Design and Implementation of Inductively Coupled Power and Data Transmission for Buoy Systems

Abstract

1. Introduction

- (1)

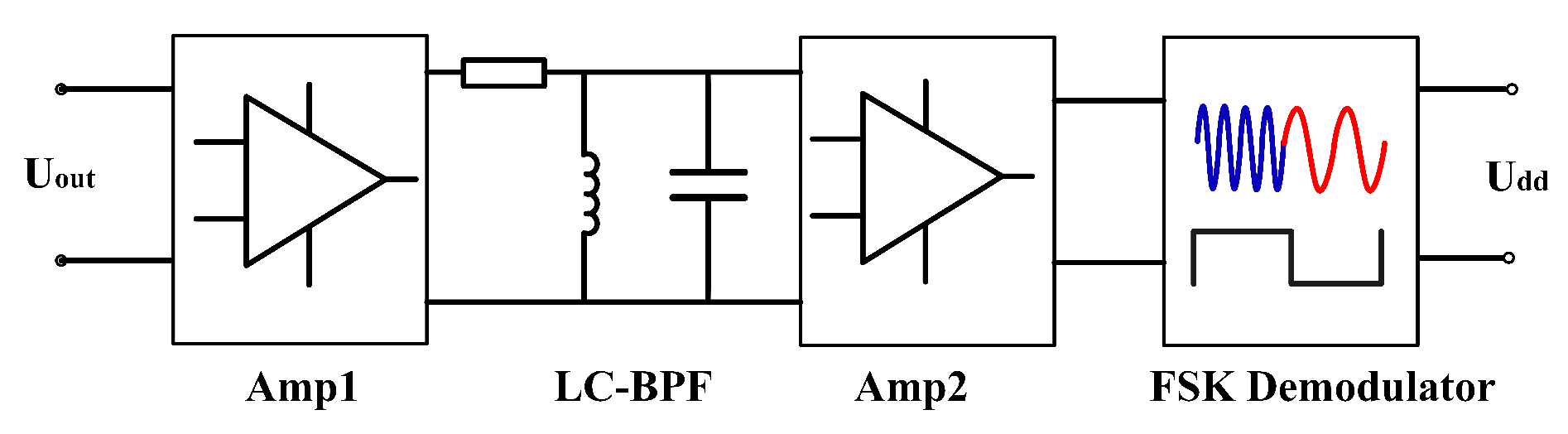

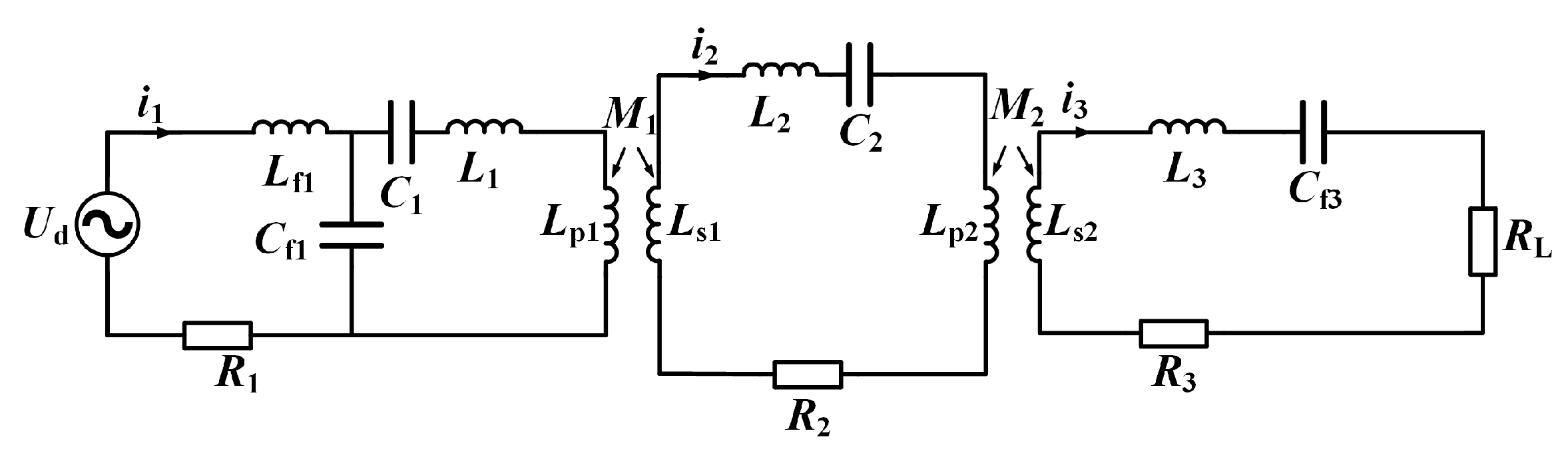

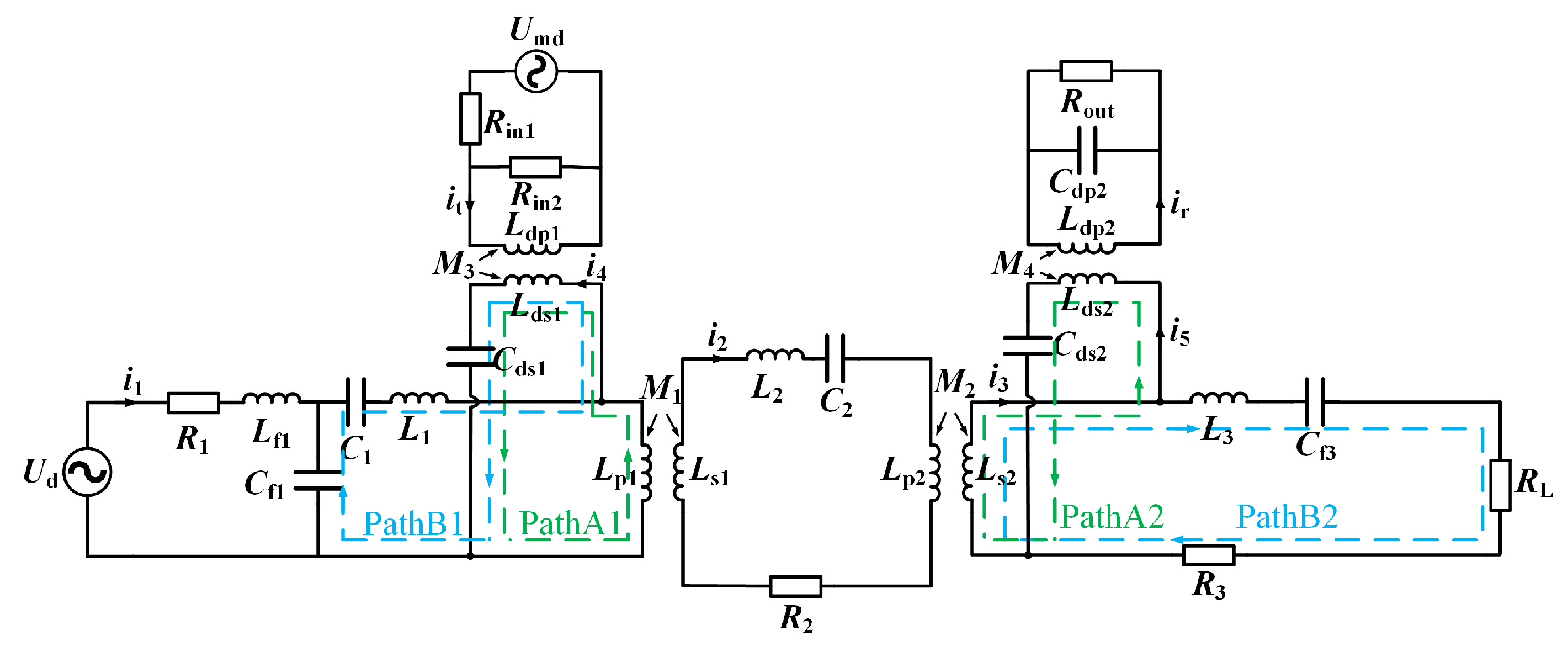

- The moored buoy ICPDT system model based on the LCCL-S-LC hybrid compensation was established and analyzed in detail, including the power and data transmission modules.

- (2)

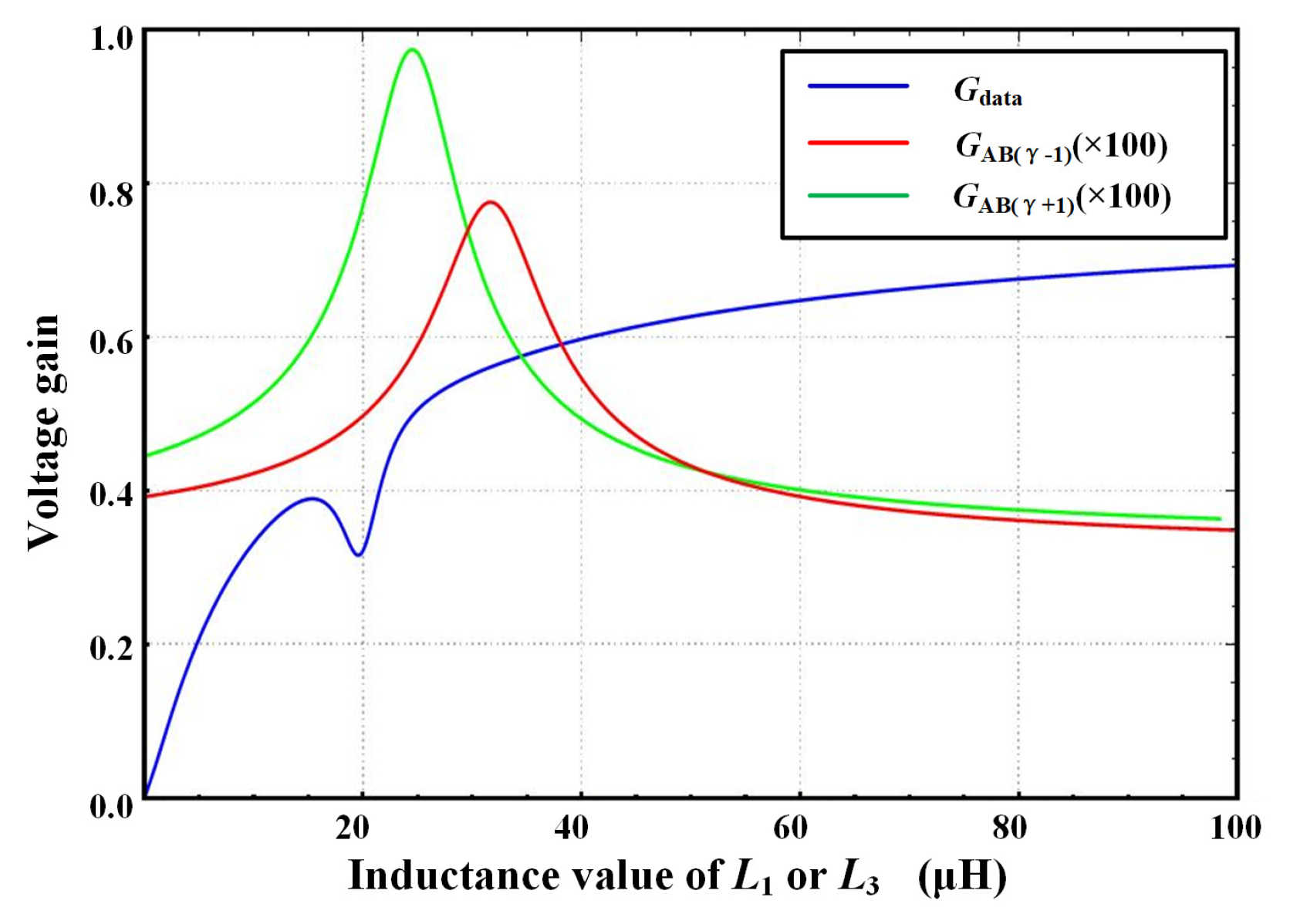

- The 2FSK modulation and demodulation technology was applied to the buoy data transmission. The demodulation circuit adopts an NE564 module with adjustable loop gain. A notch filter composed of L1/L3 was designed to reduce the interference between power and data transmission.

- (3)

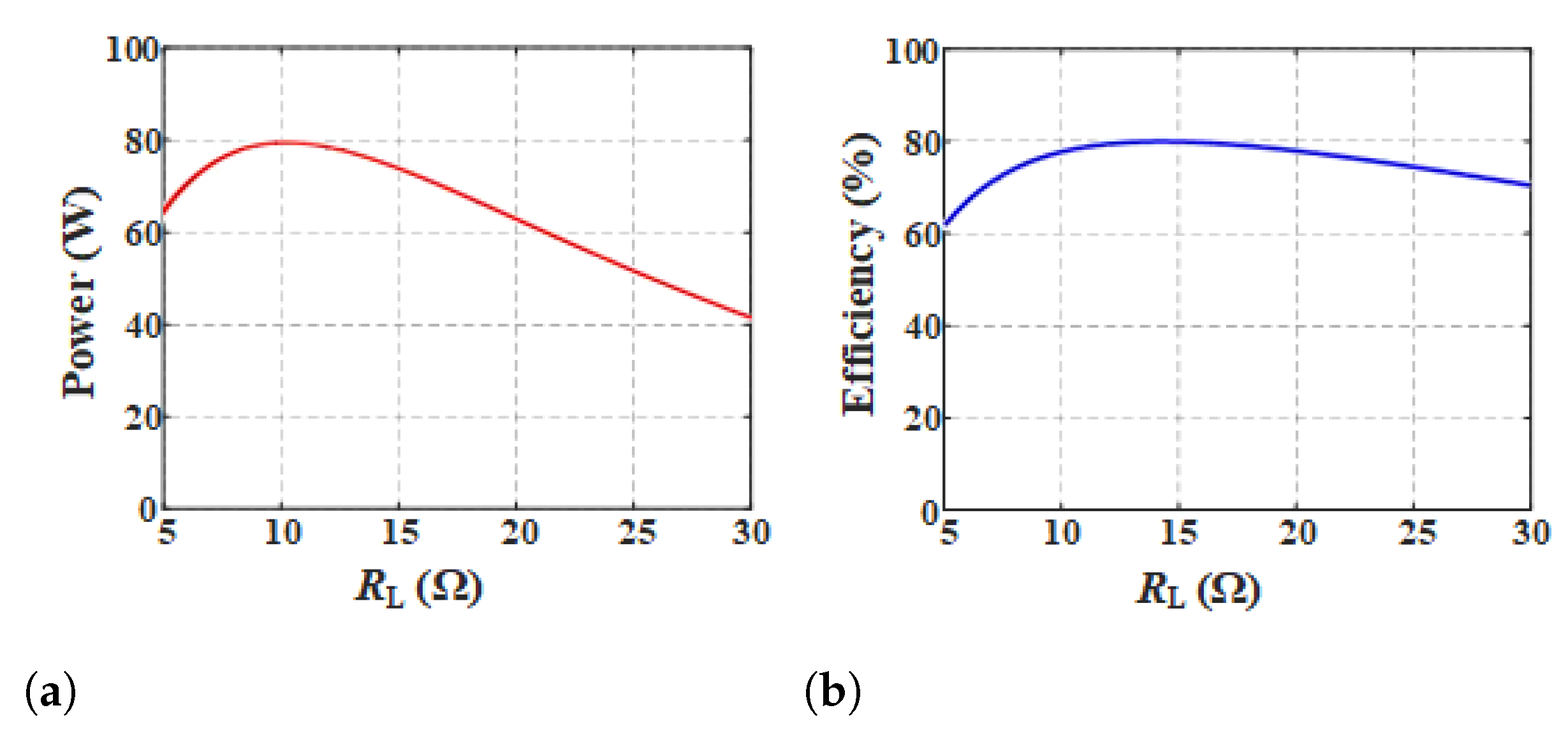

- The reliability of the proposed system was verified through experiments, where we observed that, at an output power of 61.5 W, the power efficiency was 78.1%. Additionally, the data receiving side successfully demodulated data at a rate of 100 kb/s.

2. System Modeling

2.1. System Structure

2.2. Power Transmission Analysis

2.3. Data Transmission Circuit Design and Analysis

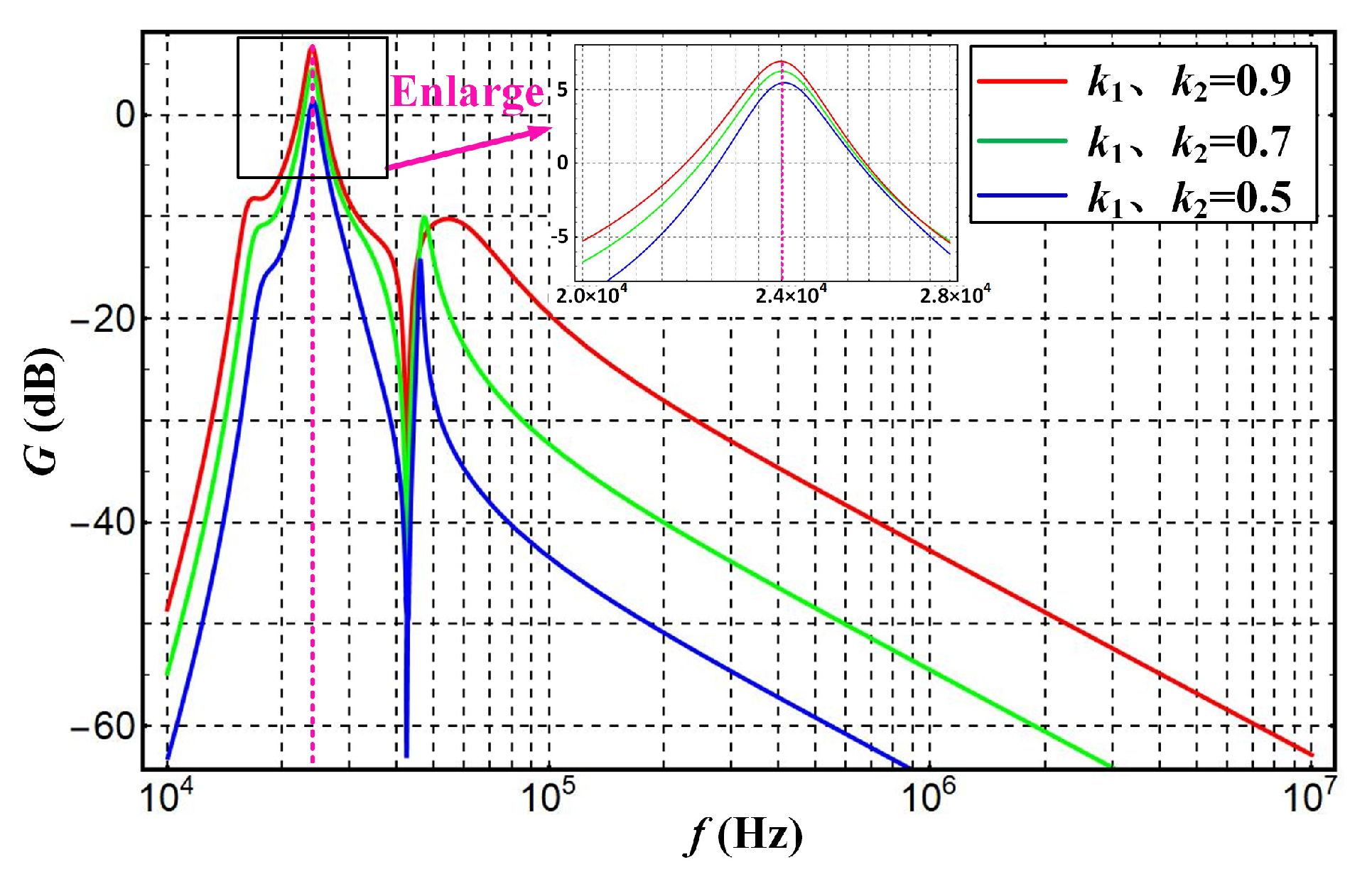

3. Crosstalk Analysis

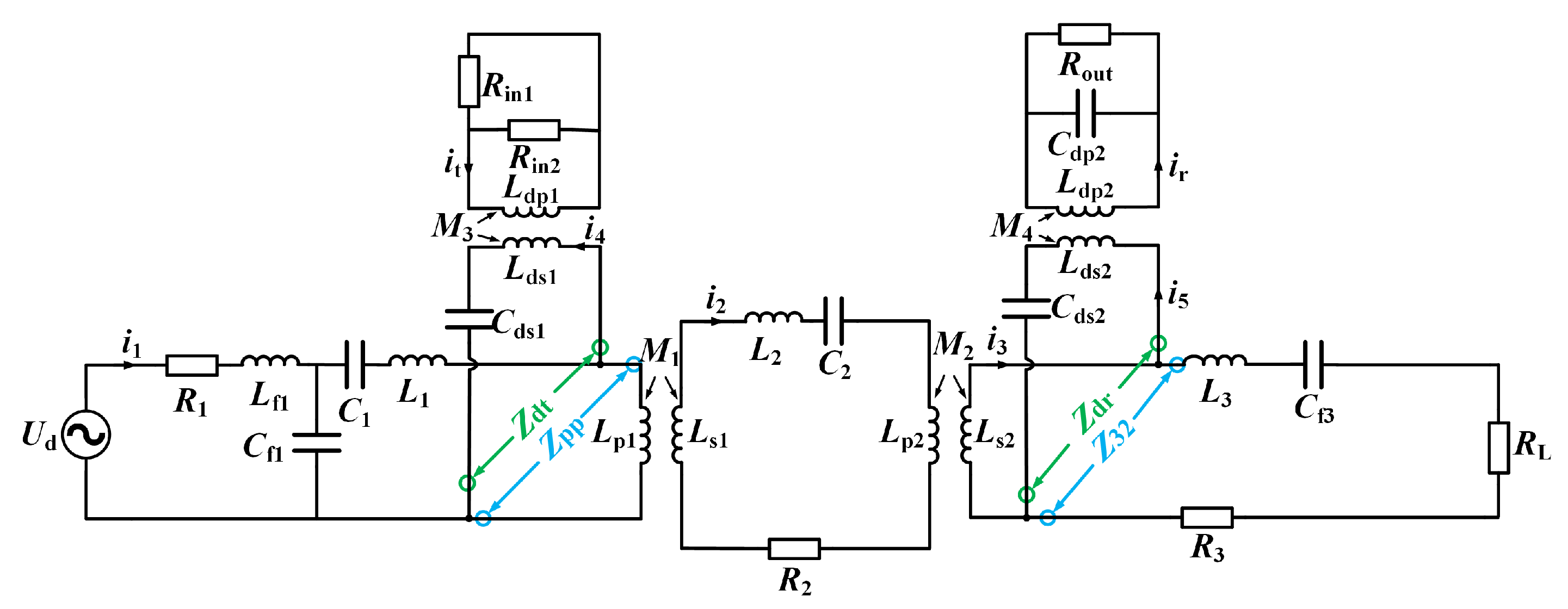

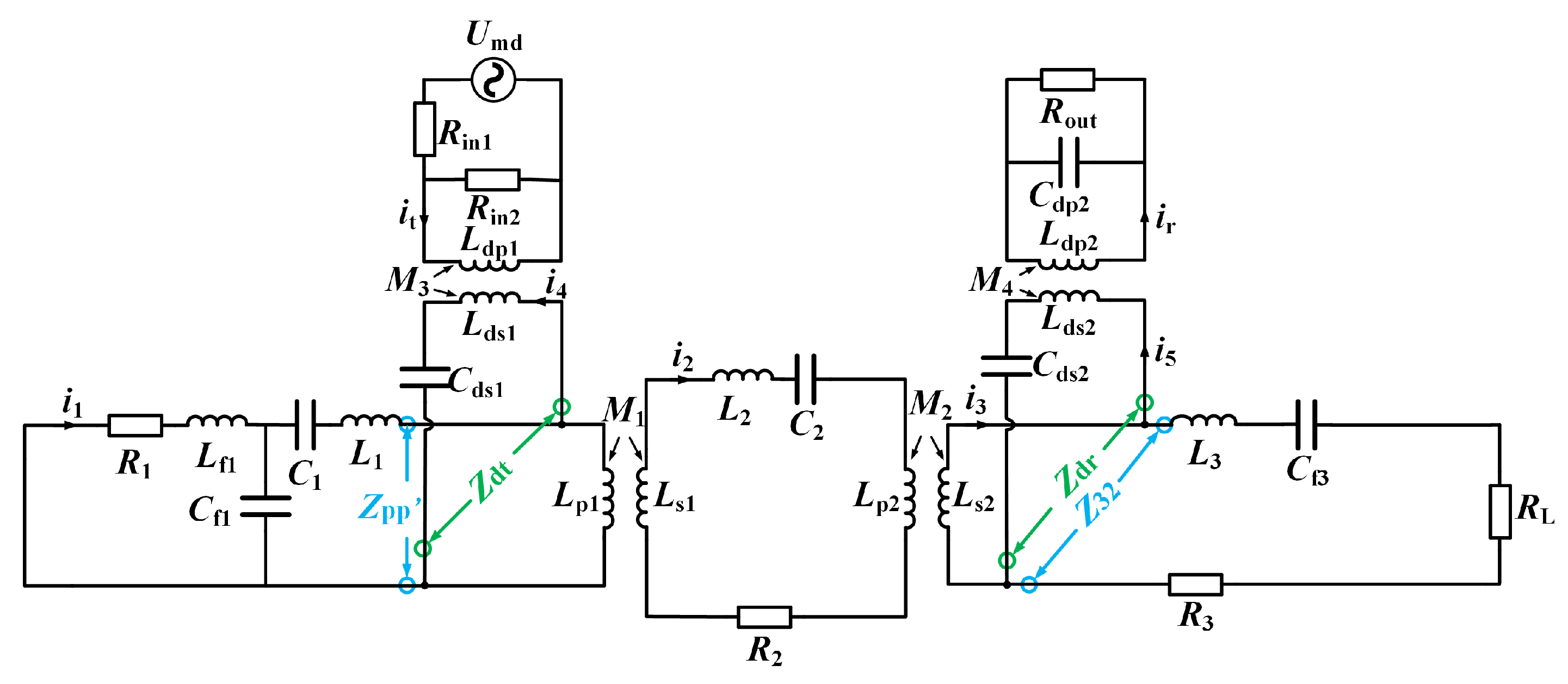

3.1. Data Transmission Interference with Power Transmission

3.2. Power Transmission Interference with Data Transmission

4. Experimental Verification

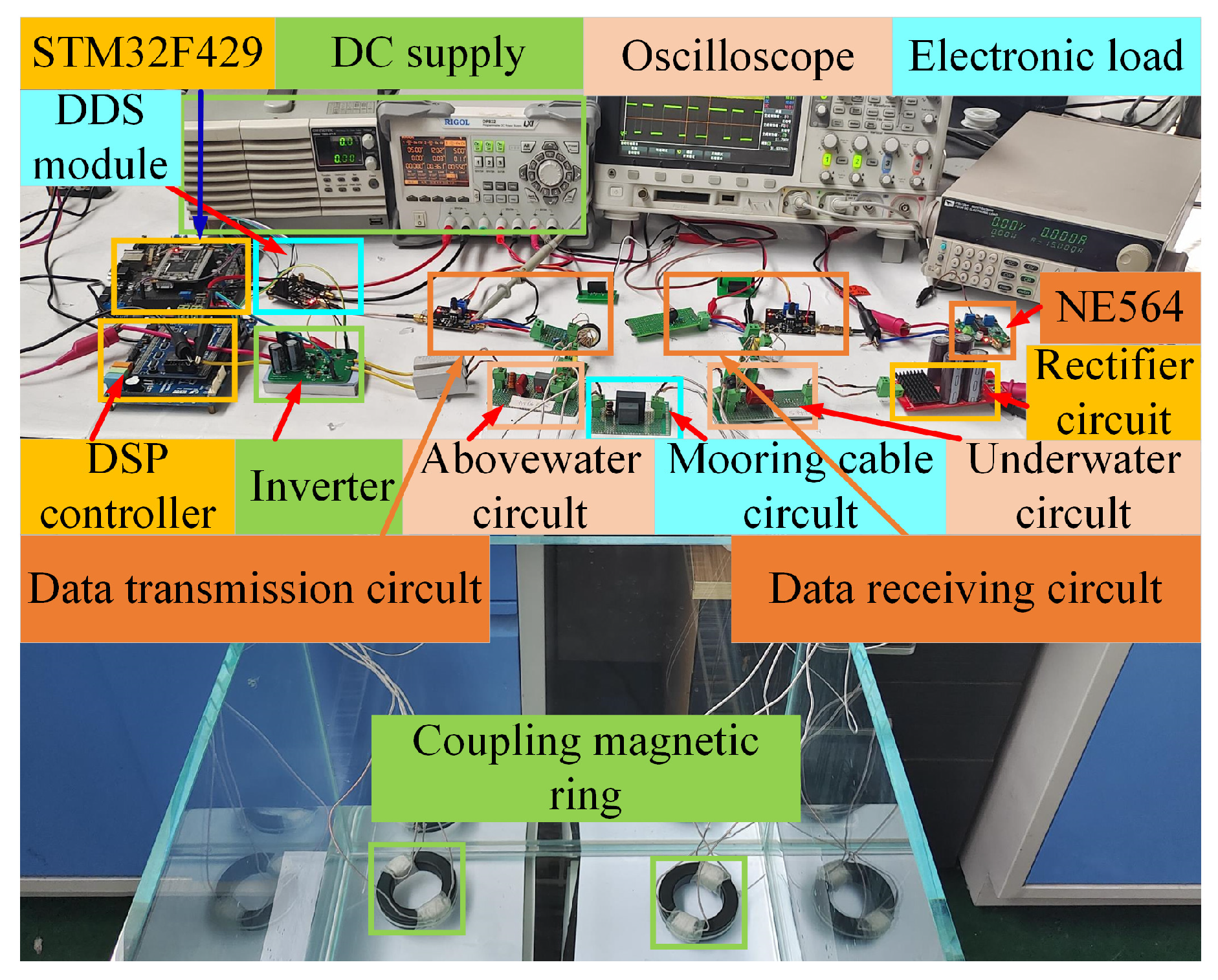

4.1. Experimental System Structure

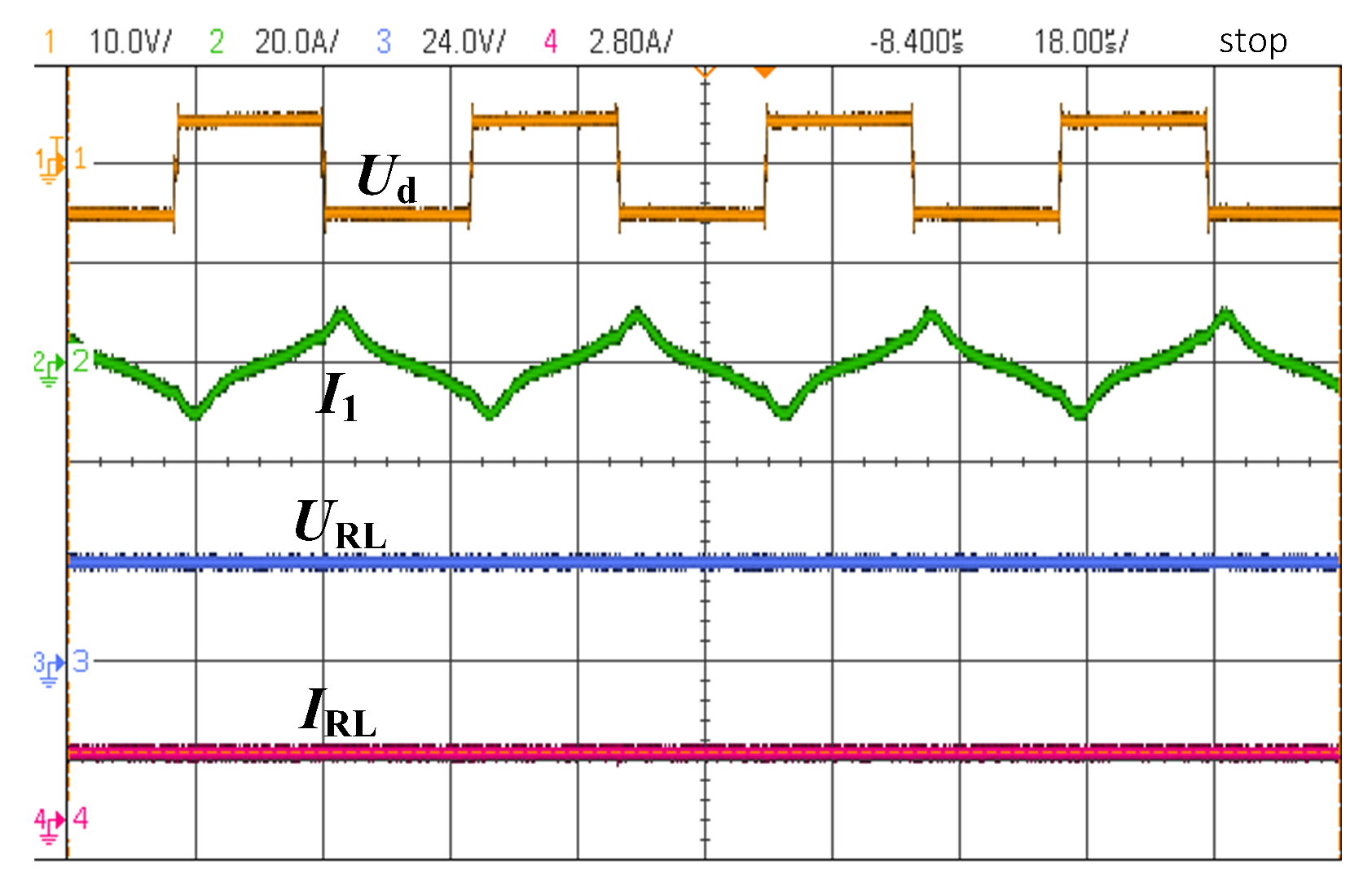

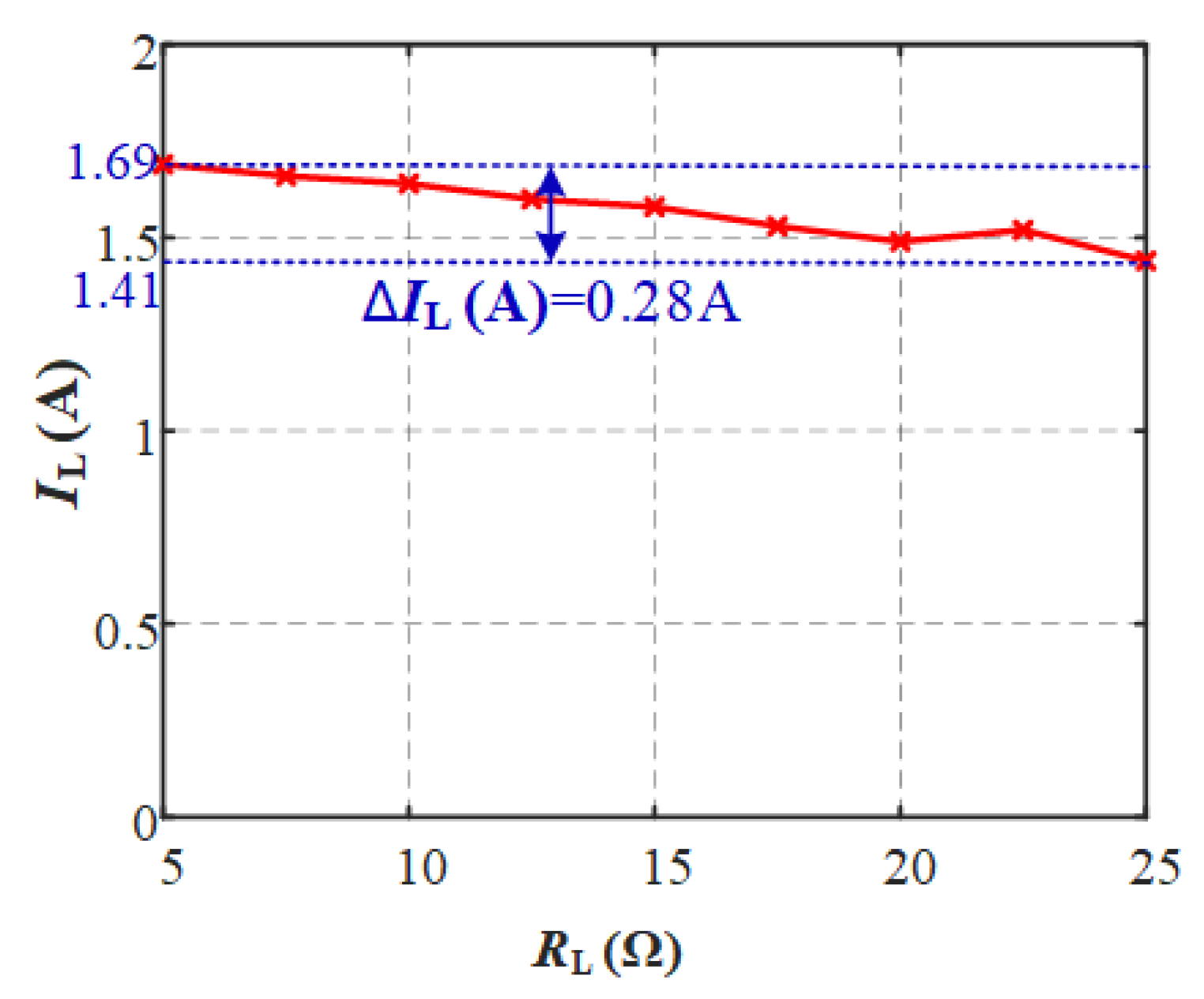

4.2. Experiment Results of Power and Data Transmission

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grosenbaugh, M.A.; Paul, W.; Frye, D.; Farr, N. Development of Synthetic Fiber-Reinforced Electro-Optical-Mechanical Cables for Use with Moored Buoy Observatories. IEEE J. Ocean. Eng. 2006, 31, 574–584. [Google Scholar] [CrossRef]

- Barrera, C.; Rueda, M.; Elgue, J.; Llinas, O. Red acomar: Coastal moored buoy network for real-time surveillance, control and observation in canary islands. In Proceedings of the OCEANS 2006, Boston, MA, USA, 18–21 September 2006; pp. 1–5. [Google Scholar]

- Xu, J.; Li, X.; Xie, Z.; Fu, C.; Du, R. Design and Analysis of Inductively Coupled Power Transfer System on Mooring Buoy with Double Ultracapacitor Chargers Using Indirect Control. IEEE Trans. Ind. Electron. 2020, 67, 4836–4845. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Li, H.; Xie, Z.; Ma, Q. Maximum Efficiency Tracking for Multitransmitter Multireceiver Wireless Power Transfer System on the Submerged Buoy. IEEE Trans. Ind. Electron. 2022, 69, 1909–1919. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Y.; Ding, L.; Wu, P. Underwater Wireless Charging and Communication Integrated System. In Proceedings of the OCEANS 2019, Marseille, France, 17–20 June 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Ahn, D.; Hong, S. Wireless Power Transmission with Self-Regulated Output Voltage for Biomedical Implant. IEEE Trans. Ind. Electron. 2014, 61, 2225–2235. [Google Scholar] [CrossRef]

- Cheng, Z.; Lei, Y.; Song, K.; Zhu, C. Design and Loss Analysis of Loosely Coupled Transformer for an Underwater High-Power Inductive Power Transfer System. IEEE Trans. Magn. 2015, 51, 8401110. [Google Scholar] [CrossRef]

- Yan, Z.; Song, B.; Zhang, Y.; Zhang, K.H.; Mao, Z.; Hu, Y. A Rotation-Free Wireless Power Transfer System with Stable Output Power and Efficiency for Autonomous Underwater Vehicles. IEEE Trans. Power Electron. 2019, 34, 4005–4008. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, A.; Yuan, H.; Zhao, C.; Chen, F.; Wang, X.; Rong, M. Efficiency optimization and power allocation of omnidirectional wireless power transfer for multiple receivers. IEEE Trans. Ind. Electron. 2023, 70, 9689–9699. [Google Scholar] [CrossRef]

- Yuan, H.; Liang, C.; Zhang, R.; Ruan, Z.; Zhou, Z.; Yang, A.; Wang, X.; Rong, M. A Novel Anti-Offset Interdigital Electrode Capacitive Coupler for Mobile Desktop Charging. IEEE Trans. Power Electron. 2023, 38, 4140–4151. [Google Scholar] [CrossRef]

- Pang, S.; Xu, J.; Li, H.; Ma, Q.; Li, X. Dual-Frequency Modulation to Achieve Power Independent Regulation for Dual-Load Underwater Wireless Power Connector. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 2377–2389. [Google Scholar] [CrossRef]

- Yan, Z.; Xiang, Z.; Wu, L.; Wang, B. Study of Wireless Power and Information Transmission Technology Based on the Triangular Current Waveform. IEEE Trans. Power Electron. 2018, 33, 1368–1377. [Google Scholar] [CrossRef]

- Yoshioka, D.; Sakamoto, H.; Ishihara, Y.; Matsumoto, T.; Timischl, F. Power Feeding and Data-Transmission System Using Magnetic Coupling for an Ocean Observation Mooring Buoy. IEEE Trans. Magn. 2007, 43, 2663–2665. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, G.; Yu, H.; Zhang, X. An anchor mooring profile monitoring buoy based on underwater non-contact wireless communication. In Proceedings of the OCEANS’10 IEEE SYDNEY, Sydney, Austrilia, 24–27 May 2010. [Google Scholar] [CrossRef]

- Kojiya, T.; Sato, F.; Matsuki, H.; Sato, T. Automatic power supply system to underwater vehicles utilizing non-contacting technology. In Proceedings of the Oceans ’04 MTS/IEEE Techno-Ocean ’04, Kobe, Japan, 9–12 November 2004. [Google Scholar] [CrossRef]

- Nakanishi, K.; Sasaki, M. Data transmission system using magnetic resonance wireless power transfer. In Proceedings of the 2017 IEEE Wireless Power Transfer Conference (WPTC), Taiwan, China, 10–12 May 2017. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, L.; Guo, Y.; Liao, C.; Li, F. Applying LCC Compensation Network to Dynamic Wireless EV Charging System. IEEE Trans. Ind. Electron. 2016, 63, 6557–6567. [Google Scholar] [CrossRef]

- Sun, Y.; Yan, P.-X.; Wang, Z.-H.; Luan, Y.-Y. The Parallel Transmission of Power and Data with the Shared Channel for an Inductive Power Transfer System. IEEE Trans. Power Electron. 2016, 31, 5495–5502. [Google Scholar] [CrossRef]

- Qiu, H.; Sakurai, T.; Takamiya, M. Coupling-Dependent Data Flipping in Wireless Power and Data Transfer System. In Proceedings of the 2019 IEEE International Symposium on Circuits and Systems (ISCAS), Sapporo, Japan, 26–29 May 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Son, Y.-H.; Jang, B.-J. Simultaneous data and power transmission in resonant wireless power system. In Proceedings of the 2013 Asia-Pacific Microwave Conference Proceedings (APMC), Seoul, Republic of Korea, 5–8 November 2013; pp. 1003–1005. [Google Scholar] [CrossRef]

- Liu, J.-Y.; Tang, K.-T. A novel wireless power and data transmission ac to dc converter for an implantable device. In Proceedings of the 2013 35th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Osaka, Japan, 3–7 July 2013; pp. 1875–1878. [Google Scholar]

- Wu, J.; Zhao, C.; Lin, Z.; Du, J.; Hu, Y.; He, X. Wireless Power and Data Transfer via a Common Inductive Link Using Frequency Division Multiplexing. IEEE Trans. Ind. Electron. 2015, 62, 7810–7820. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.; Guan, Y.; Liu, X.; Liu, M.; Xu, D. A novel modulation and demodulation method for wireless power and data transmission. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A Double-Sided LCC Compensation Network and Its Tuning Method for Wireless Power Transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Y.; Liu, X.; Cheng, H.; Liu, M.; Xu, D. Analysis, Design, and Implementation of a Wireless Power and Data Transmission System Using Capacitive Coupling and Double-Sided LCC Compensation Topology. IEEE Trans. Ind. Appl. 2019, 55, 541–551. [Google Scholar] [CrossRef]

- Zhigang, H.; Shen, Z.; Jian, C.; Chunjie, Q. A research on the non-coherent demodulation method of the underwater 2FSK signal. In Proceedings of the IEEE 2011 10th International Conference on Electronic Measurement & Instruments, Chengdu, China, 16–19 August 2011; Volume 3, pp. 185–188. [Google Scholar]

- Ishii, M.; Yamanaka, K.; Sasaki, M. Multiple FSK Data and Power Transmission System using Magnetic Resonance Wireless Power Transfer. In Proceedings of the 2019 IEEE Wireless Power Transfer Conference (WPTC), London, UK, 18–21 June 2019; pp. 208–211. [Google Scholar] [CrossRef]

- Fu, C. Research on Inductively Coupled Power and Data Transmission Based Anchored Buoy; Tianjin University: Tianjin, China, 2019; pp. 1–72. [Google Scholar]

- Lang, Z.; Li, X.; Xu, J.; Xie, Z.; Li, H. An Inductively Coupled Power and Data Transfer System Based on Three-Coil Coupled Structure Used for Mooring Buoy; Tianjin University: Tianjin, China, 2022; pp. 7–15. [Google Scholar]

- Barmada, S.; Dionigi, M.; Tucci, M.; Mezzanotte, P. Design and experimental characterization of a combined WPT-PLC system. Wirel. Power Transf. 2017, 4, 160–170. [Google Scholar] [CrossRef]

- Barmada, S.; Dghais, W.; Fontana, N.; Raugi, M.; Tucci, M. Design and realization of a multiple access wireless power transfer system for optimal power line communication data transfer. Energies 2019, 12, 988. [Google Scholar] [CrossRef]

- Hatanaka, K.; Sato, F.; Matsuki, H.; Kikuchi, S.; Murakami, J.; Kawase, M.; Satoh, T. Power transmission of a desk with a cord-free power supply. IEEE Trans. Magn. 2002, 38, 3329–3331. [Google Scholar] [CrossRef]

- Yang, L.; Huang, J.; Feng, B.; Zhang, F.; Zhang, Y. Undersea Wireless Power and Data Transfer System with Shared Channel Powered by Marine Renewable Energy System. IEEE J. Emerg. Sel. Top. Circuits Syst. 2022, 12, 242–250. [Google Scholar] [CrossRef]

| Symbol | Simulation Value | Experimental Value | Symbol | Simulation Value | Experimental Value |

|---|---|---|---|---|---|

| 24 V | 24 V | 10 H | 10.2 H | ||

| 5 V | 5 V | 115 H | 115.3 H | ||

| 24 kHz | 24 kHz | 115 H | 114.8 H | ||

| 1.3/2 MHz | 1.3/2 MHz | 356 nF | 356.0 nF | ||

| ,, | 0.2 | 0.24 | , | 0.9 | 0.9 |

| 133 H | 133.1 H | 15 | 15 | ||

| 330 nF | 330.5 nF | , | 2.5 nF | 2.5 nF | |

| 170 nF | 170.2 nF | , , , | 4.4 H | 4.4 H | |

| , | 1∼100 H | 13 H | , | 0.95 | 0.95 |

| 114 H | 114.5 H | , | 200 | 200 | |

| 115 H | 115.6 H | 2.5 nF | 2.5 nF | ||

| 183 nF | 183.9 nF | 200 | 200 |

| Symbol | Value in Air | Value in Seawater |

|---|---|---|

| 114.8 H | 114.5 H | |

| 115.1 H | 115.6 H | |

| 109.2 H | 109.3 H | |

| 114.7 H | 115.3 H | |

| 115.3 H | 114.8 H | |

| 109.3 H | 109.3 H |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, X.; Xu, J.; Pang, S.; Li, X.; Li, H. Design and Implementation of Inductively Coupled Power and Data Transmission for Buoy Systems. Energies 2023, 16, 4417. https://doi.org/10.3390/en16114417

Cui X, Xu J, Pang S, Li X, Li H. Design and Implementation of Inductively Coupled Power and Data Transmission for Buoy Systems. Energies. 2023; 16(11):4417. https://doi.org/10.3390/en16114417

Chicago/Turabian StyleCui, Xiangbiao, Jiayi Xu, Shui Pang, Xingfei Li, and Hongyu Li. 2023. "Design and Implementation of Inductively Coupled Power and Data Transmission for Buoy Systems" Energies 16, no. 11: 4417. https://doi.org/10.3390/en16114417

APA StyleCui, X., Xu, J., Pang, S., Li, X., & Li, H. (2023). Design and Implementation of Inductively Coupled Power and Data Transmission for Buoy Systems. Energies, 16(11), 4417. https://doi.org/10.3390/en16114417