Abstract

Oil shale is an important unconventional oil and gas resource, but it is poorly utilized in the Dalianhe coal mining area, northeastern China. Systematic sampling and test analysis were used to evaluate the characteristics of oil shale quality. The research shows that the oil shale between the middle and lower coal seams in the coal-bearing member is a rich ore with a high oil content, medium calorific value, high ash content, medium volatile content, low moisture, and ultralow sulfur content. The oil shale has good quality and is suitable for low-temperature carbonization for oil refining or low-calorific fuel. The ash content is silicon–aluminum-rich, has low calcium–magnesium, is iron-poor, and has a high ash melting point. The middle oil shale member is a poor ore with low quality. However, there is a dense section of oil shale with a high organic matter content and good quality above the upper coal seam. It is recommended to implement combined mining of coal and oil shale in the mineshaft and to reasonably recover oil shale between the coal seams and oil shale above the upper coal seam to improve the resource utilization rate.

1. Introduction

As an important unconventional oil and gas resource, oil shale is mainly distributed in the United States, Russia, Canada, China, Estonia, and other countries [1,2]. Its mineralization theory and comprehensive development research have attracted much attention [1,3,4,5,6]. There is a large amount of oil shale as an associated mineral in the Dalianhe coal mining area, northeastern China. The resource survey estimates 456 million tons of oil shale and 29 million tons of shale oil in the Dalianhe coal mining area. The oil shale resource of 48% occurs underground at less than 800 m depth [6]. However, oil shale is treated as waste during open pit coal mining and piled into gangue hillocks, which not only pollutes the environment but also wastes resources. In recent years, a new shaft project has been completed and put into operation in the Dalianhe coal mining area. However, the oil shale has not been fully developed and utilized rationally.

Previous studies on oil shale in the Dalianhe coal mining area have mostly focused on the genesis of oil shale [6,7,8,9,10,11], sedimentary characteristics [12,13], elemental geochemistry [14,15], and gasification tests [16]. The oil shale of the Dalianhe Formation mainly formed in the lacustrine phases, with the Yilan-Basin-controlled fractures controlling their distribution, and the warm, humid subtropical climate and weak surface winds during the development of the lakes where the Dalianhe Formation was deposited were conducive to a reducing and stable deep lake environment for oil shale formation [7,9]. The analyses of organic geochemistry and the sedimentary environment show that the organic matter type in the semideep lacustrine facies in the oil shale member of the Dalianhe Formation is type II1, and the organic matter type in the lacustrine facies in the coal-bearing member is type I-II1, which has greater hydrocarbon generation potential. The organic matter source and gravity flow are the main factors controlling the differential enrichment of organic matter in the two types of oil shale [17]. The oil shale of the Dalianhe Formation has a medium ash content and low oil content, and the genetic type is mixed and humic. The oil shale formed mainly in semideep lake facies and is associated with peat swamp facies coal [12]. However, there are few feasibility studies on the properties and utilization of organic matter and inorganic minerals related to the characteristics of oil shale quality.

The research on the feasibility of utilizing organic matter and inorganic minerals of oil shale in the Dalianhe coal mining area, northeastern China, can provide useful knowledge for improving the resource development and recovery and clarifying the direction of industrial utilization. In this research, we analyze the organic petrology, organic geochemistry, geochemical characteristics, and properties of the main oil shale process, study the characteristics of oil shale quality, and explore the prospects of development and utilization based on the requirements of oil shale for possible development and utilization purposes, such as manufacturing shale oil and industrial fuel.

2. Geological Settings

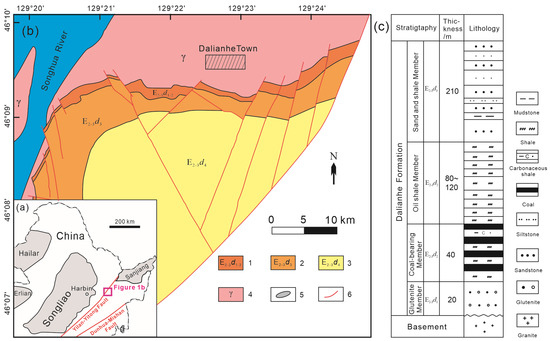

The Dalianhe coal mining area in northeastern China is located in a Cenozoic fault basin in northeastern China (Figure 1a). It is tectonically located in the Yilan–Yitong fault zone, which is the northern extension of the Tanlu fault zone on the eastern edge of the Asian continent [7,15,17]. The basement lithology of the basin is mainly pre-Mesozoic granite, and the sedimentary cover is the Paleogene Dalianhe Formation (E2–3d; Figure 1b). The Dalianhe Formation is a coal- and oil-shale-bearing clastic sedimentary assemblage formed from river and lake environmental phases, and the formation can be divided into four lithologic sections according to the characteristics of the lithologic assemblage [9,10]. From bottom to top, the members are the bottom sand conglomerate member, the coal-bearing member, the middle oil shale member, and the upper sand shale member (Figure 1c). The Dalianhe Formation is the result of a complete cycle of the following: low-water system activity, transgressive systems tract, high water level systems tract to regressive systems tract, developing fluvial phase, swamp phase, semideep lake–deep lake phase, and delta phase. The water body in the basin has undergone a filling process from shallow to deep [12].

Figure 1.

The main topographic units in northeast China (a) (modified from Refs. [6,9]), the geological map of the Dalianhe coal mining area in northeastern China (b) (modified from Refs. [6,9]), and the stratigraphic column of the Dalianhe Formation (c). 1—The first and second members of the Dalianhe Formation, 2—The third member of the Dalianhe Formation, 3—The fourth member of the Dalianhe Formation, 4—Granite, 5—Basin, 6—Fault.

Two sets of oil shales developed mainly in the Dalianhe coal mining area. The lower first set is associated with coal, which is located in the coal-bearing member, and the oil shale layers between the coal seams are distributed mainly between the upper, middle, and lower coal seams. The middle to lower oil shale layers have good development quality, thicknesses of 0.78–10.5 m, different mining values, and other interbedded oil shales are distributed in the middle of the coal mining area, which can be mined simultaneously with coal within the open pit area. The second set of oil shale in the upper part is accompanied by dark mudstone and is located in the thick oil shale member above the middle of the upper coal seam, with thicknesses of approximately 80–120 m. The key sections of this study are the coal-bearing member of the lower oil shale layer and the middle oil shale member.

3. Methods

The samples were collected from 29 shallow wells in the open pit area of the Dalianhe coal mine and 2 wells in the lower coal-bearing member in the deep part of the mine and the middle oil shale member of the Dalianhe Formation. The identification of organic macerals in 25 samples was completed by the Laboratory of Material Physics, China University of Geosciences. The detection of kerogen macerals was carried out by the transmission light-fluorescence kerogen maceral identification and classification method (SY/T5125-1996) using an Axiophot-type transmission light-fluorescence advanced biological microscope. Mineral X-ray diffraction analysis tests were carried out by a D/max-2500 instrument, using the methods of the total number of clay minerals in sedimentary rocks and the common nonclay mineral X-ray diffraction analyses (SY/T6210-1996). Oil shale electron microscope analyses were carried out by scanning electron microscopy of rock samples (SY/T5162-1997). The samples were tested using a LEO-435VP scanning electron microscope. The 31 samples for rock pyrolysis were analyzed by a ROCK-EVAL 2plus (France) rock pyrolysis analyzer with an OGE-II (China) oil and gas evaluation workstation of the China Institute of Petroleum Exploration and Development; the hydrocarbon production potential of oil shale was determined by rock pyrolysis analysis (GB/T18602-2001). The 31 samples for organic carbon analysis were analyzed at the Petroleum Geology Experimental Research Center of the China Institute of Petroleum Exploration and Development. The low-temperature dry distillation of oil shale was performed by the Heilongjiang Coal Quality Supervision and Inspection Station (Class A qualification) using the Gray-King low-temperature dry distillation test method for coal (GB1341-1987). The Gray-King method uses a heating rate of 5 °C per min and a maximum temperature of 600 °C, which is maintained for 15 min. It uses a higher maximum temperature compared with the ASTM Fisher assay method of 510 °C.

4. Results and Discussion

4.1. Inorganic Mineral Compositions

The results of the inorganic mineral analysis of the oil shale (Table 1) show that the inorganic minerals of the oil shale are clay minerals, land-derived clastic particles, siderite, and pyrite.

Table 1.

The compositions of inorganic and clay minerals of oil shales in the Dalianhe coal mining area.

The land-derived debris is mainly chalk and fine-grained quartz, which are distributed in the bituminous mineral matrix in various forms, and the quartz content in the oil shale between the coal seams is high; feldspar is visible in potassium feldspar and plagioclase, and plagioclase is distributed only in the middle thick oil shale member. Pyrite and siderite within oil shale are mainly formed from syngenetic chemical sediments. The pyrite content in oil shale between the coal seams is high and is mostly in the form of aggregates, which are not visible in the middle oil shale member.

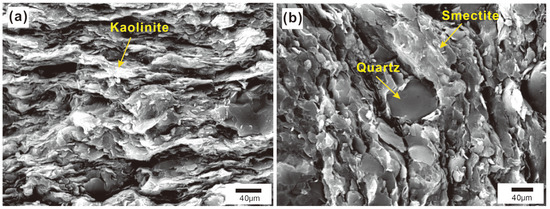

X-ray diffraction analysis of clay minerals in oil shale in the Dalianhe coal mining area (Table 1) revealed three types of clay minerals, namely, kaolinite, illite, and mixed-layer clay minerals (illite–montmorillonite). The kaolinite contents are 63–90%; the illite contents are 1–3%; and the clay mineral contents of the mixed layer are 9–34%. The clay types of the oil shale layer in the middle thick oil shale member and the middle–lower coal-bearing member are the same, and the content changes little. The content of kaolinite in the thin oil shale between the coal seams is high.

The clay minerals in oil shale are visible under the scanning electron microscope as lamellar kaolinite on common grain surfaces (Figure 2a). The kaolinite crystals are visible between the thick lamellar mica and feldspar crystals, followed by lamellar montmorillonite on grain surfaces (Figure 2b) and lamellar I/S mixed layers, which have various morphologies on grain surfaces, and the clay minerals have a certain degree of crystallization.

Figure 2.

The scanning electron microscope images of the clay minerals of the oil shales in the Dalianhe coal mining area. (a) shows the flaky kaolinite from sample 043-11. (b) shows the quartz grain and the flaky smectite from sample 2.

4.2. Characteristics of Organic Macerals

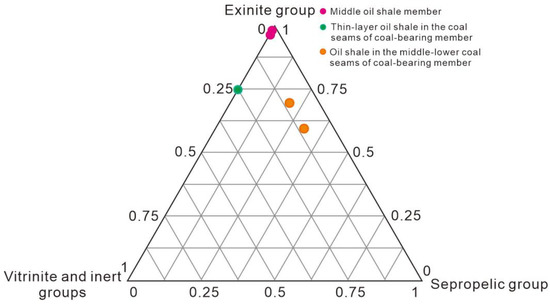

The organic macerals of oil shale in the Dalianhe coal mining area are mainly composed of vitrinite, exinite, and sapropel, which are characterized by rich vitrinite, microsporite, resin, and a humic–sapropel mineral asphalt matrix. The organic maceral content of the oil shale member is generally less than 5%, with a range of 0.57–21.63%, and the organic maceral content of oil shale between the coal seams is higher, with a range of 13.19–37.97% (data from Ref. [15]). The organic matter in the oil shale in the Dalianhe coal mining area is mainly kerogen. Due to the poor resolution of a conventional optical microscope (reflected white light) on the thin section, it is difficult to identify amorphous bodies and to accurately quantify the sapropel and sapropel–humic asphalt mineral matrix. Selecting some samples for kerogen microscopic analysis is a better method. The analytical results show obvious differences among the kerogen macerals of oil shale in different horizons. The kerogen in the middle oil shale member is dominated by biodegradable aquatic organisms (humic amorphous), and no sapropel is found. The contents of other components are very low. The oil shale between the coal-bearing members is rich in sapropel and humic amorphous material, and the contents of vitrinite, algae, inertinite, and sporophytes are high (Figure 3).

Figure 3.

The organic micro components of the kerogen of oil shales in the Dalianhe coal mining area (data from Ref. [15]).

The compositions of organic maceral and kerogen in oil shale indicate that the source of organic matter was mainly terrestrial higher plants [11,15], and most of the dispersed organic matter was transported from peat swamps to deep-water parts and then deposited. At the same time, a small amount of aquatic low-level phytoplankton (e.g., algae) is admixed, and the main kerogen components are humic mud and humic amorphous material, and the kerogen in oil shale is mainly humic–sapropel- and humosapropelic-type kerogen, which contains higher quality organic matter and can produce higher quality oil through pyrolysis.

4.3. Organic Matter Abundance, Types, and Maturity

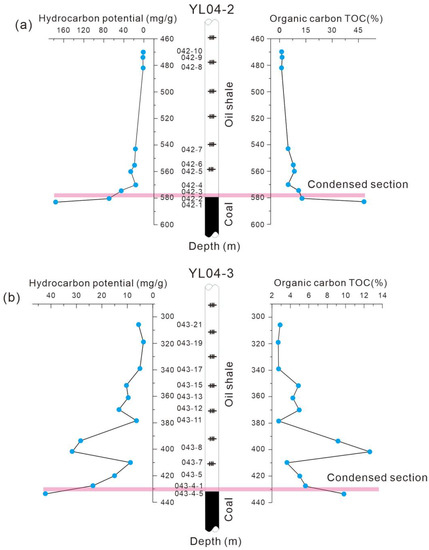

The results of the organic carbon analysis of oil shale in the Dalianhe coal mining area (Table 2) show that the organic carbon (TOC) contents of oil shale vary widely in different layers. For example, the organic carbon contents of 21 samples from the oil shale member above the middle of the upper coal seam vary from 1.14% to 12.84%, with an average value of 5.47%, while the organic carbon contents of 7 samples from the oil shale layer between the middle and lower coal seams have a minimum value of 7.31% and a maximum value of 18.59%, with an average value of 14.23%, all of which are higher than the values in the middle oil shale member. The organic carbon contents of the oil shale in the same layer fluctuate, but the overall difference is not obvious; for example, among the seven samples of the middle–lower coal, which is interbedded with oil shale, the organic carbon content is approximately 15%, except for the samples from mining sites 4 and 18. The average organic carbon content in the middle oil shale member is 5.10% in well YL04-3 and 5.97% in well YL04-2, which are similar in both wells, but there is a more obvious trend in the organic carbon content of both wells with depth, i.e., the organic carbon content increases with depth, and both show a peak value at approximately 3 m at the top of the upper coal seam (Figure 4). The hydrogen and hydrocarbon indices also show the existence of an intensive section of oil shale above the upper coal seam. The organic matter in the intensive section of oil shale is enriched to a higher degree and is of better quality.

Table 2.

The results of pyrolysis analysis, organic matter abundance, and vitrinite reflectance (Ro) of oil shales in the Dalianhe coal mining area.

Figure 4.

The variation of the organic matter abundance of oil shales of the wells YL04-2 (a) and YL04-3 (b).

The results of the hydrocarbon potential analysis of the oil shale show that the hydrocarbon potential of oil shale from different layers varies widely (Table 2). The average value is 85.49 mg/g, which is approximately 5 times higher than the hydrocarbon production potential of the middle oil shale member, indicating that the hydrocarbon production quality of the middle and lower oil shale layers via pyrolysis is better. The organic carbon content and hydrocarbon potential, which characterize the organic matter abundance of wells YL04-2 and YL04-3, show a stepwise increasing trend with increasing depth (Figure 4). Based on the locations of wells YL04-3 and YL04-2 (the distance between the two wells is approximately 2 km) and the pattern of organic matter variation, the organic matter abundance of the middle oil shale member is relatively evenly distributed, and the corresponding dense oil shale section has a stable distribution and high organic matter abundance. By combining the relationship between hydrocarbon source rock evaluation parameters and oil shale quality indices in related literature [18], the analysis concluded that the quality of the oil shale section in the central part of the mining area is low grade, and the quality of the oil shale layer between the middle and lower coal seams is medium grade.

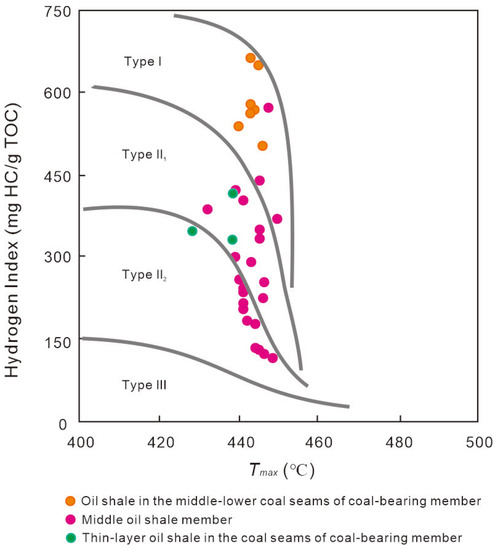

As it is difficult to observe the sapropel on the thin sections as mentioned above, we also use the hydrogen index (IH) vs. maximum pyrolysis temperature (Tmax) plot to identify the kerogen types. This shows that the kerogen in the oil shale between the middle and lower coal seams in the coal-bearing member is mainly concentrated in the type-I area, indicating that the parent material type is algae [19,20]. The kerogen in the oil shale in the middle of the YL04-2 well is mainly concentrated in the type-II1 area, and the kerogen in the oil shale in the middle of the YL04-3 well is mainly distributed in the type-II1–2 transition area, indicating that the parent material type is a mixed source [19,20]. In general, the organic matter in the middle oil shale member is partial to type II1 and type II2 (Figure 5). The type-I organic matter in the oil shale between the middle and lower coal seams of the coal-bearing member is better than that of the middle oil shale member, and its oil shale quality is more suitable for low-temperature dry distillation to extract shale oil.

Figure 5.

The plot of maximum pyrolysis temperature (Tmax) vs. hydrogen index (IH) identifying the kerogen type of oil shales in the Dalianhe coal mining area.

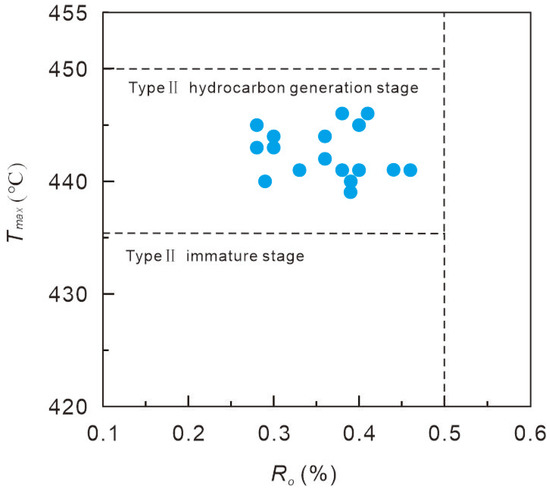

The reflectance of the vitrinite group (Ro) of oil shale and the maximum temperature of hydrocarbon pyrolysis (Tmax) are shown in Table 2, and the reflectance of the oil shale in the vitrinite group is less than 0.5. According to the classification of the reflectance of the hydrocarbon source rock in the vitrinite group [21], the organic matter is basically at the immature stage. However, according to the classification standard of the maximum temperature of hydrocarbon source rock pyrolysis [22], the oil shale in the study area is in the oil production stage (Figure 6). The comprehensive analysis suggests that the organic matter of oil shale in the Dalianhe coal mining area is still in the immature stage of thermal evolution. The conversion rate of organic matter into hydrocarbons is low. The more preserved organic matter can be favorable for the refining of oil shale oil by pyrolysis.

Figure 6.

The plot of Ro vs. Tmax identifying the maturity of oil shales in the Dalianhe coal mining area.

4.4. Major Process Properties of Oil Shale

4.4.1. Oil Shale Industry Analysis

Moisture

The results of oil shale moisture (Mad%) analysis in the Dalianhe coal mining area (Table 3) show that the moisture values of thick oil shale between the middle and lower coal seams in the Dalianhe coal mining area are 0.85–1.69%, with an average of 1.18%. The oil shale moisture values in the middle oil shale member of the YL04-3 well are 1.29–1.63%, with an average of 1.50%. The low moisture of oil shale is favorable for rapid drying and dry distillation.

Table 3.

The results of technical analysis and low-temperature carbonization of oil shales in the Dalianhe coal mining area.

Ash

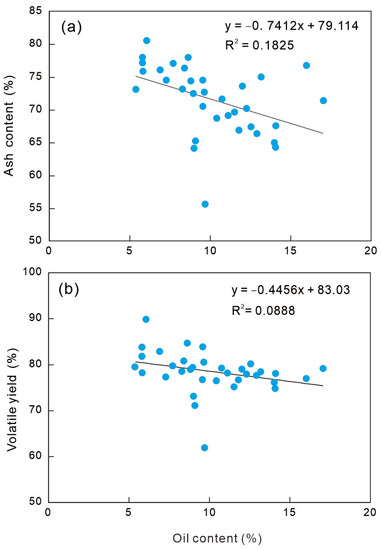

The results of the ash (Aar%) analysis of oil shale in the Dalianhe coal mining area are shown in Table 3. The ash contents of thick oil shale between the middle and lower coal seams in the Dalianhe coal mining area are 55.69–80.57%, with an average of 71.61%. The ash contents of the middle oil shale member of the YL04-3 well are 79.40–88.85%, with an average of 84.19%, which indicates high-ash-content oil shale. The analytical results show that there is a relationship between the high ash content and oil content in the oil shale. When the ash contents of oil shale are 60–70%, the tar yields are generally greater than 10%. When the ash contents are 70–80%, the tar yields of most samples are less than 10%. When the ash contents are 80–90%, the tar yields are less than 5%. The oil content of oil shale decreases with increasing ash content (Figure 7a).

Figure 7.

The plots of oil content vs. ash content (a) and volatile yield (b).

Volatiles

The results of the volatile yield (Vdaf%) analysis of oil shale in the Dalianhe coal mining area (Table 3) show that the volatile yields of thick oil shale between the middle and lower coal seams in the Dalianhe coal mining area are 61.94–89.86%, with an average of 78.52%, indicating a medium volatile yield. The volatile yields of the middle oil shale member of the YL04-3 well range from 74.47 to 97.74%, with an average of 87.95%, as shown by the relationship between the oil content and volatile yield of oil shale in the Dalianhe coal mining area (Figure 7b). The volatile yield of oil shale between the coal seams in the coal-bearing member is low, with most samples having a volatile yield of 70–80% and a tar yield of more than 5%. The volatile yield of oil shale in the middle oil shale member is generally more than 80%, and the tar yield is less than 5%. The oil content in the oil shale and the volatile yield show a general negative correlation, and the relevant literature reports that the two parameters are not simply positive [23,24]. This anomaly is due to the influence of inorganic minerals, such as siderite in oil shale, as well as different kerogen types in oil shale.

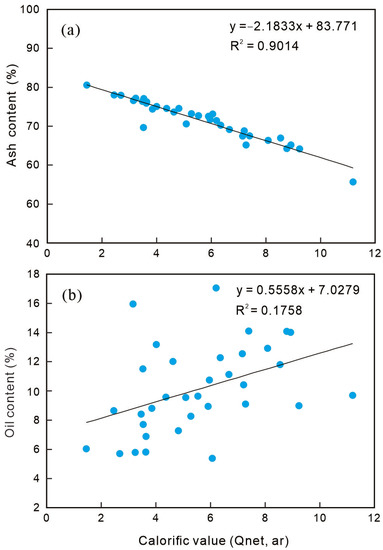

Calorific Value and Total Sulfur

The results of the analyses of the calorific value (Qnet, ar) and total sulfur (St, d%) of oil shale in the Dalianhe coal mining area are shown in Table 3, and the calorific values of oil shale in the thick layer between the middle and lower coal seams in the Dalianhe coal mining area are generally 1.45–11.2 MJ/kg, with an average of 5.57 MJ/kg, which indicates good combustibility. From the graph of the correlation analysis of calorific power with ash and oil contents (Figure 8), it can be determined that the calorific power of oil shale becomes larger with increasing oil content, but the calorific power decreases with increasing ash content. When the ash contents of oil shale are between 60% and 70%, the calorific values are more than 6 MJ/kg. When the ash contents are between 70% and 80%, the calorific values are approximately 2–6 MJ/kg. When the ash contents are more than 80%, the calorific values are less than 2 MJ/kg. Therefore, the calorific values of the middle oil shale member are very low. This is not conducive to combustion, as the ash content is quite high.

Figure 8.

The plots of calorific value vs. ash (a) and oil (b) contents.

The sulfur content of the oil shale in the Dalianhe coal mining area is low. The total sulfur (St, d%) contents of oil shale between the middle and lower coal seams are 0.02–1.28%, with an average of 0.66%. The total sulfur contents of the middle oil shale member of the YL04-3 well are generally lower than 0.51%, with an average of 0.12%. Oil shale is especially low in sulfur and produces low potential environmental pollution. Pyrite is not observed in samples of oil shale from the middle oil shale member. This indicates that the sulfur of oil shale from the middle oil shale member is mainly organic sulfur.

4.4.2. Low-Temperature Carbonization Analysis

The results of the low-temperature dry distillation analysis of oil shale in the Dalianhe coal mining area are shown in Table 3. The oil shale between the middle and lower coal seams shows a high tar yield value with an average of 10.12%, high oil content, low total dry distillation water, low semicoke yield, and high gas and loss. On the contrary, the oil shale in the middle oil shale member shows a low tar yield value with an average of 2.80%, low oil content, high total dry distillation water, high semicoke yield, and low gas and loss. The coke type of oil shale in the Dalianhe coal mining area is A, which indicates semicoke without bonding, powder, or powder with a small number of small pieces. According to the classification standard of the oil content in oil shale [21], the oil shale between the middle and lower coal seams is high grade, whereas the oil shale in the middle oil shale member is low grade. The oil shale between the middle and lower coal seams is suitable for low-temperature dry distillation oil refining.

4.4.3. Characteristics of Oil Shale Ash

The results of the ash compositional analysis of oil shale are shown in Table 4. The ash composition is mainly SiO2, Al2O3, Fe2O3, CaO, and MgO. The ash composition of the thick oil shale between the middle and lower coal seams in the Dalianhe coal mining area is 52.2–55.02% SiO2, averaging 53.7%, which is higher than 49.83% in the middle oil shale member. The ash is 14.99–19.61% Al2O3, averaging 16.48%, which is lower than 24.34% in the middle oil shale member. The ash is 1.45–3.22% Fe2O3, averaging 2.43%, which is lower than the middle oil shale member value of 5.09%. The CaO contents are 0.15–0.35%, averaging 0.24%, which is slightly lower than the middle oil shale member value of 0.27%. The MgO contents are 0.27–0.44%, averaging 0.33%, which is lower than the middle oil shale member value of 0.53%. The ash composition is rich in silica–alumina, low in calcium and magnesium, and iron-poor.

Table 4.

The major element compositions (%) of ash from oil shales in the Dalianhe coal mining area.

The ash composition is closely related to the ash melting point and determines the ash melting point [23]. Generally, the higher the values of SiO2 and Al2O3, the higher the ash melting point. The higher the values of Fe2O3, CaO, MgO, Na2O, and K2O, the lower the ash melting point. The relationship between the ash composition and the ash melting point of oil shale in the Dalianhe coal mining area also has such characteristics.

4.5. Development and Utilization of Oil Shale

4.5.1. Feasibility of Refining Shale Oil by Oil Shale Retorting

An important quality indicator of oil shale as a raw material for the shale oil industry is the oil content. The tar yield (Tar, ad%) of the thick oil shale between the middle and lower coal seams is 10.12% on average in this study; the tar yield is 2.92% on average in the middle thick oil shale member, with the YL04-3 well as an example, which is relatively high in the lower part. The tar yield sampled within 1 m from the upper coal seam roof is 3.90% on average, and the tar yield sampled within 10 m from the roof is 3.73% on average. According to the existing technical conditions of oil shale mining, the dry distillation process, and mineral geological survey specifications in China [21,23,25], the oil content of the general industrial index is more than 5%. Compared with the oil contents of the Fushun and Maoming oil shales, which have been industrially produced, the oil contents are 6.0–8.0% [26,27]. The thick layer of oil shale between the middle and lower coal seams meets the requirements and has the feasibility of dry distillation for refining shale oil. The comparison with the results of the dry distillation analysis of the representative oil shale shows that the characteristics and dry distillation effect of oil shale in the Dalianhe coal mining area and Fushun oil shale are very close (Table 5). A similar dry distillation process can be selected for the preliminary industrial experimental study.

Table 5.

The results of low-temperature carbonization and technical analysis of oil shales in the Dalianhe coal mining area compared with those in typical oil shale deposits.

The resource reserves of the thick oil shale member above the coal seam are large; the tar yield is low; the local layer is rich in resources; the overall oil content does not reach the general industrial requirement of 5%; and shale oil cannot yet be refined by applying ground dry distillation technology.

4.5.2. Feasibility of Oil Shale as Fuel

As a low-calorific fuel, oil shale is burned to produce steam for electricity and calorific power, which is the main method of oil shale energy utilization [23,28]. Since oil shale generally has the characteristics of easy ignition, low ignition temperature, volatile yield with burning, difficult combustion, and easy slagging, which affect combustion utilization, understanding the combustion characteristics of oil shale in mining areas is the key to developing and utilizing oil shale resources. The thick oil shale between the middle and lower coal seams in the Dalianhe mining area is compared with the representative oil shales in Jilin Huadian, Liaoning Fushun, and Guangdong Maoming, which are used for combustion via calorific power in China [27,29] (Table 5). This shows that the oil shale in the Dalianhe coal mining area has low moisture, slightly higher calorific power than the Liaoning Fushun oil shale, and lower calorific power than the Maoming and Huadian oil shales. The ash content and volatile yield (converted to Vad) are close to those of the Maoming, Huadian, and Fushun oil shales. The total sulfur content is lower than that of the Maoming oil shale and slightly higher than that of the Huadian and Fushun oil shales. The ash composition is mainly silica–alumina; the ash melting point is high; and the combustion characteristics are basically similar. Oil shale can be considered a low-calorific fuel, and advanced furnace-type and combustion technology should be chosen for gas production and power generation or for combined coal–oil-shale combustion power generation; however, oil shale can also significantly reduce environmental pollution.

4.5.3. Feasibility of Oil Shale Ash as Building Material

The oil shale ash residue is 60–80% of the weight of oil shale. It is very important to use it rationally by considering various factors, such as environmental protection requirements, social benefits, and economic benefits. Fushun and Maoming have the experience and technology for using oil shale to produce cement and shale-sintered bricks [23]. As shown in Table 5 above, the ash composition of oil shale in the Dalianhe coal mining area is slightly lower than that of the Maoming oil shale in terms of SiO2 and Al2O3. The ash is the lowest in Fe2O3 and CaO, and the MgO content is lower than that of the Fushun and Maoming oil shales. The ash melting point is close to that of Maoming oil shale; the ash composition is mainly silica–alumina; and the ash composition is similar to that of the Maoming oil shale.

By analyzing the characteristics of organic and inorganic minerals of oil shale in typical mining areas, which have been developed and utilized, the oil shale between the middle and lower coal seams in the Dalianhe coal mining area is suitable for dry distillation to produce oil and gas, combustion to produce steam for power generation, and shale ash as raw material for building materials. The combined production path of oil refining, thermal power and building materials is adopted to form a circular economic industrial chain. However, the potential environment impacts are still addressed before oil shale production in the Dalianhe coal mining area.

5. Conclusions

- The organic matter of oil shale in the Dalianhe coal mining area, northeastern China, is mainly kerogen of types I and II2. The kerogen of the oil shale section in the middle oil shale member is mainly humic amorphous material, which is mainly composed of biodegradable aquatic organisms. The organic carbon content and hydrocarbon generation increase with increasing depth. The thick oil shale between the middle and lower coal seams is enriched in amorphous sapropel and humic substances. The main source is higher plants and lower phytoplankton, such as algae.

- The inorganic minerals of oil shale are mainly clay minerals, terrigenous clastic particles, siderite, and pyrite. The terrigenous debris is dominated by fine-grained quartz and feldspar particles. The clay minerals are mainly kaolinite with crystallization. The oil shales in the middle oil shale member and in the middle–lower coal seams of the coal-bearing member show the same clay types. The contents of quartz, siderite, and pyrite in oil shale between the coal seams are high. The oil shale between the middle and lower coal seams is characterized by a high ash content, high silicon and aluminum, low calcium and magnesium, poor iron, and a high ash melting point.

- The oil shale between the middle and lower coal seams in the Dalianhe coal mining area is enriched in oil, with a medium calorific value, a high ash content, medium volatile matter, low moisture, and ultralow sulfur-type oil shale. This indicates quality and good development value. The tar yield is positively correlated with the organic matter content and calorific value and is related to the organic matter type but negatively correlated with the ash content and volatile matter. The volatile matter is greatly affected by siderite and the kerogen type. The oil shale between the middle and lower coal seams is enriched in oil, and the middle oil shale layer is poor in oil, with low quality.

- The oil shale between the middle and lower coal seams in the Dalianhe coal mining area is suitable for low-temperature dry distillation for oil refining and low-calorific fuel. The oil shale ash is suitable for building materials and clay raw materials for cement production, and it has good prospects for development and utilization. The new coal mining shaft can be used to recover oil shale between the coal seams and oil shale above the upper coal seam. The joint mining of coal and oil shale should be carried out to improve the utilization rate of resources. The comprehensive development of oil shale in the Dalianhe coal mining area is suitable for the joint production of oil refining, thermal power and building materials to form a circular economic industrial chain and realize the efficient and clean utilization of oil shale resources.

Author Contributions

Conceptualization, Z.L.; formal analysis, Z.L. and H.R.; investigation, Z.L.; writing—original draft preparation, Z.L.; writing—review and editing, Z.L., H.R., H.Y., S.Y. and C.M.; visualization, Z.L. and H.R.; supervision, Z.L.; funding acquisition, Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China National Administration of Coal Geology, grant number DRC-2017-XR-008.

Data Availability Statement

All the data required to evaluate the conclusions of this study are present in the paper. The authors will provide additional data related to this paper upon request.

Acknowledgments

We thank three anonymous reviewers who improved the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dyni, J.R. Geology And Resources of Some World Oil-Shale Deposits. Oil Shale 2003, 3, 193–252. [Google Scholar] [CrossRef]

- Ran, H.; Ran, S.M.; Wang, F.J. Introduction of Oil Shale Resource Characteristics and the Prospects for Development in Central Inner Mongolia: Taking Wulatehouqi as an Example. Nat. Resour. Econ. China 2012, 8, 31–32+46. [Google Scholar]

- Bradely, W.H.; Eugster, H.P. Geochemistry and Palimnology of the Trona Deposits and Associated Auhigenic Minerals of Green River Formation of Wyoming. U S Geol. Surv. Prof. Pap. 1969, 803, 53. [Google Scholar]

- Brendow, K. Global Oil Shale Issues and Perspectives. Oil Shale 2003, 20, 81–92. [Google Scholar] [CrossRef]

- Talumaa, R. Oil shale power prevails in Estonia. Oil Shale 2005, 22, 93–94. [Google Scholar] [CrossRef]

- Liu, Z.X.; Huang, W.H.; Zhang, J.Q.; Wang, D.J. The Properties, Genesis and Resource Potential of Oil Shale in Dalianhe Mining Area of Yilan Coalfield, Heilongjiang Province; Geological Publishing House: Beijing, China, 2011; pp. 1–115. [Google Scholar]

- Liu, R.; Liu, Z.J.; Liu, S.Y.; Liu, D.Q.; Li, B.Y.; Yang, X.H.; Xu, Y.B. Coal and oil shale occurrence characteristic and metallogenic regularity in Yilan Basin. J. China Coal Soc. 2012, 37, 776–781. [Google Scholar]

- Liu, R.; Liu, Z.J.; Du, J.F.; Liu, D.Q.; Yang, X.H.; Xu, Y.B. New Research on Oil Shale Origin of Eocene Dalianhe Formation in Yilan Basin. J. Jilin Univ. 2012, 42, 941–947. [Google Scholar]

- Liu, Z.X.; Zhang, X.G.; Ma, T.; Ge, Z.; Dai, H.Z. Ore-forming models and types of oil shale in Dalianhe Formation of Yilan Basin. Geol. China 2013, 40, 1872–1879. [Google Scholar]

- Wang, D.D.; Li, Z.X.; Wang, Z.F.; Lv, D.W.; Liu, H.Y.; Wang, P.L.; Zheng, X.; Lv, Y.L.; Lin, X.W. Paleogene Coal and Oil Shale Paragenetic Features and Sequence Stratigraphic Framework in Yilan Basin, Heilongjiang. Coal Geol. China 2013, 25, 1–7. [Google Scholar]

- Liu, Z.X.; Dai, H.Z.; Zhang, X.G.; Ma, T.; Ge, Z.; Jia, Y.C. Study on ore-controlling factors of Dalianhe oil shale in Yilan Basin. Chin. J. Geol. 2014, 49, 1232–1246. [Google Scholar]

- Zhang, J.; Liu, Z.J.; Du, J.F.; Liu, R.; Wang, W.T.; Liu, S.Y.; Jing, B.Z. Sedimentary Characteristics of the Oil Shale in the Paleogene Dalianhe Formation in the Yilan Basin, Heilongjiang Province. J. Jilin Univ. 2006, 36, 980–985. [Google Scholar]

- Zhang, X.G.; Liu, Z.X.; Ma, T. Sedimentary characteristics and distribution of oil shale in Dalianhe Formation of Yilan Basin. Chin. J. Geol. 2013, 48, 932–944. [Google Scholar]

- Wang, S.H.; Chen, C.R.; Zheng, Y.L.; Liu, S.Y. Study on Geochemical Characteristics and Genesis of the Dalianhe Oil Shale in Heilongjiang Province. J. Jilin Univ. 2006, 36, 933–937. [Google Scholar]

- Liu, Z.X.; Ma, T.; Zhang, X.G.; Zhang, J.; Ge, Z. Characteristics and geological significance of oil shale biological marker compound in Dalianhe Formation of the Yilan coal basin in Heilongjiang Province. Geol. Bull. China 2013, 32, 1447–1452. [Google Scholar]

- Zhao, S.G.; Wang, J.G.; Sun, H.J.; Ai, X.Y. Study on Yilan oil shale gasification oil co-production of syngas. Coal Process. Compr. Util. 2007, 3, 51–53. [Google Scholar]

- Gao, J.J.; Meng, Q.T.; Zeng, W.R.; Li, J.G.; Li, L.; Kang, J.N. Organic Geochemical Characteristics and Depositional Environment Analysis of Eocene Dalianhe Formation Oil Shale in Yilan Basin. J. Jilin Univ. 2023, 53, 60–72. [Google Scholar]

- Liu, S.P.; Zhou, Z.X.; Wang, B.Z. Relationship Between Industrial Indexes and Source Rock Evaluation Parameters of Oil Shale. Nat. Gas Geosci. 2012, 23, 561–569. [Google Scholar]

- Tissot, B.; Durand, B.; Espitalie, J. Influence of Nature and Diagenesis of Organic Matter in Formation of Petroleum. AAPG Bull. 1974, 58, 499–506. [Google Scholar]

- Liu, G.D.; Zhang, H.F. Petroleum Geology; Petroleum Industry Press: Beijing, China, 2009; pp. 115–266. [Google Scholar]

- Liu, Z.J.; Yang, H.L.; Dong, Q.S.; Zhu, J.W.; Guo, W.; Ye, Q.S.; Liu, R.; Meng, Q.T.; Zhang, H.L.; Gan, S.C. Oil Shale in China; Petroleum Industry Publishing House: Beijing, China, 2009; pp. 3–302. [Google Scholar]

- Wu, L.Y.; Gu, X.Z.; Sheng, Z.W.; Fan, C.L.; Tong, Z.Y.; Cheng, K.M. Rapid Quantitative Evaluation of Oil Rock Pyrolysis; Science Press: Beijing, China, 1986; pp. 1–96. [Google Scholar]

- Qian, J.L.; Yin, L. Oil Shale—The Supplementary Energy of Oil; China Petrochemical Press: Beijing, China, 2008; pp. 10–385. [Google Scholar]

- Dang, H.L.; Li, Y.H.; Tong, H.K.; Huang, Y.B.; Fan, W.K.; Yun, Q.C. Correlativity Analysis of Oil Shale Industrial Quality Indices in Qinghai Province. Coal Geol. China 2018, 30, 24–27. [Google Scholar]

- Liu, R.; Liu, Z.J. Oil Shale Resource Situation and Multi-Purpose Development Potential in China and Abroad. J. Jilin Univ. 2006, 36, 892–898. [Google Scholar]

- Han, F.; Li, H.Z.; Li, N.Y. Analysis of Fushun Oil Shale Development and Utilization. J. Jilin Univ. 2006, 36, 915–920. [Google Scholar]

- Zhao, Y.H. The Main Characteritics and Use of Oil Shale in Our Country. Shenyang Chem. Ind. 2000, 29, 37–60. [Google Scholar]

- Wang, Q.Q.; Ma, Y.; Li, S.Y.; Qian, J.L. Global Oil Shale Research, Development and Utilization Today—Two International Oil Shale Symposiums Held in 2016. Sino-Glob. Energy 2017, 22, 23–29. [Google Scholar]

- Liu, B.Q.; Li, Y.F.; Li, Y.; Fu, Z.Z. Chinese Oil Shale and its Fluidized Bed Combustion. Energy China 1995, 6, 6–8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).