double-glazing systems could increase energy conservation by 39% to 53% [25]. The use of low-E glazing filled with air or argon helps building owners not only save energy (when compared with single-glazing units) but also improve indoor thermal comfort [52]. Triple-glazing systems have the potential to reduce energy consumption to a greater extent when compared with double-glazing systems. However, double-glazing systems are generally considered more cost-effective [27]. For a heritage building in a mild climate, the application of low-E double-glazing units was shown to reduce the annual energy demand by almost 14% [4]. Mousavi et al. [53] state that previous studies have shown that the use of double low-E glazing units and triple-glazing units in the hot, humid climate of Malaysia could reduce the annual energy consumption by up to 6.4% and 5.5%, respectively [53].

A residential building with a 3 mm single-clear-glazing unit and aluminum frame (with a U-value of 6.3 and a g-value of 0.858) in Cairo was modeled for comparing the energy performance of different glazing solutions. The results revealed that the single-clear-glazing system showed the worst behavior in terms of cooling demands. However, the clear double-glazing unit did not show significantly better performance than the single-clear-glazing unit. On the other hand, the use of double grey glazing showed the best performance by reducing the cooling loads up to 19.53% compared to the reference case [54]. Research proved that the use of reflective coatings on the glazing systems could reduce heat flux indoors by up to 73% in a hot climate in comparison to a typical clear-double-glazing unit [53]. The solar control films were also reported to reduce cooling energy needs compared with typical clear glazing in hot climates [55]. In addition, in recent years, the application of low-E window films has attracted designers and researchers. In a study conducted by Moghaddam et al. [3], it was discovered that the use of a low-E window film on the outward-facing surface of the inner pane of a double-glazing window helped reduce the building’s annual energy consumption for heating purposes by 6%. In another study, the use of low-E window films on the interior side of a glazing system in both cold and mild climates showed a reduction in the U-value. Nonetheless, the benefits of the low-E film started disappearing as the outdoor temperature dropped to −17 °C in the cold climate of Stockholm due to a huge reduction in the temperature of the glazing’s indoor surface and the risk of indoor condensation [56].

Several research endeavors have aimed to examine the factors and arrangements that contribute to the enhanced performance of multiple glazing systems. For instance, some studies investigated various aspects, such as the optimal number of panes, the thickness of the glass, the gap width between panes, and the emissivity of the surface, among others. In a simulation study for a building located in Semnan City (in Iran) with a hot, arid climate, the findings were that for a single-glazing unit, increasing the glass thickness resulted in a large reduction in the heating load while a slight increase in the cooling load was observed. Regarding a double-glazing unit, the highest and lowest cooling loads belonged to krypton and air as the insulator gases, respectively. However, the opposite effects showed up for the heating loads [57]. In a numerical study carried out by Arıcı et al. [28], the impacts of the number of window panes, gap thickness, and outdoor temperature on the performance of a glazing system were investigated. It was revealed that when the gap thickness increased from 6 mm to 9 mm, the heat loss reduced considerably since the convection currents were not established yet. However, the positive impacts of increasing the gap thickness stopped (and even reversed) at very large widths due to the fact that convective heat transfer started to show its effect. It was discussed that a reduction of 50% or 67% in heat loss through the glazing unit could be achieved by replacing the double glazing with a triple- and quadruple-glazing system in all cities of Turkey. The benefit of the application of triple- or quadruple-glazing systems was more considerable in cold regions. It was concluded that the order of importance of the investigated parameters on the thermal performance of the glazing system was: the number of panes, the emissivity of the glass surface, and the gap thickness.

In recent years, there has been a substantial focus on advancing various types of glazing systems, as demonstrated in the literature. These advancements include the development of innovative glazing systems such as water flow glazing, aerogel glazing, vacuum glazing, PCM integrated glazing, PV glazing, and smart glazing systems (incorporating intelligent coatings that respond to environmental cues, leading to modifications in solar radiation, radiant energy, and visible light) to improve the energy/thermal behavior of buildings [58].

In a field test study performed on a small office building located in Sofia, Bulgaria, the energy performance of water flow glazing (WFG) panels was investigated. It was discovered that the use of the water flow glazing panels helped to save 62% of the primary energy in comparison to a reference triple-glazing system. The authors believed that savings associated with the use of the WFG panels during their operating lifetime could compensate for the capital cost required for initial implementation [59]. In the results of another study on the performance of a WFG system as a radiant heating and cooling system in office spaces with a large glass area, the benefits of such a system were proven in terms of energy conservation and thermal comfort. It was reported that the WFG system helped to maintain the indoor air temperature in an acceptable range (between 25 °C and 27 °C). The authors considered the WFG system a valid energy retrofitting option for office buildings [8].

In a study carried out by Khaled Mohammad and Ghosh [45], a two-story residential building in Falmouth, UK, was modeled through simulation to investigate the impacts of various aerogel systems as alternatives for standard double-glazing systems. The results of the study showed that the aerogel glazing technology has a high potential to reduce the heating demand by 15.5% (compared to a standard double-glazing system) by providing solar heat gain owing to the high g-values up to 0.738 and low U-values down to 0.381 (). It was also discussed that monolithic aerogel systems would have more energy-saving potential while providing greater daylighting in comparison to granular aerogel. The research concluded that utilizing aerogel glazing as a means of retrofitting buildings in the UK was deemed a viable and effective option for improving energy efficiency, particularly for providing space heating.

In a one-year-long field study, the performance of a double-clear glazed window filled with PCM in an office building in Santiago, Chile, with an east-oriented façade having a WWR of 56%, was compared against a typical air-filled clear double glazing placed in another similar office (used as a reference case). The results from this study showed the high potential of the PCM-integrated glazing system for reducing energy consumption during the summer and mid-season as well as during peak loads in the summer [60]. The potential of PCM-integrated glazing systems for energy behavior improvement was also confirmed in [30]. Another study conducted by Wei et al. [61] revealed that PCM-integrated multilayer glazing systems could reduce energy consumption in comparison to a pure glazing unit. The energy-saving rates associated with the integration of PCM into the glazing system in comparison to a double-, triple-, and quadruple-glazing unit were reported to be 14.55%, 33.89%, and 50.71%, respectively. It is noteworthy to mention that PCM-integrated glazing systems may compromise the desirable solar heat gain in cold climates [62], while the right positioning of the PCM may help to compensate for this weakness [63].

Depending on the WWR, climate, type, and configuration, PV window glazing systems have the capacity for energy savings of around 12% to 76% [64]. By combining PV glazing systems with other technologies, it becomes possible to enhance the thermal performance of smart glazing solutions, resulting in improved energy efficiency. The literature review conducted by Cuce et al. [65] introduced thin-film PV glazing systems as one of the best options for energy conservation, especially in climates such as the Middle East, which are dependent on cooling energy. In contrast, the benefits of PV glazing application in extreme climates, especially in very cold climates, were put into question by Romaní et al. [66]. The authors emphasized the need to enhance the solar control properties of PV windows. They suggested that improvements should be made to ensure that during extremely cold weather, the windows are able to allow sufficient solar radiation into the room, while during extremely hot weather, the system effectively prevents excessive solar radiation from entering the room.

Many research studies have investigated the impacts of smart glazing systems on the energy performance of buildings in different climates. The literature revealed that thermochromic glazing systems have the potential to save both heating and cooling energy use in the range of 5.0% to 84.7% when compared to plain glass, depending on the building type and the climatic conditions [67]. For intermediate climates, the use of newly developed thermochromic glazing resulted in an improvement of the annual energy consumption by 22% when compared to clear glass [68]. A numerical study discovered the high potential of thermochromic glazing systems for minimizing heating and cooling loads in an office room in different climates of Lisbon and Copenhagen. Nevertheless, the reduction in heating/cooling energy consumption may come at the expense of increased lighting energy usage [69]. For the humid subtropical climate of Turin, in the northwest of Italy, the integration of a thermotropic layer in a triple-glazing unit caused the cooling load through the glazing parts to decrease by one-third in comparison to a traditional triple-glazing unit [63]. In another study, the benefits of combining electrochromic and thermochromic layers on the outer pane of a triple-glazing unit in an office building with a large glazing area located in Athens and Stockholm were investigated. It was proven that such a system could contribute to an 18.5% and an 8.1% reduction in annual primary energy use in the climates of Athens and Stockholm, respectively. The authors highlighted the importance of a good switching strategy in such a way that proper heat gain and daylight could be maintained [33]. A parametric simulation research study for a typical office building in tropical and subtropical climates investigated three window solutions, including laminated, insulated, and electrochromic glazing, together with hybrid ventilation. The results revealed that the electrochromic solution contributed to an energy saving of up to 8.6% in Curitiba, Brazil. The authors considered the solar radiation incidence, external illuminance level, and outdoor air temperature as the most influential factors affecting the glazing performance [70]. The performance of a dynamic glazing system in the south-facing offices on the top floor of an old university campus building in the Vancouver area was compared against an existing clear glazing system using a dynamic simulation tool. It was concluded that the dynamic glazing solution could successfully provide indoor thermal comfort in all spaces while avoiding the use of mechanical cooling [71]. Ganji Kheybari et al. [72] investigated the performance of electrochromic glazing for the energy retrofitting of a typical office room in Mannheim, Germany. The results revealed that, regarding operational energy, the electrochromic glazing system performed somewhat better than the glazing with a solar coating, but this small benefit could not justify the high amount of embodied energy used for the electrochromic glazing system. The literature showed that factors such as window size, orientation, climatic conditions, latitude, and the control strategy applied for automation significantly impact the overall performance of smart glazing systems [73].

Several studies have explored the effects of upgrading glazing within an energy retrofitting package that incorporates additional measures such as wall insulation, infiltration improvement, and others. The aim of these studies was to examine the interaction between these measures and develop a more practical and realistic solution. For instance, for a historical building equipped with a 3 mm single-glazing window (with an overall U-value of 5.8 ), the authors compared the energy and cost benefits of 63 advanced and traditional retrofit combinations, focusing on the glazing units, internal walls, and the building’s airtightness improvement. The building was equipped with a 3 mm single-glazing window (with an overall U-value of 5.8 ). For the glazing upgrade, five different glazing solutions were considered, including a double-glazing system with low-E coating (with the U-value of 1.8 , labeled as a traditional solution), a triple-glazing unit (with the U-value of 0.8 , labeled as a traditional solution), vacuum glazing (with the U-value of 0.9 , labeled as an advanced solution), a double-vacuum-glazing unit (with the U-value of 0.6 , labeled as an advanced solution), and a double-vacuum-glazing unit with a low-E coating (with the U-value of 0.4 , also labeled as an advanced solution). Each glazing solution was evaluated in combination with the other façade retrofitting measures. In addition, the glazing solutions were divided into traditional and advanced retrofitting groups based on availability, dominance, and cost on the market. The results of the study clearly showed that although the use of an advanced retrofitting package (double vacuum glazing with low-E coating + a gypsum air infiltration reduction solution + vacuum insulation 8 cm, with an initial cost of GBP 891,492) resulted in the maximum energy saving potential of 66.8%, the traditional solutions (double glazing with low-E coating + draught proofing + polyisocyanurate 8 cm, with an initial cost of GBP 66,296) provided the energy savings of 52.3%, which was slightly lower than the complex ones. A simple comparison from an energy and economic standpoint can show that the latter solution is more reasonable than the advanced solution [74].

Numerous studies have demonstrated the advantages of incorporating shading devices into glazing solutions. Zoure and Genovese [75] emphasized the importance of avoiding excessive dependence on HVAC systems and replicating Western standards for window-to-wall ratio (WWR) in energy-constrained developing countries such as Burkina Faso. Instead, they recommended prioritizing simple and cost-effective glazing energy upgrading solutions, such as tinted glass and horizontal louvers, which serve as shading devices to mitigate overheating issues within office buildings. In addition, it was recommended to keep a 30% WWR because of the local climate in Ouagadougou (in Burkina Faso). In line with the concept of advocating the advantages of suitable and user-friendly shading solutions, Ariosto et al. [76] highlighted the affordability and effectiveness of cellular shades and Venetian blinds in reducing the g-value of glazing systems in hot climates. Furthermore, these shading solutions were identified as viable options in mixed climates to reduce the U-value of glazing systems to different extents, depending on their operation. Mousavi et al. [53] mentioned that the impacts of effective shading were proven to have savings of about 35% in cooling energy consumption for office buildings in a continental climate. Regarding curtain selection, it was discussed that overhangs outperformed interior blinds by saving energy by around 2% to 10% in hot climates [53]. Shading systems have the potential to yield energy savings ranging from 10% to 75% annually, depending on factors such as the type of glazing, climate conditions, and the positioning of the shading devices [64]. Ganji Kheybari et al. [73] stated that the literature showed that automated dynamic shading could save more energy than manual operations or static systems. For example, using automated blinds resulted in 21% cooling and lighting energy savings compared to a fixed shading device in private offices in Oakland, California. However, the wrong selection, absence, or improper use of shading on glazing systems could result in penalties [77]. For instance, it was mentioned that limited benefits could be achieved from using a smart shading system on the high-performance triple-glazing unit [16].

Another research study noted that the performance of the overall window system is influenced by the interaction between the glazing component and another crucial element, namely the frame. The authors recommended taking the frame into account when studying or selecting a glazing system to achieve an optimal window solution [78].

Besides advancements in glazing technology, an essential factor to consider in the glazing selection process is the window-to-wall ratio (WWR). The WWR represents the proportion of the glazed area in relation to the total outer wall area. This parameter can affect the heating load, cooling load, as well as natural daylighting in a building [79]. It is reported that the extensive use of glass in facades in office buildings has resulted in an 8.7% increase in the AC market in Europe in the last decade, especially in Mediterranean countries [8]. The general guideline for WWR suggests a range of 0.3 to 0.45 [79]. However, WWR should be precisely determined based on the building type, climate, orientation, and other building attributes. For instance, Košir et al. [80] recommended larger window areas for harvesting solar radiation for heating purposes together with appropriate shading (to avoid overheating in the cooling season) in central European climatic conditions. In another study, it was revealed that in cold climates, a larger WWR could provide desirable solar heat gain, compensating for an increase in cooling demand in the summer [81]. Hwang and Chen [82] stated that the results of their study highlighted that an increase in the WWR would result in an increase in the cooling energy needs in the hot-humid climate zone. Therefore, the annual energy use would increase since, in the hot-humid climate zone, the main share of energy consumption belongs to cooling. The contrasting recommendations about the optimal WWR in buildings highlight the importance of considering the local climate when designing a building’s façade. It is noteworthy to mention that for most of the façade retrofitting cases, the WWR remains unchanged. Therefore, the glazing solution should be chosen based on the existing WWR and the other façade attributes.

In the literature, the importance of building type in the glazing system selection has been highlighted. For instance, it has been said that the use of smart glazing (e.g., thermochromic glazing) might not affect the performance of a domestic building since domestic buildings are usually less occupied during the daytime, meaning that less heating, cooling, and lighting are required when compared to commercial buildings [67]. Another study stated that office buildings usually have low thermal inertia, which could influence their energy performance. The use of large glazed façades in office buildings could lead to overheating and excessive daylight gain, resulting in an increase in the cooling demand as well as thermal and visual discomfort in the office spaces. [60]. Hence, the potential energy savings for smart shading are expected to be even higher for commercial buildings with very large glazed walls [16]. Regarding school buildings, it was emphasized that they are mostly used during the day. Therefore, the use of sunlight in school buildings should be considered while controlling the incoming solar radiation to avoid overheating or overcooling, depending on the local climate. This study investigated a school building in Istanbul and revealed that the best glazing solution in terms of total energy savings was a triple-clear-glazing unit (with air as the filling gas) with no shading. The best glazing solution in terms of heating energy savings was triple glazing with the low-E coating (with air as the filling gas) with no shading. And the best option from the point of view of lighting (only) was, naturally, a single-clear-glazing unit without shading. However, it should be said that this study did not include the economic aspect of the glazing selection [83].

In the process of considering glazing upgrades (or glazing selection for new buildings) and determining suitable glazing U-values and g-values, it is essential to not only take into account factors such as the WWR, façade components, building orientations, and the specific building type but also give significant consideration to the climatic zone. Furthermore, it is crucial to recognize the interrelationship between all the building- and glazing-related parameters for optimal decision making. The general recommendation is that the lowest g-value could result in lower cooling energy consumption (cooling) in warm climates, and the lowest U-values showed lower heating needs in cold climates [84]. It has been discovered that the importance of these values, to a great extent, depends on the climate [18]. The literature suggests that in the tropical climate of Singapore, reducing the g-value of a glazing unit is more effective in reducing cooling loads than reducing the U-value of the glazing. [85]. Liu et al. [86] conducted a study investigating the impact of the g-value on building thermal loads. The study involved modeling a house with a total floor area of 139 m2 and a total window surface of 44 m2. The results indicated that the g-value had a noteworthy effect on the building’s annual load. Specifically, when the g-value decreased from 0.8 to 0.2, a substantial decrease of 180% in the cooling load was observed [86]. In buildings with high WWR and effective insulation, the findings indicated a significant reduction in total energy consumption (ranging from 18.4% to 29.7%) as the solar gain decreased. Additionally, in cases with low WWR, the heat loss through the building envelope has a greater impact on the overall energy demand compared to heat gains from solar radiation [87]. In extremely cold climates, it is indeed advantageous to minimize heat transfer through a high level of insulation. Therefore, opting for windows with a low U-value of 1.2 () is considered beneficial [88].

Figure 5 depicts the decision-making process for selecting an energy-efficient glazing system, taking into account the various influencing factors.

Figure 5.

Illustration of the decision-making process for selecting an energy-efficient glazing system, taking into account the various influencing factors.

Table 1 presents a concise overview of the key aspects found in the literature in regard to the energy evaluation of glazing systems.

Table 1.

Summary of the main findings in terms of the energy evaluation of glazing systems.

4. Impacts of Glazing Systems on Buildings’ Thermal Comfort

It has been proven that indoor thermal comfort has particular importance since it interacts with occupants’ health and productivity and buildings’ energy performance [89]. In the initial design phase of new energy-efficient buildings or during the implementation of energy retrofitting projects, it is crucial to incorporate considerations for thermal comfort [53,90]. The proper orientation of the facades and the appropriate layout of rooms can help avoid thermal discomfort [90]. The significance of glazing systems for indoor thermal comfort cannot be disregarded, particularly when selecting a suitable glazing solution. It is vital to choose a glazing solution that aligns with building-related attributes and climatic conditions in order to ensure optimal indoor thermal comfort. The literature has shown several cases where inappropriate glazing solutions and design led to indoor thermal discomfort [90]. For example, having large glazing areas without the use of shading devices may cause serious thermal and visual discomfort [8,91,92], or using glazing systems with a high g-value may cause overheating even in the heating season [90]. It has been proven that thermal comfort and cooling loads are highly sensitive to the g-value of glazing systems, especially in hot and humid climate zones [82]. The need for more research into the impacts of glazing systems on the thermal comfort of buildings is inevitable [93,94].

Teixeira et al. [95] pointed out that solar control films (SCFs) have the potential to improve thermal and visual comfort in warm climates. However, different factors can affect the performance of SCFs, including the type and size of the glazing, local weather conditions, position of the film, solar orientation of the glazing, existence, and type of the shading systems, cleaning and maintenance practices of the building, etc. It was discussed that the lower solar altitude during winter would increase the gain of solar radiation (perpendicular to the glazing), affecting the visual performance of SCFs. Regarding cold climates, the use of Low-E films was suggested since these can control the heat gain/loss through the glazing unit in such a way that better thermal comfort is achieved throughout the entire year [55]. Moghaddam et al. [3] stated that the use of the low-emissivity window film on the outward-facing surface of the inner pane of a double-glazed window in a historical building in a cold climate of Sweden resulted in an almost 36% reduction in heat loss through the windows in winter and unwanted heat gains in summer. This led to an improvement in indoor thermal comfort in such a way that the percentage of total occupant hours with thermal dissatisfaction was reduced from 14% (without the film) to 11% (with the film). It is important to highlight that while tinted glazing and coating films contribute to shielding interior spaces from solar radiation, they can also lead to reduced daylight transmittance, creating darker conditions within the room. However, by making wise selections of glazing and shading systems, it is possible to strike a balance between the thermal and lighting requirements of a building. Mobile shading devices can control the penetration of solar radiation into the building in the summer, leading to better indoor thermal comfort [91].

A research study assessed the effect of outdoor parameters (especially solar radiation), shading, and glazing configurations on indoor thermal comfort in multi-purpose halls in Auckland, New Zealand. In order to ensure indoor thermal comfort, it has been discovered that varying glazing and shading configurations should be employed during different time periods, even within the same building. Achieving this level of adaptability can be accomplished through the utilization of dynamic shading and glazing solutions [89]. The benefits of incorporating a PCM into a double-glazing unit were proven in terms of thermal comfort thanks to its ability to control the mean radiant temperature for the whole year [60]. Another solution that showed improvement in indoor thermal comfort was the use of silica aerogel together with a PCM in a triple-glazing system [30]. A numerical study investigated the indoor thermal comfort conditions for an unfurnished room in a temperate climate in the UK for two types of glazing solutions, including a BIPV-vacuum glazing system and a similar dimension of BIPV-double-glazing system. The BIPV-vacuum glazing showed better overall heat performance and lower solar heat gain while possessing benign onsite electricity. This system improved thermal comfort by 39% compared to the BIPV double-glazing system [96]. In another study, the impacts of an electrically heated window on the thermal comfort of permanently occupied spaces were tested. The results showed that the predicted mean vote (PMV) could be considerably affected by the heated glass surface. Thanks to the glazing control unit, the surface temperature could be adjusted by users based on their preferences. It was concluded that the application of electrically heated glazing would be capable of enhancing indoor thermal comfort [97]. In a hot, semi-arid climate, the application of thermochromic glazing showed a contribution to a reduction in the indoor temperature from 42 °C (in the presence of a typical single glazing) to 33 °C in the summer, resulting in a thermal comfort improvement. In the winter, it was also reported that the thermochromic glazing solution performed better than typical single glazing in terms of thermal comfort [98]. In the study conducted by Nundy and Ghosh [94] on the thermal behavior of a low-heat-loss switchable suspended particle device-vacuum (SPD-vacuum) glazing solution in a temperate climate, a thermal comfort analysis was carried out using PMV and PPD methods. It was found that the varying g-value of this glazing system (in the range of 0.31 for the switch-off state and 0.58 for the switch-on state) helped to provide better thermal comfort on a clear, sunny day [94]. In addition, integrating the insulating materials with the glazing integrated photovoltaics (GIPV) disclosed a potential solution for decreasing indoor thermal discomfort [99].

Solar radiation passing through glazing systems has a great impact on energy consumption and occupants’ well-being in buildings [82]. Glazed walls have been identified as the primary source contributing to the negative solar impact on occupants, with their effects being described in terms of thermal and visual comfort. To optimize the benefits of solar radiation in terms of both thermal and visual aspects, a ratio called the light-to-solar gain (LSG) has been introduced. The LSG is determined by the visible light transmittance divided by the g-value, and it serves as a measure of the balance between light transmission and solar heat gain (LSG is suggested to be in the range of 1.2 to 1.6) [100]. The energy/thermal impacts of solar radiation should be examined from two perspectives. Firstly, it is important to assess the impact of solar radiation on the temperature increase within indoor spaces and the subsequent implications for the building and its occupants. Secondly, the direct exposure of occupants to solar radiation in close proximity to glazing areas should be considered, along with the resulting consequences for occupants and the subsequent energy requirements for air conditioning to mitigate its effects [82,101,102,103]. In addition to the environmental conditions (ambient temperature, relative humidity, air velocity, etc.), solar radiation falling over the occupant’s body plays an important role in the thermal sensation of a user in an indoor space. Although dynamic simulations typically account for solar radiation, the impact of solar radiation directly falling on the occupant is often overlooked in various comfort models [103,104]. The thermal comfort conditions around glazing areas can differ considerably from those in the center of rooms, depending on factors such as the exposure of the glazing to solar radiation, the geometry of the space, and the ratio between the glazing area and the floor area. Temperature variations ranging from 0.5 °C to 2.5 °C have been reported as a result of changing these factors [102].

Arens et al. [103] introduced a calculation method that includes the impact of solar radiation directly hitting occupants through glazing areas (see Figure 6). In this method, several factors, such as solar radiation distribution, surrounding context, direct and indirect solar transmittance of the window system, occupant position and posture, body exposure, sun position, irradiance value, and clothing absorptivity, were considered. Therefore, the mean radiant temperature (MRT) is adjusted by summing up the contributions of the calculated longwave and shortwave MRT [103,104]. A public online tool named “SolarCal” incorporated the aforementioned method that can be used to determine the temperature offset for the affected occupants cooling and the allowable transmittance of glazing systems in a perimeter office [103]. An experimental study on the performance of a responsive glazing system (a triple-glazing unit with a PCM-filled cavity and thermotropic pane) during the summer season in Turin, Italy, revealed the difference between two different thermal comfort calculation methods, including a traditional PMV method and the method with the modified PMV indices (considering the direct solar radiation impinging on the occupants). The former was not influenced by the position of the PCM, while the second method disclosed that placing the PCM in the innermost cavity presented the best comfort conditions [105].

Figure 6.

Occupant exposed to direct solar irradiation. Reproduced from [103].

It is noteworthy to mention that there is a delicate relationship between thermal comfort, visual comfort, and the energy performance of a building. For instance, achieving indoor thermal comfort often necessitates the use of heating or cooling systems, but at the expense of heightened energy consumption. Similarly, employing coated glazing solutions and/or internal or external shading devices to regulate solar radiation entry for thermal comfort improvement can compromise daylighting levels and subsequently lead to increased electricity usage [90]. Therefore, an ideal solution is one that effectively balances these factors, allowing for trade-offs that optimize overall performance.

Table 2 provides a concise overview of the main findings from the literature with regard to the impacts of glazing systems on the thermal comfort of the occupants of buildings.

Table 2.

Summary of the impacts of glazing systems on indoor thermal comfort.

5. Cost-Effectiveness of Different Glazing Systems

From a purely energetic point of view, there is a wide range of glazing technologies that have proven to be energy effective for different buildings. However, not all of them are necessarily cost-effective. For instance, advanced glazing solutions such as smart glazing, aerogel glazing, vacuum glazing, super airtight solutions, PV glazing, PCM-integrated glazing, and smart shading devices have shown higher initial costs leading to longer payback periods due to their relatively low market maturity and high production costs [20,27,65,70,74]. Even replacing existing single-glazing units with typical double- or triple-glazing systems (which have been playing a dominant role in the market) can result in payback periods that extend over multiple decades. The cost of multiple glazing systems varies considerably based on factors such as their coatings, filling gas, glass type, and their impacts on U-values and g-values (energy and solar performance). Consequently, it is essential to consider both the energy/thermal performance and cost-effectiveness of a glazing solution when making a decision [21,27,63,76,88]. It is important to highlight that as time progresses and the cost of manufacturing advanced glazing systems decreases, the market landscape is anticipated to undergo significant changes. Consequently, the use of these solutions is expected to become economically viable and justifiable in the future [65]. In addition, in the case of smart glazing systems, adopting optimized controlling methods could lead to efficiency improvements and lower payback periods [106]. The following paragraphs will explore the factors that can affect the cost-effectiveness of glazing systems.

The literature shows that, similarly to the energy/thermal performance of a glazing system, its cost-effectiveness is dependent on factors such as the building type, orientation, WWR, and climate. A study conducted by Kadrić et al. [107] revealed that the cost of implementing energy efficiency measures per occupant for single-family houses would be, on average, 2.8 times higher than for multi-family houses, apartment buildings, and high-rise buildings. Regarding the orientation of glazing systems, Altun [108] conducted a thermo-economic analysis for a reference room in two cities with different climatic conditions in Turkey. The results showed that due to passive heating and increased solar radiation levels, south-oriented façades consistently exhibit a lower net present cost compared to north-oriented façades, assuming they have the same window size and glazing type. Bastian et al. [51] stated that the cost-optimal glazing solution relies greatly on the climatic conditions in such a way that in cold climates, any decrease in heat losses is valued, while in hot climates around the equator, solar protective glazing solutions are usually cost-effective, and for temperate climates that are found in large areas of the United States and Europe, triple glazing and even quadruple glazing systems may be beneficial. However, the specific choice between the two solutions depends on factors such as the glazing size and orientation, showing the interrelationship between the climate, WWR, and orientation.

In addition to the climate and building-related parameters, the literature highlights other factors that can influence the cost-effectiveness of glazing solutions, including the price of the energy source, the economy of the region, and energy accessibility. Romaní et al. [66] stated that the economic viability of the application of PV glazing heavily relies on the electricity pricing schedules. In another study conducted by Kadrić et al. [107], results showed that in a middle-income country such as Bosnia and Herzegovina, implementing energy retrofitting measures in buildings fueled by relatively cheap energy sources (e.g., coal and wood) may not be economically justifiable and feasible. In contrast, high-rise buildings that are mainly supplied by more expensive energy sources (e.g., natural gas and light distillate fuel oil) would demonstrate significant profitability potential when undergoing energy-efficient retrofitting. Another study that investigated the impacts of the application of low-E films on the performance of a district heating-connected building revealed that the relatively high price of the films compared to the low cost of district heating caused the payback period for installing these films to be quite long—estimated at around 30 years [3]. To investigate the economic profits associated with façade energy retrofitting, Elaouzy and El Fadar [109] used the electricity price to gross domestic product (EPGDP) ratio, which integrates both energy prices and citizens’ well-being. In regions where energy is affordable, such as Qatar and the United States, the EPGDP ratio is typically lower as a result of low electricity prices and/or high per capita GDP. Conversely, in areas where energy accessibility is limited, the EPGDP ratio tends to be higher. The results of the research demonstrated that in the context of facade retrofitting measures, including upgrading glazing systems, the most significant economic advantages are observed in regions characterized by a high EPGDP ratio. This suggests that energy is relatively unaffordable in such regions.

It is important to note that examining a glazing solution from a single perspective may not lead to an optimal outcome. For instance, for a typical residential building across six different locations with diverse climate types, among different upgrading strategies (i.e., different WWR, double glazing, triple glazing, and internal/external Venetian blinds), the highest energy savings were achieved with the triple-glazing system for all the climates. While the highest economic benefits were acquired by double glazing, the highest energy savings and economic benefits were obtained in the presence of exterior Venetian blinds for all the locations [109].

Certain studies have taken more comprehensive approaches beyond solely considering payback periods when examining glazing upgrades. For instance, Gonzalo et al. [31] stated that despite the high initial price of a water flow triple-glazing system as a building-integrated solar thermal collector in comparison to traditional curtain walls, taking a holistic approach that incorporates a life cycle analysis of energy savings, energy generation, and CO2 emissions reduction could potentially justify the adoption of such a system. Some studies consider the life cycle cost (LCC) methodology, which revolves around maximizing design efficiency and reducing the total expenses of construction, operation, and demolition throughout the lifespan of a building. The LCC of the building envelope encompasses the costs incurred during its construction, operation, and demolition [110]. Another study took a broader perspective to investigate the energy, economic, and environmental implications of implementing a novel thermochromic/low-E smart window glazing specifically for the Netherlands. It was discussed that the continued advancement of thermochromic smart windows towards market-ready products would have the potential for significant economic, ecological, and societal improvement across intermediate climate regions in the northern hemisphere [68].

Table 3 provides an overview of the primary findings concerning the cost-effectiveness evaluation of glazing systems.

Table 3.

Summary of the main findings in the literature on the cost-effectiveness of glazing solutions.

6. Environmental Impacts of Different Glazing Systems

In recent times, considerable endeavors have been dedicated to diminishing the environmental footprint of the construction industry by employing passive techniques to create environmentally friendly buildings that prioritize energy efficiency and thermal performance [75]. To mitigate climate change emissions across the complete lifespan of a building, it is essential to focus not only on reducing energy usage during the operational phase but also on addressing the embodied energy and CO2 emissions associated with the construction and demolishing of the building [111]. Embodied energy (10% to 20%) and operational energy (80% to 90%) constitute the biggest part of the life cycle energy in buildings. It is anticipated that embodied energy will rise in energy-efficient buildings and may even surpass operational energy. Therefore, it is crucial to bear in mind that reducing operational energy should not be achieved at the cost of an unjustifiable increase in embodied energy [72]. Among the façade components, glazing systems have an important impact on the operational performance of a building [112]. Asdrubali et al. [111] stated that the recyclability of window materials plays a critical role in mitigating environmental impacts, especially when frequent replacements are involved. Around 65% of glass is currently sent to landfills, while the remaining portion is recycled for various purposes. However, only a small portion (10%) is utilized in the production of new float glass due to the requirement for high-quality material. The authors addressed a significant challenge in drawing meaningful conclusions about the overall life cycle impacts of glazing systems. This challenge arises from the fact that environmental product declarations (EPDs) predominantly adopt a cradle-to-gate approach, leading them to neglect the reporting of information regarding the operational and end-of-life impacts linked to glazing systems and frames. Additionally, the absence of EPDs for innovative and dynamic windows was discussed, which can be attributed to both the limited market distribution of such windows and the lack of literature studies exploring life cycle assessment (LCA) for these products. Saadatian et al. [113] numbered several factors affecting the embodied impacts of window systems, including the type of window frame, number of glass panes (e.g., single, double, or triple), gas filling the cavity (e.g., air or argon), and coatings (e.g., low emissivity or solar control). The authors believed that more attention should be paid to the glazing part of a window while investigating the environmental impacts.

Some studies investigated the impacts of glazing technologies from an energy-environmental point of view. In a life cycle analysis conducted by Pereira et al. [114], the advantages of utilizing various solar control films were evaluated in comparison to replacing the existing windows. It was revealed that the carbon emissions associated with manufacturing the new windows were twice as high as those generated during the production of the films. While numerous advanced high-performance glazing systems exhibit improved energy efficiency during the operational phase and enhance indoor comfort, it is important to note that these systems may consume more energy during the pre-use and post-use stages, potentially leading to negative environmental consequences [115]. A comparison was made between EC-glazing and high-performance glazing with solar coating for a standard 30 m2 office room in Mannheim, Germany. In terms of operational energy, the EC-glazing showed slightly better performance compared to the solar-coated glazing. However, the findings indicated that the significant amount of embodied energy in the EC-glazing could not be justified by the relatively minor savings in operational energy. Nevertheless, as electrochromic windows become more widely adopted on the market, it is expected that resource consumption and carbon emissions will decrease [72].

The building type is one of the important factors that should be taken into consideration when choosing an eco-friendly glazing solution. For instance, in a study conducted by Günkaya et al. [116], it was discovered that the operational stage of a university building represents the primary contributor to its environmental impacts. Consequently, when selecting the glazing solution, priority was given to addressing the environmental aspects during the operational phase. However, the other phases of the building’s life cycle were not disregarded in the analysis.

The window-to-wall ratios (WWRs) have a notable influence on the embodied carbon of building envelopes. There is a substantial difference in embodied carbon emissions between double and triple glazing. Particularly in high WWR envelopes, this difference can be as significant as 30%. Higher WWRs often lead to increased embodied carbon for most building assemblies. In regions where the power sources have high carbon emissions, significant enhancements in facade insulation requirements can be quickly offset in terms of net carbon impact. However, in areas with predominantly clean power sources, the embodied carbon emissions linked to investments in improving facade performance are unlikely to be recovered over time. Moreover, focusing solely on achieving maximum operational savings in building design can lead to unnecessary emissions due to excessive embodied impacts. This situation arises particularly in moderate climates with low carbon grids, where the benefits of using triple glazing are not significant and the additional embodied carbon is not justified. It can be concluded that the connection between embodied and operational carbon is highly dependent on the local context, and optimal design variables can vary significantly [117]. Therefore, the most environmentally friendly glazing solution for a building may be chosen through a comprehensive approach that considers the interrelationship between influential factors such as the WWR, orientation, local climate, carbon intensity of the grid, and the operational and embodied impacts of the glazing solution.

Saadatian et al. [84] adopted an integrated life cycle (LC) approach with Pareto bi-objective optimization to effectively assess the influence of each window component (glazing and framing) and window properties (U-value and g-value) on the overall life-cycle environmental and cost impacts for various orientations in three different European climate regions. It was found that the glazing component had the most significant impact on total environmental impacts, primarily related to operational factors. These impacts were heavily dependent on the U-values and g-values of the windows. Additionally, the life-cycle cost analysis revealed that the initial investment in windows had a substantial influence on the overall cost, even when considering a lifespan of 30 years. In another study, Saadatian et al. [118] tried to find a trade-off between the U-value and embodied impacts (energy and environmental) of window solutions using the Pareto optimal frontier method. Environmental impacts were calculated for five main categories, including non-renewable primary energy, global warming, acidification, eutrophication, and ozone layer depletion, as recommended by European standards EN 15804: 2012 [119] and EN 15978: 2011 [120]. An evaluation of eight glazing solutions (for single, double, and triple glazing) revealed that the embodied impacts are greatly influenced by the type of glass employed. Glass emerges as the most significant component, accounting for over 62% of the total embodied impacts within a glazing solution. The use of tempered glass and glass coating (low-E film) increased the embodied impacts of glazing solutions. In addition, it was discovered that among the framing materials, wood had the lowest embodied impacts, while aluminum represented the highest impacts for the double- and triple-glazing solutions.

The study carried out by O’Neill et al. [121] introduced an innovative integrated framework that combines building energy modeling, life-cycle analysis, and life-cycle costing models. The framework was employed to evaluate the effects of four different glazing types (single glazing, single glazing with a low-E coating, clear double glazing, and low-E double glazing) on a 15-story office building in a sub-tropical climate. The research findings indicated that the low-E double-glazing solution was the most energy- and cost-effective option, despite having higher embodied energy and carbon compared to the alternatives. However, it is worth noting that from a purely embodied impact viewpoint, single clear glazing (baseline) would appear to be the preferable choice due to its lower energy and carbon footprint during manufacturing and transportation, despite its poor operational performance. The findings underscore the significance of adopting a life-cycle perspective rather than concentrating solely on a single phase (such as production, operation, or end phase).

In summary, an environmentally reasonable glazing solution for a specific building case would be one that exhibits the lowest overall life cycle impacts while minimally compromising the energy/thermal performance and cost-effectiveness of the glazing. Table 4 presents a brief overview of the primary findings concerning the environmental impacts of glazing solutions.

Table 4.

Summary of the findings regarding the environmental impacts of glazing solutions.

7. Critical Review

A nearly zero-energy building (NZEB) can be described as a building that demonstrates exceptional energy performance. It aims to minimize energy consumption to such an extent that the remaining energy needs, which are extremely low, are primarily met through the utilization of renewable energy sources. These renewable sources can be generated either on-site or near the building [6,7]. In order to attain the objective of widespread adoption of NZEBs, it is crucial to not only focus on new constructions but also prioritize the renovation of existing buildings, particularly those with inadequate performance, such as older structures. Around 35% of European Union (EU) buildings are over 50 years old, and an astonishing 90% were constructed before 1990. Despite the Renovation Wave initiative aiming to accelerate the current low rate of building renovations, renovating existing buildings to meet NZEB standards remains the most difficult challenge for Europe [7].

As buildings advance towards their nearly zero-energy targets, the window systems, including the glazing components, can have a substantial impact on improving building energy performance and mitigating the effects of climate change [9]. In numerous countries, including some developed ones, single-glazing windows continue to be prevalent. For instance, in Portugal, over 70% of residential buildings still feature windows with simple glass. This information was obtained from a 2011 survey focused on energy consumption in the residential sector. Consequently, implementing a nationwide initiative to upgrade glazing systems would bring about a significant transformation [122]. It was estimated that if all existing and new homes were to replace their single-glazing windows with optimal low-E double-glazing solutions, it could result in a reduction of approximately 0.5%, or 32 Petajoules in Australia’s total annual energy requirements [21]. Therefore, improving the energy efficiency of glazing systems is essential to reduce the reliance on fossil fuels, lower carbon emissions, and enhance indoor comfort, all of which are crucial factors for achieving NZEBs [30].

Figure 7 depicts how glazing systems can influence a building’s thermal comfort and energy requirements over the course of a year, encompassing nine distinct conditions. In regions characterized by hot climates and extended cooling periods, it is crucial to avoid excessive solar gain (condition 3) and heat gain resulting from the temperature difference between indoor and outdoor environments (condition 5). This prevention is essential to avoid thermal discomfort and limit the building’s overall energy needs. Conversely, in cold climates with prolonged heating seasons, it is important to prevent heat loss prompted by indoor/outdoor temperature differences (condition 4) while benefiting from the positive aspects of solar gain (condition 2) to ensure both thermal comfort and a reduction in the building’s energy use. Additionally, during times and in areas where the sun’s angle is lower in the sky, direct solar radiation on occupants (condition 1) can lead to thermal discomfort and a subsequent increase in the building’s energy needs. Therefore, the implementation of solar control strategies becomes essential.

Figure 7.

Effects of glazing systems on a building’s thermal comfort and energy demands throughout the year considering nine distinct conditions (each number belongs to a specific condition).

A common strategy for employing nearly zero-energy buildings (NZEBs) in the United Kingdom (UK) to achieve the national target for 2050 is improving the thermal insulation in glazing units to reduce the space heating load in cold climates. Current UK government standards for double-glazed windows state that windows should be constructed to achieve U-values no more than 1.6 () [45]. According to the National Building Code of Finland, the U-values are as follows: Windows U-value: standard: 1 (); maximum: 1.8 () [123]. The findings obtained from the ZEBRA2020 project in Europe concerning over 400 NZEBs, whether newly constructed or renovated, reveal that the majority of U-values for windows fell within the range of 0.9 () to 1.1 () [7,124,125]. Figure 8 presents the average U-value of glazing and overall window, alongside the glazing g-value of passive houses located in Sweden, Belgium, and Portugal with three different climates. The data are sourced from the Passive House database [126]. This illustration distinctly demonstrates the favorable reception of lower glazing U-values in cold climates, such as Sweden. Moreover, it is evident that the average g-value of glazing systems in all three countries is constrained to 0.5, underscoring the significance of regulating the indoor influx of solar radiation. It is worth mentioning that in Portugal, double glazing emerged as the prevailing glazing solution in passive houses, whereas in Sweden and Belgium, triple glazing took precedence as the dominant choice.

Figure 8.

Average glazing U-value (Ug), glazing g-value, and entire window U-value (Uw) of passive houses in Sweden, Belgium, and Portugal with three different climates.

It is important to acknowledge that the relationship between glazing systems and climate change is mutually influential, as both can impact each other. On the one hand, the focus should be on how glazing systems can contribute to mitigating climate change. On the other hand, it is crucial to examine which type of glazing solution can effectively maintain its benefits in the face of evolving future conditions caused by climate change. Climate change significantly affects the facade building materials as they are exposed to diverse weather conditions. Furthermore, the impacts of climate change on facade building materials have the potential to cause occupational health risks [127]. It has been observed that in mild and warm climates such as those found in Australia, Italy, Qatar, and Iran, climate change can lead to increased temperatures and reduced HVAC (heating, ventilation, and air conditioning) system efficiency, resulting in overheating issues. This highlights the growing significance of implementing glazing systems with improved solar control capacity to mitigate the impact of these factors [128,129,130,131]. As global warming progresses, it has been noted that the increase in cooling energy consumption due to a warmer climate offsets the decrease in heating energy usage [129]. This reality may serve as a motivation to take climate change into account when designing or retrofitting energy-optimized buildings [132].

The review of existing literature has demonstrated that evaluating a glazing solution solely based on one criterion, such as energy efficiency or cost-effectiveness, may not lead to an optimal solution. Some energy-efficient glazing solutions were found to be impractical in terms of cost-effectiveness or environmental friendliness. Furthermore, the number of studies considering multiple evaluation criteria simultaneously is limited. Even in comprehensive studies, the focus is mostly on three aspects named “3Es: energy, economic, and environmental impacts of glazing retrofitting [133]”. The present review paper aims to highlight the significant impact of glazing systems on the thermal comfort of buildings, suggesting they must be considered alongside the 3Es aspects. Consequently, the authors of the present study propose a new comprehensive evaluation framework named “EThCE”, representing energy, thermal comfort, cost-effectiveness, and environmental impacts and their interrelationships (see Figure 9). The interrelationships between these evaluation criteria can be intricate to the point that enhancing one aspect may have potentially negative consequences for another aspect (see Table 5). Table 5 underlines that the EThCE aspects should be arranged in order of importance based on the desired objectives.

Figure 9.

Illustration of the interrelationship between the four main evaluation criteria (EThCE).

Table 5.

Examples of the interrelationships including potential conflicts between glazing systems’ four main evaluation criteria.

The literature review demonstrated that providing general recommendations for the selection of glazing solutions may not be reasonable. The thermal and optical properties of a glazing system, such as U-value and g-value, are heavily influenced by climatic conditions, orientation, window frame, and size [11]. When considering environmental and economic factors, other facade components, building type, regional energy prices, energy accessibility, economic conditions, and more can also play a significant role in choosing an optimum glazing solution. These factors are interrelated, making it impossible to find a universal solution for glazing selection. However, adopting a comprehensive approach for the selection of glazing systems, while complex, towards NZEBs is feasible.

The present study proposes the comprehensive approach depicted in Figure 10 to guide the glazing selection process. When dealing with an existing building destined to be retrofitted into a nearly zero-energy building (NZEB), the initial step involves evaluating the thermal and optical characteristics of the current glazing systems, ideally utilizing reliable in situ techniques. These methods are preferable as they account for actual boundary conditions and the present state of the glazing. In contrast, simulations or manufacturer data might not accurately reflect these conditions and potential glazing degradation. Subsequently, an initial assessment of the energy performance and thermal comfort of the existing building, considering the acquired glazing and other building attributes, offers insight into the impacts of the glazing units on the building’s performance. The following stages of glazing selection are identical for both NZEBs and existing buildings. Initially, determining appropriate U-values and g-values requires consideration of climatic conditions, along with building and façade attributes, in alignment with local building codes. Once the glazing’s desired thermal and optical properties are identified, the exploration of potential commercially available solutions follows. This exploration considers factors such as eco-environmental glazing impacts, local energy, economic conditions, and the available budget. Next, the performance of the chosen solutions within the building is assessed using the EThCE approach, with the aspects ordered by significance. In cases where the predefined objectives are not met, the process can be iterated for alternative glazing options. This iterative process should lead to the ultimate achievement of a solution that effectively balances the interrelated aspects of EThCE.

Figure 10.

The comprehensive glazing selection approach towards NZEBs proposed by the authors.

It is essential to highlight that currently, due to factors such as market maturity, reasonable production costs, variety, and ease of use, conventional glazing and shading systems (e.g., double or triple glazing, coatings, low-E, solar control films, internal/external shading devices) are more feasible for most cases in retrofitting or constructing NZEBs worldwide. Over time, the integration of advanced solutions (e.g., vacuum glazing, photovoltaic glazing, aerogel glazing, PCM-integrated glazing, water flow glazing, smart glazing, etc.) in NZEBs will become more viable. However, despite the limited maturity of advanced glazing technologies currently available on the market, there is still a possibility for their application in certain cases when considering the entire life cycle.

Finally, it is important to highlight that future studies can incorporate additional evaluation criteria, such as glare and visual comfort, into the proposed approach for selecting glazing solutions.

8. Conclusions

With the progression towards nearly zero-energy goals for buildings, the incorporation of window systems, including the glazing components, becomes crucial in enhancing building energy efficiency and addressing the challenges posed by climate change. The use of high-performance glazing systems plays a crucial role in ensuring natural light, ventilation, favorable solar gain, aesthetics, and positive psychological effects in buildings while maintaining high energy performance and thermal comfort. This review study assessed different glazing solutions based on four perspectives: Energy performance, thermal comfort, cost-effectiveness, and environmental impact (EThCE), while also taking into account their interrelationships. It was concluded that offering general recommendations for selecting glazing solutions may not be practical. The thermal and optical properties of a glazing system (i.e., the U-value and g-value) are significantly influenced by factors such as local climatic conditions, building orientation, window frame characteristics, and window size. Additionally, when considering environmental and economic factors, various elements of the building envelope, the type of construction, regional energy pricing, energy availability, economic considerations, and numerous other factors come into play in determining the most suitable glazing solution. These factors are interrelated. However, it was shown that it would be feasible to adopt a comprehensive approach as proposed by the authors for the intelligent selection of glazing systems towards NZEBs. In the end, for future studies, it was suggested that additional aspects such as glare and visual comfort could be incorporated into the proposed approach for selecting glazing solutions.

Author Contributions