1. Introduction

Compressed air is the most widely used energy carrier in pneumatic systems, with the advantages of low initial capital cost, cleanliness, ease of maintenance, etc. [

1]. However, compressed air is one of the most expensive energy carriers and the energy efficiency of pneumatic systems is much lower than the hydraulic and electric counterparts [

2]. For example, in the generating process of compressed air, about 50% to 85% of energy dissipates as heat, and only a fraction is converted into pressure energy of compressed air, thereby significantly increasing the energy cost in the life cycle [

3]. In various countries, compressed air systems consume approximately 7% to 15% of total industrial electricity consumption [

4]. The pneumatic system has become an important contributor to energy consumption worldwide [

5,

6]. With the increasing concern for green and sustainable manufacturing, the drawback of low energy efficiency of pneumatic systems has become more evident. Therefore, the demand for pneumatic energy saving has become increasingly urgent. In recent years, many efforts have been made in this field. Wang et al. [

7] proposed an isobaric compressed air storage device by integrating compressed gas energy storage with a nonlinear cam transformation mechanism, thereby obtaining the desirable constant-pressure characteristics and energy-saving performance. Yu et al. [

8] proposed a novel compressed air utilization system by recovering and reusing exhausted compressed air from pneumatic cylinders. Cummin et al. [

9] developed an isobaric accumulator based on the high elasticity properties of rubber materials and applied it to pneumatic circuits for recovering and reusing exhausted compressed air. Dindorf et al. [

10] examined compressed air receiver tanks for improving the energy efficiency of various pneumatic systems. Rufer [

11] developed a new electrically driven gas booster to replace traditional air-driven gas boosters, thereby increasing the energy efficiency of gas boosters for hydrogen storage and refueling stations. Besides, there is significant progress in other directions for promoting the energy efficiency of pneumatic systems, such as the near isothermal air compression technology [

12,

13], expansion energy utilization energy-saving technology [

14], piezoelectric energy capture technology for pneumatic system applications [

15], and so on. There is no doubt that the research on energy saving of pneumatic technology is constantly developing and becoming more sophisticated.

At present, although there are many studies on pneumatic energy saving, we think the fundamental theory and methods of evaluating and analyzing the energy efficiency of pneumatic systems and components are lagging and cannot satisfy the development of more elaborate energy-saving pneumatic technology.

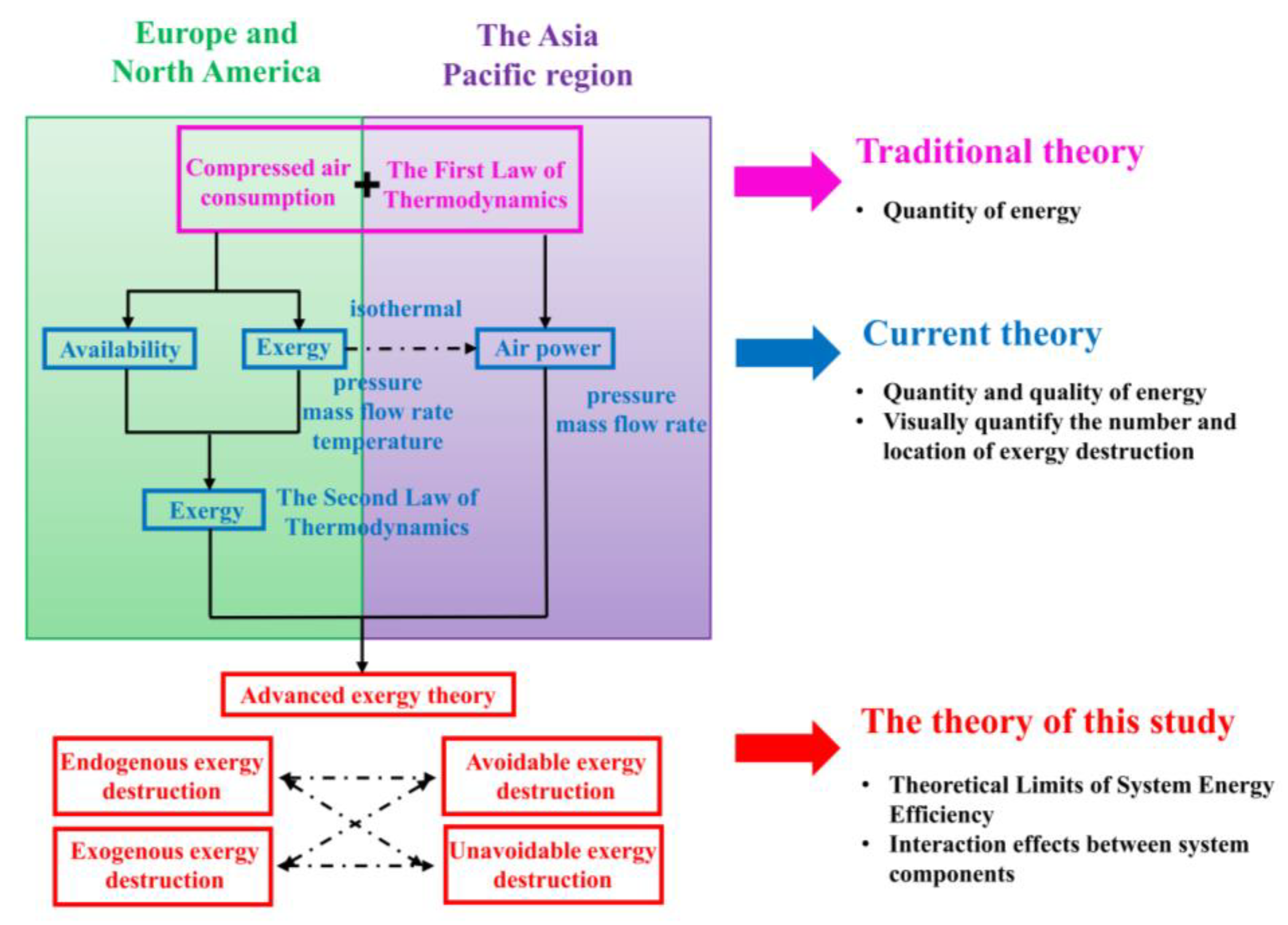

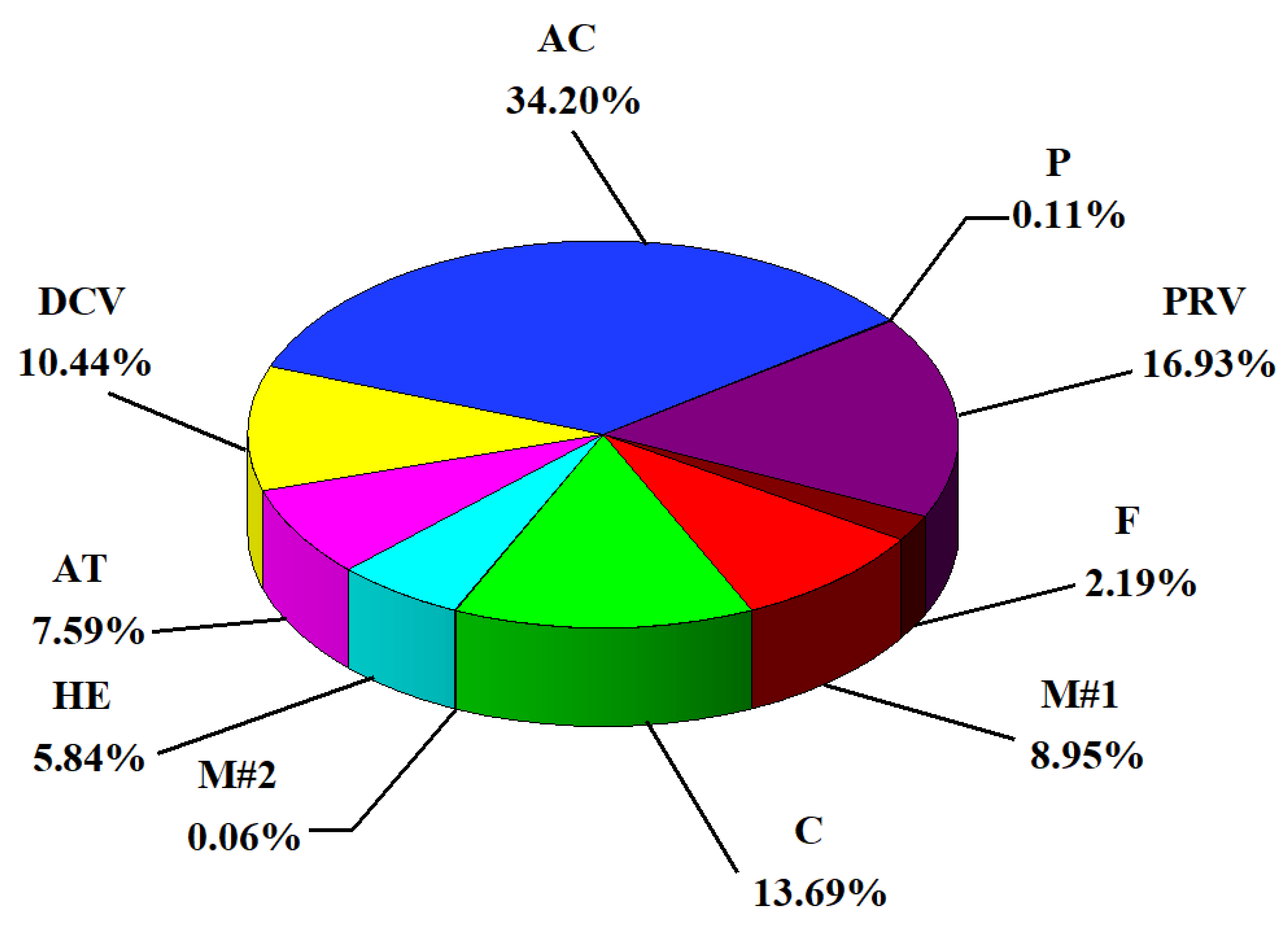

Figure 1 summarizes the development and main concepts of the basic theory for evaluating and analyzing energy efficiency in pneumatic systems. The most conventional theory and methods are established based on calculating and auditing compressed air consumption and applying the First Law of Thermodynamics, which emphasizes enthalpy and internal energy. However, as we all know, this approach can only provide a rough estimation of energy quantity and overlooks the quality differences among different forms of energy. Despite its limitations, this method is still extensively used in various industries due to its simplicity and effectiveness. As pneumatic energy-saving technology progressed, more precise theories are needed. In Europe and North America, the availability and exergy of compressed air based on the Second Law of Thermodynamics are widely accepted and investigated by giving more consideration to the quality of energy. In the Asian Pacific region, the concept of air power was proposed by Cai and Kagawa based on the exergy theory [

16,

17,

18]. Air power is the mechanical/pressure exergy while neglecting the thermal exergy of compressed air. The exergy covers a broader scope with a comprehensive consideration of pressure, mass flow rate, and temperature of compressed air. However, the expression and calculation of air power are simpler and more convenient, primarily taking pressure and mass flow rate into account while ignoring temperature effects. Most recent studies on pneumatic energy-saving technologies accept exergy and air power [

19,

20,

21,

22]. Compared to the traditional methods based on compressed air consumption and the First Law of Thermodynamics, the current methods based on exergy and air power consider both quantity and quality of energy. This enables an intuitive quantification of energy loss and its location, thereby significantly promoting the development of energy-saving applications in pneumatic systems. Nevertheless, in pneumatic systems, the interaction effects between components and their impacts on system energy efficiency cannot be directly revealed by air power and exergy. Furthermore, the theoretical limits of pneumatic system energy efficiency and the relationship between local and global optima remain unquantified. The introduction of advanced exergy analysis could be an enabler to overcome these limitations. By conducting detailed calculations on the four sections of exergy destruction (unavoidable, avoidable, endogenous, and exogenous), advanced exergy analysis could facilitate the optimized design and operational potential for energy conversion systems.

Advanced exergy analysis is a powerful tool for revealing, quantifying, and improving the energy performance of energy systems. It has been widely used and investigated in various fields. Szablowski and Morosuk [

23] applied advanced exergy analysis to evaluate a particular case of an adiabatic underwater energy storage system. It revealed the interaction effect between system components and the potential for improving the system performance from both the component level and the system level. The round-trip efficiency of this system was 64.1% and 87.9% for real and unavoidable operation conditions, respectively. Tian et al. [

24] designed a recuperative organic Rankine cycle with a three-fluid condenser and conducted both conventional and advanced exergy analyses. The results indicated that the condenser, which accounted for 62.6% of total exergy destruction, should be the priority of optimization from the perspective of conventional exergy analysis, while the advanced exergy analysis prioritized the improvement of the expander, and the avoidable endogenous exergy destruction rate of the expander was up to 54.0%. Zhong et al. [

25] analyzed the experimental thermodynamic performance of a novel 100 kW wind-to-heat system. Conventional exergy analysis attributed the wind turbine accounted for most of the system’s total exergy destruction at high wind speeds, whereas advanced exergy analysis suggested that an average of 87.32% of exergy destruction in the compressor was endogenous and avoidable. Exergy destruction could be decreased by optimizing the internal structure parameters. Anvari et al. [

26] conducted conventional and advanced exergy analyses on a tri-generation cycle for heat, cold, and power production. The air pre-heater was given a higher improvement priority compared to the heat recovery steam generator in advanced exergy analysis, whereas this distinction was not evident in conventional exergy analysis. Currently, advanced exergy analysis has been developed into advanced exergy economic analysis and advanced exergy environmental analysis, making significant contributions to the advancement of various fields [

27,

28,

29]. Overall, previous studies have demonstrated that advanced exergy analysis generally reveals more profound insights, such as the details of energy loss in energy systems and the interactions among system components. The advanced exergy analysis provides a more comprehensive explanation for certain one-sided and even incorrect conclusions that may be derived from conventional exergy analysis.

In summary, there have been numerous cases where exergy analysis has been applied to analyze and optimize the energy performance of various systems. The industrial pneumatic system is also a typical energy system that faces energy efficiency challenges. However, the application of advanced exergy analysis to pneumatic systems is still lacking. There is still a gap in understanding the real improvement potential, understanding the interaction effects between pneumatic components, and determining the theoretical limits of energy efficiency in pneumatic systems. The advanced exergy analysis is expected to be a promising solution. Therefore, this study aims to conduct advanced exergy analysis on a simple but typical industrial pneumatic system. Possible interactions between system components and their improvement potential are revealed. Furthermore, we explore the theoretical limits of energy efficiency of the pneumatic system. We hope this study could provide valuable ideas for future elaborate energy saving in pneumatic systems. The structure of this study is as follows.

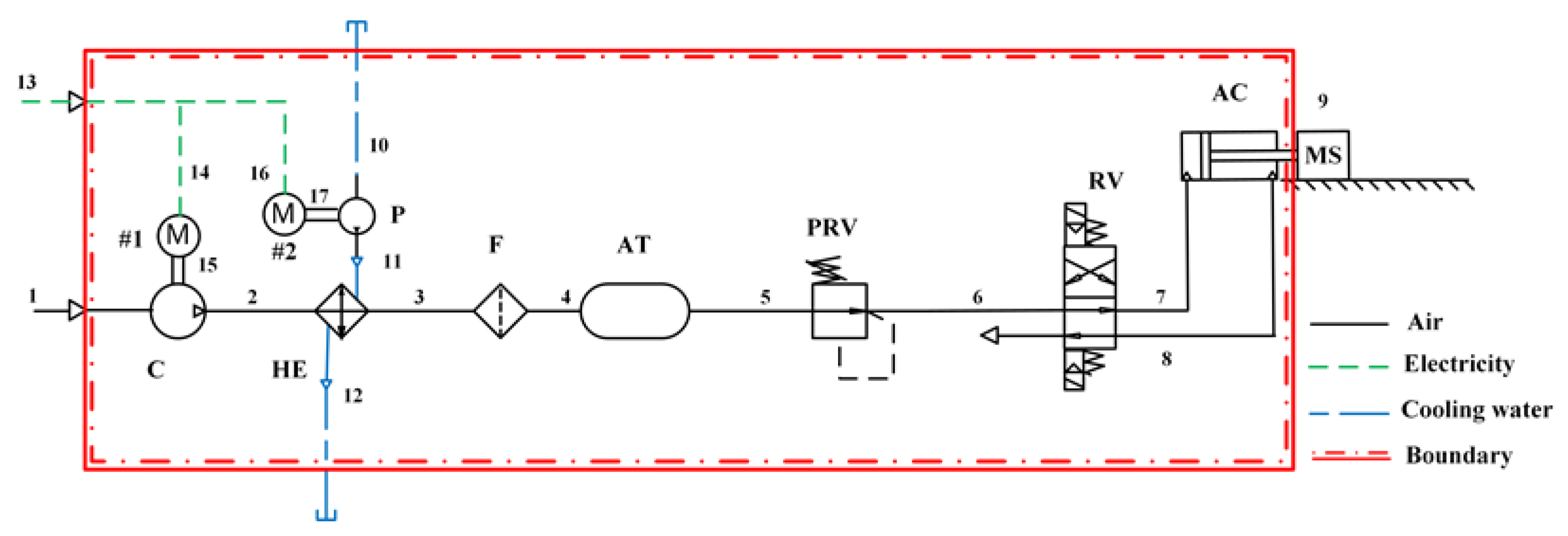

Section 2 establishes a mathematical model of a typical pneumatic system under different operating conditions.

Section 3 provides an overview of the relevant theoretical concepts of conventional and advanced exergy.

Section 4 conducts conventional and advanced exergy analyses by adjusting system parameters, and compares the results to obtain valuable and reliable insights for pneumatic system design and optimization. Finally, conclusions are drawn in

Section 5.

3. Exergy Analysis

Exergy is the work potential of a system in a specified environment and represents the maximum amount of useful work that can be obtained as the system is brought to equilibrium with the environment [

40]. The total exergy of compressed air can be calculated by:

where

,

,

, and

are the physical exergy, kinetic exergy, potential exergy, and chemical exergy, respectively.

Generally, there are no significant changes in the height of compressed air and no chemical reactions. The kinetic energy of compressed air is not evident for most pneumatic components. Therefore, the potential exergy, chemical exergy, and kinetic exergy could be ignored in this study. Thus, the Equation (32) can be simplified as:

The specific exergy of compressed air can be calculated by:

When compressed air is regarded as an ideal gas, the sum of its temperature and pressure exergy can be calculated by:

where

is the mass flow rate of compressed air,

is the specific exergy,

represents the constant pressure specific heat capacity of the compressed air, and

and

represent the temperature exergy and pressure exergy, respectively. In this study, the total exergy of an ideal gas is the sum of temperature exergy and pressure exergy. From Equations (35) and (36), it can be seen that the temperature exergy and pressure exergy are determined by the temperature and pressure of the state point, respectively.

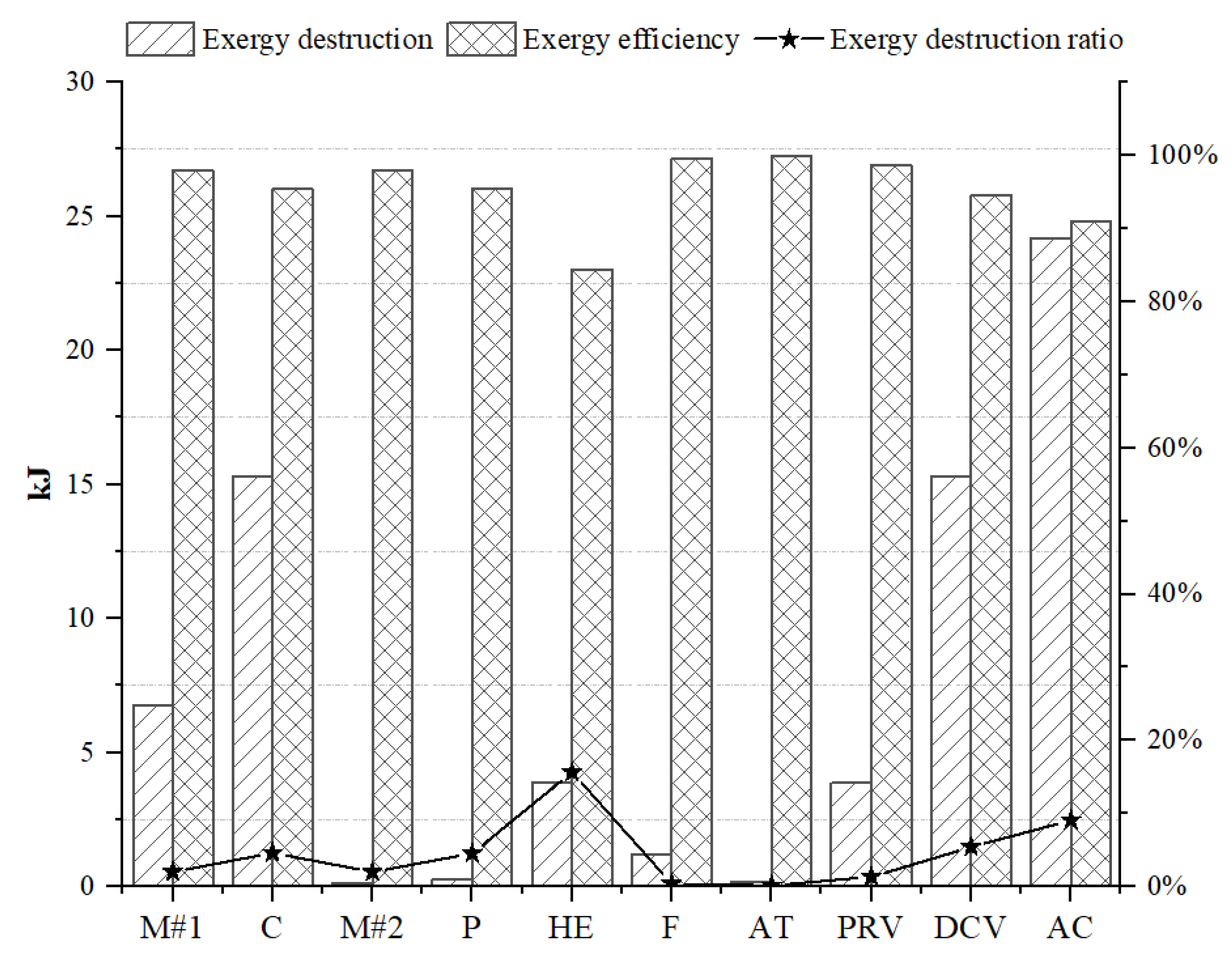

3.1. Conventional Exergy Analysis

Typically, there are two distinct approaches to define exergy efficiency, i.e., the “input–output” approach and the “fuel-product” approach. In this study, exergy efficiency is defined using the “fuel-product” approach, as it offers a better understanding of the potential for improving exergy efficiency [

41].

In a system, the establishment of the exergy equilibrium equation is the foundation of analysis. For the

K-th component, the exergy equilibrium equation is:

The exergy efficiency of the

K-th component is:

The exergy destruction ratio of the

K-th component is:

The relative exergy destruction of the

K-th component is:

For better understanding the improvement potential of a component, a new variable is defined as [

42]:

For this variable, the larger it is, the greater the potential for improvement of the component.

Table 2 shows the definitions of fuel exergy and product exergy of various pneumatic components.

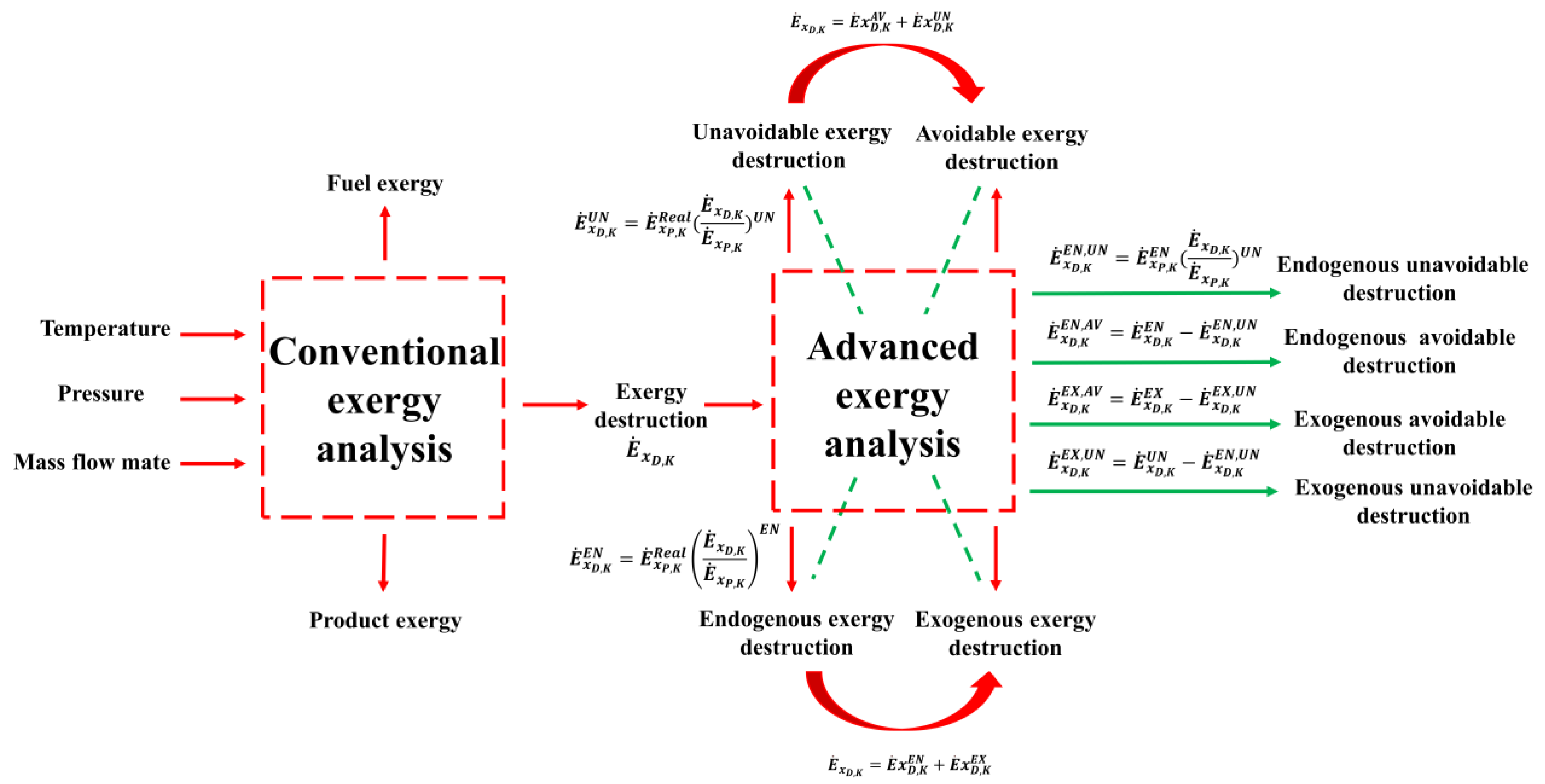

3.2. Advanced Exergy Analysis

Through conventional exergy analysis of the system, it is possible to determine the exergy destruction incurred by each component. To reveal the interactions between various components and identify potential approaches for improving the energy efficiency of the whole system, advanced exergy analysis is conducted. The exergy destruction is decomposed and analyzed in detail. Consequently, two decomposition methods are employed for analyzing the exergy destruction rate of the

K-th component:

where

represents the endogenous exergy destruction rate of the

K-th component. The endogenous exergy destruction is the destruction caused by the internal irreversible process of the

K-th component when all other components operate under ideal conditions and the

K-th component operates under the actual/real condition.

is the exogenous exergy destruction rate of the

K-th component. The exogenous exergy destruction is caused by the irreversible process of other components in the system except for the

K-th component.

refers to the avoidable exergy destruction rate that can be avoided through optimization.

is the unavoidable exergy destruction rate of the

K-th component. The unavoidable exergy destruction refers to the part of the exergy destruction that cannot be avoided due to material, technology, manufacturing methods, or cost limitations. As long as the component is used in the system, unavoidable exergy destruction will always exist. In a system, by comparing endogenous and exogenous exergy destruction, the degree of interaction between the

K-th component and other components can be obtained. By comparing avoidable and unavoidable parts, the real potential for improving system and component performance can be obtained.

Based on the above decomposition of exergy destruction, advanced exergy theory combines avoidable/unavoidable concepts with endogenous/exogenous concepts to obtain a more detailed classification [

43]:

By using the above Equations (45)–(48), it can be deduced that:

where

is the endogenous avoidable exergy destruction rate, which can be avoided by improving the performance of the

K-th component itself,

is the endogenous unavoidable exergy destruction rate, which cannot be reduced even if the

K-th component operates at its maximal attainable efficiency while all other components operate in an ideal way,

is the exogenous avoidable exergy destruction rate, which can be reduced by improving the performance of other components in the system, and

is the exogenous unavoidable exergy destruction rate, which cannot be avoided even if other components of the system are working in their optimal state.

In advanced exergy analysis, it is essential to determine the endogenous avoidable, endogenous unavoidable, exogenous avoidable, and exogenous unavoidable exergy destruction rate. Various methods have been developed with the development of advanced exergy analysis, including the thermodynamic cycle method, engineering method, exergy balance method, equivalent component method, and structural theory method [

44,

45,

46]. By comparing these methods, it can be found that the engineering method is suitable for practical engineering situations and a significant amount of data are required. The exergy balance method is more suitable for complex systems. The energy and mass of each ideal component may not reach equilibrium by idealizing the system, so it is necessary to fabricate a mass flow rate to achieve equilibrium. The principle of the equivalent component method involves approximating the studied component with another component that is easier to analyze. The structural theory method is only applicable to theoretical systems. Each component is analyzed independently of the system, resulting in a significant discrepancy in energy conversion compared to actual scenarios. Among these methods, the thermodynamic cycle method is the simplest and yields the best system results achievable through the definition of different thermodynamic cycles. Thus, the thermodynamic cycle method is adopted in this study. Within the thermodynamic cycle method, it is necessary to define three types of thermodynamic cycles: the real thermodynamic cycle, the unavoidable thermodynamic cycle, and the hybrid thermodynamic cycle. The real thermodynamic cycle represents all components under real irreversible working conditions. The unavoidable thermodynamic cycle indicates that all components operate under unavoidable operating conditions, which correspond to the possible optimal operating condition. The hybrid cycle involves some components operating under real conditions, while others operate under ideal working conditions. Component assumptions for the real, unavoidable, and ideal conditions corresponding to these three cycles are presented in

Table 1. By comparing the results of the real thermodynamic cycle with those of the unavoidable thermodynamic cycle, both avoidable and unavoidable exergy destruction can be obtained. Similarly, by comparing the real thermodynamic cycle with the hybrid cycle, endogenous and exogenous exergy destruction can be determined.

The unavoidable, avoidable, and endogenous unavoidable exergy destruction rate of the

K-th component can be calculated by:

where

is the unavoidable index, which is the ratio of exergy destruction rate to product exergy in the unavoidable thermodynamic cycle, and

is the ratio of exergy destruction rate to product exergy in a hybrid thermodynamic cycle.

After conducting the conventional and advanced exergy analyses, it can be observed that assuming a constant input energy flow rate

or a constant output energy flow rate

results in the same results when analyzing the unavoidable/avoidable parts. This is because each component is considered separately. However, this assumption is important for endogenous/exogenous parts analysis. This is because a component’s assumption is changed, and the energy conversion of the system needs to be carried out again. At the same time, the choice of assumption also affects the endogenous exergy destruction. Keeping

or

can yield different results [

43]. Considering the dynamic characteristics of the pneumatic system, this study chooses to maintain

while simulating for 600 s. In simulations, all components reach a stable working condition, and the product and fuel exergy of each component are integrated. It should be mentioned that, while analyzing the air storage tank, only accumulative exergy analysis for the period from the 250 s to 600 s after achieving stability was conducted. This is due to the unique working nature of the air storage tank within this system. The relationships between the different exergy destruction rates mentioned above are organized and illustrated in

Figure 3.