On the Simulations of Thermal Liquid Foams Using Lattice Boltzmann Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Lattice Boltzmann Method

2.2. Shan-Chen Multiphase Multicomponent Model

2.3. Forcing Scheme

2.4. Two Relaxation Time

2.5. Mid-Range Interaction Model

2.6. Thermal Field

2.7. Units and Non-Dimensional Groups

- Reynolds Number:

- 2.

- Atwood Number:

- 3.

- Bonds Number:

- 4.

- Prandtl Number:

3. Model Verification and Validation

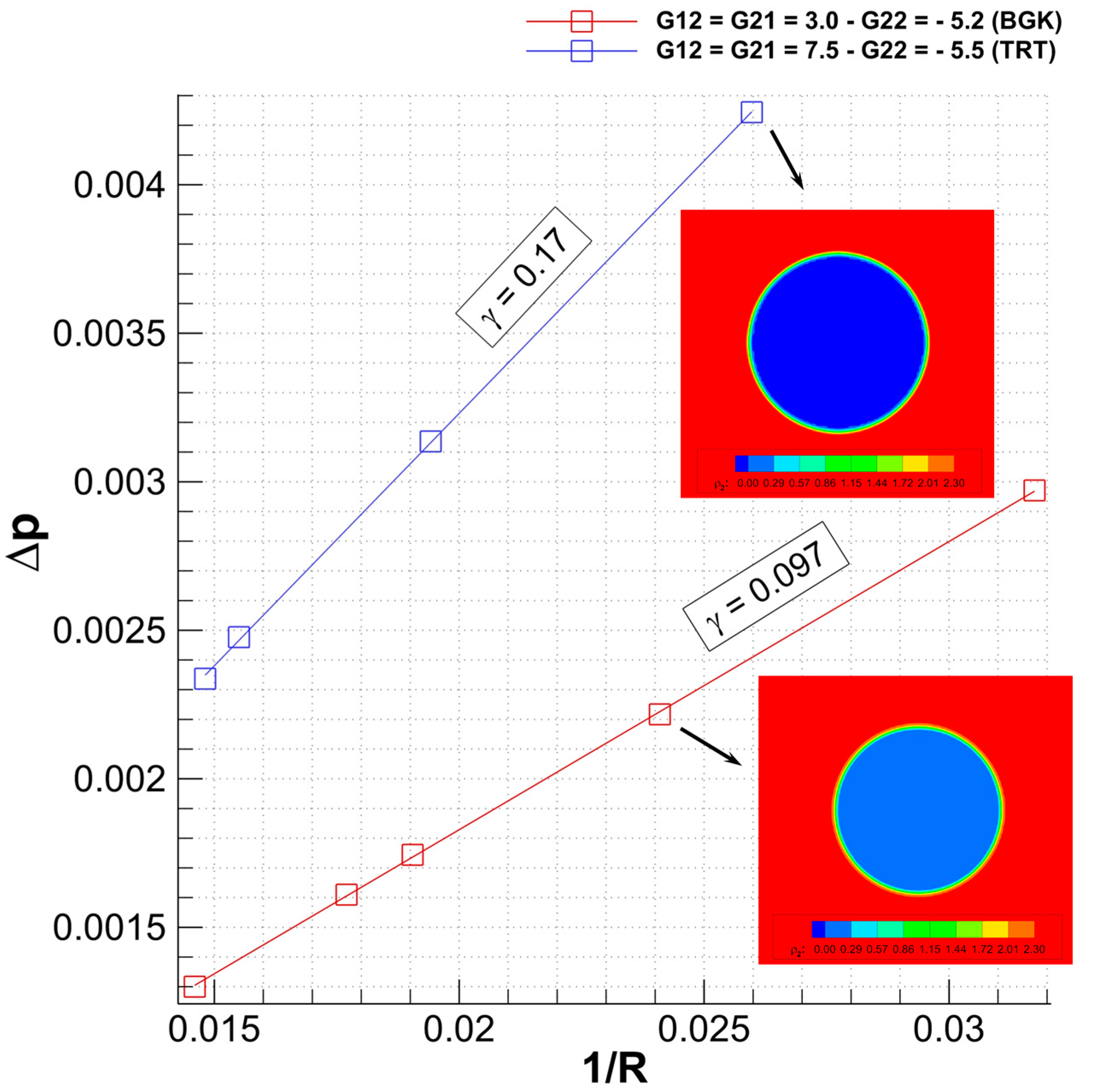

3.1. Young–Laplace Test

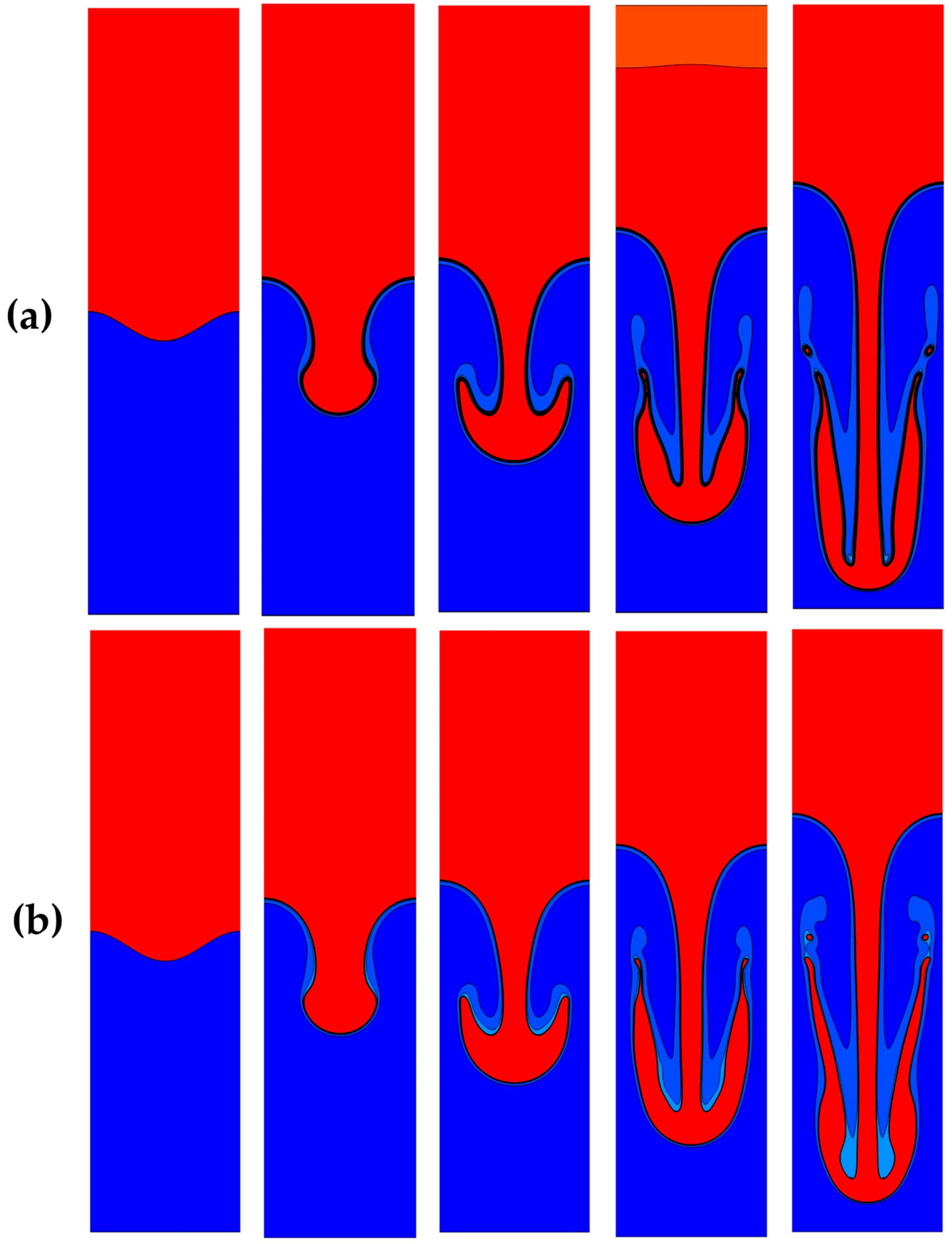

3.2. Rayleigh–Taylor Instability

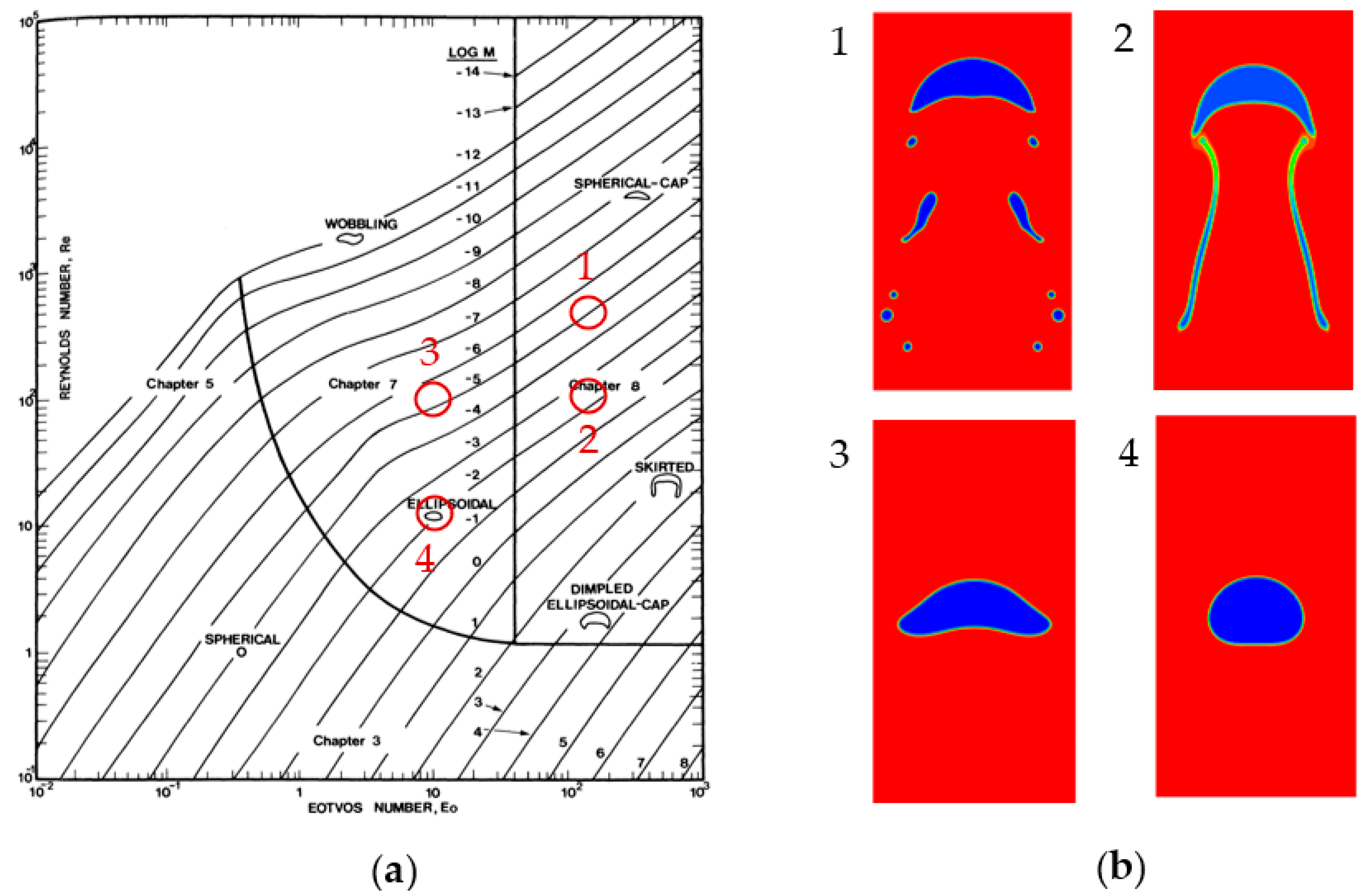

3.3. Bubble Rise Diagram

- Bo = 100, Re = 500

- Bo = 100, Re = 100

- Bo = 10, Re = 100

- Bo = 10, Re = 10

4. Application

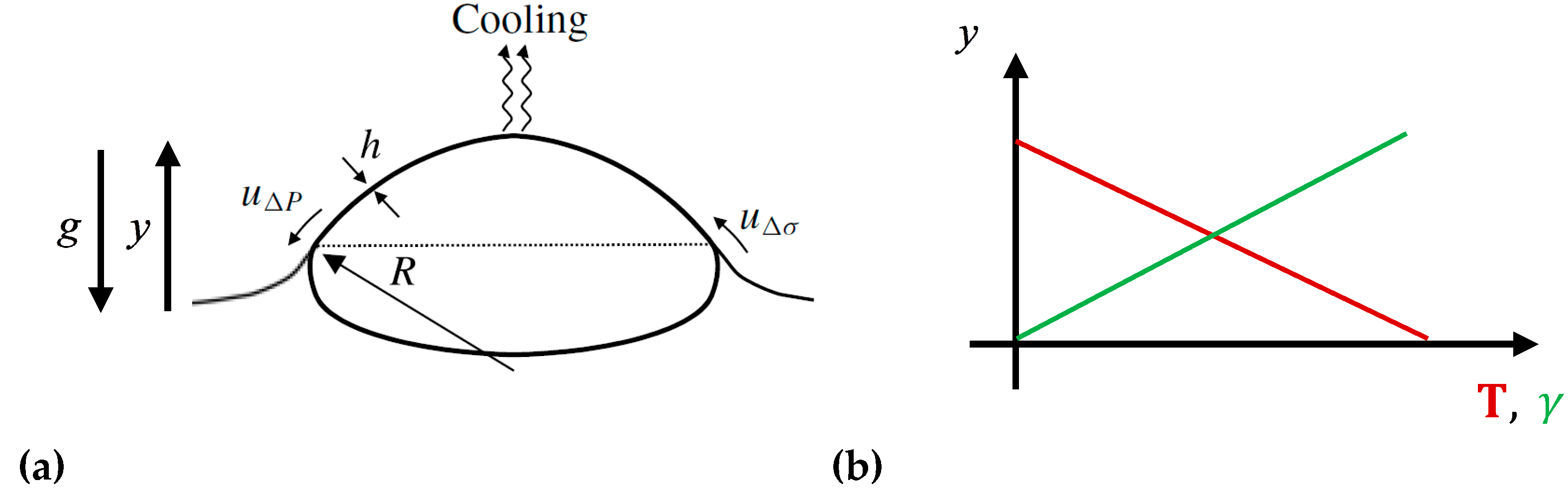

4.1. Thermal Field in Liquid Foam

4.2. Locally Variable Surface Tension Due to Temperature

5. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cantat, I.; Cohen-Addad, S.; Elias, F.; Graner, F.; Höhler, R.; Pitois, O.; Rouyer, F.; Saint-Jalmes, A. Foams: Structure and Dynamics; OUP: Oxford, UK, 2013. [Google Scholar]

- Saint-Jalmes, A. Physical chemistry in foam drainage and coarsening. Soft Matter 2006, 2, 836–849. [Google Scholar] [CrossRef] [PubMed]

- Exerowa, D.; Gochev, G.; Platikanov, D.; Liggieri, L.; Miller, R. Foam Films and Foams: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Bergeron, V.; Radke, C.J. Equilibrium measurements of oscillatory disjoining pressures in aqueous foam films. Langmuir 1992, 8, 3020–3026. [Google Scholar] [CrossRef]

- Stevenson, P. Foam Engineering: Fundamentals and Applications; John Wiley & Sons: Oxford, UK, 2012. [Google Scholar]

- Poulain, S.; Villermaux, E.; Bourouiba, L. Ageing and burst of surface bubbles. J. Fluid Mech. 2018, 851, 636–671. [Google Scholar] [CrossRef]

- Chen, S.; Doolen, G.D. Lattice Boltzmann method for fluid flows. Annu. Rev. Fluid Mech. 1998, 30, 329–364. [Google Scholar] [CrossRef]

- Swift, M.R.; Osborn, W.R.; Yeomans, J.M. Lattice Boltzmann simulation of nonideal fluids. Phys. Rev. Lett. 1995, 75, 830. [Google Scholar] [CrossRef]

- Swift, M.R.; Orlandini, E.; Osborn, W.R.; Yeomans, J.M. Lattice Boltzmann simulations of liquid-gas and binary-fluid systems. Phys. Rev. E 1996, 54, 5041. [Google Scholar] [CrossRef]

- Shan, X.; Chen, H. Lattice Boltzmann model for simulating flows with multiple phases and components. Phys. Rev. E 1993, 47, 1815. [Google Scholar] [CrossRef]

- Shan, X.; Chen, H. Simulation of nonideal gases and liquid-gas phase transitions by the lattice Boltzmann equation. Phys. Rev. E 1994, 49, 2941. [Google Scholar] [CrossRef]

- Yuan, P.; Schaefer, L. Equations of state in a lattice Boltzmann model. Phys. Fluids 2006, 18, 042101. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Krüger, T.; Kusumaatmaja, H.; Kuzmin, A.; Shardt, O.; Silva, G.; Viggen, E.M. The Lattice Boltzmann Method; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Körner, C.; Thies, M.; Hofmann, T.; Thürey, N.; Rüde, U. Lattice Boltzmann model for free surface flow for modeling foaming. J. Stat. Phys. 2005, 121, 179–196. [Google Scholar] [CrossRef]

- Ataei, M.; Shaayegan, V.; Costa, F.; Han, S.; Park, C.; Bussmann, M. LBfoam: An open-source software package for the simulation of foaming using the Lattice Boltzmann Method. Comput. Phys. Commun. 2021, 259, 107698. [Google Scholar] [CrossRef]

- Thies, M. Lattice Boltzmann Modeling with Free Surfaces Applied to Formation of Metal Foams. Ph.D. Dissertation, Friedrich-Alexander-Universitaet Erlangen-Nuernberg, Erlangen, Germany, 2005. [Google Scholar]

- Sukop, M.C. Lattice Boltzmann Modeling Lattice Boltzmann Modeling; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Chen, L.; Kang, Q.; Mu, Y.; He, Y.L.; Tao, W.Q. A critical review of the pseudopotential multiphase lattice Boltzmann model: Methods and applications. Int. J. Heat Mass Transf. 2014, 76, 210–236. [Google Scholar] [CrossRef]

- Falcucci, G.; Ubertini, S.; Succi, S. Lattice Boltzmann simulations of phase-separating flows at large density ratios: The case of doubly-attractive pseudo-potentials. Soft Matter 2010, 6, 4357–4365. [Google Scholar] [CrossRef]

- Sbragaglia, M.R.L.S.K.; Benzi, R.; Biferale, L.; Succi, S.; Sugiyama, K.; Toschi, F. Generalized lattice Boltzmann method with multirange pseudopotential. Phys. Rev. E 2007, 75, 026702. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Boghosian, B.M.; Coveney, P.V.; Nekovee, M. A ternary lattice Boltzmann model for amphiphilic fluids. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2000, 456, 2043–2057. [Google Scholar] [CrossRef]

- Nekovee, M.; Coveney, P.V.; Chen, H.; Boghosian, B.M. Lattice-Boltzmann model for interacting amphiphilic fluids. Phys. Rev. E 2000, 62, 8282. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, S.; Berghout, P.; Van den Akker, H.E. A lattice boltzmann approach to surfactant-laden emulsions. AIChE J. 2019, 65, 811–828. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, P. A lattice Boltzmann method for simulation of liquid–vapor phase-change heat transfer. Int. J. Heat Mass Transf. 2012, 55, 4923–4927. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, P.; Yan, H.J. Improved thermal lattice Boltzmann model for simulation of liquid-vapor phase change. Phys. Rev. E 2017, 96, 063303. [Google Scholar] [CrossRef]

- Huang, R.; Wu, H.; Cheng, P. A new lattice Boltzmann model for solid–liquid phase change. Int. J. Heat Mass Transf. 2013, 59, 295–301. [Google Scholar] [CrossRef]

- He, Y.L.; Liu, Q.; Li, Q.; Tao, W.Q. Lattice Boltzmann methods for single-phase and solid-liquid phase-change heat transfer in porous media: A review. Int. J. Heat Mass Transf. 2019, 129, 160–197. [Google Scholar] [CrossRef]

- Clift, R.; Grace, J.R.; Weber, M.E. Bubbles, Drops, and Particles; Academic Press: London, UK, 1978. [Google Scholar]

- Succi, S. The Lattice Boltzmann Equation: For Fluid Dynamics and Beyond; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- Koelman, J.M.V.A. A simple lattice Boltzmann scheme for Navier-Stokes fluid flow. Europhys. Lett. 1991, 15, 603. [Google Scholar] [CrossRef]

- Wilde, D.; Krämer, A.; Küllmer, K.; Foysi, H.; Reith, D. Multistep lattice Boltzmann methods: Theory and applications. Int. J. Numer. Methods Fluids 2019, 90, 156–169. [Google Scholar] [CrossRef]

- Hussein, M.A. On the Theoretical and Numerical Development of Lattice Boltzmann Models for Biotechnology and Its Applications. Ph.D. Dissertation, Technical University of Munich, Munich, Germany, 2010. [Google Scholar]

- Guo, Z.; Zheng, C.; Shi, B. Discrete lattice effects on the forcing term in the lattice Boltzmann method. Phys. Rev. E 2002, 65, 046308. [Google Scholar] [CrossRef]

- Buick, J.M.; Greated, C.A. Gravity in a lattice Boltzmann model. Phys. Rev. E 2000, 61, 5307. [Google Scholar] [CrossRef]

- Yu, Z.; Fan, L.S. Multirelaxation-time interaction-potential-based lattice Boltzmann model for two-phase flow. Phys. Rev. E 2010, 82, 046708. [Google Scholar] [CrossRef]

- Seta, T.; Rojas, R.; Hayashi, K.; Tomiyama, A. Implicit-correction-based immersed boundary–lattice Boltzmann method with two relaxation times. Phys. Rev. E 2014, 89, 023307. [Google Scholar] [CrossRef]

- Postma, B.; Silva, G. Force methods for the two-relaxation-times lattice Boltzmann. Phys. Rev. E 2020, 102, 063307. [Google Scholar] [CrossRef]

- Guo, Z.; Shi, B.; Zheng, C. A coupled lattice BGK model for the Boussinesq equations. Int. J. Numer. Methods Fluids 2002, 39, 325–342. [Google Scholar] [CrossRef]

- He, X.; Chen, S.; Zhang, R. A lattice Boltzmann scheme for incompressible multiphase flow and its application in simulation of Rayleigh-Taylor instability. J. Comput. Phys. 1999, 152, 642–663. [Google Scholar] [CrossRef]

- Chiappini, D.; Bella, G.; Succi, S.; Toschi, F.; Ubertini, S. Improved lattice Boltzmann without parasitic currents for Rayleigh-Taylor instability. Commun. Comput. Phys. 2010, 7, 423. [Google Scholar] [CrossRef]

- Chen, S.; Martinez, D.; Mei, R. On boundary conditions in lattice Boltzmann methods. Phys. Fluids 1996, 8, 2527–2536. [Google Scholar] [CrossRef]

- Guo, Z.; Zheng, C.; Shi, B. An extrapolation method for boundary conditions in lattice Boltzmann method. Phys. Fluids 2002, 14, 2007–2010. [Google Scholar] [CrossRef]

- Davies, R.M.; Taylor, G.I. The mechanics of large bubbles rising through extended liquids and through liquids in tubes. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1950, 200, 375–390. [Google Scholar]

- Dollet, B.; Scagliarini, A.; Sbragaglia, M. Two-dimensional plastic flow of foams and emulsions in a channel: Experiments and lattice Boltzmann simulations. J. Fluid Mech. 2015, 766, 556–589. [Google Scholar] [CrossRef]

- Fei, L.; Scagliarini, A.; Montessori, A.; Lauricella, M.; Succi, S.; Luo, K.H. Mesoscopic model for soft flowing systems with tunable viscosity ratio. Phys. Rev. Fluids 2018, 3, 104304. [Google Scholar] [CrossRef]

| 0 | 4/9 |

| 1, 2, 3, 4 | 1/9 |

| 5, 6, 7, 8 | 1/36 |

| 0 | 247/420 |

| 1, 2, 3, 4 | 4/63 |

| 5, 6, 7, 8 | 4/135 |

| 9, 10, 11, 12 | 1/180 |

| 13, 14, …, 20 | 2/945 |

| 21, 22, 23, 24 | 1/15,120 |

| Simulation Parameter | Value |

|---|---|

| Resolution | 1000 × 1000 |

| Re | 10 |

| Bo | 0.1 |

| 0.72 | |

| 6.0 | |

| G12 = G21 | 5.45 |

| G11 = G22 | −2.0 |

| 5.0 | |

| θ * | 20˚ |

| 1.0 | |

| 0.25 | |

| 20 LU | |

| - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mobarak, M.; Gatternig, B.; Delgado, A. On the Simulations of Thermal Liquid Foams Using Lattice Boltzmann Method. Energies 2023, 16, 195. https://doi.org/10.3390/en16010195

Mobarak M, Gatternig B, Delgado A. On the Simulations of Thermal Liquid Foams Using Lattice Boltzmann Method. Energies. 2023; 16(1):195. https://doi.org/10.3390/en16010195

Chicago/Turabian StyleMobarak, Mohammad, Bernhard Gatternig, and Antonio Delgado. 2023. "On the Simulations of Thermal Liquid Foams Using Lattice Boltzmann Method" Energies 16, no. 1: 195. https://doi.org/10.3390/en16010195

APA StyleMobarak, M., Gatternig, B., & Delgado, A. (2023). On the Simulations of Thermal Liquid Foams Using Lattice Boltzmann Method. Energies, 16(1), 195. https://doi.org/10.3390/en16010195