Evaluation of Mechanical Properties and HPM Pulse Shielding Effectiveness of Cement-Based Composites

Abstract

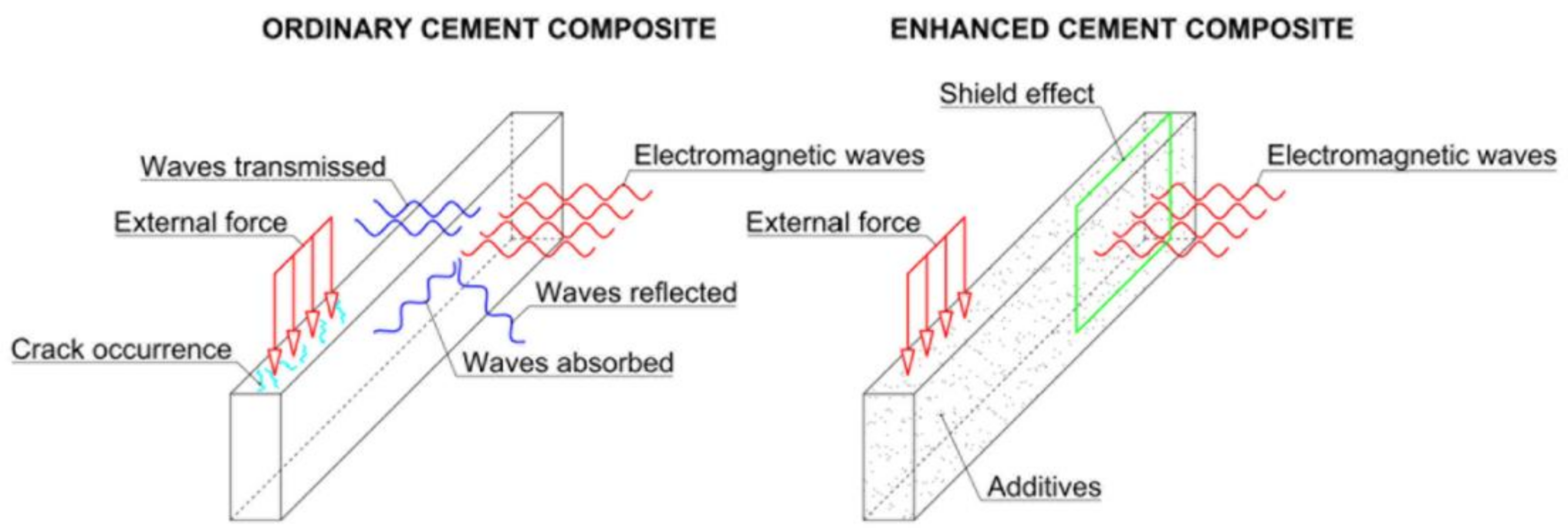

1. Introduction

2. Significance of This Research

3. Materials and Mix Proportions

| Series | Symbol | Admixture | 0.5% [g] | 1% [g] | 3% [g] | 5% [g] | 10% [g] | 36% [g] | Cement Paste Type |

|---|---|---|---|---|---|---|---|---|---|

| S0 | M | Standard mortar | - | - | - | - | - | - | I |

| S1 | FA | Fly ash | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S2 | FG | Graphite in form of FG597 flakes | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S3 | MG | Graphite in form of MG1596 powder | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S4 | CB1 | Carbon black Reoil RCB_615 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S5 | CB2 | Carbon black N772 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S6 | CB3 | Carbon black N990 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S7 | CB4 | Carbon black P803 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S8 | CN | Multifaceted carbon nanotubes | 2.7 | 5.4 | - | - | - | - | II |

| S9 | Ni | Nickel (Ni) nanopowder 30–70 nm | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S10 | NiO | Nickel monoxide (NiO) nanopowder 20–30 nm | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S11 | FF | Filler FF + ferrite | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S12 | CI | Carbonyl iron | - | 5.4 | 16.2 | - | 54.0 | 194.4 | I |

| S13 | F | Ferrite FMS 0.05 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S14 | FAA | Ashporite aggregate | - | - | - | - | - | - | III |

| S15 | FAA + CB4 | Ashporite aggregate + P803 | - | - | - | - | 54.0 | - | III |

| S16 | FAA + FG | Ashporite aggregate + FG597 | - | - | - | - | 54.0 | - | III |

| S17 | Ni2O3 | Nickel oxide Ni2O3 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S18 | CIM | Carbonyl iron modified with SiO2 | - | 5.4 | 16.2 | - | 54.0 | - | I |

| S19 | AIR | Air-entraining admixture Sika PRO3 | - | - | - | 27.0 | - | - | III |

| Series | Symbol | Admixture | 6% [g] | 7.4% [g] | Cement paste type | ||||

| S20 | BA | Barite aggregate | - | - | IV | ||||

| S21 | SF | Steel fibers | - | 500 | V | ||||

| S22 | PF | Polypropylene fibers | 60 | - | VI | ||||

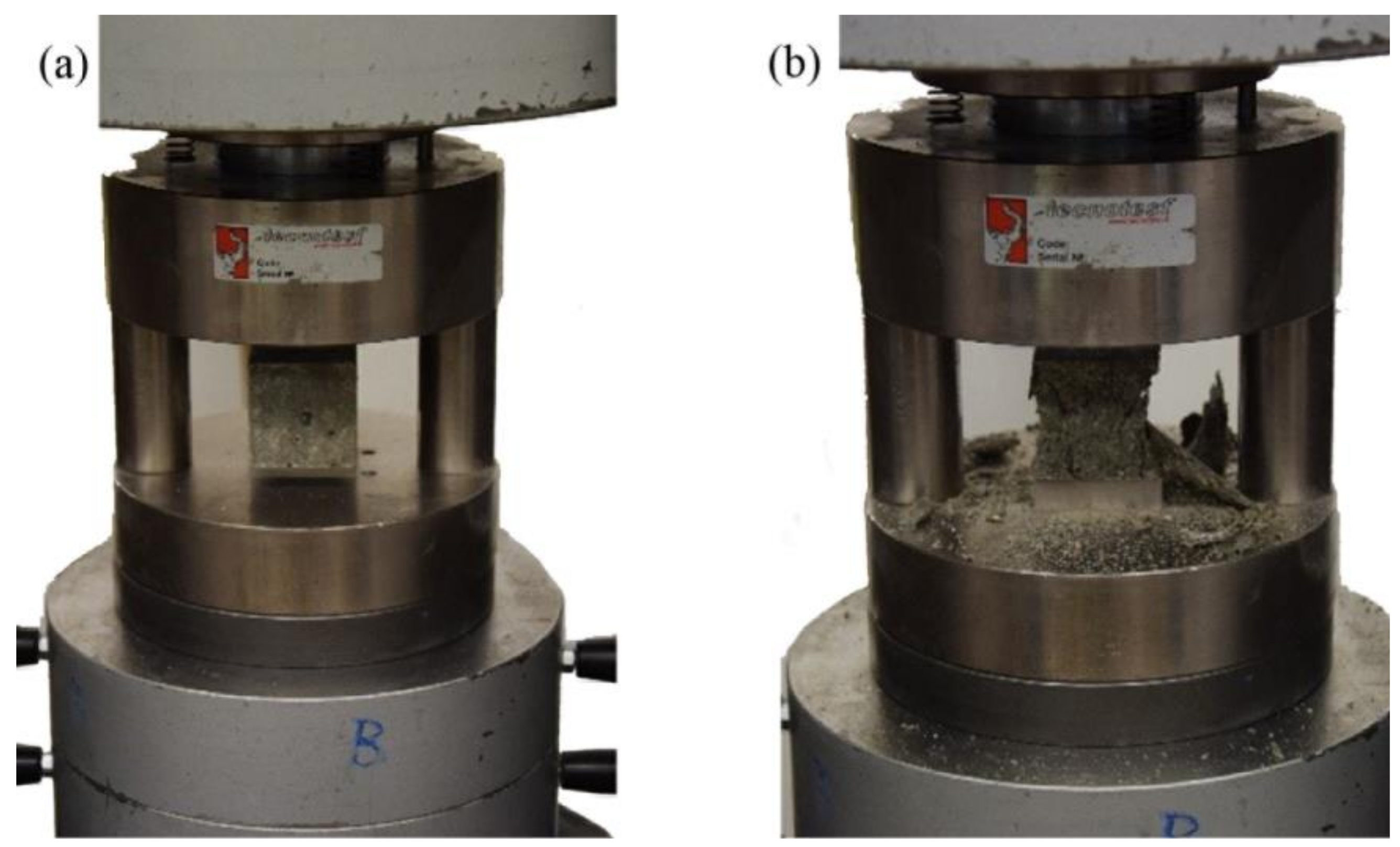

4. Specimen Preparation and Test Methods

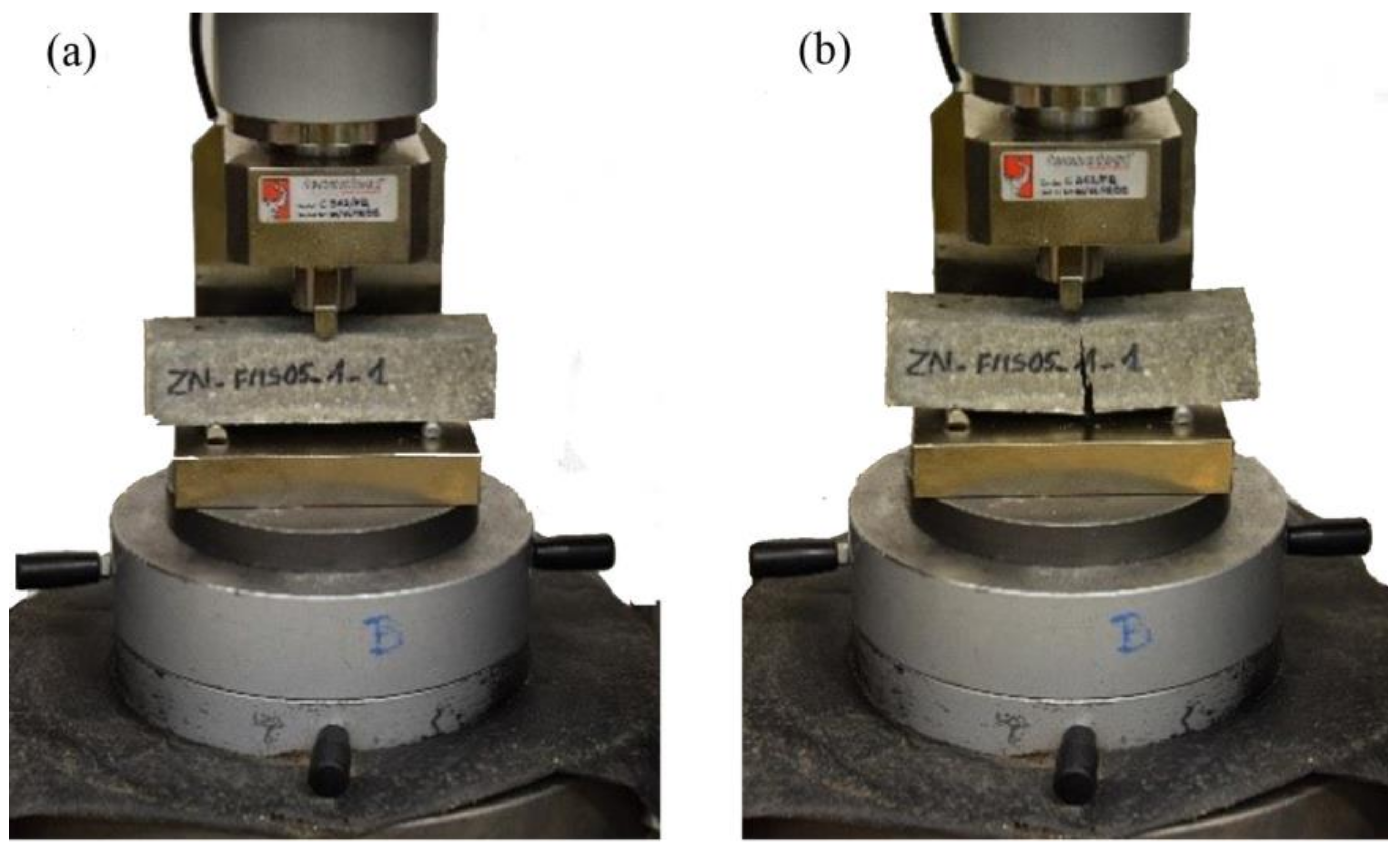

4.1. Mechanical Properties

4.2. Shielding Effectiveness Testing

5. Test Results and Their Analysis

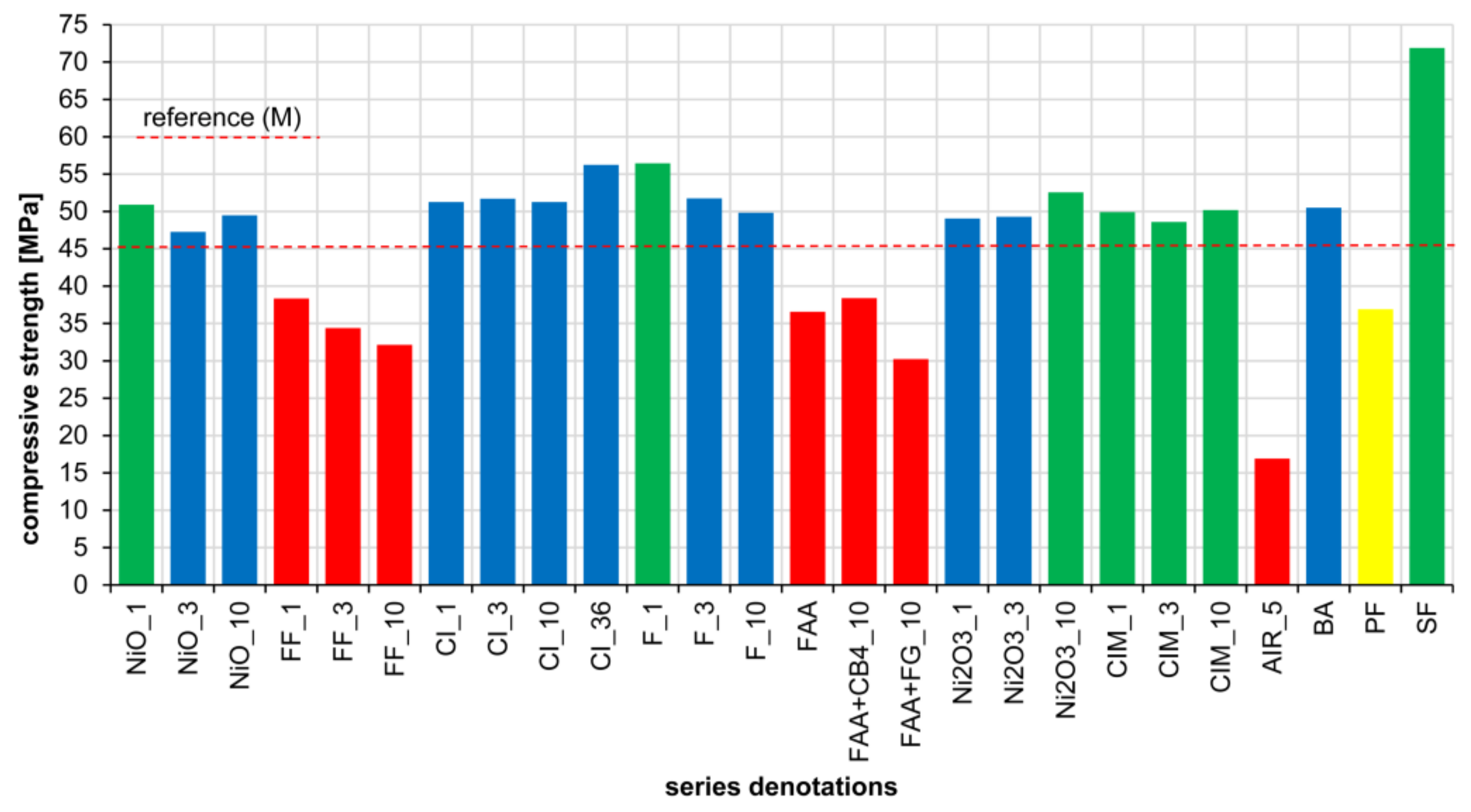

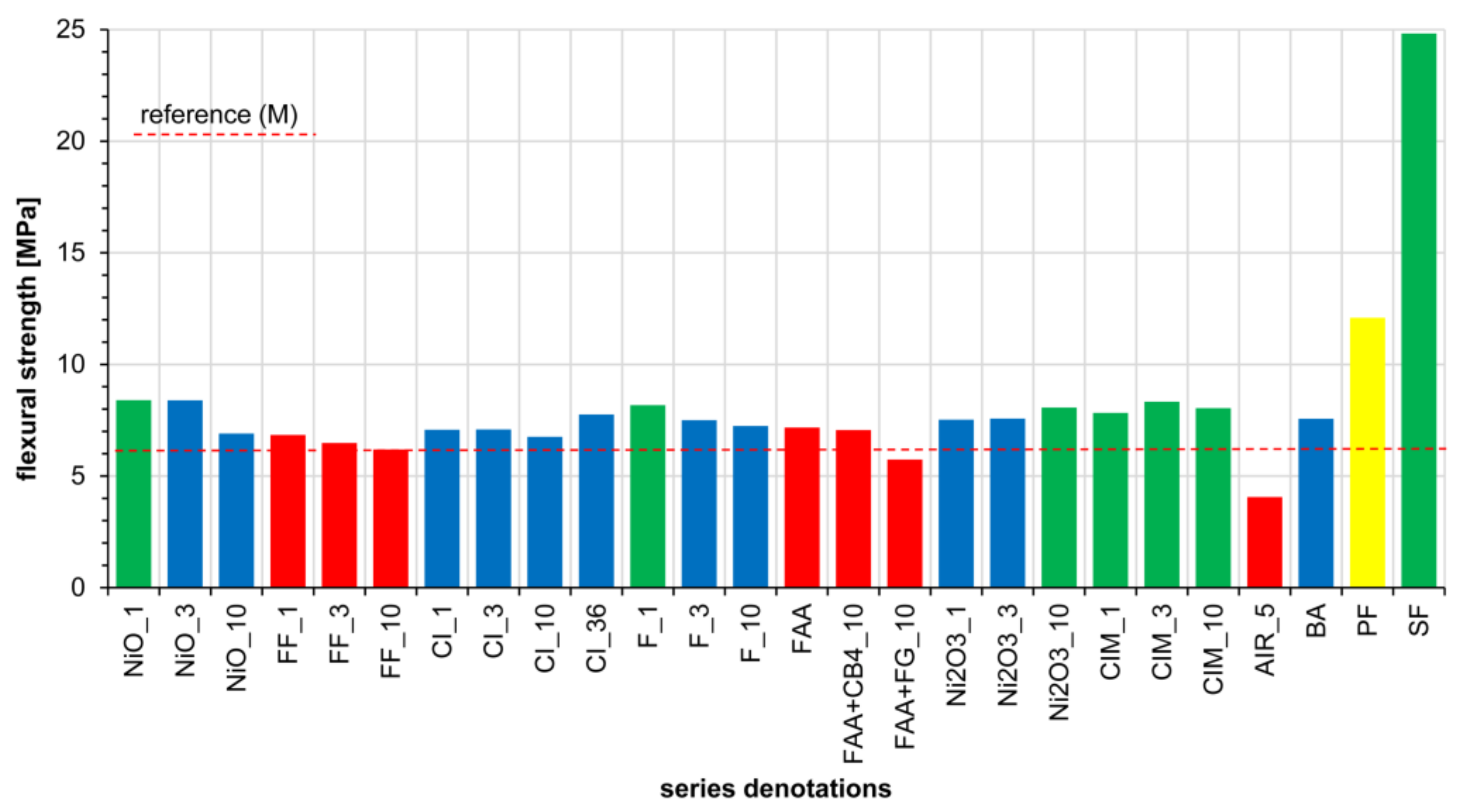

5.1. Mechanical Properties

| No. | Specimen | fc [MPa] | ftb [MPa] | No. | Specimen | fc [MPa] | ftb [MPa] |

|---|---|---|---|---|---|---|---|

| 1 | M | 48.06 | 7.88 | 27 | NiO_1 | 50.90 | 8.40 |

| 2 | FA_1 | 50.74 | 8.03 | 28 | NiO_3 | 47.25 | 8.39 |

| 3 | FA_3 | 55.05 | 7.97 | 29 | NiO_10 | 49.47 | 6.90 |

| 4 | FA_10 | 54.68 | 8.60 | 30 | FF_1 | 38.34 | 6.84 |

| 5 | FG_1 | 50.57 | 8.18 | 31 | FF_3 | 34.38 | 6.48 |

| 6 | FG_3 | 49.44 | 8.64 | 32 | FF_10 | 32.14 | 6.19 |

| 7 | FG_10 | 43.66 | 7.49 | 33 | CI_1 | 51.25 | 7.07 |

| 8 | MG_1 | 51.32 | 8.51 | 34 | CI_3 | 51.69 | 7.08 |

| 9 | MG_3 | 45.81 | 7.07 | 35 | CI_10 | 51.24 | 6.75 |

| 10 | MG_10 | 38.27 | 7.33 | 36 | CI_36 | 56.23 | 7.75 |

| 11 | CB1_1 | 55.72 | 8.09 | 37 | F_1 | 56.45 | 8.17 |

| 12 | CB1_3 | 53.28 | 7.41 | 38 | F_3 | 51.73 | 7.50 |

| 13 | CB1_10 | 47.64 | 6.36 | 39 | F_10 | 49.80 | 7.24 |

| 14 | CB2_1 | 53.61 | 8.26 | 40 | FAA | 36.57 | 7.17 |

| 15 | CB2_3 | 48.88 | 7.14 | 41 | FAA + CB4_10 | 38.38 | 7.06 |

| 16 | CB2_10 | 51.19 | 7.51 | 42 | FAA + FG_10 | 30.23 | 5.74 |

| 17 | CB3_1 | 52.19 | 7.76 | 43 | Ni2O3_1 | 49.04 | 7.52 |

| 18 | CB3_3 | 48.51 | 8.11 | 44 | Ni2O3_3 | 49.28 | 7.57 |

| 19 | CB3_10 | 46.04 | 7.04 | 45 | Ni2O3_10 | 52.56 | 8.07 |

| 20 | CB4_1 | 51.26 | 8.18 | 46 | CIM_1 | 49.90 | 7.83 |

| 21 | CB4_3 | 57.87 | 8.00 | 47 | CIM_3 | 48.60 | 8.33 |

| 22 | CB4_10 | 58.35 | 8.50 | 48 | CIM_10 | 50.18 | 8.04 |

| 23 | CN_0.5 | 46.03 | 7.27 | 49 | AIR_5 | 16.92 | 4.06 |

| 24 | CN_1 | 31.11 | 6.08 | 50 | BA | 50.48 | 7.56 |

| 25 | Ni_1 | 39.38 | 7.04 | 51 | PF | 36.90 | 12.09 |

| 26 | Ni_3 | 29.90 | 6.07 | 52 | SF | 71.89 | 24.82 |

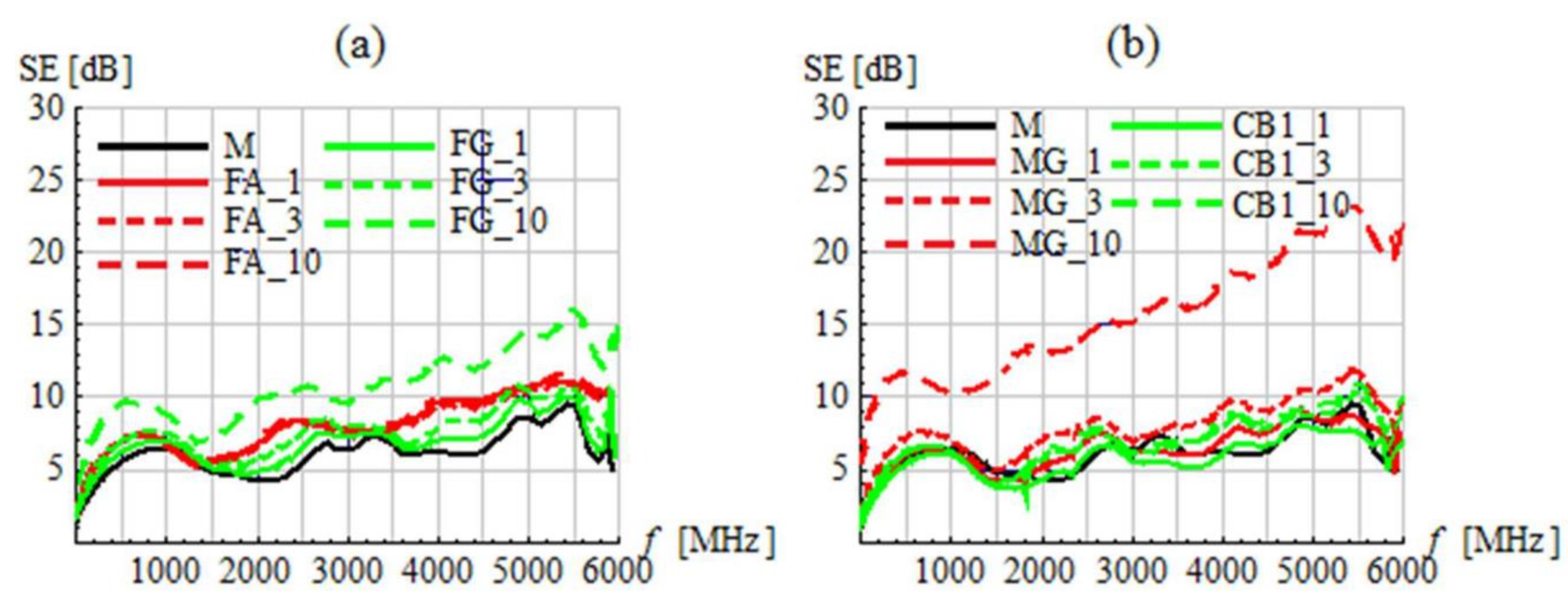

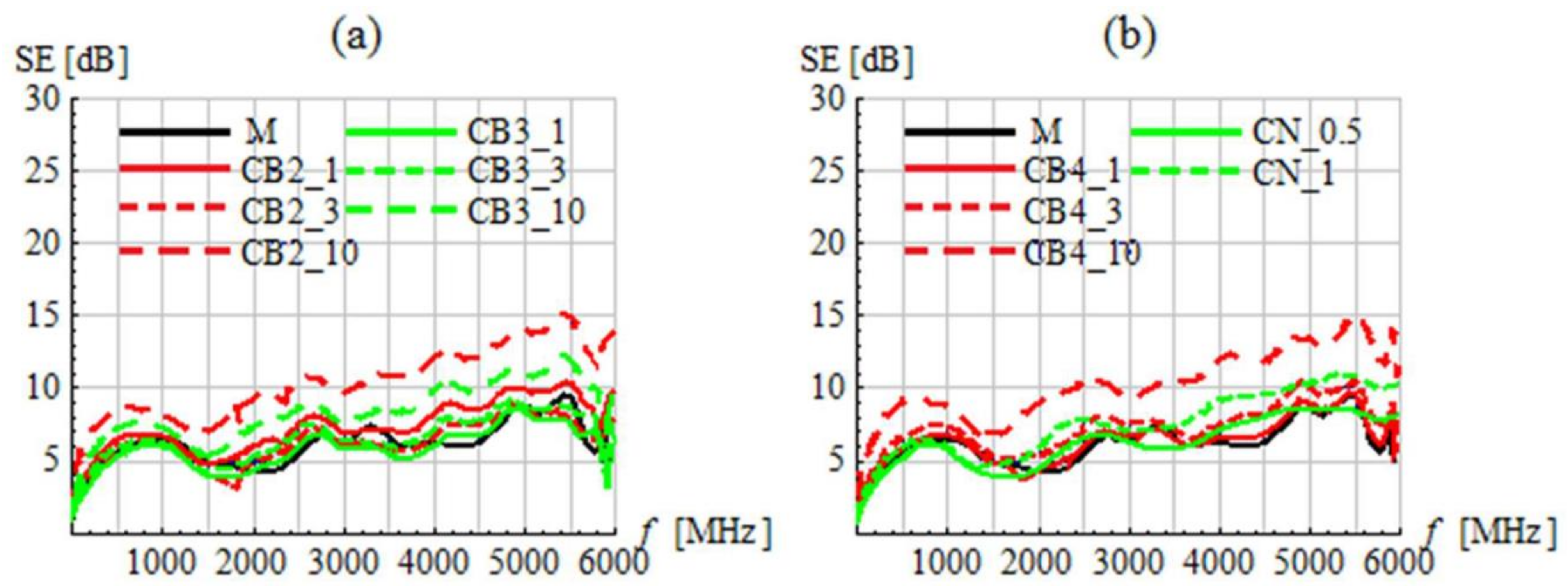

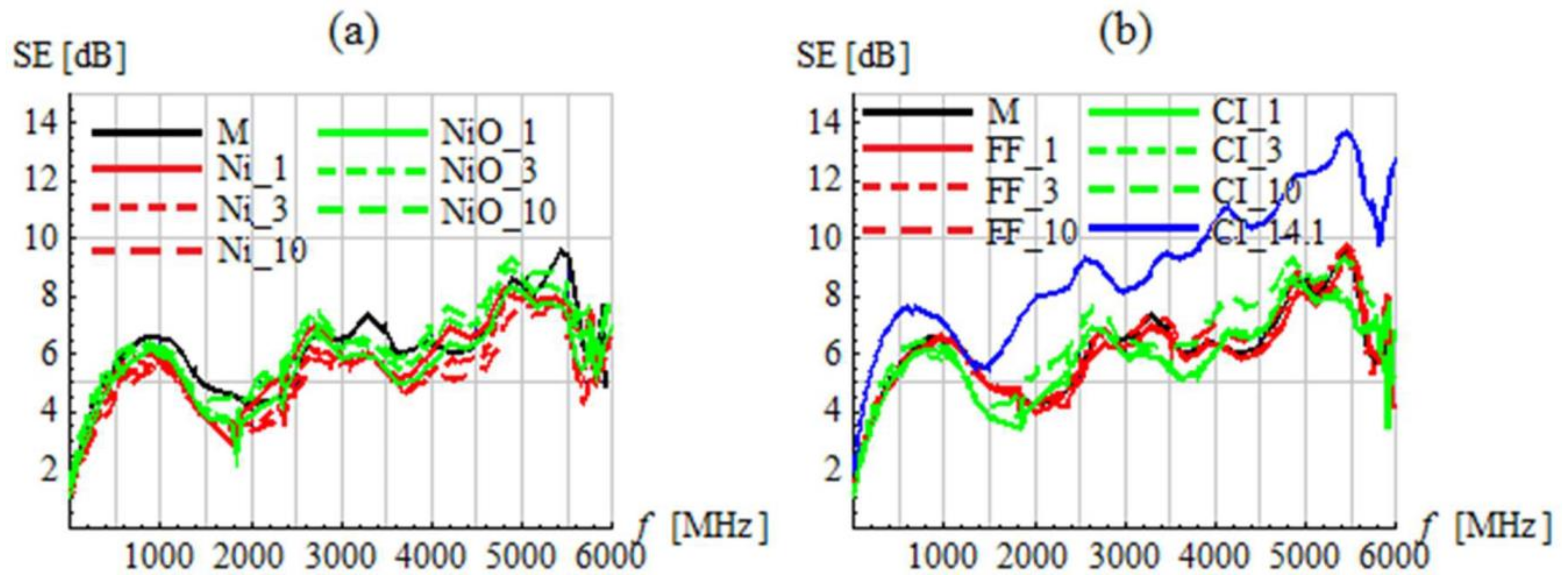

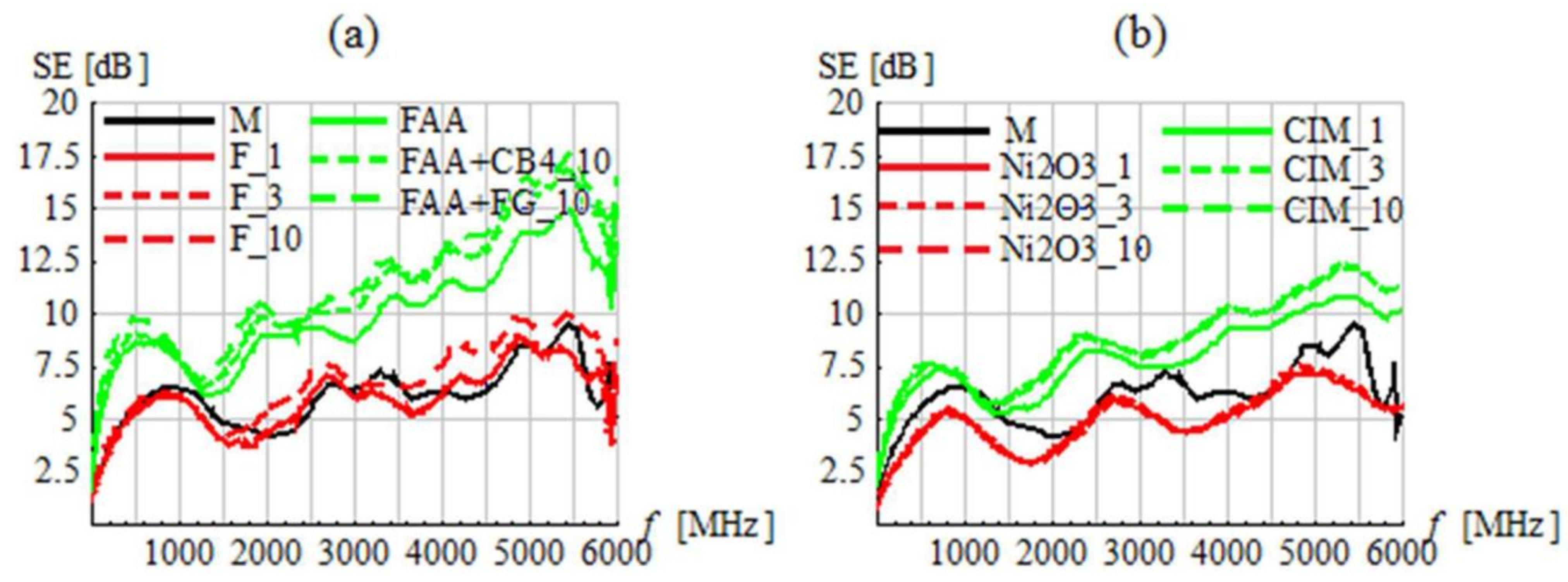

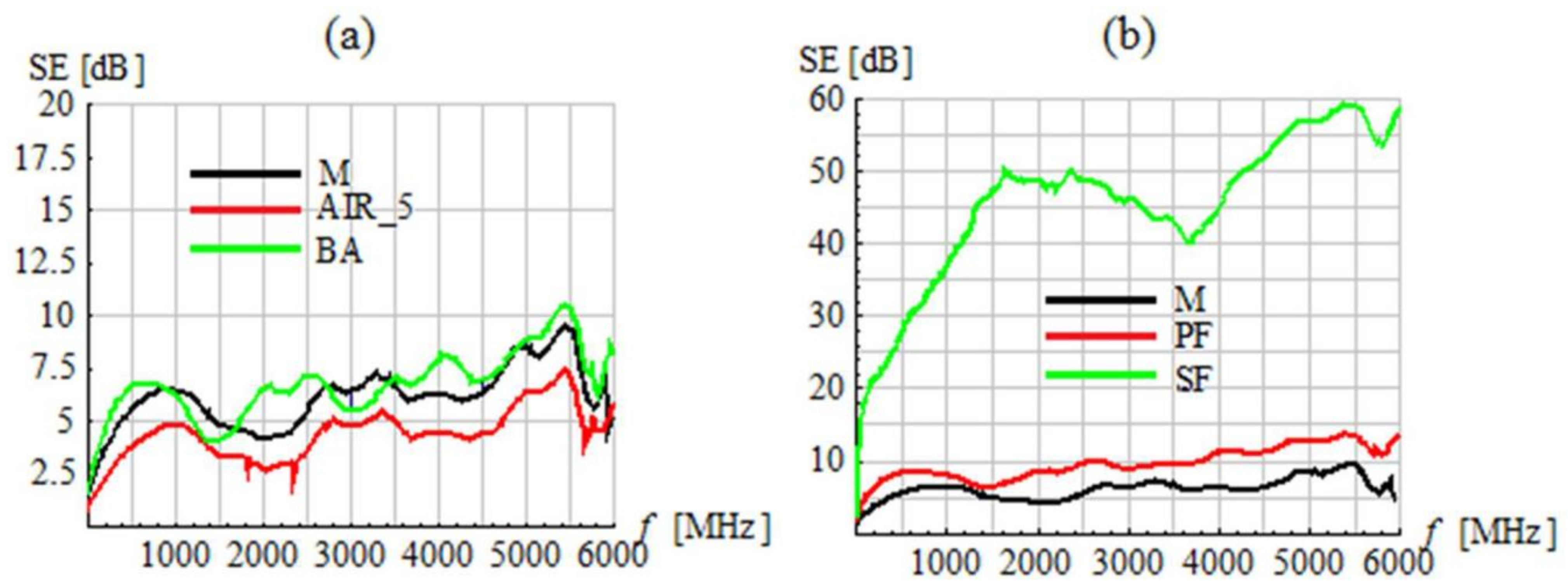

5.2. Shielding Effectiveness

- specimens AE for which an over 50% improvement in shielding effectiveness was achieved for both <1 GHz and 1–6 GHz in comparison with reference standard mortar M (green): FG_10, MG_10, CB2_10, CB4_10, FAA + CB4_10, FAA + FG_10, PF, SF;

- specimens BE for which an up to 50% improvement in shielding effectiveness was achieved for both <1 GHz and 1–6 GHz in comparison with reference standard mortar M (blue): FA_1, FA_3, FA_10, FG_1, FG_3, MG_1, MG_3, CB1_3, CB1_10, CB2_1, CB3_10, CB4_1, CB4_3, CN_1, FF_10, CI_10, CI_36, FAA, CIM_1, CIM_3, CIM_10, BA;

- specimens CE for which no improvement in shielding effectiveness was achieved for frequencies < 1 GHz relative to reference standard mortar M (red): CB1_1, CB2_3, CB3_1, CB3_3, CN_0.5, Ni_1, Ni_3, NiO_1, NiO_3, NiO_10, FF_1, FF_3, CI_1, CI_3, F_1, F_3, F_10, Ni2O3_1, Ni2O3_3, Ni2O3_10, AIR_5.

| No. | Specimen | Shielding Effectiveness SE [dB] | No. | Specimen | Shielding Effectiveness SE [dB] | ||

|---|---|---|---|---|---|---|---|

| <1 GHz | 1–6 GHz | <1 GHz | 1–6 GHz | ||||

| 1 | M | 4.87 | 6.54 | 27 | NiO_1 | 4.59 | 5.86 |

| 2 | FA_1 | 6.22 | 8.59 | 28 | NiO_3 | 4.93 | 6.45 |

| 3 | FA_3 | 6.15 | 8.33 | 29 | NiO_10 | 4.62 | 6.77 |

| 4 | FA_10 | 6.16 | 8.58 | 30 | FF_1 | 4.86 | 6.32 |

| 5 | FG_1 | 5.45 | 7.28 | 31 | FF_3 | 4.88 | 6.36 |

| 6 | FG_3 | 5.99 | 8.06 | 32 | FF_10 | 4.89 | 6.75 |

| 7 | FG_10 | 8.35 | 11.3 | 33 | CI_1 | 4.54 | 6.18 |

| 8 | MG_1 | 5.24 | 7.03 | 34 | CI_3 | 4.31 | 6.17 |

| 9 | MG_3 | 6.32 | 8.37 | 35 | CI_10 | 5.03 | 6.83 |

| 10 | MG_10 | 10.56 | 16.68 | 36 | CI_36 | 6.50 | 9.57 |

| 11 | CB1_1 | 4.52 | 6.08 | 37 | F_1 | 4.51 | 6.37 |

| 12 | CB1_3 | 5.43 | 7.11 | 38 | F_3 | 4.53 | 6.35 |

| 13 | CB1_10 | 5.34 | 7.47 | 39 | F_10 | 4.67 | 7.30 |

| 14 | CB2_1 | 5.23 | 7.77 | 40 | FAA | 7.51 | 10.53 |

| 15 | CB2_3 | 4.78 | 6.55 | 41 | FAA + CB4_10 | 7.85 | 11.77 |

| 16 | CB2_10 | 7.61 | 11.24 | 42 | FAA + FG_10 | 8.45 | 12.29 |

| 17 | CB3_1 | 4.73 | 6.15 | 43 | Ni2O3_1 | 3.96 | 5.29 |

| 18 | CB3_3 | 4.84 | 6.88 | 44 | Ni2O3_3 | 3.98 | 5.41 |

| 19 | CB3_10 | 6.35 | 9.13 | 45 | Ni2O3_10 | 3.82 | 5.42 |

| 20 | CB4_1 | 5.28 | 6.81 | 46 | CIM_1 | 6.15 | 8.37 |

| 21 | CB4_3 | 5.69 | 7.75 | 47 | CIM_3 | 6.52 | 9.30 |

| 22 | CB4_10 | 7.96 | 11.01 | 48 | CIM_10 | 6.36 | 9.16 |

| 23 | CN_0.5 | 4.72 | 6.66 | 49 | AIR_5 | 3.48 | 4.73 |

| 24 | CN_1 | 5.28 | 8.04 | 50 | BA | 5.76 | 7.03 |

| 25 | Ni_1 | 4.46 | 6.16 | 51 | PF | 7.45 | 10.27 |

| 26 | Ni_3 | 4.06 | 5.64 | 52 | SF | 26.79 | 49.30 |

6. Discussion

7. Conclusions

- The specimens with a high steel fiber content show the greatest improvement in mechanical properties (fc, ftb) and in HPM impulse shielding effectiveness in comparison to the standard mortar. The great improvement in shielding effectiveness can be ascribed to the probable occurrence of the Faraday cage effect.

- Electric charge conducting admixtures, such as carbon black or graphite, show an improvement in their ability to absorb HPM pulses as the admixture content in the mortar increases, but at the admixture content of 10% by the weight of the cement, the compressive and flexural strength of the cement paste decreases.

- The use of absorbers (e.g., a large amount of polypropylene fibers), which reduce the possibility of electric charge flow, results in the effective shielding of HPM pulses, but this effect is weaker than in the case of the electric charge conducting specimens.

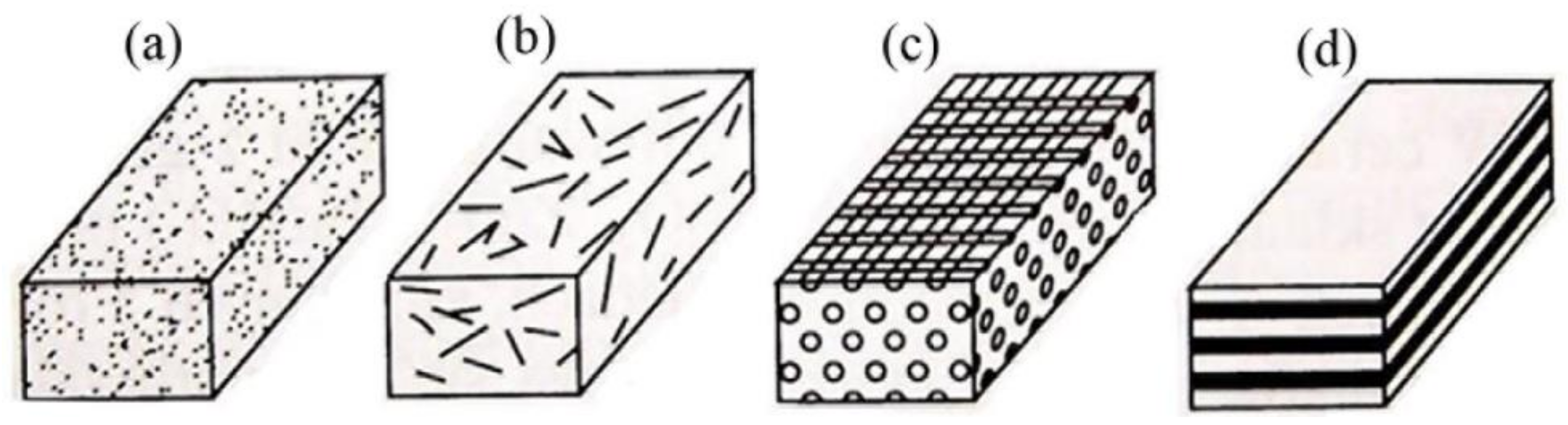

- The test results indicate that the use of admixtures in a hybrid configuration to improve the synergistic electromagnetic radiation shielding effect makes sense. However, admixtures significantly differing in their specific gravity and electrical conductivity should not be introduced into the same cement paste but rather separately into cement pastes placed in layers perpendicularly to the direction of HPM pulse action.

- The optimization and development of the proposed hybrid solutions requires further extensive research in this regard (e.g., including microstructure analysis of cementitious mortars [49]).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuchta, M.; Paś, J. Electromagnetic terrorism—Threats in buildings. Bull. Milit. Univ. Technol. 2015, 64, 135–147. (In Polish) [Google Scholar] [CrossRef]

- Dras, M.; Kałuski, M.; Szafrańska, M. HPM pulses—Disturbances and systems interaction—Basic issues. Przegląd Elektrotechniczny 2015, 11, 11–14. (In Polish) [Google Scholar]

- Kołodziejski, J.F.; Kubiak, I. Protection of Electronic Equipment against Directed Energy of Electromagnetic Radiation. Elektronika B2B. (In Polish). Available online: https://elektronikab2b.pl/technika/31417-ochrona-sprzetu-elektronicznego-przed-kierowana-energia-promieniowania-elektromagnetycznego (accessed on 8 March 2023).

- Koppel, T.; Shishkin, A.; Haldre, H.; Toropov, N.; Tint, P. Reflection and transmission properties of common construction materials at 2.4 GHz frequency. Energy Procedia 2017, 113, 158–165. [Google Scholar] [CrossRef]

- Ozturk, M.; Depci, T.; Bahceci, E.; Karaaslan, M.; Akgol, O.; Sevim, U.K. Production of new electromagnetic wave shielder mortar using waste mill scales. Constr. Build. Mater. 2020, 242, 118028. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F. A review on recent advancement of electromagnetic interference shielding novel metallic materials and processes. Compos. Part B Eng. 2019, 176, 107207. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W. Electromagnetic shielding and absorption properties of fiber reinforced cementitious composites. J. Wuhan Univ. Technol Sci. Ed. 2012, 27, 172–176. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Ma, G.; Habibi, D. Advancements in electromagnetic interference shielding cementitious composites. Constr. Build. Mater. 2020, 231, 117116. [Google Scholar] [CrossRef]

- Xie, P.; Gu, P.; Beaudoin, J.J. Electrical percolation phenomena in cement composites containing conductive fibres. J. Mater. Sci. 1996, 31, 4093–4097. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Q.; Luo, Z.; Lin, X.; Wu, G. A novel structure of Ferro-Aluminum based sandwich composite for magnetic and electromagnetic interference shielding. Mater. Des. 2016, 89, 71–77. [Google Scholar] [CrossRef]

- Sato, H.; Domae, H.; Takahashi, M.; Abe, M. Reflection and transmission control of electromagnetic wave for concrete walls. Electron. Commun. JPN (Part II Electron.) 2000, 83, 12–21. [Google Scholar] [CrossRef]

- Luoa, J.; Wanga, S.; Penga, S.; Zhangb, T.; Haoa, G.; Xiaoa, L.; Hua, Y.; Jianga, W. High-performance electromagnetic wave absorbers based on Fe-based MOFs-derived Fe/C composites. Synth. Met. 2021, 272, 116663. [Google Scholar] [CrossRef]

- Ozturk, M.; Sevim, U.K.; Akgol, O.; Unal, E.; Karaaslan, M. Investigation of the mechanic, electromagnetic characteristics and shielding effectiveness of concrete with boron ores and boron containing wastes. Constr. Build. Mater. 2020, 252, 119058. [Google Scholar] [CrossRef]

- Majcher, K.; Musiał, M.; Pakos, W.; Różański, A.; Sobótka, M.; Trapko, T. Methods of Protecting Buildings against HPM Radiation—A Review of Materials Absorbing the Energy of Electromagnetic Waves. Materials 2020, 13, 5509. [Google Scholar] [CrossRef] [PubMed]

- Majcher, K.; Musiał, M.; Pakos, W.; Różański, A.; Sobótka, M.; Trapko, T. A Systematic Review of HPM Energy Absorbers for Building Applications. Energies 2021, 14, 6061. [Google Scholar] [CrossRef]

- Yee, S.K.; Jenu, M.Z.M. Shielding effectiveness of concrete with graphite fine powder in between 50 MHz to 400 MHz. In Proceedings of the 2013 Asia-Pacific Symposium on Electromagnetic Compatibility (APEMC), Melbourne, Australia, 20–23 May 2013. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Ma, G. Electromagnetic shielding properties of cementitious composites containing carbon nanofibers, zinc oxide, and activated carbon powder. Constr. Build. Mater. 2021, 285, 122842. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Guo, S. High-performance electromagnetic wave absorption by designing the multilayer graphene/thermoplastic polyurethane porous composites with gradient foam ratio structure. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105522. [Google Scholar] [CrossRef]

- Mazzoli, A.; Corinaldesi, V.; Donnini, J.; Di Perna, C.; Micheli, D.; Vricella, A.; Pastore, R.; Bastianelli, L.; Moglie, F.; Mariani Primiani, V. Effect of graphene oxide and metallic fibers on the electromagnetic shielding effect of engineered cementitious composites. J. Build. Eng. 2018, 18, 33–39. [Google Scholar] [CrossRef]

- Zhu, B.; Li, Y.; Tian, Y.; Wang, K.; Wang, Y.; Wen, G.; Liang, L.; Zhang, K.; Li, G. Rational design of FeCo/C/FA by recycling of fly ash for electromagnetic pollution. Coll. Surf. A Physicochem. Eng. Asp. 2021, 627, 127127. [Google Scholar] [CrossRef]

- Ozturk, M.; Karaaslan, M.; Akgol, O.; Sevim, U.K. Mechanical and electromagnetic performance of cement based composites containing different replacement levels of ground granulated blast furnace slag, fly ash, silica fume and rice husk ash. Cem. Concr. Res. 2020, 136, 106177. [Google Scholar] [CrossRef]

- Guan, H.; Liu, S.; Duan, Y.; Cheng, J. Cement based electromagnetic shielding and absorbing building materials. Cem. Concr. Compos. 2006, 28, 468–474. [Google Scholar] [CrossRef]

- Cao, J.; Chung, D.D.L. Coke powder as an admixture in cement for electromagnetic shielding. Carbon 2003, 41, 2433–2436. [Google Scholar] [CrossRef]

- Chung, D.D.L. Review article: Comparison of submicron-diameter carbon filaments and conventional carbon fibers as fillers in composite materials. Carbon 2001, 39, 1119–1125. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Submicron-diameter-carbon-filament cement–matrix composites. Carbon 1998, 36, 459–462. [Google Scholar] [CrossRef]

- González, M.; Mokry, G.; De Nicolás, M.; Baselga, J.; Pozuelo, J. Carbon Nanotube Composites as Electromagnetic Shielding Materials in GHz Range. In Carbon Nanotubes—Current Progress of Their Polymer Composites; Berber, M.R., Hafez, I.H., Eds.; IntechOpen Ltd.: London, UK, 2016; pp. 297–321. [Google Scholar] [CrossRef]

- Cao, M.S.; Wang, X.X.; Cao, W.Q.; Yuan, J. Ultrathin graphene: Electrical properties and highly efficient electromagnetic interference shielding. J. Mater. Chem. C 2015, 3, 6589–6599. [Google Scholar] [CrossRef]

- Cao, J.; Chung, D.D.L. Use of fly ash as an admixture for electromagnetic interference shielding. Cem. Concr. Res. 2004, 34, 1889–1892. [Google Scholar] [CrossRef]

- Duan, Y.; Liu, S.; Wen, B.; Guan, H.; Wang, G. A discrete slab absorber: Absorption efficiency and theory analysis. J. Compos. Mater. 2006, 40, 1841–1851. [Google Scholar] [CrossRef]

- Yao, W.L.; Xiong, G.X.; Yang, Y. Electromagnetic shielding effectiveness of nickel fiber-reinforced cement composites. Mater. Sci. Forum. 2017, 898, 2065–2070. [Google Scholar] [CrossRef]

- Lu, Z.; Jian, C.; Wan, S.; Liu, P. Research on New Technology on Protection of Electronic Systems from High Power Electromagnetic Pulse. In Proceedings of the Progress Electromagnetics Research Symposium, Xi’an, China, 22–26 March 2010. [Google Scholar]

- Wu, L.Z.; Ding, J.; Jiang, H.B.; Chen, L.F.; Ong, C.K. Particle size influence to the microwave properties of iron based magnetic particulate composites. J. Magn. Magn. Mater. 2005, 285, 233–239. [Google Scholar] [CrossRef]

- Wang, M.; Duan, Y.; Liu, S.; Li, X.; Ji, Z. Absorption properties of carbonyl-iron/carbon black double-layer microwave absorbers. J. Magn. Magn. Mater. 2009, 321, 3442–3446. [Google Scholar] [CrossRef]

- Chmielińska, J.; Kuchta, M.; Kubacki, R.; Dras, M.; Wierny, K. Wybrane metody ochrony urządzeń elektronicznych przed bronią elektromagnetyczną. Przegląd Elektrotechniczny 2016, 92. (In Polish) [Google Scholar] [CrossRef]

- Valko, L.; Bucek, P.; Dosoudil, R.; Usakova, M. Magnetic Properties of Ferrite-Polymer Composites. J. Electr. Eng. 2003, 54, 100–103. [Google Scholar]

- Gairola, S.P.; Vivek, V.; Singh, A.; Purohit, L.P.; Kotnala, R.K. Modified Composition of Barium ferrite to act as a Microwave Absorber in X-band Frequencies. Solid. State Commun. 2010, 150, 147–151. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W. Microwave absorbing properties of double-layer cementitious composites containing Mn–Zn ferrite. Cem. Concr. Compos. 2010, 32, 726–730. [Google Scholar] [CrossRef]

- Guan, B.; Ding, D.; Wang, L.F.; Wu, J.; Xiong, R. The electromagnetic wave absorbing properties of cement-based composites using natural magnetite powders as absorbers. Mater. Res. Express 2017, 4, 056103. [Google Scholar] [CrossRef]

- Garcés, P.; Fraile, J.; Vilaplana-Ortego, E.; Cazorla-Amorós, D.; Alcocel, E.G.; Andión, L.G. Effect of carbon fibres on the mechanical properties and corrosion levels of reinforced portland cement mortars. Cem. Concr. Res. 2005, 35, 324–331. [Google Scholar] [CrossRef]

- Jiang, S.; Zhou, D.; Zhang, L.; Ouyang, J.; Yu, X.; Cui, X.; Han, B. Comparison of compressive strength and electrical resistivity of cementitious composites with different nano- and micro-fillers. Arch. Civ. Mech. Eng. 2018, 18, 60–68. [Google Scholar] [CrossRef]

- Yang, H.; Cui, H.; Tang, W.; Li, Z.; Han, N.; Xing, F. A critical review on research progress of graphene/cement based composites. Compos. A Appl. Sci. Manuf. 2017, 102, 273–296. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Wu, Q.; Wu, Y.; Tong, W.; Ma, H. Utilization of nickel slag as raw material in the production of Portland cement for road construction. Constr. Build. Mater. 2018, 193, 426–434. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, F.; Ren, J.; Xie, H. Modeling and experimental study of multiple factors on mechanical strength of iron sand modified cement mortars. Constr. Build. Mater. 2018, 178, 144–152. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Zaporowski, P. Mechanical Properties of Shielding Concrete with Magnetite Aggregate Subjected to High Temperature. Procedia Eng. 2015, 108, 39–46. [Google Scholar] [CrossRef]

- EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. Available online: https://www.scirp.org/(S(i43dyn45teexjx455qlt3d2q))/reference/ReferencesPapers.aspx?ReferenceID=762757&utm_campaign=8504943975_134186287357&utm_source=lixiaofang&utm_medium=adwords&gad=1&gclid=EAIaIQobChMI-uKcr57t_gIVWwRyCh1yEwm9EAAYASAAEgKyVfD_BwE (accessed on 14 March 2023).

- Glabisz, W.; Hoła, J.; Łydżba, D.; Wójcicki, Z.; Trapko, T.; Majcher, K.P.; Musiał, M.P.; Pakos, W.M.; Różański, A.; Sobótka, M.; et al. Methods and Ways of Protecting and Defending from HPM Impulses—The Technology Concept of Building Absorbers; Report of Faculty of Civil Engineering of Wroclaw University of Science and Technology no SPR 58/2018; Wroclaw University of Science and Technology: Wroclaw, Poland, 2018. [Google Scholar]

- ASTM D4935-10; Standard Test Method for Measuring the Electromagnetic Shielding Effectiveness of Planar Materials. Available online: https://shieldingeffectiveness.com/astm-d-4935-10/ (accessed on 14 March 2023).

- Stefaniuk, D.; Sobótka, M.; Jarczewska, K.; Logoń, D.; Majcher, K.; Musiał, M.; Niewiadomski, P.; Pakos, W.; Różański, A.; Trapko, T. Microstructure properties of cementitious mortars with selected additives for electromagnetic waves absorbing applications. Cem. Concr. Compos. 2022, 134, 104732. [Google Scholar] [CrossRef]

| Symbol | Components | Characteristics |

|---|---|---|

| - | Portland cement CEM I 42.5R | Supplied by Górażdże Cement LC, Górażdże, Poland. Characterized by the specific density of 3090 kg/m3 and the specific surface of 4090 cm2/g. |

| - | Quartz aggregate CEN | According the standard PN-EN 196-1 [46]. The maximum particle size < 2 mm, the bulk density of 1440 kg/m3, the specific density of 2620 kg/m3. |

| - | Mains potable water | With the temperature of 20 °C. |

| FAA | Ashporite aggregate | Supplied by CERTYD, Białystok, Poland. Obtained from fly ash subjected to an industrial thermal process, with the maximum particle size being <2 mm, the bulk density of 900 kg/m3 ± 10%, and the <0.063 mm particles content of 30%. |

| BA | Barite aggregate | With the 0–8 mm fraction, density of 3850 kg/m3, heavy minerals (including BaSO4) content min. 70%. |

| FA | Fly ash | Supplied by CEZ, Skawina, Poland. With the specific density of 2190 kg/m3, the <0.063 mm particles content of 83% and the SiO2 content of 54.11%. |

| FG | Graphite in the form of FG597 flakes | Supplied by SINOGRAF, Toruń, Poland. With the minimum flake size of 300 µm, the carbon content of 97%, and the bulk density of 600 kg/m3. |

| MG | Graphite in the form of MG1596 powder | Supplied by SINOGRAF, Toruń, Poland. With the maximum flake size of µm, the carbon content of 96%, and the bulk density of 200–300 kg/m3. |

| CB1 | Carbon black RCB_615 | Supplied by REOIL, Bukowno, Poland. With the bulk density of 100–115 kg/m3, the specific surface of 65–80 m2/g, and the particle size distribution of 5–25 µm. |

| CB2 | Carbon black N772 | Supplied by FERMINTRADE, Konin, Poland. With the iodine absorption of 24–34 g/kg, the maximum ash content of 0.40%, and the minimum pour density of 420 kg/m3. |

| CB3 | Carbon black N990 | Supplied by FERMINTRADE, Konin, Poland. With the iodine absorption of 6–12 g/kg, the maximum ash content of 0.20%, and the pour density of 600 kg/m3. |

| CB4 | Carbon black P803 | Supplied by FERMINTRADE, Konin, Poland. With the conventional specific surface of 14–18 m2/g, the maximum ash content of 0.45%, and the pour density of 320–400 kg/m3. |

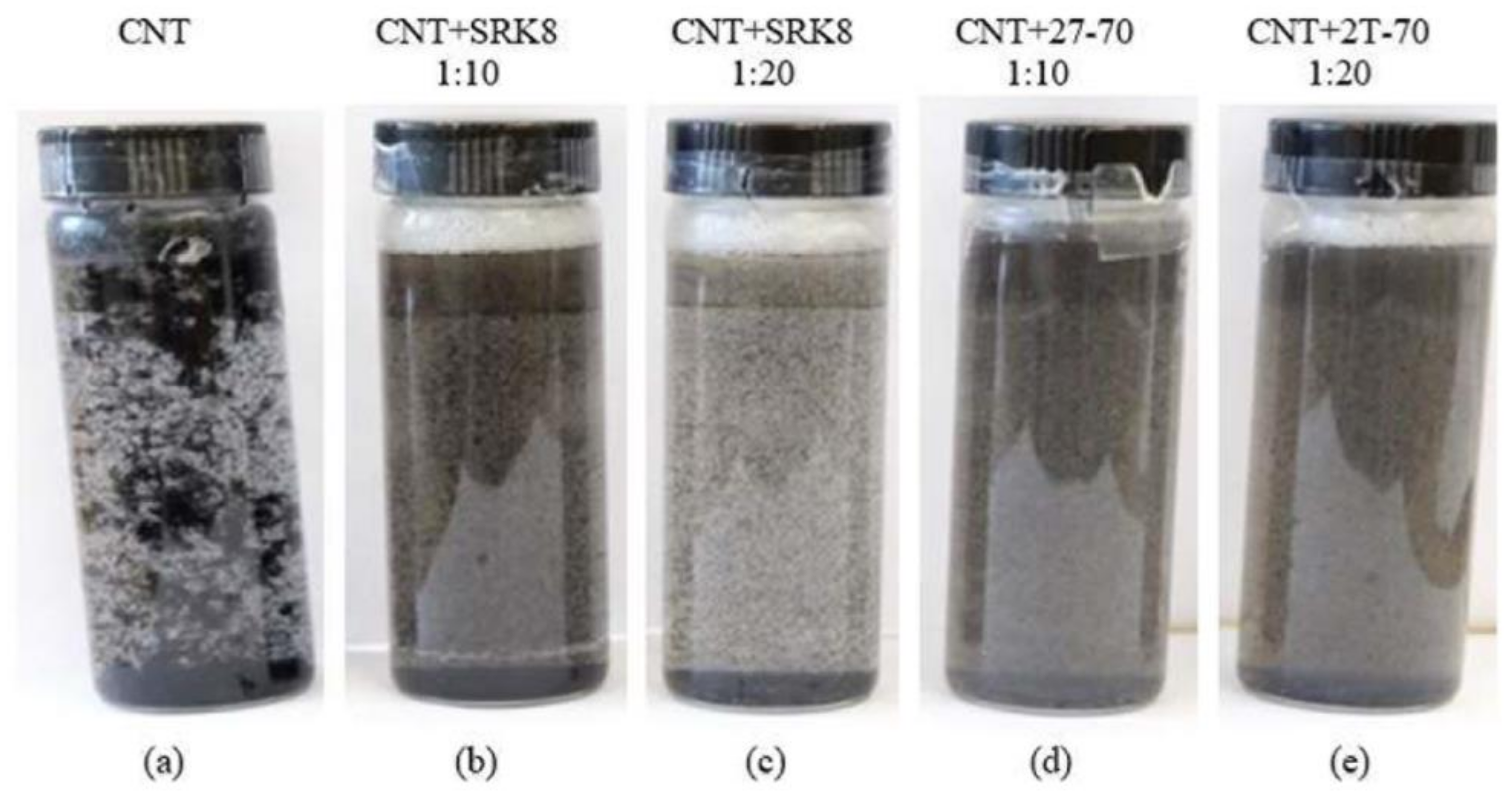

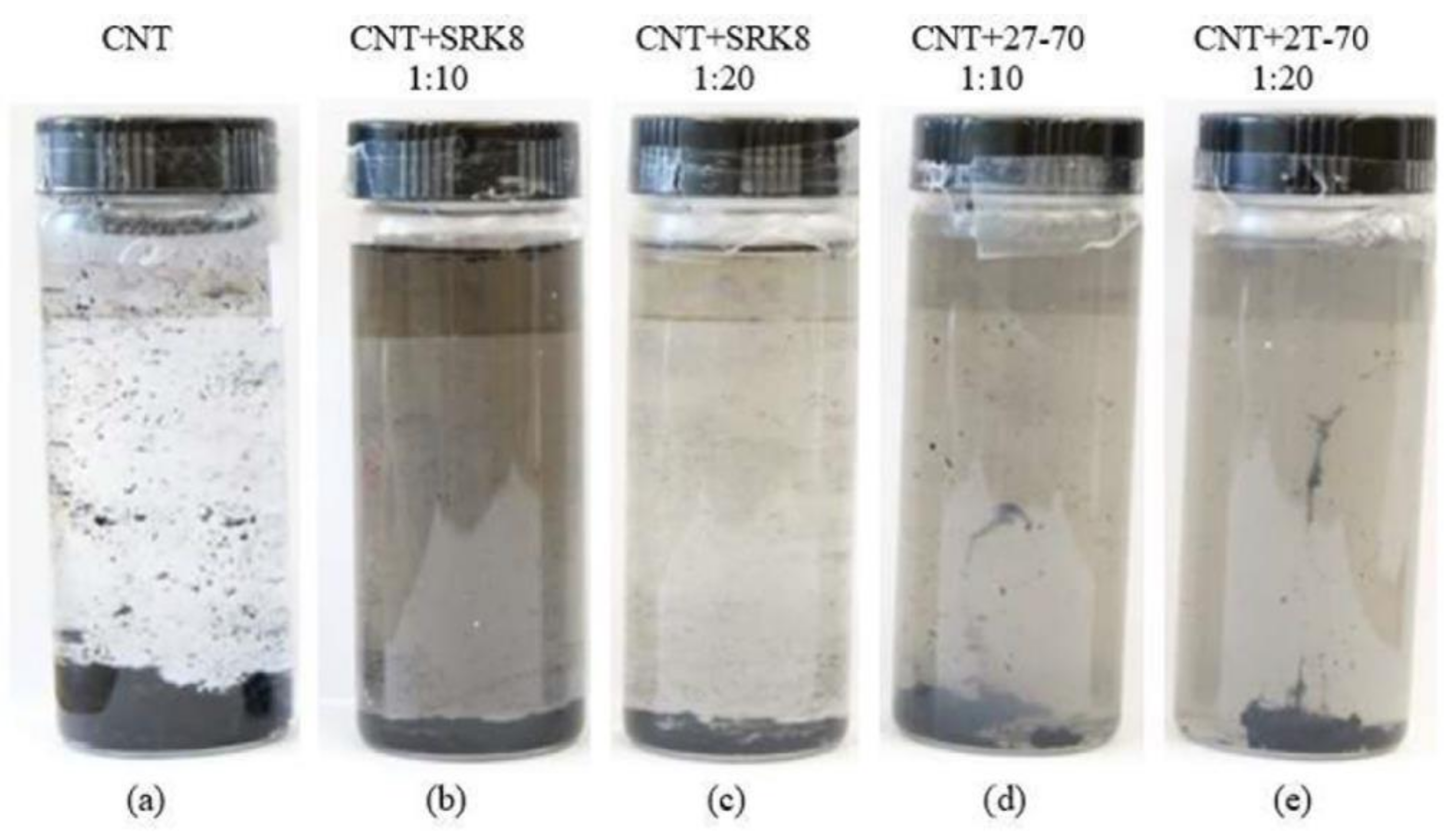

| CN | Multifaceted carbon nanotubes (mCNT) | Supplied by SMART NANOTECHNOLOGIES Inc, Alwernia, Poland. In the form of powder, with length of 1–25 µm, the bulk density of 230 kg/m3, the specific density of 1750–2100 kg/m3. |

| Ni | Nickel (Ni) nanopowder | Supplied by BIMO TECH, Wrocław, Poland. With a spherical shape, the particle size of 30–70 nm, the purity of 99.9%, and the specific density of 8900 kg/m3. |

| NiO | Nickel monoxide (NiO) nanopowder | Supplied by BIMO TECH, Wrocław, Poland. With a nearly spherical shape, the particle size of 20–30 nm, the purity of 99.9%, and the bulk density of 760 kg/m3. |

| FF | Filler FF + ferrite | Characterized by the specific density of 4900 kg/m3. |

| CI | Carbonyl iron CIP HQ | Supplied by BASF, Warszawa, Poland. With an onion skin structure, the minimum Fe content of 97.8%, the C and N content of 0.6–0.9%, and a very small particle size, i.e., 90% (by wt.) of particles < 3 μm, the specific density of 7860 kg/m3. |

| F | Ferrite FMS 0.05 | Supplied by Ferroxcube Poland Ltd, Skierniewice, Poland. With the composition: ~71% of iron oxide, ~21% of manganese oxide and ~8% of zinc oxide; most of the ferrite (>90%) has a particle size < 60 μm; the bulk density amounts to 1900 kg/m3. |

| Ni2O3 | Nickel oxide Ni2O3 | Characterized by the bulk density of 800 kg/m3, the specific density of 6800 kg/m3. |

| CIM | Carbonyl iron modified with SiO2 | - |

| AIR | Air-entraining admixture Sika PRO3 | Supplied by SIKA, Warszawa, Poland. Characterized by the density of 1005 kg/m3. |

| SF | Steel fibers | With a length of 6 mm, a diameter of 0.2 mm and ft = 2500 MPa, and hooked-end steel fibers with a length of 50 mm, a diameter of 1 mm and ft = 1100 MPa, the specific density of 7800 kg/m3. |

| PF | Polypropylene fibers | With a length of 10 mm, a diameter of 0.03 mm and ft = 300–400 MPa, and with a length of 45 mm, a diameter of 0.95 and ft = 400 MPa, the specific density of 900 kg/m3. |

| Component | Types of Cement Paste | |||||

|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | |

| Symbol | ||||||

| M | CN | FAA | BA | SF | PF | |

| [g/dm3] | [g/dm3] | [g/dm3] | [g/dm3] | [g/dm3] | [g/dm3] | |

| Cement CEM I 42.5R | 540 | 540 | 540 | 540 | 675 | 1012.5 |

| Quartz aggregate | 1620 | 1620 | - | - | - | - |

| Water | 270 | 400 | 420 | 270 | 506.25 | 506.25 |

| Ashporite aggregate | - | - | 930 | - | - | - |

| Barite aggregate | - | - | - | 2445 | - | - |

| Standard sand | - | - | - | - | 1000 | 1000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musiał, M.; Logoń, D.; Majcher, K.; Niewiadomski, P.; Trapko, T.; Jarczewska, K.; Pakos, W.; Różański, A.; Sobótka, M.; Stefaniuk, D. Evaluation of Mechanical Properties and HPM Pulse Shielding Effectiveness of Cement-Based Composites. Energies 2023, 16, 4062. https://doi.org/10.3390/en16104062

Musiał M, Logoń D, Majcher K, Niewiadomski P, Trapko T, Jarczewska K, Pakos W, Różański A, Sobótka M, Stefaniuk D. Evaluation of Mechanical Properties and HPM Pulse Shielding Effectiveness of Cement-Based Composites. Energies. 2023; 16(10):4062. https://doi.org/10.3390/en16104062

Chicago/Turabian StyleMusiał, Michał, Dominik Logoń, Krzysztof Majcher, Paweł Niewiadomski, Tomasz Trapko, Kamila Jarczewska, Wojciech Pakos, Adrian Różański, Maciej Sobótka, and Damian Stefaniuk. 2023. "Evaluation of Mechanical Properties and HPM Pulse Shielding Effectiveness of Cement-Based Composites" Energies 16, no. 10: 4062. https://doi.org/10.3390/en16104062

APA StyleMusiał, M., Logoń, D., Majcher, K., Niewiadomski, P., Trapko, T., Jarczewska, K., Pakos, W., Różański, A., Sobótka, M., & Stefaniuk, D. (2023). Evaluation of Mechanical Properties and HPM Pulse Shielding Effectiveness of Cement-Based Composites. Energies, 16(10), 4062. https://doi.org/10.3390/en16104062