1. Introduction

Conventional energy sources like coal, oil, nuclear energy and natural gas have been frontrunners in the energy market despite their drawbacks and limitations [

1]. The energy demand across the globe has been continually climbing due to the rising global population, with an estimated population of 9 billion by 2050. The corresponding rise in the use of petroleum equivalents is projected to range from 12 billion to 16 billion tons [

2]. However, the traditional form of energy sources is non-renewable and existing reserves are depleting rapidly, resulting in an increase in energy costs [

3]. On the other hand, the excessive usage of conventional energy sources has created a severe impact on the environment that is claimed to be responsible for the occurrence of global warming, ozone layer depletion, acid rain and the greenhouse effect [

4]. Such scenarios have highlighted the need to look for alternative sources of energy that are clean, available in abundance and eco-friendly. To counter environmental impacts and the rising demand for electricity, the scientific community has proposed renewable energy sources as the primary solution [

5]. Various sources of renewable energies such as wind energy and solar photovoltaics (PV) have proven to be promising alternatives. Additionally, renewable energy sources offer several advantages like enhanced reliability, eco-friendly power generation, reduced manufacturing costs, large-scale installations, yearlong availability and noise-free operation. Recent reports introduced by the International Energy Agency (IEA) state that global annual installations reached 280 GW in 2020, constituting a 45% increase from past figures. This achievement is coupled with an expansion of global electrical capacity (90%) [

6].

The effectiveness of renewable energy sources has not yet been fully exploited due to certain constraints like high maintenance costs, rigorous planning needs and initial capital requirements [

7]. Additionally, setting up large PV or wind farms requires large geographical regions for installation to produce a competitive supply of energy. Moreover, the efficiency and reliability of renewable energy sources can further be affected by dynamic environmental and climatic conditions. Solar PV energy generation, the second most popular alternative source of energy, faces off annual energy losses due to the occurrence of faults and degradation over time [

8]. The occurrence of various faults in PV modules can create an irreversible deterioration or drop in output performance [

9,

10]. To eliminate the PV module power loss, the timely monitoring, classification, localization and diagnosis of faults in PV modules is essential [

11,

12,

13]. For instance, the presence of certain faults like aging [

14], cracks [

15], delamination [

16] and corrosion [

17] can degrade the lifespan of PV modules, thereby elevating the energy costs involved [

18]. PV module faults can be broadly classified into visual and electrical faults; visual faults pave the way for the occurrence of electrical faults [

19]. Fault diagnosis and detection in PV modules were initially performed through manual inspections. However, in the case of large PV farms, such manual inspections can be challenging and unprofitable. Thus, there is a need to adopt an automated technique that can detect, diagnose and localize fault occurrences in PV modules. Fault diagnosis and detection techniques for PV modules can be broadly categorized into two methods: (i) vision- or image-based methods (photoluminescence imaging [

20], electroluminescence imaging [

21,

22], RGB imaging [

23], fluorescence imaging [

24] and infrared thermography [

25,

26,

27]) and (ii) electrical measurement methods (IV curves [

28,

29], power spectral analysis, signal processing and reflectometry).

Automated fault diagnosis methods have in recent times become effective with the advent of unmanned aerial vehicles (UAVs). UAVs are aircraft that fly remotely or autonomously without the presence of a human pilot. UAVs are generally mounted with cameras, sensors and other payloads that enable them to perform a variety of activities including aerial photography, mapping, surveillance and delivery. Lower costs, less risk to human pilots and better deployment and operating flexibility are certain advantages of UAVs over manned aircraft. Additionally, UAVs are capable of entering regions that human pilots would find difficult or dangerous including disaster zones, building sites or military war zones. Over the years, thermal imaging cameras were widely equipped in UAVs to detect faults in PV modules. However, thermal image cameras have been replaced with high-resolution digital cameras due to the following reasons: (i) minor faults may be precisely spotted by high-resolution digital cameras, (ii) thermal cameras have bad image resolution and (iii) thermal cameras are unable to detect hotspots such as micro-cracks, solid bond failure, partial shading, etc., at higher temperatures [

30]. High-resolution images of PV module arrays acquired from UAVs are then analyzed using image analysis and machine learning techniques to find and identify defects [

31]. Various researchers have proposed several types of image processing techniques to find defects in PV modules by utilizing UAVs, such as aerial triangulation [

32], image mosaicking [

33], object detection [

34] and extraction of correlated textural features [

35]. Additionally, histogram feature analysis was applied by Dashtdar et al. for the localization and detection of faults [

36]. However, the quality of the images captured by a UAV has a major role in the efficiency of all of the methods listed above. The image resolution can also be negatively influenced by various factors such as (i) vibration due to flight, (ii) atmospheric haze, (iii) high wind speeds and (iv) reflection from sun/light.

Of late, researchers have begun to apply artificial intelligence (AI)-based techniques for fault diagnosis tasks. Deep learning and machine learning in particular have been claimed to be the most promising methods due to their accurate and instantaneous result generation along with their pattern learning capabilities [

37]. Numerous studies have focused on diagnosing PV module faults using convolutional neural networks (CNNs). Broadly, CNNs can be applied to any problem at hand in two different ways, namely, (i) building a model from scratch and (ii) adopting a pre-trained version. Pre-trained versions (GoogLeNet [

38], ResNet-50 [

39], DenseNet201, AlexNet [

40], VGG16 [

41] and much more) have been preferred due to their ease of availability, prior domain knowledge and wide adaptability. Additionally, renowned machine learning algorithms like support vector machines (SVM) [

42], Naïve Bayes [

43], k-nearest neighbor [

44], decision trees [

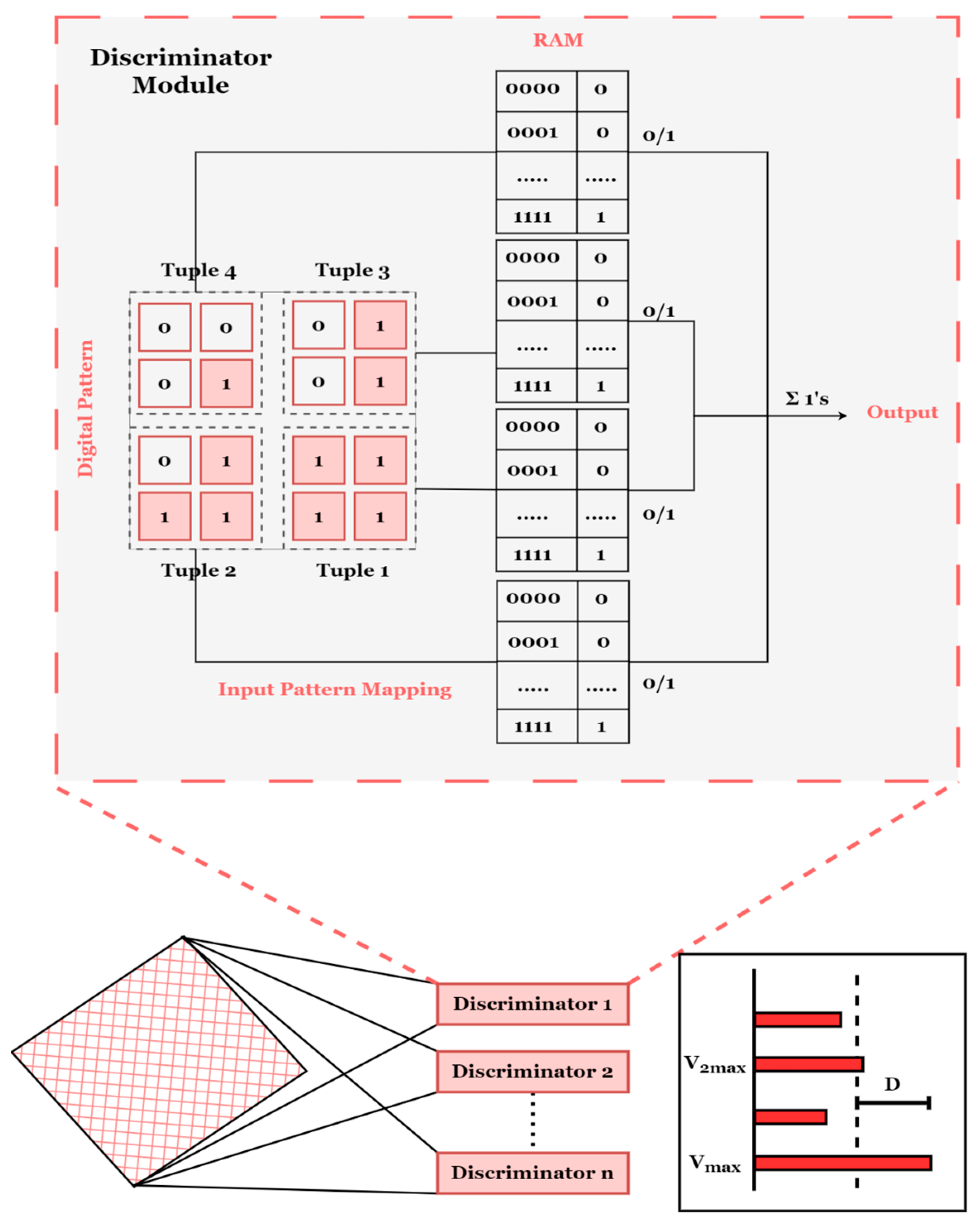

23] and much more have been applied in the field of PV module fault diagnosis. The aforementioned techniques work on the weights assigned to neurons to form a pattern and classify the input data into the respective classes. However, the introduction of WNN has created a significant impact due to the absence of a mathematical model or residual weights to determine faults in a system with minimal false rate alarms. WNNs, also termed wavelet neural networks, were introduced by Aleksander [

45], who used a digital model built using random access memory (RAM) devices [

46]. The learning process in WNNs is carried out through the memory inserts at neurons that take the shape of truth tables. Unlike weighted models, WNNs possess various advantages due to their diverse use of memory units through the elimination of network retraining, non-requirements for residual generation, the generation of accurate and precise results, swift and flexible algorithms with adaptive learning, a similar working principle to that of traditional digital systems, and effectiveness in classification and pattern recognition.

WNNs for classification and pattern recognition tasks have been minimally used in several applications like time series forecasting [

47], clustering of data streams [

48], navigation in robots [

49], face feature identification [

50] and fingerprint recognition [

51]. However, the usage of WNNs in the field of fault diagnosis and detection is still in the nascent stages of application. The context of WNNs was approached in several articles by De Gregorio; nevertheless, the works do not deal with fault diagnosis tasks [

52,

53]. The following points were derived based on the abovementioned literature and studies performed.

Weightless neural networks have not been applied in the diagnosis of PV module faults.

Most of the published works utilized electroluminescence or thermal images in the detection of PV module faults, specifically, cracks and hotspots.

To minimize the consumption of inspection duration, manpower and capital costs, unmanned aerial vehicles have been widely adopted.

The lack of a public repository and acquisition of a PV module fault dataset is a challenge.

Researchers have applied artificial intelligence-based techniques, namely, machine learning and deep learning, to fault diagnosis in PV modules.

Over the years, deep learning or machine learning has been individually applied in the detection and diagnosis of PV module faults. However, a combined approach is still in the initial stages.

Based on the literature summary provided above, there were some motivational factors that are listed below:

First, there have been minimal attempts to use true color or RGB images for diagnosing faults in PV modules, guiding the direction of research. Since numerous works have studied the adoption of thermal or electroluminescence images.

Secondly, UAVs for the acquisition of PV module images have been considered another driving force in reducing monitoring time and manpower.

Further, a combined approach of machine and deep learning in the process of fault detection can be considered a prime innovation.

Finally, to the best of the authors’ modest knowledge, this is the first study where a WNN is applied to diagnose and classify visual faults in PV modules.

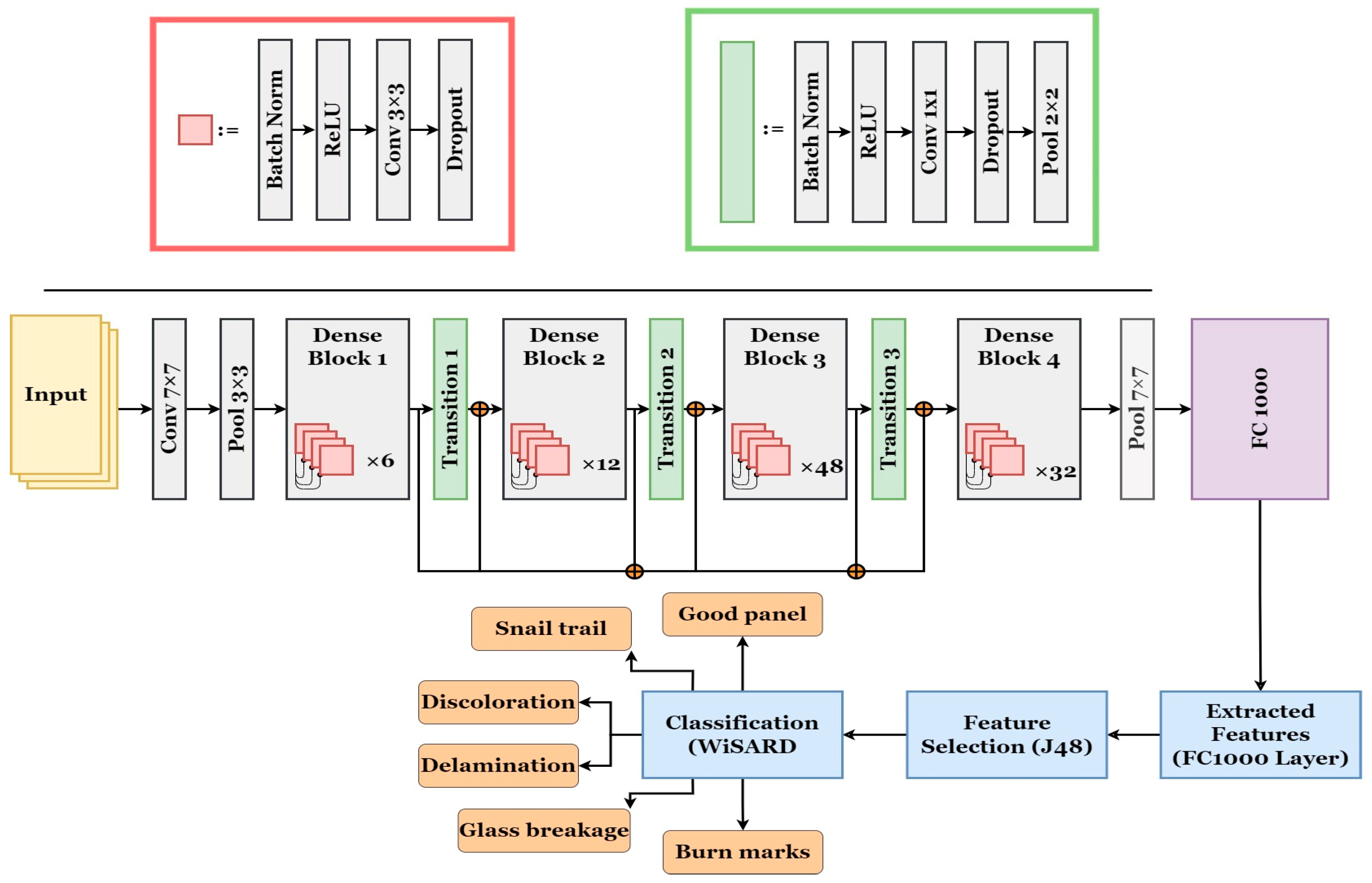

The prime objective of the present study was to develop a fault diagnosis model for PV module visual faults with the aid of deep learning features (DenseNet201) and a WNN (WiSARD classifier). This study aims to develop a simple model that is accurate and precise that can be further implemented into a low-cost device like a microcontroller or microprocessor.

The major contributions of this study are listed as follows:

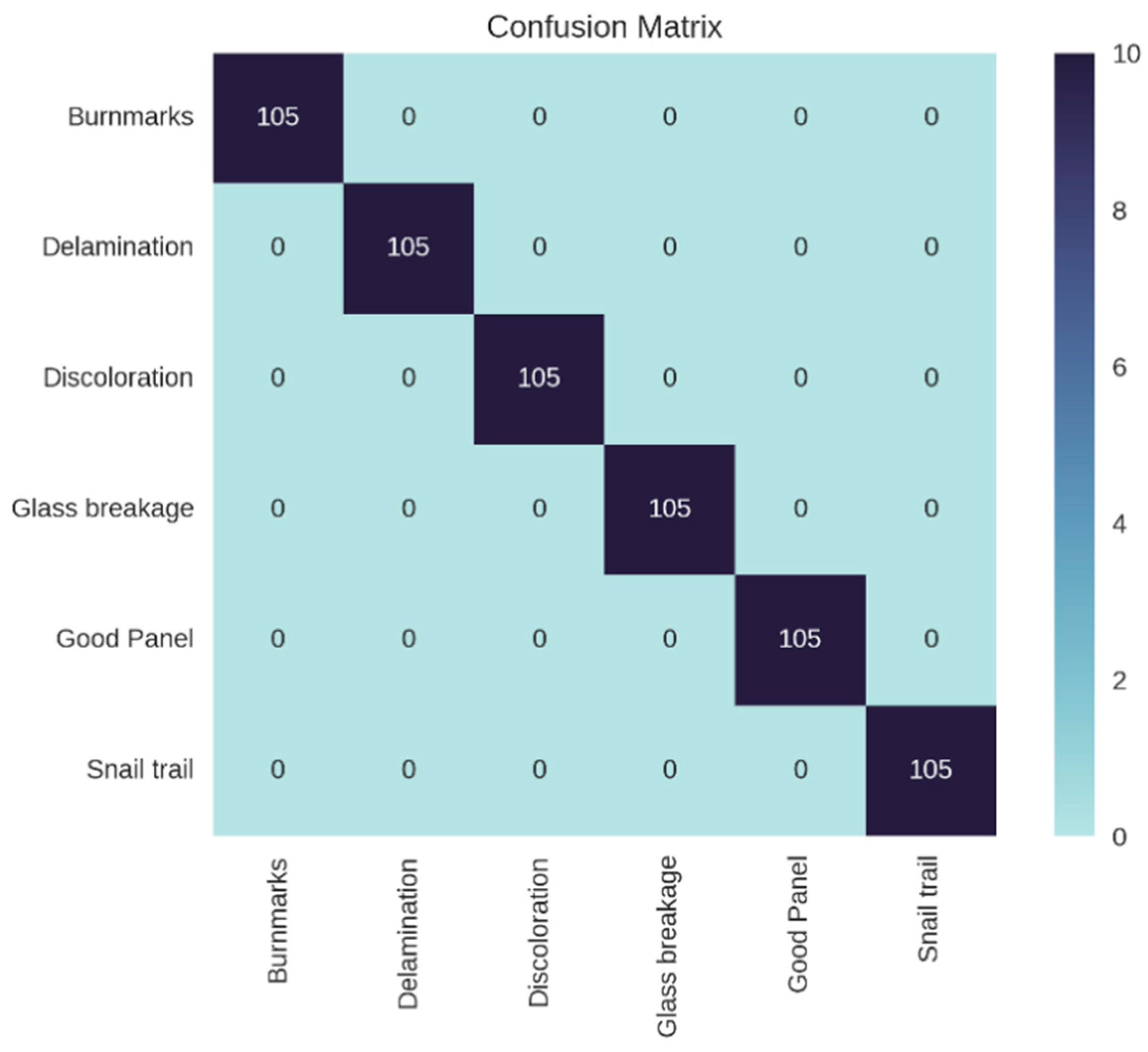

A PV module dataset was created with six different conditions like good panel, delamination, snail trail, burn marks, discoloration and glass breakage. The dataset was acquired using an unmanned aerial vehicle and pre-processed for further usage.

The obtained dataset was augmented artificially through application image transforms to enhance the learning capability of the pre-trained network adopted. The augmented dataset was split into training and testing datasets (with a ratio of 0.8:0.2) resized to a size of 224 × 224 to be fed as input to DenseNet-201.

The features from the final fully connected layer (fc1000) of DenseNet-201 were extracted and saved as a data file. These extracted features were passed onto a J48 decision tree to select the impactful and contributing features.

The selected features were used to train the WNN (WiSARD classifier). The trained model was used to classify the PV module conditions with the supplied test dataset.

To improve the classification accuracy of the adopted WNN, several hyperparameters like tic number, bleach configuration, bit number, bleach flag, map type and bleach step were configured.

The novelty of the present study:

The prime novelty of the study revolves around the usage of a WNN (WiSARD classifier) in the detection and diagnosis of six different PV module conditions, namely, good panel, delamination, snail trail, burn marks, discoloration and glass breakage, through the use of an unmanned aerial vehicle (UAV). To improve the learning capability of the adopted model, the dataset was artificially augmented using image transforms. A hybrid approach involving the fusion of deep learning and machine learning techniques was adopted in this study. The features from the final fully connected layer (fc1000) of DenseNet-201 were extracted and a J48 decision tree was employed to select the most impactful and contributing features. These selected features were then utilized to train the WiSARD classifier (WNN), a novel approach for PV module condition classification. This study further optimized the WNN’s accuracy by configuring various hyperparameters, such as tic number, bleach configuration, bit number, bleach flag, map type and bleach step. The results demonstrated the effectiveness of the proposed methodology and the potential of the WiSARD classifier to accurately classify PV module conditions for various applications in the renewable energy domain.