Study on Intermittent Microwave Convective Drying Characteristics and Flow Field of Porous Media Food

Abstract

1. Introduction

- To acquire the drying characteristics of apple slices during IMCD and compare those with CD;

- To investigate the mechanism of evaporation interface movement under intermittent microwave in multi-physics fields and analyze its migration effect;

- To explore the effect of flow-field distribution on IMCD through different curvatures of the inlet and outlet.

2. Model Development

2.1. Problem Description and Assumptions

- The medium is regarded as continuous and homogeneous, based on the definition of a representative elementary volume (REV);

- Thermophysical properties of air during drying are constants. The airflow in oven is laminar and steady;

- No shrinkage and other deformation occur during drying;

- The initial temperature and moisture distribution inside the material are uniform.

2.2. Governing Equations

2.2.1. Calculation of Forced-Flow Subdomain

2.2.2. Calculation of Porous Media Subdomain

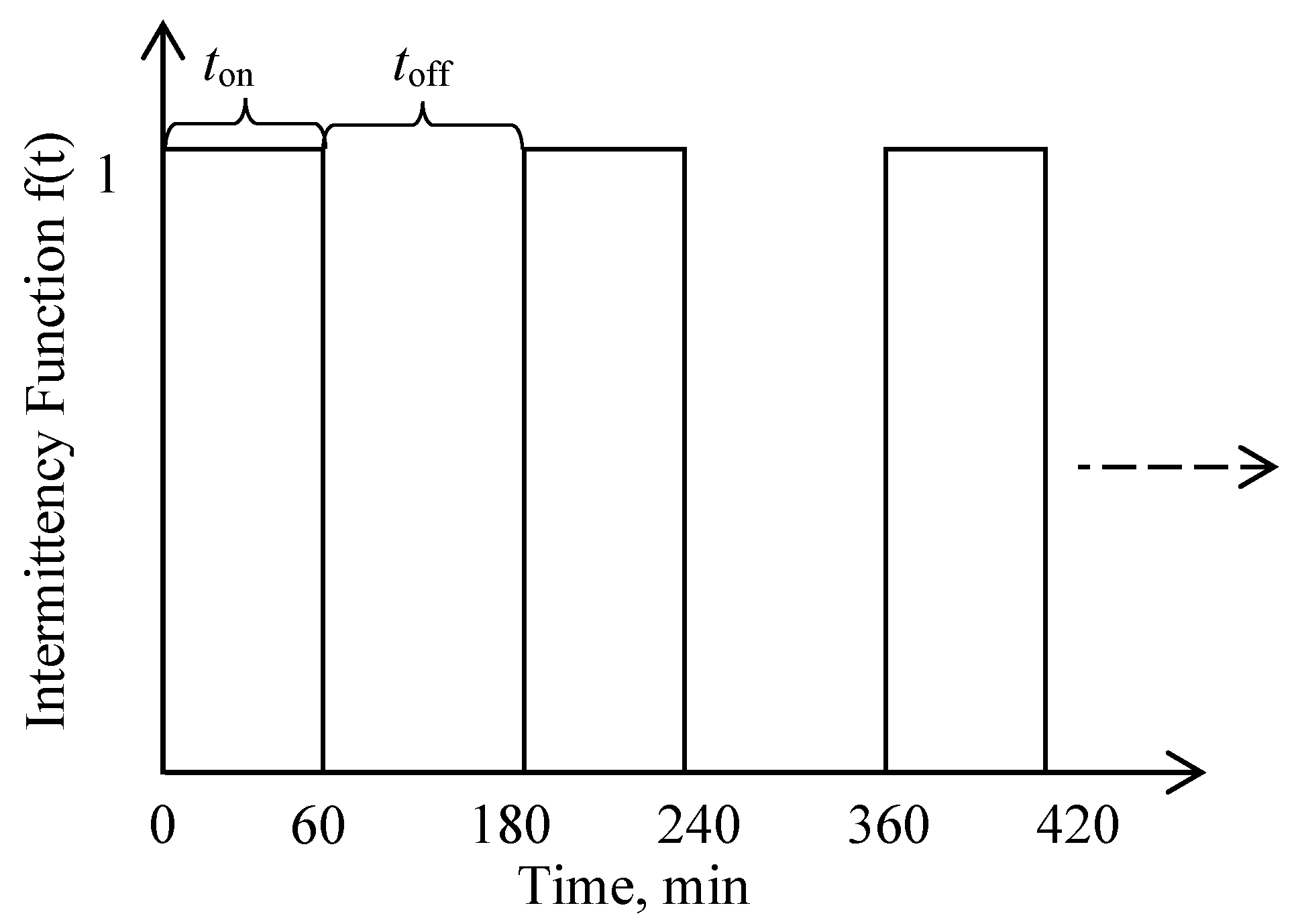

2.2.3. Intermittency Function

2.2.4. Boundary Conditions

2.2.5. Initial Condition

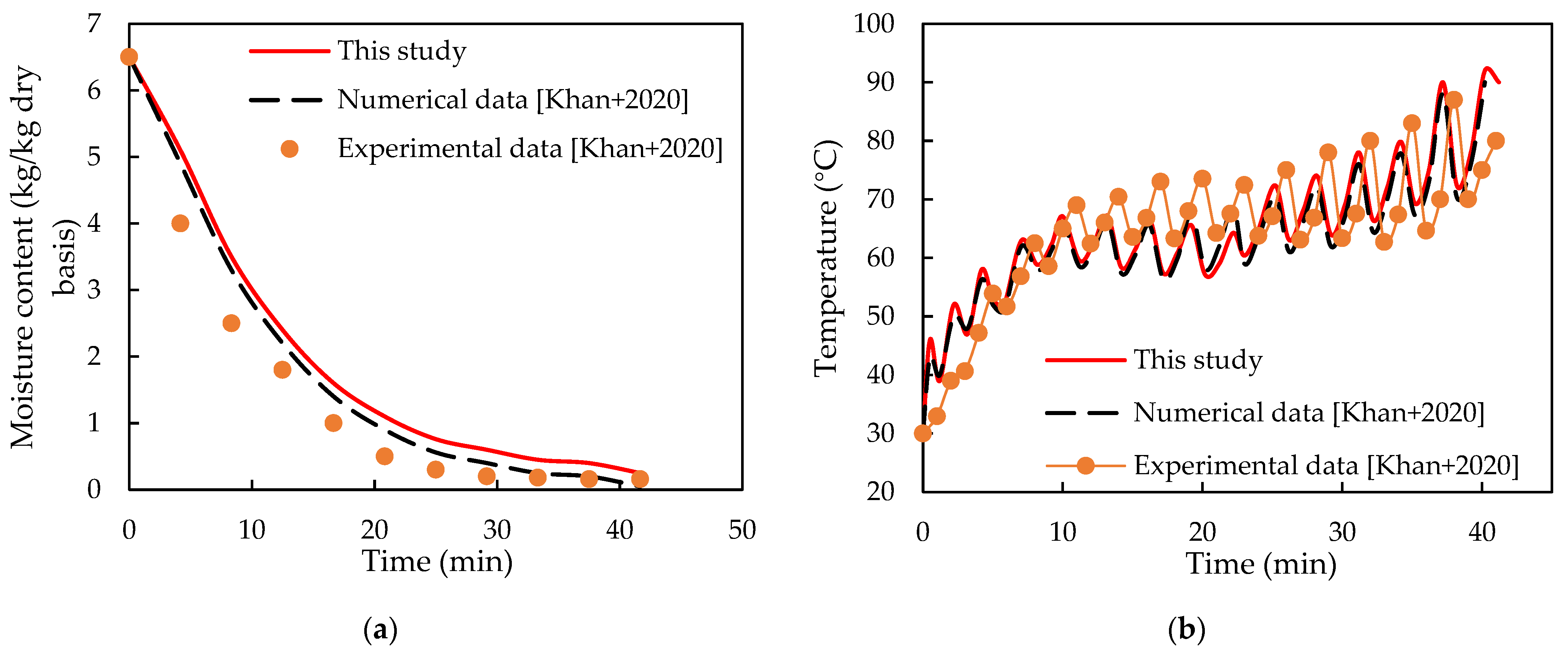

2.3. Grid Sensitivity and Model Validation

3. Results and Discussions

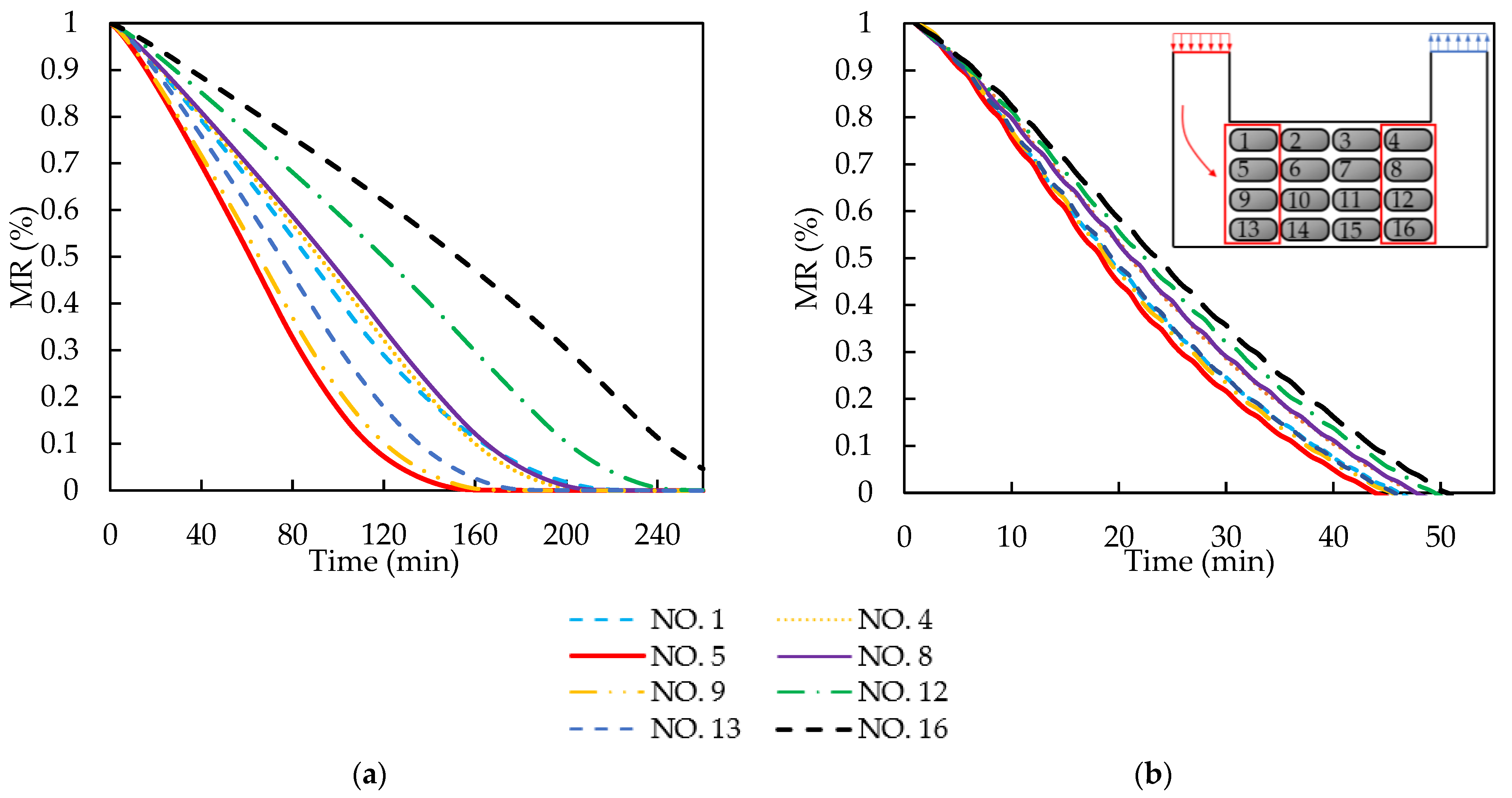

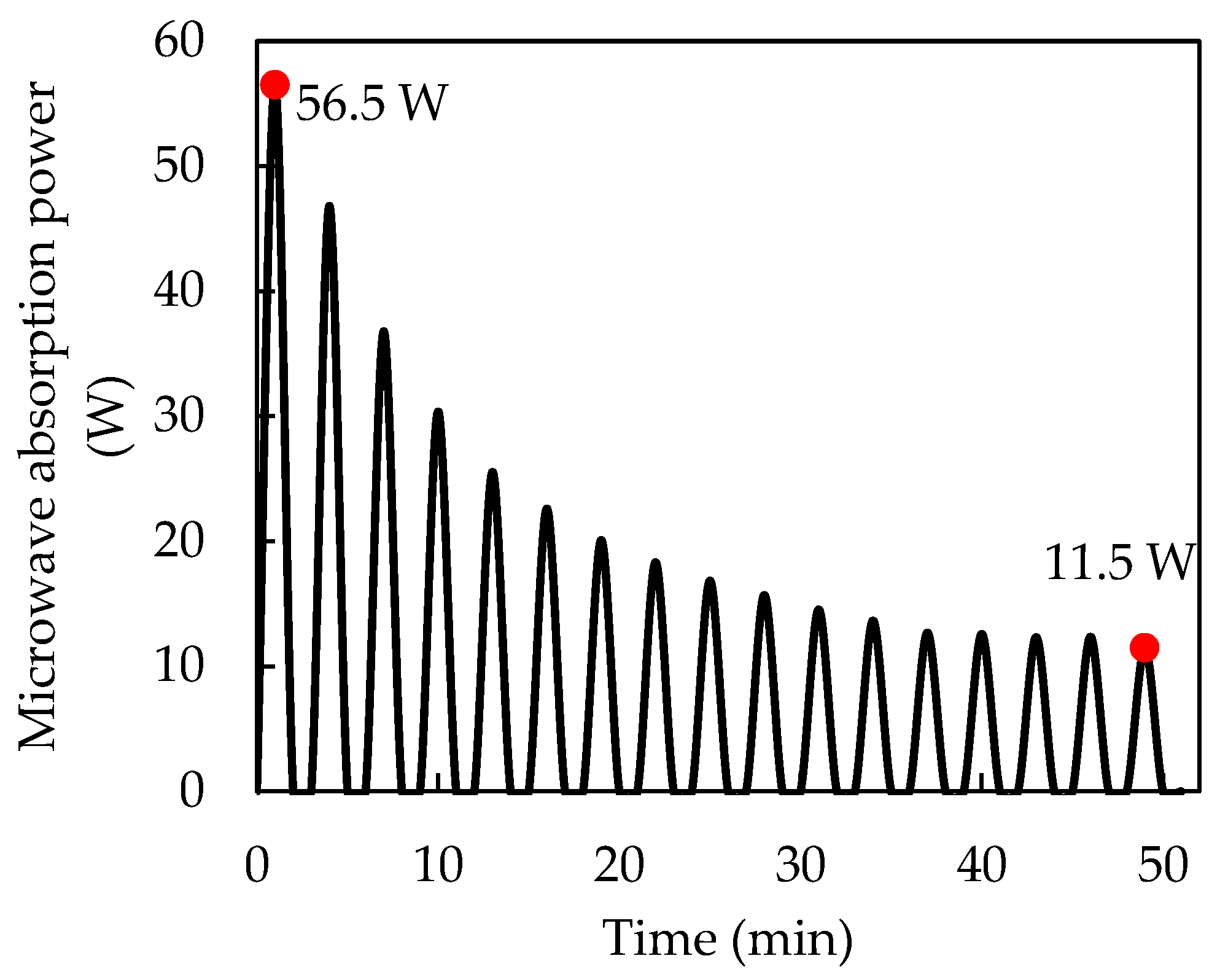

3.1. Drying Characteristics of IMCD

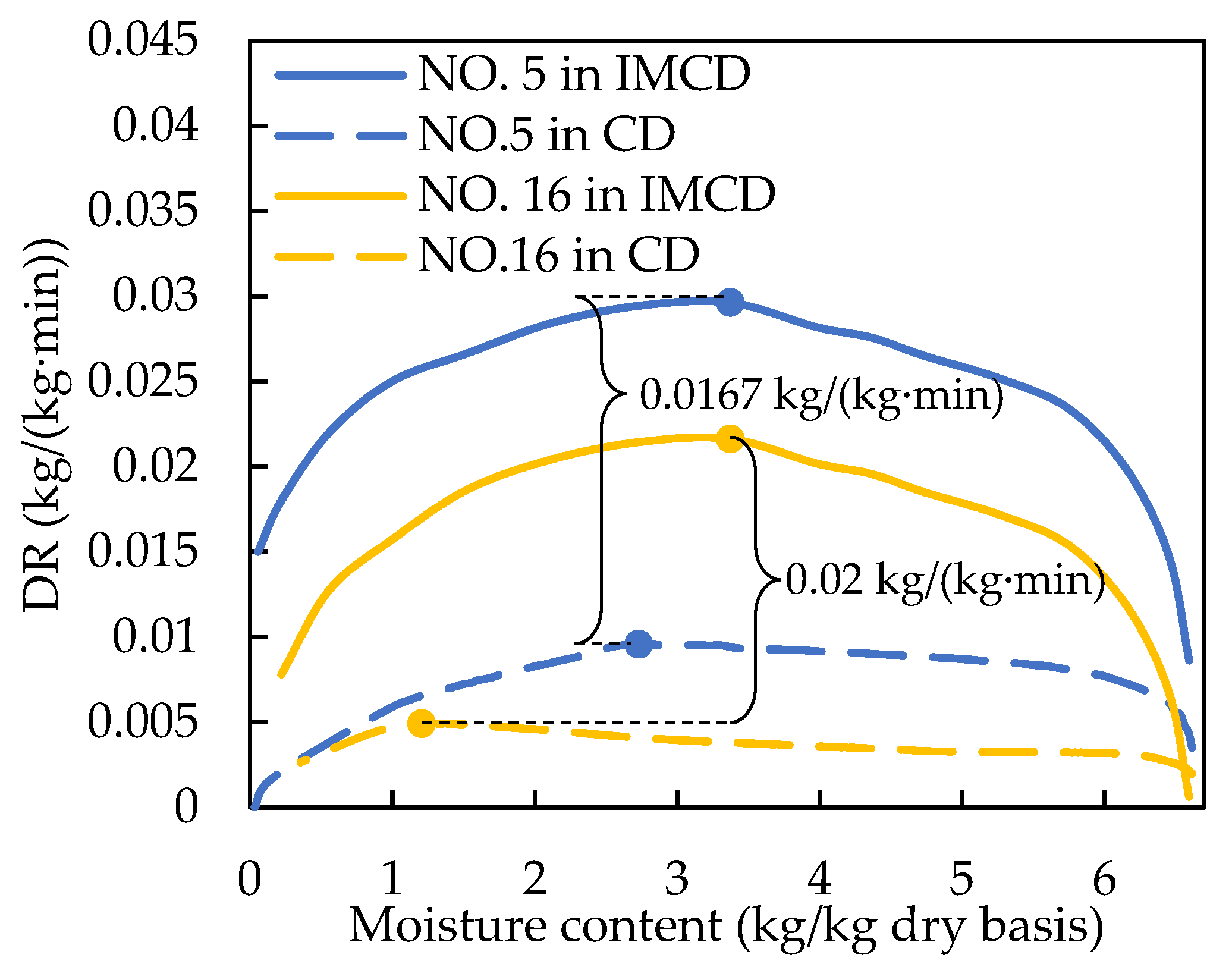

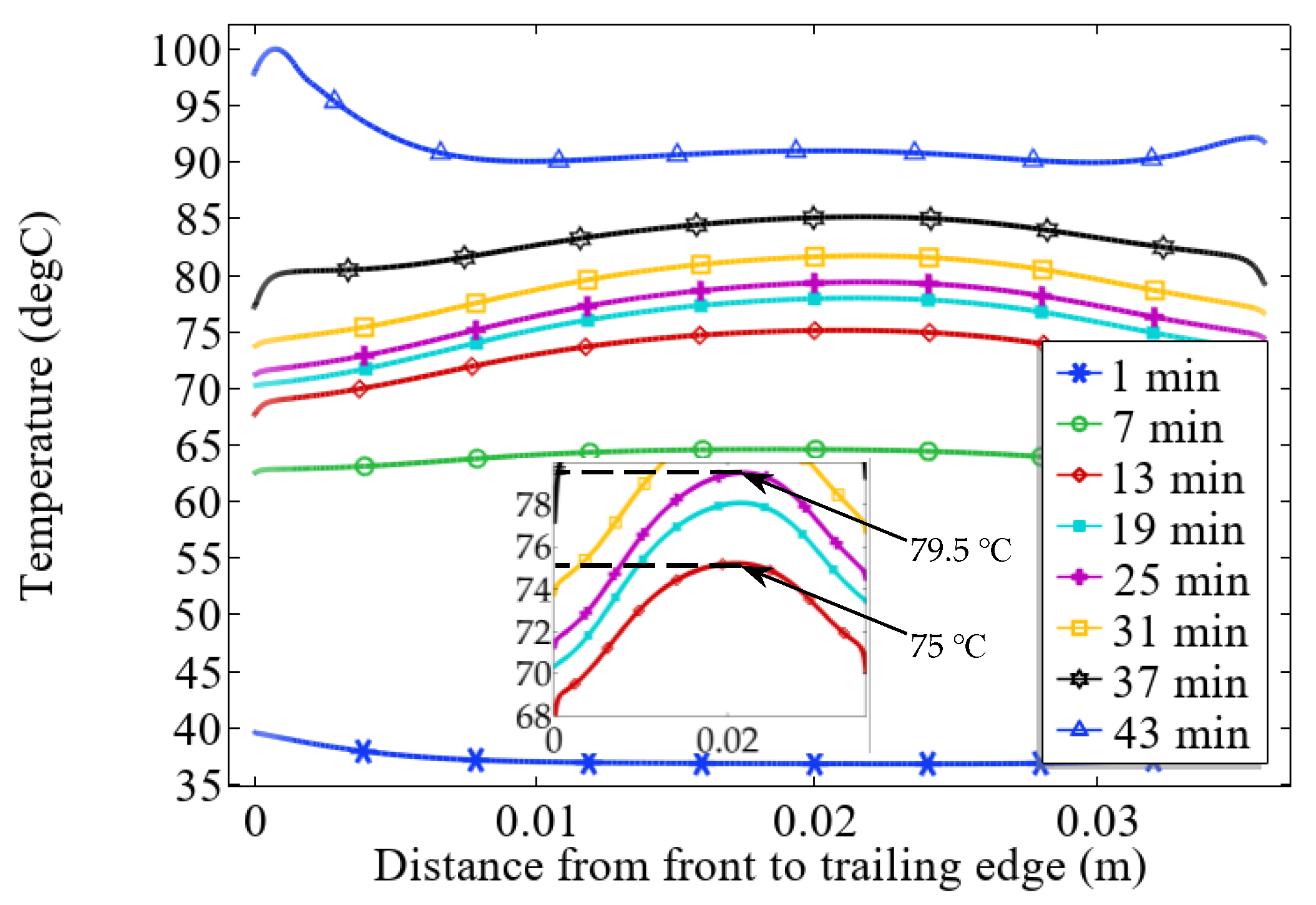

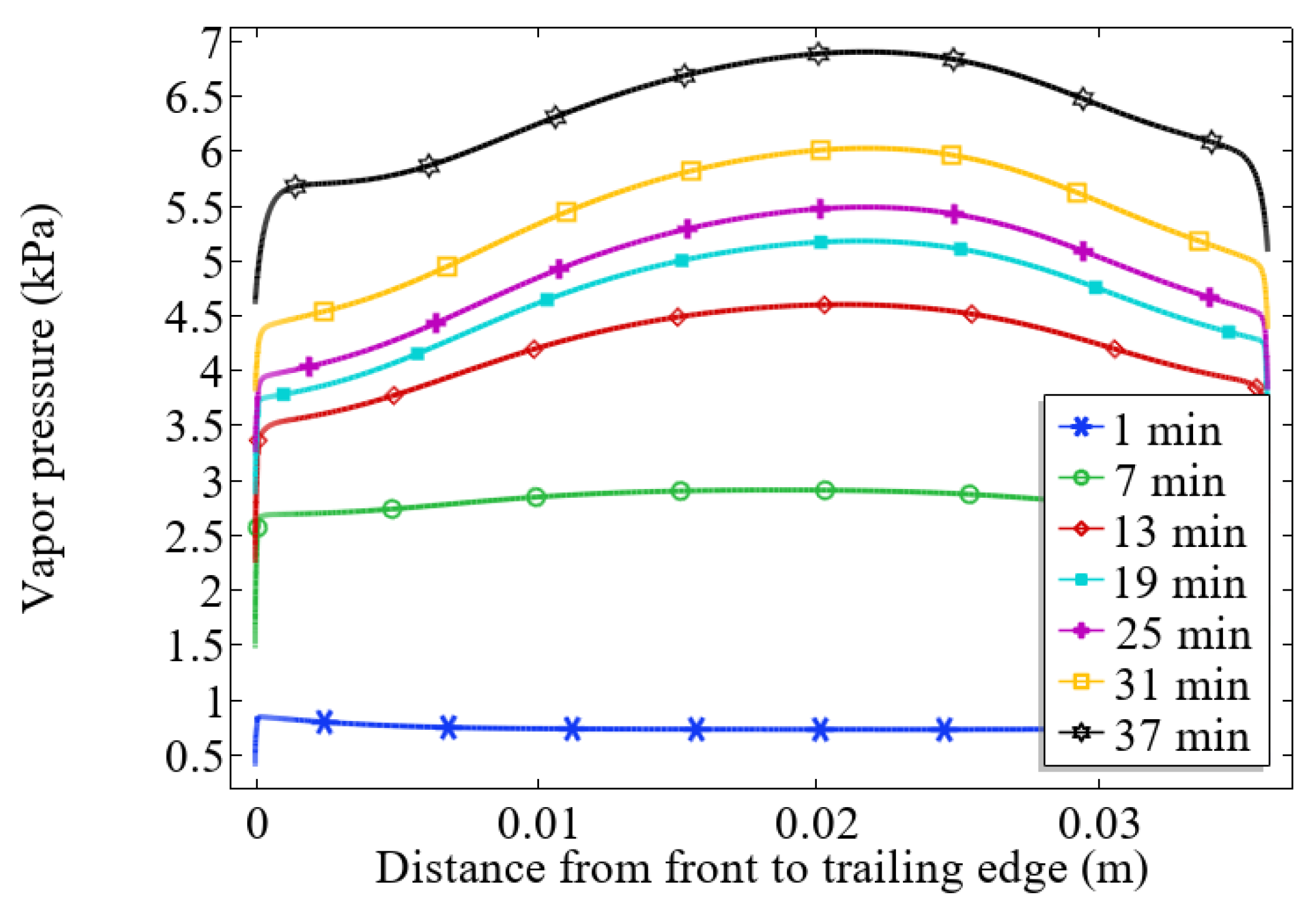

3.2. Distribution of Evaporation Interface

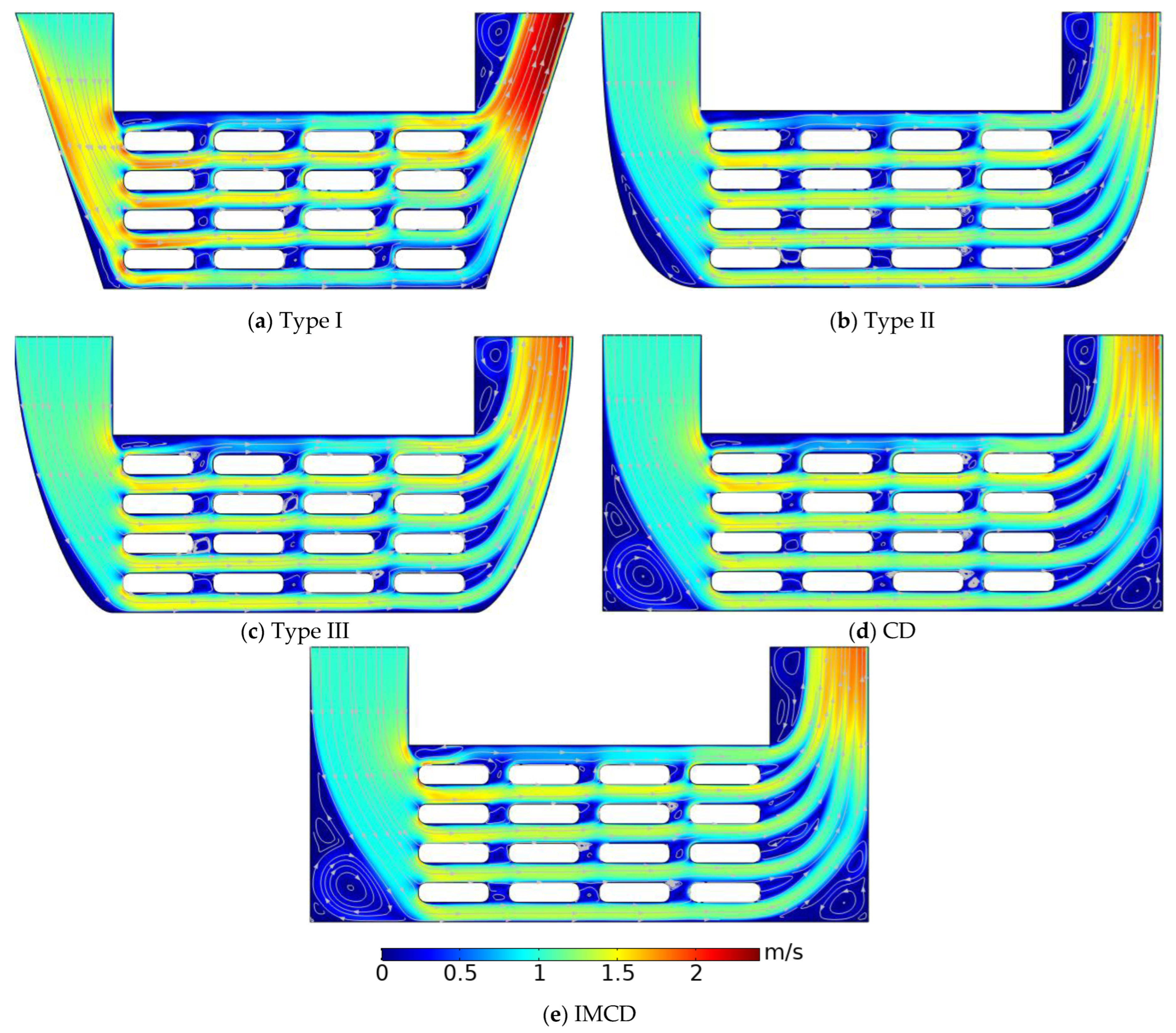

3.3. Flow-Field Distribution and Its Effect on Drying Kinetics

4. Conclusions

- Compared with convection drying, intermittent microwave convection drying can shorten the drying time by 81.35% and enhance the drying uniformity by 28.1%, thus realizing drying optimization;

- In the later stage of drying, most of the moisture needs to migrate outside the material for evaporation. Because intermittent microwave energy directly penetrates into water and promotes its rapid migration, IMCD performs better in the later stage of drying. In particular, application of intermittency microwaves provides additional drying energy to the back-row samples, and the optimization effect is more pronounced in a multi-materials oven;

- Through comprehensive analysis of the drying uniformity, heat transfer, and energy consumption of the ovens with different inlet and outlet wall curvatures, it is concluded that the drying uniformity is significantly improved by reducing the vortex below the inlet and outlet. Type III provides the greatest improvement in IMCD uniformity and drying performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.; Jia, B.; Liu, F.; Yuan, S. Study on optimization of hot air drying temperature for apple slices. J. Shandong Jianzhu Univ. 2021, 36, 67–74. [Google Scholar]

- Kahveci, K. Modeling and Numerical Simulation of Simultaneous Heat and Mass Transfer during Convective Drying of Porous Materials. Text. Res. J. 2016, 87, 617–630. [Google Scholar] [CrossRef]

- Tepe, T.K.; Begüm, T. The comparison of drying and rehydration characteristics of intermittent-microwave and hot-air dried-apple slices. Heat Mass Transf. 2020, 56, 3047–3057. [Google Scholar] [CrossRef]

- Shokri, N.; Or, D. What determines drying rates at the onset of diffusion controlled stage-2 evaporation from porous media? Water Resour. Res. 2011, 47, W09513. [Google Scholar] [CrossRef]

- Kumar, C.; Karim, M.A.; Joardder, M.U.H. Intermittent drying of food products: A critical review. J. Food Eng. 2014, 121, 48–57. [Google Scholar] [CrossRef]

- Kumar, C.; Joardder, M.U.H.; Farrell, T.W.; Karim, M.A. Multiphase porous media model for intermittent microwave convective drying (IMCD) of food. Int. J. Therm. Sci. 2016, 104, 304–314. [Google Scholar] [CrossRef]

- Omolola, A.O.; Jideani, A.; Kapila, P.F. Modeling microwave drying kinetics and moisture diffusivity of Mabonde banana variety. Int. J. Agric. Biol. Eng. 2014, 7, 107–113. [Google Scholar]

- Wang, Z.; Sun, J.; Chen, F.; Liao, X.; Hu, X. Mathematical modelling on thin layer microwave drying of apple pomace with and without hot air pre-drying. J. Food Eng. 2007, 80, 536–544. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Han, X.; Ni, Y.; Zhao, D.; Hao, J. Quality evaluation and drying kinetics of shitake mushrooms dried by hot air, infrared and intermittent microwave–assisted drying methods. Lwt Food Sci. Technol. 2019, 107, 236–242. [Google Scholar] [CrossRef]

- Kumar, C.; Joardder, M.U.H.; Farrell, T.W.; Millar, G.J.; Karim, M.A. Mathematical model for intermittent microwave convective drying of food materials. Dry. Technol. 2016, 34, 962–973. [Google Scholar] [CrossRef]

- Szadzińska, J.; Kowalski, S.J.; Stasiak, M. Microwave and ultrasound enhancement of convective drying of strawberries: Experimental and modeling efficiency. Int. J. Heat Mass Transf. 2016, 103, 1065–1074. [Google Scholar] [CrossRef]

- Chen, J.; Pitchai, K.; Birla, S.; Negahban, M.; Jones, D.; Subbiah, J. Heat and mass transport during microwave heating of mashed potato in domestic ovendmodel development, validation, and sensitivity analysis. J. Food Sci. 2014, 79, E1991–E2004. [Google Scholar] [CrossRef] [PubMed]

- Jumah, R.; Mujumdar, A.S. Modeling intermittent drying using an adaptive neuro-fuzzy inference system. Dry. Technol. 2005, 23, 1075–1092. [Google Scholar] [CrossRef]

- Arballo, J.R.; Campañone, L.A.; Mascheroni, R.H. Modeling of Microwave Drying of Fruits. Part II: Effect of Osmotic Pretreatment on the Microwave Dehydration Process. Dry. Technol. 2012, 30, 404–415. [Google Scholar] [CrossRef]

- Gulati, T.; Zhu, H.; Datta, A.K.; Huang, K. Microwave drying of spheres: Coupled electromagnetics-multiphase transport modeling with experimentation. Part II: Model validation and simulation results. Food Bioprod. Process. 2015, 96, 326–337. [Google Scholar] [CrossRef]

- Kumar, C.; Joardder, M.U.H.; Farrell, T.W.; Karim, M.A. Investigation of intermittent microwave convective drying (IMCD) of food materials by a coupled 3D electromagnetics and multiphase model. Dry. Technol. 2018, 36, 736–750. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, W.; Shi, B.; Gao, J.; Zhang, S. Modelling of intermittent microwave convective drying: Parameter sensitivity. Open Phys. 2017, 15, 405–419. [Google Scholar] [CrossRef]

- Defraeye, T.; Radu, A. Insights in convective drying of fruit by coupled modeling of fruit drying, deformation, quality evolution and convective exchange with the airflow. Appl. Therm. Eng. 2018, 129, 1026–1038. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Welsh, Z.; Gu, Y.; Karim, M.A.; Bhandari, B. Modelling of simultaneous heat and mass transfer considering the spatial distribution of air velocity during intermittent microwave convective drying. Int. J. Heat Mass Transf. 2020, 153, 119668. [Google Scholar] [CrossRef]

- Zhao, J.; Fu, Z.; Jia, X.; Cai, Y. Modeling conventional drying of wood: Inclusion of a moving evaporation interface. Dry. Technol. 2016, 34, 530–538. [Google Scholar] [CrossRef]

- Chen, A.; Achkar, G.E.L.; Liu, B.; Bennacer, R. Experimental study on moisture kinetics and microstructure evolution in apples during high power microwave drying process. J. Food Eng. 2021, 292, 110362. [Google Scholar] [CrossRef]

- Purlis, E. Modelling convective drying of foods: A multiphase porous media model considering heat of sorption. J. Food Eng. 2019, 263, 132–146. [Google Scholar] [CrossRef]

- Whitaker, S. Simultaneous heat, mass, and momentum transfer in porous media: A theory of drying. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 1977; Volume 13, pp. 119–203. [Google Scholar]

- Hu, Z.; Yang, M.; Yang, Z.; Yang, L. Hot air drying model based on multi-physical field coupling and its verification. J. Southwest Univ. Nat. Sci. Ed. 2020, 42, 118–128. [Google Scholar]

- Gulati, T.; Datta, A.K. Enabling computer-aided food process engineering: Property estimation equations for transport phenomena-based models. J. Food Eng. 2013, 116, 483–504. [Google Scholar] [CrossRef]

- Halder, A.; Dhall, A.; Datta, A.K. Modeling Transport in Porous Media with Phase Change: Applications to Food Processing. J. Heat Transf. 2011, 133, 031010. [Google Scholar] [CrossRef]

- Hemis, M.; Choudhary, R.; Watson, D.G. A coupled mathematical model for simultaneous microwave and convective drying of wheat seeds. Biosyst. Eng. 2012, 112, 202–209. [Google Scholar] [CrossRef]

- Martín-Esparza, M.; Martínez-Navarrete, N.; Chiralt, A.; Fito, P. Dielectric behavior of apple (var. Granny Smith) at different moisture contents. J. Food Eng. 2006, 77, 51–56. [Google Scholar] [CrossRef]

- Datta, A.K. Porous media approaches to studying simultaneous heat and mass transfer in food processes. II: Property data and representative results. J. Food Eng. 2007, 80, 96–110. [Google Scholar] [CrossRef]

- Ni, H. Multiphase Moisture Transport in Porous Media under Intensive Microwave Heating; Cornell University: Ithaca, NY, USA, 1997. [Google Scholar]

- Białobrzewski, I. Simulation of changes in the density of an apple slab during drying. Int. Commun. Heat Mass Transf. 2006, 33, 880–888. [Google Scholar] [CrossRef]

- Pham, N.D.; Martens, W.; Karim, M.A.; Joardder, M. Nutritional quality of heat-sensitive food materials in intermittent microwave convective drying. Food Nutr. Res. 2018, 62, 1292–1303. [Google Scholar] [CrossRef]

- Rakesh, V.; Datta, A.; Walton, J.; McCarthy, K.; McCarthy, M. Microwave combination heating: Coupled electromagnetics e multiphase porous media modeling and MRI experimentation. AIChE J. 2012, 58, 1262–1278. [Google Scholar] [CrossRef]

- Cengel, Y.; Boles, M. Thermodynamics: An engineering approach. Sea 2002, 1000, 8862. [Google Scholar]

- Luo, W.J.; Lin, C.Y.; Wu, N.F.; Xu, Z.Q. Performance Enhancement of a Sludge Continuous Feed Heat Pump Drying System by Air Deflectors and Auxiliary Cooling Subsystems. Energies 2020, 13, 6651. [Google Scholar] [CrossRef]

| Parameter | Value (Unit) | Reference |

|---|---|---|

| Initial temperature, T0 | 293.15 (K) | This work |

| Drying air temperature, Tin | 333 (K) | This work |

| Drying air velocity, u0 | 1 (m/s) | This work |

| Specific heat of air, cp,a | 1005.68 (J/kg·K) | [6] |

| Specific heat of vapor, cp,v | 1.9 × 103 (J/kg·K) | [6] |

| Specific heat of water, cp,w | 4.184 × 103 (J/kg·K) | [19] |

| Air density, ρ0 | 1.073 (kg/m3) | This work |

| Relative humidity, RH | 0.15 | This work |

| Initial equivalent porosity, ε0 | 0.922 | [6] |

| Initial moisture content (dry basis), Md0 | 6.5 (kg/kg) | [19] |

| Thermal conductivity of water, λw | 0.644 (W/(m·K)) | [33] |

| Thermal conductivity of gas (air), λg | 0.026 (W/(m·K)) | [33] |

| Molecular weight of air, Ma | 0.029 (kg/mol) | [34] |

| Molecular weight of water, Mw | 0.018 (kg/mol) | [34] |

| Density of water, ρw | 1000 (kg/m3) | This work |

| Evaporation constant, Kevap | 1000 (1/s) | [6] |

| Latent heat of water evaporation, γ | 2.3586 × 106 (J/kg) | [19] |

| Number of Grid Elements | 46,088 | 80,665 | 90,084 | 102,784 | 120,683 | 140,630 |

| Relative error | 15.68% | 11.83% | 2.1% | 0.45% | 0.16% | 0% |

| Type I | Type II | Type III | CD | IMCD | |

|---|---|---|---|---|---|

| Drying uniformity | 87.94% | 86.68% | 89.28% | 40.06% | 68.16% |

| Temperature difference | 55.18 °C | 54.46 °C | 55.06 °C | 39.46 °C | 44.15 °C |

| Humidity difference | 0.0036 | 0.0047 | 0.004 | 0.0029 | 0.018 |

| Velocity difference | 0.234 m/s | 0.0992 m/s | 0.1069 m/s | 0.0596 m/s | 0.0535 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Man, Y.; Tong, J.; Wang, T.; Wang, S.; Xu, H. Study on Intermittent Microwave Convective Drying Characteristics and Flow Field of Porous Media Food. Energies 2023, 16, 441. https://doi.org/10.3390/en16010441

Man Y, Tong J, Wang T, Wang S, Xu H. Study on Intermittent Microwave Convective Drying Characteristics and Flow Field of Porous Media Food. Energies. 2023; 16(1):441. https://doi.org/10.3390/en16010441

Chicago/Turabian StyleMan, Yu, Junjie Tong, Tingyu Wang, Shuxiang Wang, and Hu Xu. 2023. "Study on Intermittent Microwave Convective Drying Characteristics and Flow Field of Porous Media Food" Energies 16, no. 1: 441. https://doi.org/10.3390/en16010441

APA StyleMan, Y., Tong, J., Wang, T., Wang, S., & Xu, H. (2023). Study on Intermittent Microwave Convective Drying Characteristics and Flow Field of Porous Media Food. Energies, 16(1), 441. https://doi.org/10.3390/en16010441