1. Introduction

Most of the thermal energy that humanity encounters on a daily basis comes from solar radiation. This fact is greatly exacerbated by the effects of global warming [

1]. The increase in heat flow in permafrost soils in northern regions [

2] leads to the loss of their load-bearing capacity and, subsequently, the collapse of buildings and structures [

3]. There are problems in southern regions too: prolonged solar radiation exposure of water reservoirs leads to increase in water evaporation [

4], which is most significant in large areas; long periods of drought reduce hydropower plant productivity [

5]; excessive increases in air and surface temperatures in buildings leads to a significant increase in energy consumption for space cooling, which has the lion’s share of the overall electricity demand growth [

6,

7].

These and other negative impacts of solar radiation on infrastructure have prompted the active development of solar-powered technologies to tackle the effects of the growing heat load. Solar-powered heat pump systems for permafrost soil thermal stabilisation [

8] are not only more efficient than traditional thermosyphons when there is a need for subsurface soil freezing, but also much cheaper than fossil fuel-driven refrigerators (largely due to the possibility of using heat for various local needs, from vegetable growing [

9] to crude oil heating in oil fields [

10]). Such solar-powered systems are suitable for protecting critical infrastructure [

11] during permafrost thawing. The installation of floatovoltaic plants [

12] on reservoirs will not only reduce the intensity of evaporation due to shielding (with an efficiency equal to the usual floating balls [

13]) but will also provide energy to power the infrastructure surrounding the reservoirs [

14]. In agriculture, it is often necessary to create artificial shading (especially in arid regions), and for the same purpose, the use of agrivoltaics is promising [

15]. The installation of solar panels with a tracking system or translucent modules with a wavelength selection on agricultural land not only prevents direct sunlight on the plants but also meets the needs of the agricultural sector for electricity (e.g., solar irrigation [

16]).

There is also significant potential for the integration of solar panels and solar collectors into the air conditioning and ventilation systems of buildings [

17]. This solution, in many cases, helps to fully cover the ever-increasing energy demand for the operation of these systems in a sustainable way. The main technological advantage of the considered systems lies precisely in the positive correlation between the solar irradiance and the need for cooling. This relation between energy production and consumption makes systems better balanced, and thus, much cheaper.

In other words, the use of solar-powered cooling can significantly reduce the consequences of the main renewable energy disadvantage—intermittent output. This positive effect is particularly pronounced when the load explicitly follows the electricity generation (i.e., it is adaptive). A classic example of adaptive load is solar-powered water pumping [

16]. However, in order to fully achieve the potential of the adaptive load concept, variability of the load is required, which is reached by frequency control (i.e., inverter mode). Only in this case will there be a smooth mode of load (energy consumption by water pump or compressor) following the stochastic generation. Another approach to the design of stand-alone systems with a load following the generation in a wide output range is the principle of reducing the threshold power by using several low-power consumers (aggregates) instead of a single one [

18]. This is the aggregation method. The distribution of the load by units at the design stage contributes to the reduction in the installed capacity of renewable energy sources (RES) by maintaining the load operation and reducing the solar electricity cost. Combined, these approaches (frequency control and aggregation) allow the load to be treated as “variable” (i.e., allowing operation within a wide power range).

If the final consumer has a high level of energy consumption inertia, the problem of the instability of RES generation is also relieved, for example, the previously mentioned soil thermal stabilisation system with HP. Storing energy in the form of cold in the ground (particularly with a water/ice phase transition) is more efficient and cheaper than other ways (e.g., electrochemical). To be able to implement the principle presented, it is also necessary to have a frequency-controlled HP (inverter) compressor in order to utilize the maximum possible amount of solar energy. Thus, the period of low power generation (and, as a consequence, a low cooling capacity) can be balanced out by the period when the generated power is higher than required.

When using HP in thermal stabilisation systems, it is often worth using the aggregation method. The distribution of the load over the aggregates ensures the optimum modes of their operation. If the output power is low, a less powerful HP is operating above its threshold power. As the cooling load follows the generation, the output power is distributed over the aggregates in the optimal way to obtain the necessary amount of cooling. It is important to note that the aggregation method does not affect the maximum power of the system determined by the sum of the maximum powers of all heat pumps in the system, which remains unchanged. Several aggregates also improve the system’s reliability but increase its HP part of CAPEX and TCO.

As noted above, the excess energy can be stored not only by means of classic BES, but also in the form of cold in the ground (for thermal stabilisation systems). Another principle worth referring to for off-grid systems is implicit storage [

19]. This approach contributes to the system technology simplification and its cost reduction by substituting expensive BES with the excess nameplate capacity of RES. The latter is suggested to be implemented using a complementary source with negative output correlation to the primary one (e.g., wind and solar) [

6].

Photovoltaic systems with heat pumps are mainly considered for grid-tied cases [

20,

21] or stand-alone with battery storage backup [

22]. The latter takes half CAPEX and an even greater share of TCO, so it is highly important to reduce this component once possible. The introduction of variable load gives a great opportunity to resolve this issue and to improve economic performance of photovoltaic systems, but it is mainly considered for peak-shaving in grids [

23,

24,

25,

26] rather than off-grid operation [

27,

28].

This paper analyses the above mentioned design principles (aggregation; variable load following the generation) impact on the economic and technical efficiency of an off-grid system for permafrost thermal stabilisation with a solar-powered HP in northern Norway (70.310, 25.535). The initial purchase of equipment (CAPEX) and the total cost of ownership (TCO) of power systems with and without battery energy storage (BES) are considered. The study is based on the analysis of meteorological data with 1 h temporal resolution. The results of this paper could be used in the design of stand-alone energy systems based on PV and Smart grids based on RES.

2. Materials and Methods

2.1. Model of the Power Supply System

The optimal configuration selection process for an off-grid power supply system requires a comprehensive operation analysis of individual components. Thus, it is necessary to simulate various configurations with different modes of HP operation in order to select optimal solutions. The calculation is based on consideration of energy balance between generation and load. The numerical model used is described in detail in [

29]. The following describes the main additions to it.

2.1.1. Battery Energy Storage

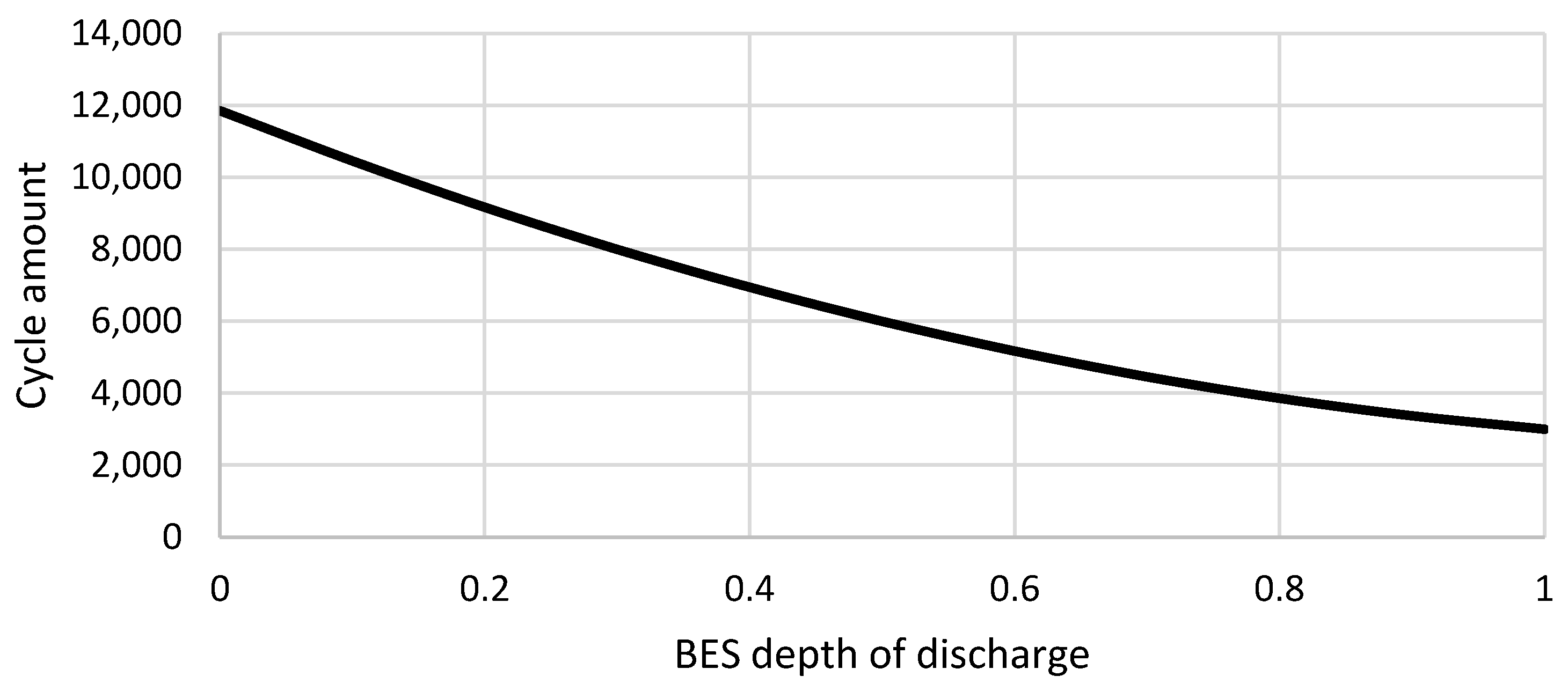

The lifetime of BES (LT) is determined by the amount of discharge cycles. The dependence of LT on the BES State of Charge (SoC) can be approximated with a polynomial [

30]:

where

—coefficients unique to different types of BES.

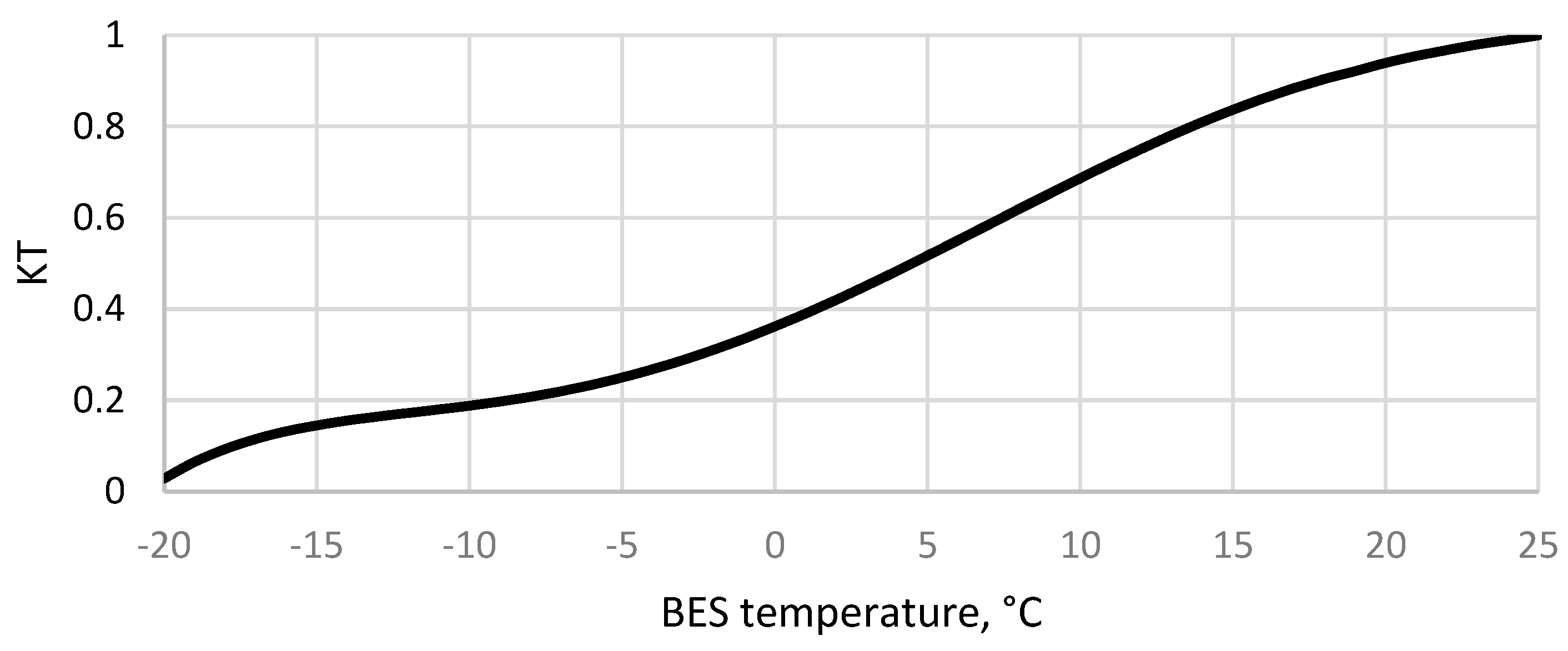

The service life of BES also largely depends on the operating temperature. The temperature correction can be taken into account in the form of a service life temperature coefficient (KT) (see

Supplementary Materials Figure S1) which represents the degree of LT decrease:

where

—coefficients individual for different types of BES.

Accordingly, the fraction of BES service life (ULT) that will be exhausted as a result of the discharge process (according to the physical meaning of KT and LT calculated by (1) and (2)):

2.1.2. Heat Pump

The main load is the compressor. This paper considers start–stop (single frequency) and inverter (frequency range) modes of the compressor operation. The compressor rotor speed is controlled by changing the frequency of AC (

f, Hz) within the range limited by

fmin and

fmax. Those are determined by the type of the compressor; continuous operation beyond these frequencies can lead to its rapid failure. It is assumed that compressor power is directly proportional to AC frequency. For heat pump COP dependence on frequency, see

Section 2.3. Therefore, HP actual power consumption (

PHP, W) is related to its rated electric power (

PHP_Rated, W) and frequency (

fRated, Hz) as [

18]:

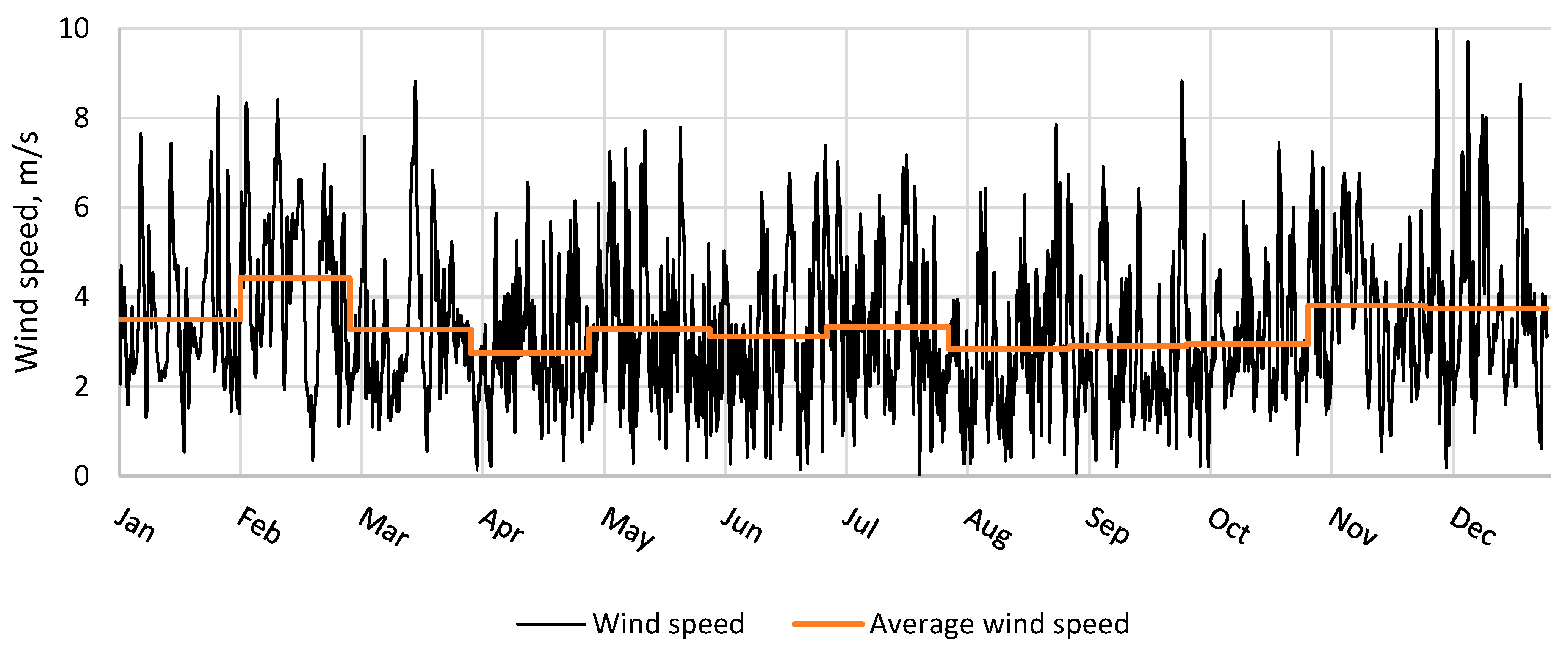

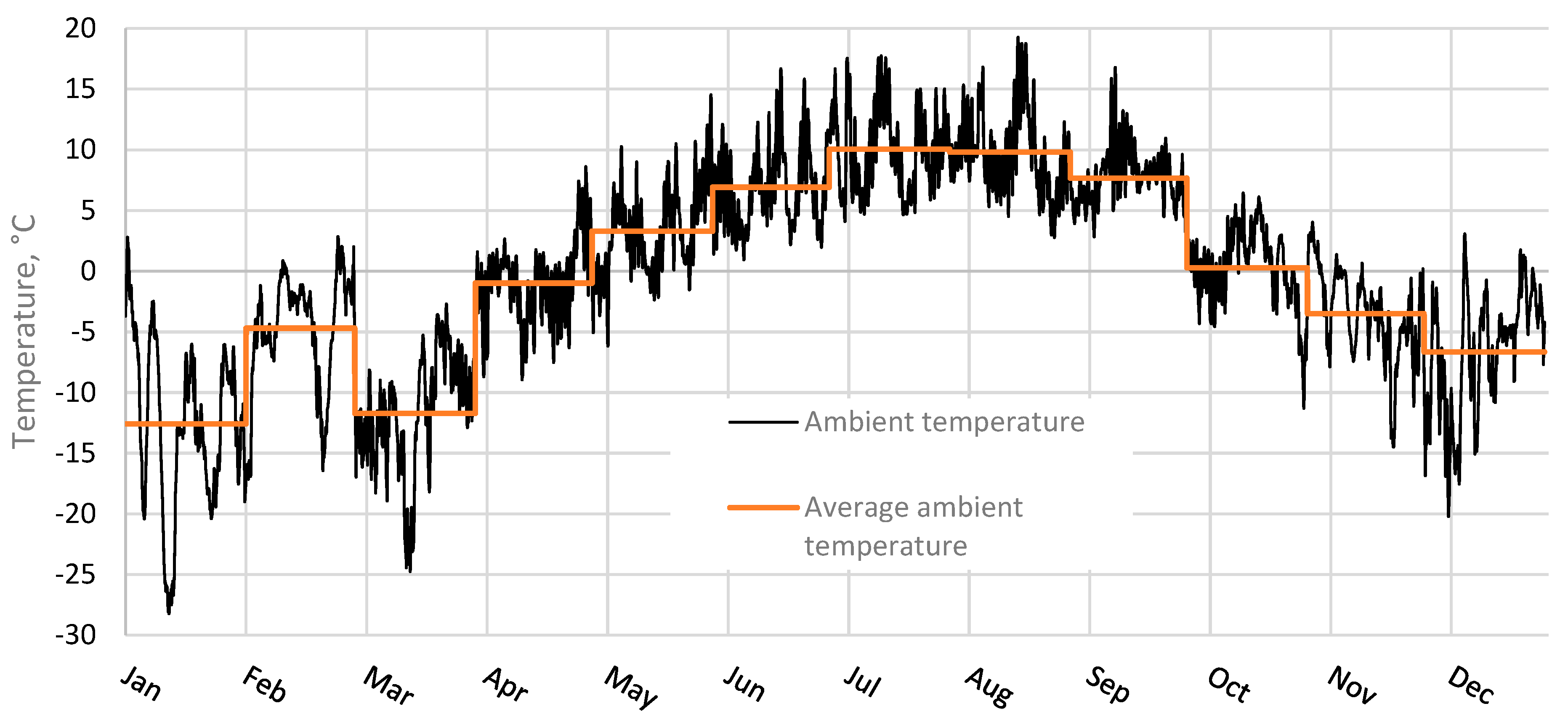

2.2. Weather Data

To simulate the operation of various stand-alone power system configurations, weather data with 1 h temporal resolution of solar irradiance, air temperature, and wind speed are used. Such high temporal resolution is necessary for a detailed behaviour analysis of an off-grid system based on RES [

29] (it is impossible using monthly averaged data).

These data were sourced from Photovoltaic Geographic Information System (PVGIS) [

31], which provides high-quality data on solar irradiation obtained from satellite images; ambient temperature and wind speed are based on climate reanalysis models. PVGIS provides data in the form of a typical meteorological year (TMY), representing a set of meteorological data of high temporal resolution, which are consistent with long-term mean annual values. The datasets used in calculations are shown in

Figure 1,

Figure 2 and

Figure 3; monthly averaged data are also presented for reference.

2.3. Load Analysis

The electric power required to fulfil the thermal load is estimated using the methodology presented in [

32]. Heat transfer is calculated according to Newton’s law. The convection heat transfer coefficient (

h, W/(m

2 × K)) is calculated according to an empirical equation (depending on the wind speed (V, m/s)) [

32]:

The dependence of HP energy efficiency ratio (EER) on ambient temperature (

tamb, °C) is calculated by [

32]:

Thermal stabilisation system is operated only in the presence of heat flow to the soil (when ambient air temperature is above 0 °C, and solar radiation is considered to be reflected by the snow). Consequently, taking into account (5) and (6), the required electric power (

PR, W

e) consumed by the HP compressor for soil thermal stabilisation of a certain area (

S, m

2) can be expressed as [

32]:

This estimation is provided for the rated frequency of compressor operation. Heat pump’s EER = COP−1 essentially depends on temperature difference between cold (heat source) and hot (heat sink) loops. The temperature in each loop is defined by the ratio of actual sink or source capacity to the power supplied by the heat pump. So COP is higher at lower compressor operation frequencies when temperature difference is decreasing due to lower actual power [

33]. Since thermal processes are more inertial than electric power balancing, and thermal load was estimated on a monthly basis, and we assumed that variations in COP could be averaged using mean operation frequency over the same period. We calculated the latter (normalised by the electric energy output) to be 53.6 ± 5.5 Hz. In this range, COP is nearly independent of frequency, according to [

33], or at least the dependency is much less pronounced than the dependency of COP on ambient temperature. So, for simplicity of calculations, we kept EER for rated frequency (50 Hz) dependent on ambient air temperature only. Moreover, the dependency of COP on frequency is due not only to a specific heat pump only, but to the whole thermal system. Thus, the findings of [

33] are very important for detailed performance evaluation of a specific system, but these are hard to consider properly in generalised calculations (unless the system is operated far from its rated conditions on average, similarly to any engine) since thorough experimental data are needed.

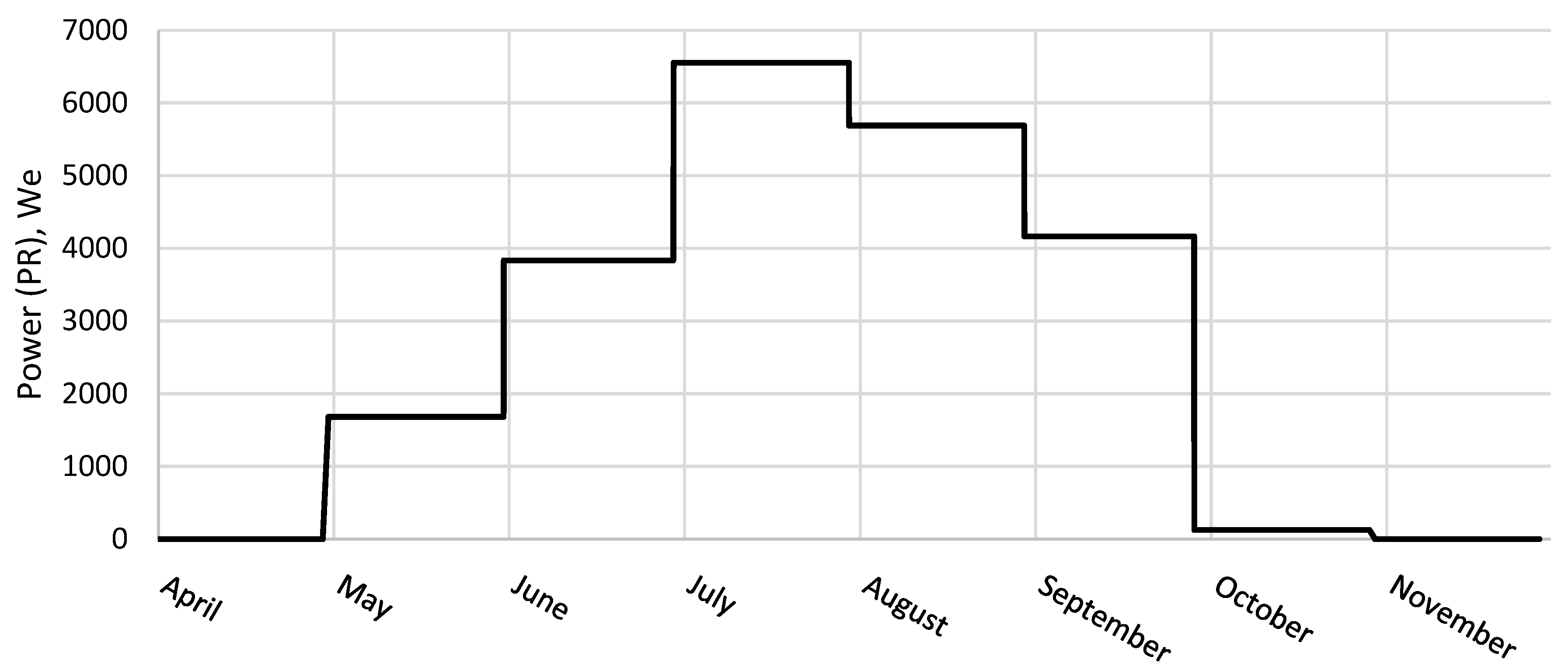

The load calculation and all further analysis of the system operation will be carried out for the period of May–October. The area of cooled soil is taken as 100 m

2. Power characteristics of the system will actually vary proportionally to the stabilised area: both HPs and PVs have rather small power steps between the different models. The distribution of HP electric power demanded for thermal stabilisation according to (6) is shown in

Figure 4.

Maximum heat load on the ground is in July. To avoid the penetration of heat into the soil during this time, it is necessary to operate the compressor at about 6.5 kWe. Consequently, the related power of the HP (PHP_Rated, We) should be sufficient to cover the corresponding annual demand for refrigeration capacity.

2.4. Considered Layouts and Loads

In this paper, different calculations are made for different power supply system layouts and operation modes. For convenience of description, the cases under consideration are numbered and presented in

Table 1:

When HP operates in «Start–Stop» mode, only rated power is allowed. The inverter operation mode implies frequency control of the power consumption within the minimum power required to start the heat pump (

fmin) and the maximum permissible power (

fmax). The aggregation uses several low-power HPs with a total rated capacity equivalent to a single HP. The adaptive load mode uses the possibility of energy storage in the soil to consume all available energy generated by PV regardless of the actual cooling demand. Non-adaptive mode of operation, on the contrary, is aimed primarily at the consumption of minimum required power (according to the actual cooling demand;

Figure 4). However, in the calculation, when considering non-adaptive modes of operation, the cold storage in the soil must still be taken into account. Hence, it is impossible to unambiguously consider the «Start–Stop» operation mode in both adaptive and non-adaptive modes for their subsequent comparison. Therefore, the «Start–Stop» mode will be considered only under consideration of the adaptive load.

The set of parameters varied in the calculation is presented in

Table 2:

2.5. Calculation Algorithm

The reliability of power supply (RPS) is the main characteristic of a stand-alone system performance. In this paper, to evaluate the cooling demand satisfaction, RPS can be represented as the ratio of energy consumed by HP (

EC, J) (during the season of thermal stabilisation system operation) to the total required electric energy (

Figure 4) [

18]:

Accordingly, for each 1 h time interval, the following calculations were performed:

PV energy output.

The amount of energy consumed by HP (EC’(t) = PR(t) Δt) (4), depending on the load mode, the amount of energy generated, and energy stored in BES.

For BES, the difference between energy generated and energy consumed. In this case, no more energy can be stored in BES than maximum possible energy during the calculated time interval.

The energy capacity of BES and its SoC. SoC is restricted by maximum and minimum values.

Then, EC can be calculated as the sum of EC’(t). Accordingly, it is possible to calculate RPS (8). Also, based on the analysis of SoC profile, the lifetime of BES can be estimated. This process is based on finding SoC throughout the calculated time interval—each BES discharge cycle leads to its lifetime decrease by a certain amount (which can be estimated by Equations (1)–(3)).

The algorithm for selecting the optimal configuration of the power supply system is based on the «Brute Force» [

34]. Thus, for each possible configuration option (the main variable parameters of the system are presented in

Table 2), RPS and the configuration cost can be evaluated.

2.6. The Equipment

The values for HP cost and performance (frequency range, rated electric power, service life, and price) used in the calculations are presented in

Table 3:

In the case of aggregation (using several HP units of equal rated power), the overall cost of HP system differs from the cost of a single equivalent power HP significantly, since with the reduction in HP unit power, its cost changes disproportionately: 2 HPs–$4800; 3 HPs–$6000; 4 HPs–$8000.

The compressor lifetime is usually between 10,000 and 15,000 motor-hours. In single HP start–stop mode, we estimated 1382 motor-hours annually, which gives 10 years’ lifetime. The aggregation added ca. 340 h per unit (for 2–4 HPs), and load variability added another 623 h. On the one hand, these complications reduce the compressor’s lifetime in years, but on the other hand, the continuous operation in inverter mode and ability to provide better service to aggregates improve operation conditions. Thus, the compressor lifetime should be not affected as much as it appears. Since this issue is out of this paper’s scope, we did not consider its influence on TCO.

The use of lithium-titanate batteries (Li:LTO) is recommended in a cold climate. However, they are not well-known for their performance characteristics (Wehler curve for the number of discharge cycles; direct dependence of service life on temperature). Therefore, LiFePO

4 BES characteristics were used in the calculations. Lithium batteries have longer life span and also allow greater depths of discharge compared to more usual AGM or GEL batteries. Accordingly, they do not require frequent replacement. These facts contribute to the conclusion that lithium batteries are more cost-effective for stand-alone systems [

35] despite higher cost at initial purchase.

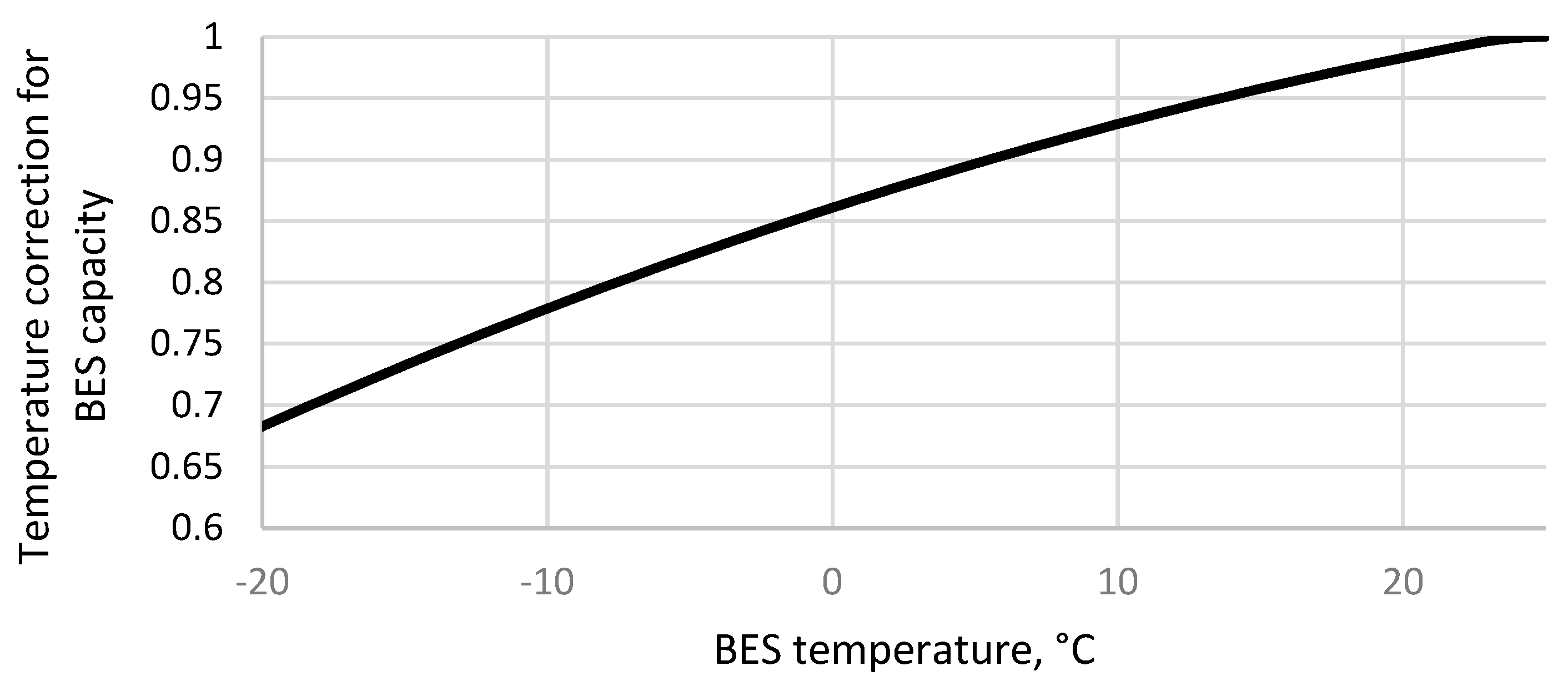

The minimum allowable SoC for LiFePO

4 is 20%. The information about the dependence of service life on the depth of discharge and the battery capacity dependence on temperature was taken from the «SunStonePower» manufacturer’s website (see

Supplementary Materials Figures S1 and S2) and converted into dependencies convenient for analysis; polynomial coefficients (according to Equations (1) and (2)) are presented in

Table 4 and

Table 5. The plots of temperature correction coefficients for BES capacity and lifetime and the plot for BES lifetime estimation are shown in

Figure 5,

Figure 6 and

Figure 7, respectively. It is assumed that BES cost depends linearly on the capacity.

Information about the cost and the main technical characteristics of PV panels used in the calculations is presented in

Table 6 (this information was taken from the manufacturer’s website; see

Supplementary Materials Figure S3). It is assumed that the cost of PV depends linearly on the installed power capacity. The efficiency of BOS is taken as η = 0.95.

Calculating TCO, we calculated initial CAPEX and additional cost of replaced equipment over time. We did not include any OPEX and discount rates. Both of these are highly variable for the specific project, and the former is also compensated by the negative annual growth rate of CAPEX for HP and BES to be replaced.

3. Results

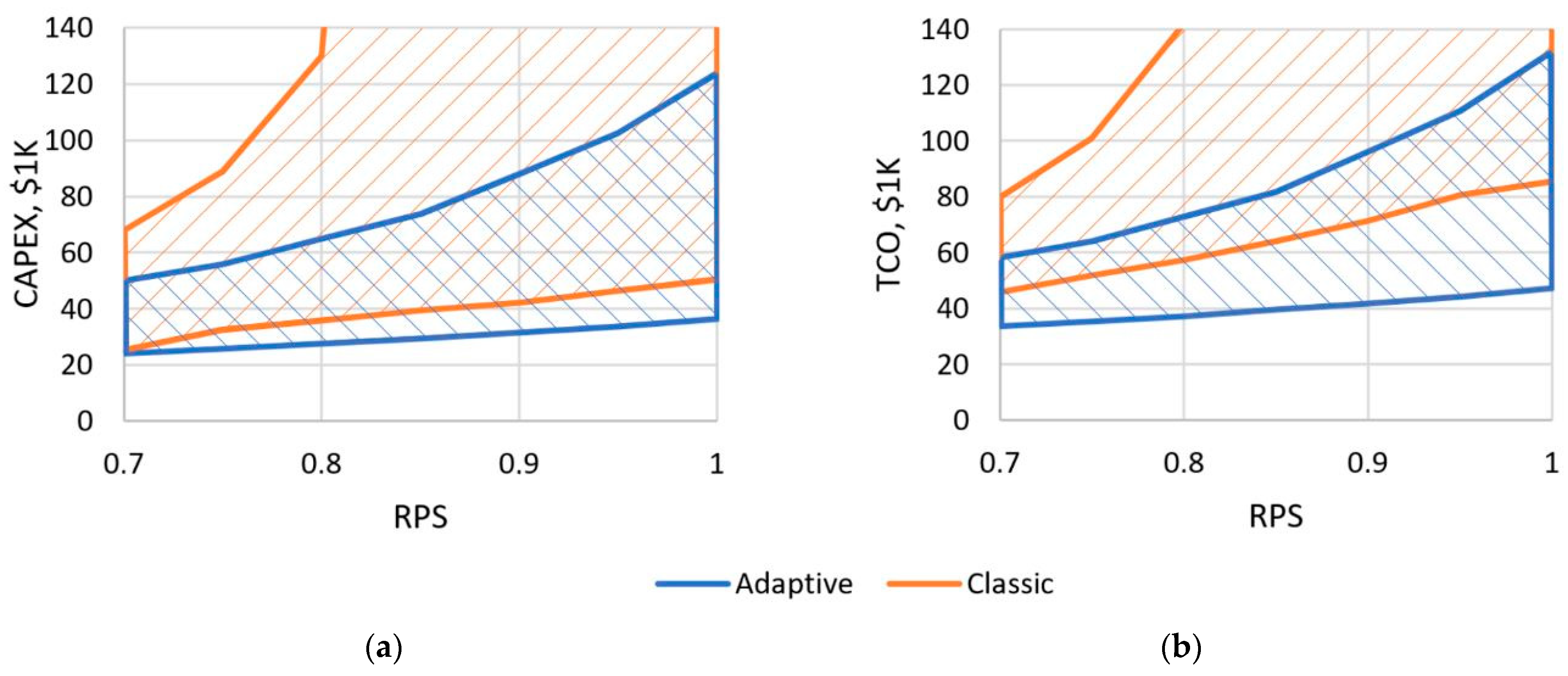

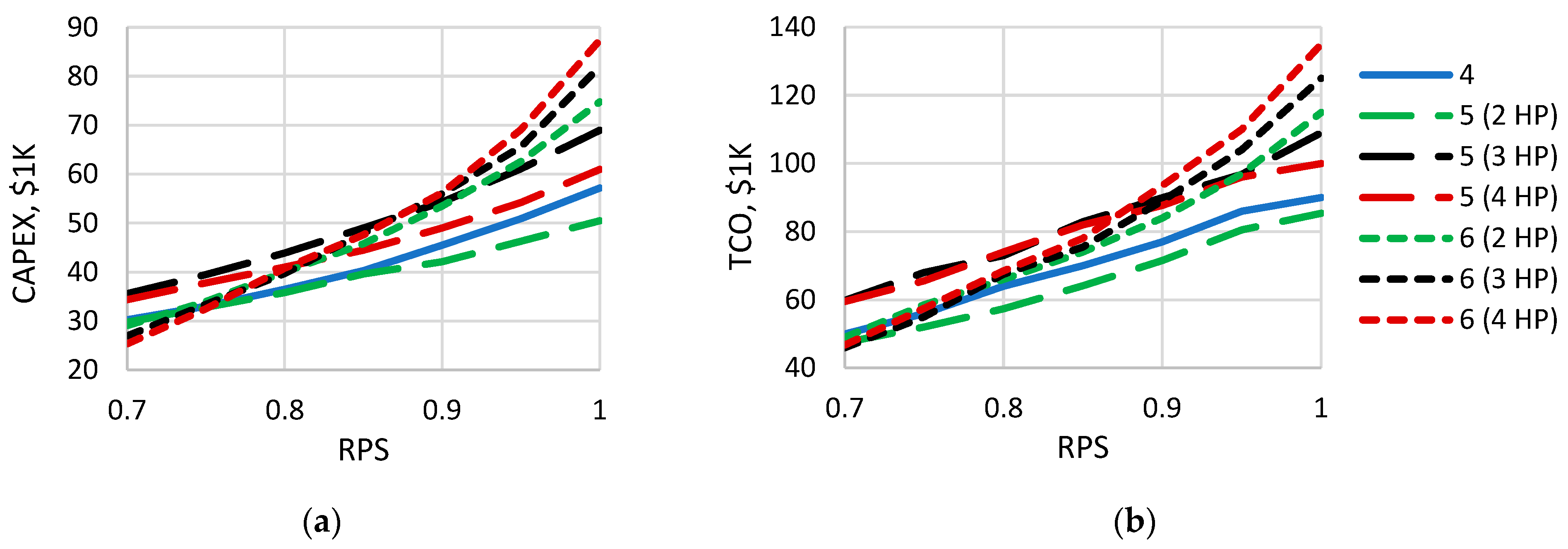

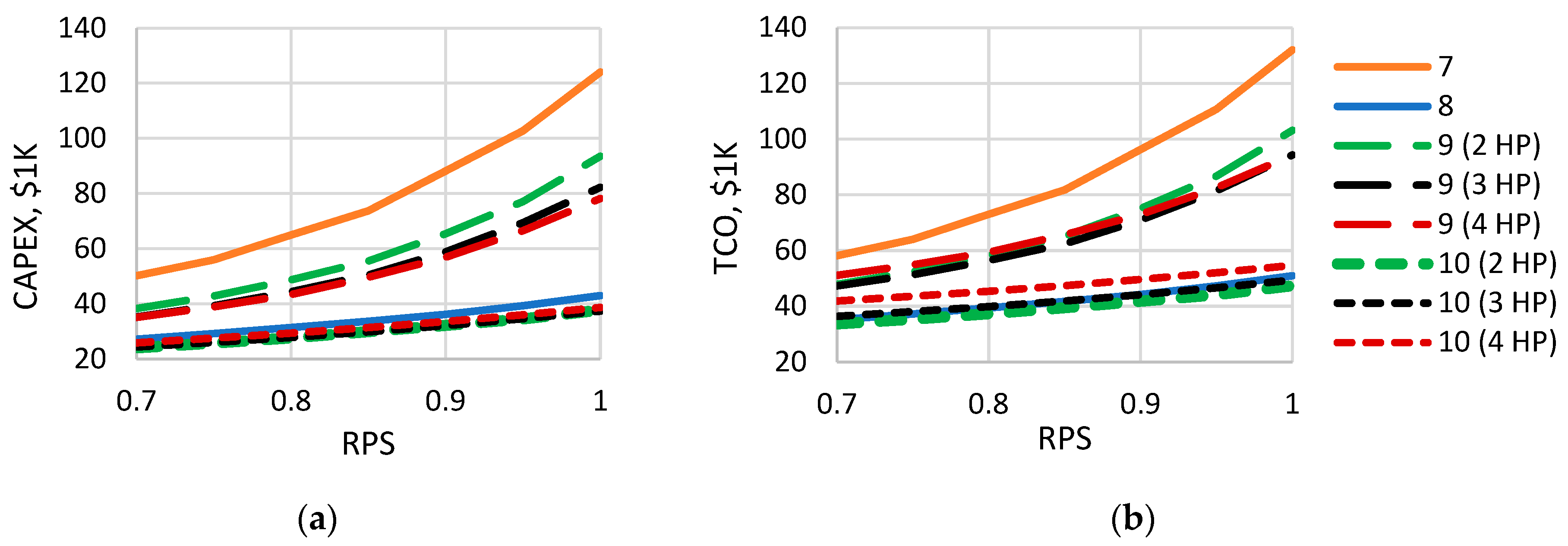

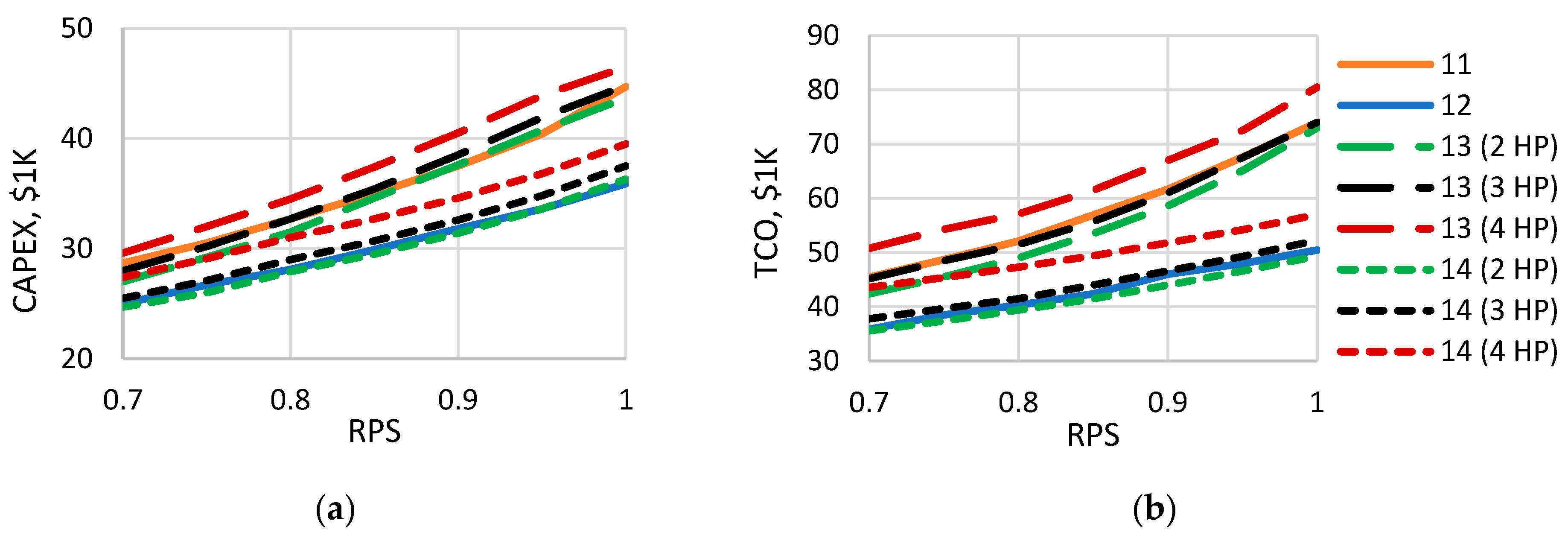

Thus, the operation of 30 different thermal stabilisation system options was simulated (for each aggregated one, the use of two to four HPs was considered). The total number of simulated systems (including variation in power system parameters) was about 292,000. For each thermal stabilisation system layout, the most efficient configurations (with RPS from 0.7 to 1, step 0.5) with minimum CAPEX and TCO were selected. The system life cycle was determined by the equipment with the maximum service life; thus, the TCO will be considered for 30 years. The TCO was affected by the need for BES and HP replacement.

Figure 8 shows the areas comprising the most efficient and cost-effective configurations (both in terms of CAPEX (a) and TCO (b)): the «Classic» area includes system variants 1–6, and the «Adaptive» area includes system variants 7–14. Of note, if thermal stabilisation requirements are not strict (RPS~0.7), there is not much difference in the efficiency of the approaches: the best «Adaptive» configuration is cheaper than «Classic» only by 5% in terms of CAPEX. However, as the requirements for preventing heat penetration into the soil increase, the difference grows as well: at RPS = 1, «Adaptive» is 28% cheaper than «Classic». When TCO is considered, the results are more pronounced: «Adaptive» is 27% cheaper when the requirements are not stringent, and 44% cheaper when the RPS = 1.

In terms of CAPEX, the most efficient (RPS = 1) and cheapest «Classic» configurations were the ones with BES and HP working in «Start–Stop» mode with light aggregation (2 HPs). But when RPS = 0.7 (using the classic approach), it is preferable to use «Inverter» mode and moderate aggregation (3 HPs). When using the adaptive load, in the same RPS ranges, in contrast, the cheapest configurations were options without BES and with aggregation (2 HPs). However, the best «Adaptive» configurations with RPS above 0.8 were the systems with BES.

Table 7 shows the main technical characteristics of the most economically and technically efficient configurations.

However, in terms of TCO, the most technically and economically efficient configurations in «Adaptive» mode are the systems without BES (

Table 8), but using the aggregation principle (2 HPs) and operation frequency control. With the classic approach to load control, the most efficient configurations are those with BES. And, as the requirements for the quality of thermal stabilisation increase, the ratio between the capacities of HP and BES also changes in optimal configurations.

3.1. «Classic» (Configurations Numbered 1–6)

This set of configurations is the least efficient.

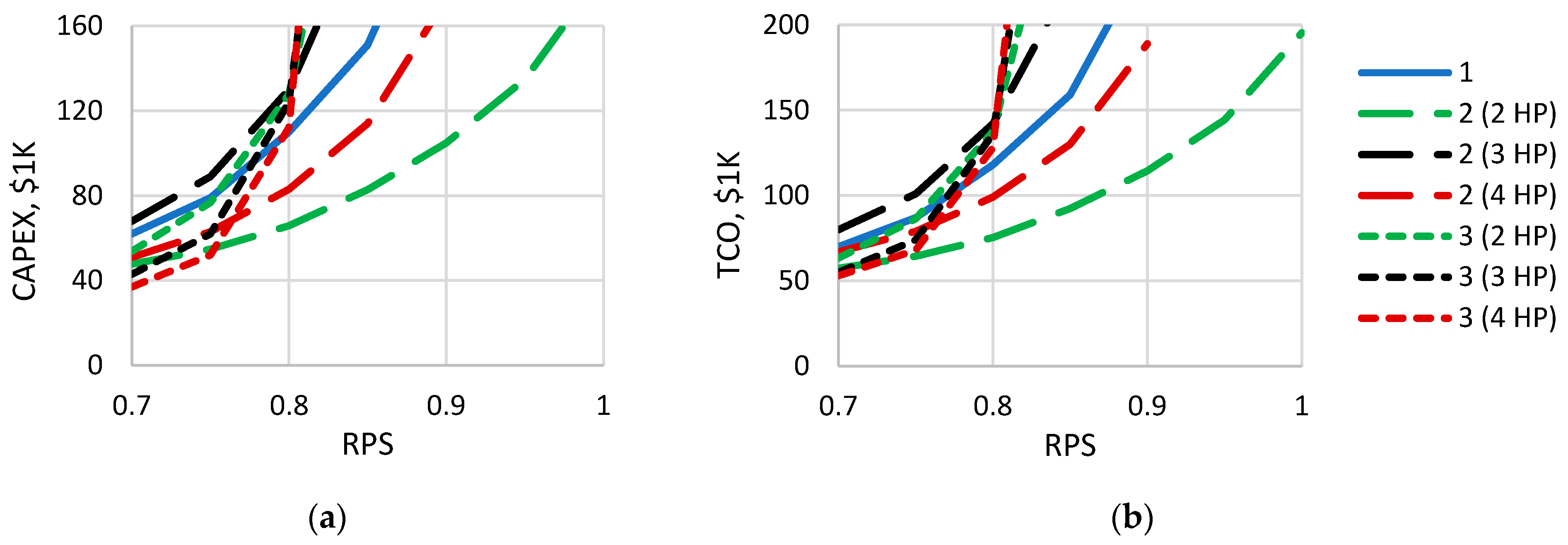

Figure 9 shows the dependencies of CAPEX (a) and TCO (b) on required RPS for systems without BES. In such systems, the aggregation method does not always increase the efficiency of the system: three or four HPs are not a viable solution with «Start–Stop» control. Although deeper aggregation of the system reduces the starting threshold power, using two HPs with «Start–Stop» control leads to better results. The transition from two HPs to three HPs reduces the minimum power required to start the aggregates.

Inverter mode is not effective compared to the «Start–Stop» control. Aiming to satisfy the electric power demand for thermal stabilisation at the given moment (

Figure 4), the «Start–Stop» system will somehow operate at a higher power than actually required, which will eventually lead to cold accumulation in the soil. When the frequency is controlled, the power is finely adjusted to the demand for cooling—without its excessive production. For the same reason, a «Start–Stop» system with four HPs loses to a system with two HPs due to the possibility of finer adjustment of power consumption: a decrease in excess cooling capacity reduces the efficiency of the thermal stabilisation system as a whole.

All the above-mentioned features are also applicable to the systems with BES (shown in

Figure 10a,b). However, the use of BES can significantly improve system efficiency and reduce cost: to achieve RPS = 0.9, the CAPEX reduction is about 60%, and TCO reduction is 38%.

3.2. «Adaptive» (Configurations Numbered 7–14)

Load adaptivity principle application (in our case, using the soil as a thermal storage) improves the overall system efficiency significantly. For non-BES systems, in the case of a «Start–Stop» operation, the aggregation leads to a significant cost reduction (CAPEX—33%, TCO—31%) for the systems capable of providing RPS = 1 (

Figure 11). However, for frequency-controlled HPs, the economic effect of aggregation is not so significant. Moreover, the most optimal solution for these systems is to use two HPs: in the 20–40k USD range, the cost of HP has a significant impact on the entire thermal stabilisation system. It is worth noting that the result obtained is valid for a certain ratio of equipment prices only, when the increase in CAPEX due to the aggregation minimises all the advantages of this approach. This fact is also observed when considering the TCO of the most optimal non-BES systems: for the «Start–Stop» system, the best option is three HPs, and for the frequency-controlled, with the best option is two HPs (the system with four HPs is a less favourable solution in terms of TCO than installing a single HP).

The introduction of BES into the system reduces the cost of the most efficient «Start–Stop» configurations. However, for inverter systems, the influence of BES is rather insignificant (

Figure 12). Of note, in the case of BES, the effect of aggregation on system efficiency is minimized (especially for «Start–Stop»).

4. Discussion

The results of our calculations unambiguously show the advantages of the adaptive load principle once it is applicable. However, it is important to note that other optimal system configurations may be observed in other price conditions (it is also valid for «Classic» configurations, but less so). According to the results of this study, for «Adaptive» systems, the use of BES is much less relevant than for classic systems: the accumulation of excess energy in the form of cold in the ground is certainly more beneficial (but only within the limits of the considered price conditions). For HP applications other than soil thermal stabilization, it means a special thermal storage is needed. This is also valid if the load has a power threshold. On the one hand, the presence of BES allows the system to gradually accumulate energy for further plant start-up, but on the other hand, the excess generating capacity also allows passing the threshold under unfavourable conditions for electricity generation (for PV, at low solar irradiance).

The aggregation method proved to be a rather efficient way of increasing the system operating time by decreasing the load power threshold that improved the soil freezing quality over the season significantly. But nevertheless, this method may not always be economically justified either; often, the load unit cost grows non-linearly as the unit power decreases, and thus, in the case of a low-cost power supply system, in certain cost conditions, it is economically inefficient to use deep aggregation (despite all the technical advantages of this method). This was found as a result of calculations for all configurations with BES and frequency control.

As a result of the calculations, it was found that, for thermal stabilisation in northern Norway, the best configuration (in terms of TCO) of an active thermal stabilisation system is a non-BES one. However, the use of small-capacity BES in real applications can increase the operation reliability in cloudy weather conditions significantly. Thus, in such systems it is recommended to install a small-capacity BES, which will slightly increase the cost of the system but will significantly improve the system quality as a whole.

The results of the present study also correlate with the results of [

18], which investigated the effect of aggregation on thermal stabilisation system performance in the same region (northern Norway). In non-BES systems with frequency-controlled HPs, the aggregation method increases the system operating time during the warm season. However, there is no significant decrease in the optimal configurations costs.

A further promising area in configuring thermal stabilisation systems is using compressed-liquid thermal storage [

36] rather than BES. So, for instance, the cost of energy removed from R32 refrigerant (when it is used as a «cold» accumulator) is three times lower than the cost of energy removed from BES. Storage in a refrigerant will have an even greater impact on TCO: in contrast to BES, thermal storage has no limit in discharge cycles, and therefore will not require replacement over the lifetime of the plant.

Another promising method of increasing the efficiency of the off-grid thermal stabilisation system is using an expander instead of a throttle system in HPs [

37]. Such a solution makes it possible to recover the energy in the expander that would be lost in the throttle at about 50% efficiency. This approach is too expensive for a grid-connected HP, but for an off-grid one, it reduces the power demand and CAPEX significantly.

5. Conclusions

The operation of a set of solar-powered cooling systems with different approaches to the design (aggregation; battery, thermal, and implicit storage) and operation («Start–Stop»; frequency conversion; adaptive load) was simulated. The analysis of energy systems design approaches and the economic and technical effect of their application was carried out.

If it is possible to organize the load following the energy generation in RES systems, this leads to a system efficiency increase compared to the classic approaches. It was found that considering HP as an adaptive load in a thermal stabilisation system will reduce capital expenditures by 28% and the total cost of ownership by 44% while preserving the soil-freezing quality. In straightforward systems (such as «Start–Stop»), the aggregation method application results in a 30–35% reduction in both CAPEX and TCO due to lower demand for PV name plate capacity. Although this could be outweighed by the increase in annual motor-hours per HP unit, the HPs’ frequency control availability leads to an average increase in system efficiency of 35%. For the systems based on inverter HPs, the aggregation brings no significant advantages and, in some cases, makes the system more expensive.

As a result of the calculations, it was found that for the thermal stabilisation of a 100 m2 area in northern Norway, the best configuration of an active thermal stabilisation system is a system with two inverter HPs (installed power of about 3.25 kWe each) and a power supply system based on PV (total installed power capacity of about 47 kW without BES). However, for real systems, it is recommended to install a slightly more expensive system with a power supply system based on PV (43.5 kW) and BES (4.35 kW × h) to increase the HPs’ operation reliability in cloudy weather conditions.