Synthesis and Performance Evaluation of Graphene-Based Comb Polymer Viscosity Reducer

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Graphene Nanosheets

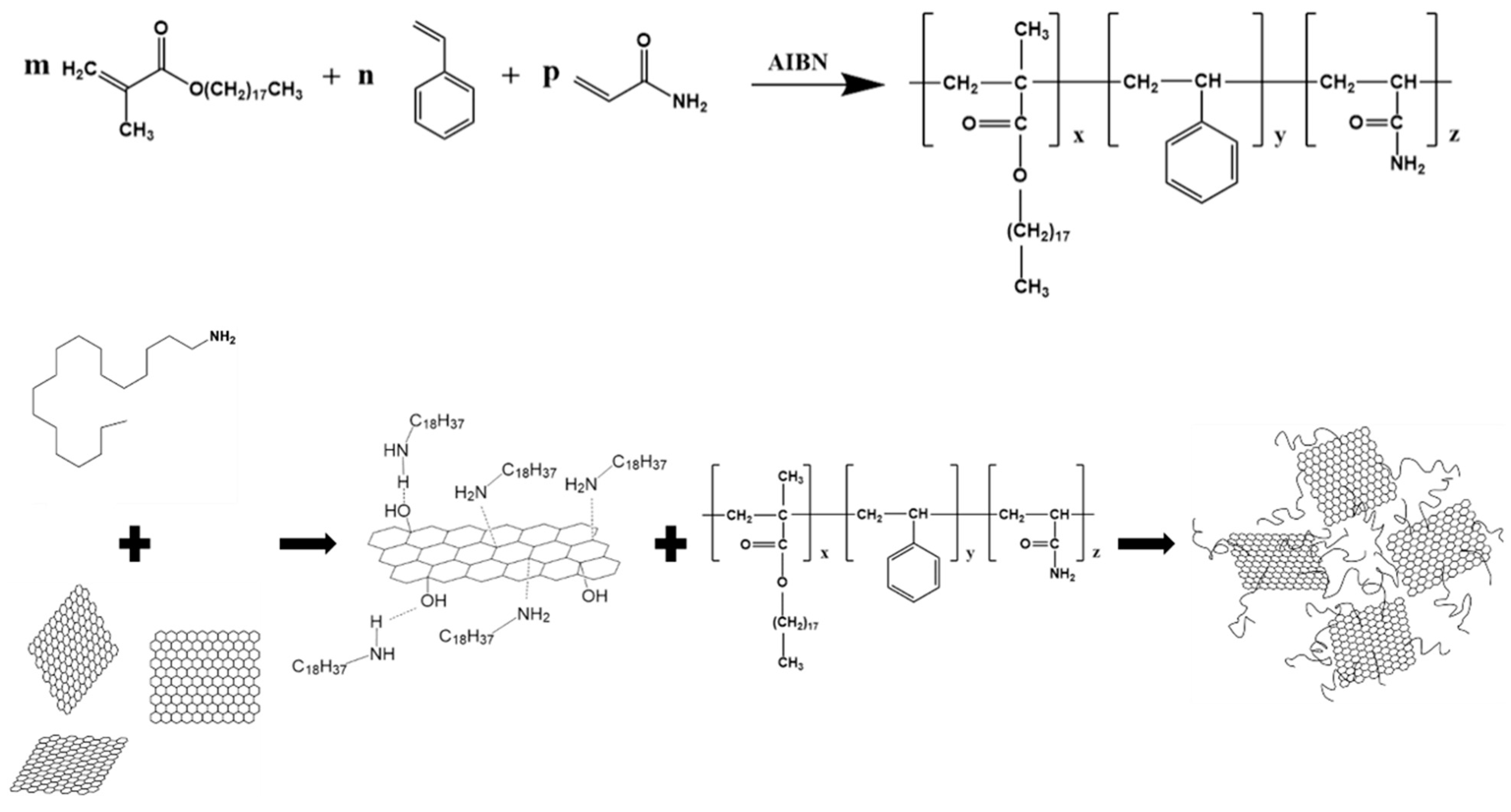

2.3. Preparation of Comb Polymer

2.4. Preparation of Graphene-Based Comb Polymer

2.5. Fourier-Transform Infrared Spectra

2.6. Thermogravimetric Analysis Determination

2.7. Dispersion Stability Analysis

2.8. Scanning Electron Microscope

2.9. Viscosity Reduction Effect Evaluation Test

3. Results

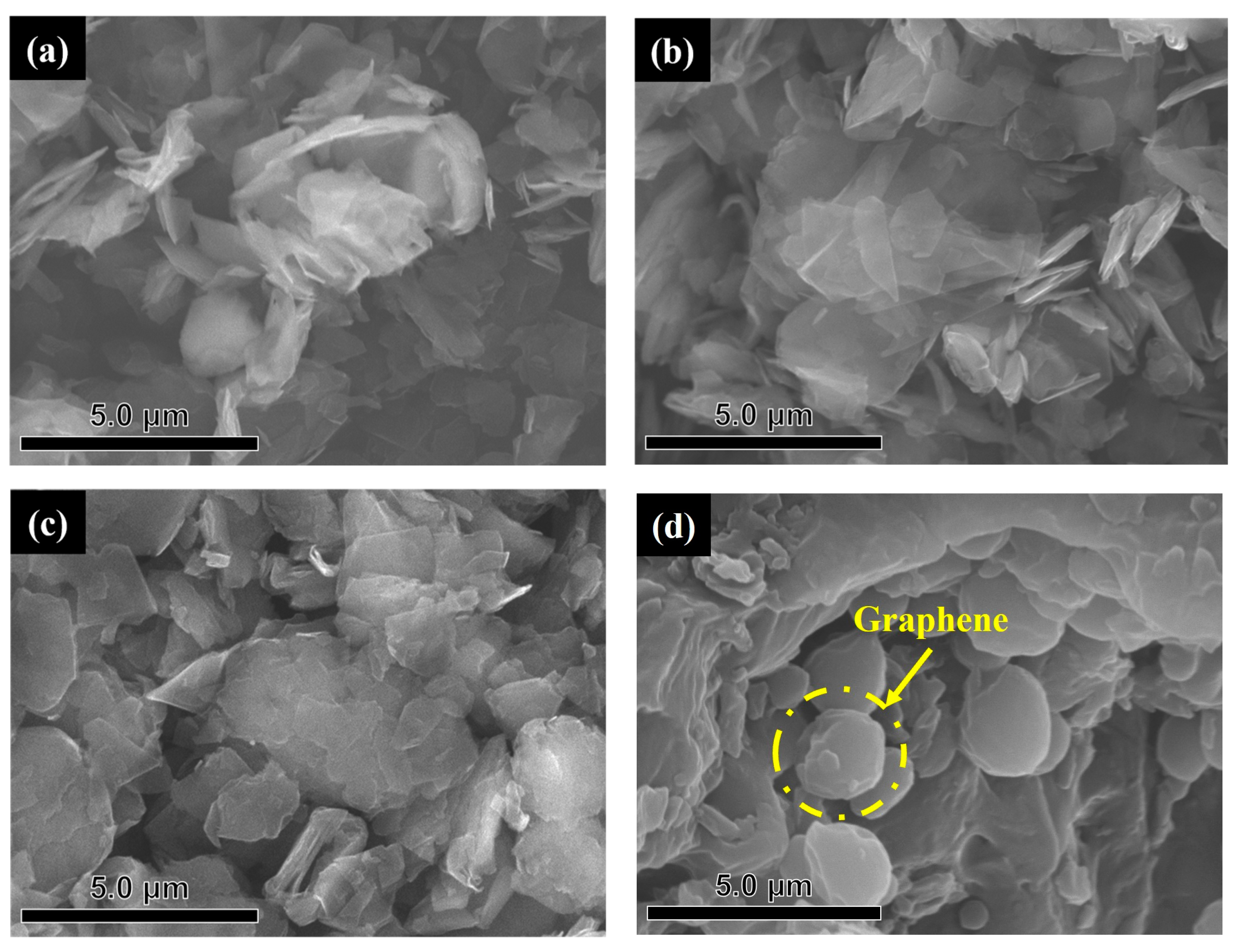

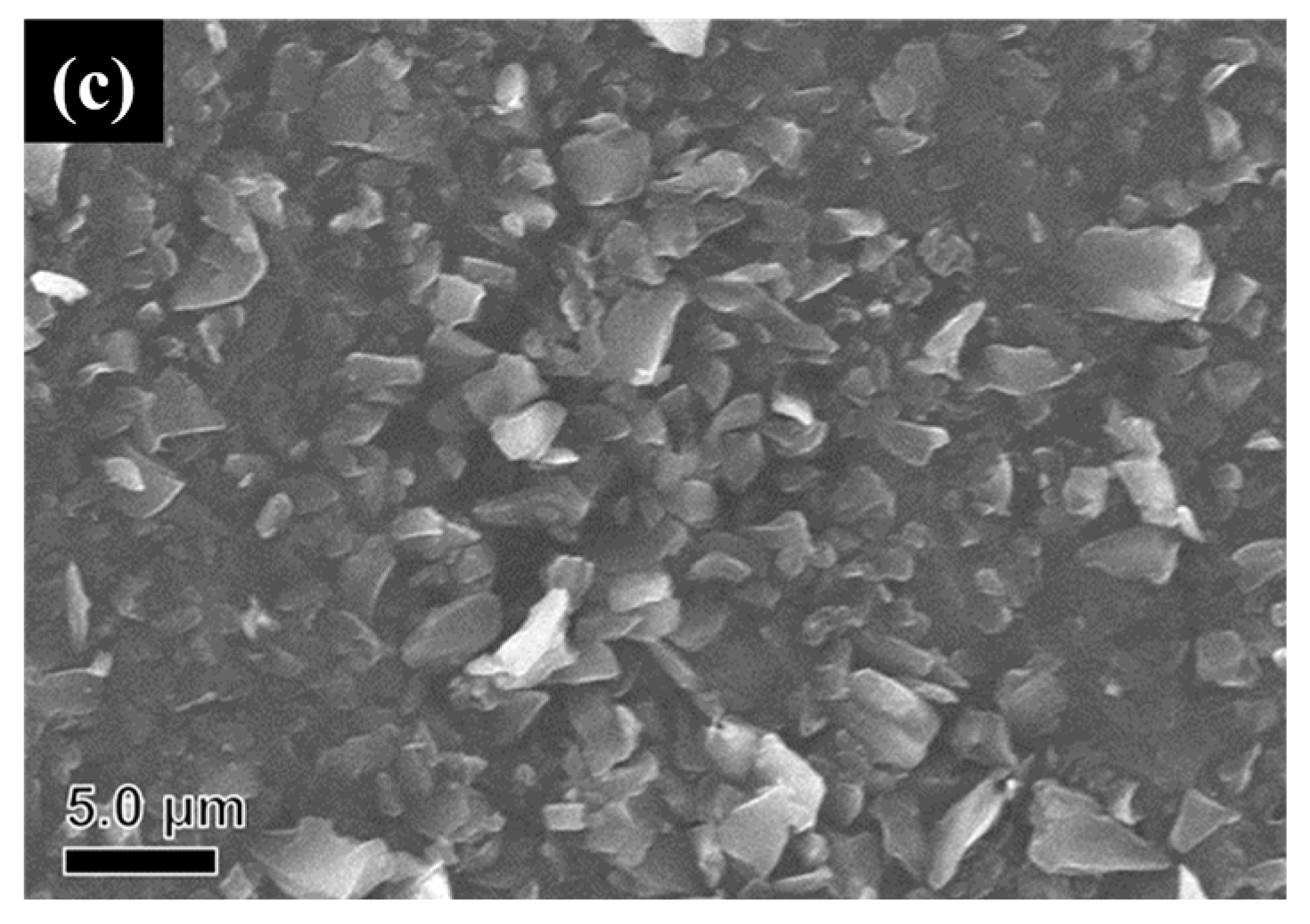

3.1. Graphene Micromorphology Analysis

3.2. Fourier-Transform Infrared Spectra

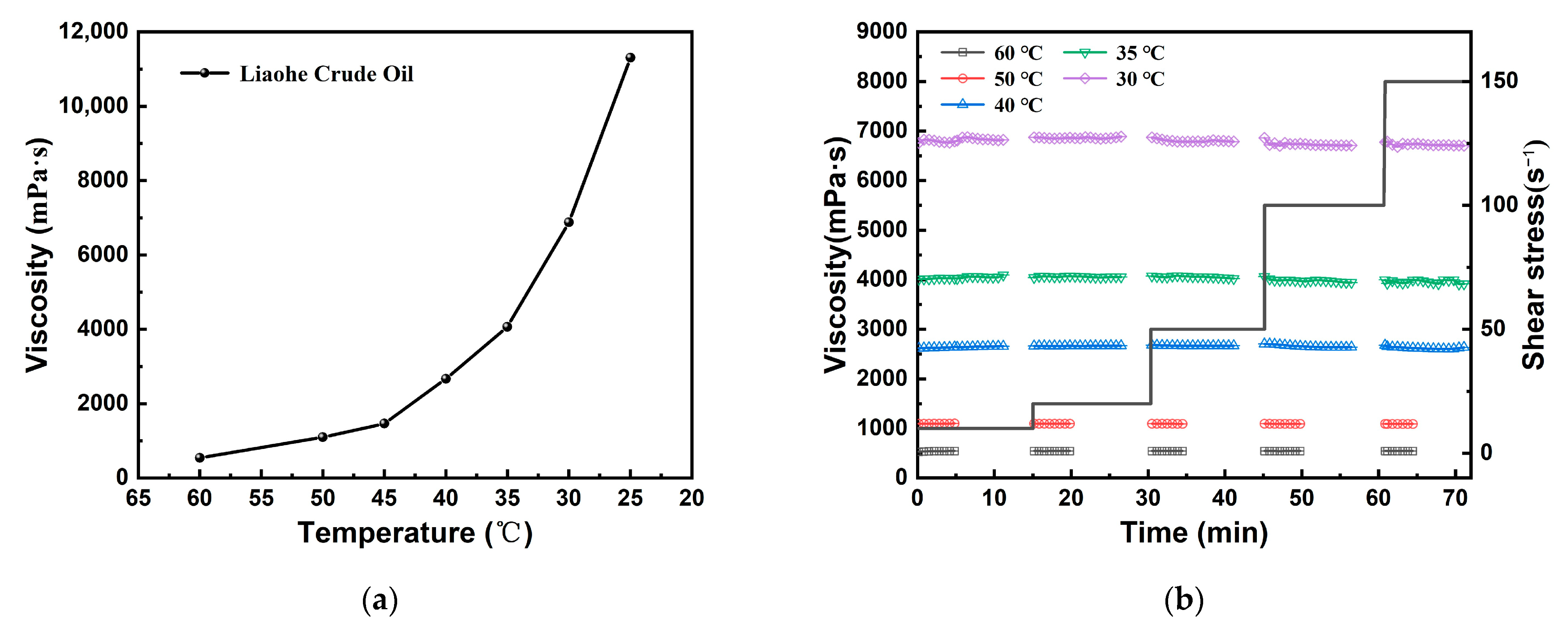

3.3. Analysis of Viscosity Temperature and Rheological Properties of Heavy Oil

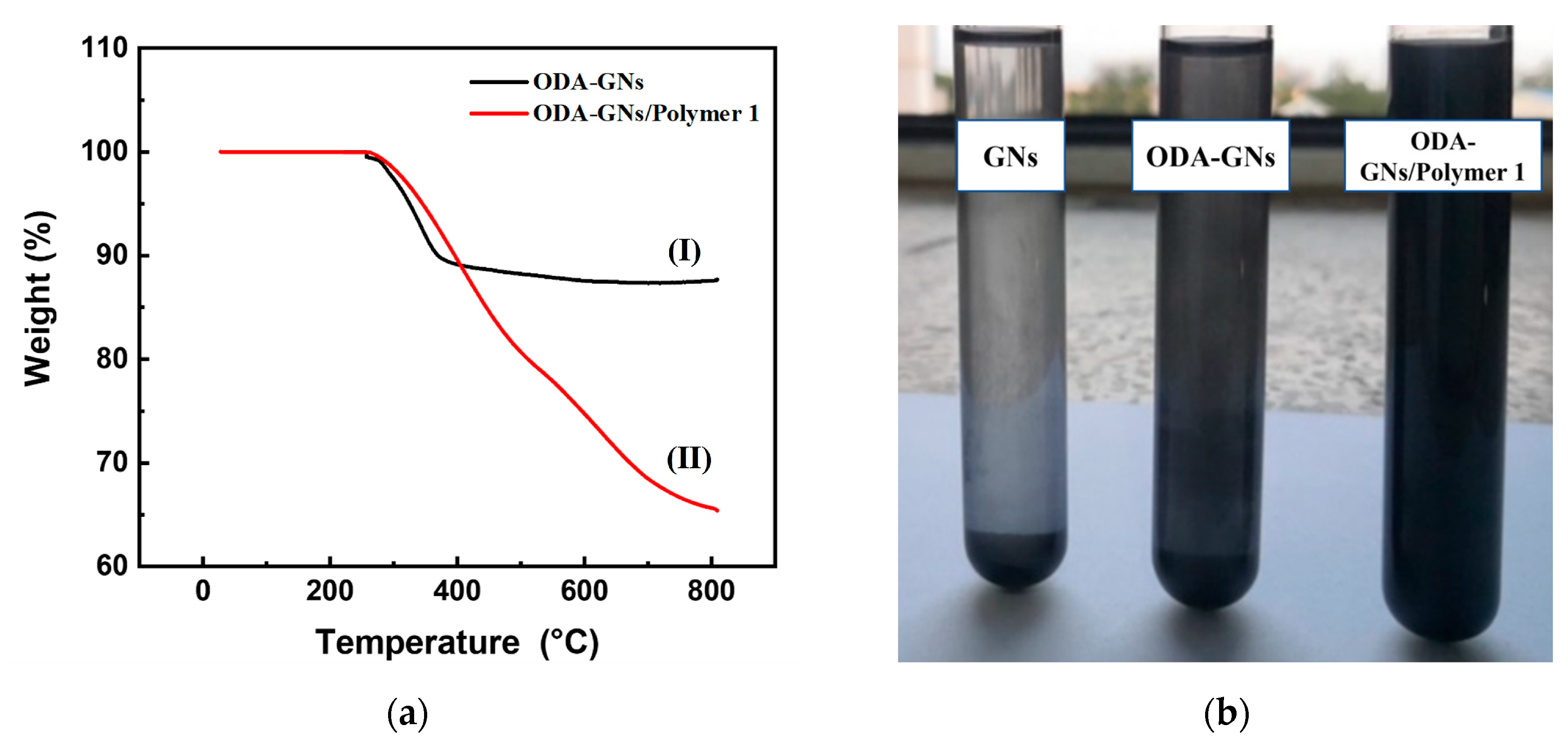

3.4. Thermogravimetric Analysis and Dispersion Stability Test

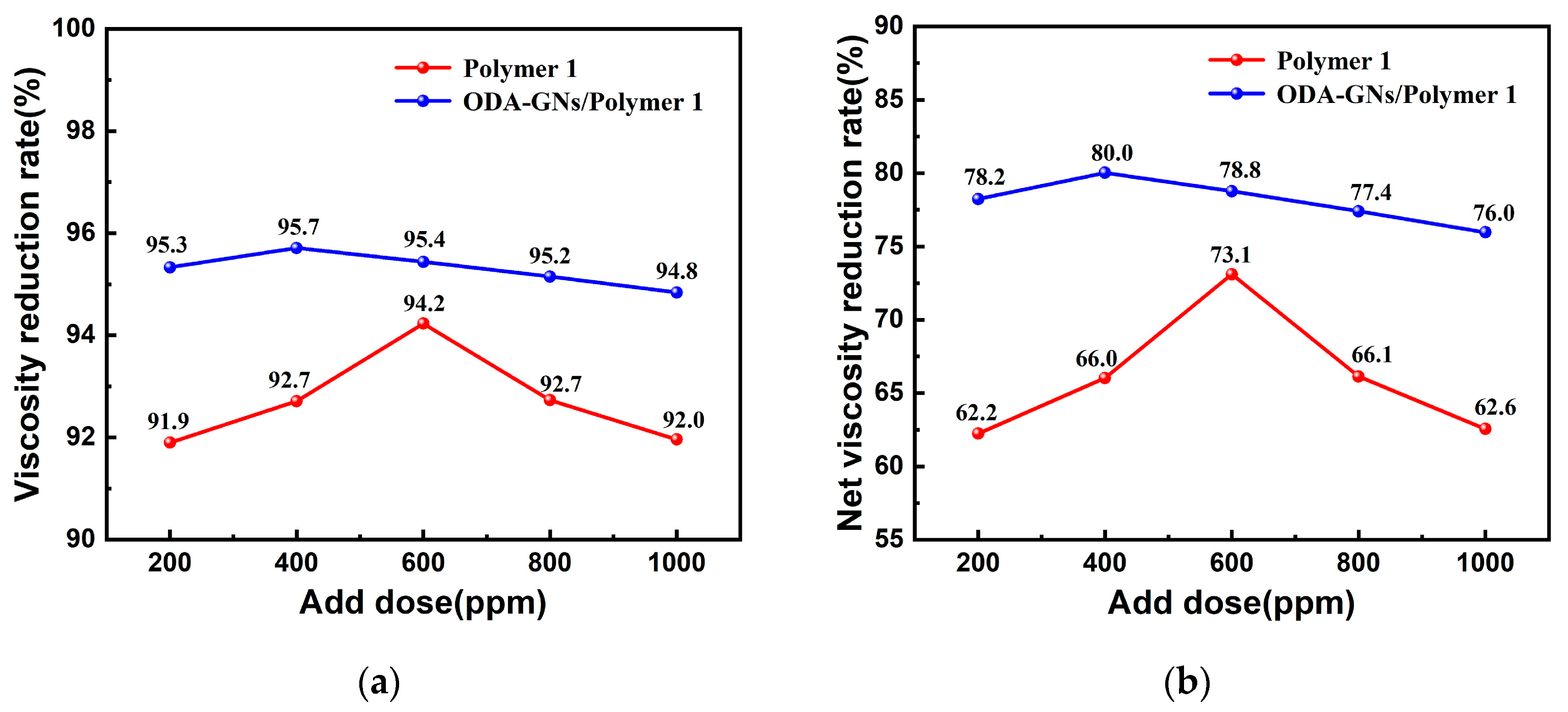

3.5. Viscosity Reduction Performance

3.6. Heavy Oil Microtopography Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FTIR | Fourier-transform infrared spectroscopy |

| TGA | thermogravimetric analysis |

| SEM | scanning electron microscopy |

| GO | graphene oxide |

| PMMA-GO | poly (methyl methacrylate) -graphene oxide |

| EVAL | ethylene-vinyl alcohol copolymer |

| GNs | graphene nanosheets |

| ODA | octadecylamine |

| ODA-GNs | ODA modified graphene nanosheets |

| ODA-GNs/Polymer 1 | graphene-based comb polymer 1 |

| TR | transmission mode |

Appendix A

| GNs/g | ODA/g | Viscosity/mPa·s | Viscosity Reduction/% | Net Viscosity Reduction/% |

|---|---|---|---|---|

| 5.0 | 0.5 | 534.2 | 95.3 | 78.0 |

| 5.0 | 1.0 | 484.6 | 95.7 | 80.0 |

| 5.0 | 2.0 | 588.4 | 94.8 | 75.8 |

| 5.0 | 4.0 | 666.3 | 94.1 | 72.5 |

| ODA-GNs/mg | Polymer 1/mg | Viscosity/mPa·s | Viscosity Reduction/% | Net Viscosity Reduction/% |

|---|---|---|---|---|

| 500 | 250 | 512.8 | 95.5 | 78.9 |

| 500 | 500 | 484.6 | 95.7 | 80.0 |

| 500 | 750 | 566.6 | 95.0 | 76.7 |

References

- Hirsch, R.L.; Bezdek, R.; Wendling, R. Peaking of world oil production and its mitigation. AIChE J. 2006, 52, 2–8. [Google Scholar] [CrossRef]

- Taborda, E.A.; Franco, C.A.; Lopera, S.H.; Alvarado, V.; Cortés, F.B. Effect of nanoparticles/nanofluids on the rheology of heavy crude oil and its mobility on porous media at reservoir conditions. Fuel 2016, 184, 222–232. [Google Scholar] [CrossRef]

- Williams, B. Heavy hydrocarbons playing key role in peak oil debate, future supply. Oil Gas. J. 2003, 101, 20–27. [Google Scholar]

- Wei, X.M.; Liu, X.L.; Wang, W.D. Overview of viscosity reduction methods for heavy Oil. Fine Petrochem. 2002, 5, 45–48. [Google Scholar]

- Xie, L.B.; Wu, Y.G.; Gong, K. Research status and development trend of heavy oil viscosity reduction methods. Appl. Chem. 2018, 47, 1291–1295. [Google Scholar]

- Gregoli, A.A. Low-Temperature Pipeline Emulsion Transportation Enhancement. U.S. Patent No. 5,156,652, 20 October 1992. [Google Scholar]

- Mcclafin, G.G. The replacement of hydrocarbon diluent with surfactant and water for the production of heavy viscous crude oil. J. Pet. Technol. 1982, 10, 2258–2264. [Google Scholar] [CrossRef]

- Jamaluddin, A.K. Controlling sand production during down hole emulsification. J. Pet. Technol. 1995, 34, 2258–2264. [Google Scholar]

- Sun, J.; Sun, L.; Liu, W. Alkaline consumption mechanisms by crude oil: A comparison of sodium carbonate and sodium hydroxide. Colloids Surf. A Physicochem. Eng. Asp. 2008, 315, 38–43. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, M.; Yue, X. Synergy of alkali and surfactant in emulsification of heavy oil in brine. Colloids Surf. A Physicochem. Eng. Asp. 2006, 273, 219–228. [Google Scholar] [CrossRef]

- Uraizee, F.A.; Venosa, A.D.; Suidan, M.T. A model for diffusion controlled bioavailability of crude oil components. Biodegradation 1997, 8, 287–296. [Google Scholar] [CrossRef]

- Clark, P.D.; Hyne, J.B.; Tyrer, J.D. Influence of PH on the high temperature hydrolysis of tetrahydrothiophene and thiophene. Fuel 1984, 63, 125–128. [Google Scholar] [CrossRef]

- Hoffman, E.J. Hydrogen for the enhance recovery of heavy crudes. Energy Sources 1989, 11, 263–272. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Ma, C.; Lu, Y.; Han, S.; Chen, C.; Zhang, J. Effect of electrical treatment on structural behaviors of gelled waxy crude oil. Fuel 2019, 253, 647–661. [Google Scholar] [CrossRef]

- Sun, Z. Molecular Dynamics Simulation of Viscosity Reduction of Heavy Oil and Study on Preparation Technology of Nanometer Modified Viscosity Reduction for Heavy Oil. Masters Thesis, Shandong University, Qingdao, China, 2016. [Google Scholar]

- Ma, C.; Zhang, J.; Feng, K.; Li, Z.; Chen, C.; Huang, Q.; Lu, Y. Influence of asphaltenes on the performance of electrical treatment of waxy oil. J. Pet. Sci. Eng. 2019, 180, 31–40. [Google Scholar] [CrossRef]

- Akinyemi, O.P.; Udonne, J.D.; Efeovbokhan, V.E.; Avoola, A.A. A study on the use of plant seed oils, triethanolamine and xylene as flow improvers of Nigerian waxy crude oil. J. Appl. Res. Technol. 2016, 14, 195–205. [Google Scholar] [CrossRef]

- Moschopedis, S.E.; Speight, J.G. Investigation of hydrogen bonding by oxygen functions in Athabasca bitumen. Fuel 1976, 55, 1187–1192. [Google Scholar] [CrossRef]

- Li, R.; Wang, C.C.; Wang, P.Z.; Pei, J.Z. Preparation of a novel flow improver and its viscosity-reducing effect on bitumen. Fuel 2016, 181, 935–941. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, C.; Li, W.; Wang, Y.; Han, Z. Study on performance mechanism of pour point depressants with differential scanning calorimeter and X-ray diffraction methods. Fuel 2003, 82, 1419–1426. [Google Scholar] [CrossRef]

- Chen, W.; Zhao, Z.; Tin, C. The interaction of waxes with pour point depressants. Fuel 2010, 89, 1127–1132. [Google Scholar] [CrossRef]

- Schmidt, D.; Shah, D.; Giannelis, E.P. New advances in polymer/layered silicate nanocomposites. Curr. Opin. Solid State Mater. Sci. 2002, 6, 205–212. [Google Scholar] [CrossRef]

- Ou, J.; Perot, B.; Rothstein, J.P. Laminar drag reduction in microchannels using ultrahydrophobic surfaces. Phys. Fluids 2004, 16, 4635–4643. [Google Scholar] [CrossRef]

- Ding, L.; Qin, F.D.; Jing, Y.L. Large slip length over a nanopatterned surface. Chin. Phys. Lett. 2007, 24, 1021–1024. [Google Scholar] [CrossRef]

- Wei, G.; Di, Q.F. Seepage model and experiments of drag reduction by nanoparticle adsorption. J. Hydrodyn. 2013, 25, 871–876. [Google Scholar]

- Yao, B.; Li, C.; Yang, F.; Sjöblom, J.; Zhang, Y.; Norrman, J.; Paso, K.; Xiao, Z. Organically modified nano-clay facilitates pour point depressing activity of polyoctadecylacrylate. Fuel 2016, 166, 96–105. [Google Scholar] [CrossRef]

- EI-Amin, M.F.; Salama, A.; Sun, S. Numerical and dimensional analysis of nanoparticles transport with two-phase flow in porous media. J. Pet. Sci. Eng. 2015, 128, 53–64. [Google Scholar] [CrossRef]

- Cheraghian, G.; Khalili Nezhad, S.S.; Kamari, M.; Hemmati, M.; Masihi, M.; Bazgir, S. Adsorption polymer on reservoir rock and role of the nanoparticles, clay and SiO2. Int. Nano Lett. 2014, 4, 114. [Google Scholar] [CrossRef]

- Yao, B.; Li, C.; Yang, F. Effect of oil dispersible polymethylsilsesquioxane microspheres on the formation and breakage of model waxy oil gels. Fuel 2017, 209, 424–433. [Google Scholar] [CrossRef]

- Song, X.; Yin, H.; Feng, Y. Effect of SiO2 nanoparticles on wax crystallization and flow behavior of model crude oil. Ind. Eng. Chem. Res. 2016, 55, 6563–6568. [Google Scholar] [CrossRef]

- Kumar, A.; Behera, B.; Thakre, G.D.; Ray, S.S. Covalently grafted graphene oxide/poly (Cn-acrylate) nanocomposites by surface-initiated ATRP: An efficient antifriction, antiwear, and pour-point-depressant lubricating additive in oil media. Ind. Eng. Chem. Res. 2016, 55, 8491–8500. [Google Scholar] [CrossRef]

- Sharmaa, R.; Mahtoa, V.; Vuthaluru, H. Synthesis of PMMA/modified graphene oxide nanocomposite pour point depressant and its effect on the flow properties of Indian waxy crude oil. Fuel 2019, 235, 1245–1259. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Z.N.; Jing, G.L.; Liu, S.; Yang, Y.H.; Xu, J.Q. Synthesis of chemical grafting pour point depressant EVAL-GO and its effect on the rheological properties of Daqing crude oil. Fuel Process. Technol. 2021, 223, 107000. [Google Scholar] [CrossRef]

- Starr, F.W.; Schroder, T.B.; Glotzer, S.C. Molecular dynamics simulation of a polymer melt with a nanoscopic particle. Macromolecules 2002, 35, 4481–4492. [Google Scholar] [CrossRef]

- Avella, M.; Cosco, S.; Di Lorenzo, M.; Di Pace, E.; Errico, M. Influence of CaCO3 nanoparticles shape on thermal and crystallization behavior of isotactic polypropylene based nanocomposites. Therm. Anal. Calorim. 2005, 80, 131–136. [Google Scholar] [CrossRef]

- Ferreira, C.I.; Dal Castel, C.; Oviedo, M.A.S.; Mauler, R.S. Isothermal and non-isothermal crystallization kinetics of polypropylene/exfoliated graphite nanocomposites. Thermochim. Acta 2013, 553, 40–48. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Betiha, M.A.; Osman, D.I.; Hashim, A.I.; EI-Sukkary, M.M.; Tahany, M. Preparation and evaluation of poly(methyl methacrylate)-graphene oxide nanohybrid polymers as pour point depressants and flow improvers for waxy crude oil. Energy Fuels 2016, 30, 7610–7621. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, W.; Zhang, F.; Zhang, X.; Dong, S.; Zhang, J.; Gang, C. Synthesis of barium alkylbenzene sulfonate and its behavior as a flow improve for crude oil. Comptes Rendus Chim. 2021, 24, 83–89. [Google Scholar] [CrossRef]

- Du, W.; Li, Y.; Yun, B.; Zhang, R.; Chen, G. Synthesis of cyclohexanone-alcohol hemiketals and evaluation as flow improve for waxy crude oil. Petrol. Sci. Technol. 2019, 37, 796–803. [Google Scholar] [CrossRef]

| Analytical Wax Point (°C) | Saturated HC (%) | Aromatic HC (%) | Resin (%) | Asphalt (%) | Wax (%) |

|---|---|---|---|---|---|

| 28.54 | 35.51 | 22.61 | 24.09 | 4.05 | 8.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Li, M.; Kong, Y.; Long, C.; Sun, Y.; Liu, G.; Yu, C.; Lu, Y.; An, J.; Yang, F. Synthesis and Performance Evaluation of Graphene-Based Comb Polymer Viscosity Reducer. Energies 2023, 16, 5779. https://doi.org/10.3390/en16155779

Xu Z, Li M, Kong Y, Long C, Sun Y, Liu G, Yu C, Lu Y, An J, Yang F. Synthesis and Performance Evaluation of Graphene-Based Comb Polymer Viscosity Reducer. Energies. 2023; 16(15):5779. https://doi.org/10.3390/en16155779

Chicago/Turabian StyleXu, Zhengdong, Mingjie Li, Yidan Kong, Changjun Long, Yankun Sun, Guohua Liu, Chunhui Yu, Yi Lu, Junpu An, and Fan Yang. 2023. "Synthesis and Performance Evaluation of Graphene-Based Comb Polymer Viscosity Reducer" Energies 16, no. 15: 5779. https://doi.org/10.3390/en16155779

APA StyleXu, Z., Li, M., Kong, Y., Long, C., Sun, Y., Liu, G., Yu, C., Lu, Y., An, J., & Yang, F. (2023). Synthesis and Performance Evaluation of Graphene-Based Comb Polymer Viscosity Reducer. Energies, 16(15), 5779. https://doi.org/10.3390/en16155779