Abstract

Electrical machines are prone to faults and failures and demand incessant monitoring for their confined and reliable operations. A failure in electrical machines may cause unexpected interruptions and require a timely inspection of abnormal conditions in rotating electric machines. This article aims to summarize an up-to-date overview of all types of bearing faults diagnostic techniques by subdividing them into different categories. Different fault detection and diagnosis (FDD) techniques are discussed briefly for prognosis of numerous bearing faults that frequently occur in rotating machines. Conventional approaches, statistical approaches, and artificial intelligence-based architectures such as machine learning and deep learning are discussed summarily for the diagnosis of bearing faults that frequently arise in revolving electrical machines. The most advanced trends for diagnoses of frequent bearing faults based on intelligence and novel applications are reviewed. Future research directions that are helpful to enhance the performance of conventional, statistical, and artificial intelligence (machine learning, deep learning) and novel approaches are well addressed and provide hints for future work.

1. Introduction

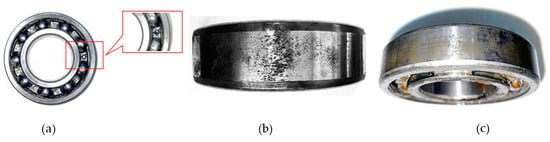

Electrical machines are considered the backbone of the industry and play a major role in industrial, commercial, and domestic applications. These electric machines have to work under different circumstances such as extreme ambient temperature, frequently varying load conditions, fluctuations in voltages and currents, high moisture, and overloads causing faults and failures [1]. Bearing faults are considered the most frequent types and are accountable for 30% to 40% of failures in rotating electric machines. Previous studies suggest that 80% of failures in bearings occur due to a lack of proper lubrication [2]. Bearings are subjected to rotation, which is mostly because of the mechanical stress endured during rotational movement and bearing currents. The failures in the bearings mostly happen due to poor installation, poor assembling, improper use, and improper maintenance. The movement of current in the bearing depends upon shaft voltages and capacitive currents caused by frequency and power supply control inverters. Another cause for the failures of bearings is contamination, mostly caused by foreign substances from external sources in the bearing lubricant. The foreign substances contain dirt (sand) and water entering through the seal, causing the failures in bearings [3]. Electrical and mechanical failures in machines have some unique features to diagnose them, and most techniques employing motor current signature analysis (MCSA) are implemented [4]. Figure 1 shows the ball bearing with broken cage, material fatigue and moisture-based corrosion.

Figure 1.

(a) Ball bearing structure. (b) Outer raceway fault. (c) Inner raceway fault.

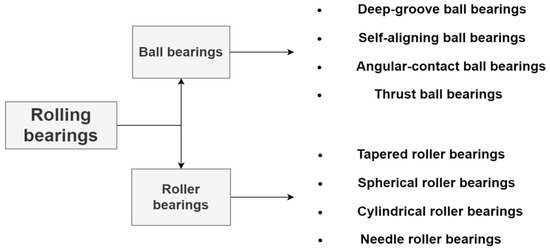

Mostly, faults and failures occur in bearings due to microscopic sub-surfaces, metal surfaces, and cyclic loading stress on the bearing. These variable and cyclic loads produce separation in the bearing surfaces, which further leads to a sapling in the rolling element of the bearings. These developments will increase noise and vibrations, which alter the internal dimension of bearings. The parameters resembling noise, vibration, and temperature cause more saplings in the bearing and damage it entirely. Thermal stress comprises 50% of failures in bearings and also wipes out the lubricant and creates conditions unsafe for consistent operations. Frequent failures in bearings are also due to flaking and pitting, unusual wear patterns, saplings, rust, corrosion, creeping, and usually some other relatively small combination of causes that are mostly correctable and predictable. Another reason for bearing failure is fluting, which occurs when alternating current (AC) or direct current (DC) passes through bearings during operation and harms the symmetry of the bearings due to circulating currents [5]. When an unfixable failure is found in the bearings, it is necessary to explore the causes of the defects to prevent future failures in these precise parts of the machines. Figure 2 shows the major types of classifications established in rolling bearings with their specific types.

Figure 2.

The major classifications of rolling bearings.

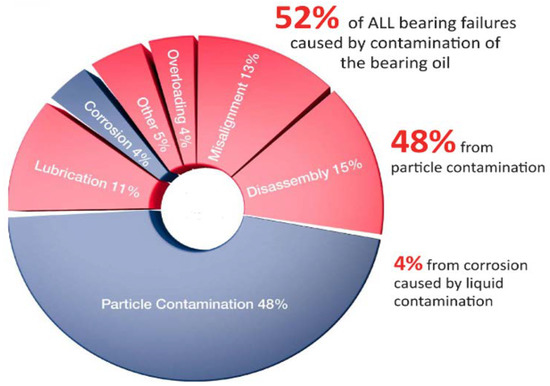

Traditionally, vibration analyses are mostly employed for the extraction of essential features through sensors for diagnostics and can also be used for the generation of datasets, which are further minimized by dimension reduction techniques such as principal component analysis (PCA) and linear discriminant analysis (LDA) for accurate measurements of distinctive values for the diagnosis of a defective bearing. To extract precise and useful information from vibration signals, signal processing techniques are adopted that change information from the time domain to the frequency domain through fast Fourier transform (FFT). The timely inspection of these abnormal conditions on rotating machines is very important for their secure and consistent operations. In the last few years, many researchers are paying attention and preceding their research with the employment of advanced techniques based on a hybrid algorithm to diagnose abnormal conditions in rotating machines. Many diagnostic techniques/algorithms are implemented to diagnose the bearing faults and are addressed by a variety of available signals, which consist of thermal imaging [6], vibration [7], acoustic noise [8], stator current spectrum [9], and many more. Figure 3 shows the different percentage contributions of faults and failures in rolling bearings, the detail can be studied in [10].

Figure 3.

Causes of failures in rolling bearings.

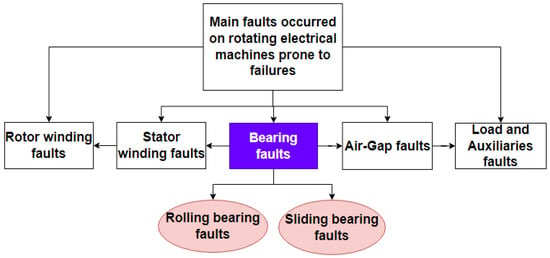

Several types of diagnostic approaches are available for different types of faults that occur on rotating machines, including conventional approaches, which mostly use vibration signals to diagnose the faults, statistical approaches, model-based approaches, hard-ware-based approaches, history-based approaches, and artificial intelligence-based approaches (machine learning and deep learning). These approaches employ different signals that follow patterns such as motor current signature analysis (MCSA), vibration signals, acoustic signals, electromagnetic signals, voltage, and current signals to diagnose numerous types of faults in rotating machines [10]. Currently, condition monitoring techniques are utilized on a variety of equipment such as revolving machines and auxiliary equipment to prevent serious issues that may result from their damage. Condition monitoring of electrical machines implements multiple types of sensors that are used to sense any abnormal condition that happened during operation and collect useful information for long-term prediction. In electrical motors, condition monitoring is implemented individually on different parts, and measurements are taken by employing vibration-based techniques, signal processing techniques, and temperature differences for their diagnostics. The importance of bearing failure diagnosis in revolving electric machines is clear because it is estimated that half of the failures that occur in revolving electrical machines are bearing faults [11]. A variety of different faults investigated in the literature that influence the performance of rotating electric machines is displayed in Figure 4.

Figure 4.

A variety of different faults occurring in rotating electrical machines.

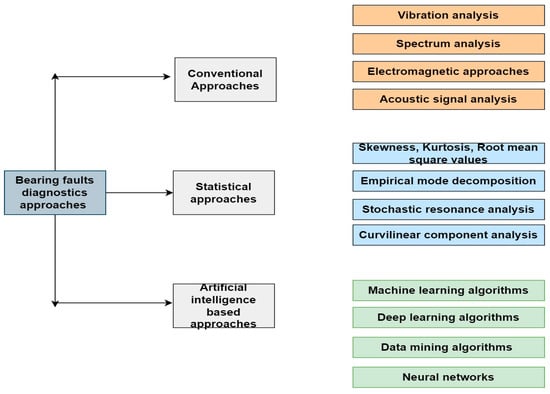

There are three targets of failure analysis: detection, isolation, and identification. Condition monitoring of revolving electric machines ensures the chances of taking the minimum risk for operations and reduces the minimum effective cost of maintenance. In online condition monitoring, the operating system will generate real-time data at critical moments of the machine during running conditions. Periodic condition monitoring investigates monitoring during a fixed interval of time and reduces the chances of fault in machines [12]. The classification of proposed approaches discussed briefly in this article is shown in Figure 5.

Figure 5.

Different bearing fault diagnostic approaches.

2. Conventional Techniques for Diagnosis of Bearing Faults

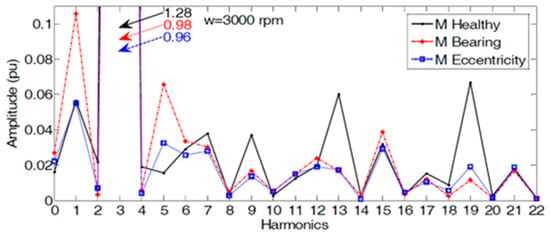

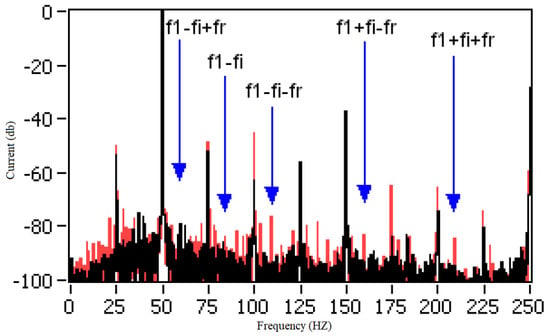

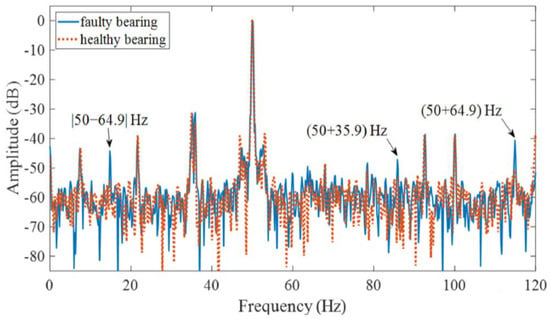

Fault diagnostic techniques such as conventional approaches are the typical method for the detection and diagnosis of bearing faults by employing vibration, current, voltage, stray flux, temperature, acoustic measurements, etc. These conventional approaches are utilized to extract useful attributes from the vibration spectrum, waveforms, and signals to accurately classify abnormal conditions. In [13,14], wavelet packet decomposition was employed to observe the stator current and detect the abnormal conditions in the bearing of IM. The WPT can analyze different bearing faults under varying load conditions and detect the non-stationary nature of faults in diverse frequency modes. In [15], the authors investigated the ball bearings’ faults by utilizing a modified winding-based model (MWFM) with the coupled circuit model through variations in the air gap of IM. Stator current spectrum analysis is employed to observe the amplitudes of faulty current signatures for the diagnosis of bearing faults. Figure 6 shows the development of harmonics in stator current due to bad bearing.

Figure 6.

The comparison of harmonics in stator current to diagnose healthy and outer race bearing conditions [15].

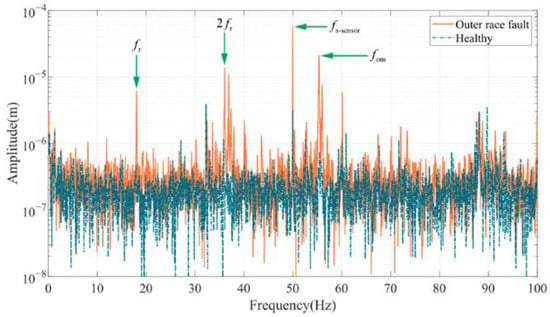

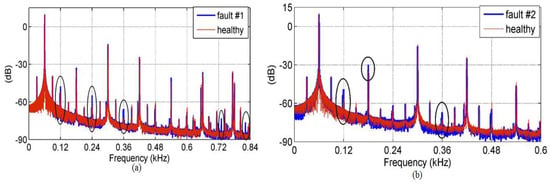

In [16], the authors proposed a strategy to diagnose the bearing and eccentricity fault in permanent magnet synchronous machines (PMSM) by utilizing the motor current signature analysis (MCSA) and stator current harmonics. The stator current spectrum is used as a healthy indicator of the reference spectrum at different speed tests with the vibratory indicator to diagnose bearing faults. Figure 7 shows the stator current harmonics spectrum to diagnose bearing (redline) and eccentricity faults (blue-line) in electric machines.

Figure 7.

Stator current spectrum to diagnose bearing faults (redline) and eccentricity faults (blueline) in PMSM [16].

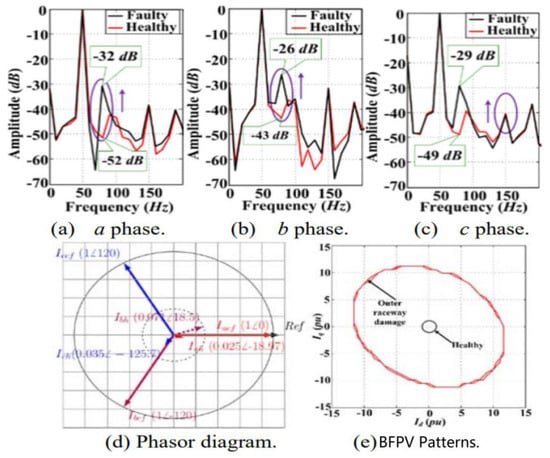

In [17], the authors proposed a technique to diagnose linear bearing faults in linear brushless AC machines by utilizing the frequency spectrum of vibration signals. In [18], the authors recommended bearing fault-finding of PMSM under dynamic conditions through discrete wavelet decomposition and finite element analysis (FEA). From stator current harmonics, DWT is utilized to extract a significant attribute from vibration signals for bearing fault diagnosis. In [19,20,21,22], the authors investigated the park’s vector approach to diagnosing bearing faults in IM through motor supply current and bearings ball pass frequencies (BPFs). Figure 8 points out the comparison of healthy bearings frequency with failure in the outer race of bearings by implementing the park’s vector approach via current signals.

Figure 8.

The impact of outer raceway fault on (a) phase a (b) phase b, (c) phase c, (d) overall phasor diagram, (e) bearing fault Park’s vector (BFPV) [19].

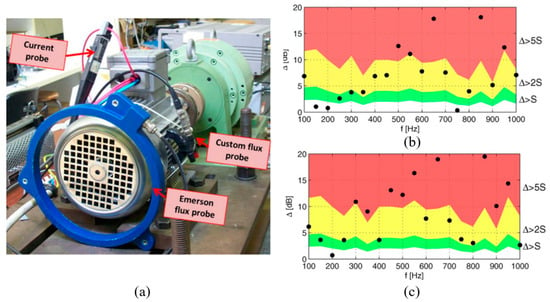

In [23], the authors suggested the procedure to identify inner raceway and outer raceway bearing defects of induction motors via spectral analysis. Discrete wavelets transform (DWT) is used for extracting useful information from the faulty bearing of induction motors and comparing characteristic frequencies of healthy and faulty indicators for fault investigation. In [24,25,26], the authors anticipated the noninvasive bearing faults of IM by employing stray flux measurements and flux probes for the analysis of different kinds of bearing faults. Figure 9 shows the spectrum of healthy bearings (black spectral lines) and faulty bearings (red spectral lines) obtained by stray flux measurements and power spectral density for bearing fault diagnosis.

Figure 9.

Magnetic stray flux spectrum for healthy bearing (black spectral lines) and inner raceway fault (red spectral lines) to diagnose bearing faults. Reproduced with permission of [26].

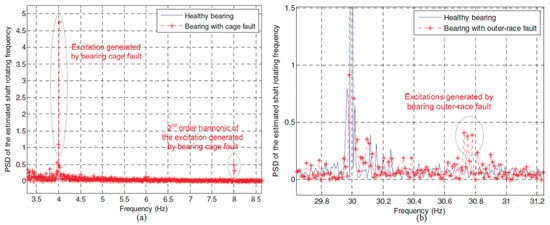

In [27,28],the authors suggested a methodology to evaluate the normal operating conditions and faulty conditions of bearings for IM depending on the instantaneous value of the motor voltage. Figure 10 shows the results of bearing healthy conditions and outer raceway defects obtained from applying the instantaneous frequency of motor voltage.

Figure 10.

PSD of the stator current for bearings: (a) Healthy case; (b) outer raceway defect obtained from the instantaneous frequency of motor voltage [27].

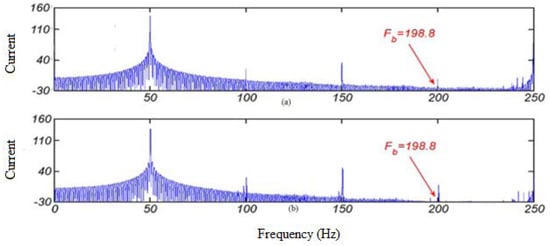

In [29], the authors suggested the technique of identifying the generalized roughness during abnormal conditions in bearings through spectral kurtosis energy utilizing vibration or current signals. In [30], the authors suggested a methodology to diagnose bearing faults of variable-speed wind turbines through power spectral density (PSD) for extracting features of faults from stator current measurements. Characteristic features, stator current, and fault signatures of bearings are utilized for the diagnosis of wind turbine bearing faults. Figure 11 shows the results of the bearing cage fault and outer race fault by implementing threshold impulse values and power spectral density.

Figure 11.

Power spectral density (PSD) results for the diagnosis of bearing fault in the wind turbine for (a) bearing cage fault and (b) outer race fault. Reproduced with permission of [30].

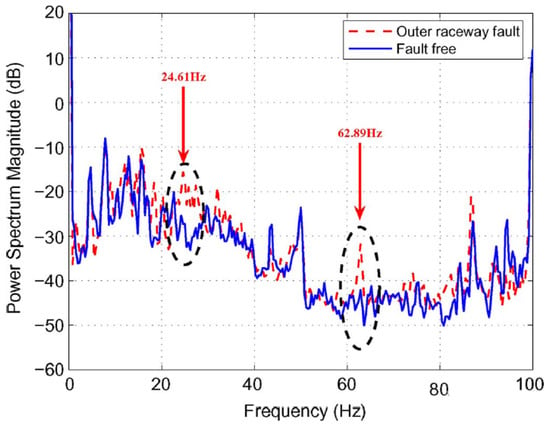

In [31], the authors proposed the prognostic methodology to diagnose the bearing failures in electric railway traction motors by placing a high-frequency inductance coil near the railway traction bearing to extract useful information for the classification of bearing faults. In [32,33], the authors recommended bearing faults of variable-speed converter-fed electrical machines by applying systematic approaches to investigate bearing wear conditions and incipient bearing faults through mutual analysis of electrical current signals and vibration signals. In [34], the authors suggested a technique to point out the ball bearing failures by utilizing bearing-rated frequency and vibration indicators. The fundamental frequency is compared with the frequency of the inner raceway and outer raceway of the bearing to diagnose abnormal conditions. In [35], the authors investigated the detection of bearing faults in PMSM by employing the instantaneous power factor and the torque oscillations in damaged bearings. The diagnostic index was developed to validate healthy and faulty bearings conditions at variable loads. Figure 12 shows the results of the fault index for healthy and outer raceway bearings faults by employing instantaneous power factor and the torque oscillations in PSPM.

Figure 12.

Power spectrum density based on frequency spectrum for diagnostics of bearing healthy condition and outer raceway fault [35].

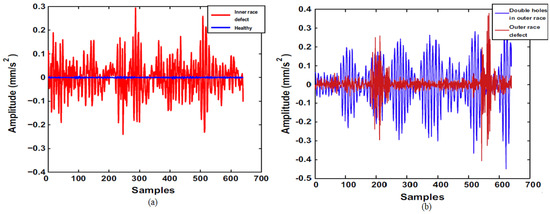

In [28], the authors implemented angular contact for evaluating the bearing faults by employing the envelope technique to identify inner race, outer race, and ball bearing failures. In [36,37], the authors applied vibration analysis to remove the nonbearing fault component (RNFC) filter to detect healthy, inner race, outer race, and double holes in the outer race bearings. Frequency-domain features are compared with time-domain features to analyze the abnormal conditions. Figure 13 shows the outcomes obtained by the RNFC filter to detect healthy, inner race, outer race, and double holes in the outer race bearings.

Figure 13.

RNFC filter results for the diagnosis of (a) healthy and inner race defects and (b) outer race defects and double holes in outer race defects [36].

In [38], the authors suggested the wireless sensor-based network to observe the situation of bearings and to be able to explore the characteristics of vibration signals using accelerometers. The measurements of accelerometers are compared with a piezoelectric transducer, which is set as a reference signal to evaluate the results of the bearing faults. In [39,40], the authors proposed to diagnose the bearing faults of a brushless direct current motor (BLDC) at different speed variations through its phase current examination. Multiple signal processing techniques were applied, such as zero-phase filtering, Hilbert transform, and accurate rotating angle curves, to obtain frequency characteristics of the noisy current signal for faulty bearings assessment. In [41], the authors proposed an application for the diagnosis of bearing gearbox faults in high-speed locomotives employing temperature sensor signals. Axle box monitoring for bearing health is applied based on temperature signals that are obtained through sensors from the wireless transmission. In [42], the authors proposed a wavelet-based approach to find out the bearing faults in the rotating electrical machines using vibration analysis via wavelet transform. Multiple techniques such as temporal analysis, spectral analysis, envelope analysis, and wavelet transformation are applied as fault diagnostic approaches.

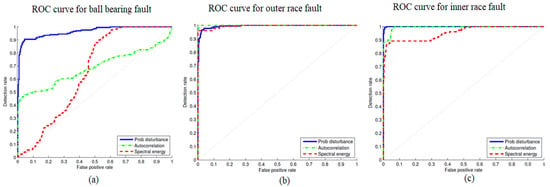

In [43], the authors suggested an improved variational mode decomposition (IVMD) to trace the incipient faults in rolling bearings using a combination of traditional variational mode decomposition and empirical mode decomposition (EMD). The intrinsic mode function (IMF) set the evaluation index for the reconstruction of signals employing the transient impulse monitoring index and Hilbert envelope analysis to evaluate bearing failures. In [44], the authors proposed to diagnose the inner race and outer race faults of roller bearings by IM, utilizing high-resolution spectral analysis of the stator current. Fourier transform was implemented to visualize the stator current and observe the frequencies of small magnitudes via high resolution. In [45], the authors suggested an approach to finding out the inner raceway, outer raceway, and ball bearings failures through the probabilistic model of fault vibrations obtained from accelerometers. Figure 14 shows the results of receiver operating characteristic (ROC) curves for evaluating the performance of the probabilistic model to diagnose ball bearing faults, inner race faults, and outer race faults.

Figure 14.

ROC curves for evaluating the performance of (a) ball bearing fault, (b) outer race fault, and (c) inner race fault. Reproduced with permission of [45].

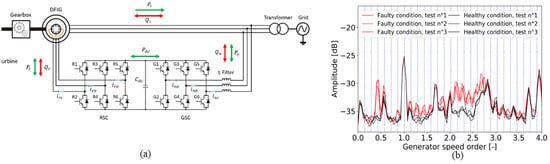

In [46], the authors proposed the phase-locked loop-based approach to find out the bearing faults of doubly fed induction generators (DFIG) used in windmills. Vibration signals were obtained via a resampling technique based on the angle of the rotor position, and experimental results were validated with simulation results. Figure 15 shows the comparison results of the auto-power spectrum for the diagnosis of bearing faults in direct wind turbines through the current demodulated signals.

Figure 15.

(a) DFIG wind turbine topology. (b) Comparison of the auto-power spectrum for healthy and faulty bearing faults in wind turbines for doubly fed induction generators. Reproduced with permission of [46].

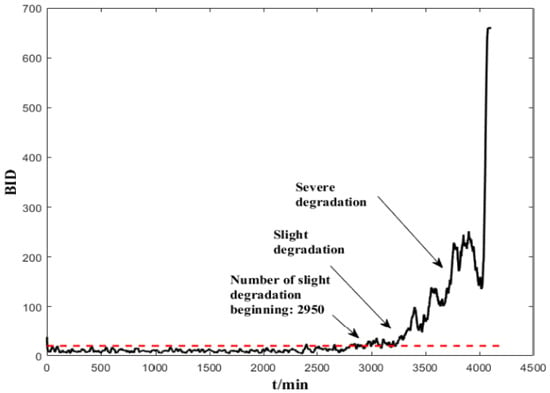

In [47], the authors suggested an intelligent-based strategy for bearing fault diagnosis in a brushless direct current motor (BLDC) and permanent magnet synchronous generators (PMSG) employing synchro-squeezing wavelet transform (SWT) with touch-less order tracking (TOT). SWT can extract instantaneous frequencies of fault signals and also restructure the harmonic components correctly to diagnose abnormal bearing conditions. In [48], the authors recommended the diagnostic techniques for multiple kinds of bearing failures (outer race, inner race, lack of lubrication, and healthy status) in IM by utilizing noninvasive, contactless thermal infrared imaging. DWT was employed to extract data in the form of two dimensional and converted it into thermal images for evaluation of bearing faults in electric machines. In [49,50], authors proposed electrostatics-based sensors for the diagnosis of roller bearing fault performance degradation by implementing spectral regression. The constructive attribute was extracted through the time and frequency domain from normal operating conditions of bearings through the Gaussian model to predict the remaining useful life (RUL) of the bearings. Figure 16 shows the results of the electrostatic sensor for evaluating the degradation assessment depending on the fusion of various attributes and shows the assessment of the bearing whole life with time.

Figure 16.

Performance evaluation of complete life of a bearing through time [47].

In [51], the authors proposed a scheme to diagnose corrosion failures in bearings of a doubly fed induction generator in windmills based on a bi-spectrum modulation signal. Outcomes obtained from the bi-spectrum are compared with fundamental frequency and characteristic frequency to identify faulty harmonics in the current spectrum. Figure 17 shows the stator current waveform in the time domain to classify healthy and faulty bearings.

Figure 17.

The waveform of the stator current in the frequency domain for healthy and faulty bearings. Reproduced with permission of [51].

In [52,53], the authors proposed conditional monitoring of journal bearings by implementing motor current signature analysis (MCSA) of induction machines. The experimental setup was created for low voltage rotating machines for evaluation of journal bearing faults by comparing the observations of different designs. In [54], the authors suggested an online fault diagnostic methodology for the evaluation of bearing failures in brushless DC machines and brushed DC motors by employing a stochastic resonance-based adaptive filter. The stochastic resonance-based adaptive filter was utilized to obtain the phase of purified signal for the analysis of diverse bearing faults in rotating machines.

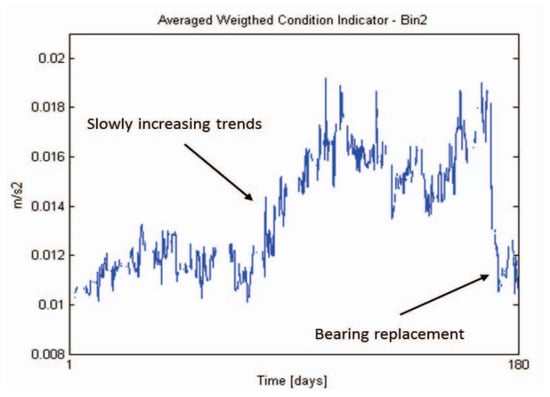

In [55], the authors proposed an embedded system for the diagnosis of bearing failures in permanent magnet synchronous motors (PMSM) using tachometer-based fast and online order analysis (FOOA) composed of two algorithms for obtaining useful information from sinusoidal currents and calculating the envelope order spectrum for the classification of bearing faults. In [56], the authors suggested the diagnosis of inner race creep bearing faults of wind turbine generators by utilizing vibration and temperature analysis. Failures of bearing creep were achieved by continuous monitoring through vibration speed harmonic and absolute temperature values. Figure 18 shows the recognition of generator bearing inner race creep by utilizing vibration and temperature investigation and their replacement by showing slowly developing trends in the behavior of the bearing.

Figure 18.

The behavior of the weighted average condition indication for bearing replacement. Reproduced with permission of [56].

The authors of [57] suggested a strategy for the recognition of outer race-bearing faults in IM by employing the homogeneity algorithm (HA). The homogeneity algorithms (HO) can identify the changes in normal regime from vibration signals and alarm the presence of bearing faults in IM efficiently. In [58], the authors proposed bearing fault diagnostic indicators by employing MCSA based on normalized triple covariance for IM. In [59], the authors paid attention to diagnosing the faulty bearings through the envelope harmonic product spectrum and the adaptive second order cyclo-stationarity blind deconvolution algorithm for the recognition of incipient bearing faults in locomotives. A comparison of different conventional diagnostic techniques is presented in Table 1.

Table 1.

A summary of different conventional techniques for bearing fault diagnosis.

3. Statistical Techniques for Diagnosis of Bearing Faults

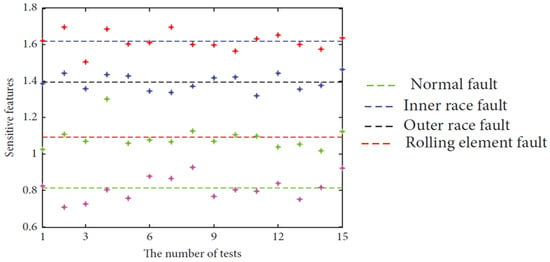

Statistical approaches are generally employed in research to collect and explore a large amount of data and find out hidden trends. These techniques are implemented to explore the trends, the relationship between variables, and approximation analysis by using quantitative data. Statistical parameters commonly implement root mean square values, mean values, variance, skewness, kurtosis, and crest factor attributes for measuring the consequences of bearing faults. In [60], the authors proposed an approach to diagnosing the outer race and inner race bearing faults of IM using statistical time features with neural networks. Statistical time features for bearing failures were obtained from vibration signals and compressed by using curvilinear component analysis for visualization behavior. Feature-extracted signals were employed to identify a crack in the outer race, deformation of the seal, and a hole in the outer race. Figure 19 shows the frequency plot for the damaged bearing seal condition and hole in the outer race fault by implementing stray flux measurements.

Figure 19.

(a) Applied probes for amplification and filtering (b) frequency plot for the damaged bearing seal condition and (c) hole in outer race fault [60].

In [61], the authors implemented empirical mode decomposition (EMD) of acoustic signals obtained through kurtosis and crest factors of the time domain for checking the status of healthy and faulty roller bearings. In [62], the authors suggested a step-varying vibrational resonance (SVVR) algorithm to investigate the faulty status of a bearing by regulating the diverse parameters. Extraction features by SVVR were compared with simulated signals and practical signals, and results from SVVR depicted incredible precision in extracting and enhancing the weak information status of bearing fault detection in the time domain. In [63], the authors pointed out the bearing faults by employing the empirical cumulative distribution function to explore hidden patterns collected from extracted features through the signal-to-noise ratio (SNR). Extracted features were employed to diagnose the statistical spectral images and classify the multiple bearing faults that frequently take place in revolving electrical machines.

In [64], the authors proposed a methodology for bearing fault diagnosis under steady and inconsistent speed operations. Absolute value principal component analysis (AVPCA) was employed for plotting images of vibration signals through the time–frequency domain, fast Fourier transform, and probability plot. By applying AVPCA, the identification of bearing faults was made possible and could also be used to diagnose gearbox faults. Figure 20 shows the result of the outer race, inner race, and ball bearing fault detection and their classification by implementing the sum of square error (SSE) distance evaluation.

Figure 20.

Sum of square error (SSE) distance variation for outer race inner race and ball bearing fault. Reproduced with permission of [64].

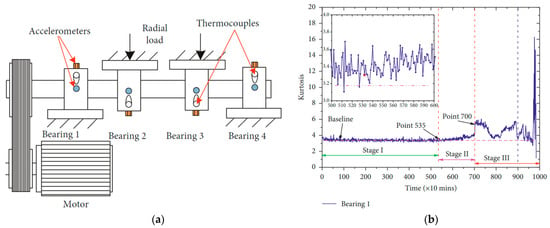

In [65], the authors suggested a variety of research trends for the diagnosis of roller bearing faults depending on the time-varying Kalman filter for accurate prediction of the remaining useful life (RUL). The Kalman filter is employed on linear and quadratic functions to forecast the RUL in roller bearings. Figure 21 shows the bearing test rig diagram for the prediction of RUL in roller bearings.

Figure 21.

Degradation tracking for the RUL of roller bearings [65].

In [66], the authors suggested the identification of incipient bearing faults in rotating machinery through single value decomposition (SVD) and the squared envelope spectrum (SES) by employing vibration signals. The optimal singular component (SC) was utilized through the kurtosis of SES for information gain and to demonstrate the results of incipient faults. Figure 22 shows the setup for detecting bearing faults and their related results using the kurtosis variation for different stages.

Figure 22.

(a) Bearing test rig and (b) kurtosis variation of incipient bearing faults at different stages [66].

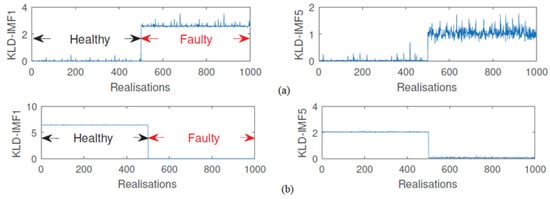

In [67], the authors proposed a methodology to identify and distinguish the multiple kinds of ball bearing failures extracted by empirical mode decomposition (EMD) of non-stationary time series signals. The Case Western Reserve University (CWRU) dataset was applied to check the validity of the work to diagnose multiple kinds of bearing failures at different loading conditions. Figure 23 shows the results of ball bearing faults at 0% loading conditions and 100% loading conditions by implementing Kullback–Leibler divergence based on empirical mode decomposition (EMD).

Figure 23.

Ball bearing results based on EMD at (a) 0% loading conditions and (b) 100% loading conditions. Reproduced with permission of [67].

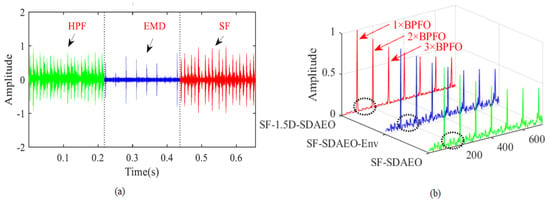

In [68], the authors proposed 1.5-dimensional symmetric difference analytical energy operators to enhance the extracted features for bearing fault diagnosis. A statistical filtering channel was employed to reduce the background noise and improve the signal-to-noise ratio SNR for the faulty bearing’s characteristic frequency. Figure 24 shows the results for the diagnosis of abnormal conditions in faulty bearings through different high-pass filters and matches their effects with statistical filtering.

Figure 24.

(a) Time domain of three different statistical filtering algorithms using high pass filter (HPF, green), Empirical mode decomposition (EMD, blue) and statistical filtering (SF, red). (b) Feature extraction spectrum result for the diagnosis of bearing fault characteristic frequency. Reproduced with permission of [68].

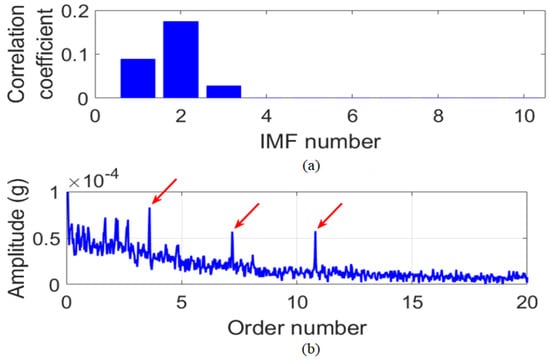

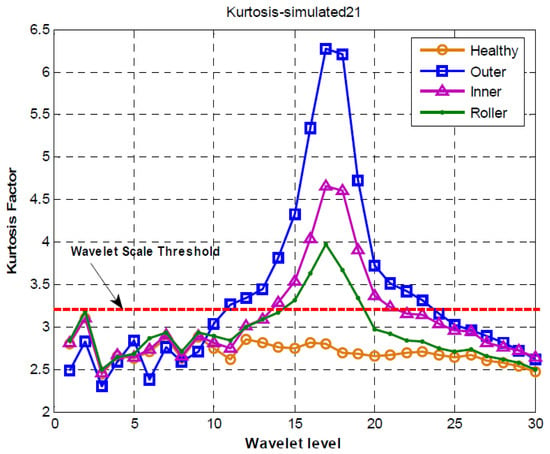

In [69],the authors suggested an approach for the investigation of roller bearing faults detection and classification using radial internal clearance (RIC). Statistical condition indicators, fast Fourier transform (FFT), and continuous wavelet transform (CWT) techniques were utilized to evaluate the results. An experimental setup was created to validate the RIC measurements to predict the lifetime of roller bearings accurately. In [70], the authors proposed the bearing fault diagnosis of hybrid stepper motors by employing the revolving angle estimation of motor current. Variational nonlinear chirp mode decomposition was applied for the extraction of features from the vibration signals spectrum order and resembledthe rotating angle curve to diagnose bearing faults. In [71], the writers suggested a hybrid approach utilizing the kurtosis spectrum and envelope spectrum analysis of the stator current for the prognosis of roller bearing faults detection and classification in aerospace and industrial applications. An estimation index was set with different bearings experiments performed under variable load conditions. Figure 25 shows the results of the stator current spectrum with healthy and damaged bearings for different bearing faults by employing a fast kurtogram and a wavelet kurtogram and enhancing the results of envelope analysis for bearing fault diagnosis.

Figure 25.

Comparison of the stator current spectrum for (a) healthy bearing and (b) faulty bearing, where significant change in the amplitude of certain harmonics is highlighted by circles [71].

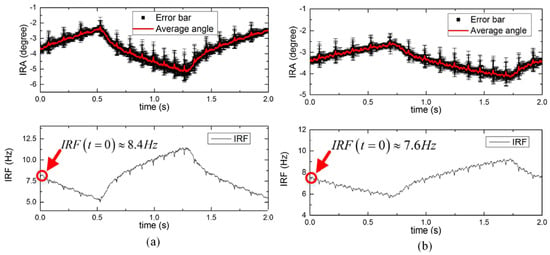

In [72], the authors suggested a methodology that depends on the improved version of singular value decomposition (SVD) for the selection of the kurtosis envelope and optimized by an enhanced version of wavelet packet transform (WPT) for the diagnosis of roller bearing faults detection and classification. An indicator-based filter was designed to extract frequency characteristics from an envelope spectrum analysis for the bearing fault diagnosis. In [73], the authors proposed the rectangular resampling methodology for the diagnosis of bearing faults in electric motors under variable speeds using the Kanade–Lucas–Tomasi (KLT) algorithm. Faulty indications were obtained through the microphone and recorded by a high-speed camera in an angular domain-based angle curve for obtaining characteristic frequency in brushless direct current motors (BLDC). Figure 26 shows the instantaneous rotating angle (IRA) and instantaneous rotating frequency (IRF) for the diagnosis of the inner race and outer race bearing faults.

Figure 26.

Instantaneous rotating angle (IRA) and instantaneous rotating frequency (IRF) curve for diagnosis of (a) outer race bearing fault and (b) inner race bearing fault. Reproduced with permission of [73], the initial value of IRF at t = 0 is shown by red circle and arrow.

In [74], the authors suggested failures of roller bearings in inverter-fed revolving machines during transient bearing current patterns and estimate the remaining useful life (RUL). In [75], the authors proposed an efficient technique to find out the unknown abnormal conditions of bearings employing time-varying speed characteristics and strong background noise. Stochastic resonance was utilized on the input signal to evaluate the non-stationary features of the faulty signal, and an imaginary index was set up to convert the angular domain into a spectrum for bearing fault diagnosis. In [76], the authors proposed a speed-based methodology to evaluate the main bearing fault of wind turbines (MBWT) by implementing the signals of shaft speed under a steady-state load. Various kinds of ball/roller bearing faults, such as outer-race faults were diagnosed through tower signals and empirical mode decomposition. Figure 27 shows the geometry of the wind turbines main bearing.

Figure 27.

Wind turbine main bearing (WTMB) geometry [76].

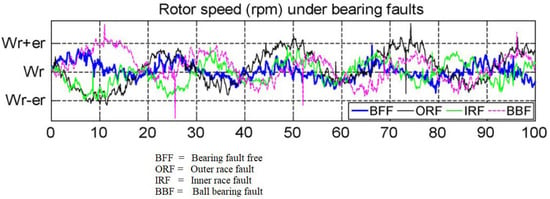

Figure 28 shows the results of the main wind turbine bearing fault by employing absolute value principal component analysis (AVPCA) via the shaft speed signal under constant loads. Ball-free fault (BFF), ball outer race fault (BOF), ball inner race fault (BIF), and ball bearing fault (BBF) are evaluated by different input schemes to diagnose bearing faults.

Figure 28.

(a) IMF order of faulty generator bearing vibration signal (b) Sum of square error (SSE) distance variation to diagnose wind turbine main bearing fault (WTMB) detection at different inputs (red arrow shows the outer race fault order and its harmonics) [76].

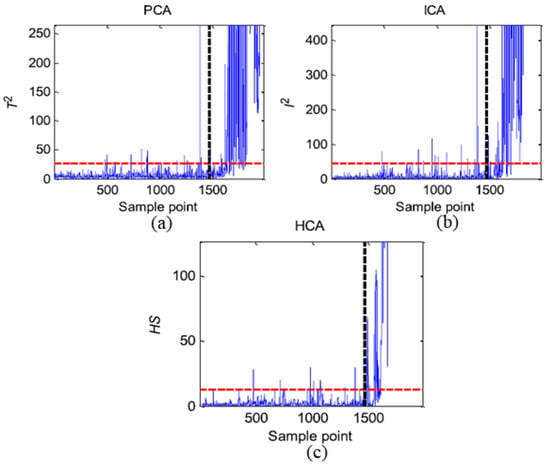

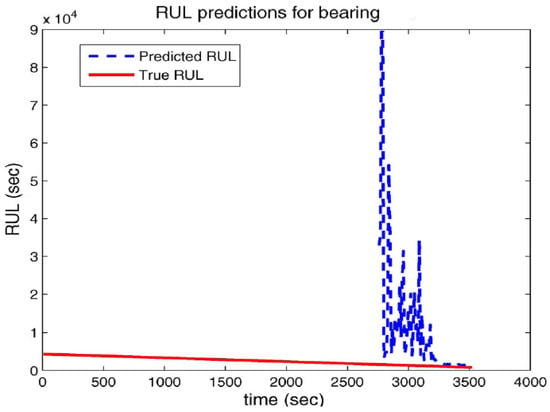

In [77], the authors proposed the identification of roller bearing faults by implementing multivariable statistical process control methods (MSPC) such as higher-order cumulants analysis (HCA), independent composite analysis (ICA), and principal component analysis (PCA). Two bearings’ life datasets were evaluated, and the outcomes provided the suggested approaches and showed the paramount precision for the diagnosis of bearing faults. Figure 29 shows the results of higher order cumulants analysis (HCA), independent component analysis (ICA), and principal component analysis (PCA) through multivariate statistical process control (MSPC) to diagnose the rolling elements bearing faults; the red horizontal lines show dynamic control limits, and the black dashed lines demonstrate the incipient bearing fault.

Figure 29.

Dynamic monitoring of bearing faults by (a) PCA, (b) ICA, and (c) HCA approaches. Reproduced with permission of [77] (The X label shows the total number of sample points, and the Y-label shows the number of training samples).

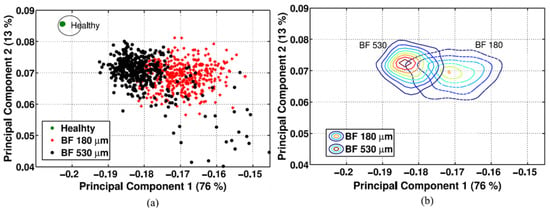

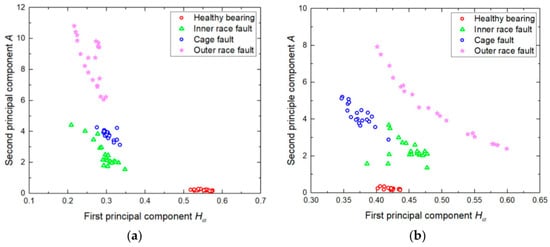

In [78], the authors proposed a hybrid strategy to investigate wind turbine generator bearing faults by employing sparse representation and shift-invariant dictionary learning for the extraction of features in the frequency domain. In [79], the authors suggested linear discriminant analysis (LDA) and principal component analysis (PCA) for the judgment of ball bearing faults focused on global spectrum analysis. Envelope spectrums were applied for the extraction of features from vibration signals and to obtain useful information from bearing-specific characteristics and frequencies. Figure 30 shows the results of ball bearing failures depending on the global pattern of vibration signals by utilizing PCA.

Figure 30.

(a) Discrimination of bearing faults by PCA; (b) contour of PDF for estimated class of ball bearing fault [79].

Similarly, Figure 31 shows the results of a faulty ball bearing based on the global range of vibration signals by utilizing LDA for the diagnosis of ball bearing faults.

Figure 31.

(a) Discrimination of bearing faults by LDA; (b) contour of PDF for estimated class of ball bearing fault [79].

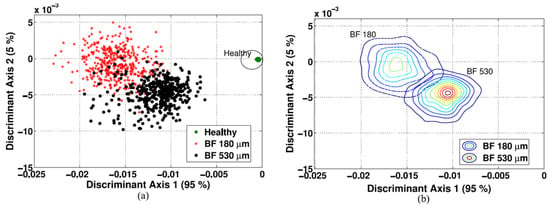

In [80], the authors suggested a statistical-based indicator for the diagnosis of bearing faults in PSPM by employing the stator currents for the replacement of faulty bearings with healthy bearings. Figure 32 shows the replacement of faulty bearings with healthy ones utilizing a vibration indicator. N-change stands for when a bearing is replaced with a faulty one, and N-default stands for when a vibration indicator starts to respond.

Figure 32.

Replacement of healthy bearings with faulty ones by using statistical indicators [80].

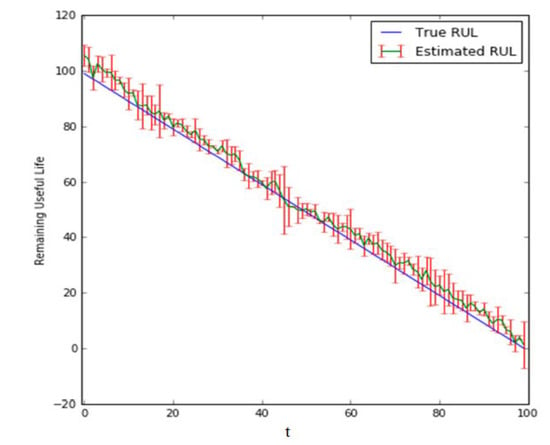

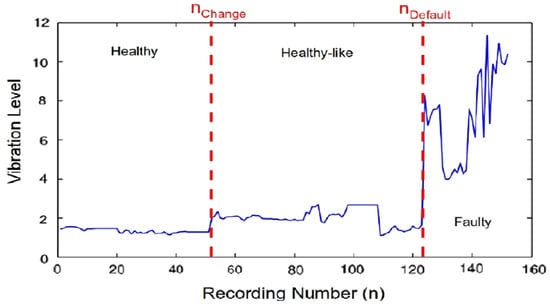

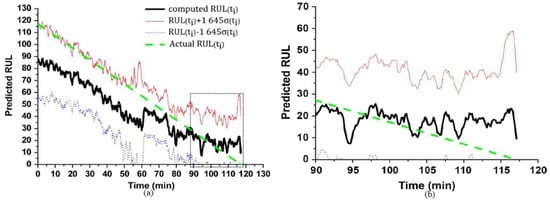

In [81], the authors proposed a prognostic approach to forecasting the remaining useful life (RUL) of a bearing by utilizing the bidirectional strategy based on multiple statistics of vibration signals. An enhanced Kalman filter was implemented as a maximization algorithm to estimate the remaining useful life (RUL) of bearings. In [82], authors proposed to estimate the remaining useful life (RUL) and identification of bearing faults by introducing the time–frequency characteristics for extracting features from vibration signals. Curve fitting and extended Kalman filtering approaches were employed for the assessment of bearing RUL. Figure 33 shows the predicted results for the RUL of the bearing by employing an extended Kalman filter with a curve-fitting approach.

Figure 33.

RUL estimation of bearings (RUL prediction versus actual prediction) Reproduced with permission of [82].

In [83], the authors proposed a signal processing strategy to recognize rolling bearing failures in revolving electric machines by employing an adaptive morphological update lifting wavelet (AMULW). In [84], the authors suggested diagnosing the bearing faults by utilizing stator current noise cancellation and statistical control to suppress dominant components and bearing fault frequencies. Sigma limits were applied to detect the variation in the magnitude of noise cancellation stator current and statistical process control technique for accurate diagnosis of bearing faults. In [85,86], the authors proposed a statistical approach to find out the multiple kinds of abnormal conditions in roller bearings by implementing vibration energy on the spectra Quest machinery fault simulator. Table 2 shows a comparative analysis of several statistical diagnostic techniques.

Table 2.

A summary of different statistical techniques for bearing fault diagnosis.

4. Artificial Intelligence (AI) Techniques for Diagnosis of Bearing Faults

In the past few years, researchers are paying attention to artificial intelligence-based approaches (ML and DL) for the diagnosis of bearings’ abnormal conditions in electric machines. These techniques follow hidden patterns to diagnose bearing faults and offer sufficient diagnostic results. In [87], the authors implemented artificial bee colony architecture to identify bearing faults in three-phase induction motors. Faulty data was taken out by characteristics of the joint in the sequence between the stator current signals in the time domain. In [88,89], the authors suggested the efficient net optimizer for bearing fault classification and their degradation level. Acoustic signals were employed to gain faulty knowledge from spectrograms in the time domain. In [90], the authors proposed a technique, a defective signature wavelet image (DWSI), with deep convolution networks to trace the bearing faults by utilizing acoustic emission signals.

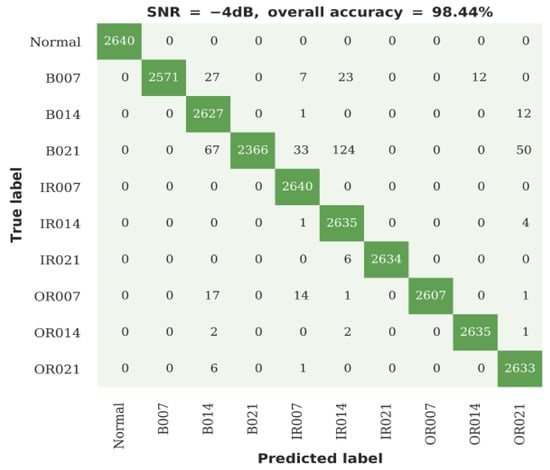

In [91,92], the authors diagnosed multiple roller bearing faults by experimental tests and obtained the images by spectrograms to train CNN for bearing fault diagnosis in an IM. In [93], the authors suggested an influential ML algorithm support vector machine (SVM) with adaptive cascade fault observer and fuzzy orthonormal regressive to diagnose the bearing faults of rotary machines. In [94], authors proposed support vector machines (SVM) and decision trees (DT) to sort out the bearing faults in electric machines. Attribute withdrawal methodology was employed to extract features from bearings that were optimized by employing particle swarm optimization to recognize bearing faults. In [95],the authors proposed a recurrent neural network (RNN) to detect faulty bearings in a noisy environment and create a dataset by adding random noise for training the RNN. Figure 34 shows the confusion matrix plot for the RNN-WDCNN on the CWRU dataset to evaluate bearing faults. Diagonal elements in the confusion matrix are accurately classified, and non-diagonal elements are unclassified (normal, ball bearing, inner race, outer race) bearing faults.

Figure 34.

Confusion matrix plot for proposed algorithm RNN-WDCNN to diagnose ball bearing, inner raceway, and outer raceway bearing faults [95].

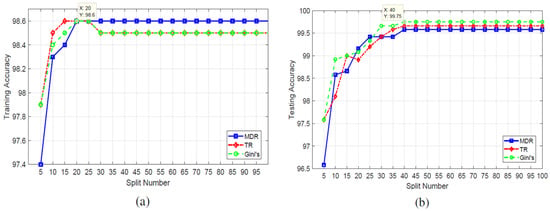

In [96], the authors utilized a support vector machine (SVM), K-nearest neighbor (KNN), and decision trees (DT) for the classification of incipient bearing faults by utilizing the CWRU dataset. Features of the dataset were tuned by EMD-KLD for bearing fault classification. Figure 35 shows the results of the direct acyclic graph support vector machine (DAG-SVM), KNN, and DT for evaluating bearing faults.

Figure 35.

Analysis results of bearing faults: (a) training accuracy; (b) testing accuracy. Reproduced with permission of [96].

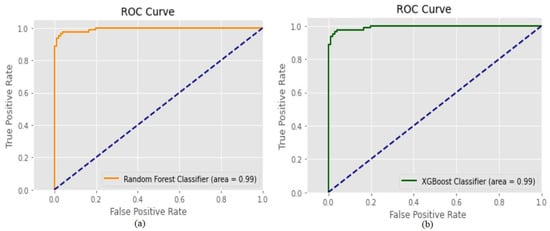

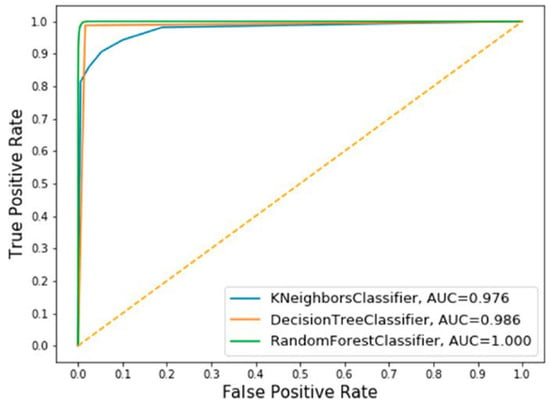

In [97], the authors recommended the diagnosis of bearing faults by employing discrete wavelet transform (DWT) and the ensemble ML algorithm. Current signals were used to extract features using discrete wavelet transform (DWT) for creating a dataset for training the random forest (RF) and extreme gradient boosting for bearing fault classification. Figure 36 shows the ROC curve for evaluating the classification performance of RF and extreme gradient boosting for the diagnosis of bearing faults.

Figure 36.

ROC curves for (a) RF and (b) XG-Boost for bearing fault classification [97].

In [98], the authors suggested deep belief network and the Dempster–Shafer theory for the diagnosis of bearings in rotating AC machines. CWRU was put into practice to validate the performance of the proposed algorithm. In [99], the authors proposed a feed-forward neural network (FFNN) to identify the outer-race bearing faults for one HP induction motor at its early stages. Linear discriminant analysis (LDA) was utilized for extracting features to train the FFNN. Figure 37 shows the outcomes of projection regions for the classification of multiple bearing faults by using an FFNN at different stages.

Figure 37.

Projection of decisions region for multiple faults classification obtained by FFNN [99].

In [100], authors suggested an approach to diagnose the roller bearing faults in electrical machines utilizing ensemble local x-tics-scale decomposition (ELCD) and an extreme learning machine (ELM). Figure 38 shows the results for the prediction of fault diagnosis in rolling bearing elements by implementing ELCD and ELM.

Figure 38.

Test classification results for the diagnosis of rolling bearing element faults in rotating machines [100].

In [101], the authors suggested an intelligent neuro-wavelet neural network in combination with variational mode decomposition (VMD) to diagnose bearing faults. Vibration signals were employed to extract useful information and remove the redundant features to construct a dataset for training the intelligent neuro-wavelet neural network and estimating bearing faults. In [102], the authors suggested an improved shuffled frog leaping algorithm (ISFLA) for incipient fault detection of roller bearings. Particle swarm optimization was utilized to tune the parameters of ISFLA for the detection of roller bearing faults. In [103], the authors proposed a stack sparse auto-encoder (SSAE) with a deep neural network (DNN) for the diagnosis of bearing faults by employing envelope spectrum analysis. The complex envelope spectrum had silent features to extract features of each fault type present in bearing at variable speeds. In [104], the authors proposed the Wasserstein generative adversarial network and convolutional neural network (WG-CNN) for the diagnosis of roller bearing faults. A high-quality bearing fault dataset was produced, and outcomes were compared with the CWRU dataset for evaluation. In [105], the authors suggested an artificial neural network (ANN) with a multilayer perception artificial neural network (MLP-ANN) for roller bearing fault diagnosis. In [106], the authors suggested an artificial neural network incorporated with Laplace transform to diagnose the inner race, outer race, and rolling element faults. Time domain vibration signals were further processed with Laplace transform for extracting useful information from bearings. Figure 39 shows the Laplace wavelet kurtosis for the diagnosis of multiple bearing faults from simulated vibration signals.

Figure 39.

Laplace wavelet kurtosis for the diagnosis of multiple bearing faults [106].

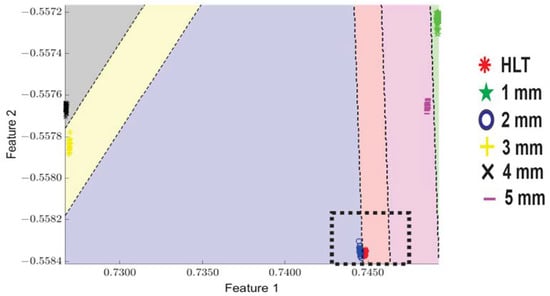

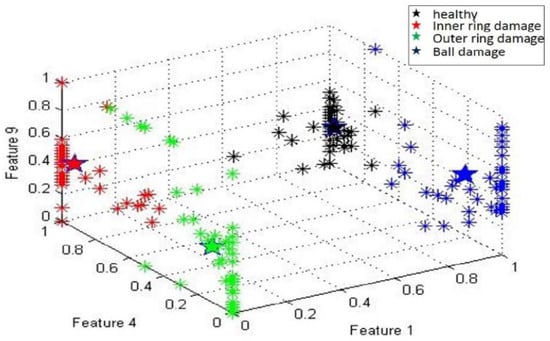

In [107], the authors proposed discriminant feature distribution analysis for the diagnosis of IM bearing faults with a genetic algorithm (GA) filter to optimize the attributes and train KNN to classify bearing faults. In [108], the authors suggested compressive sampling (CS) on the numerous measurements vector (MMV) and feature ranking framework for the categorization of roller bearing faults obtained through pulsation indication. Support vector machines (SVM), artificial neural networks (ANN), and logistic regression (LR) were employed to validate the outcomes. In [109], the authors proposed K-means clustering optimized by a genetic algorithm (GA). The genetic algorithm can overcome the drawbacks of K-means clustering for extracting useful information to point out faulty bearings. Figure 40 shows the 3D plot of clustering results for testing data to diagnose bearing faults for the healthy, inner race, outer race, and ball damage conditions.

Figure 40.

The 3D plot of the clustering algorithm for the diagnosis of different bearing faults. Reproduced with permission of [109].

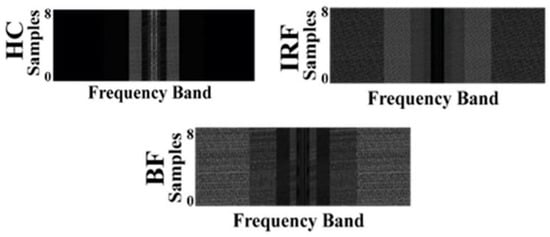

In [110], the authors proposed an FGPA-based online multi-core system to diagnose and monitor in real-time the bearing faults signature extraction by employing time–frequency analysis of acoustic signals through multiclass support vector machines. In [111], the authors suggested the convolutional neural network (CNN) and envelope spectrum (ES) for the diagnosis of roller bearing faults utilizing acoustic emission analysis (AE) under variable speeds operations. The envelope spectrum was used to extract raw signals and provide useful information about frequency peaks to create datasets and train the CNN for the diagnosis of faults in roller bearings. In [112], the authors suggested the discrete orthogonal Stock-well transform (DOST) with transfer learning to diagnose the healthy condition, outer race, and inner race bearing faults through vibration imaging. Figure 41 shows vibration-based images obtained from the DOST to diagnose the healthy condition, inner raceway, and outer raceway faults.

Figure 41.

Vibration-based images from discrete orthogonal Stock-well transform (DOST) for a bearing’s healthy conditions (HC),inner race fault (IRF), and ball fault (BF) [112].

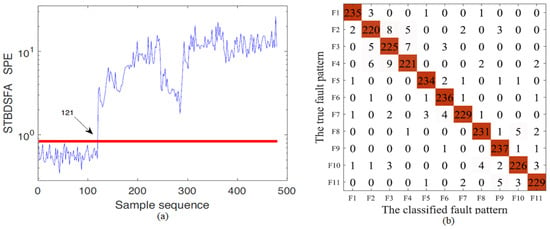

In [113], the authors diagnosed the abnormal conditions in bearing and gears by utilizing feature sparse representation through slow feature analysis (SFA) and long short-term memory (LSTM). Figure 42 shows the monitoring chart for the diagnosis of bearing fault using sparse three-way data-based dynamic SFA (STBDSFA).

Figure 42.

(a) Monitoring chart for the diagnosis of bearing fault by employing STBDSFA to detect fault at the 121st point in the total of 500 samples. (b) Confusion matrix plot for bearing faults classification [113].

In [114], the authors proposed a fuzzy sliding mode observer with decision trees (DT) for the diagnosis of roller bearing faults in industrial applications. In [115], the authors proposed a hybrid algorithm by employing empirical wavelet transform (EWT), fuzzy entropy, and SVM (EWTFSFD) to diagnose bearing faults. The proposed algorithm, EWTFSFD, was utilized to decompose vibration signals into frequency and amplitude modulation to achieve effective outcomes for bearing fault diagnosis. In [116], the authors proposed the fault diagnosis of rolling element bearings by employing detrended fluctuation analysis (DFA) and improved detrended fluctuation analysis (IDFA) incorporated with linear discriminant analysis to trace out the bearing healthy state, inner race, outer race, and cage fault in feature vectors. Figure 43 shows the testing results of DFA and IDFA for tracing the multiple kinds of bearing faults.

Figure 43.

Testing results for multiple kinds of bearing faults by implementing (a) DFA and (b) IDFA [116].

In [117], the authors recommended K-nearest neighbor (KNN) and random forest (RF) and decision trees (DT) to classify the bearing faults of IM. The autocorrelation technique was employed for the extraction of the informative attribute from bearings and generated a dataset by using the accelerometer. Figure 44 shows the confusion matrix plot to diagnose the healthy condition, inner raceway, and outer raceway faults of IM bearings through KNN and RF.

Figure 44.

Combined ROC curve for proposed machine learning classifiers [117].

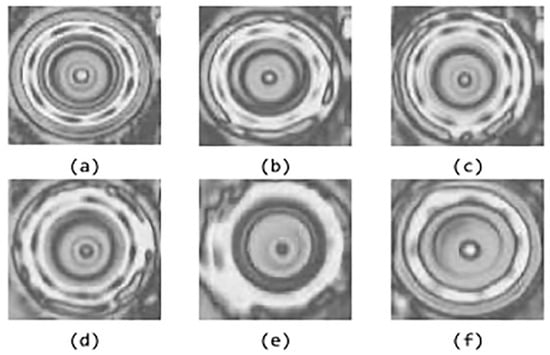

In [118], the authors proposed the diagnosis of incipient roller bearing faults through wavelet transform (WT) optimized by particle swarm optimization (PSO) from vibration signals at diverse speeds. In [119], the authors proposed an artificial neural network (ANN) and convolutional neural network (CNN) for the diagnosis of bearing faults in rotating machines using thermal images. Six kinds of thermal images of the rolling element were diagnosed (one healthy and five faulty). Figure 45 shows the results of thermal images to diagnose bearing faults for a healthy state, outer race, inner race, ball defect, cage defect, and lack of lubrication.

Figure 45.

Thermal images results for (a) healthy state, (b) outer race, (c) inner race, (d) ball defect, (e) cage defect, and (f) lack of lubrication. Reproduced with permission of [119].

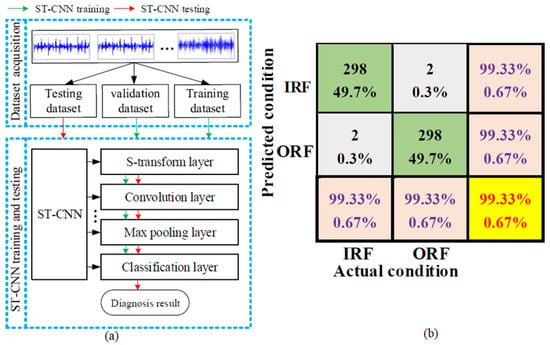

In [120], the authors proposed a sensor-driven technique to diagnose the bearing faults using a convolutional neural network with s-transform (ST-CNN). To enhance the performance of the proposed algorithm, data from the sensor were converted into a 2D time–frequency matrix, and the coefficient matrix was fed to ST-CNN to diagnose the bearing faults. Figure 46 shows the block diagram of ST-CNN for training and testing procedures and also shows the confusion matrix plot for diagnosing IRF and ORF.

Figure 46.

(a) ST-CNN block diagram for training and testing. (b) Confusion matrix plot for IRF and ORF [120].

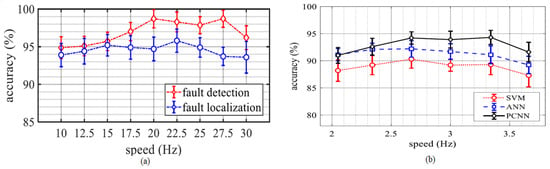

In [121], the authors suggested a physics-based convolutional neural network (PCNN) algorithm utilizing kurtosis and envelope analysis for rolling bearing fault diagnosis. Figure 47, shows the results of rolling bearing faults detection and their localization through PCNN and their comparison with SVM and ANN.

Figure 47.

(a) Speed tests for the diagnosis of bearing faults using PCNN. (b) Comparison of fault detection and localization results with SVM and ANN. Reproduced with permission of [121].

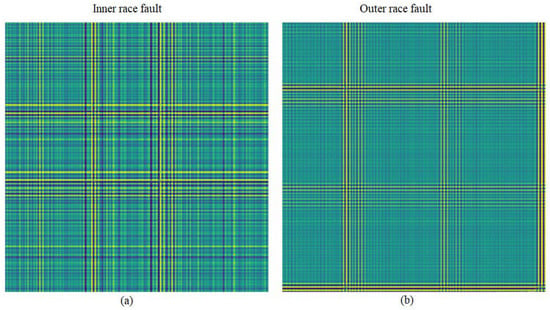

In [122], the authors recommended Gramian angular field (GAF) integrated with Dense-Net for feature extraction and convert them into 1D time series images to diagnose the bearing faults. Figure 48 shows the patterns of GAF with Dense-Net for diagnosing inner race and outer race faults bearing faults in electric machines.

Figure 48.

Gramian angular field (GAF) with Dense-Net patterns for recognition of the (a) inner race and (b) outer race bearing faults expressed by using [122].

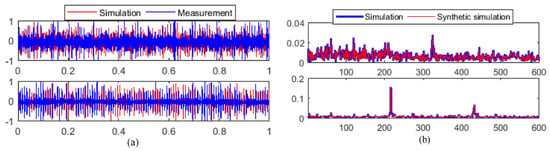

In [123], the authors proposed a convolutional neural network through Fault-Net for the classification of multiple types of bearing faults employing vibration signals. Mean and median channels were applied to extract information acquire from raw signals to create a dataset and train CNN for bearing fault diagnosis. In [124], the authors proposed support vector machines for bearing fault diagnosis using radial basis function (RBF) kernel in rotating machines. A hybrid feature pool was obtained through time-domain features, envelope power spectrum, and wavelet energy optimized by the kernel function for providing input to the SVM for bearing fault diagnosis. In [125], the authors suggested the finite element method (FEM) to overcome the shortage of data that are a much-needed part of the field of machine learning (ML) for diagnosis of bearing faults. Simulation-based finite element methods were employed to enlarge the datasets and applied to ML classifiers to sort out bearing faults. Figure 49 shows the simulation results of the inner race and outer race bearing faults in comparison with experimental data and synthetic data for their diagnosis.

Figure 49.

Inner race and outer race bearing results were obtained by (a) experimental data and (b) synthetic data. Reproduced with permission of [125].

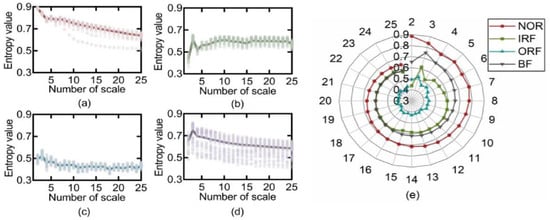

In [126,127], the authors proposed support vector machines (SVM) to diagnose the bearing faults, employing complex signals in the rotating machines. Composite multiscale weighted permutation entropy (CMWPE) was utilized to extract features and convert them into the high dimensional feature set to input SVM for fault diagnosis. Figure 50 shows the results of bearing faults using CMWPE incorporated with SVM to diagnose the normal state (NOR), inner race fault (IRF), outer race fault (ORF), and ball bearing faults(BBF) in rolling element bearings.

Figure 50.

CMWPE entropy curves to diagnose (a) normal, (b) inner raceway, (c) outer raceway, (d) ball bearing faults, and (e) mean values for all states of fault faults. Reproduced with permission of [126].

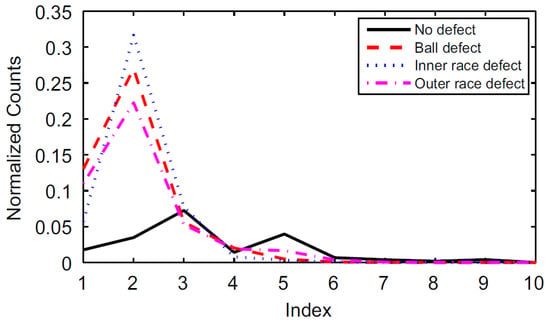

In [128], the authors proposed the characteristics of time-domain zero-crossing features and defected frequencies obtained by vibration signals to classify bearing faults. The defective frequencies are represented by spectral analysis, and classification is completed by using FFNN for bearing fault diagnosis. Figure 51 shows the results of multiple bearing failures by employing time domain zero-crossing with FFNN.

Figure 51.

Zero-crossing features characteristics for the diagnosis of multiple bearing faults. Reproduced with permission of [128].

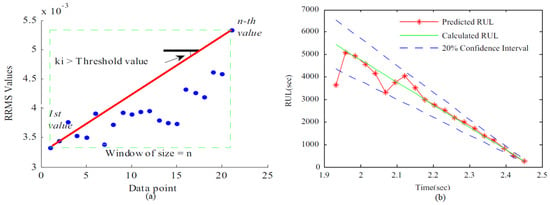

In [129], the authors suggested the incorporation of a multivariable feedback extreme learning machine (MFELM) with convolutional neural networks (CNN) for the diagnosis of IM faulty bearings. The MFELM provided the ultimate decision about layers of neural networks from vibration signals through sensors to generate datasets through a spectrogram. Figure 52 shows the results of roller bearing faults and the prediction of their useful remaining life using MFELM and relative root mean square value (RRMS).

Figure 52.

(a) Short-term degradation results for bearing faults prediction. (b) Performance of the proposed diagnostic methodology for forecasting of remaining useful life (RUL) [129].

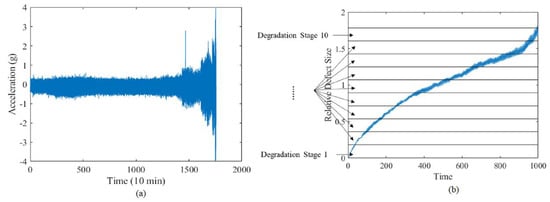

In [130], the authors proposed incipient fault detection and health monitoring of bearings through complementary ensemble empirical mode decomposition (CEEMD) incorporated with kernel-based support vector machines. Figure 53 shows the results of CEEMD incorporated with kernel-based SVM for estimating the lifetime bearings and their degradation stages based on experimental data.

Figure 53.

(a) Test data of bearing lifetime. (b) Degradation stages based on experimental data [130].

In [131], the authors suggested support vector machines and decision trees for the diagnosis of bearing faults in rotating machines through noncurrent defects obtained by statistical features for dataset generation. In [132], the authors recommended data-driven probabilistic E-support vector regression for estimating the remaining useful life of roller bearings. Wavelet transform was utilized for extracting informative features from the time domain, frequency domain, and time scale domain through accelerometers. Figure 54 shows the actual and computed RUL for provided data.

Figure 54.

(a) Prognosis result for prediction of RUL. (b) Zoom view [132].

In [133], the writers proposed a deep neural network (DNN) for the diagnosis of bearing faults. Vibration signals were employed for feature extraction to convert multi-domain images and fed to the DNN for the classification of bearing faults. In [134], the authors proposed health monitoring of ball bearings using Hilbert–Huang, support vector machines SVM, and support vector regression SVR. Hilbert–Huang was implemented to haul out attributes from stationary vibration signals. SVM and SVR were utilized to classify and estimate the RUL of bearings, respectively.

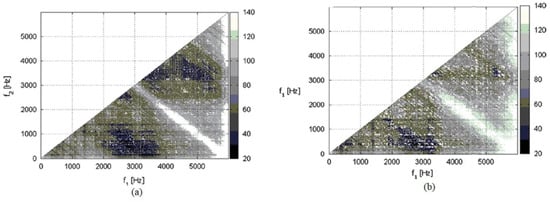

In [135], the authors suggested the sparse representation theory incorporated with kernel functions of support vector machines (SVM) for the diagnosis of bearing faults. Root mean square error (RMSE) and mean square correlation coefficient (MSCC)were utilized for feature extraction optimized by PSO to obtain significant information for training purposes. In [136], the authors recommended a Bayes classifier for the classification of bearing faults in PMSM employing linear discriminant analysis (LDA) of the stator currents. In [137], the authors suggested a stacked pruning sparse denoising auto encoder (sPSDAE) for evaluating the rolling bearing faults. The auto encoder was used for extracting features from subsequent layers to feed sPSDAE for learning. In [138], the authors proposed the classification of bearing faults by implementing support vector machines (SVM), which uses bi-spectrum analysis to extract features for generating datasets. Bi-spectrum analyses were further subjected by PCA to reduce dimensions and input to SVM for classification of bearing faults as shown in Figure 55.

Figure 55.

Bi-spectra results for the diagnosis of (a) outer race fault and (b) ball bearing fault [139].

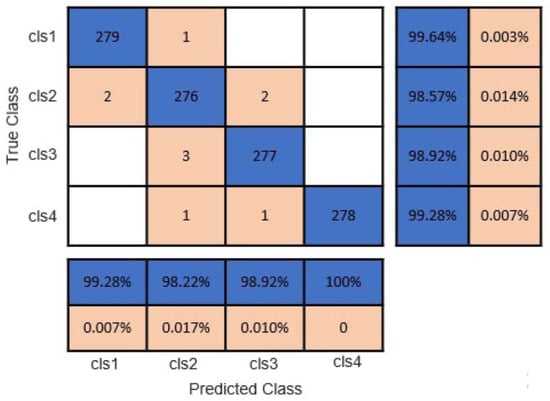

In [139], the authors investigated the methodology for evaluating the bearing fault diagnosis of metallic, ceramic, and hybrid bearings based on an adaptive stacked auto encoder. In [140], the authors suggested a complete ensemble empirical mode decomposition with adaptive noise (CEEMDAN) with piecewise aggregate approximation (PAA) for the decomposition of long signals to enhance the demodulation and filtering for the diagnosis of the bearing’s abnormal conditions accurately. In [141], the authors suggested continuous wavelet transform CWT and convolutional neural networks to predict the bearing fault size diagnosis based on deep transfer learning algorithms (DTL) and time–frequency images. Vibrations signals were employed to obtain useful information to create datasets using continuous wavelet transform (CWT) and scalogram images. Figure 56 shows the confusion matrix plot by employing the proposed methodology for the true class and predicted class.

Figure 56.

Confusion matrix plots and their accuracies for prediction of bearing fault size using a convolutional neural network with continuous wavelet transform [141].

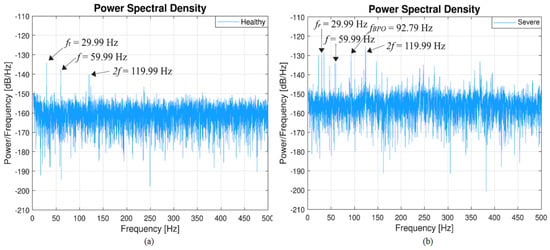

In [142], the authors proposed multichannel and multilevel one-dimensional convolutional neural networks (1D-CNN) for the detection of enhanced bearing faults in electric motors by employing vibration signals obtained through accelerometers. In [143], the authors suggested support vector machines (SVM) and fiber Bragg grating (FBG) to detect bearing failures in three-phase induction motors. Outer race faults were diagnosed in the proposed work at 47 different frequencies, and principal component analysis (PCA) was employed as a feature reduction technique for the dimension reduction of the dataset for gaining excellent results. Figure 57 shows the power spectral density (PSD) results for the recognition of healthy bearings and outer raceway abnormal conditions at different loading conditions.

Figure 57.

Power spectral density PSD of dynamic strain signal for (a) healthy bearings and (b) outer raceway faults. Reproduced with permission of [143].

In [144], the authors investigated abnormal conditions of ball bearings by employing maximal overlap discrete wavelet transform (MODWT) and image edge detection for grid-fed three-phase induction machines. In [145], the authors recommended the methodology to diagnose bearing faults in electric machines by employing a convolutional neural network with wireless sensor network data fusion. In [146], the authors suggested the progressive detection of bearing faults in three-phase induction motors by employing the matrix pencil method and MUSIC algorithm via pre-fault frequency cancellation. A very comprehensive review article on sound and acoustic emission-based fault diagnostic techniques is presented in [147]. Some AI based fault detection techniques are summarized in Table 3.

Table 3.

A summary of different artificial intelligence techniques for bearing fault diagnosis.

5. Recommendations and Suggestions

The successful implementation of different approaches to implementing conventional, statistical, and artificial intelligence-based approaches demands physically powerful correlations between different variables and makes a strong feature extraction capability for excellent results. For researchers and engineers, to implement conventional, statistical, and artificial intelligence-based approaches for bearing fault identification, we have the following suggestions.

- Make a proper environmental setup to examine the working conditions of all possible working combinations; for example, select the fixed operating point for varying loads at different speeds.

- For high-speed applications, in which chances of faults are complicated by external sources such as in the case of electrical motors fed by external sources, such as variable frequency devices (VFD), deep learning algorithms are proposed for accurate results.

- Sensors that are very helpful for recording the abnormal conditions produced in symmetry due to certain conditions are mounted close to the bearings for accurate results, and for machine learning/deep learning-based approaches, multiple sensors are required for processing of high-level data.

- The dataset which is used to implement machine learning/deep learning models must have used labeled data for high-level accuracy because unlabeled data in the dataset provides unsatisfactory results.

5.1. Gaps and Thoughts for Future Investigation

Although major developments are made in the field of fault detection and diagnosis of multiple issues found in rotating electrical machines, various types of issues are still unsolved. The following issues discussed below need the concentration of researchers and engineers to tackle them:

5.2. Current Challenges

- In the case of distributed faults in bearings, roughness and waviness forms of bearing faults have a huge untold impact on the frequency spectrum. For that reason, fault characteristics and frequency components are not addressed properly.

- For generating datasets, the majority of the work is performed in laboratories to train machine learning and deep learning models, so there is a need to make arrangements to record the real data for making datasets.

- The collection of data from different sources makes it easier to generate datasets, but accurate and excellent results demand labeled data, and that is why machine learning and deep learning models are not able to give high-accuracy results.

- The data imbalance is mostly due to data collected when bearings are in healthy condition, and limited samples are collected during faulty conditions, producing an imbalance of data in datasets, which also affects the performance of models.

- Usually, vibration signals are used to accumulate information through imposing accelerometers in laboratories, but real series of data nearly have lots of noise in their measurements. This is an open query for researchers: is it feasible to generate datasets from practical work without noisy measurements?

5.3. Future Work Directions

- To implement transfer learning as a promising approach instead of vibration signals, which have an excellent ability to transfer knowledge, and learn from past experiences to identify unexpected faulty conditions in real-world applications.

- Distinctive transfer learning-to-know strategies include domain randomization and area adaptation, which can successfully increase the range of the source domain (present datasets) and facilitate quicker studying and higher overall performance in the goal area (real-world applications).

- The datasets, which have limited labeled data points and are imbalanced, are proposed to implement semi-supervised learning to make possible the full utilization of data points for excellent results.

- The data augmentation approach is employed to solve the unbalancing in the dataset and is also used to identify the fake data points in the dataset, which badly affect the performance of artificial intelligence techniques.

- To introduce a few short learning techniques in combination with transfer learning, which addresses the data unbalance and scarcity in datasets and is very helpful for generating datasets from practical, real-world applications?

- The data points in datasets that have noise and are measured by vibration signals are suggested to use other types of sensors such as acoustic emission sensors and implement sensor fusion techniques to improve the strength of data points in the dataset.

6. Conclusions

This paper comprehensively reviewed state-of-the-art existing prose by employing conventional, statistical, and artificial intelligence (machine learning and deep learning)- based approaches for the diagnosis of all major types of bearing faults in electrical machines. From the previous literature, different fault detection and diagnosis (FDD)-based approaches (conventional, statistical, and artificial intelligence) were discussed, namely, vibration measurements, acoustic emission, temperature analysis, thermal imaging, spectral analysis, wavelet techniques, signal processing, and other mentioned techniques used for searching for bearing faults in rotating machines. Bearing fault diagnosis approaches were discussed by defining their merits, demerits, applications, and specific type of abnormal conditions that occurred on the bearings. Conventional techniques highlighted the previous literature-based methodologies to trace the abnormal conditions in bearings and also reviewed the advancements in research with hybrid mechanisms. Current and vibration analysis were most commonly employed with other techniques to characterize faults due to their robust and noninvasive nature. Conventional techniques also pointed out the time-varying conditions on variable speed drives and large locomotives’ linear bearing faults using high-frequency analysis. Mostly statistical approaches were used in the extraction of useful information and featured reduction analysis such as principal component analysis (PCA) and linear discriminant analysis (LDA) and were the important statistical parameters employed. Statistical approaches (skewness, kurtosis, root mean square values, stochastic resonance analysis, empirical mode decomposition, curvilinear component analysis) implemented data analysis and descriptive analysis-based approaches to diagnose all types of bearing faults in different applications. Statistical approaches mainly employed feature reduction techniques to optimize the parameters for excellent results in diagnosing the bearing faults. All the statistical techniques were discussed in the form of a table with their specific applications, merits and demerits, and bearing fault types taking place on bearings. Artificial intelligence-based approaches such as machine learning and deep learning demand large numbers of data points for training, and these algorithms have the capability to extract attributes for excellent results. Artificial intelligence-based approaches (machine learning and deep learning) were mostly discussed with all types of algorithms (support vector machines, K-nearest neighbors, random forest, fuzzy logic, neural networks, deep belief network, artificial bee colony) with different optimization and feature reduction techniques for the diagnosis of bearing faults in electrical machines. Machine learning and deep learning algorithms employed the Case Western Reserve University (CWRU) dataset to validate their performance for the diagnosis of bearing faults. Feature reduction techniques such as principal component analysis (PCA) and linear discriminant analysis (LDA) were employed in the datasets, and trained algorithms provided more efficient results for bearing fault diagnosis. Similarly, artificial intelligence-based approaches (machine learning and deep learning) were summarily discussed in the form of a table to discuss their merits and demerits, bearing fault type, applications, and their relevant references to search out the related articles. In the end, some recommendations and suggestions about current challenges and future directions were addressed briefly.

Author Contributions

Conceptualization, M.A.K. and B.A.; methodology, M.A.K.; software, M.A.K.; validation, B.A. and T.V.; formal analysis, K.K.; investigation, A.K.; resources, A.K.; data curation, M.A.K.; writing—original draft preparation, M.A.K. and B.A.; writing—review and editing, M.A.K.; visualization, T.V.; supervision, B.A. All authors have read and agreed to the published version of the manuscript.

Funding

The “Industrial Internet methods for electrical energy conversion systems monitoring and diagnostics” benefits from a 993,000 € grant from Iceland, Liechtenstein and Norway through the EEA Grants. The aim of the project is to provide the research in field of energy conversion systems and to develop artificial intelligence and virtual emulator-based prognostic and diagnostic methodologies for these systems. Project contract with the Research Council of Lithuania (LMTLT) No is S-BMT-21-5 (LT08-2-LMT-K-01-040).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nandi, S.; Toliyat, H.A.; Li, X. Condition Monitoring and Fault Diagnosis of Electrical Motors—A Review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, P.; He, S.; Huang, J. A Review of Modeling and Diagnostic Techniques for Eccentricity Fault in Electric Machines. Energies 2021, 14, 4296. [Google Scholar] [CrossRef]

- Tiboni, M.; Remino, C.; Bussola, R.; Amici, C. A Review on Vibration-Based Condition Monitoring of Rotating Machinery. Appl. Sci. 2022, 12, 972. [Google Scholar] [CrossRef]

- Gritli, Y.; Bellini, A.; Rossi, C.; Casadei, D.; Filippetti, F.; Capolino, G.-A. Condition monitoring of mechanical faults in induction machines from electrical signatures: Review of different techniques. In Proceedings of the 2017 IEEE 11th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives, SDEMPED 2017, Tinos, Greece, 29 August–1 September 2017; pp. 77–84. [Google Scholar] [CrossRef]

- Frosini, L. Monitoring and Diagnostics of Electrical Machines and Drives: A State of the Art. In Proceedings of the IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 8–9 April 2019; pp. 169–176. [Google Scholar] [CrossRef]

- Capolino, G.-A.; Antonino-Daviu, J.A.; Riera-Guasp, M. Modern Diagnostics Techniques for Electrical Machines, Power Electronics, and Drives. IEEE Trans. Ind. Electron. 2015, 62, 1738–1745. [Google Scholar] [CrossRef]

- Basak, D.; Tiwari, A.; Das, S.P. Fault diagnosis and condition monitoring of electrical machines—A Review. In Proceedings of the IEEE International Conference on Industrial Technology, Mumbai, India, 15–17 December 2006; pp. 3061–3066. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Friswell, M.I. Defect Diagnosis for Rolling Element Bearings Using Acoustic Emission. J. Vib. Acoust. 2009, 131, 061012. [Google Scholar] [CrossRef]

- Trajin, B.; Regnier, J.; Faucher, J. Bearing fault indicator in induction machine using stator current spectral analysis. In Proceedings of the 2008 4th IET Conference on Power Electronics, Machines and Drives, York, UK, 2–4 April 2008. [Google Scholar] [CrossRef]

- Moundekar, N.D.; Deshmukh, B.D. Study of failure modes of rolling bearings: A review. Int. J. Mod. Eng. Res. (IJMER) 2014, 4, 139. [Google Scholar]

- Hamadache, M.; Jung, J.H.; Park, J.; Youn, B.D. A comprehensive review of artificial intelligence-based approaches for rolling element bearing PHM: Shallow and deep learning. JMST Adv. 2019, 1, 125–151. [Google Scholar] [CrossRef]

- Frosini, L. Novel Diagnostic Techniques for Rotating Electrical Machines—A Review. Energies 2020, 13, 5066. [Google Scholar] [CrossRef]

- Eren, L.; Devaney, M.J. Bearing Damage Detection via Wavelet Packet Decomposition of the Stator Current. IEEE Trans. Instrum. Meas. 2004, 53, 431–436. [Google Scholar] [CrossRef]

- Cung, L.E.; Hien, B.M.; Son, N.T. Gear and bearing fault detection using wavelet packet and Hilbert method via acoustic signals. ASEAN Eng. J. 2016, 6, 5–13. [Google Scholar]

- Huang, L.; Hu, N.; Yang, Y.; Chen, L.; Wen, J.; Shen, G. Study on Electromagnetic–Dynamic Coupled Modeling Method—Detection by Stator Current of the Induction Motors with Bearing Faults. Machines 2022, 10, 682. [Google Scholar] [CrossRef]

- Rosero, J.A.; Cusido, J.; Garcia, A.; Ortega, J.A.; Romeral, L. Broken bearings and eccentricity fault detection for a permanent magnet synchronous motor. In Proceedings of the IECON 2006—32nd Annual Conference on IEEE Industrial Electronics, Paris, France, 6–10 November 2006; pp. 964–969. [Google Scholar]

- Rosero, J.; Cusido, J.; Ortega, J.A.; Romeral, L.; Garcia, A. PMSM Bearing Fault Detection by means of Fourier and Wavelet transform. In Proceedings of the IECON 2007—33rd Annual Conference of the IEEE Industrial Electronics Society, Taipei, Taiwan, 5–8 November 2007; pp. 1163–1168. [Google Scholar]

- Rosero, J.; Romeral, L.; Rosero, E.; Urresty, J. Fault Detection in dynamic conditions by means of Discrete Wavelet Decomposition for PMSM running under Bearing Damage. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 951–956. [Google Scholar]

- Vilhekar, T.G.; Ballal, M.S.; Suryawanshi, H.M. Application of Multiple Parks Vector Approach for Detection of Multiple Faults in Induction Motors. J. Power Electron. 2017, 17, 972–982. [Google Scholar] [CrossRef]

- Silva, J.L.; Cardoso, A.M. Bearing failures diagnosis in three-phase induction motors by extended Park’s vector approach. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society, Raleigh, NC, USA, 6–10 November 2005. [Google Scholar]

- Salem, S.B.; Touti, W.; Bacha, K.; Chaari, A. Induction motor mechanical fault identification using Park’s vector approach. In International Conference on Electrical Engineering and Software Applications; IEEE: Piscataway Township, NJ, USA, 2013; pp. 1–6. [Google Scholar]

- Corne, B.; Vervisch, B.; Derammelaere, S.; Knockaert, J.; Desmet, J. The reflection of evolving bearing faults in the stator current’s extended park vector approach for induction machines. Mech. Syst. Signal Process. 2018, 107, 168–182. [Google Scholar] [CrossRef]

- Bessous, N.; Zouzou, S.E.; Bentrah, W.; Sbaa, S.; Sahraoui, M. Diagnosis of bearing defects in induction motors using discrete wavelet transform. Int. J. Syst. Assur. Eng. Manag. 2018, 9, 335–343. [Google Scholar] [CrossRef]

- Harlişca, C.; Szabó, L.; Frosini, L.; Albini, A. Bearing faults detection in induction machines based on statistical processing of the stray fluxes measurements. In Proceedings of the IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Valencia, Spain, 27–30 August 2013; pp. 371–376. [Google Scholar]

- Frosini, L.; Magnaghi, M.; Albini, A.; Magrotti, G. A new diagnostic instrument to detect generalized roughness in rolling bearings for induction motors. In Proceedings of the IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Guarda, Portugal, 1–4 September 2015; pp. 239–245. [Google Scholar]

- Zamudio-Ramírez, I.; Osornio-Ríos, R.A.; Antonino-Daviu, J.A.; Quijano-Lopez, A. Smart-Sensor for the Automatic Detection of Electromechanical Faults in Induction Motors Based on the Transient Stray Flux Analysis. Sensors 2020, 20, 1477. [Google Scholar] [CrossRef]

- Dalvand, F.; Kalantar, A.; Safizadeh, M.S. A Novel Bearing Condition Monitoring Method in Induction Motors Based on Instantaneous Frequency of Motor Voltage. IEEE Trans. Ind. Electron. 2015, 63, 364–376. [Google Scholar] [CrossRef]

- Zanini, R.A.A.; Freitas, T.; Silva, L.N.; Gutierres, A.; Santos, G. Evaluation of the Method of Failure Analysis in Angular Contact Bearings through the Envelope Technique. In SAE International 21st SAE Brasil International Congress and Exhibition; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Immovilli, F.; Cocconcelli, M.; Bellini, A.; Rubini, R. Detection of Generalized-Roughness Bearing Fault by Spectral-Kurtosis Energy of Vibration or Current Signals. IEEE Trans. Ind. Electron. 2009, 56, 4710–4717. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W. Current-based online bearing fault diagnosis for direct-drive wind turbines via spectrum analysis and impulse detection. In Proceedings of the IEEE Power Electronics and Machines in Wind Applications, Denver, CO, USA, 16–18 July 2012; pp. 1–6. [Google Scholar]

- Attaianese, C.; De Falco, P.; Del Pizzo, A.; Di Noia, L.P. Bearing Failure Prognostic Method Based on High Frequency Inductance Variation in Electric Railway Traction Motors. In Proceedings of the IEEE Texas Power and Energy Conference (TPEC), virtually, 2–5 February 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Tischmacher, H. Bearing Wear Condition Identification on Converter-fed Motors. In Proceedings of the IEEE International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 19–25. [Google Scholar] [CrossRef]

- Kudelina, K.; Baraškova, T.; Shirokova, V.; Vaimann, T.; Rassõlkin, A. Fault detecting accuracy of mechanical damages in rolling bearings. Machines 2022, 10, 86. [Google Scholar] [CrossRef]