Toward Zero Emission Construction: A Comparative Life Cycle Impact Assessment of Diesel, Hybrid, and Electric Excavators

Abstract

:1. Introduction

- What is the hot spot of environmental impact stemming from construction machinery according to a life cycle perspective?

- How does the level of electrification influence the environmental impact of construction machinery?

- Which measures are key to reducing construction machinery’s environmental impact?

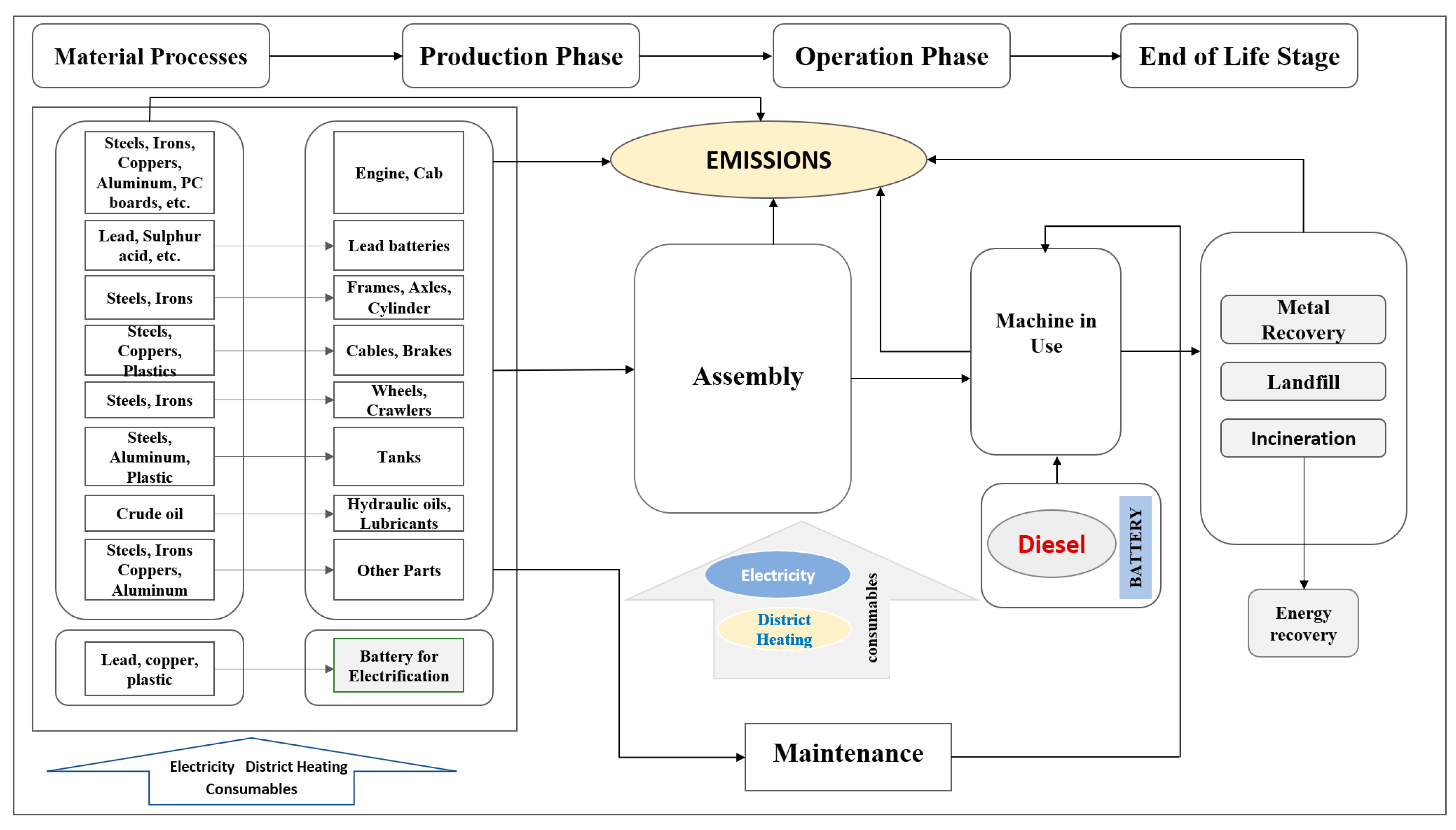

2. Materials and Methods

2.1. Goal and Scope

2.2. Inventory Analysis

2.2.1. Manufacturing, Maintenance, End-of-Life

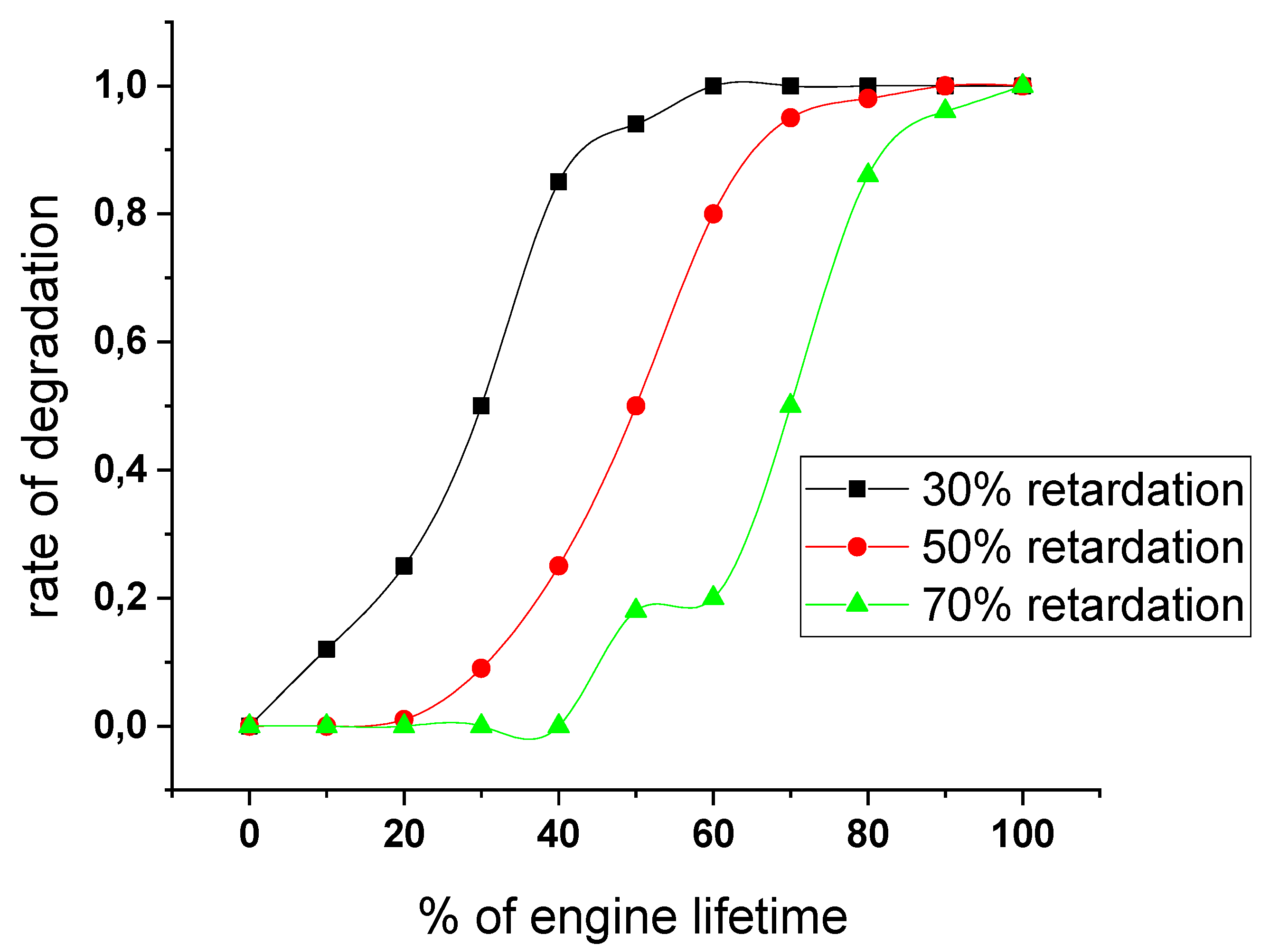

2.2.2. Operation

2.2.3. Data Collection

2.3. Impact Assessment

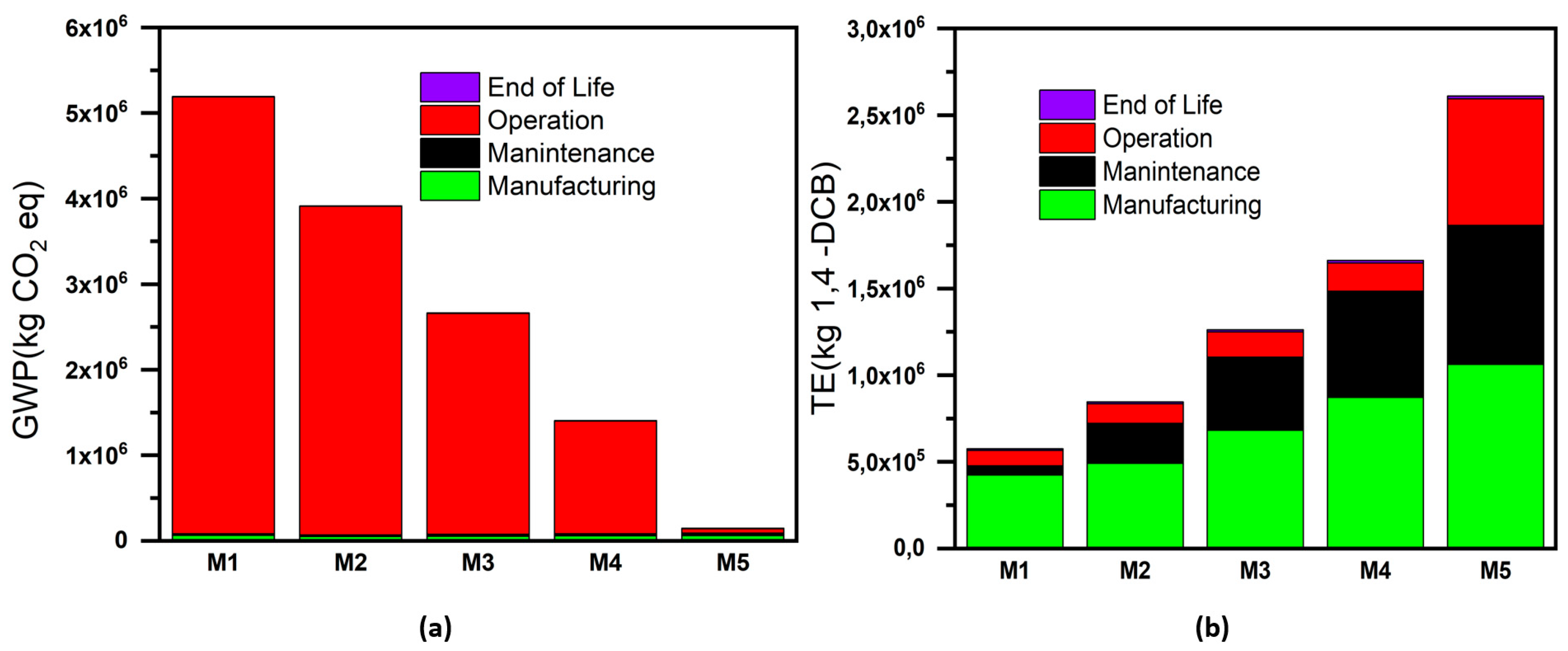

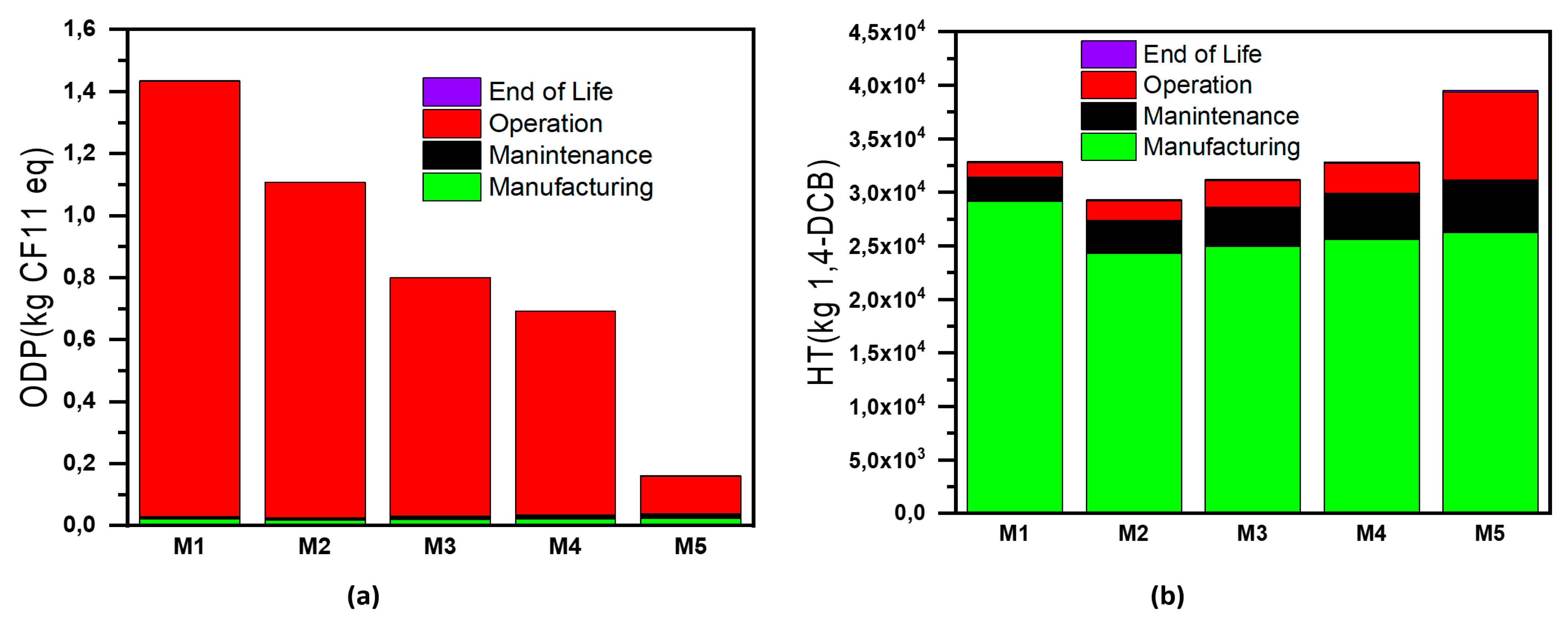

3. Results

Sensitivity Analysis

4. Discussion

5. Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A review of carbon footprint reduction in construction industry, from design to operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef] [PubMed]

- Barati, K.; Shen, X. Modelling Traffic Conditions on Fuel Use and Emissions of On-Road Construction Equipment. In Proceedings of the ISARC International Symposium on Automation and Robotics in Construction, Banff, AL, Canada, 21–24 May 2019; Available online: https://www.proquest.com/docview/2268537821?pq-origsite=gscholar&fromopenview=true (accessed on 25 March 2023).

- Barati, K.; Shen, X. Comprehensive methodology for emission modelling of earthmoving equipment. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction and Mining (ISARC 2016), Auburn, AL, USA, 18–21 July 2016. [Google Scholar]

- Kaboli, A.S.; Carmichael, D.G. Emission and cost configurations in earthmoving operations. Organ. Technol. Manag. Constr. Int. J. 2012, 4, 393–402. [Google Scholar] [CrossRef]

- Lewis, P.; Rasdorf, W. Fuel use and pollutant emissions taxonomy for heavy duty diesel construction equipment. J. Manag. Eng. 2017, 33, 4016038. [Google Scholar] [CrossRef]

- Aragones, M.; Serafimova, T. Zero Emission Construction Sites: The Possibilities and Barriers of Electric Construction Machinery. Bellona Europe. 2018. Available online: https://bellona.org/publication/zero-emission-construction-sites-the-possibilities-and-barriers-of-electric-construction-machinery (accessed on 16 April 2023).

- Eremeeva, A.M.; Kondrasheva, N.K.; Khasanov, A.F.; Oleynik, I.L. Environmentally Friendly Diesel Fuel Obtained from Vegetable Raw Materials and Hydrocarbon Crude. Energies 2023, 16, 2121. [Google Scholar] [CrossRef]

- Hajjari, M.; Tabatabaei, M.; Aghbashlo, M.; Ghanavati, H. A review on the prospects of sustainable biodiesel production: A global scenario with an emphasis on waste-oil biodiesel utilization. Renew. Sustain. Energy Rev. 2017, 72, 445–464. [Google Scholar]

- Petrova, T.A.; Rudzisha, E.; Alekseenko, A.V.; Bech, J.; Pashkevich, M.A. Rehabilitation of disturbed lands with industrial wastewater sludge. Minerals 2022, 12, 376. [Google Scholar] [CrossRef]

- Eremeeva, A.; Ilyashenko, I.; Korshunov, G. The Possibility of Application of Bioadditives to Diesel Fuel at Mining Enterprises. Personalii. Spmi. Ru. 2022. Available online: http://personalii.spmi.ru/ru/details/36105 (accessed on 25 January 2023). [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Khalife, E.; Shojaei, T.R.; Dadak, A. Exergoeconomic analysis of a DI diesel engine fueled with diesel/biodiesel (B5) emulsions containing aqueous nano cerium oxide. Energy 2018, 149, 967–978. [Google Scholar] [CrossRef]

- Du, J.; Sun, W.; Guo, L.; Xiao, S.; Tan, M.; Li, G.; Fan, L. Experimental study on fuel economies and emissions of direct-injection premixed combustion engine fueled with gasoline/diesel blends. Energy Convers. Manag. 2015, 100, 300–309. [Google Scholar] [CrossRef]

- Joshi, S.; Dahodwala, M.; Koehler, E.W.; Franke, M.; Tomazic, D.; Naber, J. Trade-Off Analysis and Systematic Optimization of a Heavy-Duty Diesel Hybrid Powertrain; SAE Technical Paper; SAE Intenational: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Meng, Z.; Feng, X.; Wang, J.; Zhou, H.; Li, J.; Shi, J.; Chen, Q.; Shi, H. Study on Emission Characteristics and Emission Reduction Effect for Construction Machinery under Actual Operating Conditions Using a Portable Emission Measurement System (Pems). Int. J. Environ. Res. Public Health 2022, 19, 9546. [Google Scholar] [CrossRef]

- Koch, C.; Kifokeris, D. Heavy-duty construction equipment: Dinosaurs of black energy? Management 2021, 694, 703. [Google Scholar]

- Komatsu Ltd. Developed an Electric Battery Driven Excavator. 2019. Available online: https://home.komatsu/en/press/2019/technology/1202112_1836.html (accessed on 15 January 2023).

- Leonida, C. Metso Makes Waves at bauma 2019. Eng. Min. J. 2019, 220, 40–43. [Google Scholar]

- Nevrly, J.; Fichta, M.; Jurik, M.; Nemec, Z.; Koutny, D.; Vorel, P.; Prochazka, P. Battery electric drive of excavator designed with support of computer modeling and simulation. Proceedings 2020, 58, 25. [Google Scholar] [CrossRef]

- Casoli, I.P.; Riccò, L.; Campanini, F.; Lettini, A.; Dolcin, C. Hydraulic Hybrid Excavator: Layout Definition, Experimental Activity, Mathematical Model Validation and Fuel Consumption Evaluation. 2016. Available online: https://core.ac.uk/download/pdf/236373206.pdf (accessed on 28 February 2023).

- Vauhkonen, N.; Liljeström, J.; Maharjan, D.; Mahat, C.; Sainio, P.; Kiviluoma, P.; Kuosmanen, P. Electrification of Excavator. In Proceedings of the 9th International DAAAM Baltic Conference “Industrial Engineering”, Tallinn, Estonia, 24–26 April 2014; Available online: https://www.researchgate.net/publication/287088407_Electrification_of_excavator (accessed on 21 January 2023).

- Zhang, D.; Gong, J.; Zhao, Y.; Liu, C.; Hu, P.; Tang, Z. Research on a new energy-recovery system for hybrid hydraulic excavators. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 42003. [Google Scholar] [CrossRef]

- Yu, Y.; Do, T.C.; Yin, B.; Ahn, K.K. Improvement of energy saving for hybrid hydraulic excavator with novel powertrain. Int. J. Precis. Eng. Manuf. Green Technol. 2023, 10, 521–534. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Naseem, R.J. Electrification of the Hydraulic Control System of Off-Road Vehicles; Politecnico di Torino: Torino, Italy, 2022; Available online: https://webthesis.biblio.polito.it/24703/ (accessed on 5 May 2023).

- Volvo Maskin, A.S. Volvo Construction Equipment’s Product Range- Quality and Productivity. 2023. Available online: https://www.volvoce.com/norge/nb-no/volvo-maskin-as/ (accessed on 24 February 2023).

- Ramkumar, M.S.; Reddy, C.; Ramakrishnan, A.; Raja, K.; Pushpa, S.; Jose, S.; Jayakumar, M. Review on Li-Ion Battery with Battery Management System in Electrical Vehicle. Adv. Mater. Sci. Eng. 2022, 2022, 3379574. [Google Scholar] [CrossRef]

- Bellona. Bellona Welcomes EU Battery Strategy but Concrete Actions Must Follow. Available online: https://bellona.org/news/transport/electric-vehicles/2018-05-bellona-welcomes-eu-battery-strategy-but-concrete-actions-must-follow (accessed on 27 January 2023).

- European Monitoring and Evaluation Programme (EMEP). EEA Air Pollutant Emission Inventory Guidebook. Technical Guidance to Prepare National Emission Inventories; EEA Report; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- EMEP Centre on Emission Inventories and Projections (E.C.o.E.I.a). Data Viewer–Reported Emissions Data. 2020. Available online: https://www.ceip.at/data-viewer (accessed on 3 March 2023).

- Ebrahimi, B.; Wallbaum, H.; Jakobsen, P.D.; Booto, G.K. Regionalized environmental impacts of construction machinery. Int. J. Life Cycle Assess. 2020, 25, 1472–1485. [Google Scholar] [CrossRef]

- European Monitoring and Evaluation Programme (EMEP). EEA Air Pollutant Emission Inventory Guidebook 2016. In Technical Guidance to Prepare National Emission Inventories; EEA Report; European Environment Agency: Copenhagen, Denmark, 2016; Available online: https://www.gtkp.com/knowledge/emep-eea-air-pollutant-emission-inventory-guidebook-2016 (accessed on 5 February 2023).

- Nielsen, O.-K. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2013. Technical Guidance to Prepare National Emission Inventories. 2013. Available online: https://www.osti.gov/etdeweb/biblio/22128042 (accessed on 12 April 2023).

- Lindgren, M. A Methodology for Estimating Annual Fuel Consumption and Emissions from Non-Road Mobile Machinery. 2007. Available online: https://pub.epsilon.slu.se/3791/ (accessed on 25 May 2023).

- Bouwen, P. Lobbying the European Union: Institutions, Actors, and Issues; The European Commission: Brussels, Belgium, 2009; pp. 1–38. Available online: https://lobbyists.ru/eu1/lobbyingeu.pdf#page=36 (accessed on 19 March 2023).

- Bellona. Database: Emission-Free Construction Equipment by Manufacturer. 2023. Available online: https://bellona.org/database-emission-free-construction-equipment-by-manufacturer (accessed on 1 February 2023).

- Relion Battery. Lithium Iron Phosphate Battery. Available online: https://ceb8596f236225acd007-8e95328c173a04ed694af83ee4e24c15.ssl.cf5.rackcdn.com/docs/product/Relion-Data-Sheet-RB200-noRU.pdf (accessed on 24 February 2023).

- Higashimoto, K.; Homma, H.; Uemura, Y.; Kawai, H.; Saibara, S.; Hironaka, K. Automotive lithium-ion batteries. Hitachi Rev. 2011, 60, 17–21. [Google Scholar]

- Arshad, F.; Lin, J.; Manurkar, N.; Fan, E.; Ahmad, A.; Tariq, M.-u.-N.; Wu, F.; Chen, R.; Li, L. Life Cycle Assessment of Lithium-ion Batteries: A Critical Review. Resour. Conserv. Recycl. 2022, 180, 106164. [Google Scholar] [CrossRef]

- Lajunen, A.; Sainio, P.; Laurila, L.; Pippuri-Mäkeläinen, J.; Tammi, K. Overview of powertrain electrification and future scenarios for non-road mobile machinery. Energies 2018, 11, 1184. [Google Scholar] [CrossRef]

- Nie, Y.; Wang, Y.; Li, L.; Liao, H. Literature Review on Power Battery Echelon Reuse and Recycling from a Circular Economy Perspective. Int. J. Environ. Res. Public Health 2023, 20, 4346. [Google Scholar] [CrossRef] [PubMed]

- Vandepaer, L.; Cloutier, J.; Amor, B. Environmental impacts of Lithium Metal Polymer and Lithium-ion stationary batteries. Renew. Sustain. Energy Rev. 2017, 78, 46–60. [Google Scholar] [CrossRef]

- Kang, D.H.P.; Chen, M.; Ogunseitan, O.A. Potential environmental and human health impacts of rechargeable lithium batteries in electronic waste. Environ. Sci. Technol. 2013, 47, 5495–5503. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.S.; Lam, J.S.L. Life cycle assessment of diesel and hydrogen power systems in tugboats. Transp. Res. Part D Transp. Environ. 2022, 103, 103192. [Google Scholar] [CrossRef]

- Lavigne Philippot, M.; Costa, D.; Cardellini, G.; De Sutter, L.; Smekens, J.; Van Mierlo, J.; Messagie, M. Life cycle assessment of a lithium-ion battery with a silicon anode for electric vehicles. J. Energy Storage 2023, 60, 106635. [Google Scholar] [CrossRef]

- Maslennikova, A.; Udachin, V.; Deryagin, V.; Artemyev, D.; Filippova, K.; Gulakov, V.; Udachin, N.; Aminov, P. Sediment records of lake eutrophication and oligotrophication under the influence of human activity and climate warming in the Urals metallurgical region (Russia). Hydrobiologia 2023, 850, 1669–1698. [Google Scholar] [CrossRef]

- Dean, S.; Akhtar, M.S.; Ditta, A.; Valipour, M.; Aslam, S. Microcosm Study on the Potential of Aquatic Macrophytes for Phytoremediation of Phosphorus-Induced Eutrophication. Sustainability 2022, 14, 16415. [Google Scholar] [CrossRef]

- Vidhi, R.; Shrivastava, P. A review of electric vehicle lifecycle emissions and policy recommendations to increase EV penetration in India. Energies 2018, 11, 483. [Google Scholar] [CrossRef]

- Tsai, W.-S.; Huang, C.; Huang, C.-C.; Yang, C.-C.; Lee, M. Environmental trade-offs and externalities of electrochemical-based batteries: Quantitative analysis between lithium-ion and vanadium redox flow units. J. Environ. Manag. 2023, 326, 116807. [Google Scholar] [CrossRef]

- Steen, M.; Lebedeva, N.; Di Persio, F.; Boon-Brett, L. EU Competitiveness in Advanced Li-Ion Batteries for E-Mobility and Stationary Storage Applications–Opportunities and Actions; Publications Office of the European Union: Luxembourg, 2017; Volume 44, Available online: https://core.ac.uk/download/pdf/132627095.pdf (accessed on 20 January 2023).

- Peters, J.F.; Weil, M. Providing a common base for life cycle assessments of Li-Ion batteries. J. Clean. Prod. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Nunez, P.; Jones, S. Cradle to gate: Life cycle impact of primary aluminium production. Int. J. Life Cycle Assess. 2016, 21, 1594–1604. [Google Scholar] [CrossRef]

- Lajunen, A. Lifecycle costs and charging requirements of electric buses with different charging methods. J. Clean. Prod. 2018, 172, 56–67. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Eremeeva, A.M. Production of Biodiesel Fuel from Vegetable Raw Materials. J. Min. Inst. 2023, 260, 248–256. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, Z.; Wu, B.; Tang, Y.; Evans, S. Environmental life cycle assessment of recycling technologies for ternary lithium-ion batteries. J. Clean. Prod. 2023, 389, 136008. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Contestabile, M.; Panero, S.; Scrosati, B. A laboratory-scale lithium battery recycling process. J. Power Sources 1999, 83, 75–78. [Google Scholar] [CrossRef]

- Dewulf, J.; Van der Vorst, G.; Denturck, K.; Van Langenhove, H.; Ghyoot, W.; Tytgat, J.; Vandeputte, K. Recycling rechargeable lithium ion batteries: Critical analysis of natural resource savings. Resour. Conserv. Recycl. 2010, 54, 229–234. [Google Scholar] [CrossRef]

- Mohammadi, F.; Saif, M. A comprehensive overview of electric vehicle batteries market. e-Prime Adv. Electr. Eng. Electron. Energy 2023, 3, 100127. [Google Scholar] [CrossRef]

- Wang, S.; Yu, J. A comparative life cycle assessment on lithium-ion battery: Case study on electric vehicle battery in China considering battery evolution. Waste Manag. Res. 2021, 39, 156–164. [Google Scholar] [CrossRef]

- Xu, J.; Thomas, H.R.; Francis, R.W.; Lum, K.R.; Wang, J.; Liang, B. A review of processes and technologies for the recycling of lithium-ion secondary batteries. J. Power Sources 2008, 177, 512–527. [Google Scholar] [CrossRef]

- Bankole, O.E.; Gong, C.; Lei, L. Battery recycling technologies: Recycling waste lithium ion batteries with the impact on the environment in-view. J. Environ. Ecol. 2013, 10, 14–28. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Arcese, G.; Bella, G. Recycling technologies of nickel–metal hydride batteries: An LCA based analysis. J. Clean. Prod. 2020, 273, 123083. [Google Scholar] [CrossRef]

- Quan, J.; Zhao, S.; Song, D.; Wang, T.; He, W.; Li, G. Comparative life cycle assessment of LFP and NCM batteries including the secondary use and different recycling technologies. Sci. Total Environ. 2022, 819, 153105. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Hua, H.; Zhang, L.; Liu, X.; Wu, H.; Yuan, Z. Environmental impacts of hydrometallurgical recycling and reusing for manufacturing of lithium-ion traction batteries in China. Sci. Total Environ. 2022, 811, 152224. [Google Scholar] [CrossRef]

- Feng, T.; Guo, W.; Li, Q.; Meng, Z.; Liang, W. Life cycle assessment of lithium nickel cobalt manganese oxide batteries and lithium iron phosphate batteries for electric vehicles in China. J. Energy Storage 2022, 52, 104767. [Google Scholar] [CrossRef]

- Larsen, M.L.; Dupuy, K. Greening industry: Opportunities and challenges in electricity access for Norwegian industry firms. J. Clean. Prod. 2023, 396, 136534. [Google Scholar] [CrossRef]

- Romejko, K.; Nakano, M. Life cycle analysis of emissions from electric and gasoline vehicles in different regions. Int. J. Autom. Technol. 2017, 11, 572–582. [Google Scholar] [CrossRef]

| Scenarios | Diesel (%) | Electric (%) | Details | Battery (kWh) |

|---|---|---|---|---|

| 1 | 100 | 0 | Fully diesel powered | - |

| 2 | 75 | 25 | Hybrid | 75 |

| 3 | 50 | 50 | Hybrid | 150 |

| 4 | 25 | 75 | Hybrid | 225 |

| 5 | 0 | 100 | Fully electric | 300 |

| Engine Power (kW) | Technology Level | Pollutant | BEF | Pollutant | BEF |

|---|---|---|---|---|---|

| 75 ≤ P < 560 | Stage V | BC | 0.002 | NOx | 0.4 |

| CH4 | 0.003 | PM | 0.0 | ||

| CO | 1.5 | VOC | 15 | ||

| NH3 | 0.002 | CO2 | 0.1 | ||

| N2O | 0.035 | SO2 | 3 |

| Pollutant | Deterioration Factor (% Avg. Engine Lifetime) |

|---|---|

| CH4 | 0.15 |

| CO | 0.151 |

| CO2 | 0.1 |

| NOX | 0.008 |

| PM | 0.3 |

| VOC | 0.027 |

| SO2 | 0.1 |

| FC | 0.1 |

| Life Cycle Stages | Data Sources |

|---|---|

| Manufacturing | Ecoinvent (v3.9); Volvo EPDs [26]; EMEP/EEA [26,29,30,31,32,33,37,38] |

| Maintenance | Ecoinvent (v3.9); [18,31,32,33,37,38,39] |

| Operation | Ecoinvent (v3.9); [31,32,33] |

| End-of-life | Ecoinvent (v3.9); [31,39] |

| Contribution (%) | |||||||

|---|---|---|---|---|---|---|---|

| Impact category | Unit | Total | Manufacturing | Maintenance | Operation | End of life | Scenarios |

| Global warming (GWP) | ton CO2 eq | 5191.61 | 1 | 0.3 | 98 | 0.7 | 1 |

| 3914.09 | 1.3 | 0.5 | 97.7 | 0.5 | 2 | ||

| 2662.83 | 2 | 0.8 | 97 | 0.2 | 3 | ||

| 1405.15 | 4 | 1.8 | 93.8 | 0.4 | 4 | ||

| 145.39 | 42.3 | 19.3 | 34.5 | 3.9 | 5 | ||

| Terrestrial ecotoxicity (TE) | ton 1,4- DCB | 574.99 | 73.9 | 9.1 | 15.5 | 1.5 | 1 |

| 845.79 | 58.2 | 27.3 | 13.3 | 1.2 | 2 | ||

| 1261.93 | 54 | 33.4 | 11.6 | 1 | 3 | ||

| 1661.18 | 52 | 37 | 10 | 1 | 4 | ||

| 2609.51 | 40.7 | 30.8 | 27.8 | 0.7 | 5 | ||

| Stratospheric ozone depletion (ODP) | ton CFC11 eq | 1.43 × 10−3 | 1.5 | 0.46 | 97.99 | 0.05 | 1 |

| 1.11 × 10−3 | 1.6 | 0.7 | 97.6 | 0.1 | 2 | ||

| 0.80 × 10−3 | 2.4 | 1.3 | 96.1 | 0.2 | 3 | ||

| 0.69 × 10−3 | 3 | 1.8 | 95 | 0.2 | 4 | ||

| 0.16 × 10−3 | 15 | 9 | 75 | 1 | 5 | ||

| Human carcinogenic toxicity (HT) | ton 1,4-DCB | 32.86 | 88.7 | 6.9 | 4.2 | 0.2 | 1 |

| 29.30 | 83 | 10.4 | 6.3 | 0.3 | 2 | ||

| 31.21 | 80 | 11.7 | 8 | 0.3 | 3 | ||

| 32.85 | 78 | 13 | 8.6 | 0.4 | 4 | ||

| 39.52 | 66.4 | 12.4 | 20.8 | 0.4 | 5 | ||

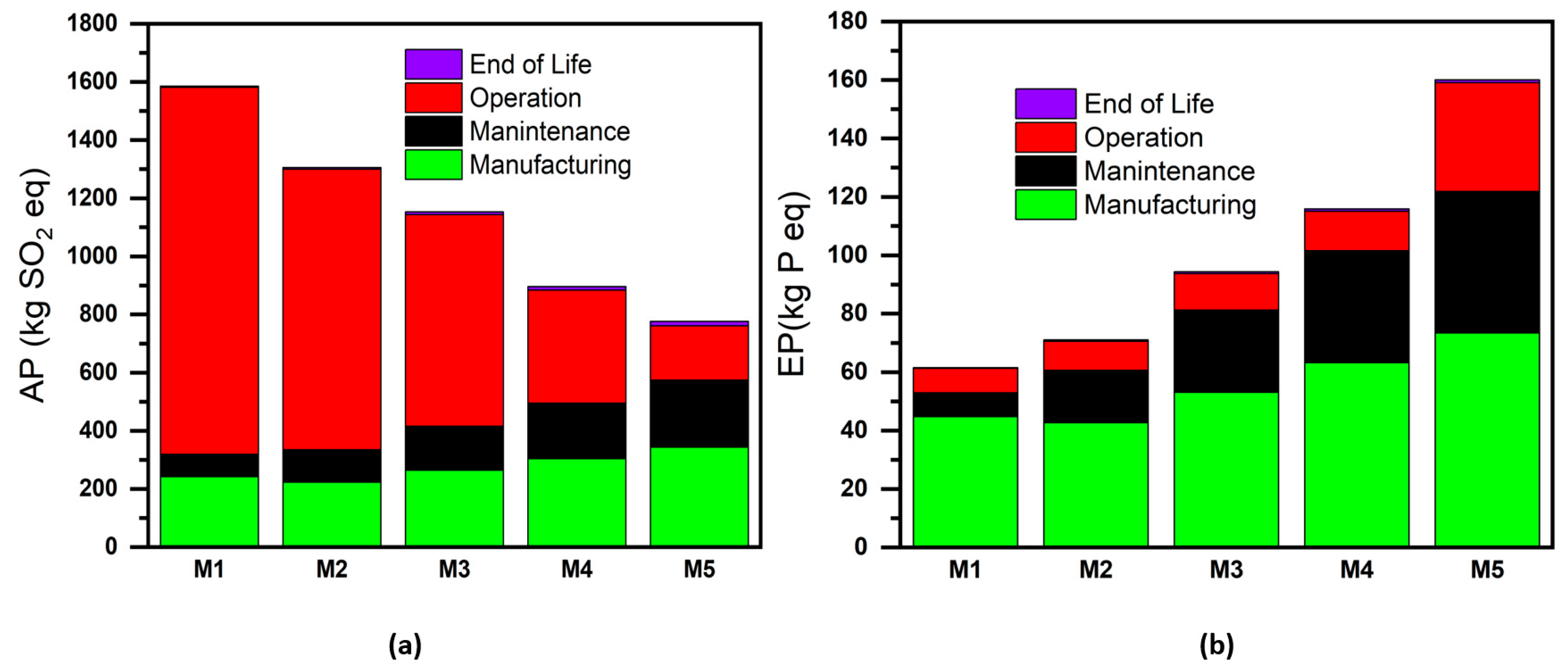

| Terrestrial acidification (AP) | ton SO2 eq | 1.58 | 15.3 | 4.5 | 80 | 0.2 | 1 |

| 1.30 | 17 | 8.6 | 73.9 | 0.5 | 2 | ||

| 1.15 | 23 | 13.1 | 63.1 | 0.8 | 3 | ||

| 0.90 | 34 | 21 | 44 | 1 | 4 | ||

| 0.78 | 44.3 | 29.7 | 24 | 2 | 5 | ||

| Freshwater eutrophication (EP) | ton P eq | 0.06 | 72.9 | 13.3 | 13.5 | 0.3 | 1 |

| 0.07 | 60.13 | 25.37 | 14 | 0.5 | 2 | ||

| 0.09 | 56.2 | 30 | 13.2 | 0.6 | 3 | ||

| 0.11 | 54.6 | 33 | 11.7 | 0.7 | 4 | ||

| 0.16 | 46 | 30.2 | 23.2 | 0.6 | 5 | ||

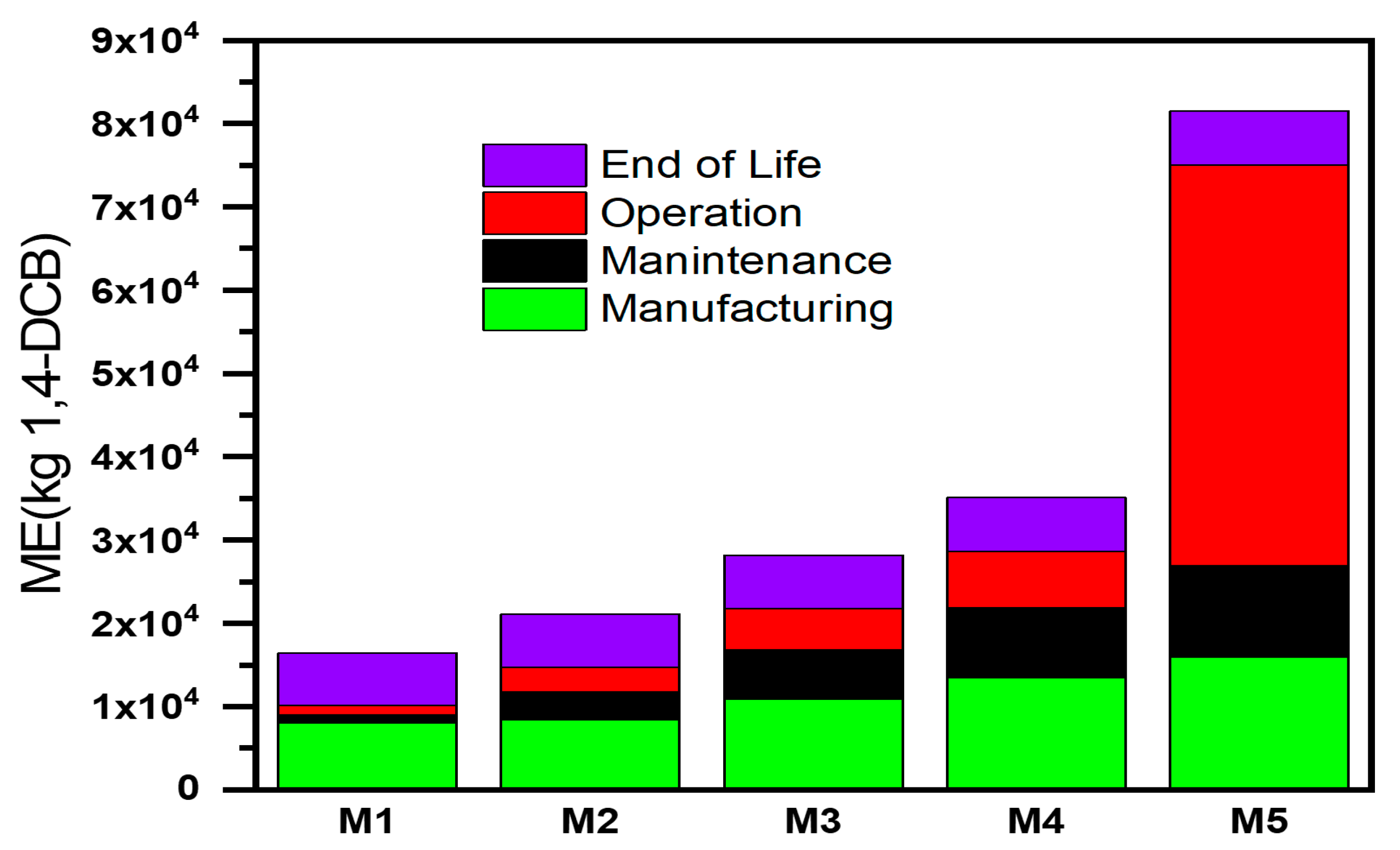

| Marine ecotoxicity (ME) | ton 1,4-DCB | 16.46 | 49 | 6 | 6 | 39 | 1 |

| 21.13 | 40 | 16 | 14 | 30 | 2 | ||

| 28.21 | 38.6 | 21 | 17.4 | 23 | 3 | ||

| 35.09 | 38.3 | 24 | 19.2 | 18.5 | 4 | ||

| 81.55 | 19.6 | 13.4 | 59 | 8 | 5 | ||

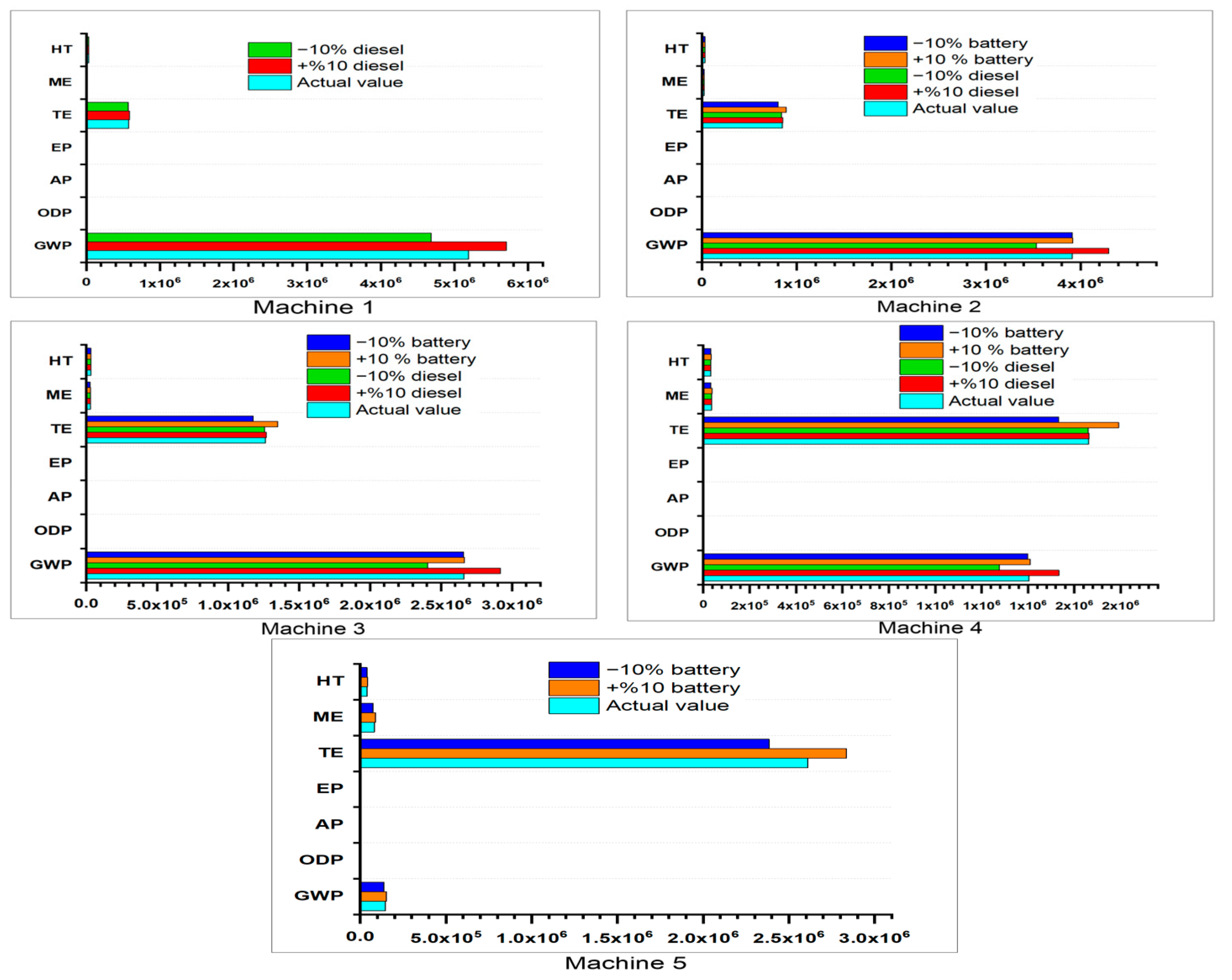

| Impact Category | Machine Type | Diesel (±10%) | Battery (±10%) |

|---|---|---|---|

| Global warming (GWP) | 1 | 9.83 | 0 |

| 2 | 9.78 | 0.04 | |

| 3 | 9.61 | 0.14 | |

| 4 | 9.1 | 0.40 | |

| 5 | 0 | 5.45 | |

| Stratospheric ozone depletion (ODP) | 1 | 9.80 | 0 |

| 2 | 9.51 | 0.30 | |

| 3 | 8.90 | 0.83 | |

| 4 | 2.74 | 0.48 | |

| 5 | 0 | 8.68 | |

| Terrestrial acidification (AP) | 1 | 7.97 | 0 |

| 2 | 7.19 | 0.82 | |

| 3 | 4 | 2.69 | |

| 4 | 3.5 | 3.59 | |

| 5 | 0 | 6.64 | |

| Freshwater eutrophication (EP) | 1 | 1.34 | 0 |

| 2 | 0.85 | 3.42 | |

| 3 | 0.51 | 5.15 | |

| 4 | 0.17 | 6.29 | |

| 5 | 0 | 7.44 | |

| Terrestrial ecotoxicity (TE) | 1 | 1.55 | 0 |

| 2 | 0.77 | 5 | |

| 3 | 0.41 | 6.8 | |

| 4 | 0.13 | 7.75 | |

| 5 | 0 | 8.65 | |

| Marine ecotoxicity (ME) | 1 | 0.6 | 0 |

| 2 | 0.3 | 3.42 | |

| 3 | 0.2 | 5.12 | |

| 4 | 0.07 | 6.18 | |

| 5 | 0 | 8.39 | |

| Human carcinogenic toxicity (HT) | 1 | 0.41 | 0 |

| 2 | 0.34 | 0.71 | |

| 3 | 0.25 | 1.35 | |

| 4 | 0.10 | 1.92 | |

| 5 | 0 | 3.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.U.; Huang, L. Toward Zero Emission Construction: A Comparative Life Cycle Impact Assessment of Diesel, Hybrid, and Electric Excavators. Energies 2023, 16, 6025. https://doi.org/10.3390/en16166025

Khan AU, Huang L. Toward Zero Emission Construction: A Comparative Life Cycle Impact Assessment of Diesel, Hybrid, and Electric Excavators. Energies. 2023; 16(16):6025. https://doi.org/10.3390/en16166025

Chicago/Turabian StyleKhan, Asmat Ullah, and Lizhen Huang. 2023. "Toward Zero Emission Construction: A Comparative Life Cycle Impact Assessment of Diesel, Hybrid, and Electric Excavators" Energies 16, no. 16: 6025. https://doi.org/10.3390/en16166025

APA StyleKhan, A. U., & Huang, L. (2023). Toward Zero Emission Construction: A Comparative Life Cycle Impact Assessment of Diesel, Hybrid, and Electric Excavators. Energies, 16(16), 6025. https://doi.org/10.3390/en16166025