Determining and Verifying the Operating Parameters of Suppression Nozzles for Belt Conveyor Drives

Abstract

:1. Introduction

2. Materials and Methods

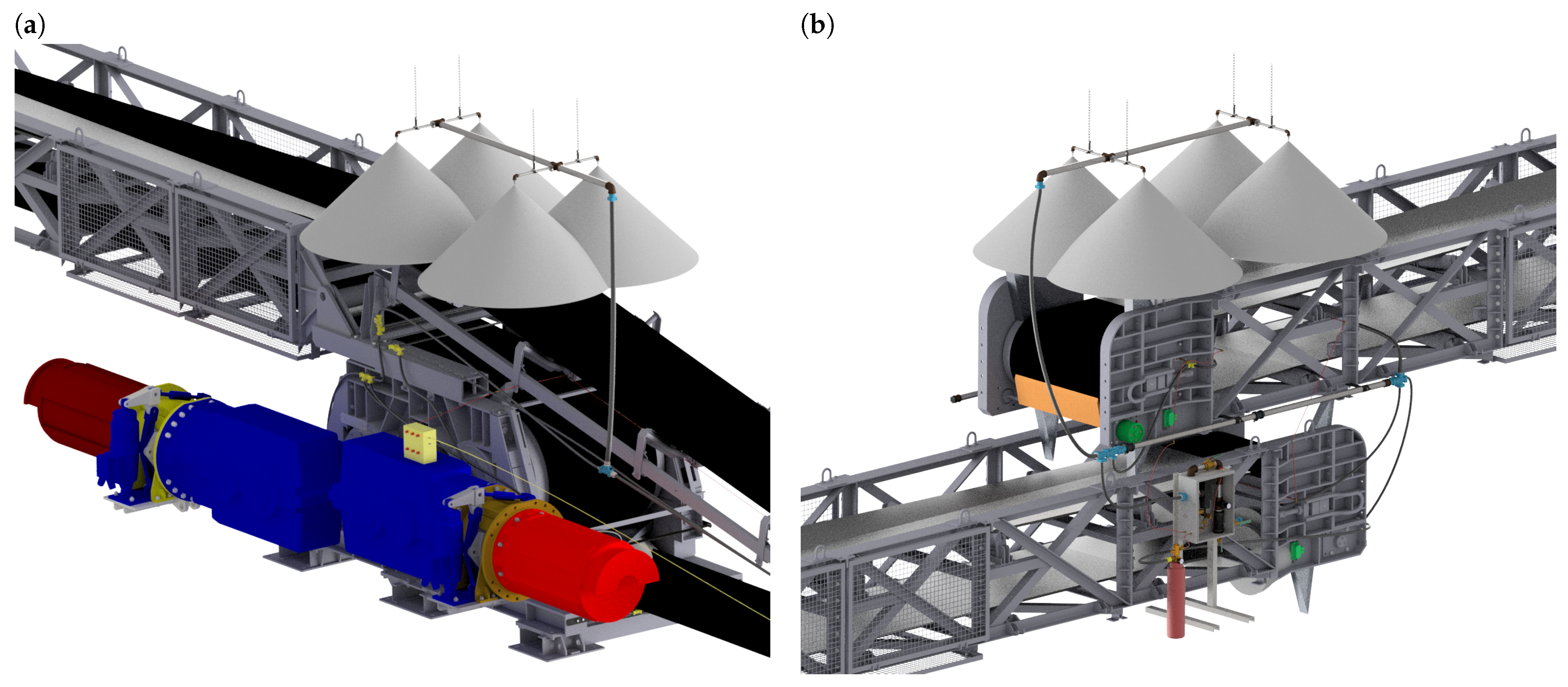

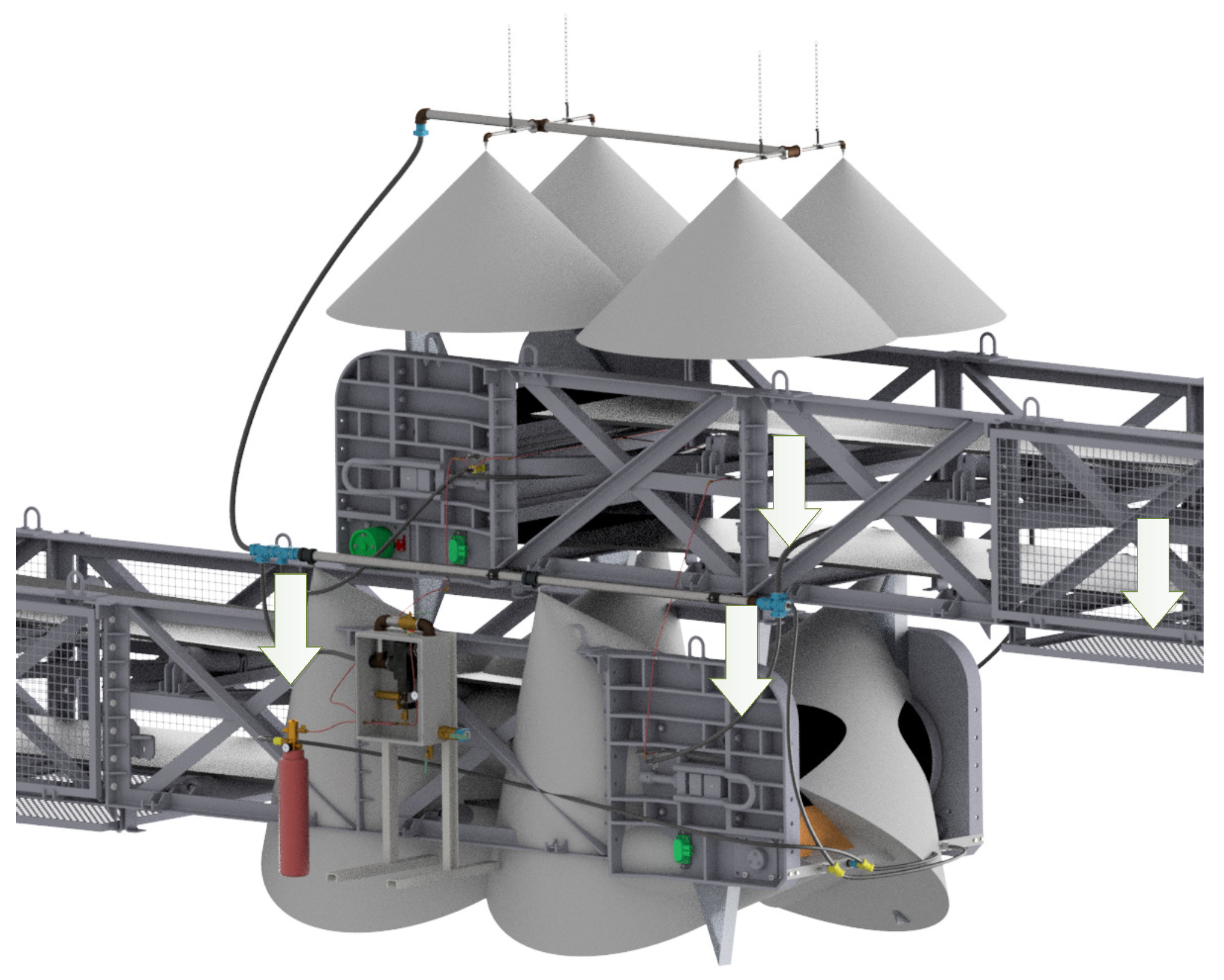

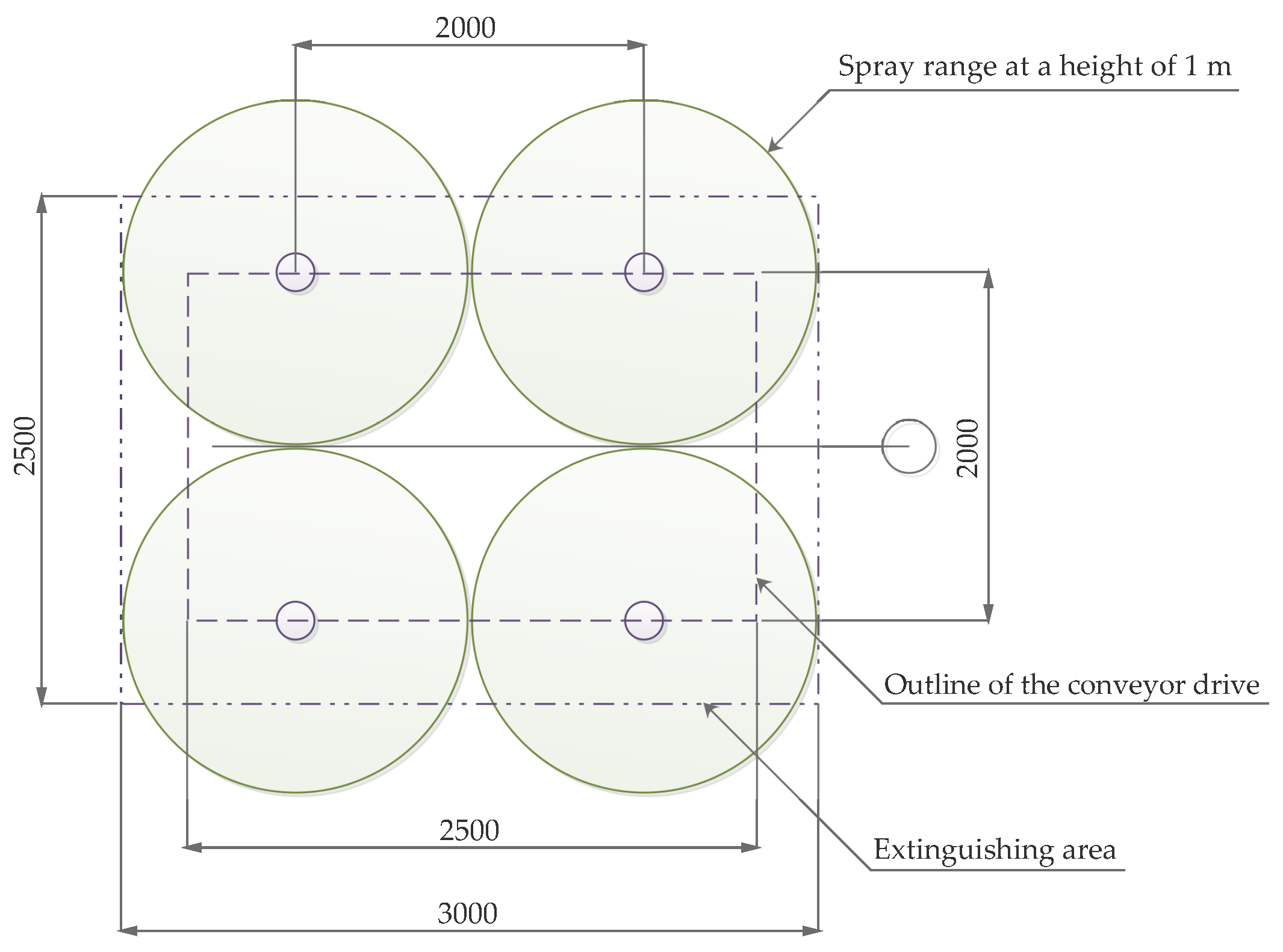

2.1. Construction of the AMIGA Fire Suppression System

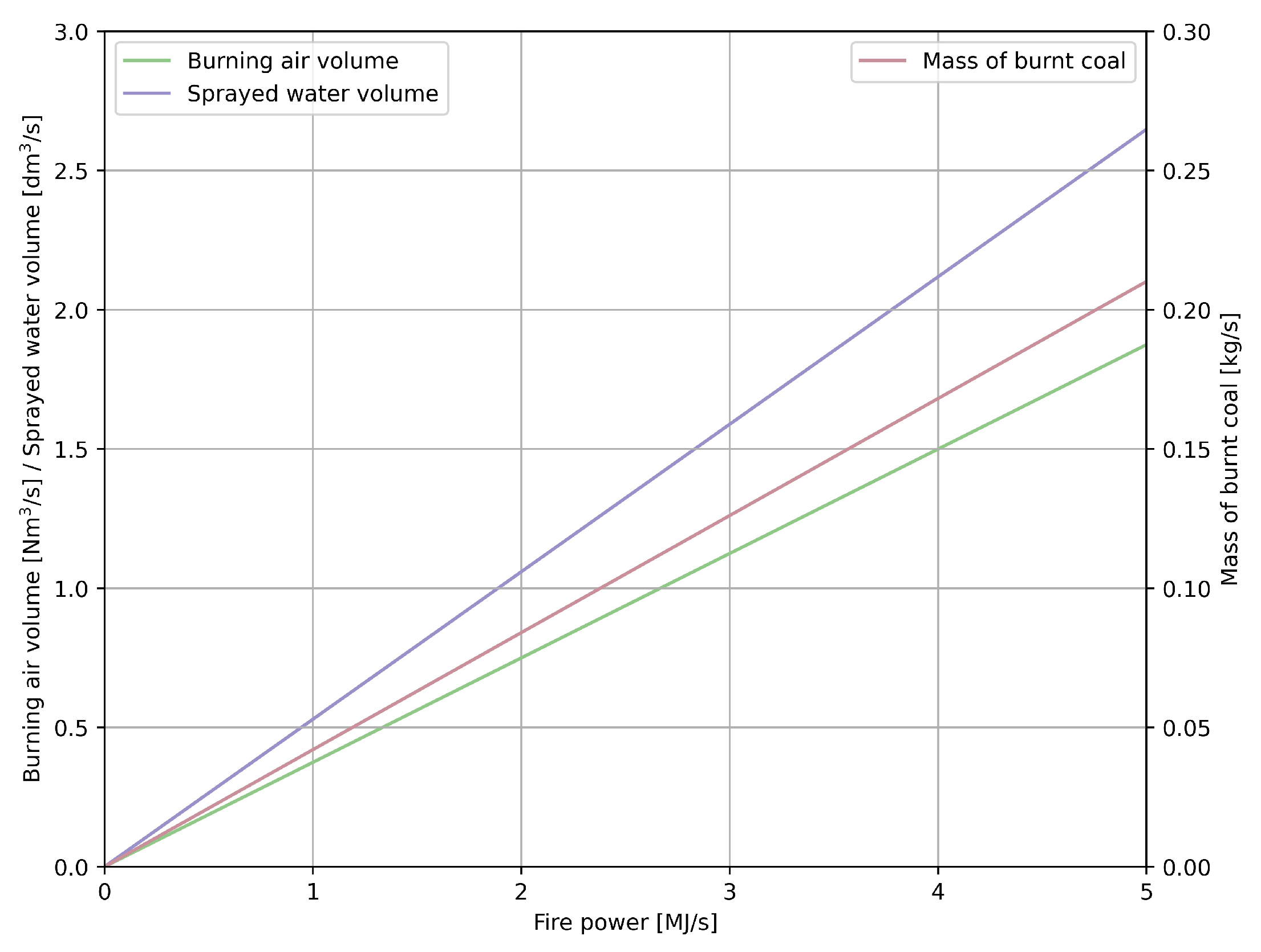

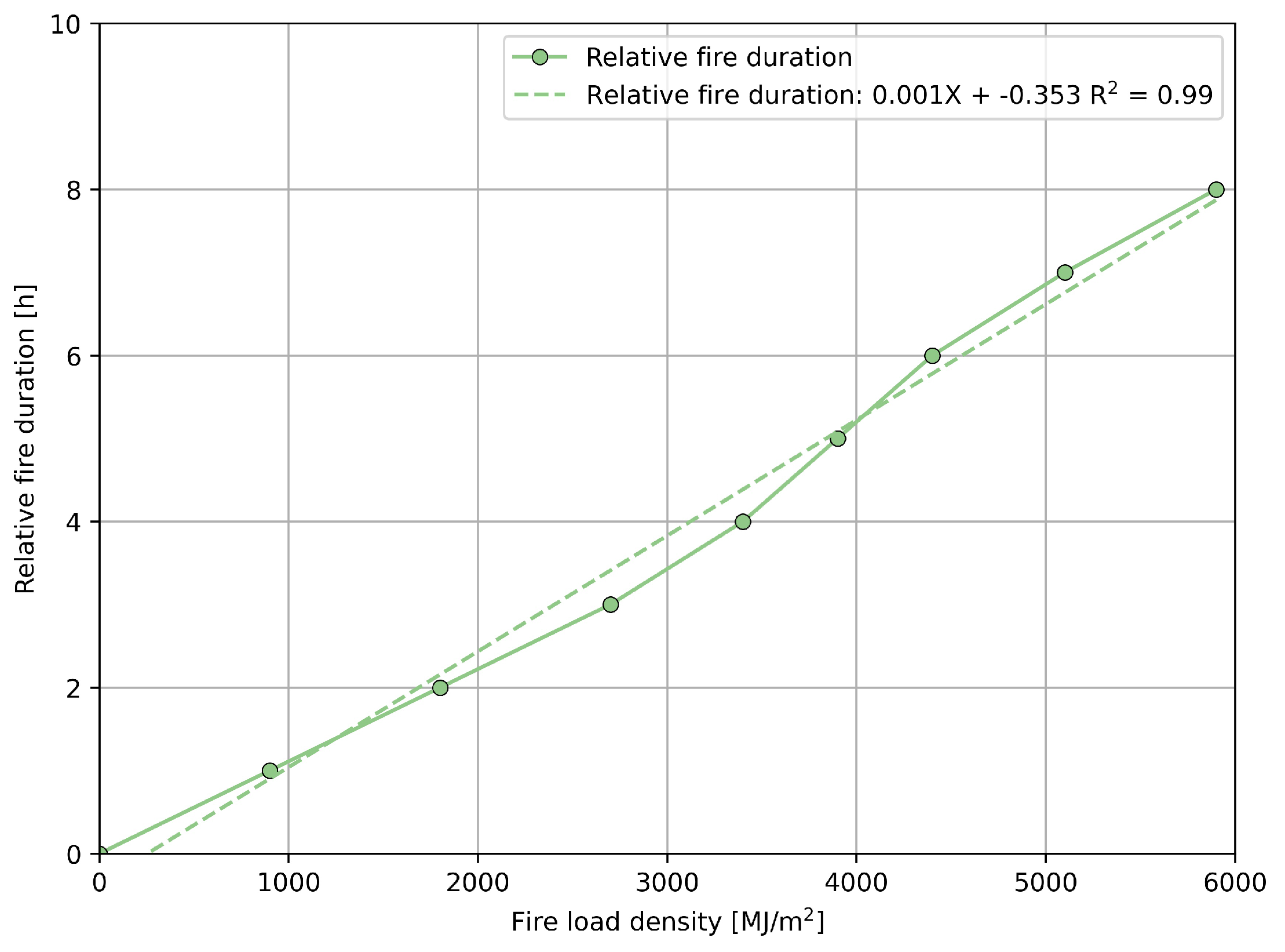

2.2. Methodology for Determining the Parameters of Extinguishing Nozzles

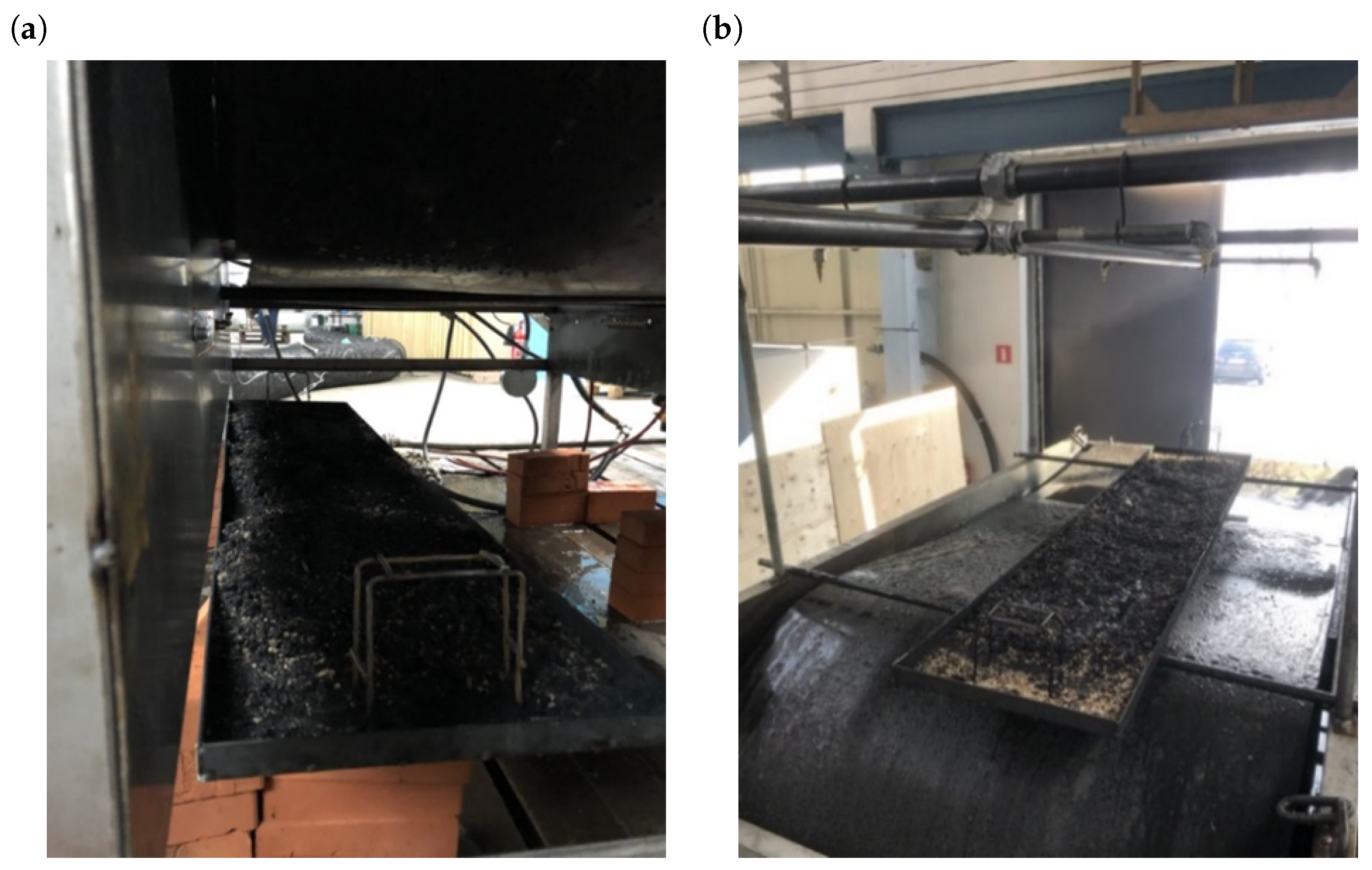

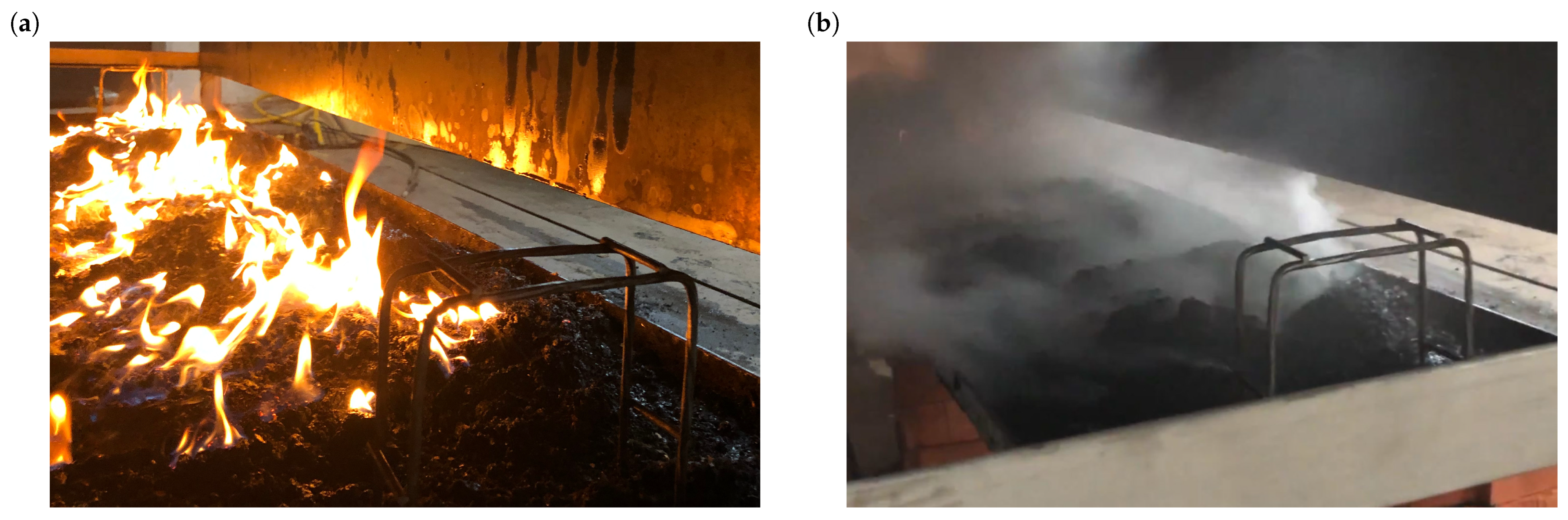

2.3. Measurement Station and Bench Tests

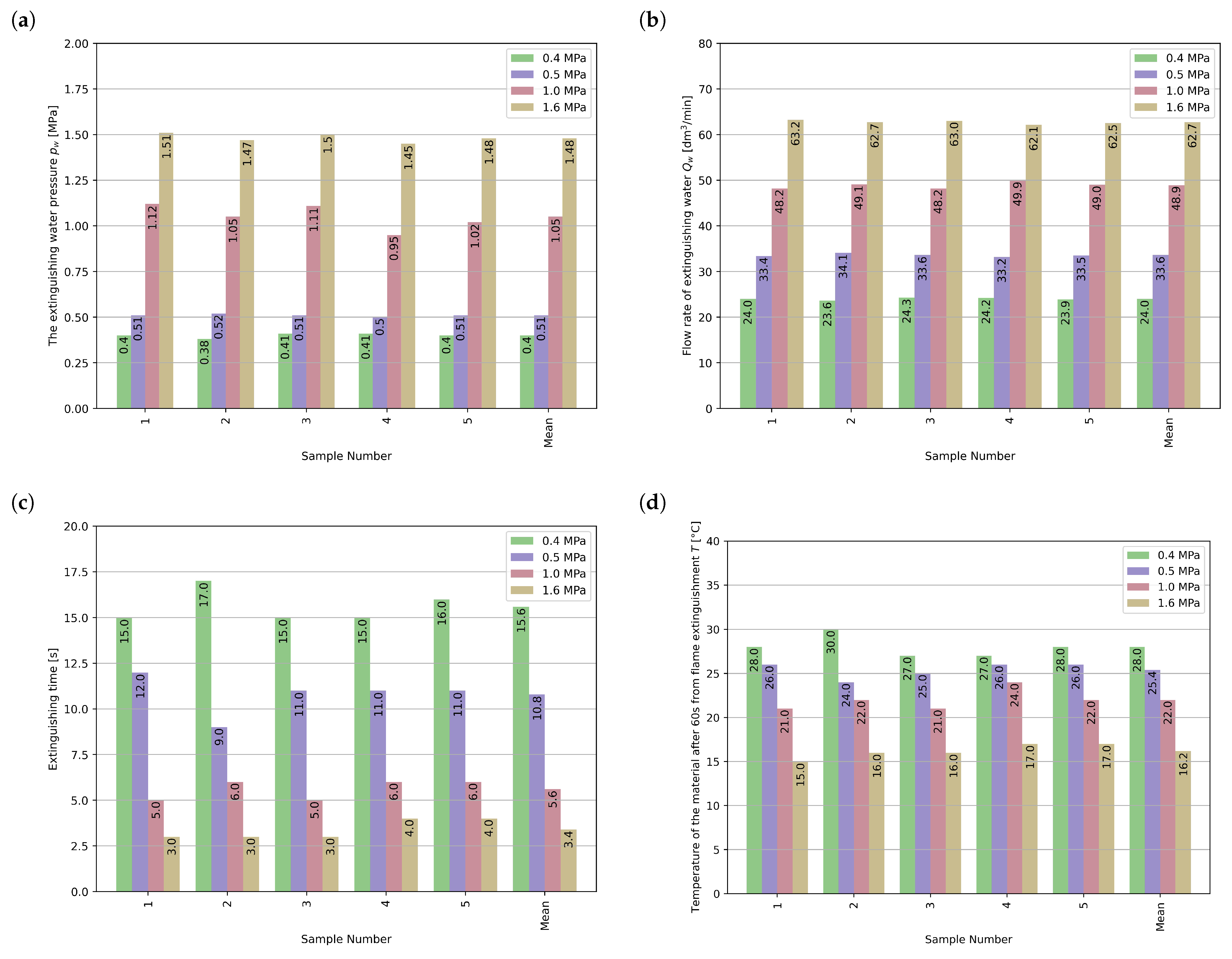

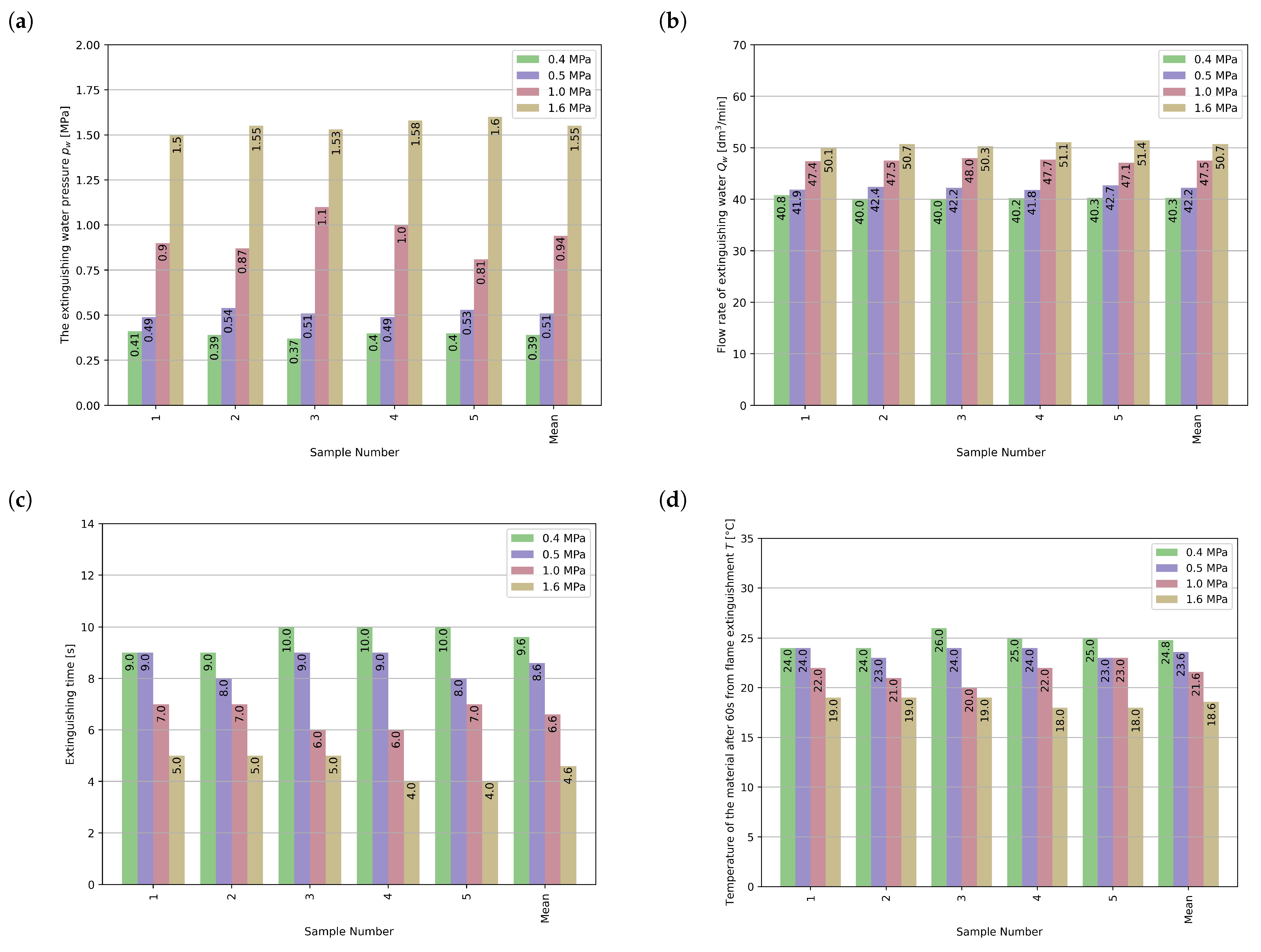

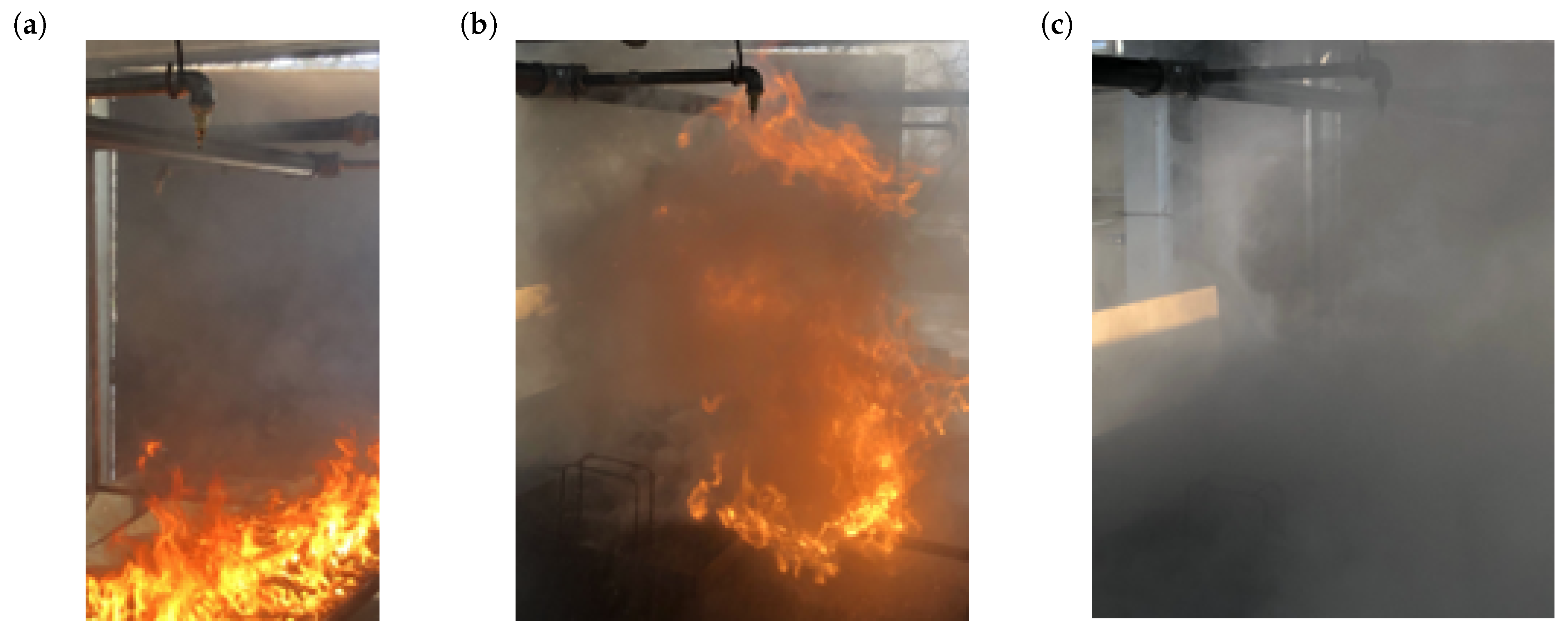

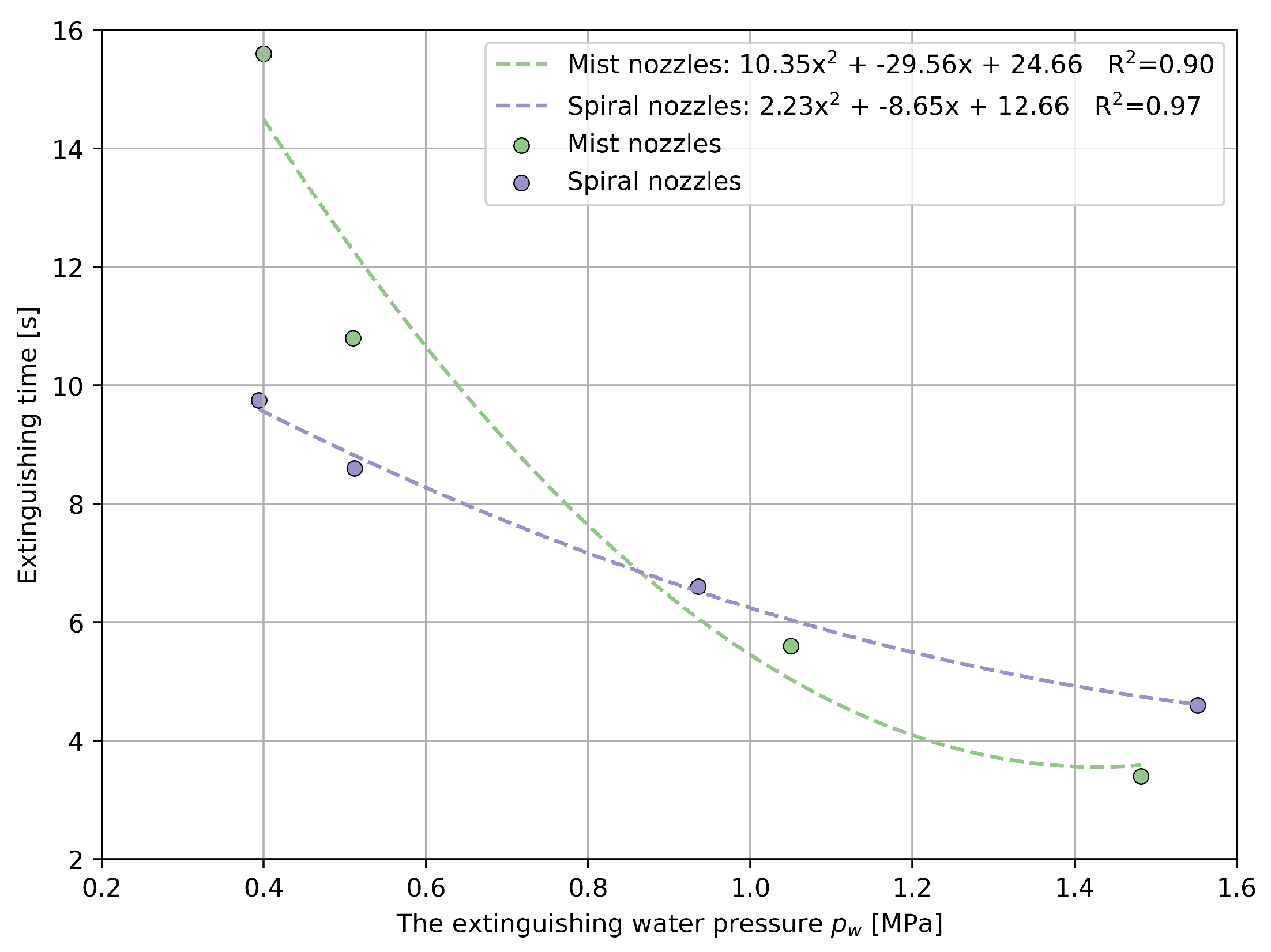

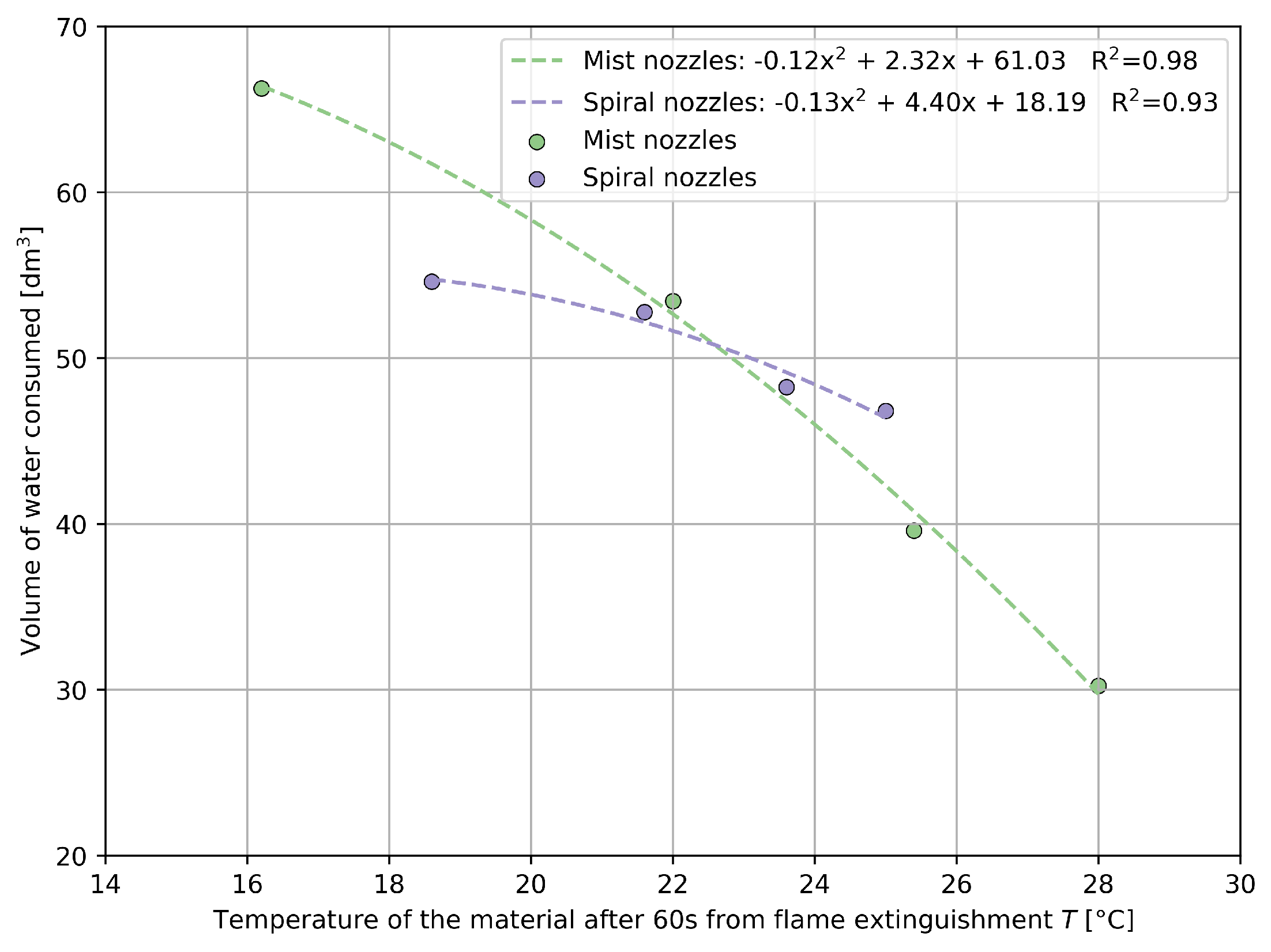

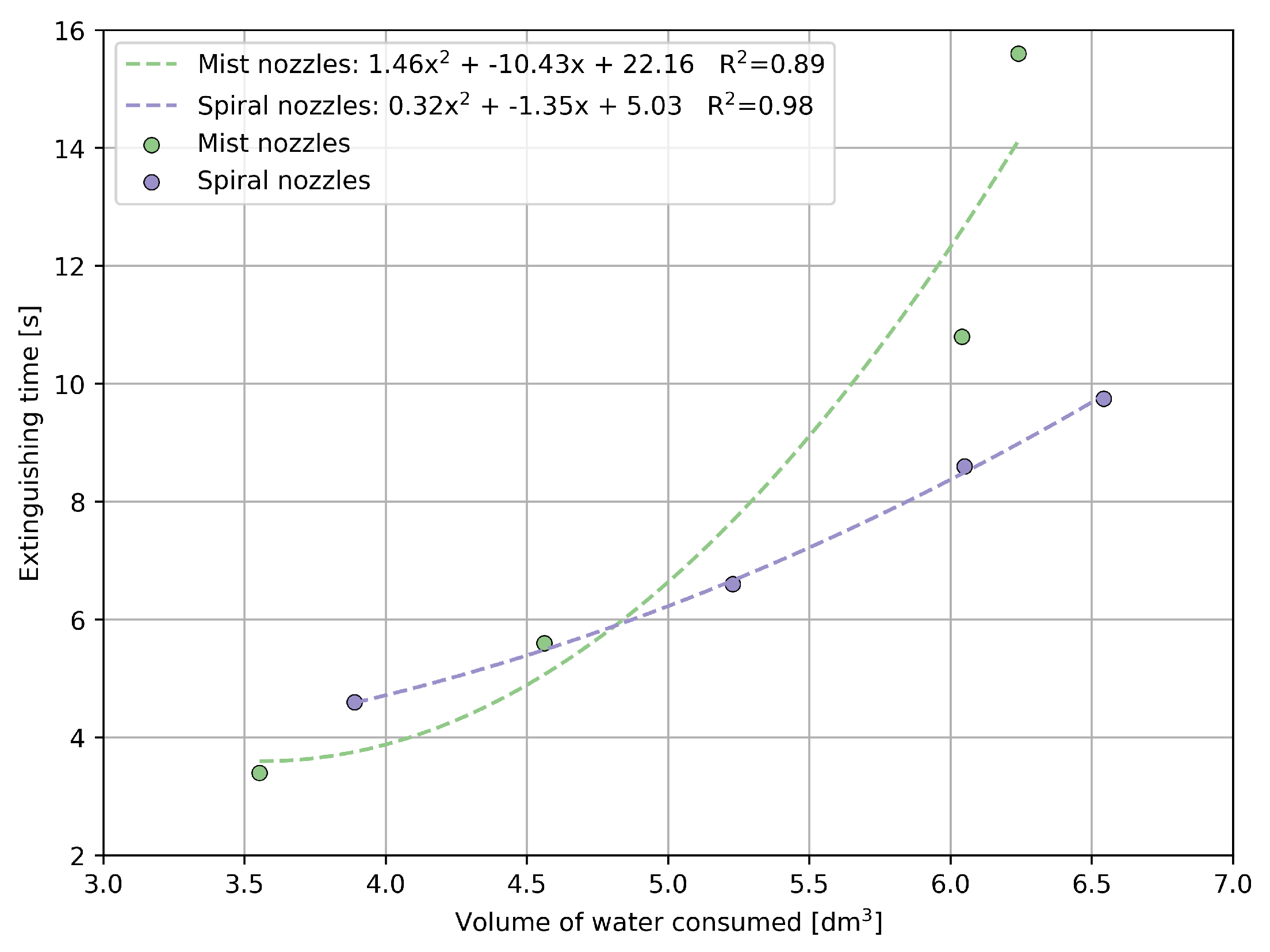

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Braun, T.; Hennig, A.; Lottermoser, B.G. The need for sustainable technology diffusion in mining: Achieving the use of belt conveyor systems in the German hard-rock quarrying industry. J. Sustain. Min. 2017, 16, 24–30. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, X. Optimal control of operation efficiency of belt conveyor systems. Appl. Energy 2010, 87, 1929–1937. [Google Scholar] [CrossRef]

- Mathaba, T.; Xia, X. Optimal and energy efficient operation of conveyor belt systems with downhill conveyors. Energy Effic. 2017, 10, 405–417. [Google Scholar] [CrossRef]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Ananth, K.N.S.; Rakesh, V.; Visweswarao, P.K. Design and selecting the proper conveyor-belt. Int. J. Adv. Eng. Technol. 2013, 4, 43–49. [Google Scholar]

- Schools, T. Condition monitoring of critical mining conveyors. Eng. Min. J. 2015, 216, 50. [Google Scholar]

- Haidai, O.; Ruskykh, V.; Ulanova, N.; Prykhodko, V.; Cabana, E.C.; Dychkovskyi, R.; Howaniec, N.; Smolinski, A. Mine Field Preparation and Coal Mining in Western Donbas: Energy Security of Ukraine—A Case Study. Energies 2022, 15, 4653. [Google Scholar] [CrossRef]

- Szkudlarek, Z.; Ivanova, T.N. Mechanization of cleaning the area of operating belt conveyor system. Min. Mach. 2021, 39, 2–12. [Google Scholar] [CrossRef]

- Nieśpiałowski, K.; Chelyadyn, L.; Romanyshyn, T. Cooling system for high-power drives in belt conveyors. Min. Mach. 2022, 40, 54–63. [Google Scholar] [CrossRef]

- Ray, S.K.; Khan, A.M.; Mohalik, N.K.; Mishra, D.; Varma, N.K.; Pandey, J.K.; Singh, P.K. Methodology in early detection of conveyor belt fire in coal transportation. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Barros-Daza, M.J.; Luxbacher, K.D.; Lattimer, B.Y.; Hodges, J.L. Mine conveyor belt fire classification. J. Fire Sci. 2022, 40, 44–69. [Google Scholar] [CrossRef]

- Shijie, P.; Huang, Z.; Dong, D.W. Numerical simulation study on fire hazard of a coal mine transport roadway. Min. Sci. 2022, 29, 33–52. [Google Scholar] [CrossRef]

- Litton, C.D.; Lazzara, C.P.; Perzak, F.J. Fire Detection for Conveyor Belt Entries; US Department of the Interior, Bureau of Mines: Washington, DC, USA, 1991; Volume 9380.

- Semenchenko, A.; Stadnik, M.; Belitsky, P.; Semenchenko, D.; Stepanenko, O. The impact of an uneven loading of a belt conveyor on the loading of drive motors and energy consumption in transportation. East.-Eur. J. Enterp. Technol. 2016, 4, 42–51. [Google Scholar] [CrossRef]

- Homišin, J.; Grega, R.; Kaššay, P.; Fedorko, G.; Molnár, V. Removal of systematic failure of belt conveyor drive by reducing vibrations. Eng. Fail. Anal. 2019, 99, 192–202. [Google Scholar] [CrossRef]

- Persson, B. Conveyor belt drive physics. Tribol. Lett. 2020, 68, 1–9. [Google Scholar] [CrossRef]

- Chakraborty, S.; Arvind, P.; Poddar, S.; Acharya, A.K.; Kumar, S.D. Integration of IoT Based PLC for Smart Relaying of a PV-Fed Induction Motor Driven Conveyor Belt. In Proceedings of the Fifth International Conference on Microelectronics, Computing and Communication Systems: MCCS 2020; Springer: Singapore, 2021; pp. 155–165. [Google Scholar] [CrossRef]

- Edomah, N. Effects of voltage sags, swell and other disturbances on electrical equipment and their economic implications. In Proceedings of the CIRED 2009—20th International Conference and Exhibition on Electricity Distribution—Part 1. IET, Prague, Czech Republic, 8–11 June 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Hamacher, S.; Hamacher, S. Common conveyor drives. In The Drum Motor: The All-Rounder in Modern Unit Handling Conveyor Technology; Springer: Berlin/Heidelberg, Germany, 2020; pp. 29–53. [Google Scholar] [CrossRef]

- Wijaya, H.; Rajeev, P.; Gad, E.; Vivekanamtham, R. Distributed optical fibre sensor for condition monitoring of mining conveyor using wavelet transform and artificial neural network. Struct. Control. Health Monit. 2021, 28, e2827. [Google Scholar] [CrossRef]

- Goldbeck, L. Improved maintenance reduces risk, raises profitability in conveyor operations. In Proceedings of the 2011 IEEE-IAS/PCA 53rd Cement Industry Technical Conference, St. Louis, MO, USA, 22–26 May 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Cheremushkina, M.; Poddubniy, D. Reducing The Risk of Fires in Conveyor Transport. IOP Conf. Ser. Earth Environ. Sci. 2017, 50, 012043. [Google Scholar] [CrossRef]

- Francart, W. Reducing belt entry fires in underground coal mines. In Proceedings of the 11th US/North American Mine Ventilation Symposium 2006, Philadelphia, PA, USA, 5–7 June 2006; pp. 303–308. [Google Scholar]

- Cheng, L.; Ueng, T.; Liu, C.W. Simulation of ventilation and fire in the underground facilities. Fire Saf. J. 2001, 36, 597–619. [Google Scholar] [CrossRef]

- Ajrash, M.J.; Zanganeh, J.; Moghtaderi, B. The effects of coal dust concentrations and particle sizes on the minimum auto-ignition temperature of a coal dust cloud. Fire Mater. 2017, 41, 908–915. [Google Scholar] [CrossRef]

- Thakur, P. Advanced Mine Ventilation: Respirable Coal Dust, Combustible Gas and Mine Fire Control; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Brake, D. Fire modelling in underground mines using Ventsim Visual VentFIRE Software. In Proceedings of the Australian Mine Ventilation Conference, Adelaide, SA, Australia, 1–3 July 2013; pp. 1–3. [Google Scholar]

- European Union. ATEX (Atmosphères Explosibles). In Directive 94/9/EC; European Union: Brussels, Belgium, 2003. [Google Scholar]

- VdS. Sprinkleranlagen. Planung und Einbau; VdS Schadenverhütung GmbH: Cologne, Germany, 2002. [Google Scholar]

- PN-EN 12845+A2:2010; Stałe Urządzenia Gaśnicze—Automatyczne Urządzenia Tryskaczowe—Projektowanie, Instalowanie i Konserwacja. Polski Komitet Normalizacyjny: Warsaw, Poland, 2010.

- Ministerstwo Energii. Rozporządzenie Ministra Energii z Dnia 23 Listopada 2016 r. w Sprawie Szczegółowych Wymagań Dotyczących Prowadzenia Ruchu Podziemnych Zakładów Górniczych, 2016. Dz.U. 2016 Poz. 2077. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001118 (accessed on 14 August 2023).

- FM Global. FM Global Data Sheet 5-32: Automatic Sprinkler Systems; FM Global: Johnston, RI, USA, 2019. [Google Scholar]

- Liu, Y.; Wang, X.; Tang, Q.; Li, G.; Pan, C.; Liu, T.; Ni, X.; Wu, Y. Mechanism insight of shielded methane non-premixed jet flame extinction with water mist: OH-PLIF visualization and quantitative analysis of critical fire extinguishing. Fire Saf. J. 2022, 132, 103642. [Google Scholar] [CrossRef]

- Santangelo, P.E.; Tartarini, P. Full-scale experiments of fire suppression in high-hazard storages: A temperature-based analysis of water-mist systems. Appl. Therm. Eng. 2012, 45, 99–107. [Google Scholar] [CrossRef]

- Chiu, C.W.; Li, Y.H. Full-scale experimental and numerical analysis of water mist system for sheltered fire sources in wind generator compartment. Process Saf. Environ. Prot. 2015, 98, 40–49. [Google Scholar] [CrossRef]

- Hansen, R. Investigation on Fire Causes and Fire Behaviour: Vehicle Fires in Underground Mines in Sweden 1988–2010. 2013. Available online: https://www.diva-portal.org/smash/get/diva2:646570/FULLTEXT03.pdf (accessed on 14 August 2023).

- Liu, H.; Wang, F. Research on N2-inhibitor-water mist fire prevention and extinguishing technology and equipment in coal mine goaf. PLoS ONE 2019, 14, e0222003. [Google Scholar] [CrossRef]

- Hansen, R. Design Fires in Underground Mines. 2010. Available online: https://www.diva-portal.org/smash/get/diva2:305101/FULLTEXT01.pdf (accessed on 14 August 2023).

- Hansen, R. Design of fire scenarios for Australian underground hard rock mines—Applying data from full-scale fire experiments. J. Sustain. Min. 2019, 18, 163–173. [Google Scholar] [CrossRef]

- Stein, R.A. Economic and safety advantages of sprinklers. Risk Manag. 1995, 42, 27. [Google Scholar]

- Zhang, L.; Li, Y.; Duan, Q.; Chen, M.; Xu, J.; Zhao, C.; Sun, J.; Wang, Q. Experimental study on the synergistic effect of gas extinguishing agents and water mist on suppressing lithium-ion battery fires. J. Energy Storage 2020, 32, 101801. [Google Scholar] [CrossRef]

- Wen, X.; Wang, M.; Su, T.; Zhang, S.; Pan, R.; Ji, W. Suppression effects of ultrafine water mist on hydrogen/methane mixture explosion in an obstructed chamber. Int. J. Hydrogen Energy 2019, 44, 32332–32342. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, J. Research progress of water mist fire extinguishing technology and its application in battery fires. Process Saf. Environ. Prot. 2021, 149, 559–574. [Google Scholar] [CrossRef]

- Ray, S.; Singh, R.; Ghosh, A. Water mist-An emerging fire suppression system to control coal mine fire. J. Mines Met. Fuels 2008, 56, 129–134. [Google Scholar]

- Roguski, J.; Zbrożek, P.; Czerwienko, D. Wybrane Aspekty Stosowania w Obiektach Budowlanych Urządzeń Gaśniczych na Mgłę Wodną; Wydawnictwo Centrum Naukowo-Badawczego Ochrony Przeciwpożarowej im. Józefa Tuliszkowskiego Państwowy Instytut Badawczy. 2012. Available online: https://depot.ceon.pl/bitstream/handle/123456789/7741/wybrane-aspekty-stosowania-w-obiektach_1.pdf?sequence=1&isAllowed=y (accessed on 14 August 2023).

- National Fire Protection Association. Standard for Water Mist Fire Suppression Systems; NFPA—National Fire Protection Association: Quincy, MA, USA, 2000. [Google Scholar]

- Ruland, S.; Aebersold, T. Effective water mist system design lessens fire danger. Power Eng. 1999, 103, 200. [Google Scholar]

- Liu, Z.; Kim, A.K. A review of water mist fire suppression systems—Fundamental studies. J. Fire Prot. Eng. 1999, 10, 32–50. [Google Scholar] [CrossRef]

- PN-B-02852:2001; Ochrona Przeciwpożarowa Budynków—Obliczanie Gęstości Obciążenia Ogniowego Oraz Wyznaczanie Względnego Czasu Trwania Pożaru. Polski Komitet Normalizacyjny: Warsaw, Poland, 2001.

| Type of Mist Nozzle | Number of Nozzles | Flow Rate at 2.5 bar Pressure [dm3/min] | Total [dm3/min] |

|---|---|---|---|

| Cone | 4 | 3.6 | 14.4 |

| Flat | 5 | 1.4 | 7.0 |

| Total [dm3/min] | 21.4 | ||

| Type of Installation | Water Pressure [MPa] | Water Flow Rate [dm3/min] | Extinguishing Time [s] | Water Energy [kJ] | Water Energy Per 1 s [kJ] | Energy Used for Extinguishing E [kJ] | Energy Per Spraying Nozzle [kJ] |

|---|---|---|---|---|---|---|---|

| Mist | 0.4 | 24 | 15.6 | 9.60 | 0.16 | 2.50 | 0.28 |

| 0.5 | 33.56 | 10.8 | 16.78 | 0.28 | 3.02 | 0.34 | |

| 1 | 48.88 | 5.6 | 48.88 | 0.81 | 4.56 | 0.51 | |

| 1.48 | 62.7 | 3.4 | 92.80 | 1.55 | 5.26 | 0.58 | |

| Spiral | 0.394 | 40.26 | 9.75 | 15.86 | 0.26 | 2.58 | 0.64 |

| 0.512 | 42.2 | 8.6 | 21.61 | 0.36 | 3.10 | 0.77 | |

| 0.936 | 47.54 | 6.6 | 44.50 | 0.74 | 4.89 | 1.22 | |

| 1.55 | 50.72 | 4.6 | 78.62 | 1.31 | 6.03 | 1.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bałaga, D.; Kalita, M.; Siegmund, M.; Nieśpiałowski, K.; Bartoszek, S.; Bortnowski, P.; Ozdoba, M.; Walentek, A.; Gajdzik, B. Determining and Verifying the Operating Parameters of Suppression Nozzles for Belt Conveyor Drives. Energies 2023, 16, 6077. https://doi.org/10.3390/en16166077

Bałaga D, Kalita M, Siegmund M, Nieśpiałowski K, Bartoszek S, Bortnowski P, Ozdoba M, Walentek A, Gajdzik B. Determining and Verifying the Operating Parameters of Suppression Nozzles for Belt Conveyor Drives. Energies. 2023; 16(16):6077. https://doi.org/10.3390/en16166077

Chicago/Turabian StyleBałaga, Dominik, Marek Kalita, Michał Siegmund, Krzysztof Nieśpiałowski, Sławomir Bartoszek, Piotr Bortnowski, Maksymilian Ozdoba, Andrzej Walentek, and Bożena Gajdzik. 2023. "Determining and Verifying the Operating Parameters of Suppression Nozzles for Belt Conveyor Drives" Energies 16, no. 16: 6077. https://doi.org/10.3390/en16166077

APA StyleBałaga, D., Kalita, M., Siegmund, M., Nieśpiałowski, K., Bartoszek, S., Bortnowski, P., Ozdoba, M., Walentek, A., & Gajdzik, B. (2023). Determining and Verifying the Operating Parameters of Suppression Nozzles for Belt Conveyor Drives. Energies, 16(16), 6077. https://doi.org/10.3390/en16166077