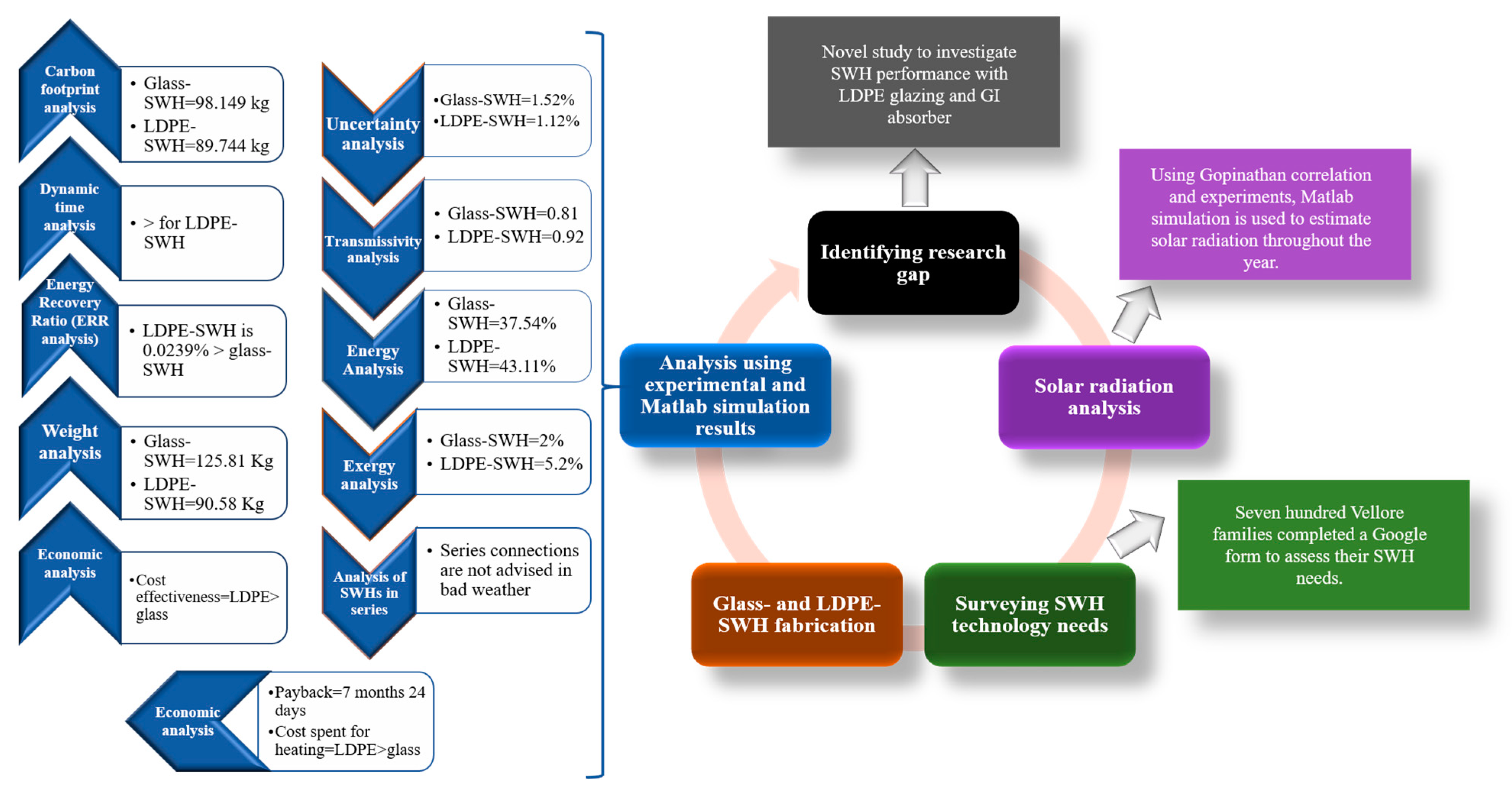

Extensive Analysis of a Reinvigorated Solar Water Heating System Using Low-Density Polyethylene Glazing

Abstract

:1. Introduction

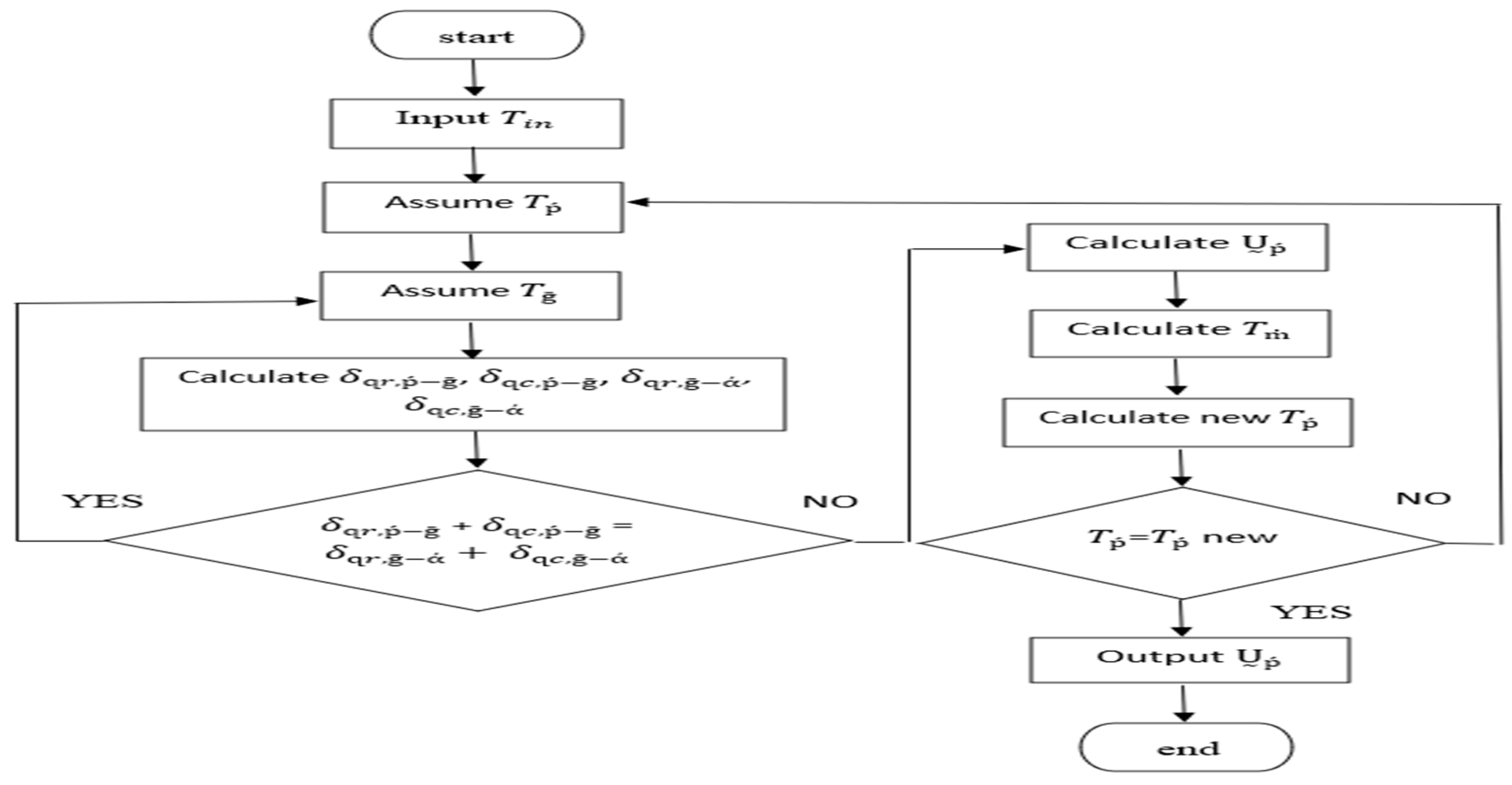

2. Experimental Methods

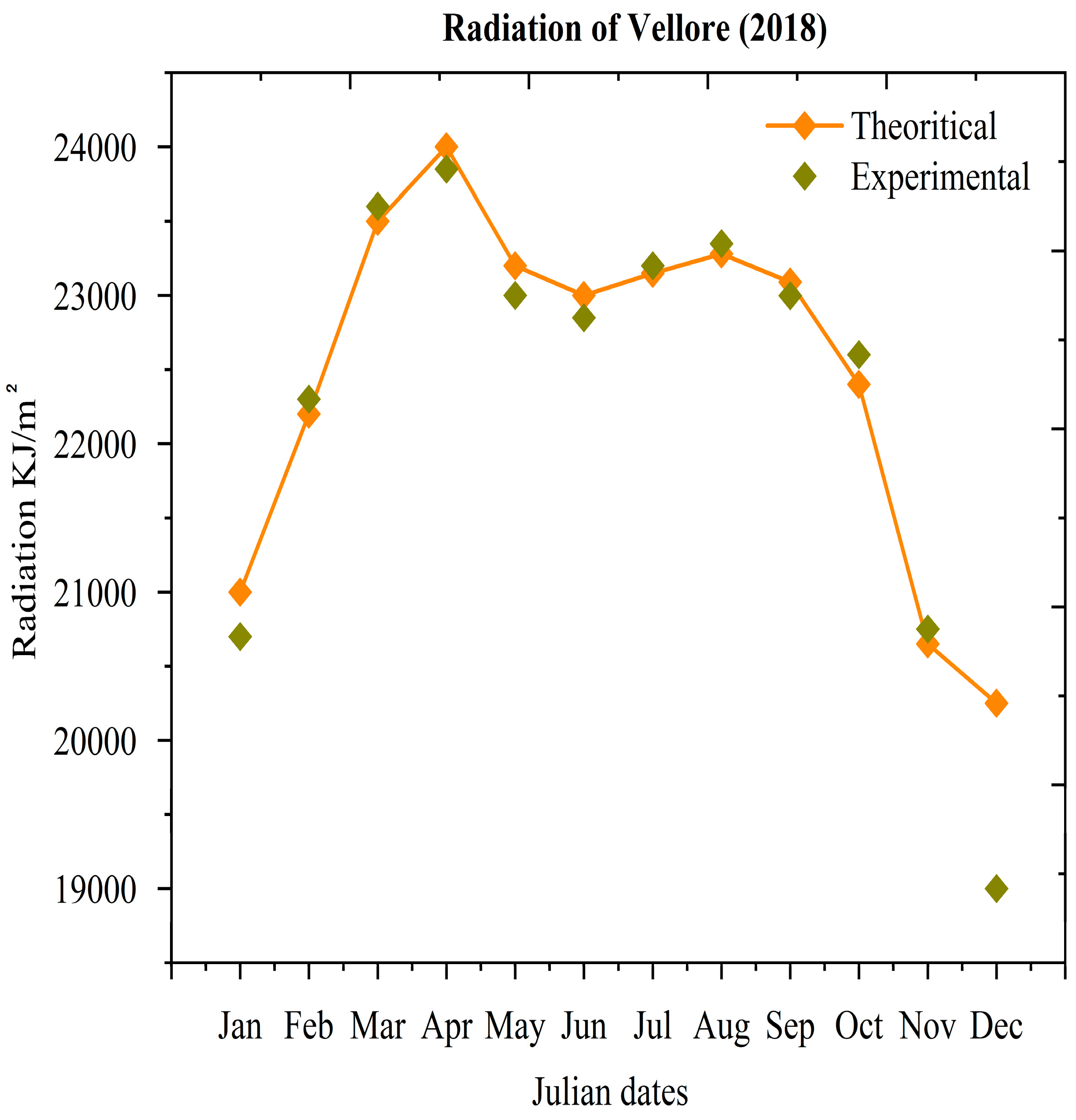

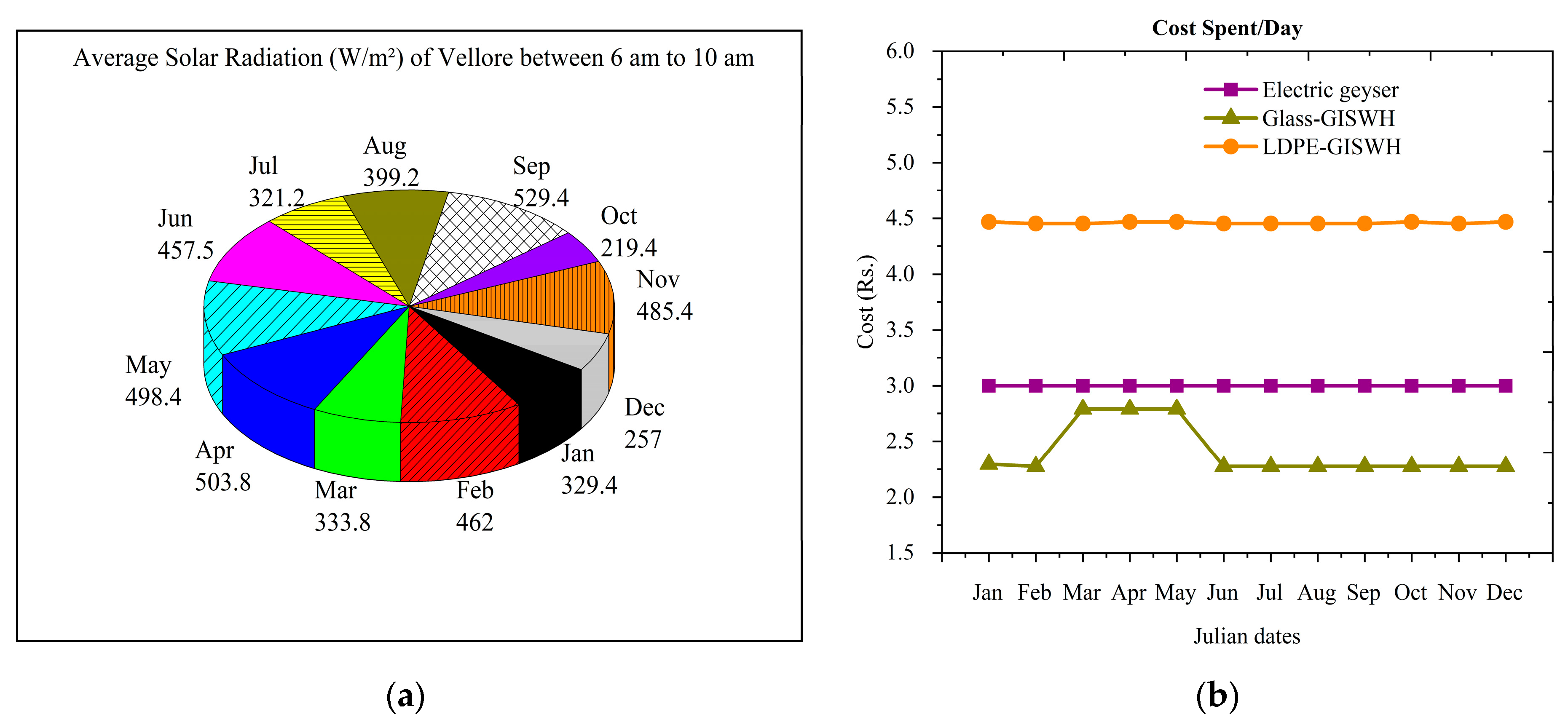

2.1. Solar Radiation Analysis

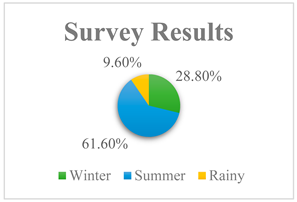

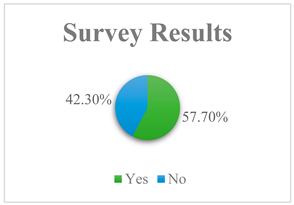

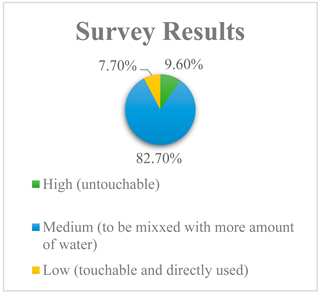

2.2. Survey

2.3. Experiment

2.3.1. Thermophysical and Radiometric Characterization

2.3.2. Working

2.3.3. Experimental Procedure

2.3.4. Energy Efficiency

2.3.5. Exergy Efficiency

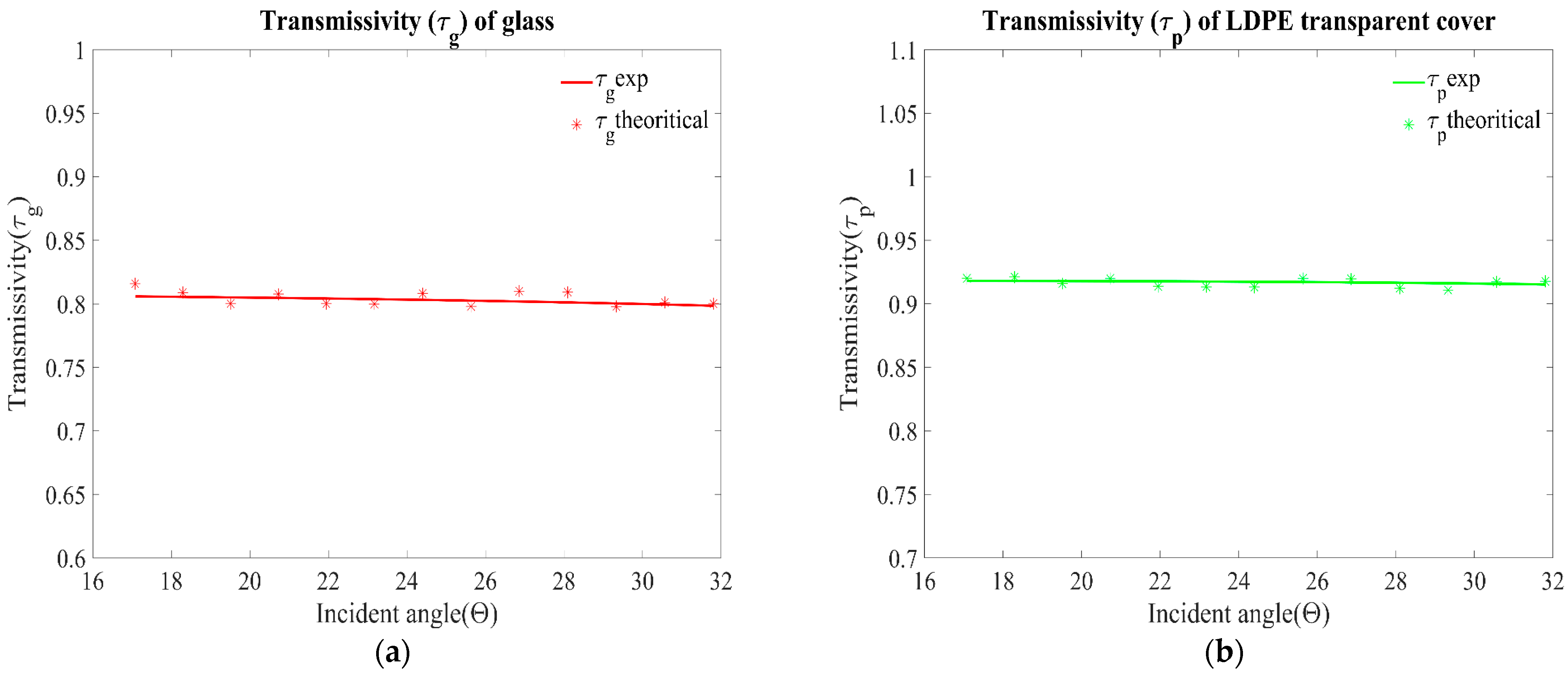

2.3.6. Transmissivity

2.3.7. Uncertainty

2.3.8. Payback Period

2.3.9. CO2 Emissions

3. Results and Discussion

3.1. Solar Transmissivity Analysis

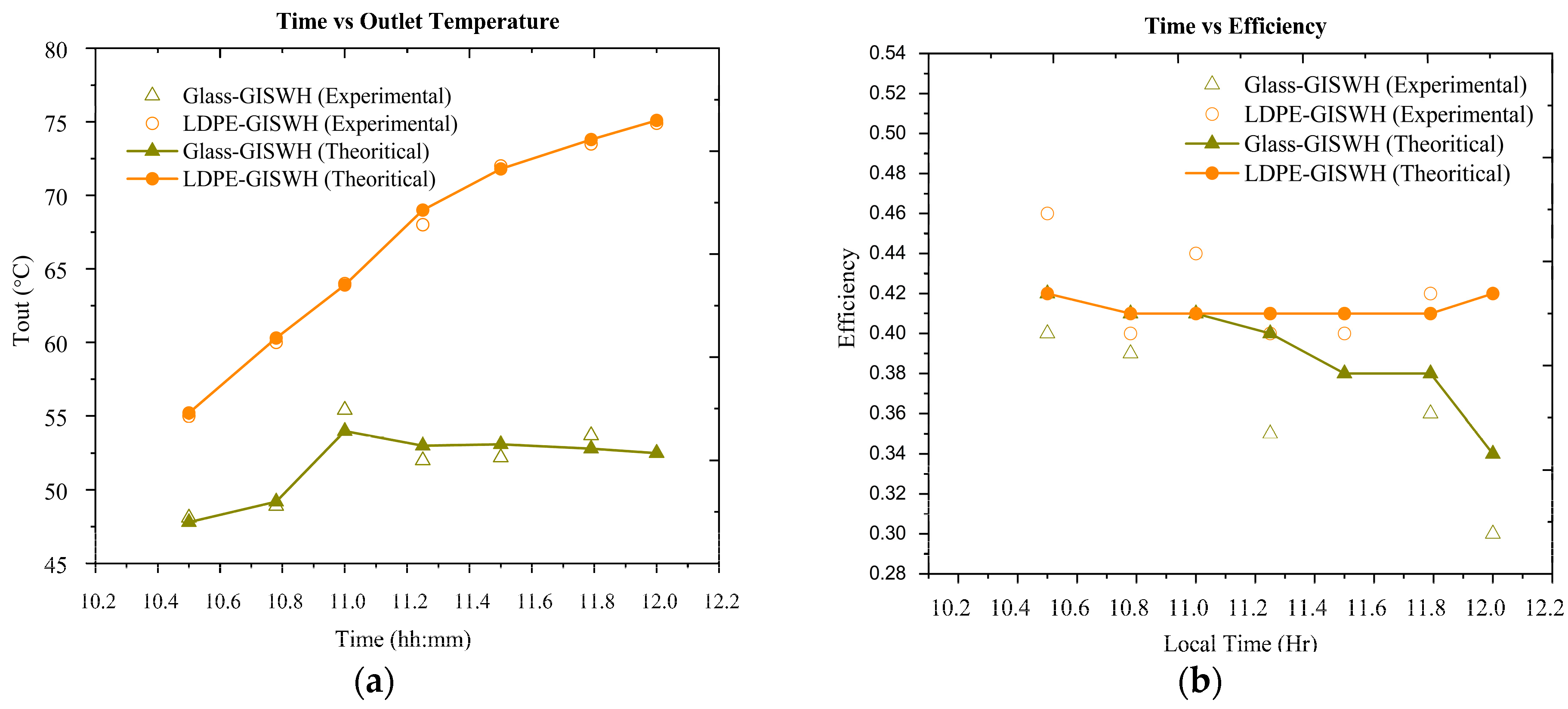

3.2. Energy Analysis

3.3. Series Connection of Fabricated Solar Water Heaters

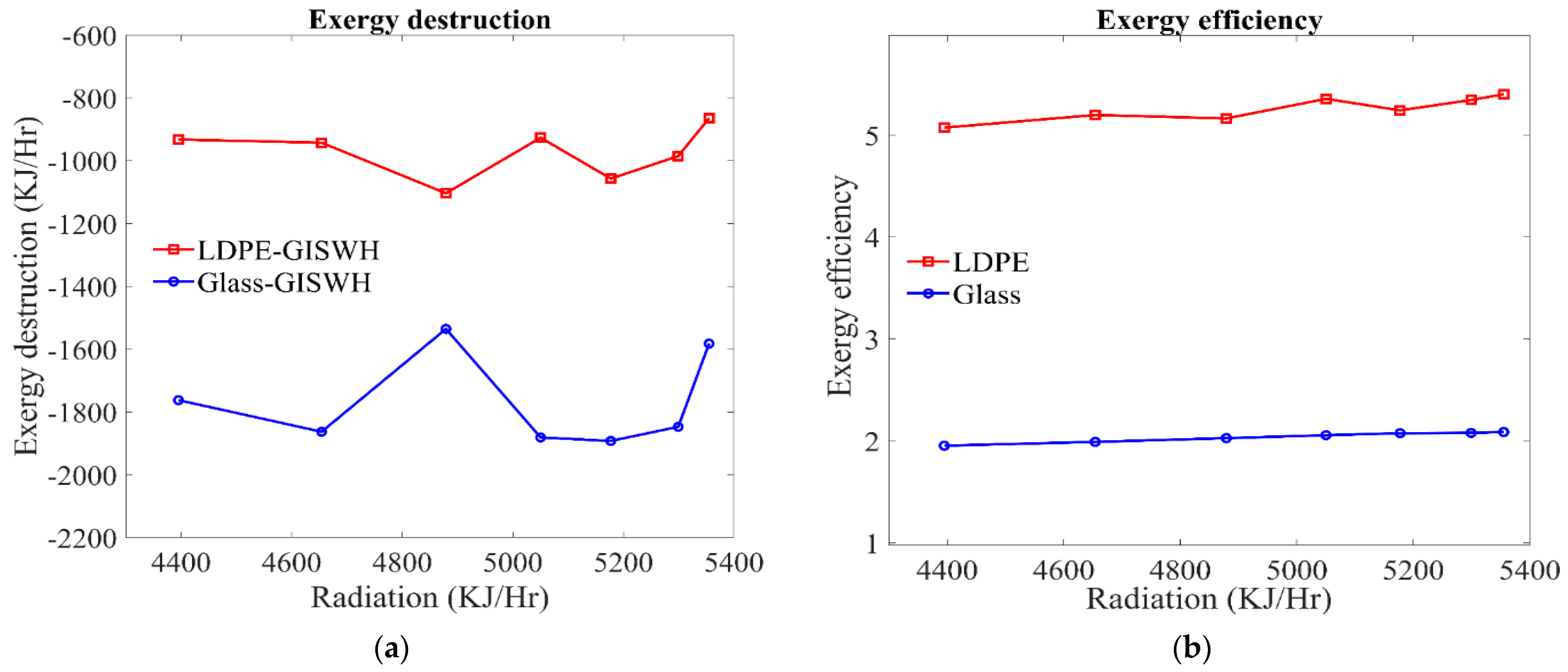

3.4. Exergy Analysis

3.5. Economic Analysis

3.5.1. Payback Period

3.5.2. Cost Spent Based on Power Rating

3.5.3. Cost-Effectiveness

3.6. Weight Reduction on Proposed Model

3.7. ERR Analysis

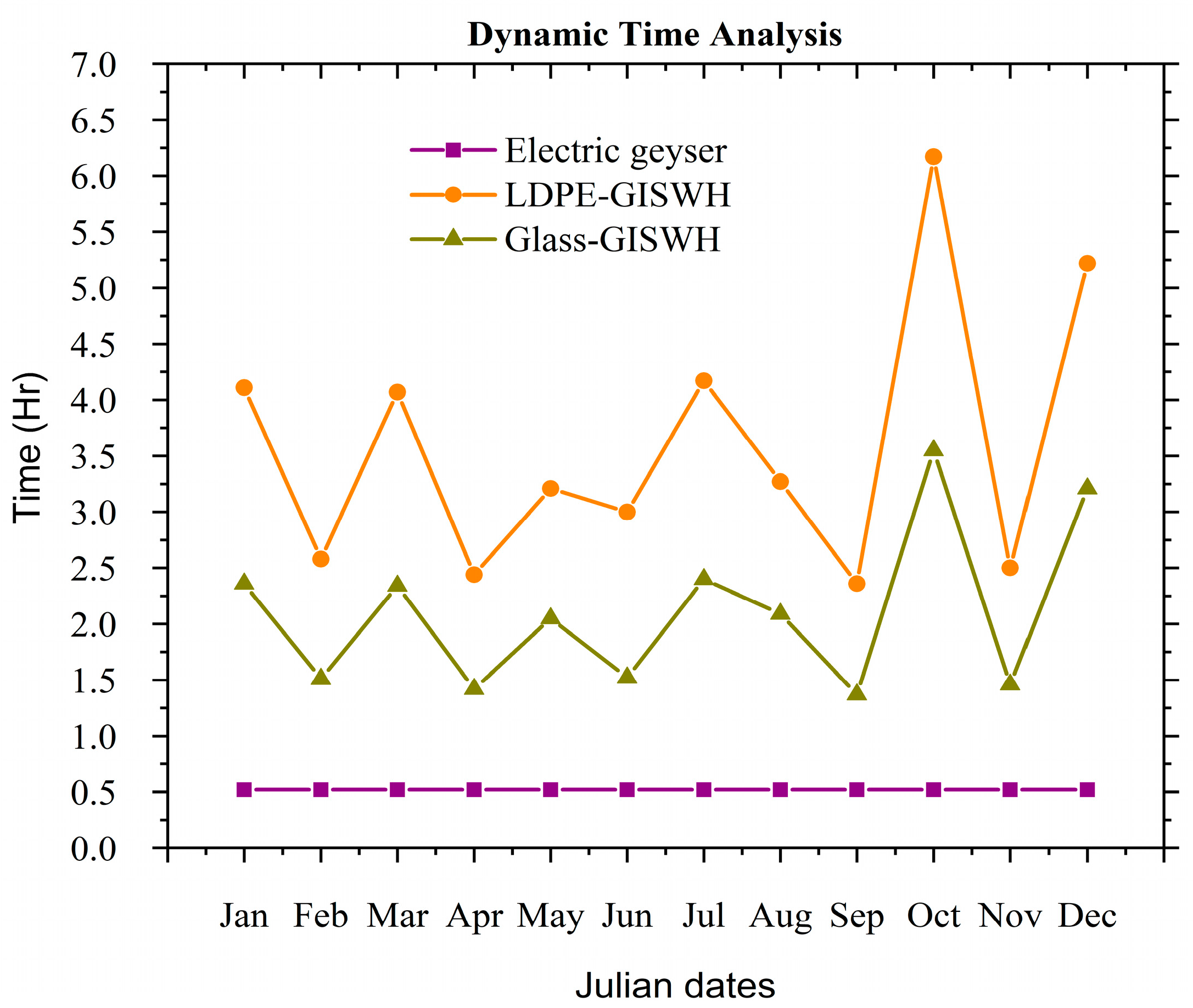

3.8. Dynamic Time Analysis

3.9. CO2 Analysis

4. Conclusions

- During the experiment, the uncertainty difference between the SWHs was 0.4%. The solar transmissivity study shows that LDPE has a higher transmissivity coefficient than glass. The typical experimental and quantitatively calculated solar transmissivity coefficient values for LDPE and glass were around 0.92 and 0.81, respectively.

- The energy and exergy efficiencies of LDPE SWHs were found to be higher than those of glass SWHs, which can be explained by the solar transmissivity coefficient of LDPE being 12.71% higher than that of glass, which increases the temperature difference between the inlet and outlet of the LDPE SWH.

- For LDPE SWHs and glass SWHs, the highest average energy efficiency was 43.11% and 37.54%, respectively, and the highest average exergy efficiency was 5.1% and 2%.

- From 6 to 10 am, the simulation’s highest average outlet temperature was 33 °C for LDPE and 31 °C for glass SWHs. In bad weather, series connections are not recommended.

- The economic analysis was performed, and the payback period was calculated as 7 months and 24 days. The most and the least amount spent by LDPE SWHs for energy conversion is INR 138.57 and INR 124.74, respectively, while glass SWHs spent INR 86.49 and INR 63.7. LDPE SWHs cost more, which can be explained by the fact that LDPE has a longer dynamic duration than glass. According to a cost-effectiveness study, installing revitalized LDPE SWHs can save INR 9,170,000 in the 700 family members that participated in the survey from Brahmapuram, Vellore.

- LDPE glazing reduces SWH weight by 32.56%, improving handling and positioning.

- LDPE SWHs’ efficiency recovery ratio (ERR) is 0.0239% higher than that of glass SWHs.

- The dynamic time to raise the water temperature to 50 °C is longer for an LDPE SWH, taking up to six hours in October and as little as two hours in September.

- The total embodied energy required to create glass and LDPE SWHs was estimated to be 1553.4 kWh and 1419.7 kWh, respectively. The CO2 emissions from glass and LDPE SWHs were calculated to be 98.149 kg and 89.744 kg, respectively. A glass SWH has a bigger CO2 mitigation than an LDPE SWH, which is 2.53 tons and 2.2 tons. Glass and LDPE SWHs obtain large annual carbon credits valued at INR 125.02 (USD 1.52) and INR419.46 (USD 5.1), respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | |

| EPA | Environmental Protection Agency |

| FPSWH | Flat plate solar water heater |

| GI | Galvanized iron |

| glass SWH | glass solar water heater |

| HTF | Heat transfer fluid |

| LDPE | Low-density polyethylene |

| LDPE SWH | Low-density polyethylene solar water heater |

| ERR | Efficiency Recovery ratio |

| SWH | Solar water heater |

| Nomenclature | |

| Collector area (m2) | |

| Annual net savings | |

| Capital cost | |

| Specific heat enthalpy of the HTF used (J/(Kg °C) | |

| Embodied energy | |

| Entropy generation | |

| Annual energy output in terms of exergy | |

| Thermal energy output | |

| Flux absorbed by absorber plate (W/m2) | |

| , | Enthalpy out and Enthalpy in |

| Beam radiation (W/m2) | |

| Diffuse radiation (W/m2) | |

| Total radiation (W/m2) | |

| Extinction coefficient | |

| Lifetime of SWH | |

| Mass flux (kg/s) | |

| Payback period | |

| Thickness of the cover | |

| Heat loss (W) | |

| Available energy from solar radiation (W) | |

| Useful heat gain (W) | |

| , | Entropy out and Entropy in |

| Transmissivity | |

| Ambient temperature (K) | |

| Transmissivity by considering absorption | |

| Transmissivity by considering reflection and refraction | |

| Two components of polarization | |

| Tilt factor for beam radiation | |

| Tilt factor for diffuse radiation | |

| Average temperature of glazing (K) | |

| Average temperature of metal tube (K) | |

| Outlet and Inlet temperature of HTF used (K) | |

| Average absorber plate temperature (K) | |

| Tilt factor for reflected radiation | |

| Surface temperature of sun | |

| Heat loss coefficient of absorber plate | |

| Uncertainty of rotameter | |

| Uncertainty of the whole experimentation | |

| Uncertainty of K-type thermocouple wire | |

| Sum of uncertainties of individual parameters | |

| Uncertainty of pyranometer | |

| Greek Letters | |

| Exergy destruction | |

| Exergy in available radiation | |

| Exergy in mass inlet | |

| Exergy in mass outlet | |

| Convective heat transfer from glazing to environment | |

| Convective heat transfer from absorber plate to glazing | |

| Radiative heat transfer from glazing to environment | |

| Radiative heat transfer from absorber plate to glazing | |

| Collector efficiency | |

| Exergy efficiency | |

| τα)b, (τα)d | Transmissivity constants of absorber plate in case of beam and diffuse radiation |

References

- Li, J.; Huang, J. The expansion of China’s solar energy: Challenges and policy options. Renew. Sustain. Energy Rev. 2020, 132, 110002. [Google Scholar] [CrossRef]

- Eltaweel, M.; Abdel-Rehim, A.A. Energy and exergy analysis of a thermosiphon and forced-circulation flat-plate solar collector using MWCNT/Water nanofluid. Case Stud. Therm. Eng. 2019, 14, 100416. [Google Scholar] [CrossRef]

- Sint, N.K.C.; Choudhury, I.; Masjuki, H.; Aoyama, H. Theoretical analysis to determine the efficiency of a CuO-water nanofluid based-flat plate solar collector for domestic solar water heating system in Myanmar. Sol. Energy 2017, 155, 608–619. [Google Scholar] [CrossRef]

- Koholé, Y.W.; Fohagui, F.C.V.; Tchuen, G. Flat-plate solar collector thermal performance assessment via energy, exergy and irreversibility analysis. Energy Convers. Manag. X 2022, 15, 100247. [Google Scholar] [CrossRef]

- Chen, B.-R.; Chang, Y.-W.; Lee, W.-S.; Chen, S.-L. Long-term thermal performance of a two-phase thermosyphon solar water heater. Sol. Energy 2009, 83, 1048–1055. [Google Scholar] [CrossRef]

- Baruah, E.; Konwar, P. Design of a Solar Flat Plate Collector. 2017. Available online: www.ijlera.com (accessed on 27 July 2020).

- Kundu, B. Performance analysis and optimization of absorber plates of different geometry for a flat-plate solar collector: A comparative study. Appl. Therm. Eng. 2002, 22, 999–1012. [Google Scholar] [CrossRef]

- Natarajan, E.; Sathish, R. Role of nanofluids in solar water heater. Int. J. Adv. Manuf. Technol. 2009, 45, 1–5. [Google Scholar] [CrossRef]

- Kumar, A. Investigation of twisted tape inserted solar water heaters—Heat transfer, friction factor and thermal performance results. Renew. Energy 2000, 19, 379–398. [Google Scholar] [CrossRef]

- El Nady, J.; Kashyout, A.; Ebrahim, S.; Soliman, M. Nanoparticles Ni electroplating and black paint for solar collector applications. Alex. Eng. J. 2016, 55, 723–729. [Google Scholar] [CrossRef]

- Hellstrom, B.; Adsten, M.; Nostell, P.; Karlsson, B.; Wackelgard, E. The impact of optical and thermal properties on the performance of flat plate solar collectors. Renew. Energy 2003, 28, 331–344. [Google Scholar] [CrossRef]

- Gowtham, G.; Kishan, P.; Natarajan, M. Prediction of most appropriate models for estimating monthly average daily global radiation in Vellore. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability (ICEETS), Nagercoil, India, 10–12 April 2013; pp. 607–610. [Google Scholar] [CrossRef]

- Korachagaon, I.; Bapat, V.N. Global solar radiation estimation by Iranna-Bapat’s models for India. In Proceedings of the 2012 International Conference on Computing, Electronics and Electrical Technologies (ICCEET), Nagercoil, India, 21–22 March 2012; pp. 394–398. [Google Scholar] [CrossRef]

- Gangane, S.D. Economical Solar Water Heater. IOSR J. Mech. Civ. Eng. 2017, 17, 68–71. [Google Scholar] [CrossRef]

- Ertekin, C.; Kulcu, R.; Evrendilek, F. Techno-economic analysis of solar water heating systems in Turkey. Sensors 2008, 8, 1252–1277. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Diao, Y.; Zhao, Y.; Wang, Z.; Zhu, T.; Wang, T.; Liang, L. Numerical evaluation of the thermal performance of different types of double glazing flat-plate solar air collectors. Energy 2021, 233, 121087. [Google Scholar] [CrossRef]

- Bakari, R.; Minja, R.J.A.; Njau, K.N. Effect of Glass Thickness on Performance of Flat Plate Solar Collectors for Fruits Drying. J. Energy 2014, 2014, 247287. [Google Scholar] [CrossRef]

- Salazar, A.; Rios, I. Sustainable Agriculture: Technology, Planning and Management; Nova Science Pub Inc.: New York, NY, USA, 2010. [Google Scholar]

- Gopinathan, K.K. A General Formula for Computing the Coefficients of the Correlation Connecting Global Solar Radiation to Sunshine Duration. Sol. Energy 1988, 41, 499–502. [Google Scholar] [CrossRef]

- Kumar, A.; Ferdous, R.; Luque-Ayala, A.; McEwan, C.; Power, M.; Turner, B.; Bulkeley, H. Solar energy for all? Understanding the successes and shortfalls through a critical comparative assessment of Bangladesh, Brazil, India, Mozambique, Sri Lanka and South Africa. Energy Res. Soc. Sci. 2019, 48, 166–176. [Google Scholar] [CrossRef]

- Makade, R.G.; Chakrabarti, S.; Jamil, B. Prediction of global solar radiation using a single empirical model for diversified locations across India. Urban Clim. 2019, 29, 100492. [Google Scholar] [CrossRef]

- Samanta, S.; Patra, P.K.; Banerjee, S.; Narsimhaiah, L.; Chandran, M.A.S.; Kumar, P.V.; Bandyopadhyay, S. Generation of common coefficients to estimate global solar radiation over different locations of India. Theor. Appl. Clim. 2019, 136, 943–953. [Google Scholar] [CrossRef]

- Sukhatme, S.P.; Nayak, J.K. Solar Energy Principles of Thermal Collection and Storage, 3rd ed.; Tata McGraw Hill Education Private Limited: New Delhi, India, 2008. [Google Scholar]

- Mousavi Maleki, S.A.; Hizam, H.; Gomes, C. Estimation of hourly, daily and monthly global solar radiation on inclined surfaces: Models re-visited. Energies 2017, 10, 134. [Google Scholar] [CrossRef]

- Disaster Management Draft Revised Goals 2017 | Vellore District, Government of Tamil Nadu|India. Available online: https://vellore.nic.in/document/disaster-management-draft-revised-goals-2017/ (accessed on 16 September 2020).

- Office of Management and Budget (OMB). Standards and Guidelines for Statistical Surveys; OMB: Washington, DC, USA, 2006.

- IS 12933-5 (2003); Solar Flat Plate Collector, Part 5: Test Methods [MED 4: Non-Conventional Energy Sources]. Bureau of Indian Standards: Delhi, India, 2003.

- Qureshy, A.M.M.I.; Dincer, I. Energy and exergy analyses of an integrated renewable energy system for hydrogen production. Energy 2020, 204, 117945. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, H.; Wang, H.; Zhang, S.; Guan, X. Exergy analysis of flat plate solar collectors. Entropy 2014, 16, 2549–2567. [Google Scholar] [CrossRef]

- Popiel, C.O.; Wojtkowiak, J. Simple formulas for thermophysical properties of liquid water for heat transfer calculations (from 0 °C to 150 °C). Heat Transf. Eng. 1998, 19, 87–101. [Google Scholar] [CrossRef]

- Eltaweel, M.; Abdel-Rehim, A.A.; Attia, A.A. A comparison between flat-plate and evacuated tube solar collectors in terms of energy and exergy analysis by using nanofluid. Appl. Therm. Eng. 2021, 186, 116516. [Google Scholar] [CrossRef]

- Yang, M.H. Payback period investigation of the organic Rankine cycle with mixed working fluids to recover waste heat from the exhaust gas of a large marine diesel engine. Energy Convers Manag. 2018, 162, 189–202. [Google Scholar] [CrossRef]

- Dwivedi, V.K.; Tiwari, G.N. Thermal modeling and carbon credit earned of a double slope passive solar still. Desalination Water Treat. 2010, 13, 400–410. [Google Scholar] [CrossRef]

- Prabhakant; Tiwari, G.N. Evaluation of carbon credits earned by energy security in India. Int. J. Low-Carbon Technol. 2009, 4, 42–51. [Google Scholar] [CrossRef]

- Wong, J.H.; Royapoor, M.; Chan, C.W. Review of life cycle analyses and embodied energy requirements of single-crystalline and multi-crystalline silicon photovoltaic systems. Renew. Sustain. Energy Rev. 2016, 58, 608–618. [Google Scholar] [CrossRef]

- Li, D.; Zhou, L.; Wang, X.; He, L.; Yang, X. Effect of crystallinity of polyethylene with different densities on breakdown strength and conductance property. Materials 2019, 12, 1746. [Google Scholar] [CrossRef]

- Kiessling, A.; Simavilla, D.N.; Vogiatzis, G.G.; Venerus, D.C. Thermal conductivity of amorphous polymers and its dependence on molecular weight. Polymer 2021, 228, 123881. [Google Scholar] [CrossRef]

- Tropin, T.V.; Schulz, G.; Schmelzer, J.W.P.; Schick, C. Heat capacity measurements and modeling of polystyrene glass transition in a wide range of cooling rates. J. Non-Cryst. Solids 2015, 409, 63–75. [Google Scholar] [CrossRef]

- Borhani Zarandi, M.; Bioki, H.A.; Mirbagheri, Z.A.; Tabbakh, F.; Mirjalili, G. Effect of crystallinity and irradiation on thermal properties and specific heat capacity of LDPE & LDPE/EVA. Appl. Radiat. Isot. 2012, 70, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Dondapati, R.S.; Agarwal, R.; Saini, V.; Vyas, G.; Thakur, J. Effect of Glazing Materials on the Performance of Solar Flat Plate Collectors for Water Heating Applications. Mater. Today Proc. 2018, 5, 27680–27689. [Google Scholar] [CrossRef]

- ISO 9050:2003; Glass in Building—Determination of Light Transmittance, Solar Direct Transmittance, Total Solar Energy Transmittance, Ultraviolet Transmittance and Related Glazing Factors. International Organization for Standardization: Geneva, Switzerland, 2003. Available online: https://www.iso.org/standard/35062.html (accessed on 31 August 2020).

- Choi, Y.; Mae, M.; Kim, H.B. Thermal performance improvement method for air-based solar heating systems. Sol. Energy 2019, 186, 277–290. [Google Scholar] [CrossRef]

- Xiaowu, W.; Ben, H. Exergy analysis of domestic-scale solar water heaters. Renew. Sustain. Energy Rev. 2005, 9, 638–645. [Google Scholar] [CrossRef]

- Koussa, M.; Saheb, D.; Belkhamsa, H.; Lalaoui, M.A.; Hakem, S.A.; Sami, S.; Zoubir, B.; Mustapha, H. Effect of parallel and serie connection configuration of solar collector on the solar system performances. In Proceedings of the 2015 6th International Renewable Energy Congress (IREC 2015), Sousse, Tunisia, 24–26 March 2015; Institute of Electrical and Electronics Engineers Inc.: Piscataway Township, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Mohammed, A.K.; Hamakhan, I.A. Analysis of energy savings for residential electrical and solar water heating systems. Case Stud. Therm. Eng. 2021, 27, 101347. [Google Scholar] [CrossRef]

- Guidelines on Implementation of Phase-II of Grid Connected Rooftop Solar Programme for Achieving 40 GW Capacity from Rooftop Solar by the Year 2022. Available online: www.solarrooftop.gov.in (accessed on 21 September 2020).

- Wellford, B.W. Calculating the Efficiency of Energy Recovery Ventilation and its Effect on Efficiency and Sizing of Building HVAC Systems; AHRI: Arlington, VA, USA, 2011. [Google Scholar]

- Rao, V.T.; Sekhar, Y.R. Comparative analysis on embodied energy and CO2 emissions for stand-alone crystalline silicon photovoltaic thermal (PVT) systems for tropical climatic regions of India. Sustain. Cities Soc. 2022, 78, 103650. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A.; Nuntadusit, C. Thermo-environomical and drying kinetics of bitter gourd flakes drying under north wall insulated greenhouse dryer. Sol. Energy 2018, 162, 205–216. [Google Scholar] [CrossRef]

- Shrivastava, V.; Kumar, A. Embodied energy analysis of the indirect solar drying unit. Int. J. Ambient. Energy 2017, 38, 280–285. [Google Scholar] [CrossRef]

- Alsabri, A.; Al-Ghamdi, S.G. Carbon footprint and embodied energy of PVC, PE, and PP piping: Perspective on environmental performance. Energy Rep. 2020, 6, 364–370. [Google Scholar] [CrossRef]

- Sharma, M.; Atheaya, D.; Kumar, A. Performance evaluation of indirect type domestic hybrid solar dryer for tomato drying: Thermal, embodied, economical and quality analysis. Therm. Sci. Eng. Prog. 2023, 42, 101882. [Google Scholar] [CrossRef]

| Sl. No. | Survey Questions | Survey Results |

|---|---|---|

| 1. | Is there any specific climate requirement for working of solar water heater? |  |

| 2. | Does the area have hard water (with soap solutions from less white foam)? |  |

| 3. | What is the required life of the solar water heating system? |  |

| 4. | What is the temperature of the hot water required? |  |

| 5. | Where do you want it to be installed? |  |

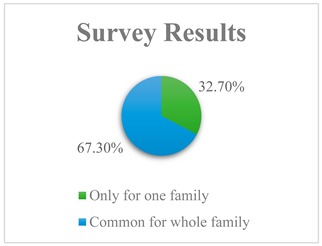

| 6. | Do you want it to be common for the whole building or only for your family? |  |

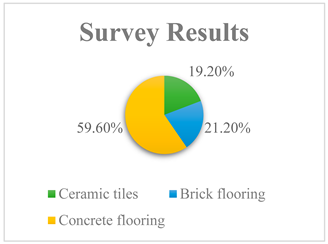

| 7. | What is the type of terrace flooring used? |  |

| 8. | What direction is your residence facing? |  |

| 9. | Which type of water is to be used? |  |

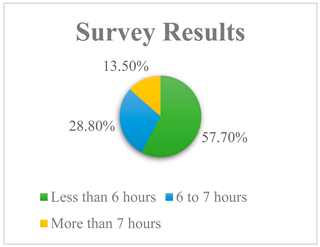

| 10 | How many hours are required to heat the water? |  |

| Component | Specifications |

|---|---|

| Absorber plate | Material—Galvanized iron Length—1.8 m Width—1.2 m Thickness—0.0012 m Thermal conductivity—68 W/m-K Absorptivity—0.92 Emissivity—0.23 Space between plate and glazing—0.065 m |

| HTF pipe | Riser pipes: Material—Galvanized iron Outer diameter—0.01905 m Length—1.8 m The center-to-center distance of Tubes—1.2 m No. of tubes—5 Header and footer pipes: Material—galvanized iron Outer diameter—0.03175 m Length—1.3 m |

| Glazing | Glass: Thickness—0.004 m Refractive index—1.52 Transmissivity—0.81 LDPE: Thickness—0.00018 m Refractive index—1.49 Transmissivity—0.92 |

| Frame | Material—wood Length—2.2 m Width—1.4 m |

| Insulation | Material—Thermocol and Glass wool Thickness—0.08 m Thermal conductivity—0.04 W/m-K |

| Parameter | Uncertainty in Glass Cover Experiment | Uncertainty in the Transparent Cover Experiment |

|---|---|---|

| Flow rate | 0.2% | 0.17% |

| Temperature difference | 0.59% | 0.35% |

| Description | Quantity | Cost (Rupees) |

|---|---|---|

| G.I Riser pipes | 5 nos. | 850 |

| G.I header and footer pipes | 2 nos. | 350 |

| G.I absorber sheet | 1 no. | 1550 |

| Welding | - | 600 |

| Solar Paint | 1 no. | 500 |

| Wooden box | 1 no. | 1250 |

| Insulation | - | 600 |

| Glass Plate | 1 | 1150 |

| LDPE transparent cover | - | 500 |

| Storage tank | 1 | 2000 |

| Other expenses | - | 700 |

| Total | - | 10,050 |

| LLDPE | LDPE | MDPE | HDPE | |

|---|---|---|---|---|

| Name | Linear low-density polyethylene | Low-density polyethylene | Medium-density polyethylene | High-density polyethylene |

| Density | 0.922 g/cm3 | 0.918 g/cm3 | 0.935 g/cm3 | 0.954 g/cm3 |

| Crystallinity | 39.45% Semi-crystalline | 38.73% Low crystalline and high amorphous | 48.36% Medium crystalline and amorphous | 51.17% High crystalline and amorphous |

| Material | Embodied Energy Coefficient (kWh/kg) |

|---|---|

| GI (absorber and pipe) | 9.72 |

| Glass | 7.28 |

| LDPE | 2.14 |

| Paint | 27.25 |

| Fittings | 47.99 |

| Glass wool | 2.89 |

| CO2 Emission, CO2 Mitigation, Net CO2 Mitigation and Carbon Credit Earned | ||||

|---|---|---|---|---|

| Cases | ||||

| CO2 Emission (kg) | CO2 Mitigation (ton) | Net CO2 Mitigation (ton) | Carbon Credit Earned (Rupees) | |

| Glass SWH | 98.149 | 2.53 | 0.076 | 125.02 |

| LDPE SWH | 89.744 | 2.2 | 0.225 | 419.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duraivel, B.; Muthuswamy, N.; Shaik, S.; Cuce, E.; Owolabi, A.B.; Li, H.X.; Kavgic, M. Extensive Analysis of a Reinvigorated Solar Water Heating System Using Low-Density Polyethylene Glazing. Energies 2023, 16, 5902. https://doi.org/10.3390/en16165902

Duraivel B, Muthuswamy N, Shaik S, Cuce E, Owolabi AB, Li HX, Kavgic M. Extensive Analysis of a Reinvigorated Solar Water Heating System Using Low-Density Polyethylene Glazing. Energies. 2023; 16(16):5902. https://doi.org/10.3390/en16165902

Chicago/Turabian StyleDuraivel, Balamurali, Natarajan Muthuswamy, Saboor Shaik, Erdem Cuce, Abdulhameed Babatunde Owolabi, Hong Xian Li, and Miroslava Kavgic. 2023. "Extensive Analysis of a Reinvigorated Solar Water Heating System Using Low-Density Polyethylene Glazing" Energies 16, no. 16: 5902. https://doi.org/10.3390/en16165902

APA StyleDuraivel, B., Muthuswamy, N., Shaik, S., Cuce, E., Owolabi, A. B., Li, H. X., & Kavgic, M. (2023). Extensive Analysis of a Reinvigorated Solar Water Heating System Using Low-Density Polyethylene Glazing. Energies, 16(16), 5902. https://doi.org/10.3390/en16165902