Abstract

Every type of agricultural production is a burden for the natural environment. The paper’s objective is to assess the energy use efficiency, GHG emissions, and provide an economic analysis of buckwheat production for Central Europe (Poland). The analysis and comparison involved two production systems: low-input and high-input ones. The experiment involved three varieties of buckwheat, Panda, Volma, and Mancan. The yields for analysis were obtained from the field experiment which was set up in 3k-p fractional design was applied in two replications in which at the same time five factors were tested (A—variety, B—mineral fertilisation, C—sowing rate, D—weed control, E—growth regulator). A quartile was used as a statistical tool to select production systems. A high-input buckwheat production regime required, on average, 74.00% more energy than a low-input system. The total mean energy input for three varieties ranged from 7532.7 to 13,106.9 MJ ha−1 for low- and high-input systems, respectively. The results show that the energy use efficiency, specific energy, and net energy gain for the low-input system were on average 1.51, 9.6 MJ kg−1, and 3878.8 MJ ha−1, respectively, for the investigated varieties. For the high-input system, it was 1.35, 10.9 MJ kg−1, 4529.9 MJ ha−1, respectively. The total CO2 equivalent emissions during buckwheat production were higher for the high-input system than for the low-input system by more than 40%. The economic analysis demonstrated that the high-input system had better economic efficiency (without EU payment), 1.01 on average, than the low-input system, 1.07 on average. The international literature does not offer research on energy analysis for the production of common buckwheat and GHG emissions. The findings of this study demonstrate how the production systems affect energy and economic efficiency as well as GHG emissions. The authors suggest further research in Europe and globally, particularly on the energy use efficiency and GHG emissions in the production of common buckwheat, to verify the present results and improve production technologies (reduce inputs and costs).

1. Introduction

Common buckwheat (Fagopyrum esculentum Moench) is a dicotyledon of the family Polygonaceae and genus Fagopyrum [1]. Buckwheat comes from China, first cultivated six thousand years ago [2,3]. It is considered a pseudocereal, similarly to amaranth (Amaranthus spp.) and quinoa (Chenopodium quinoa Willd) [4]. Pseudocereals are dicotyledons, and although not related to cereals, their seeds share certain similarities with grain [5]: they have a similar appearance and contain substantial amounts of starch, the same as cereals proper [6]. Buckwheat is used as food and fodder for poultry and cattle. It is also used as weed control [7] and green manure [8]. Its advantage is that it can be cultivated in light soils because it can absorb nutrients that other plants struggle with, so it can exploit soil better. Poland is among the leading producers of buckwheat. With crops reaching 108.4 thousand tonnes (according to international statistics), it is the fifth-largest producer of buckwheat globally. Russia takes first place (1214.6 thou. t), followed by China (1197.6 thou. t), Ukraine (164.6 thou. t), and France (127.9 thou. t) [9]. However, buckwheat crops and consumption remain minuscule compared to cereals. The cause for its limited popularity is the low efficiency and profitability of production (despite the high unit price) and insufficient consumption trends for buckwheat products.

It is buckwheat that offers the potential to meet the ever growing food demand of the expanding population from among pseudocereals. It is one of the most suitable crops for very short growing seasons. It develops well in diverse cultivation systems owing to its short time requirements (3–4 months) [10] and better adaptation to low temperatures and moisture stress [11].

It is one of the fundamental challenges for the world to produce sufficient food and other materials for the current population and generations to come [12]. Therefore, development and continuous improvements in agriculture are crucial for humanity [13]. Moreover, as agriculture grows more advanced, its energy consumption increases due to the expanding population, limited availability of arable land, and better living standards [14,15].

Farmers employ new and often energy-greedy production technologies to improve yield [16]. This leads to significant growth in energy demand (even up to 300–400%). Therefore, the issue of energy use in agriculture gains weight [17]. Furthermore, the effective use of energy is one of the fundamental requirements of sustainable farming [18,19].

Energy is the sine qua non resource in agriculture. Energy (E) is defined as fossil energy in joules (J). The premise is that all fuels and electric power come from fossil energy sources. Energy use (EU) is defined as the net energy consumed for producing an agricultural product until it is sold and leaves the farm or is used as fodder for farm animals [20]. Energy is used first and foremost to power machines and equipment in the sector. Technological upgrades in agriculture directly affect production energy needs as well [21]. Energy supply for modern and sustainable agricultural production and processing systems is one of the primary drivers of agricultural production growth [22,23,24,25]. Effective use of energy in plant production minimises greenhouse gas emissions (GHG), preserves natural resources, and promotes sustainable farming as an economically rational production system [14].

Note that apart from consuming energy, agriculture also produces it [26,27,28]. Its potential in this regard is colossal. It depends on the pace of introducing high-yield energy crops and environmental matters [29,30,31,32,33,34,35,36,37].

Energy use efficiency in agriculture is among the primary goals of energy policies in countries with large agricultural sectors [38,39,40]. Many authors emphasise the strong relationship between energy use and productivity in agriculture [36,41]. The main driver of improved productivity was technological advance through mechanisation and employment of machinery [42]. Developing countries are where agricultural energy consumption was particularly high [43,44]. The need for improved energy use efficiency in agriculture to stabilise the balance of energy inputs and plant production is obvious. Agronomic modifications may play an important role in increasing energy use efficiency in agriculture [45].

Any agricultural product or service production affects the environment and consumes energy stored in renewable and nonrenewable natural resources. Additionally, every agricultural system depends on the inflow of anthropogenic resources and goods. The balance, environmental impact, and energy use of specific agricultural production also depend on the human commitment and how inputs are put to work. Sustainable methods focus on using environmental energy first [46].

In terms of economics, it is the goal of every agricultural activity to maximise profit. However, in developed countries, the economic profitability of various production systems today is obfuscated by subsidies that affect both production factors (inputs) and the final product (output). Apart from any external aid, energy balances should identify the most efficient and, therefore, the most advisable form of farming for each agroclimatic region. In this context, energy balances can lead to more efficient and environmentally friendly production systems [47].

The novelty and objectives of the work.

Research on energy use efficiency has been conducted in various agricultural systems in many parts of the world and on many crops, such as apricot [48], winter rape [49,50,51,52], maize [53,54,55], cotton [56], cherries [57], sugar beet [14,58,59], citrus [60,61], potato [62], herbs [63], greenhouse cucumber [64,65], barley [66], peas [67,68], triticale [69], faba bean [70], flax [71], and even entire farming systems for sustainable agriculture [72].

The international literature does not offer research on energy analysis for the production of common buckwheat (only two papers in Polish are available). Furthermore, the authors did not find any GHG emissions research for common buckwheat production. Therefore, the paper’s objective is to assess the energy use efficiency and GHG emissions for common buckwheat production. In addition, the paper presents an economic analysis of buckwheat production for Central Europe (Poland) to provide a better picture. The analysis and comparison involved two production systems: low-input and high-input ones.

2. Materials and Methods

2.1. Experimental Site

The data come from a three-year scientific research project on common buckwheat cultivation during 2013 to 2015 by the department of Agrotechnology and Agribusiness of the University of Warmia and Mazury in Olsztyn, Educational and Research Station in Tomaszkowo, near Olsztyn (53°71′74″ N; 20°40′62″ E). The experiment involved three varieties of buckwheat: Panda, a Polish variety, Volma, a Belarusian variety, and Mancan, a Canadian variety, popular in the USA. The yields for analysis were obtained from the field experiment. The experiment was set up in 3k-p fractional design and applied in two replications in which at the same time five factors were tested (A—variety, B—mineral fertilisation, C—sowing rate, D—weed control, E—growth regulator) on three levels (0, 1, 2). Plot size was 15 m2 (10 m by 1.5 m). A quartile was used as a statistical tool to select technologies. The results of the study were analysed in two groups of technologies divided by buckwheat yield, i.e., in the largest (Q1) and the lowest (Q3). Buckwheat can be successfully grown on light soils, which in Poland is about 60%. In addition, a strongly developed tap root system with adventitious roots facilitates the uptake of nutrients. Therefore, reduced mineral fertilisation is possible.

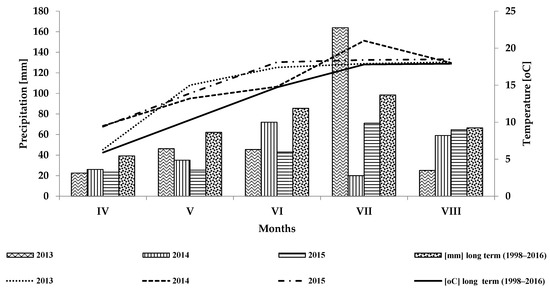

The cultivation took place in light soil with 26.6 of P, 26.3 of K, 5.0 of Mg, and 18.4 Nmin (0–90 cm) (mg kg−1 of soil). The precrop for buckwheat in all the years of the research was winter triticale. The experiment involved traditional, nonreduced tillage. The sowing period in each year was the third decade of May. Details of each production system can be found in Table 1, and the weather conditions during the experiment are shown in Figure 1.

Table 1.

Differences between buckwheat production systems.

Figure 1.

Weather conditions during the experiment (2013–2015) vs. the long–term average (1998–2016).

2.2. Energy Efficiency

Energy balancing was performed to determine productivity for buckwheat. The analysis involves energy inputs for the production of common buckwheat, including labour, operation of assets (tractors, machines, equipment), energy resources (diesel fuel), and material consumption (seed, mineral fertilisers, pesticides) [73,74]:

where:

Ei total—the total energy input for buckwheat production (GJ ha−1);

Ei human labour—the energy input for human labour (GJ ha−1);

Ei fixed assets—the energy input for fixed assets (GJ ha−1);

Ei diesel—the energy input for diesel fuel consumption (GJ ha−1);

Ei materials—the energy input for materials (GJ ha−1).

According to Hülsbergen et al. [75] and Beheshti Tabar et al. [76], differences in methods for calculating energy efficiency cause differences in energy equivalents employed for an energy assessment. Energy equivalents are not constant and need to be adapted to local conditions and changing production methods. Most energy equivalents in the literature come from international contributions. The present article uses the energy input equivalents characteristic of Poland as proposed by Wójcicki [77] (Table 2).

Table 2.

Energy equivalence of inputs and output associated with buckwheat production.

Considering the substantial variability of local conditions, the authors decided not to include energy inputs necessary to transport crops from the cultivation site to storage, nor labour and nonrenewable energy (fuel) used for transporting machines and equipment to the field [78]. Furthermore, the energy balance does not include the byproduct (straw) that was left to be incorporated.

With input and output energy equivalents, the authors calculated energy indices as in Erdal et al. [14], Yilmaz et al. [56], Demircan et al. [57], Mohammadi et al. [61], Mandal et al. [79], Heidari et al. [80], Pishgar-Komleh et al. [81], and Naderi et al. [82].

Energy inputs for common buckwheat were categorised into direct and indirect [56,57,60,83,84]. Direct energy inputs for buckwheat cultivation included labour and diesel fuel energy. On the other hand, indirect energy sources included mineral fertilisers, chemicals, tractors, and machinery used at all production stages. The inputs were then classified as either renewable or nonrenewable energy sources. Renewable energy included labour and seed, while nonrenewable energy sources were machines, diesel oil, and chemicals used in buckwheat production [64,79,85].

At the field level, energy use usually differs depending on the farm size, cultivated plants, production methods, and physical environment. Therefore, energy consumption was determined with energy inputs for buckwheat production from tillage following the harvest of precrop and soil preparation from sowing to buckwheat harvest.

Energy consumption was determined with diesel fuel consumption, labour, and efficiency of standard agricultural machinery and equipment used during the experiment: U1224 + U103/1 Atlas 4H (ploughing), U1224 + U774/2 (combination cultivator), U4512 + U212/2 (harrowing), U4512 + N035 RNW-3 (application of potassium and phosphorus fertilisers before sowing), U1224 + S052/C Mazur 5 (sowing), U1224 + N039 RNZ-3 (nitrogen fertilisers), U4512 + Pilmet 612 (chemical control), Bizon-Rekord (harvest).

2.3. GHG Emission

This research estimated greenhouse gas (GHG) emissions caused by common buckwheat cultivation using two systems of different production intensities: inputs and yields. Therefore, for the purposes of the paper, the GHG emissions caused by buckwheat cultivation were estimated following the methods recommended by the Biofuels, Bioliquids, and Biomass Fuels Certification System (KZR INiG) [86] applied by Wiśniewski and Kistowski [87] to GHG emissions from the cultivation of biofuel plants in Poland. It is a Polish biofuel and bioliquid certification system owned by the Oil and Gas Institute—National Research Institute. The rules of the KZR INiG System are based on requirements stated in Directive 2018/2001 of the European Parliament and of the Council of 11 December 2018, on the promotion of the use of energy from renewable sources (RED II Directive) [88]. The requirements of the KZR INiG System are in line with the aims defined in the RED II Directive, and they also take into account local conditions. Input data (variables) that affect cultivation emissions include seed, fuel, fertilisers, pesticides, yield, and emission of N2O from the soil. The calculations included indicators of the ratio of nonagricultural to agricultural harvest, dry matter content in aboveground biomass, burned fraction, combustion efficiency, carbon and nitrogen content in biomass, and the fraction of biomass removed from the field, as recommended by the Intergovernmental Panel on Climate Change [89,90] and the National Centre for Emissions Management [91].

The emissions of GHG from buckwheat production were calculated with the following equation:

where:

eec—the GHG emissions from buckwheat production;

eseed—the emissions from the use of seed;

echem—the emissions from production and transport of fertilisers and agrichemicals;

efield—the emissions from tillage (soil emissions);

emm—the emissions from agricultural and forestry machinery and other mobile or stationary equipment.

Buckwheat production GHG emissions (eec) were expressed as carbon dioxide equivalent (CO2eq) per unit of dry matter (kg CO2eq t−1), assuming the global warming potential (GWP) for N2O = 273, as per the value in the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [92]. GHG emissions from seed (eseed) include emissions generated during the production, storage, and transport of seed. The GHG emission factor for buckwheat in Polish conditions was applied at the level of 510 g CO2eq kg−1 [93].

The GHG emissions from the production and transport of fertilisers and plant protection products (echem) were calculated with the equation:

where:

echem—the emissions from production and transport of fertilisers and agrichemicals;

Qchem—the amount of fertilisers or plant protection products;

Fchem—the GHG emissions factor for production and transport of mineral fertilisers or plant protection products.

The amounts of fertilisers or plant protection products (Qchem) per unit area (ha) were expressed as a mass unit (kg) of a pure component or active substance of a plant protection product. The GHG emissions factor from the production and transport of mineral fertilisers or plant protection products (Fchem) were expressed as CO2 equivalent per mass unit of fertiliser or plant protection product. Emissions factors were applied in accordance with the BioGrace II calculator (v. 4a), recommended by the European Commission [94] and the Commission Implementing Regulation (EU) 2022/996 of 14 June 2022 on rules to verify sustainability and greenhouse gas emissions-saving criteria and low indirect land-use change-risk criteria [95].

Crops were not irrigated in the experiment.

The nitrous oxide soil emissions (efield) were calculated using the Global Nitrous Oxide Calculator (GNOC) recommended by the European Commission [96]. According to the Communication from the European Commission [97] and KZR INiG guidelines [86], N2O emissions from soil can be calculated using the IPCC method, including direct and indirect pathways. All three tiers are allowed in this approach: from the basic and popular Tier 1, which is not even founded on national data, up to the most detailed Tier 3. The GNOC used in the present paper can estimate soil emissions at Tier 2. The tool was developed using production data from a United Nations Food and Agricultural Organisation (FAO) database. Input data include such factors as crop location, cereal and straw yield, soil conditions, irrigation, fertiliser dosage, residues, and basic environmental parameters [96,98]. This tool calculates N2O emissions that are based on the approach of Stehfest and Bouwman [99]. It uses an exponential algorithm that considers site- and management-specific characteristics, such as soil texture, climate, soil organic matter, pH, and vegetation [100,101].

Emissions from fuel used in agricultural and forestry machinery (emm) was expressed as CO2 equivalent per unit area a year and calculated with the following equation:

where:

emm—the emissions from agricultural and forestry machinery and other mobile or stationary equipment;

Qmmf—the fuel consumption by agricultural and forestry machinery;

Ef—the emission factor for fuel production and use.

The fuel consumption by agricultural and forestry machinery (Qmmf) was expressed as unit volume per unit area per year (dm3 ha−1 year−1). Standard emissions factors for fuel production and use (Ef) as per the BioGrace-II (version 4a) were applied [93]. For diesel, it is 95.1 g CO2eq MJ−1.

2.4. Economic Efficiency

The authors conducted an economic analysis to ensure a thorough assessment of common buckwheat production. To this end, they combined direct costs (seed, mineral fertilisers, chemicals), operational costs of machinery and equipment used for buckwheat production, and costs of labour and land tax. The following indicators were used for the economic assessment as per [14,57,102].

All expenses, such as labour, tractor operation, seed, mineral fertilisers, and chemicals were valued at current arm’s-length prices in Q3 2022 and converted from złoty (PLN) into euro (EUR) with National Bank of Poland’s FX rate.

3. Results

3.1. Input–Output Analysis of Energy Use in Buckwheat Production

In the present project, the total energy input for common buckwheat production was 13,106.9 MJ ha−1 for the high-input system, which was 74.0% more than for the low-input regime (7532.7 MJ ha−1) (Table 3). The largest fraction of energy inputs in buckwheat production was materials: from 4279.0 (56.81%) for the low-input system to 10,248.4 MJ ha−1 (78.19%) for the high-input system. Regardless of the system, buckwheat production was highly dependent on mineral fertilisers, which amounted to the greatest fraction in material inputs: from 3160 MJ ha−1 (41.95%) to 8084.04 MJ ha−1 (61.68%) of the total energy inputs. The detailed distribution of the fertilisers is as follows: N—2310 MJ ha−1 (30.67%) for low-input technology to 6930 MJ ha−1 (52.87%); P—450 MJ ha−1 (5.97% for the low-input technology and 3.5% for the high-input technology); potassium fertilisers 400 MJ ha−1 (5.31% for the low-input regime and 3.05% for the high-input regime) and (for the high-input system only) S—224 MJ ha−1 (1.71%) and Mg—80.4 MJ ha−1 (0.61%).

Table 3.

Inputs expressed as quantity per unit area, total energy equivalent, and percentage of total energy input in buckwheat production.

Direct energy use in the form of diesel and energy for machinery was similar in both systems, if slightly greater for the low-input system. The values varied from 1712.4 MJ ha−1 (13.06%) in the high-input system to 1928.8 MJ ha−1 (25.61%) for the low-input system. The amount of energy used through seed was much lower in the low-input system (725 MJ ha−1) compared to the high-input system (1305 MJ ha−1) due to the amount of seed sown. The percentage of the total energy inputs was 9.62% and 9.96%, respectively. Technical resources amounted to 5.70 and 11.30% of the energy input structure of buckwheat production. The present research established the energy equivalent of labour at 473.5 MJ ha−1 (6.29%) for the low-input technology and 398.8 MJ ha−1 (3.04%) for the high-input technology. Energy inputs from fossil resources, such as agrichemicals (herbicides, fungicides, plant growth regulators, desiccants) were relatively small in both production systems and amounted to 5.23% (394 MJ ha−1) for the low-input system and 6.55% (859 MJ ha−1) for the high-input system. Different methods of weed management caused the increased consumption in the low-input system. The low-input system involved two mechanical treatments, whereas in the high-input system, only a single application of a chemical. Desiccation agents amounted to a small fraction of the total energy inputs for buckwheat production (375 MJ ha−1): 2.86% in the high-input system and 4.98% in the low-input system. The same percentage was identified for chemical weed control (only for the high-input system): 2.86%. Only the high-input system employed a plant growth regulator, which reached merely 0.57% of the total energy input. The lowest energy share (0.25–0.26%) was assigned to fungicide, which involved only seed treatment.

3.2. Energy Efficiency Indicators

The basic indicators for the energy assessment of common buckwheat production are shown in Table 4. The comparison of the two production systems revealed that all energy assessment indicators (for both varieties) were better for the low-input production system. Energy use efficiency and productivity are often mutually exclusive in agriculture.

Table 4.

Energy input–output ratio in buckwheat production.

3.2.1. Net Energy Gain

The energy output (buckwheat seed crop) was greater than the energy inputs during the production process (Table 4). The amount of output energy depended mainly on the biomass in the form of buckwheat seeds for each test variety. The net energy gain was significantly higher concerning residues (straw and husk). Nevertheless, the energy value of residues was not taken into account as straw was left to be ploughed. The mean net energy gain from the production of common buckwheat using the low-input technology was 3878.8 MJ ha−1, while it was greater for the high-input technology by 16.79% and amounted to 4529.9 MJ ha−1. The highest crop energy value came from Volma (in both production systems), the lowest, Mancan. The difference between extremes for the low-input system was 2073.5 MJ ha−1. For the high-input system, the difference in crop energy value among the varieties was 5118.5 MJ ha−1. The reaction of Mancan to high doses of nitrogen under Polish conditions was rather peculiar. It developed a very large number of branches and inflorescences. It then matured extremely unevenly, resulting in the lowest seed yield.

3.2.2. Specific Energy

The energy consumption indicator for common buckwheat was more advantageous in the low-input system (Table 4). This principle was noted for all the tested varieties. The mean indicator for the low-input system was 9.62 MJ kg−1, and for the high-input system, 10.63 MJ kg−1, which was 10.50% more. The lowest specific energy was identified for Volma under both systems of production.

3.2.3. Energy Productivity

Energy productivity for production of 1 kg of buckwheat seed varied among systems of production and varieties (Table 4). Its mean value for the low-input system was 0.104 kg MJ−1 and was 9.50% higher than for the high-input system (0.093 kg MJ−1).

3.2.4. Energy Use Efficiency

Energy use efficiency ranged from 1.39 to 1.67 for the low-input production system and was more advantageous than for the high-input system (1.17 to 1.56), which means that the indicator value fell as energy inputs grew for each variety (Table 4). This fact demonstrates the environmental friendliness of buckwheat production under the low-input system.

3.2.5. Direct and Indirect Energy

The present research demonstrated that the fraction of direct energy in common buckwheat production ranged from 16.11% for the high-input technology to 31.89% for the low-input technology (Table 5).

Table 5.

The total energy input in direct, indirect, renewable, and nonrenewable form for buckwheat production.

3.2.6. Renewable and Nonrenewable Energy

The fraction of renewable energy as an indicator of sustainable development of farming systems was 13.00 for the high-input buckwheat production system and 15.91 for the low-input system (Table 5).

3.3. GHG Emission

Estimated emissions from buckwheat production ranged from 160.9 kg CO2eq t−1 of dry matter for low-input Volma cultivation to 281.4 kg CO2eq t−1 for high-input Mancan cultivation (Table 6). All three varieties exhibited higher emissions per dry matter unit for intensive cultivation despite higher yields and lower fuel use for production. This fact stems from increased mineral fertilisation, most often resulting in over twice as large soil emission of nitrous oxide. The total production emissions in 2013–2015 expressed as CO2 equivalent were on average higher for the high-input regime than for the low-input system by 43.43% for Panda, 34.49% for Volma, and 49.76% for Mancan. The authors’ calculations demonstrated that the key components of GHG emissions from buckwheat production were fertiliser and agrichemicals production (over 40%) and nitrous oxide emission from soil (over 30%). The domination of these sources in the structure of the GHG emission is characteristic of both variants and all varieties. The share of emissions from fertiliser and agrichemicals production in the total buckwheat emissions were higher for intensive farming. The share of field emissions remained at a similar level. The percentage of seed and machinery operation emissions dropped significantly.

Table 6.

GHG emissions from the production of the test varieties of buckwheat and fractions of individual emission sources.

3.4. Economic Analysis

Variable costs in the high-input system amounted to 56.10%; for the low-input system, machinery operation costs dominated the total inputs (41.29%) (Table 7). Fertilisers were a significant cost in both the regimes for buckwheat production: 29.64% for the high-input system and 22.86% for the low-input system.

Table 7.

Statement on buckwheat production costs.

The aggregate buckwheat production costs for the investigated production systems of different intensities are presented in Table 8. In Poland, 0.878 Mg ha−1 yield of common buckwheat seed (the mean yield for the test varieties) costs 374.9 EUR ha−1. If the production follows the high-input system, yielding 1216 Mg ha−1, the cost is 511.6 EUR ha−1, up 36.46%.

Table 8.

Economic analysis of buckwheat production.

Profit on buckwheat production for the low-input system in Poland is highly uncertain (not taking direct subsidies into account). In the present research, only Volma reached profitability of 44.3 EUR ha−1. For the other varieties, the loss was 2.6 to 24.8 EUR ha−1. The high-input system brought a much better financial result. Production for two test varieties was profitable in this regime. Volma performed the best, 170.6 EUR ha−1, and Mancan the worst, 0.0 EUR ha−1.

The total costs in the high-input system were 36.46% higher than for the low-input system, 511.6 EUR ha−1 and 374.9 EUR ha−1, respectively (Table 8). In the present study, the economic efficiency was very low, particularly for the low-input system, which fell below the profitability threshold for Mancan, 0.93. The increase in production costs for the high-input regime improved the common buckwheat production benefit–cost ratio in Poland. The indicator grew significantly when EU subsidies of 178.6 EUR ha−1 were considered.

4. Discussion

4.1. Input–Output Analysis of Energy Use in Buckwheat Production

Energy is a primary resource largely dependent on fossil fuels, used commonly for the production and processing of food [103]. The consumption of fossil fuels in modern food production systems continues to grow globally, leading to environmental and societal changes [104]. According to Fischer et al. [105] and Shannon et al. [106], energy use grows as agriculture becomes more intensified to meet food demand. Studies show that agricultural production energy consumption grew in the period from 1989 to 2009, indicating inefficient energy use [107]. Researchers emphasise that incorrect energy use in food production may put food security at risk [41].

Energy analysis is broadly applied to improve the energy use efficiency and sustainable development of agricultural systems due to its valuable contribution to calculating financial savings and preservation of fossil fuels [108]. Energy analysis of plant production is conducted to determine where, when, why, and how energy is used. The results are then employed to improve efficiency through higher yield, reduced production costs, and limited GHG emissions [109].

Energy-consuming activities should be rational and sustainable in the long term due to limited energy resources [110]. Still, the consumption of various energy sources in plant production is high. Moreover, researchers who investigated energy use in plant production demonstrated substantial inefficiencies, particularly in developing countries. This calls for optimisation to reduce energy use and GHG emissions [111].

In papers by Polish researchers [112], the total aggregate energy inputs for buckwheat production on farms where traditional production systems were employed was 8693.3 MJ ha−1, while for an organic system, it was 11,952.8 MJ ha−1. Similarly, in her research on buckwheat, Kuczuk [113] demonstrated substantially higher energy inputs for an organic system (7838 to 8104 MJ ha−1) than for the conventional system (12,302 to 12,462 MJ ha−1). According to Lotfalian and Forootan [114], energy inputs for quinoa production were 25,514 MJ ha−1. In research by Sławiński and Bujaczek [115], the energy inputs for rye cultivation varied from 9935 to 16,120 MJ ha−1. Majchrzak and Piskier [116] calculated the energy inputs for hybrid rye to be 16,840 to 16,990 MJ ha−1. In Moitzi et al.’s research [117], the total production inputs were 1127 MJ ha−1 for rye and 1145 MJ ha−1 for barley at full NPK fertilisation. In research by Sahabi et al. [118], barley inputs were 44,866 MJ ha−1. Winter triticale research by Bielski [69] determined the total production energy inputs to be 1798 MJ ha−1 on average. They were the highest for intensive production (2174 MJ ha−1) combined with the highest nitrogen fertilisation doses. In their research on the energy efficiency of maise for silage in Poland, Konieczna et al. [55] reported the total energy inputs to vary from 12,233 to as much as 52,229 MJ ha−1.

Food production calls for new, low energy consumption technologies [119]. However, for low-energy solutions to settle in, technology changes are first necessary [120]. Producers that deploy energy-efficient technologies contribute to sustainable development and employ innovative treatments to preserve natural resources by finding synergies among natural, socioeconomic, and energy flow systems [26].

In buckwheat studies by Polish researchers Sławiński et al. [112], the fraction of materials was 5462.0 MJ ha−1 (62.8%) for the conventional technology and 6140 MJ ha−1 (51.4%) for the organic technology. Kuczuk [113] determined material inputs for buckwheat production to be 3274.6 for conventional cultivation and up to 6662.9 MJ ha−1 for organic cultivation, which was 41.1 and 62.5%, respectively.

According to Lotfalian and Forootan [114], the energy consumed in nitrogen fertilisers for the production of quinoa was 6449 MJ ha−1 or 25.27% of the total energy inputs. In Bielski’s research [69], mineral fertilisation accounted for 37.7 to 64.6% of the total energy inputs for the production of winter triticale, depending on the production system. In intensive cultivation (sugar beet), the fraction of mineral fertilisation in the energy input structure was 49.33% [14] and 41.97% [121].

Mineral fertilisers are widely used in farming and consume significant direct energy inputs for production, mainly in the nitrogen fertiliser industry [58]. According to Canakci et al. [122], the energy consumption fraction of mineral fertilisation can amount up to 50%. It is one of the key arguments for additional research and optimisation to achieve economically profitable [123] and environmentally efficient production [60,72,124]. Nitrogen is the primary element that affects yield directly. However, at increased doses of mineral nitrogen, only part of it is consumed by plants. The remaining fraction pollutes the environment. Apart from productivity issues, improper nitrogen management can lead to environmental threats and losses [125,126,127,128,129,130]. Production intensity usually determines the consumption of fertilisers and fuel [131]. Rathke and Diepenbrock [49] believed optimal nitrogen management to be the key factor for energy input savings in plant production.

In Polish research by Sławiński et al. [112], the fraction of fuel was 2020.8 MJ ha−1 (23.2%) for conventional technology and 3177.6 MJ ha−1 (26.6%) for organic technology. In her research on buckwheat, Kuczuk [113] identified diesel fuel energy fraction in the total energy consumption to be 2837.4 MJ ha−1 (35.6%) for the conventional technology and 2398.1 MJ ha−1 (22.48%) for the organic technology. In research by Lotfalian and Forootan [114], the share of fuels in quinoa production energy inputs was 5632 MJ ha−1 (22.07%). In an assessment of energy use efficiency of winter triticale production in Poland [69], the fraction of fuel in the total energy input varied from 1811 MJ ha−1 (14.5%) for the lowest-yield technology to 1935 MJ ha−1 (8.8%) for the highest-yield technology.

In buckwheat research by Sławiński et al. [112], the energy use of technical resources amounted to 10.4–17.1%, while Kuczuk [113] found them to range from 9.45% for organic production technology to 12.9% for conventional technology. In winter triticale production, the amounts varied from 3.5 to 5.7% [69], and for camelina (Camelina sativa), from 6.7 to 10.3% [132]. Kuczuk and Pospolita [110] believed technical resources could account for over 70% of production energy consumption.

In buckwheat research by Sławiński et al. [112], the fraction of labour in the total energy consumption ranged from 3.5 to 4.9%, whereas in research by Kuczuk [113], the energy equivalent of labour was from 10.41% for the conventional technology to 5.58% for the organic technology. In Stolarski et al.’s research on camelina [132], the fraction of labour in the total energy consumption ranged from 2.6 to 3.9%.

4.2. Energy Efficiency Indicators

According to Green [133], low productivity is energy efficient, while high productivity is heavy on energy in agriculture. The present results are consistent with this statement.

4.2.1. Energy Efficiency Indicators

In a different Polish study on buckwheat, the energy output was 3906.7 MJ ha−1 [112]. Kuczuk [113] obtained a much higher net energy gain: in the organic buckwheat production technology, it was 5012.4, while for the conventional technology, 8887.4 MJ ha−1. In their study on quinoa, Lotfalian and Forootan [114] achieved merely 1864.4 MJ ha−1.

According to Hülsbergen et al. [75], the net gain of accumulated energy is one of the key parameters, particularly when access to arable land is limited, such as in densely populated regions. A study by Rathke and Diepenbrock [49] demonstrated that net energy production depends mostly on the energy from the agricultural product.

Many producers use their resources in excess and ineffectively, hoping to achieve higher productivity. However, many researchers noted excessive use of resources and room for greater productivity or energy savings with no harm to productivity, thus improving energy use efficiency [66,134,135,136,137].

4.2.2. Specific Energy

Sławiński et al. [112] determined the buckwheat specific energy indicator to be 9.0 MJ kg−1 for both organic and conventional systems. Kuczuk [113] calculated the specific energy indicator to be 9.78 MJ kg−1 for the organic system, more than for the conventional system (6.79 MJ kg−1). Lotfalian and Forootan [114] suggested a much higher indicator for quinoa: 16.66 MJ kg−1, similarly to Choobin et al. [138] for rapeseed production: 16.00 MJ kg−1. Bielski [69] obtained much better values for winter triticale (1.86 to 2.14 MJ kg−1).

4.2.3. Energy Productivity

In research by Sławiński et al. [112], the indicator was 0.092 kg MJ−1 for the organic technology and 0.161 kg MJ−1 for the conventional technology. Results by Kuczuk [113] demonstrated a higher indicator for buckwheat production under the organic regime (0.102 kg MJ−1) compared to the conventional system (0.147 kg MJ−1). Its value for quinoa was very low, merely 0.060 kg MJ−1 [114].

Numerous past studies demonstrated that lower energy inputs reduce specific energy for low-input systems [139,140,141,142,143,144,145,146,147].

4.2.4. Energy Use Efficiency

Sławiński et al. [112] demonstrated an opposite relationship. The energy use efficiency for the conventional buckwheat cultivation system was 1.45, while for the organic regime, 0.83. Foster et al. [148] indicated that the energy use efficiency could be lower than 1 for the organic regime (below the energy use efficiency threshold). In the Polish study by Kuczuk [113], the indicator was 1.47 for organic production and up to 2.11 for the conventional system of buckwheat production. In their study on quinoa, Lotfalian and Forootan [114] obtained a value of 1.07. Although it suggests effective production of quinoa seed, it is very low. Sławiński and Bujaczek [115] found the organic cultivation of rye to be more energy efficient (2.29) than conventional farming (2.02). Majchrzak and Piskiera [116] calculated the energy inputs for hybrid rye to be 16,840 to 16,990 MJ ha−1 with an energy use efficiency of 3.81–3.96. Sahabi et al. [118] reached 1.83 for barley, and Ziaei et al. [149] 1.49 for wheat. Intensive species, such as winter rapeseed, reached 1.56 [138]. Many authors concluded that the highest values of energy use efficiency were reached for low-input production systems and declined with increasing production intensity [75,150,151]. The present study corresponds with these results. Alluvione et al. [72] investigated the energy use efficiency of three production systems: low input, integrated, and conventional. They concluded that the energy use efficiency indicators of the first two were, respectively, 32.7% and 31.4% higher than the latter. Jankowski and Sokólski [71] noted that the application of 120 kg ha−1 of nitrogen fertiliser reduced the energy use efficiency of camelina by 49%.

Rathke and Diepenbrock [49] emphasised that the energy inputs and energy gain from production were two important factors determining the energy use efficiency in plant production. Hence, improved energy use efficiency would lead to more environmentally friendly production systems.

4.2.5. Direct and Indirect Energy

However, the fraction of direct energy was much higher in Lotfalian and Forootan’s study on quinoa [114]: 68%. Agricultural production is based mainly on fossil energy. Direct energy use includes fuels necessary for treatments. Indirect sources of energy for the production of farming inputs, such as fertilisers or pesticides, are used as well. Although the discussion on energy use in agriculture tends to focus on direct energy use, not less than 50% of the total energy use is related to the production of nitrogen fertilisers and other indirect streams of energy consumption [41,103,152,153].

4.2.6. Renewable and Nonrenewable Energy

In other case studies, the fraction of nonrenewable energy was for sugar beet 17.57% [14], potato 25.73% [62], barley 34.09% [66] and 14.60% [149], wheat 19.60% [149], and quinoa 32% [114].

The common use of nonrenewable energy sources is yet another serious challenge for the agricultural industry. Chemicals, machinery, fuels, and electricity are among the key inputs consumed in large quantities in the production of various agricultural products. The production, distribution, and use of these inputs depend mainly on large volumes of nonrenewable energy [60,64,122].

4.3. GHG Emission

Considering estimated GHG emissions from the production of other cultivars in western Poland as provided by Wiśniewski and Kistowski [87] using the same method ranging from 41.5 kg CO2eq t−1 for rye to 147.2 kg CO2eq t−1 for maize, the production of buckwheat exhibited relatively high CO2 equivalent emissions per dry matter unit. The reason was relatively low buckwheat yields, reaching 0.3 to 1.3 t ha−1 in soil and climate conditions typical of Poland [154]. Numerous researchers demonstrated that a lower yield resulted in higher estimated GHG farming emissions per unit of dry matter [155,156,157].

4.4. Economic Analysis

Natural resources economics focuses on the optimal distribution of renewable and nonrenewable natural resources [158]. As the resources are limited, the crux is to manage them rationally, which is one of the key concepts in economics. Here, rationality means the optimal selection of expenditure fractions when resources are limited, or a resource is difficult to attain due to its scarcity or limited access elevating costs. The rational policy grows particularly important in the twenty-first century in light of diminishing natural resources. An example of a natural resource that is rare or expensive is energy, both from renewable and nonrenewable sources. In classic economics, energy was considered a free resource, but this approach fails to resonate with the needs of the agricultural practice. With the technological progress and tremendous increase in the production of goods, energy is no longer a free resource and became, like most natural resources, a good that needs to be managed due to its limited nature.

The primary motivation for owners of holdings and farmers is the financial gain leading to survival and thriving in business. Therefore, due to its apparent impact on improving the analysed system and life of farmers, economic analysis is employed—be it formally or informally—to assess virtually any agricultural system [108].

Energy savings provide significant but unsatisfactory economic gains in plant production. A system of energy-efficient production practices is not inherently better in terms of economy. A combined economic and energy analysis of a production system can be more versatile and lead to the best management strategies [159]. Effective energy use is a sine qua non of sustainable production in agriculture through financial savings, preservation of fossil fuels, and limited air pollution. Cultivar production systems have to be designed to help manufacturers maintain economic profitability while preserving external energy resources and farming in an environmentally responsible fashion [160].

In research by Bharti and Kujur [161], fertilisation amounted to 18.18 to 19.68%. In research by Sredojević et al. [162], the largest fraction was the seed (28%), followed by machinery operation (18%), mineral fertilisers (11%), and labour (8%). In the present research, a greater consumption of fertiliser in the high-input system is set off by improved yield despite increased energy use.

Chhetri et al. [163] determined the benefit–cost ratio to be 1.74 to 2.74, while the benefit–cost ratio for buckwheat production was 1.25 in a study by Dhakal et al. [164]. Bharti and Kujur [161] obtained a much higher value of the indicator. The ratio ranged from 3.07 to 3.12, depending on the size of the holding. Sredojević et al. [162] found the benefit–cost ratio to be 3.72 for the conventional system and 3.93 for the organic regime.

A sustainable increase in agricultural production at competitive costs is fundamental for improving the financial position of farmers [165]. Therefore, apart from yield improvement through nitrogen supplementation, one should consider fertiliser effectiveness in light of its high cost and environmental impact [166].

5. Conclusions

Every type of agricultural production is a burden for the natural environment. Therefore, when choosing their niche, producers should consider profit and limit excessive use of natural resources. Analysis of aggregate energy use efficiency of production is a method that can assess the environmental impact of agricultural production.

Production of all varieties of common buckwheat in northeastern Poland demonstrated an energy gain for the investigated production systems. Even though the increased energy consumption for the high-input system improved the yield of all the test varieties of common buckwheat, the increase in crop energy was lower than the increase in the specific energy of farming inputs employed to this end. As a result, the energy assessment indicators for the high-input system were lower than for the low-input regime, 1.35 and 1.51, respectively. Therefore, research on energy efficiency in plant cultivation is necessary to improve energy use efficiency and implement energy-efficient practices, leading to sustainable production systems with the lowest possible consumption of natural resources. The fraction of renewable energy as an indicator of sustainable development of agricultural systems was 15.91 for the low-input system and 13.00% for the high-input system. Therefore, low-input buckwheat production seems to be more energy-efficient than the high-input system for the investigated region.

The results demonstrate higher common buckwheat CO2eq t−1 emission from the high-input system than the low-input system (251.2 and 175.7 kg on average, a 30.06% difference). Similarly, the average soil emission of N2O-N was more than twice lower for the low-input system compared to the high-input system, 0.1358 and 0.2915 kg N2O-N ha−1, respectively.

Agricultural producers are usually guided by economic factors when deciding the type of production and farming system. In the Polish economic conditions (prices of inputs and seed), the production of common buckwheat under the high-input system is much more profitable than for the low-input system (Volma was the only test variety to provide profit under this regime, subsidies excluded). Increased costs (followed by energy consumption) inherent in the high-input system aimed at a greater yield resulted in higher profit compared to the low-input system. Still, one should not forget that higher inputs may lead to excessive use of natural resources. Basic indicators of economic assessment were better for the high-input system than for the low-input system: gross return without EU payment 76.3 EUR ha−1 and 5.6 EUR ha−1, benefit–cost ratio without EU payment 1.15 and 1.01, respectively. Mancan demonstrated the lowest values of energy and economic assessment among all the test varieties.

The authors suggest further research in Europe and globally, particularly on the energy use efficiency and GHG emissions in the production of common buckwheat to verify the present results and improve production technologies (reduce inputs and costs).

Author Contributions

Conceptualization, S.B.; methodology, S.B.; software, P.W. and R.M.-B.; validation, S.B., P.W. and R.M.-B.; formal analysis, R.M.-B.; investigation, S.B., P.W. and R.M.-B.; resources, S.B.; data curation, P.W.; writing—original draft preparation, S.B., P.W. and R.M.-B.; writing—review and editing, S.B., P.W. and R.M.-B.; supervision, S.B.; project administration, S.B.; funding acquisition, S.B. and P.W. All authors have read and agreed to the published version of the manuscript.

Funding

The results presented in this paper were obtained as part of a comprehensive research study conducted at the University of Warmia and Mazury in Olsztyn (grant no. 20.610.020-300). The APC was funded by grant no. 30.610.013.-110).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature, Symbols and Abbreviations

| GHG | greenhouse gas emissions |

| E | energy |

| J | joule |

| GJ | gigajoule |

| MJ | megajoule |

| CO2 | carbon dioxide |

| NO2 | nitrous oxide |

| N | nitrogen |

| P2O5 | superphosphate |

| K2O | potash salt |

| NH4NO3 | ammonium nitrate |

| MgO | magnesium oxide |

| SO3 | sulphur trioxide |

| Mg | magnesium |

| S | sulphur |

| flurochloridon | the active substance of the weed control preparation |

| triadimenol, triadimenol, fuberizadol | the active substances of the fungal preparation |

| trinexapac-ethyl | the active substances of the growth regulator preparation |

| dimetipin | the active substances of the accelerates ripening preparation |

| GNOC | Global Nitrous Oxide Calculator |

| IPCC | Intergovernmental Panel on Climate Change |

| FAO | Food and Agricultural Organisation |

| KOBiZE | The National Centre for Emissions Management |

| Ei total | the total energy input for buckwheat production (GJ ha−1): |

| Ei human labour | the energy input for human labour (GJ ha−1); |

| Ei fixed assets | the energy input for fixed assets (GJ ha−1); |

| Ei diesel | the energy input for diesel fuel consumption (GJ ha−1); |

| Ei materials | the energy input for materials (GJ ha−1). |

| eec | the GHG emissions from buckwheat production: |

| eseed | the emissions from the use of seed; |

| echem | the emissions from production and transport of fertilisers and agrichemicals; |

| eirr | the emissions from irrigation; |

| efield | the emissions from tillage (soil emissions); |

| emm | the emissions from agricultural and forestry machinery and other mobile or stationary equipment; |

| echem | the emissions from production and transport of fertilisers and agrichemicals. |

| Qchem | the amount of fertilisers or plant protection products |

| Fchem | the GHG emissions factor for production and transport of mineral fertilisers or plant protection products |

| emm | the emissions from agricultural and forestry machinery and other mobile or stationary equipment |

| Qmmf | the fuel consumption by agricultural and forestry machinery |

| Ef | the emission factor for fuel production and use |

References

- Campbell, C.G. Buckwheat: Fagopyrum esculentum Moench. In Promoting the Conservation and Use of Underutilized and Neglected Crops, 19; International Plant Genetic Resources Institute: Rome, Italy, 1997. [Google Scholar]

- Jacquemart, A.L.; Cawoy, V.; Kinet, J.M.; Ledent, J.F.; Quinet, M. Is buckwheat (Fagopyrum Esculentum Moench) Still a Valuable Crop Today? Eur. J. Plant. Sci. Biotechnol. 2012, 6, 1–10. Available online: http://www.globalsciencebooks.info/Online/GSBOnline/images/2012/EJPSB_6%28SI2%29/EJPSB_6%28SI2%291-10o.pdf (accessed on 4 November 2021).

- Small, E. Buckwheat—The world’s most biodiversity-friendly crop? Biodiversity 2017, 18, 108–123. [Google Scholar] [CrossRef]

- Bekkering, C.S.; Tian, L. Thinking outside of the cereal box: Breeding underutilized (pseudo) cereals for improved human nutrition. Front. Genet. 2019, 10, 1289. [Google Scholar] [CrossRef] [PubMed]

- Koval, D.; Plocková, M.; Kyselka, J.; Skřivan, P.; Sluková, M.; Horáčková, Š. Buckwheat secondary metabolites: Potential antifungal agents. J. Agric. Food Chem. 2020, 68, 11631–11643. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Villaluenga, C.; Peñas, E.; Hernández-Ledesma, B. Pseudocereal grains: Nutritional value, health benefits and current applications for the development of gluten-free foods. Food Chem. Toxicol. 2020, 137, 111178. [Google Scholar] [CrossRef]

- Kumar, V.; Brainard, D.C.; Bellinder, R.R. Suppression of Powell amaranth (Amaranthus powellii), shepherd’spurse (Capsella bursa-pastoris), and corn chamomile (Anthemis arvensis) by buckwheat residues: Role of nitrogen and fungal pathogens. Weed Sci. 2008, 56, 271–280. [Google Scholar] [CrossRef]

- Arcand, M.A.; Lynch, D.H.; Voroney, R.P.; Straaten, P. Residues from a buckwheat (Fagopyrum esculentum) green manure crop grown with phosphate rock influence bioavailability of soil phosphorus. Can. J. Soil Sci. 2010, 90, 257–266. [Google Scholar] [CrossRef]

- FAOSTAT 2016-1018. Available online: http://www.fao.org/food-agriculture-statistics/en/ (accessed on 4 November 2021).

- Rana, J.C.; Chauhan, R.C.; Sharma, T.R.; Gupta, N. Analyzing problems and prospects of buckwheat cultivation in India. Eur. J. Plant Sci. Biotechnol. 2012, 2, 50–56. Available online: http://www.globalsciencebooks.info/Online/GSBOnline/images/2012/EJPSB_6(SI2)/EJPSB_6(SI2)50-56o.pdf (accessed on 4 November 2021).

- Luitel, D.R.; Siwakoti, M.; Jha, P.K.; Jha, A.K.; Krakauer, N. An overview: Distribution, production, and diversity of local landraces of buckwheat in Nepal. Adv. Agric. 2017, 2, 2738045. [Google Scholar] [CrossRef]

- Ferraro, D.O. Energy use in cropping systems: A regional long-term exploratory analysis of energy allocation and efficiency in the Inland Pampa (Argentina). Energy 2010, 44, 490–497. [Google Scholar] [CrossRef]

- Wang, Y.W. Sustainable Agricultural Practices: Energy Inputs and Outputs, Pesticide, Fertilizer and Greenhouse Gas Management. Asia Pac. J. Clin. Nutr. 2009, 18, 498–500. Available online: https://apjcn.nhri.org.tw/server/APJCN/18/4/498.pdf (accessed on 4 November 2021).

- Erdal, G.; Esengün, K.; Erdal, H.; Gündüz, O. Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy 2007, 1, 35–41. [Google Scholar] [CrossRef]

- Wise, M.; Dooley, J.; Luckow, P.; Calvin, K.; Kyle, P. Agriculture, land use, energy and carbon emission impacts of global biofuel mandates to midcentury. Appl. Energy 2014, 114, 763–773. [Google Scholar] [CrossRef]

- Lal, B.; Rajput, D.S.; Tamhankar, M.B.; Agarwal, I.; Sharma, M.S. Energy use and output assessment of food-forage production systems. J. Agron. Crop Sci. 2003, 189, 57–62. [Google Scholar] [CrossRef]

- Falcone, G.; Stillitano, T.; De Luca, A.I.; Di Vita, G.; Iofrida, N.; Strano, A.; Gulisano, G.; Pecorino, B.; D’Amico, M. Energetic and economic analyses for agricultural management models: The Calabria PGI Clementine case study. Energies 2020, 13, 1289. [Google Scholar] [CrossRef]

- López-Vázquez, A.; Cadena-Zapata, M.; Campos-Magaña, S.; Zermeño-Gonzalez, A.; Mendez-Dorado, M. Comparison of energy used and effects on bulk density and yield by tillage systems in a semiarid condition of Mexico. Agronomy 2019, 9, 189. [Google Scholar] [CrossRef]

- Ilyas, H.M.A.; Safa, M.; Bailey, A.; Rauf, S.; Khan, A. Energy efficiency outlook of New Zealand dairy farming systems: An application of data envelopment analysis (DEA) Approach. Energies 2020, 13, 251. [Google Scholar] [CrossRef]

- Uhlin, H.E. Why energy productivity is increasing: An I-O analysis of Swedish agriculture. Agric. Syst. 1998, 56, 443–465. [Google Scholar] [CrossRef]

- Kondratieva, N.P.; Vladykin, I.R.; Litvinova, V.M.; Krasnolutskaya, M.G.; Bolshin, R.G. Energy-saving technologies and electric equipment applied in agriculture. Res. Agric. Electr. Eng. 2016, 2, 62–68. [Google Scholar] [CrossRef]

- Mushtaq, K.; Abbas, F.; Ghafoor, A. Energy use for economic growth: Cointegration and causality analysis from the agriculture sector of Pakistan. Pak. Dev. Rev. 2007, 46, 1065–1073. [Google Scholar] [CrossRef]

- Qiao, F. Increasing wage, mechanization, and agriculture production in China. China Econ. Rev. 2017, 46, 249–260. [Google Scholar] [CrossRef]

- Kalita, A. Changes in labor pattern and agricultural mechanization. J. Manag. Res. Anal. 2019, 6, 9–13. [Google Scholar] [CrossRef]

- Perea, R.G.; Poyato, E.C.; Montesinos, P.; Díaz, J.R. Prediction of irrigation event occurrence at farm level using optimal decision trees. Comput. Electron. Agric. 2018, 157, 173–180. [Google Scholar] [CrossRef]

- Haberl, H.; Fischer-Kowalski, M.; Krausmann, F.; Weisz, H.; Winiwarter, V. Progress towards sustainability? What the conceptual framework of material and energy flow accounting (MEFA) can offer. Land Use Policy 2004, 21, 199–213. [Google Scholar] [CrossRef]

- Ballarin, A.; Vecchiato, D.; Tempesta, T.; Marangon, F.; Troiano, S. Biomass energy production in agriculture: A weighted goal programming analysis. Energy Policy 2011, 39, 1123–1131. [Google Scholar] [CrossRef]

- Gabrielle, B.; Bamière, L.; Caldes, N.; De Cara, S.; Decocq, G.; Ferchaud, F.; Richard, G. Paving the way for sustainable bioenergy in Europe: Technological options and research avenues for large-scale biomass feedstock supply. Renew. Sustain. Energy Rev. 2014, 33, 11–25. [Google Scholar] [CrossRef]

- Jasinskas, A.; Sakalauskas, A.; Domeika, R. Evaluation of physical-mechanical properties of herbaceous bioenergy plants. Biomass Bioenergy 2008, 32, 952–958. [Google Scholar] [CrossRef]

- Jasinskas, A.; Ulozevičiūtė, I.; Rutkauskas, G. Plant Biomass Production and Use as an Environmentally-Friendly Local Fuel. Pol. J. Environ. Stud. 2012, 21, 89–94. Available online: http://www.pjoes.com/pdf-88728-22587?filename=Plant%20Biomass%20Production.pdf (accessed on 4 November 2021).

- Godard, C.; Boissy, J.; Gabrielle, B. Life-cycle assessment of local feedstock supply scenarios to compare candidate biomass sources. Gcb Bioenergy 2013, 5, 16–29. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Harangi-Rakos, M.; Fari, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Bilgen, S.; Keleş, S.; Sarıkaya, I.; Kaygusuz, K. A perspective for potential and technology of bioenergy in Turkey: Present case and future view. Renew. Sustain. Energy Rev. 2015, 48, 228–239. [Google Scholar] [CrossRef]

- Araújo, K.; Mahajan, D.; Kerr, R.; Silva, M.D. Global biofuels at the crossroads: An overview of technical, policy, and investment complexities in the sustainability of biofuel development. Agriculture 2017, 7, 32. [Google Scholar] [CrossRef]

- Öztürk, M.; Saba, N.; Altay, V.; Iqbal, R.; Hakeem, K.R.; Jawaid, M.; Ibrahim, F.H. Biomass and bioenergy: An overview of the development potential in Turkey and Malaysia. Renew. Sustain. Energy Rev. 2017, 79, 1285–1302. [Google Scholar] [CrossRef]

- Collotta, M.; Champagne, P.; Tomasoni, G.; Alberti, M.; Busi, L.; Mabee, W. Critical indicators of sustainability for biofuels: An analysis through a life cycle sustainability assessment perspective. Renew. Sustain. Energy Rev. 2019, 115, 109358. [Google Scholar] [CrossRef]

- Jasinskas, A.; Streikus, D.; Vonžodas, T. Fibrous hemp (Felina 32, USO 31, Finola) and fibrous nettle processing and usage of pressed biofuel for energy purposes. Renew. Energy 2020, 149, 11–21. [Google Scholar] [CrossRef]

- Chang, J.; Leung, D.Y.; Wu, C.Z.; Yuan, Z.H. A review on the energy production, consumption, and prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2003, 7, 453–468. [Google Scholar] [CrossRef]

- Inumula, K.M.; Singh, S.; Solanki, S. Energy consumption and agricultural economic growth nexus: Evidence from India. Int. J. Energy Econ. Policy 2020, 10, 545. [Google Scholar] [CrossRef]

- Pamučar, D.; Behzad, M.; Božanić, D.; Behzad, M. Decision making to support sustainable energy policies corresponding to agriculture sector: Case study in Iran’s Caspian Sea coastline. J. Clean. Prod. 2020, 292, 125302. [Google Scholar] [CrossRef]

- Pelletier, N.; Audsley, E.; Brodt, S.; Garnett, T.; Henriksson, P.; Kendall, A.; Kramer, K.J.; Murphy, D.; Nemecek, T.; Troell, M. Energy intensity of agriculture and food systems. Annu. Rev. Environ. Resour. 2011, 36, 223–246. [Google Scholar] [CrossRef]

- Chen, P.-C.; Yu, M.-M.; Chang, C.C.; Hsu, S.-H. Total factor productivity growth in China’s agricultural sector. China. Econ. Rev. 2008, 19, 580–593. [Google Scholar] [CrossRef]

- Ghisellini, P.; Setti, M.; Ulgiati, S. Energy and land use in worldwide agriculture: An application of life cycle energy and cluster analysis. Environ. Dev. Sustain. 2016, 18, 799–837. [Google Scholar] [CrossRef]

- Pellegrini, P.; Fernández, R.J. Crop intensification, land use, and on-farm energy-use efficiency during the worldwide spread of the green revolution. Proc. Natl. Acad. Sci. USA 2018, 115, 2335–2340. [Google Scholar] [CrossRef] [PubMed]

- Arodudu, O.T.; Helming, K.; Voinov, A.; Wiggering, H. Integrating agronomic factors into energy efficiency assessment of agro-bioenergy production. A case study of ethanol and biogas production from maize feedstock. Appl. Energy 2017, 198, 426–439. [Google Scholar] [CrossRef]

- Tilley, D.R.; Martin, J.F. Environmental accounting of agricultural sustainability using energy analysis. In Systems Analysis Modeling in Food Agriculture Encyclopedia of Life Support Systems; Ting, K.C., Fleisher, D.H., Rodriguez, L.F., Eds.; United Nations Educational, Scientific and Cultural Organisation, Eolss Publisher: Oxford, UK, 2006. [Google Scholar]

- Gündoğmuş, M.E. Energy use on organic farming: A comparative analysis on organic versus conventional apricot production on small holdings in Turkey. Energy Convers. Manag. 2006, 47, 3351–3359. [Google Scholar] [CrossRef]

- Esengün, K.; Gündüz, O.; Erdal, G. Input–output energy analysis in dry apricot production of Turkey. Energy Convers. Manag. 2007, 48, 592–598. [Google Scholar] [CrossRef]

- Rathke, G.W.; Diepenbrock, W. Energy balance of winter oilseed rape (Brassica napus L.) cropping as related to nitrogen supply and preceding crop. Eur. J. Agron. 2006, 24, 35–44. [Google Scholar] [CrossRef]

- Unakitan, G.; Hurma, H.; Yilmaz, F. An analysis of energy use efficiency of canola production in Turkey. Energy 2010, 35, 3623–3627. [Google Scholar] [CrossRef]

- Budzyński, W.S.; Jankowski, K.J.; Jarocki, M. An analysis of the energy efficiency of winter rapeseed biomass under different farming technologies. A case study of a large-scale farm in Poland. Energy 2015, 90, 1272–1279. [Google Scholar] [CrossRef]

- Groth, D.A.; Sokólski, M.; Jankowski, K.J. A multi-criteria evaluation of the effectiveness of nitrogen and sulfur fertilization in different cultivars of winter rapeseed productivity, economic and energy balance. Energies 2020, 13, 4654. [Google Scholar] [CrossRef]

- Banaeian, N.; Zangeneh, M. Study on energy efficiency in corn production of Iran. Energy 2011, 36, 5394–5402. [Google Scholar] [CrossRef]

- Šarauskis, E.; Buragienė, S.; Masilionytė, L.; Romaneckas, K.; Avižienytė, D.; Sakalauskasa, A. Energy balance, costs and CO2 analysis of tillage technologies in maize cultivation. Energy 2014, 69, 227–235. [Google Scholar] [CrossRef]

- Konieczna, A.; Roman, K.; Roman, M.; Śliwiński, D.; Roman, M. Energy efficiency of maize production technology: Evidence from Polish farms. Energies 2021, 14, 170. [Google Scholar] [CrossRef]

- Yilmaz, I.; Akcaoz, H.; Özkan, B. An analysis of energy use and input costs for cotton production in Turkey. Renew. Energy 2005, 30, 145–155. [Google Scholar] [CrossRef]

- Demircan, V.; Ekinci, K.; Keenar, H.M.; Akbotat, D.; Ekinic, C. Energy and economic analysis of sweet cherry production in Turkey: A case study from Isparta Province. Energy Convers. Manag. 2006, 47, 1761–1769. [Google Scholar] [CrossRef]

- Asgharipour, M.; Mondani, F.; Riahinia, S. Energy use efficiency and economic analysis of sugar beet production system in Iran: A case study in Khorasan Razavi province. Energy 2012, 44, 1078–1084. [Google Scholar] [CrossRef]

- Šarauskis, E.; Romaneckas, K.; Kumhála, F.; Kriaučiūnienė, Z. Energy use and carbon emission of conventional and organic sugar beet farming. J. Clean. Prod. 2018, 201, 428–438. [Google Scholar] [CrossRef]

- Özkan, B.; Akcaoz, H.; Fert, C. Energy input–output analysis in Turkish agriculture. Renew. Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Mohammadi, A.; Rafiee, S.; Mohtasebi, S.S.; Rafiee, H. Energy inputs-yield relationship and cost analysis of kiwifruit production in Iran. Renew. Energy 2010, 35, 1071–1075. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tabatabaeefar, A.; Shahin, S.; Rafiee, S.; Keyhani, A. Energy use and economical analysis of potato production in Iran a case study: Ardabil province. Energy Convers. Manag. 2008, 49, 3566–3570. [Google Scholar] [CrossRef]

- Pahlavan, R.; Omid, M.; Akram, A. Energy input–output analysis and application of artificial neural networks for predicting greenhouse basil production. Energy 2012, 37, 171–176. [Google Scholar] [CrossRef]

- Özkan, B.; Kurklu, A.; Akcaoz, H. An input-output energy analysis in greenhouse vegetable production: A case study for Antalya region of Turkey. Biomass Bioenergy 2004, 26, 189–195. [Google Scholar] [CrossRef]

- Mohammadi, A.; Omid, M. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Keyhani, A.; Mohammadi, A.; Rafiee, S.; Akram, A. Sensitivity analysis of energy inputs for barley production in Hamedan Province of Iran. Agric. Ecosyst. Environ. 2010, 137, 367–372. [Google Scholar] [CrossRef]

- Szwejkowska, B.; Bielski, S. Comparison of Energetical and Economical Effectiveness of Different Technologies of Pea Production. Pol. J. Nat. Sc. 2007, 3, 373–382. Available online: https://www.infona.pl/resource/bwmeta1.element.agro-article-eadbabe5-ccde-4e29-b0b7-8238fed5d332 (accessed on 4 November 2021). [CrossRef]

- Salimi, P.; Ahmadi, H. Energy Inputs and Outputs in a Chickpea Production System in Kurdistan, Iran. Afr. Crop Sci. J. 2010, 18, 51–57. [Google Scholar] [CrossRef]

- Bielski, S. Energy balance evaluation of winter triticale production. Engineering for Rural Development. Proceedings 2015, 4, 552–557. Available online: http://www.tf.llu.lv/conference/proceedings2015/Papers/090_Bielski.pdf (accessed on 4 November 2021).

- Šarauskis, E.; Romaneckas, K.; Jasinskas, A.; Kimbirauskienė, R.; Naujokienė, V. Improving energy efficiency and environmental mitigation through tillage management in faba bean production. Energy 2020, 209, 118453. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Sokólski, M. Spring camelina: Effect of mineral fertilization on the energy efficiency of biomass production. Energy 2020, 220, 119731. [Google Scholar] [CrossRef]

- Alluvione, F.; Moretti, B.; Sacco, D.; Grignani, C. EUE (energy use efficiency) of cropping systems for a sustainable agriculture. Energy 2011, 36, 4468–4481. [Google Scholar] [CrossRef]

- Singh, H.; Mishra, D.; Nahar, N.M. Energy use pattern in production agriculture of a typical village in arid zone, Indiae part-I. Energy Convers. Manag. 2002, 43, 2275–2286. [Google Scholar] [CrossRef]

- Olabi, A.G. Energy quadrilemma and the future of renewable energy. Energy 2016, 108, 1–6. [Google Scholar] [CrossRef]

- Hülsbergen, K.J.; Feil, B.; Biermann, S.; Rathke, G.W.; Kalk, W.D.; Diepenbrock, W. A method of energy balancing in crop production and its application in a long-term fertilizer trial. Agric. Ecosyst. Environ. 2001, 86, 303–321. [Google Scholar] [CrossRef]

- Beheshti Tabar, I.; Keyhani, A.; Rafiee, S. Energy balance in Iran’s agronomy (1990–2006). Renew. Sust. Energ. Rev. 2010, 14, 849–855. [Google Scholar] [CrossRef]

- Wójcicki, Z. Poszanowanie Energii i Środowiska w Rolnictwie i na Obszarach Wiejskich; IBMER: Warszawa, Poland, 2007. (In Polish) [Google Scholar]

- Zentner, R.P.; Lafond, G.P.; Derksen, D.A.; Nagy, C.N.; Wall, D.D.; May, W.E. Effects of tillage method and crop rotation on non-renewable energy use efficiency for a thin Black Chernozem in the Canadian prairies. Soil Tillage Res. 2004, 77, 125–136. [Google Scholar] [CrossRef]

- Mandal, K.G.; Saha, K.P.; Ghosh, P.K.; Hati, K.M.; Bandyopadhyay, K.K. Bioenergy and economic analysis of soybean based crop production systems in central India. Biomass Bioenergy 2002, 23, 337–345. [Google Scholar] [CrossRef]

- Heidari, M.D.; Omid, M.; Mohammadi, A. Measuring productive efficiency of horticultural greenhouses in Iran: A data envelopment analysis approach. Expert Syst. Appl. 2011, 39, 1040–1045. [Google Scholar] [CrossRef]

- Pishgar-Komleh, S.H.; Omid, M.; Heidari, M.D. On the study of energy use and GHG (greenhouse gas) emissions in greenhouse cucumber production in Yazd province. Energy 2013, 59, 63–71. [Google Scholar] [CrossRef]

- Naderi, S.A.; Dehkordi, A.L.; Morteza, T. Energy and environmental evaluation of greenhouse bell pepper production with life cycle assessment approach. Environ. Sustain. Indic. 2019, 3–4, 100011. [Google Scholar] [CrossRef]

- Kizilaslan, H. Input–output energy analysis of cherries production in Tokat province of Turkey. Appl. Energy 2009, 86, 1354–1358. [Google Scholar] [CrossRef]

- Maraseni, T.; Chen, G.; Banhazi, T.; Bundschuh, J.; Yusaf, T. An Assessment of direct on-farm energy use for high value grain crops grown under different farming practices in Australia. Energies 2015, 8, 13033–13046. [Google Scholar] [CrossRef]

- Singh, H.; Mishra, D.; Nahar, N.M.; Ranjan, M. Energy use pattern in production agriculture of a typical village in Arid Zone India (Part II). Energy Convers. Manag. 2003, 44, 1053–1067. [Google Scholar] [CrossRef]

- Oil and Gas Institute—National Research Institute (INiG-PIB). Guidelines for the Determination of the Life Cycle per Unit Values of GHG Emissions for Biofuels, Biomass Fuels and Bioliquids; Oil and Gas Institute-National Research Institute: Cracow, Poland, 2021. [Google Scholar]

- Wiśniewski, P.; Kistowski, M. Greenhouse gas emissions from cultivation of plants used for biofuel production in Poland. Atmosphere 2020, 11, 394. [Google Scholar] [CrossRef]

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, L328, 82–209. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories; IPCC: Hayama, Japan, 2000. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Hayama, Japan, 2006. [Google Scholar]

- National Centre for Emission Management (KOBiZE). Poland’s National Inventory Report 2021. Greenhouse Gas Inventory for 1988–2019: Submission under the UN Framework Convention on Climate Change and Its Kyoto Protocol; KOBiZE: Warsaw, Poland, 2021. [Google Scholar]

- CarbonCloud, 2022. ClimateHub. Available online: https://apps.carboncloud.com/climatehub/ (accessed on 13 August 2022).

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Cambridge, UK; New York, NY, USA, 2021. [Google Scholar]

- BioGrace-II 2022. The BioGrace-II GHG Calculation Tool for Electricity, Heating and Cooling. Available online: https://www.biograce.net/biograce2/content/ghgcalculationtool_electricityheatingcooling/overview (accessed on 13 August 2022).

- Commission Implementing Regulation (EU) 2022/996 of 14 June 2022 on Rules to Verify Sustainability and Greenhouse Gas Emissions Saving Criteria and Low Indirect Land-Use Change-Risk Criteria (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/reg_impl/2022/996/oj (accessed on 13 August 2022).

- Köble, R. The Global Nitrous Oxide Calculator—GNOC—Online Tool Manual. Version 1.2.4; European Commission Joint Research Centre: Brussels, Belgium, 2014. [Google Scholar]

- European Union. Communication from the Commission on the Practical Implementation of the EU Biofuels and Bioliquids Sustainability Scheme and on Counting Rules for Biofuels (2010/C 160/02). Off. J. Eur. Union. 2010. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:C:2010:160:0008:0016:EN:PDF (accessed on 13 August 2022).

- Syp, A.; Faber, A.; Kozak, M. Assessment of N2O emissions from rapeseed cultivation in Poland by various approaches. Int. Agrophys. 2016, 30, 501–507. [Google Scholar] [CrossRef]

- Stehfest, E.; Bouwman, L. N2O and NO emission from agricultural fields and soils under natural vegetation: Summarizing available measurement data and modeling of global annual emissions. Nutr. Cycl. Agroecosyst. 2006, 74, 207–228. [Google Scholar] [CrossRef]

- Edwards, R.; Mulligan, D.; Giuntoli, J.; Agostini, A.; Boulamanti, A.; Koeble, R.; Marelli, L.; Moro, A.; Padella, M. Assessing GHG Default Emissions from Biofuels in EU Legislation. Review of Input Database to Calculate Default GHG Emissions, Following Expert Consultation 22–23 November 2011, Ispra (Italy). EUR 25595EN; Publication Office of the European Union: Luxembourg, 2012; JRC76057. [Google Scholar]

- Ruser, R.; Fuß, R.; Andres, M.; Hegewald, H.; Kesenheimer, K.; Köbke, S.; Räbiger, T.; Suarez Quinones, T.; Augustin, J.; Christen, O.; et al. Nitrous oxide emissions from winter oilseed rape cultivation. Agric. Ecosyst. Environ. 2017, 249, 57–69. [Google Scholar] [CrossRef]

- Ghorbani, R.; Mondani, F.; Amirmoradi, S.; Feizi, H.; Khorramdel, S.; Teimouri, M. A case study of energy use and economical analysis of irrigated and dry land wheat production systems. Appl. Energy 2011, 88, 283–288. [Google Scholar] [CrossRef]

- Woods, J.; Williams, A.; Hughes, J.K.; Black, M.; Murphy, R. Energy and the food system. Philos. Trans. R. Soc. B. 2010, 365, 2991–3006. [Google Scholar] [CrossRef]

- Pimentel, D.; Hepperly, P.; Hanson, J.; Douds, D.; Seidel, R. Environmental, energetic, and economic comparisons of organic and conventional farming systems. Bioscience 2005, 55, 573–582. [Google Scholar] [CrossRef]

- Fischer, T.; Byerlee, D.; Edmeades, G. Crop Yields and Global Food Security: Will Yield Increase Continue to Feed the World? 1st ed.; Twofoot Consulting Group: Canberra, Australia, 2014. [Google Scholar]

- Shannon, K.L.; Kim, B.F.; McKenzie, S.E.; Lawrence, R.S. Food system policy, public health and human rights in the United States. Annu. Rev. Public Health 2015, 36, 151–173. [Google Scholar] [CrossRef]

- Pereira, V.J. Energy consumption across European Union farms: Efficiency in terms of farming output and utilized agricultural area. Energy 2016, 103, 543–556. [Google Scholar] [CrossRef]

- Lu, H.; Bai, Y.; Ren, H.; Campbell, D.E. Integrated emergy, energy and economic evaluation of rice and vegetable production systems in alluvial paddy fields: Implications for agricultural policy in China. J. Environ. Manag. 2010, 91, 2727–2735. [Google Scholar] [CrossRef]

- Elsoragaby, S.; Yahya, A.; Mahadi, M.R.; Nawi, N.M.; Mairghany, M. Energy utilization in major crop cultivation. Energy 2019, 173, 1285–1303. [Google Scholar] [CrossRef]

- Kuczuk, A.; Pospolita, J. Sustainable agriculture—Energy and emergy aspects of agricultural production. Eur. Res. Stud. 2020, 4, 1000–1018. [Google Scholar] [CrossRef]

- Elsoragaby, S.; Yahya, A.; Mahadi, M.R.; Nawi, N.M.; Mairghany, M.; Elhassan, S.M.; Kheiralla, A.F. Applying multi-objective genetic algorithm (MOGA) to optimize the energy inputs and greenhouse gas emissions (GHG) in wetland rice production. Energy Rep. 2020, 6, 2988–2998. [Google Scholar] [CrossRef]

- Sławiński, K.; Grieger, A.; Sadowski, W. Energetyczna Ocena Konwencjonalnej i Ekologicznej Technologii Uprawy Gryki. Inżynieria Rol. 2009, 1, 297–302. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-article-BAR0-0044-0095/c/httpir_ptir_orgartykulypl110ir1102447pl.pdf (accessed on 4 November 2021).

- Kuczuk, A. Cumulative Energy Intensity and Energy Account in Cultivation of Buckwheat (Fagopyrum Esculentum Moench). J. Res. Appl. Agric. Eng. 2016, 61, 6–14. Available online: https://www.pimr.eu/wp-content/uploads/2019/05/2016_4_AK1.pdf (accessed on 4 November 2021).

- Lotfalian Dehkordi, A.; Forootan, M. Estimation of energy flow and environmental impacts of quinoa cultivation through life cycle assessment methodology. Environ. Sci. Pollut. 2020, 27, 21836–21846. [Google Scholar] [CrossRef]

- Sławiński, K.; Bujaczek, R. The Analysis of Energy Consumption in Link of Rotation: Winter Rye—Potato in System of Organic and Conventional Farming. Pol. J. Nat. Sci. 2012, 27, 353–358. Available online: http://www.uwm.edu.pl/polish-journal/sites/default/files/issues/articles/slawinski_and_bujaczek.pdf (accessed on 4 November 2021).