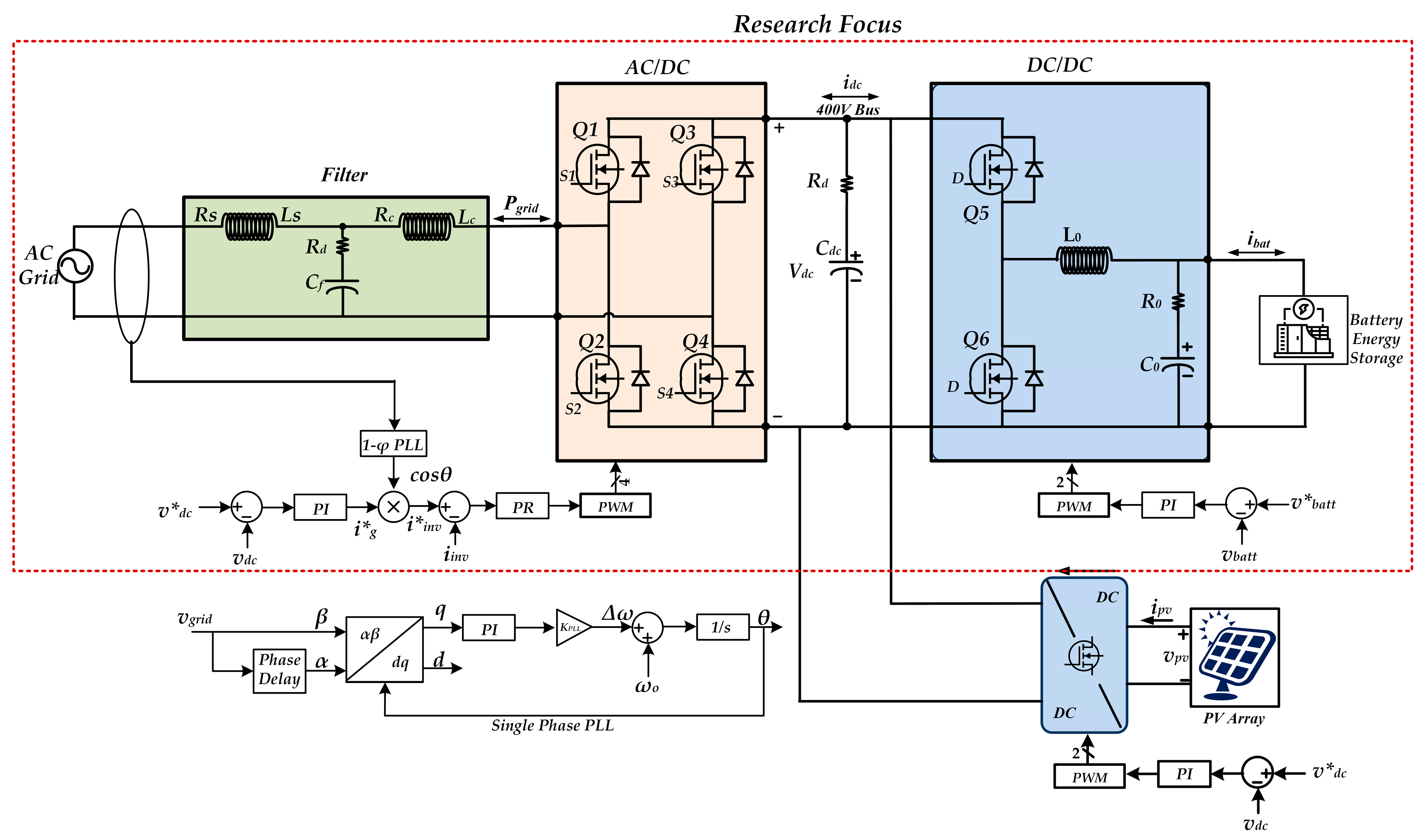

Performance Assessment of a Grid-Connected Two-Stage Bidirectional Converter for a Combined PV–Battery Energy Storage System †

Abstract

1. Introduction

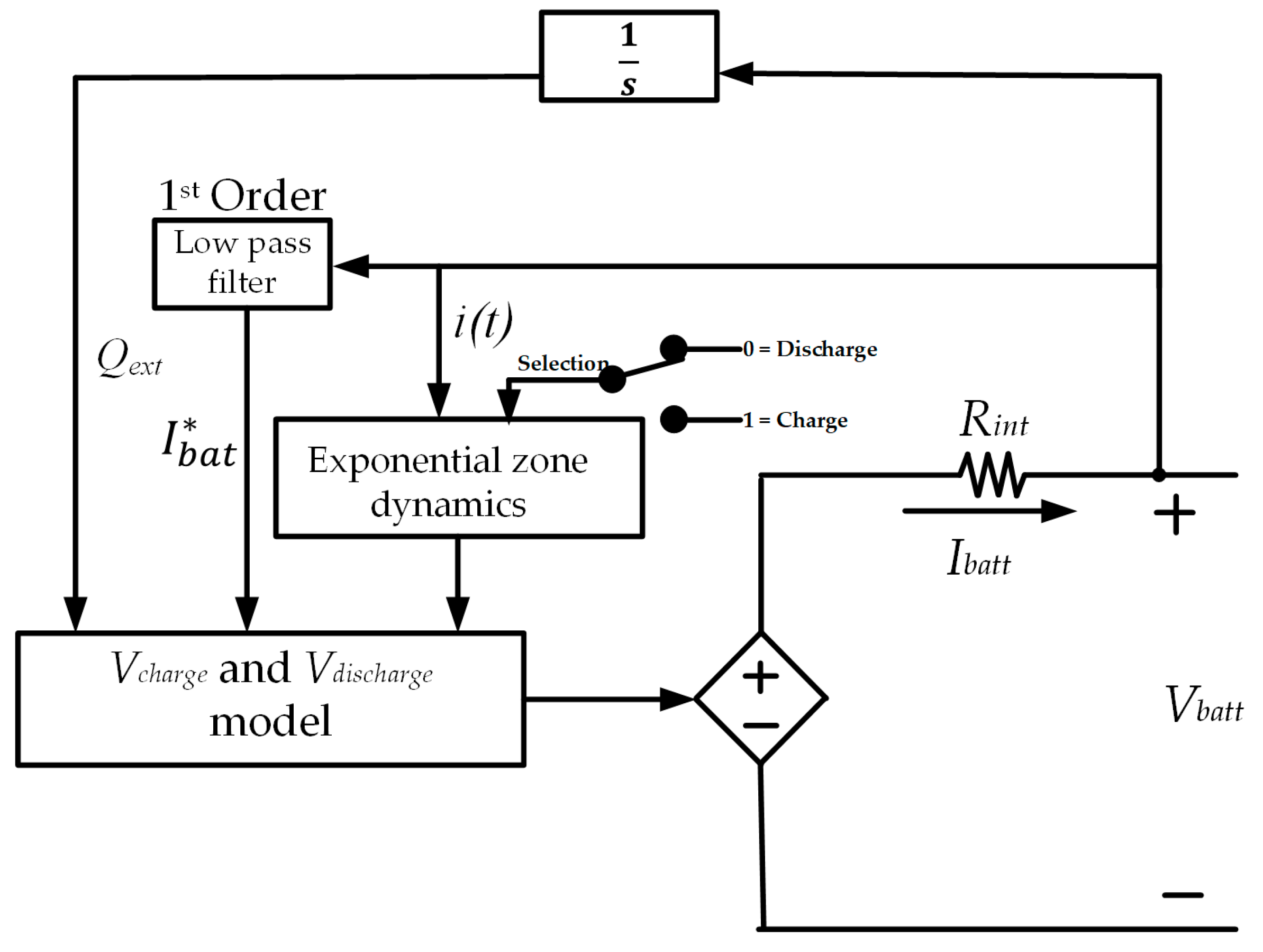

2. Battery Energy Storage System Modeling

2.1. Modeling of AC/DC Converter

2.2. Modeling of DC/DC Converter

2.3. Li-Ion Battery

3. Control Design for the Two-Stage Bidirectional Converter

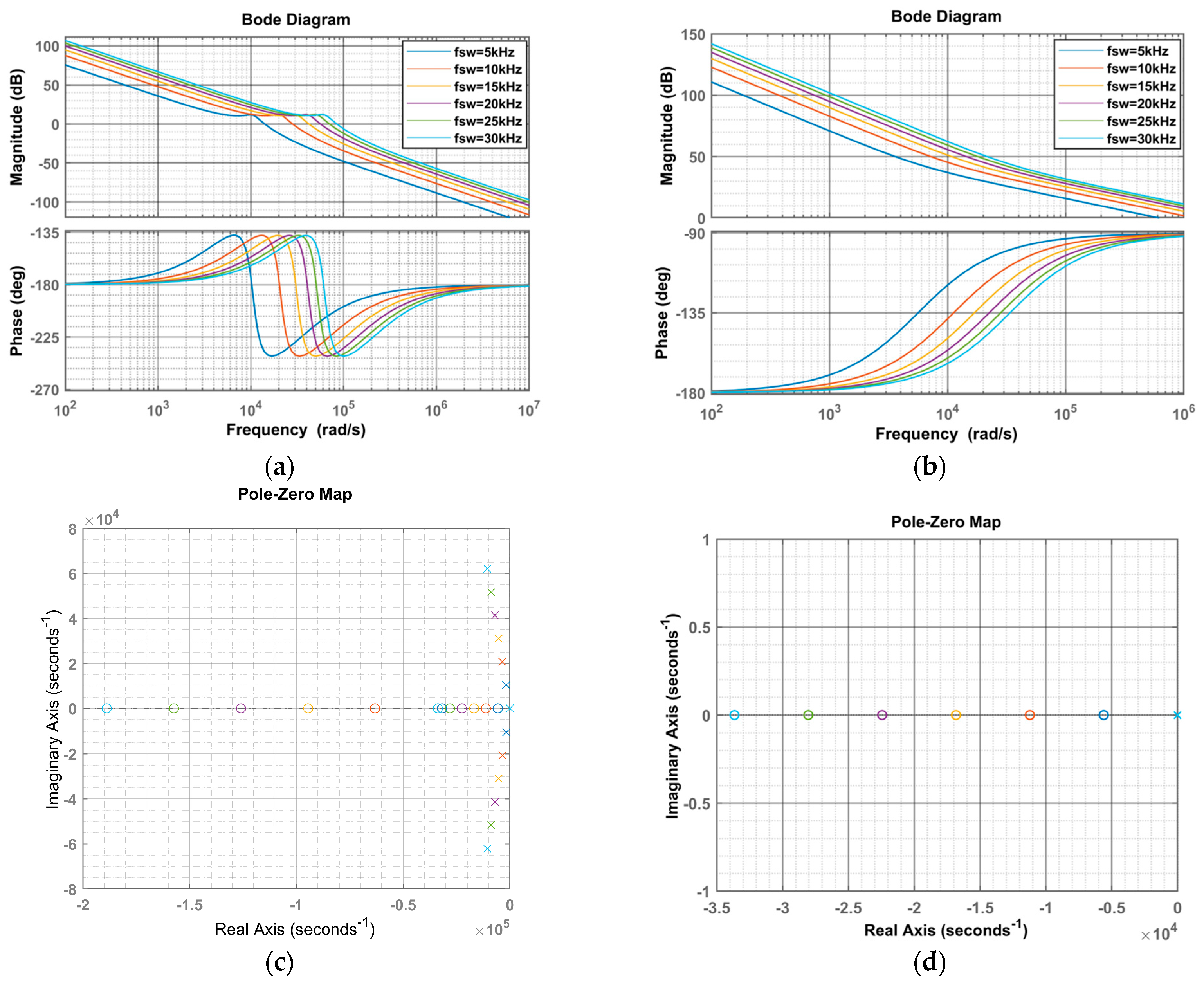

3.1. Control of AC/DC Converter

3.2. Control of DC/DC Converter

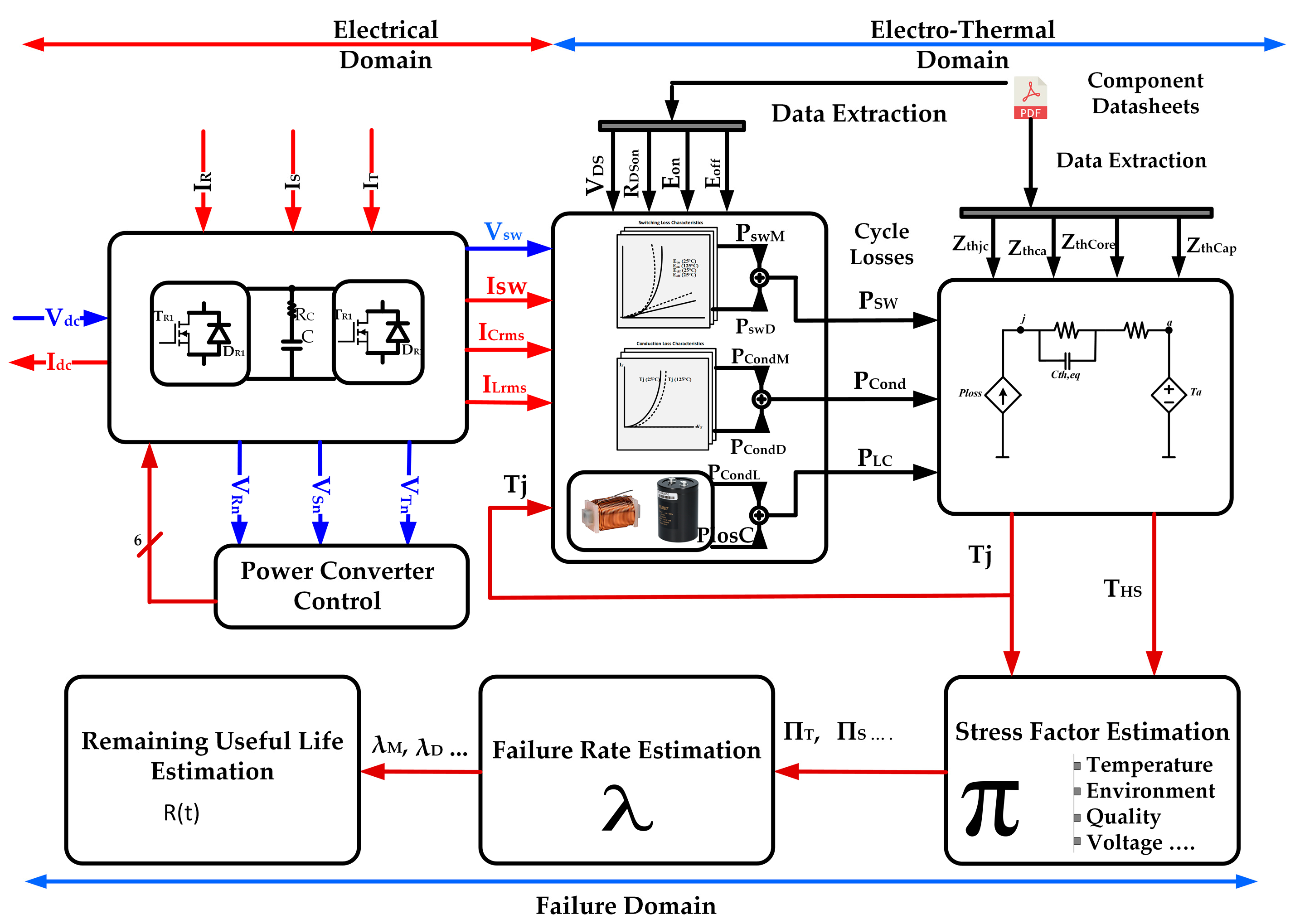

4. Power Electronics Interface Degradation

4.1. Loss Modeling

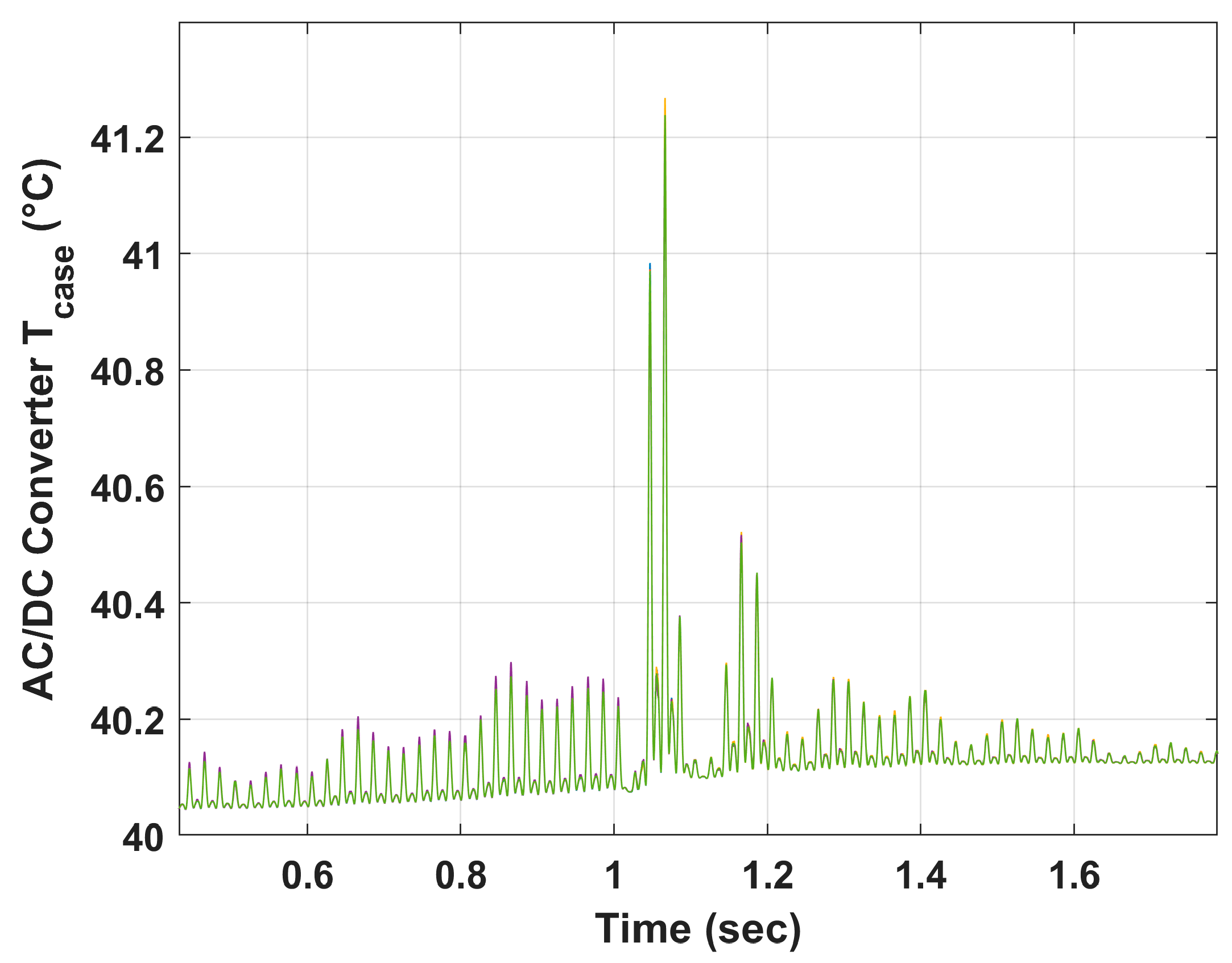

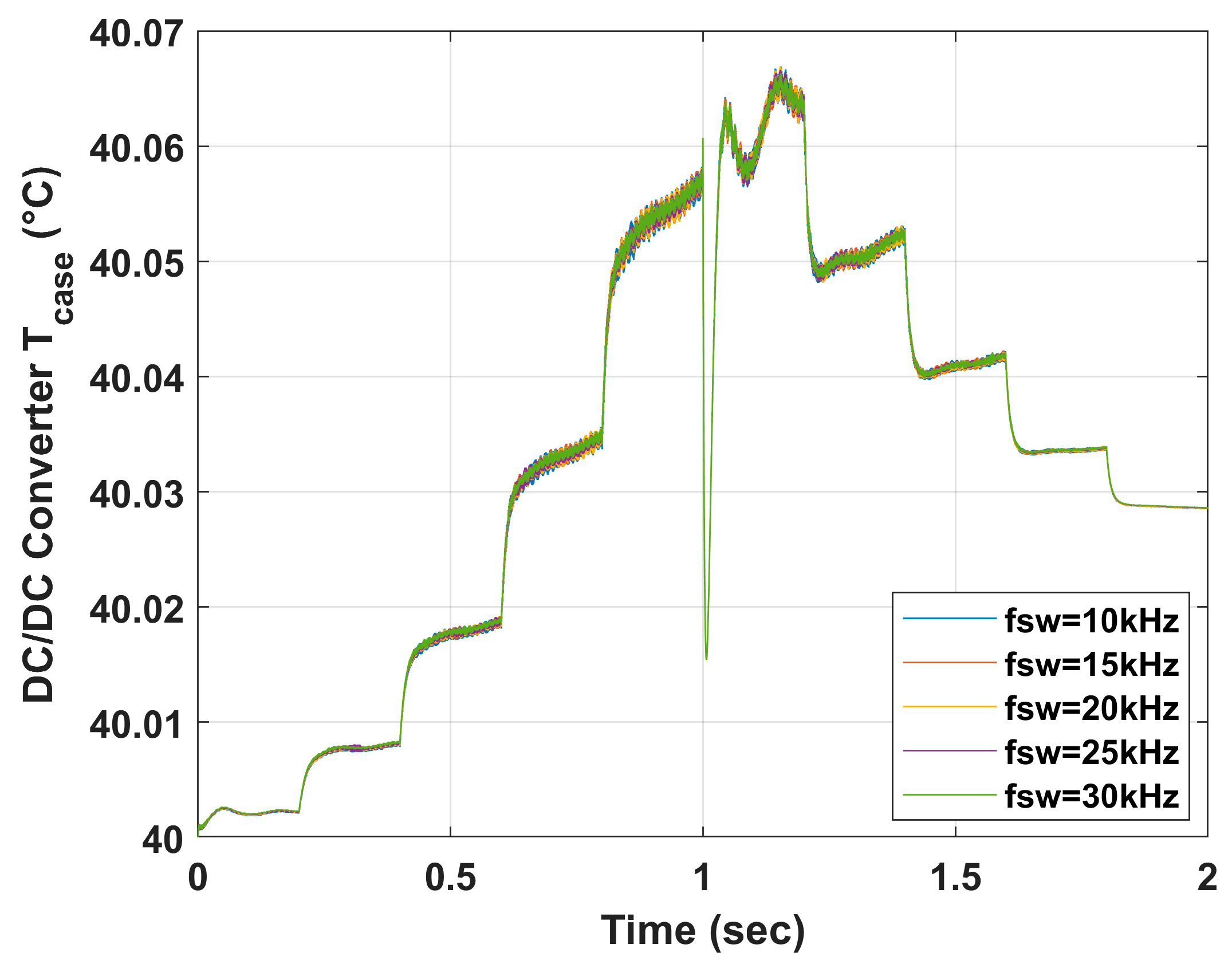

4.2. Thermal Modeling

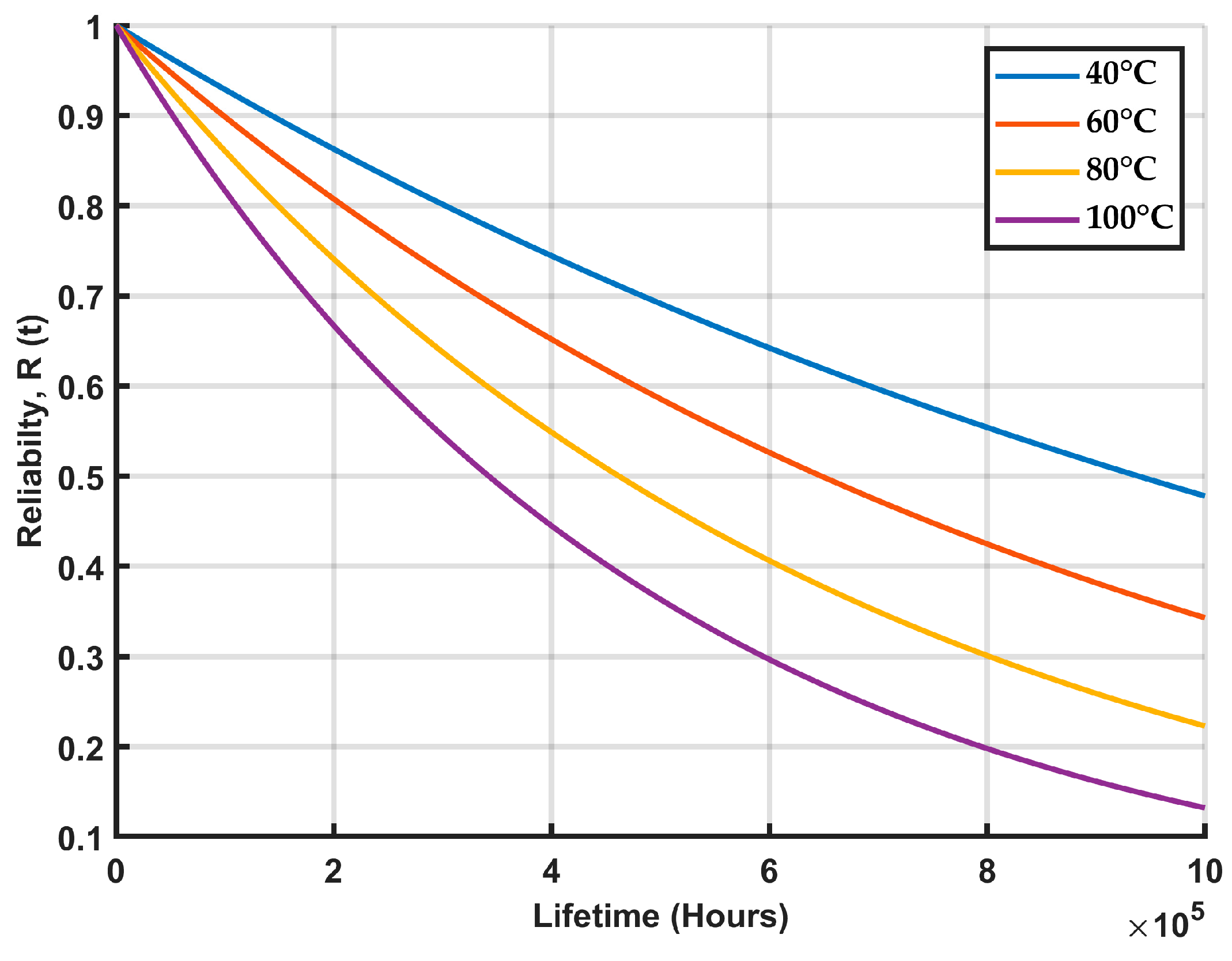

4.3. Failure Modeling

5. Results and Discussion

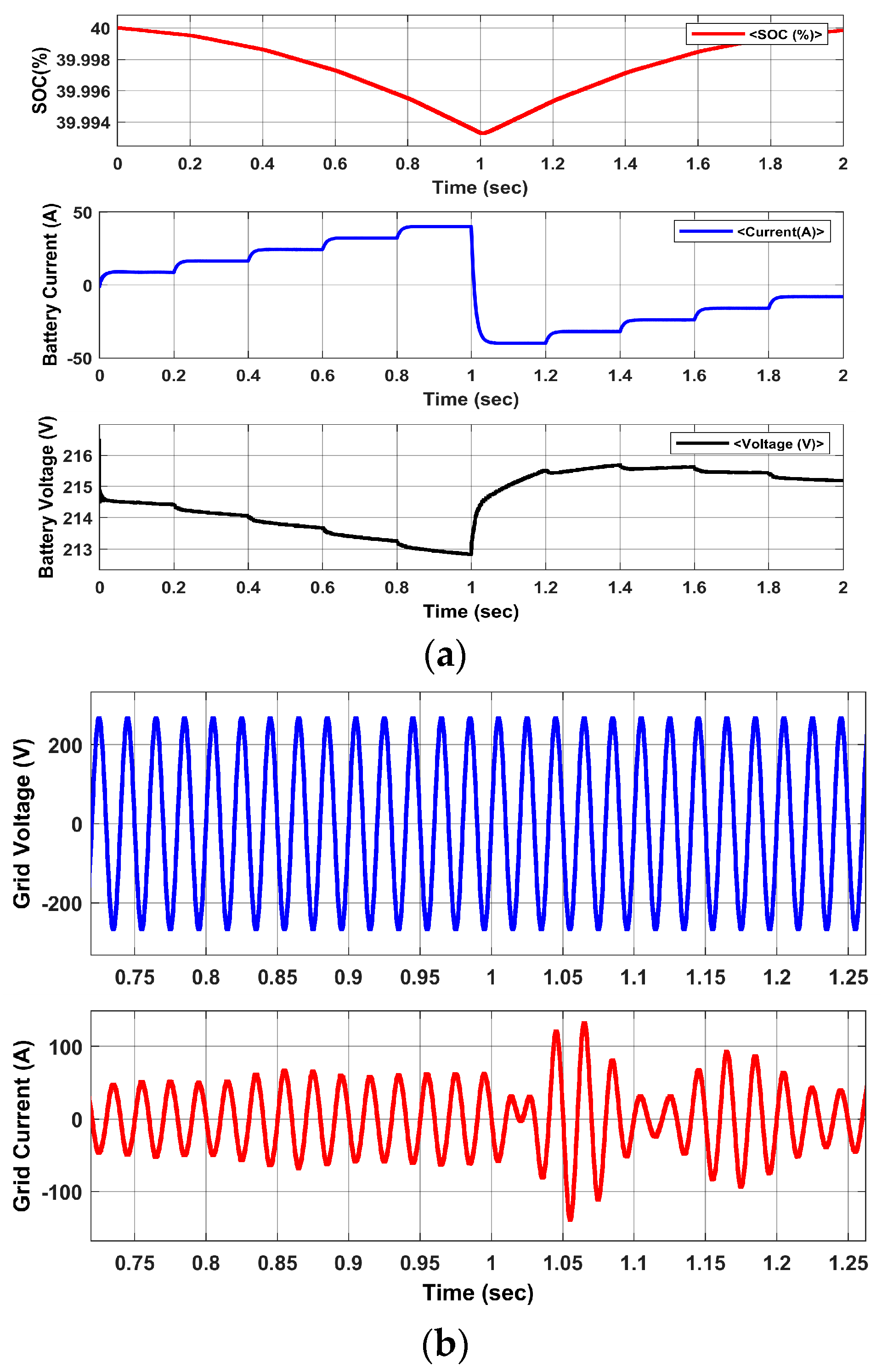

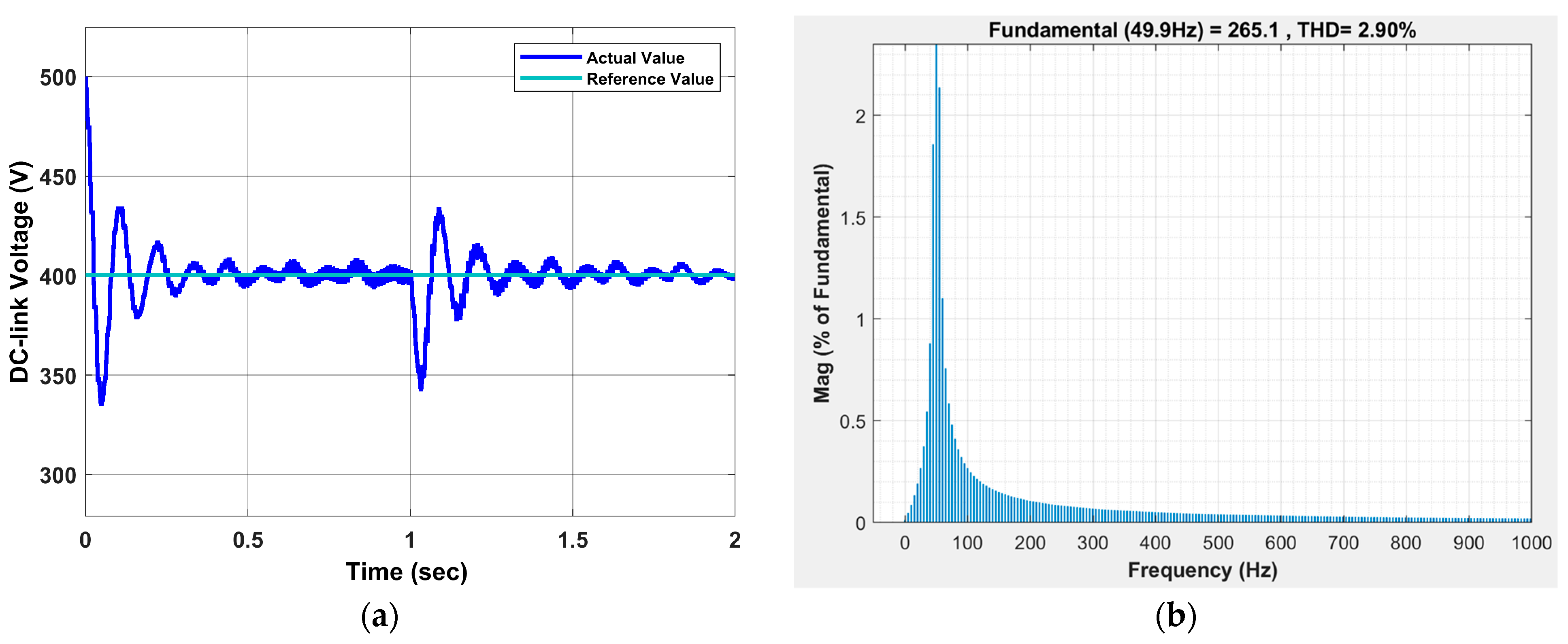

5.1. Controller Performance

5.2. System Performance

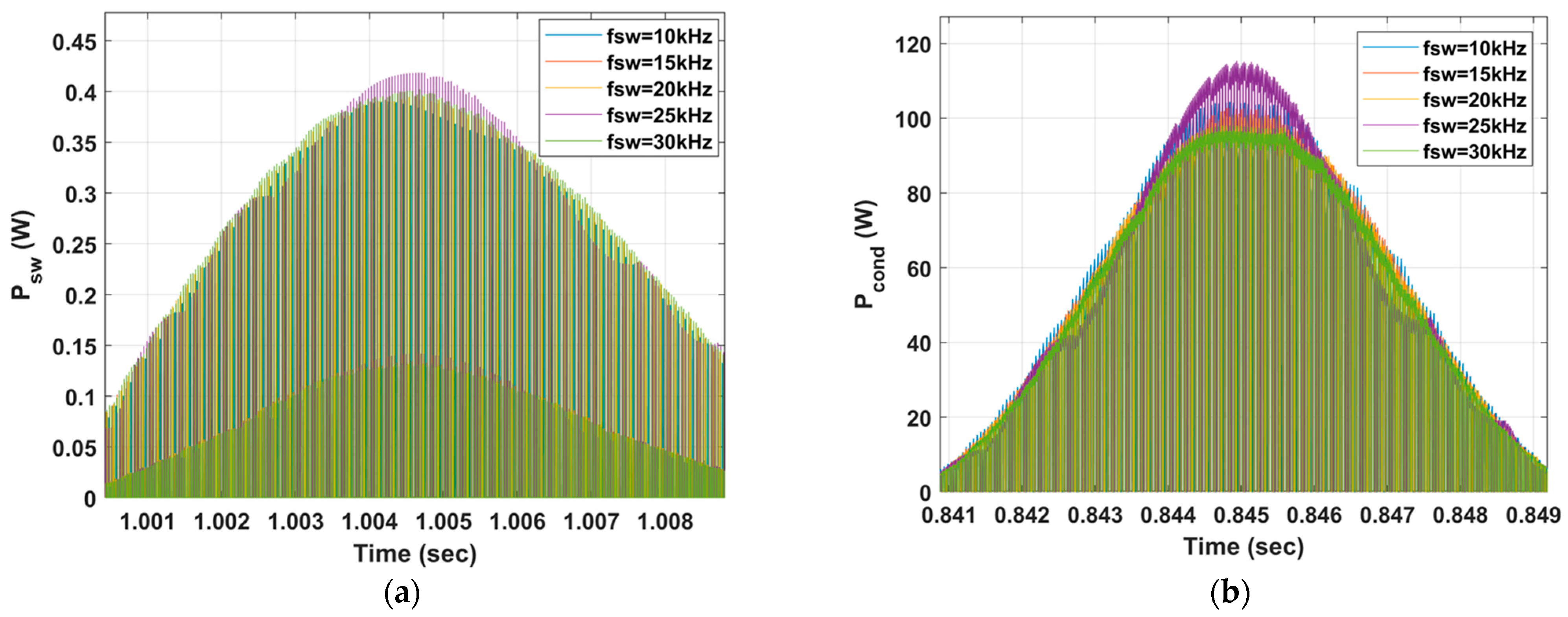

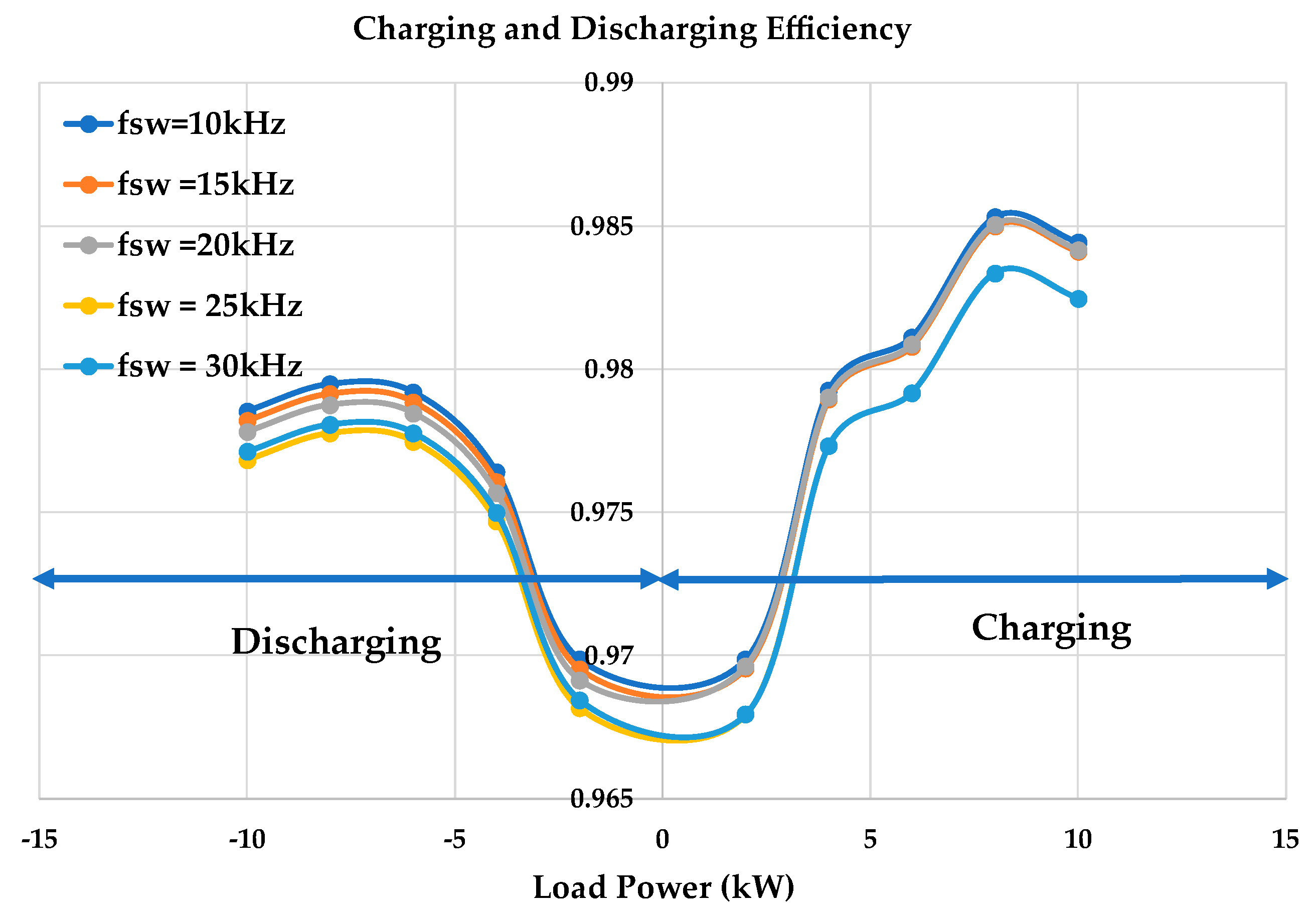

5.3. Evaluation of Losses

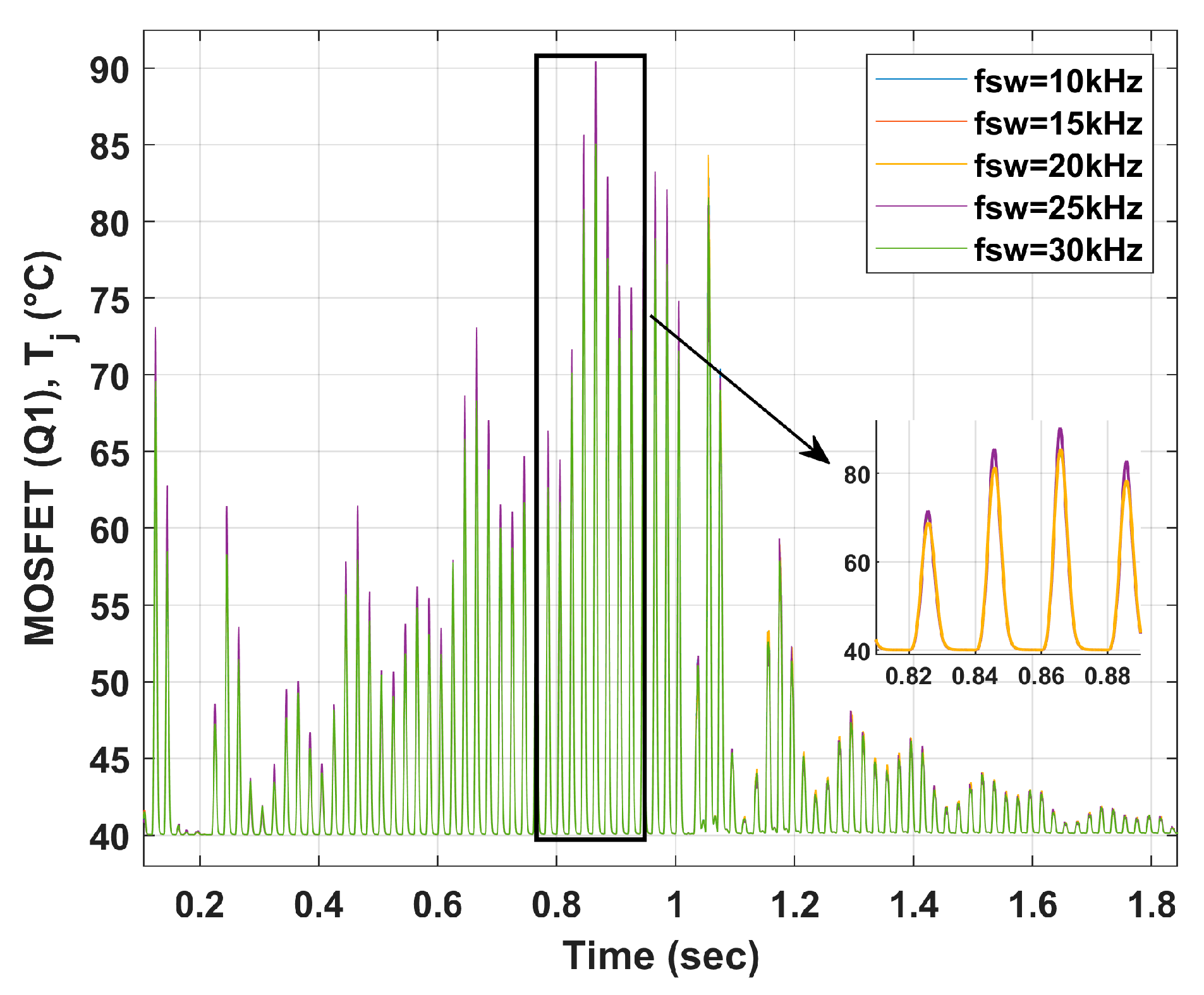

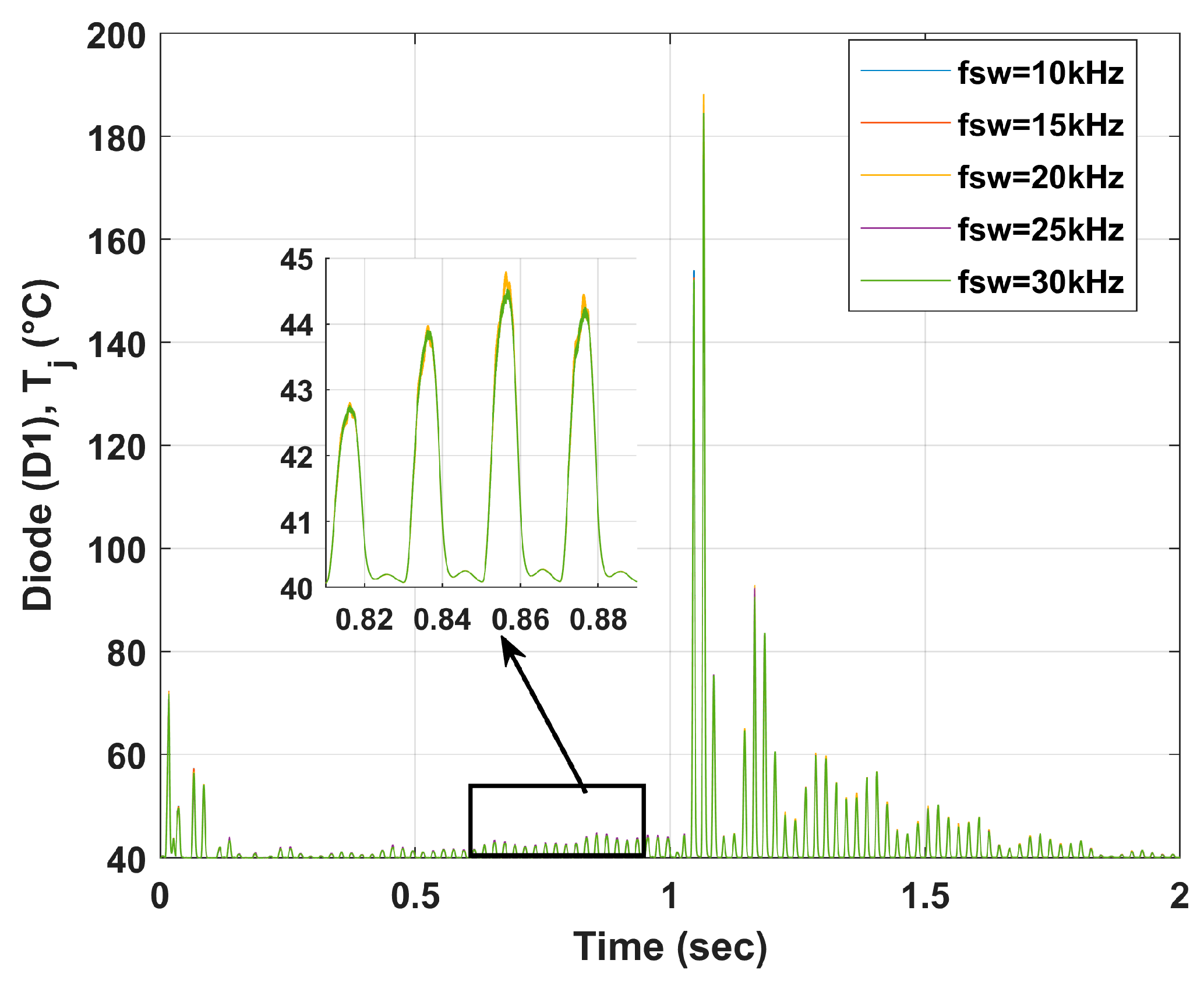

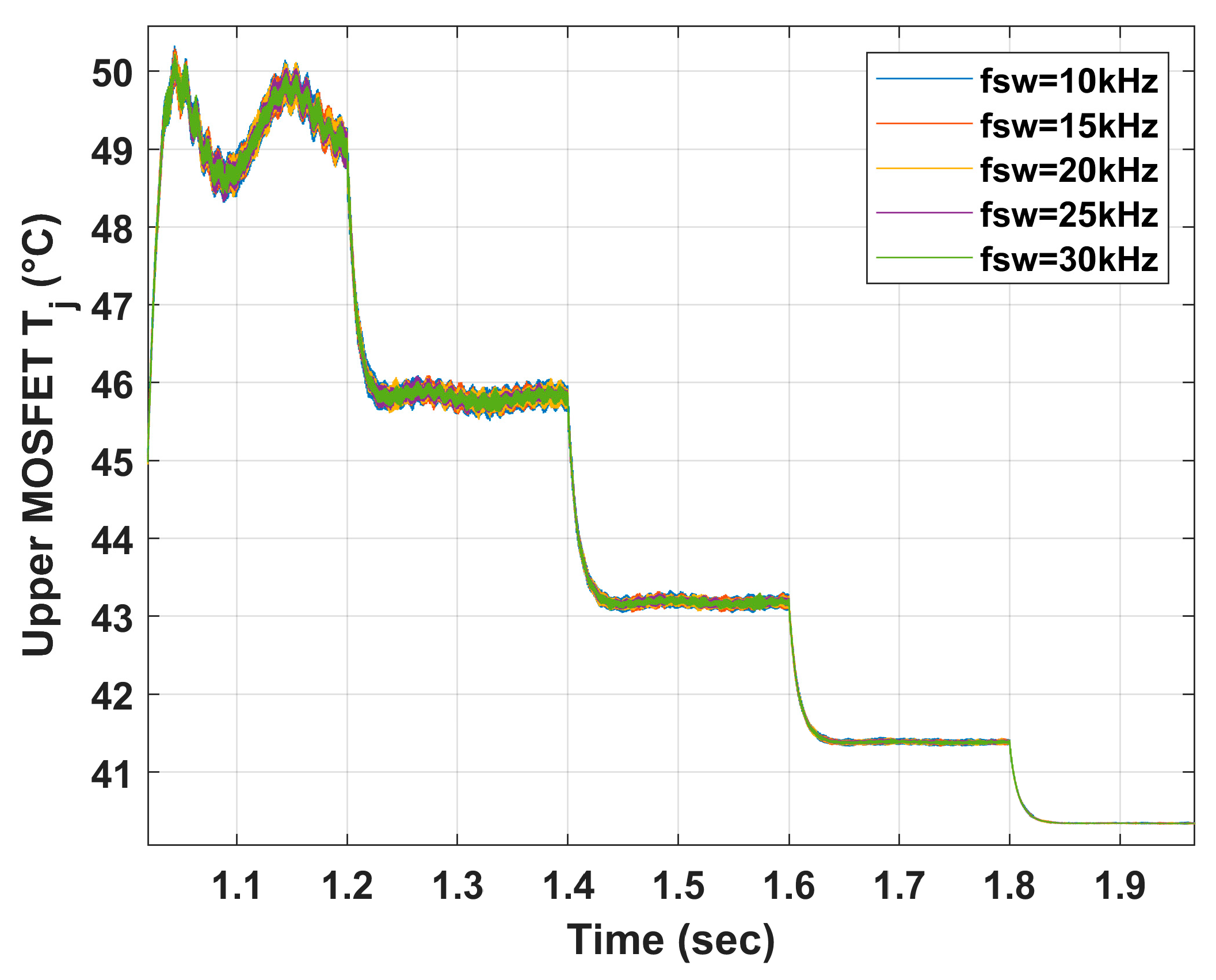

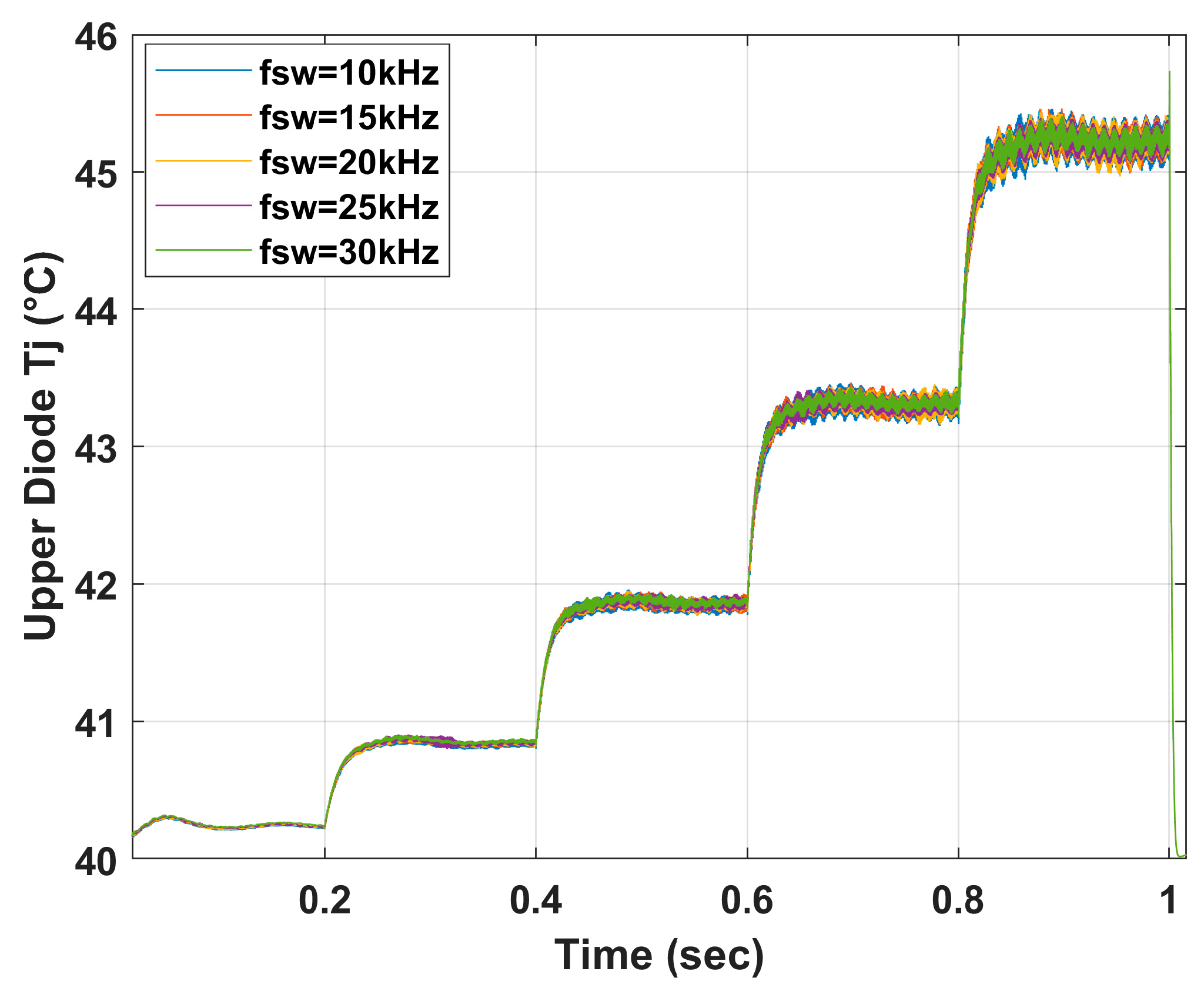

5.4. Degradation Assessment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chalamala, B. Energy Storage and the Electric Grid—Stabilizing the Renewable Energy Dominated Utility Grid Through Storage; No. SAND2020-13574C; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2020. [Google Scholar]

- Building Integrated Photovoltaics—BIPV Status Report 2020—News—BIPV Boost. Available online: https://bipvboost.eu/news-and-events/news/building-integrated-photovoltaics-bipv-status-report-2020/ (accessed on 24 January 2023).

- International Energy Agency. Innovation in Batteries and Electricity Storage, September 2020. Available online: https://iea.blob.core.windows.net/assets/77b25f20-397e-4c2f-8538-741734f6c5c3/battery_study_en.pdf (accessed on 1 March 2023).

- Lithium-Ion Battery Market for Stationary Applications—Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2020–2030. Transparency Market Research, May 2021. Available online: https://www.transparencymarketresearch.com/lithium-ion-battery-market-for-stationary-application.html (accessed on 1 March 2023).

- Townsend, A.; Gouws, R. A Comparative Review of Lead-Acid, Lithium-Ion and Ultra-Capacitor Technologies and Their Degradation Mechanisms. Energies 2022, 15, 4930. [Google Scholar] [CrossRef]

- Yudhistira, R.; Khatiwada, D.; Sanchez, F. A comparative life cycle assessment of lithium-ion and lead-acid batteries for grid energy storage. J. Clean. Prod. 2022, 358, 131999. [Google Scholar] [CrossRef]

- Institute of Electrical and Electronics Engineers. IEEE Standard for Interconnecting Distributed Resources with Electric Power Systems; IEEE: Piscataway, NJ, USA, 2003. [Google Scholar]

- Hyeon, L.J.; Yoon, Y.H.; Kim, J.M. Analysis of IEC 61727 Photovoltaic (PV) Systems Characteristics of the Utility Interface. Int. J. Internet Broadcast. Commun. 2015, 7, 90–95. [Google Scholar] [CrossRef]

- Turksoy, A.; Teke, A.; Alkaya, A. A comprehensive overview of the dc-dc converter-based battery charge balancing methods in electric vehicles. Renew. Sustain. Energy Rev. 2020, 133, 110274. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Ma, K.; Zhou, D. Power electronics and reliability in renewable energy systems. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics, Hangzhou, China, 28–31 May 2012; pp. 19–30. [Google Scholar] [CrossRef]

- Nandi, R.; Tripathy, M.; Gupta, C.P. Coordination of BESS and PV system with bidirectional power control strategy in AC microgrid. Sustain. Energy Grids Netw. 2023, 34, 101029. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, K.; Blaabjerg, F. Current Harmonics From Single-Phase Grid-Connected Inverters—Examination and Suppression. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 4, 221–233. [Google Scholar] [CrossRef]

- Zakzouk, N.E.; Abdelsalam, A.K.; Helal, A.A.; Williams, B.W. High Performance Single-Phase Single-Stage Grid-Tied PV Current Source Inverter Using Cascaded Harmonic Compensators. Energies 2020, 13, 380. [Google Scholar] [CrossRef]

- Chatterjee, A.; Mohanty, K.B. Current control strategies for single phase grid integrated inverters for photovoltaic applications-a review. Renew. Sustain. Energy Rev. 2018, 92, 554–569. [Google Scholar] [CrossRef]

- Rocabert, J.; Luna, A.; Blaabjerg, F.; Rodríguez, P. Control of Power Converters in AC Microgrids. IEEE Trans. Power Electron. 2012, 27, 4734–4749. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, B. Control of solar PV-integrated battery energy storage system for rural area application. IET Renew. Power Gener. 2021, 15, 1030–1045. [Google Scholar] [CrossRef]

- Erfani, M.J.; Thiringer, T.; Haghbin, S. Performance and losses analysis of charging and discharging mode of a bidirectional DC/DC fullbridge converter using PWM switching pattern. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Karanki, S.B.; Xu, D. Voltage droop control of dual active bridge for integrating battery energy storage to utility gird. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 15—18 September 2014; pp. 2227–2232. [Google Scholar] [CrossRef]

- Bakeer, A.; Chub, A.; Shen, Y.; Sangwongwanich, A. Reliability analysis of battery energy storage system for various stationary applications. J. Energy Storage 2022, 50, 104217. [Google Scholar] [CrossRef]

- Radionova, L.; Chernyshev, A. Mathematical Description of AFE Rectifier Closed Loop System. Procedia Eng. 2015, 129, 16–21. [Google Scholar] [CrossRef]

- Qian, K.; Gao, G.; Sheng, Z. A Maximum Current Control Method for Three-Phase PWM Rectifier for the ITER In-Vessel Vertical Stability Coil Power Supply. IEEE Trans. Plasma Sci. 2018, 46, 1689–1693. [Google Scholar] [CrossRef]

- Li, W.; Ruan, X.; Pan, D.; Wang, X. Full-Feedforward Schemes of Grid Voltages for a Three-Phase LCL-Type Grid-Connected Inverter. IEEE Trans. Ind. Electron. 2013, 60, 2237–2250. [Google Scholar] [CrossRef]

- Tao, Z.; Li, L. Control loop design and bidirectional control strategy of a bidirectional DC/DC converter. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 5720–5725. [Google Scholar] [CrossRef]

- AlZawaideh, A.; Boiko, I. Analysis of a Sliding Mode DC–DC Boost Converter through LPRS of a Nonlinear Plant. IEEE Trans. Power Electron. 2020, 35, 12321–12331. [Google Scholar] [CrossRef]

- Saldaña, G.; Martín, J.I.S.; Zamora, I.; Asensio, F.J.; Oñederra, O. Analysis of the Current Electric Battery Models for Electric Vehicle Simulation. Energies 2019, 12, 2750. [Google Scholar] [CrossRef]

- Rajanna, B.V.; Kumar, M.K. Chopper-Based Control Circuit for BESS Integration in Solar PV Grids. Energies 2021, 14, 1530. [Google Scholar] [CrossRef]

- Bae, J.-Y. Electrical Modeling and Impedance Spectra of Lithium-Ion Batteries and Supercapacitors. Batteries 2023, 9, 160. [Google Scholar] [CrossRef]

- MathWorks. Battery (Power System Toolbox); MathWorks: Natick, MA, USA, 2021; Available online: https://www.mathworks.com/help/sps/powersys/ref/battery.html (accessed on 12 March 2023).

- GopiReddy, L.R.; Tolbert, L.M.; Ozpineci, B. Power Cycle Testing of Power Switches: A Literature Survey. IEEE Trans. Power Electron. 2014, 30, 2465–2473. [Google Scholar] [CrossRef]

- Ivanovic, Z.; Blanusa, B.; Knezic, M. Power loss model for efficiency improvement of boost converter. In Proceedings of the 2011 XXIII International Symposium on Information, Communication and Automation Technologies, Sarajevo, Bosnia and Herzegovina, 27–29 October 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Torsaeter, B.N.; Tiwari, S.; Lund, R.; Midtgard, O.-M. Experimental evaluation of switching characteristics, switching losses and snubber design for a full SiC half-bridge power module. In Proceedings of the 2016 IEEE 7th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Vancouver, BC, Canada, 27–30 June 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Cree Inc. C3M0016120D Datasheet. Wolfspeed, December 2020. Available online: https://assets.wolfspeed.com/uploads/2020/12/C3M0016120D.pdf (accessed on 12 March 2023).

- Sintamarean, C.; Blaabjerg, F.; Wang, H. A novel electro-thermal model for wide bandgap semiconductor based devices. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–10. [Google Scholar] [CrossRef]

- Ye, Y.; Grossmann, I.E.; Pinto, J.M.; Ramaswamy, S. Modeling for reliability optimization of system design and maintenance based on Markov chain theory. Comput. Chem. Eng. 2019, 124, 381–404. [Google Scholar] [CrossRef]

- Aghdam, F.H.; Abapour, M. Reliability and Cost Analysis of Multistage Boost Converters Connected to PV Panels. IEEE J. Photovoltaics 2016, 6, 981–989. [Google Scholar] [CrossRef]

- USA Department of Defense. Military Handbook MIL HDBK 217F: Reliability Prediction of Electronic Equipment. Washington, USA, December 1991. Available online: http://snebulos.mit.edu/projects/reference/MIL-STD/MIL-HDBK-217F-Notice2.pdf (accessed on 12 March 2023).

- Hasan, M.; Jaman, S.; Geury, T.; Hegazy, O. Design and Simulation of a Grid-Connected Two-Stage Bidirectional Converter for a Combined PV-Stationary Energy Storage System. In Proceedings of the 2022 Second International Conference on Sustainable Mobility Applications, Renewables and Technology (SMART), Cassino, Italy, 23–25 November 2022; pp. 1–8. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Energy storage Battery capacity | 50 kWh | Filter Inductance (Grid Side) | 0.813 mH |

| Maximum Output Power | 10 kW | Filter Capacitance | 30 uF |

| Battery Nominal Voltage | 200 V | Filter Inductance (Converter Side) | 0.867 mH |

| Rated Capacity | 50 Ah | ESR+Damping resistance | 10 Ω |

| Charging/Discharging rate | 2 C | Output filter Inductance | 4.06 mH |

| Charge/discharge current at 1 C | 22 A | Output Filter Capacitance | 500 uF |

| Rated AC Input Voltage, frequency | 230 V, 50 Hz | Switching Frequency | 10 kHz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.M.; Jaman, S.; Geury, T.; Hegazy, O. Performance Assessment of a Grid-Connected Two-Stage Bidirectional Converter for a Combined PV–Battery Energy Storage System. Energies 2023, 16, 4486. https://doi.org/10.3390/en16114486

Hasan MM, Jaman S, Geury T, Hegazy O. Performance Assessment of a Grid-Connected Two-Stage Bidirectional Converter for a Combined PV–Battery Energy Storage System. Energies. 2023; 16(11):4486. https://doi.org/10.3390/en16114486

Chicago/Turabian StyleHasan, Md. Mahamudul, Shahid Jaman, Thomas Geury, and Omar Hegazy. 2023. "Performance Assessment of a Grid-Connected Two-Stage Bidirectional Converter for a Combined PV–Battery Energy Storage System" Energies 16, no. 11: 4486. https://doi.org/10.3390/en16114486

APA StyleHasan, M. M., Jaman, S., Geury, T., & Hegazy, O. (2023). Performance Assessment of a Grid-Connected Two-Stage Bidirectional Converter for a Combined PV–Battery Energy Storage System. Energies, 16(11), 4486. https://doi.org/10.3390/en16114486