Abstract

Improvement of the energy efficiency of buildings contributes to energy savings. It is obvious that thermal modernization of a building reduces the demand for energy needed to heat it. The energy demand itself also depends significantly on the temperature maintained inside the building. The article proposes a methodology for determining the economic and ecological benefits of thermal insulation of a building and the optimal thickness of thermal insulation depending on the pre-set temperature. The analysis includes various types of heat sources and materials used for thermal insulation. A range of pre-set air temperature values in residential premises from 17 °C to 26 °C was analysed. Determining the optimal thickness of the external walls, in accordance with the preferences of building users, even at the level of designing the thermal insulation of the building, is of significant importance for economic and ecological benefits. The optimum thickness of thermal insulation in the case of the ecological assessment was much higher in each variant than in the case of the economic assessment.

1. Introduction

The global economic crisis but also the high pressure on the environment of the construction sector focuses the attention of decision makers and scientists on the opportunities related to improving the energy efficiency of buildings. The global constantly growing human population and its housing needs and demand for energy to heat or cool residential premises is associated with increased energy expenditure. It is widely believed that improving energy efficiency contributes to energy savings. The energy saved is the kind of “fuel” that can be used for other purposes or for housing purposes in new buildings. Reducing the environmental pressure of the construction sector can also be achieved by increasing the production of energy from renewable sources [1]. The reason why the construction sector is of interest is the fact that this sector generates nearly 40% of greenhouse gas emissions [2]. Secondly, it is the high energy consumption required to cool and heat (due to imperfect insulation of building walls) that contributes over 70% of energy consumption in the building’s life cycle [3]. The problem of the high energy demand of buildings to heat and cool them mainly affects older buildings. The pace of thermal modernization of the world’s building resources is unfortunately not high and reaches about 0.5–1% per year [4]. In the European Union, the annual energy renovation rate is similar to the global one and amounts to 1%; however, thorough renovation of existing resources in Europe is carried out at the level of 0.2% per year [5]. The strategy for renovation entitled “The renovation wave for Europe—greening buildings, creating jobs, improving the quality of life” published by the European Commission states that in order to achieve the target of reducing greenhouse gas emissions by 55% by 2030 compared with 1990, it is necessary to reduce greenhouse gas emissions from buildings by as much as 60%, their final energy consumption by 14% and energy consumption to heat and cool by 18%. The strategy aims to at least double the annual energy renovation rate of residential and non-residential buildings by 2030 and to support deep energy renovations. The mobilization of forces at all levels to achieve these goals will lead to the renovation of 35 million building modules by 2030. The European Union’s other documents also refer to improving energy efficiency, such as the directive on the energy performance of buildings (Directive of the European Parliament and of the Council 2018/844), along with the energy efficiency directive (Directive of the European Parliament and of the Council 2018/2002). On the basis of the above, the issue of the energy renovation of the existing housing stock is a priority in the European Union.

It is obvious that the thermal modernization of buildings will contribute to reducing the demand for energy in winter. However, as noted by Nowak-Dzieszko and Rojewska-Warchał [6], the average value and amplitude of internal temperature fluctuations will increase in summer. An increase in the internal temperature may result in the increase in the energy consumption to cool the premises. In the context of the sustainable development paradigm, it is necessary to look for such solutions in the construction and installation of buildings that will contribute to reducing the pressure on the environment from the construction sector, both during the heating and cooling seasons.

It is less obvious that investments in reducing the energy demand of a building will generate economic and ecological benefits. However, it is widely recognized that thermal insulation investments generate economic benefits, but this is determined by variables such as: the cost of heat generation, the cost of thermal insulation material, the cost of labour, external and internal temperature, etc.

The scientific aim of this article is to determine the economic (NPV) and ecological (NPVE) benefits resulting from the thermal insulation of vertical, non-transparent building walls based on the optimal (economically and ecologically) thickness of thermal insulation. An additional element of the analysis is the consideration of different temperature values (17 °C–26 °C) maintained in the dwelling, which is particularly important in the current energy crisis. The further part of the article presents a review of the literature (in Section 2), mainly related to two aspects: the first concerns the methodology of the energy, economic and ecological optimization of the building, and the second the amplitude of the actual temperatures maintained by owners of residential premises in relation to the calculation temperature resulting from the methodology of determining the demand for energy. Section 3 proposes a methodology to determine the economic and ecological benefits of the thermal insulation of the building external walls depending on the temperature maintained in the dwelling. Section 4 is devoted to the analysis of the case study for the selected building in accordance with the methodology introduced in Section 3. Finally, the results obtained are discussed (Section 5), and the conclusions of the research are presented in Section 6.

Most scientific articles base their analyses on the calculated value of temperature, this is of course some kind of assumption that is justified. However, in reality, temperatures in residential premises differ significantly from this calculation temperature (20 °C). This approach to take into account a wide range of temperatures in determining the demand for thermal energy is an innovative approach in this article. The results of the economic and ecological evaluation of the building’s thermal modernization provide important information for individual investors as to what optimal thickness of thermal insulation should be used on vertical external walls in the context of the preferred temperature level maintained in residential premises.

2. Literature Review

The literature on the subject is dominated by economic assessments of the thermal modernization projects of buildings that do not take into account ecological aspects. The economic aspect is often combined with the energy aspect, but the assessment of the energy aspect is somehow the result of carrying out activities related to thermo-modernization. It can be unequivocally stated that it is not possible to carry out an economic assessment of the building’s thermal modernization without an energy assessment of the building.

Zhang et al. [3], while optimizing the economic thickness of thermal insulation, identified a similar problem as Nowak-Dzieszko and Rojewska-Warchał [6], namely that with the increase in the thickness of the insulation layer of building walls, the annual demand for energy to heat decreases but the demand for energy to cool slightly increases. Zhang et al. [3] conducted research using DeST (Designer’s Simulation Toolkit) to simulate the energy demand of a university building in Chengdu, China. The analysed building is a six-storey building with a frame structure, with a total built-up area of approx. 7500 m2. The building was situated in a mild climate and the average outside temperature ranged from −2 °C–28 °C. The heating in the building was carried out using electricity. In the article, the authors took into account five types of thermal insulation, for which they determined the economically optimal thickness of the thermal insulation for the heating and cooling seasons. Due to the mild climate, the authors obtained the following results regarding the economically optimal thickness of the thermal insulation: phenolic foam—15 mm, polyurethane foam—20 mm, polystyrene foam—35 mm, glass wool—35 mm, perlite cement—40 mm. In the article, the authors also referred symbolically to the impact of the analysed thermal insulation materials on the environment, assigning them a letter designation from A to E: the letter A signifies the material with the lowest impact, whereas the letter E indicates that the impact on the environment is the biggest. As a result of thermal insulation, the studies indicated energy savings to heat in the amount of 25.34% of the total cost per unit area. According to the authors of the study, they used a Life Cycle Cost Assessment (LCC) analysis of this building. However, the LCA (Life Cycle Assessment) analysis, from which the LCC analysis is derived, also takes into account the cost of disassembly and disposal of the thermal insulation material. This type of cost was not included in the LCC analysis.

In his article, Nasrollahzadeh [7] presented an analysis of the building outer walls in terms of energy demand, access of daylight to the rooms (transparent walls) and thermal comfort. He also noticed that the most frequently used method in single-objective optimization studies was the genetic algorithm. Genetic algorithms (GA) are artificial intelligence methods along with artificial neural networks (ANN), case-based reasoning (CBR) and hybrid systems [8].

The method of optimizing external walls using a genetic algorithm was also used by Kalinovi et al. [8]. Multilayer walls (three types) and the selection of materials used (thickness, type, price) for the construction of these walls were optimized. The goal was to obtain low construction costs for the building and the thermal comfort of users. The discussed article is interesting because the type of materials used to build the wall does not change, the optimization takes place in terms of the thickness of these materials. The most optimal choice (from the three considered wall cases) turned out to be variant three: longitudinal lime mortar—0.02 m, concrete—0.172 m, mineral wool—0.15 m, air—0.039 m, synthetics multilayer polyester board—0.104 m. The presented analysis of the optimization of external walls is a typical energy and economic analysis.

Calculations of the demand for thermal energy for a building in Poland are carried out for a designated internal temperature of 20 °C (in accordance with [9]). However, it is the user who decides on the value of the temperature maintained in rooms during use. An example of a deviation from this value (20 °C) are, for example, experimental studies conducted by Basińska and Koczyk [10]. In this study, internal temperature measurement was evaluated in four rooms, including a bathroom. In these rooms, the temperature ranged between 16.0 (min) and 23.5 °C (max.) in the winter (heating) season, whereas in the bathroom the difference in the measured temperatures was between 20.9 °C (min) and 29.2 °C (max.).

Another example of a high amplitude for the internal temperatures maintained in rooms are the studies by Adamczyk et al. [11], where the average values of temperatures inside residential premises were assumed based on the [12]. Five user profiles were included in the research. Profile 1, for which the average temperature in the rooms was 17 °C, up to profile 5, for which the temperature was 23 °C. In this case, the temperature amplitude is 6 °C and indicates various behaviours of the users of residential premises that deviate from the assumed calculation temperature (20 °C).

Szulgowska-Zgrzywa et al. [13] analysed 15 residential premises in which they measured the internal temperature during a period of two months (from 14 January to 9 March 2020—heating period), where they observed a large temperature amplitude from approx. 13.5 °C to approx. 23.0 °C.

The report [14] presents the results of research using the method of online interviews (CAWI) with flat owners who declared that during the heating season they would like to keep the temperature inside the rooms at a level from less than 18 °C to more than 27 °C. The largest number of respondents declared that they would like to keep the temperature in the rooms at 21 °C–23 °C. Among the respondents there were also users who declared this highest temperature value (>27 °C).

The literature review concerns two aspects, the first concerns the identification of the methodology for energy, economic and ecological optimization of the building, the second concerns the identification of the amplitude of the actual temperatures maintained by the owners of residential premises in relation to the calculation temperature resulting from the methodology to determine the energy demand. Energy optimization of the building (in terms of thermal modernization) is most often performed based on the assumed temperature in the rooms (20 °C). The determined value of energy demand may differ significantly from the actual one due to the fact that the owner maintains different temperatures inside the dwelling. This study is particularly important for users of residential premises due to the current energy crisis and the resulting economic consequences for the user.

Future research should be directed towards the implementation of the theory of ecological economics in the construction sector. This article is an example of implementing this theory in practice.

3. Methodology of Economic and Ecological Evaluation of Thermal Insulation in Relation to the Pre-Set Temperature Value in the Dwelling

In order to conduct an economic and ecological analysis of the thermal insulation investment, taking into account the value of the temperature in the dwelling, we first define the economic and ecological costs of heating depending on the value of this temperature. This idea is a generalization of the idea from [15].

3.1. Economic and Ecological Heating Costs Depending on the Value of the Temperature Maintained in the Dwelling

The annual economic cost of heating G0 (Tb) depending on the temperature in the dwelling Tb, referred to 1 m2 of the area of the considered external wall, must meet the following condition (see [16]):

G0 (Tb) × (U0 − Un) × p = Kc × (DUo (Tb) − DUn (Tb)) × pu [PLN/year].

Hence (1 EUR ≈ 4.70 PLN; 1 USD ≈ 4.20 PLN),

where:

G0 (Tb) = (DUo (Tb) − DUn (Tb))/(U0 − Un) × (pu/p) × Kc [(PLN∙K)/(W∙year)],

U0—heat transfer coefficient of the wall without a thermal insulation layer (W/m2K);

Un = 0.20 (W/m2K), the value of the heat transfer coefficient of a wall with a thermal insulation layer required from 2021 (according to [17]);

DU (Tb)—annual demand for energy to heat per 1 m2 of the building’s usable area, with the heat transfer coefficient U (kWh/m2year), (respectively DUo at U0 and DUn at Un), for the temperature in the dwelling Tb;

pu—usable area of the building (m2);

p—area of vertical external walls (m2);

Kc—cost of heat generation for a particular heat source and fuel (PLN/kWh), taking into account generation efficiency.

Similarly to the economic analysis, the ecological analysis first determines the annual ecological heating costs GE (Tb) depending on the temperature in the dwelling Tb. These costs must meet the following condition:

GE (Tb) × (U0 − Un) × p = Ke × (DUo (Tb) − DUn (Tb)) × pu [Pt/year].

From condition (3) we obtain:

where:

GE (Tb) = (DUo (Tb) − DUn (Tb))/(U0 − Un) × (pu/p) × Ke [(Pt∙K)/(W∙year)],

Ke—the result of the LCA analysis of obtaining 1kWh of heat energy for a particular heat source and fuel (Pt/kWh);

The rest—as before.

3.2. Economic and Ecological Analysis of Thermal Insulation Investment

Knowing the costs G0 (Tb), it is possible to assess the profitability of the thermal insulation investment for economic reasons. For this, the economic net present value NPV of the investment can be used, depending on the temperature in the dwelling Tb in relation to 1 m2 of the wall surface:

where:

NPV (Tb) = −(Km × d + Kw) + SN × G0 (Tb) × (U0 − U) [PLN/m2],

Km—cost of 1 m3 of thermal insulation material (PLN/m3);

Kw—cost of thermal insulation for 1 m2 of the surface of the building wall (PLN/m2);

d—thickness of the thermal insulation layer (m);

—cumulative discount factor;

N—number of years of use for the thermal insulation;

r—real annual interest rate;

s—real annual increase (in percent) of heating costs;

G0 (Tb)—annual economic cost of heating (according to Equation (2));

U—heat transfer coefficient of a wall with a thermal insulation layer (W/m2K),

- wherein:

1/U = 1/U0 + d/λ,

λ—thermal conductivity coefficient of the thermal insulation material (W/mK);

The rest—as before.

For the assessment of a thermal insulation investment for ecological reasons, we introduce the ecological net present value NPVE of the investment, depending on the temperature in the dwelling Tb and in relation to 1 m2 of the wall surface:

where:

NPVE (Tb) = −Kl × d + N × GE (Tb) × (U0 − U) [Pt/m2],

Kl—result of LCA analysis for 1 m3 of thermal insulation material (Pt/m3);

GE (Tb)—annual ecological cost of heating (according to Equation (4));

The rest—as before.

3.3. Optimal Thicknesses of Thermal Insulation

The NPV (Tb) indicator can be considered as a function of U. This function is strictly concave and bounded from above. Thus, based on Equation (5), it is possible to determine for which value of the U factor the NPV (Tb) indicator reaches its maximum value. For this purpose, it is necessary to determine the derivative of NPV (Tb) with respect to U and determine for what value of U this derivative is equal to 0. Let us denote this value by Uopt (Tb):

Uopt (Tb) = (λ × Km/(G0 (Tb) × SN))1/2 [W/m2K].

Consequently, with Equation (6), the optimal thickness of the thermal insulation layer for economic reasons corresponding to Uopt (Tb), is:

dopt (Tb) = λ × (1/Uopt (Tb) − 1/U0) [m].

Similarly, the ecological net present value of NPVE (Tb) can be thought of as a function of U, and it is strictly concave and bounded from above. Its maximum value can be determined with respect to U. Let us denote this value by UEopt (Tb):

UEopt (Tb) = (λ × Kl/(GE (Tb) × N))1/2 [W/m2K].

Consequently, the optimal thickness of the thermal insulation layer for ecological reasons, corresponding to UEopt (Tb), is:

dEopt (Tb) = λ × (1/UEopt (Tb) − 1/U0) [m].

4. Case Study for the Selected Building

A single-family building, typical of Polish conditions, with a usable area of pu = 139.9 m2 and a volume of 483 m3 was selected for the analysis [18]. It is a house in brick technology with a gable roof. The walls are made of cellular concrete blocks covered with mineral plaster and a wooden roof is insulated with mineral wool covered with sheet metal (U = 0.30 W/m2K). On the ground floor there are a living room, a room, a kitchen, a vestibule, a hall and a bathroom. Usable attic: three rooms, a hall, a bathroom and a utility room. The building was founded in the Polish climatic zone II (according to [9]) and in accordance with the Kȍppen-Geiger—Dfb [19] classification. The building was built in 1995 in accordance with the then applicable regulations; the heat transfer coefficient of external vertical walls is U0 = 0.52 W/m2K (and is lower than U0 = 0.55 W/m2K) [11]. The area of the vertical external walls is p = 194.7 m2.

4.1. Summary of Important Building Parameters, Data on Heat Sources and Thermal Insulation Materials

The necessary data on the considered heat sources is listed in Table 1. Three types of heat sources used in Poland were taken into account: S1—coal-fired boiler, S2—oil condensing boiler and S3—gas condensing boiler. Boiler efficiencies were: S1—85%, S2—90% and S3—90%. The calculations include a coal-fired boiler due to the high popularity of this heat source in Poland, despite the implementation of programs aimed at eliminating this source from use. The analysis of the costs of gaseous fuel did not take into account the fixed costs—the subscription fee. In Poland, the subscription fee is PLN 7.75/month and is not significant in the context of fees for the use of gas to heat. In addition, a popular solution is the use of natural gas for the needs of preparing meals if this fuel is supplied to the building. With regard to heating oil and hard coal, for orders of heating oil over 1000 litres and hard coal over 1 tonne, transport is free of charge.

For the LCA analysis, the ReCiPe E [20] method was used to determine Ke and Kl. The analysed heat sources (S1, S2, S3) and thermal insulation materials (I1, I2, I3) were subjected to an environmental impact assessment using the Ecoinvent 3.0 database of the SimaPro computer program. Let us notice that the lowest costs for heat generation, both economic and ecological, occur for the condensing gas boiler (S3). The highest economic costs are for the oil condensing boiler (S2), and the highest ecological costs for the coal boiler (S1).

Table 1.

Economic and ecological costs for heat generation.

Table 1.

Economic and ecological costs for heat generation.

| Heat Source | S1 | S2 | S3 |

|---|---|---|---|

| Kc (PLN/kWh) | 0.551 | 0.690 | 0.370 |

| Ke (Pt/kWh) | 0.1240 | 0.0391 | 0.0268 |

Source: Energy prices (2023 year) are based on: [21].

The analysis included three types of thermal insulation materials: I1—polystyrene EPS, I2—polystyrene XPS and I3—mineral wool. The most important data identifying thermal insulation materials is presented in Table 2. Let us notice that the lowest costs for thermal insulation material, both economic and ecological, occur for polystyrene EPS (I1). The highest economic costs are for mineral wool (I3), and the highest ecological costs for polystyrene XPS (I2).

Table 2.

Data on thermal insulation materials.

4.2. Demand for Energy to Heat Depending on the Temperature in the Dwelling

Table 3 summarizes the set energy demand for heating using the CERTO 2015 program, which determines the energy demand in accordance with Directive 2018/844 of the European Parliament and of the Council (EU) of 30 May 2018 on the energy performance of buildings. Two situations were taken into account, walls without a thermal insulation layer (heat transfer coefficient U0 = 0.52 W/m2K) and walls with a thermal insulation layer (heat transfer coefficient Un = 0.20 W/m2K). Moreover, various temperatures pre-set (pre-set temperature in the dwelling-understood as the average value of the temperature maintained throughout the heating season in the dwelling by its user) in the dwelling (in the range from 17 to 26 °C) were taken into account. The considered heating season in Poland lasts from mid-September to mid-March. Calculations of heat demand are based on the average number of degree days over many years. Due to the fact that one of the analysed heat sources is a hard coal boiler without a buffer tank, which is very popular in Poland, breaks in heating were not taken into account.

Table 3.

Demand for energy to heat depending on the temperature in the dwelling.

It is worth noting that the difference in the demand for energy to heat between the building without thermal insulation and the building with thermal insulation is much greater at higher temperatures set in the dwelling. At Tb = 17 °C, this difference is only 24.40 kWh/m2year, and at Tb = 26 °C, it is as much as 47.58 kWh/m2year. Obviously, the demand for thermal energy at Tb = 26 °C is much higher than at Tb = 17 °C (by more than 100%), despite the fact that the temperature difference in the dwelling is “only” 9 °C. It should also be emphasized that reducing the temperature maintained in the dwelling gives a great benefit (energy savings), in particular to those users who previously maintained higher temperatures in the dwelling. For the building with U0 = 0.52 W/m2K (without thermal insulation), reducing Tb temperature from 26 °C to 25 °C decreases energy demand by 10.42 kWh/m2year; reducing Tb from 18 °C to 17 °C reduces energy demand by 7.45 kWh/m2year. In the case of a building with Un = 0.20 W/m2K (with thermal insulation), we obtain decreases in demand of 7.21 kWh/m2year (when Tb is reduced from 26 °C to 25 °C) and 5.42 kWh/m2year (when Tb is reduced from 18 °C to 17 °C).

4.3. Analysis Results

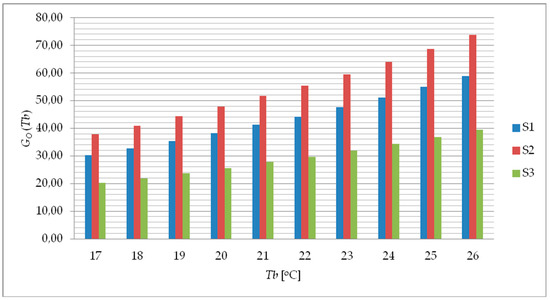

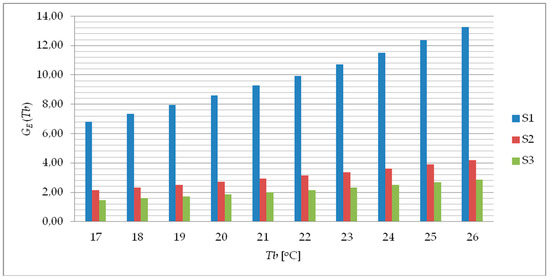

This section presents the results of the analysis undertaken using the methodology introduced in Section 3. The assumed useful life of thermal insulation is N = 25 years, and the interest rates are r = 5% and s = 3% [22]. The rates are in line with the recommendations in Poland regarding the assessment of investment projects (see [23]). First, the economic costs G0 (Tb) were determined from Formula (2) and the ecological costs GE (Tb) from Formula (4). The results are presented in Figure 1 and Figure 2.

Figure 1.

Annual economic heating cost G0 (Tb) ((PLN∙K)/(W∙year)).

Figure 2.

Annual ecological heating cost GE (Tb) ((Pt∙K)/(W∙year)).

Economic costs, in accordance with the demand for energy to heat, are correspondingly higher at higher pre-set temperatures in the dwelling. Due to the heat source, the highest economic costs occur for heat source S2 (oil condensing boiler) due to the highest economic costs for heat generation.

Similarly, ecological costs, in accordance with the demand for energy to heat, are higher at higher pre-set temperatures in the dwelling. Due to the heat source, the highest ecological costs occur for heat source S1 (coal-fired boiler) due to the highest ecological costs for heat generation (see Table 1).

To determine the optimal thickness for thermal insulation, it is first necessary to determine the optimal values for the heat transfer coefficient. The optimum values for economic reasons, depending on the temperature Tb and determined from Formula (8), are presented in Table 4. For a fixed heat source and thermal insulation material, lower values for the U coefficient are obtained for higher pre-set temperatures in the dwelling. This means that at higher pre-set temperatures in the dwelling, it is more economical to make thicker layers of thermal insulation (see Table 5).

Table 4.

Optimal values of heat transfer coefficient Uopt (Tb) [W/m2K] for economic reasons.

Table 5.

Optimal thicknesses of thermal insulation for economic reasons dopt (Tb) [m].

Knowing the optimal values for the heat transfer coefficient, it is possible to determine the optimum thickness of thermal insulation for economic reasons (see Formula (9)). The results are summarized in Table 5. For the fixed pre-set temperatures in the dwelling, the largest thicknesses were obtained for variant I1-S2 and the smallest for variant I3-S3.

Similarly, the optimal values of the coefficient U for ecological reasons, depending on the temperature Tb and determined from Formula (10), are summarized in Table 6. Additionally, for ecological reasons, for a fixed heat source and thermal insulation material, lower values for the U coefficient are obtained for higher temperatures set in the dwelling. Therefore, when higher temperatures are set in the dwelling, it is more advantageous for ecological reasons to make thicker layers of thermal insulation (see Table 7).

Table 6.

Optimal values of heat transfer coefficient UEopt (Tb) [W/m2K] for ecological reasons.

Table 7.

Optimal thicknesses of thermal insulation for ecological reasons dEopt (Tb) [m].

It is likewise possible to determine the optimal thickness of thermal insulation for ecological reasons (see Formula (11)). The results are summarized in Table 7. For the fixed pre-set temperatures in the dwelling, the largest thicknesses were obtained for variant I1-S1 and the smallest for variant I2-S3. It should be noticed that, taking into account ecological considerations, much greater thicknesses were obtained than for economic reasons. In some cases (e.g., I1-S1), these thicknesses are much greater than 0.5 m and are unrealistic to implement in practice.

Table 8 shows (see Formula (5)) economic net present values NPV (Tb) depending on the pre-set temperature in the dwelling Tb in relation to 1 m2 of the wall surface, with d = dopt (Tb) and U = Uopt (Tb). The highest NPV values were obtained for variant I1-S2. However, for variants I2-S3 and I3-S3 at the lowest values of pre-set temperatures in residential premises (17 °C and 18 °C—for the first variant and 17 °C, 18 °C and 19 °C—for the second variant), no refund was obtained from the thermal insulation investment.

Table 8.

Economic net present values NPV (Tb) [PLN/m2] for optimal insulation thicknesses for economic reasons.

Table 9 presents (see Formula (7)) ecological net present values NPVE (Tb) depending on the pre-set temperature in the dwelling Tb in relation to 1 m2 of the wall surface, with d = dEopt (Tb) and U = UEopt (Tb). A characteristic feature of this statement is that in each of the analysed variants there is a positive NPVE value. The highest ecological net present values occur for variant I1-S1, whereas the lowest are for variant I2-S3 for each value of the pre-set temperature in the dwelling.

Table 9.

Ecological net present values NPVE (Tb) [Pt/m2] for optimal thicknesses of thermal insulation for ecological reasons.

5. Discussion of the Obtained Results

Sustainable construction is construction that uses modern construction techniques to optimize the energy and ecological performance of buildings. Optimization of the thickness of thermal insulation, both ecological and economic, is aimed at reducing the level of pollutant emissions, not only during the use of the building but also in the phase of obtaining raw materials and manufacturing the thermal insulation materials and then optimizing the costs of construction, operation and maintenance of the buildings.

Due to the ecological net present value, the greatest ecological benefits for variant I1-S1 are obtained. It should be noticed that of the heat source variants, S1—a coal-fired boiler, is characterized by higher ecological benefits than the others (S2, S3). This is the result of the high emissivity of this heat source. Due to the economic aspect (NPV), the highest benefits are for the variant with the S2 heat source because of the highest cost of heat generation. On the other hand, the smallest economic benefits are with the S3 boiler as the heat generation costs are the lowest for this boiler.

Taking into account thermal insulation materials, we also obtain different results depending on whether economic or ecological benefits are considered. The economic net present values are the highest for I1 (polystyrene EPS) and the lowest for I3 (mineral wool). The ecological net present values are the highest for I1 (polystyrene EPS) and the smallest for I2 (polystyrene XPS). However, the differences are very small, not like in the case of boilers.

The values for the optimal thicknesses of thermal insulation in the case of ecological assessment are definitely higher in each variant in relation to the values of these thicknesses in the case of economic assessment. Considering the life cycle of thermal insulation over a period of 25 years, it can be seen that the decisive element of the impact on the environment of building use is the generation of energy depending on the heat source and not the production process of the thermal insulation material.

It should be emphasized that the temperature Tb maintained in the dwelling has a very large impact on both the economic benefits (NPV) and ecological benefits (NPVE). The higher the temperature Tb, the more economically viable the thermal insulation investment is (see Table 8). Similarly, the higher the temperature Tb, the greater the reduction in environmental load due to thermal insulation (see Table 9). The greatest impact on the obtained results is the demand for energy to heat DU (see Table 3). At the temperature Tb = 26 °C, this demand is about 60% higher than at Tb = 20 °C. However, at Tb = 17 °C, it is about 25% lower than at Tb = 20 °C.

6. Summary and Conclusions

Consideration of economic and ecological aspects in optimizing the thickness of thermal insulation is close to the idea of sustainable construction. Conclusions from the article:

- When optimizing the economic and ecological thickness of thermal insulation, the insulating properties of the materials and their price as well as ecological properties should also be taken into account.

- The optimal thickness for thermal insulation is also affected by the heat source used and the set value of the air temperature inside the dwelling.

- The article draws attention to the need to determine the optimal thicknesses for external walls to comply with the preferences of the user of the dwelling, even at the level of design (thermal insulation) of the building, because this aspect may be important for higher economic and ecological benefits.

- The authors focused on how the customary insulation thicknesses currently used in buildings can be changed to those that are optimal, while taking into account all ecological and economic factors.

- The main conclusion of the article is that with the rational and progressive design of buildings, tailored to the needs of the user, it is possible to significantly reduce the costs of building use and at the same time improve relations with the environment.

- The demand for energy to heat at the temperature in the premises Tb = 26 °C is about 60% higher than at Tb = 20 °C, whereas at Tb = 17 °C it is about 25% lower than at Tb = 20 °C.

- The ecological benefits of thermal insulation are more than twice as high at Tb = 26 °C than at Tb = 17 °C.

- The higher the temperature Tb, the more economically viable the thermal insulation investment is.

Author Contributions

Conceptualization, R.D. and J.A.; methodology, R.D. and J.A.; software, R.D. and J.A.; validation, R.D. and J.A.; formal analysis, R.D.; investigation, R.D. and J.A.; resources, R.D. and J.A.; data curation, R.D. and J.A.; writing—original draft preparation, R.D. and J.A.; writing—review and editing, R.D. and J.A.; visualization, R.D. and J.A.; supervision, R.D.; project administration, R.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data available on request due to restrictions privacy.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| LCA | life cycle assessment |

| LCC | life cycle cost |

| GA | genetic algorithms |

| ANN | artificial neural networks |

| CBR | case-based reasoning |

| NPV | net present value |

| NPVE | ecological net present value |

| CAWI | computer-assisted web interviewing |

References

- D’Agostino, D.; Cuniberti, B.; Bertoldi, P. Energy consumption and efficiency technology measures in European non-residential buildings. Energy Build. 2017, 153, 72–86. [Google Scholar] [CrossRef]

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Hou, C.; Hou, J.; Wei, D.; Hou, Y. Optimization analysis of thermal insulation layer attributes of building envelope exterior wall based on DeST and life cycle economic evaluation. Case Stud. Therm. Eng. 2019, 14, 100410. [Google Scholar] [CrossRef]

- Architecture2030. Why the Building Sector? Available online: https://architecture2030.org/why-the-building-sector/ (accessed on 20 October 2022).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. In A Renovation Wave for Europe—Greening our Buildings, Creating Jobs, Improving Lives; COM(2020) 662 Final; European Commission: Brussels, Belgium, 14 October 2020.

- Nowak-Dzieszko, K.; Rojewska-Warchał, M. Influence of the Balcony Glazing Construction on Thermal Comfort of Apartments in Retrofitted Large Panel Buildings. Procedia Eng. 2015, 108, 481–487. [Google Scholar] [CrossRef]

- Nasrollahzadeh, N. Comprehensive building envelope optimization: Improving energy, daylight, and thermal comfort performance of the dwelling unit. J. Build. Eng. 2021, 44, 103418. [Google Scholar] [CrossRef]

- Kalinovi, S.M.; Taniki, D.I.; Djokovi, J.M.; Nikoli, R.R.; Hadzima, B.; Ulewicz, R. Optimal Solution for an Energy Efficient Construction of a Ventilated Façade Obtained by a Genetic Algorithm. Energies 2021, 14, 3293. [Google Scholar] [CrossRef]

- PN-EN 12831-1:2017-08; Charakterystyka Energetyczna Budynków—Metoda Obliczania Projektowego Obciążenia Cieplnego—Część 1: Obciążenie Cieplne, Moduł M3-3. Polski Komitet Normalizacyjny: Warsaw, Poland, 2017. (In Polish)

- Basińska, M.; Koczyk, H. Analiza Zmienności Temperatur w Obiekcie Doświadczalnym Eksploatowanym z Osłabieniem Nocnym; Fizyka Budowli W Teorii I Praktyce, TOM II, 2007; Instytut Fizyki Budowli Katarzyna i Piotr Klemm S.C.: Łódź, Poland, 2007. (In Polish) [Google Scholar]

- Adamczyk, J.; Dylewski, R.; Sobierajewicz, P. Economic and ecological benefits of thermal insulation of external partitions depending on the temperature in residential premises. J. Clean. Prod. 2023, 384, 135622. [Google Scholar] [CrossRef]

- EnEV 02-17; Energiesparverordnung, Referentenentwurf 06-11. BMVBS: Berlin, Germeny, 2007.

- Szulgowska-Zgrzywa, M.; Stefanowicz, E.; Piechurski, K.; Chmielewska, A.; Kowalczyk, M. Impact of Users’ Behavior and Real Weather Conditions on the Energy Consumption of Tenement Houses in Wroclaw, Poland: Energy Performance Gap Simulation Based on a Model Calibrated by Field Measurements. Energies 2020, 13, 6707. [Google Scholar] [CrossRef]

- Honeywell Home. Heating Habits Campaign. Report. 2017. Available online: https://instalreporter.pl/wp-content/uploads/2017/03/Honeywell-raport-v4.pdf (accessed on 12 January 2023). (In Polish).

- Dylewski, R. Optimal Thermal Insulation Thicknesses of External Walls Based on Economic and Ecological Heating Cost. Energies 2019, 12, 3415. [Google Scholar] [CrossRef]

- Dylewski, R.; Adamczyk, J. Study on ecological cost-effectiveness for the thermal insulation of building external vertical walls in Poland. J. Clean. Prod. 2016, 133, 467–478. [Google Scholar] [CrossRef]

- Rozporządzenie Ministra Transportu. Budownictwa i Gospodarki Morskiej. In z Dnia 5 Lipca 2013 r. Zmieniające Rozporządzenie: W Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budynki i ich Usytuowanie; Dz.U. 2013 poz. 926; Ministra Transportu. Budownictwa i Gospodarki Morskiej: Warsaw, Poland, 2013. (In Polish)

- Budownictwo w 2020 Roku. GUS. Available online: https://stat.gov.pl/files/gfx/portalinformacyjny/pl/defaultaktualnosci/5478/13/9/1/budownictwo_w_2020_r.pdf (accessed on 17 January 2023). (In Polish)

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed]

- Stavropoulosa, P.; Giannoulisa, C.; Papacharalampopoulosa, A.; Foteinopoulosa, P.; Chryssolouris, G. Life cycle analysis: Comparison between different methods and optimization challenges. Procedia CIRP 2016, 41, 626–631. [Google Scholar] [CrossRef]

- Ogrzewanie. Available online: http://www.cena-pradu.pl/ogrzewanie.html (accessed on 20 April 2023). (In Polish).

- Dylewski, R.; Adamczyk, J. Impact of the Degree Days of the Heating Period on Economically and Ecologically Optimal Thermal Insulation Thickness. Energies 2021, 14, 97. [Google Scholar] [CrossRef]

- Minister Inwestycji i Rozwoju. Wytyczne w Zakresie Zagadnień Związanych z Przygotowaniem Projektów Inwestycyjnych, w Tym Projektów Generujących Dochód i Projektów Hybrydowych na lata 2014–2020. 2019. Available online: https://www.funduszeeuropejskie.gov.pl/media/68128/wytyczne_PGD_PH_2014_2020_10_01_2019.pdf (accessed on 17 January 2023). (In Polish)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).