Impact of Solar Energy Integration on the Rheological and Chemical Properties of Bitumen

Abstract

1. Introduction

2. Materials and Methods

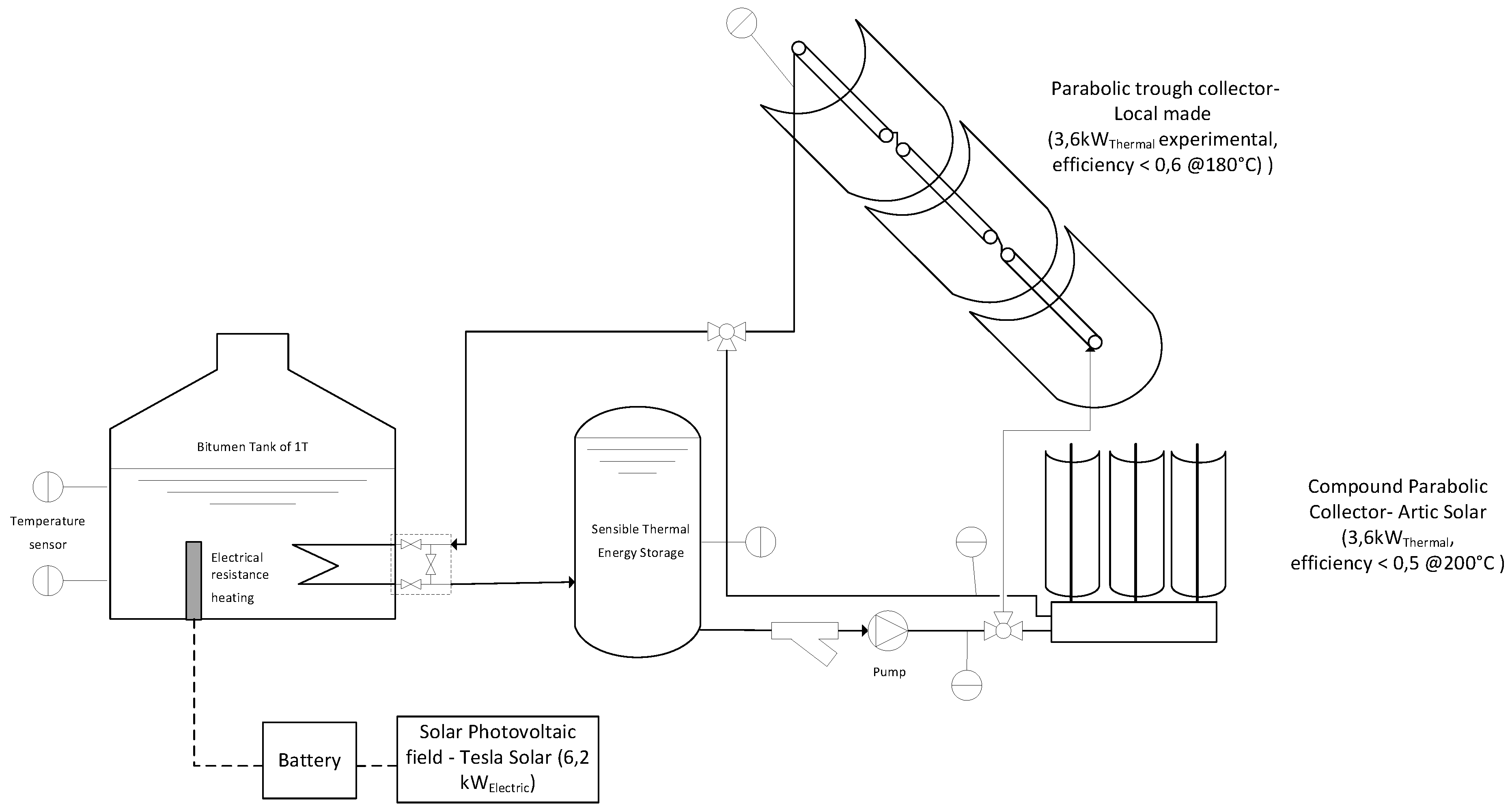

2.1. Solar Implant

2.1.1. Test Device—Major Components

Measuring Equipment

XCPC Collector

Parabolic Trough Collector

PV Solar Field

2.2. Simulation Scenarios

- ▪

- In the scenario where bitumen reaches 175 °C, the cooling time from 175 °C to 135 °C is long and the nighttime is short. Therefore, while bitumen is still cooling down during the next day’s sun hours, we opt for occasional energy storage, using the batteries that already exist in the experimental setup, and use that stored energy to start the heating if our bitumen hits 135 °C at night.

- ▪

- In the scenario where bitumen attains 155 °C, bitumen might cool down to 135 °C before the sun hours of the next day, so we might need an energy supply to prevent it from reaching temperatures <135 °C, thus the need for a fossil fuel heater.

2.3. Aging Simulation

2.4. Characterization Tests

- For the penetration test, the difference between two results should not—in a long series of tests carried out with a normal and correct application of the test method—exceed r = 2 (0.1 mm) more than one in twenty times [42];

- For the determination of softening point test, the difference between two results should not exceed r = 1.0 °C more than one in twenty times [43];

- For the DSR test, two results obtained in the same laboratory by the same operator using the same equipment in the shortest practical period of time should not be considered suspect unless the difference in the two results, expressed as a percent of their mean, exceeds the values given in Table 3 [45]:

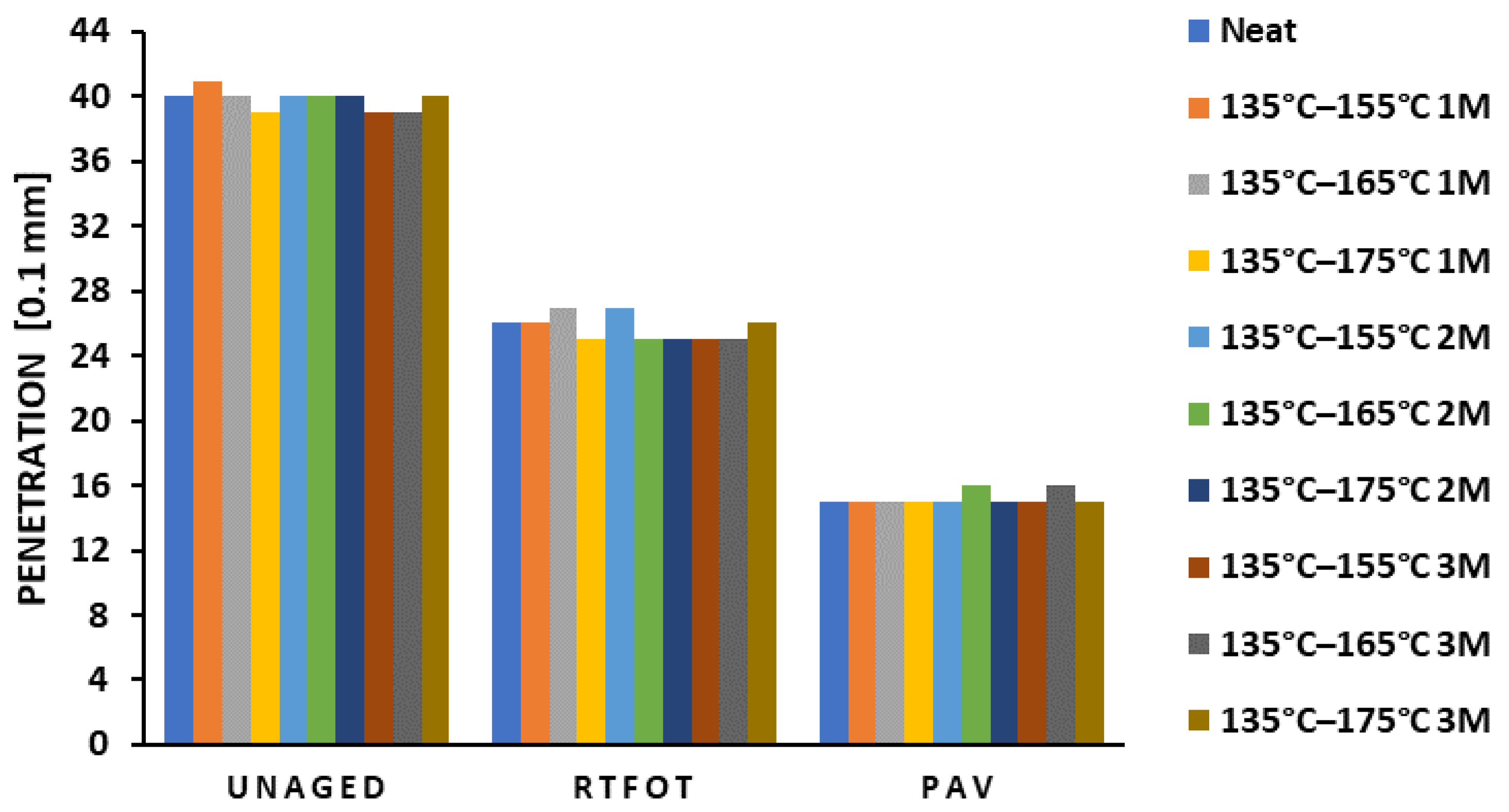

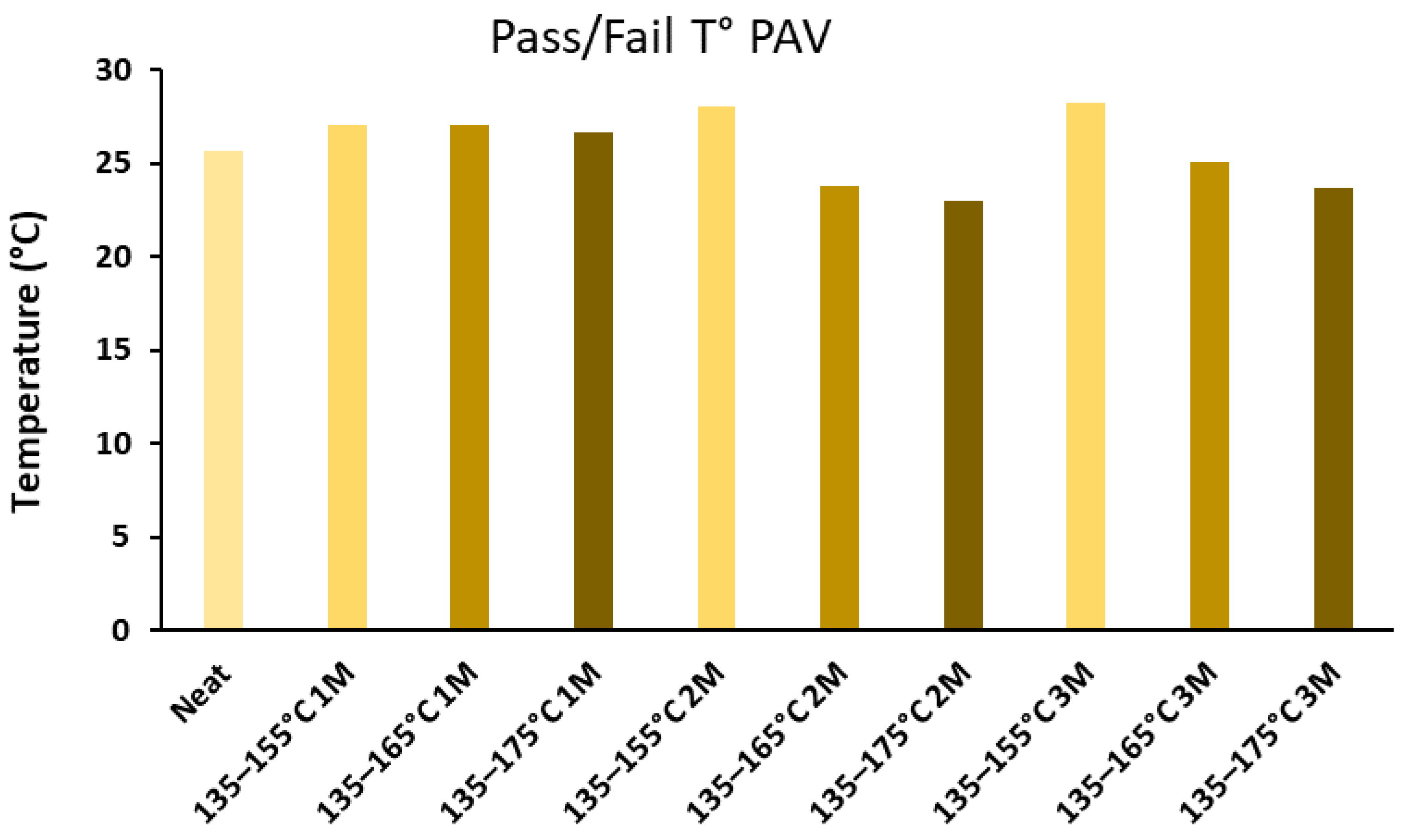

- Neat: control sample = has not been exposed to any thermal cycles;

- 135–155 °C 1 M, 135–155 °C 2 M, and 135–155 °C 3 M: the samples stored between 135 and 155 °C for one month, two months, and three months, respectively;

- 135–165 °C 1 M, 135–165 °C 2 M, and 135–165 °C 3 M: the samples stored between 135 and 165 °C for one month, two months, and three months, respectively;

- 135–175 °C 1 M, 135–175 °C 2 M, and 135–175 °C 3 M: the samples stored between 135 and 175 °C for one month, two months, and three months, respectively.

3. Results and Discussion

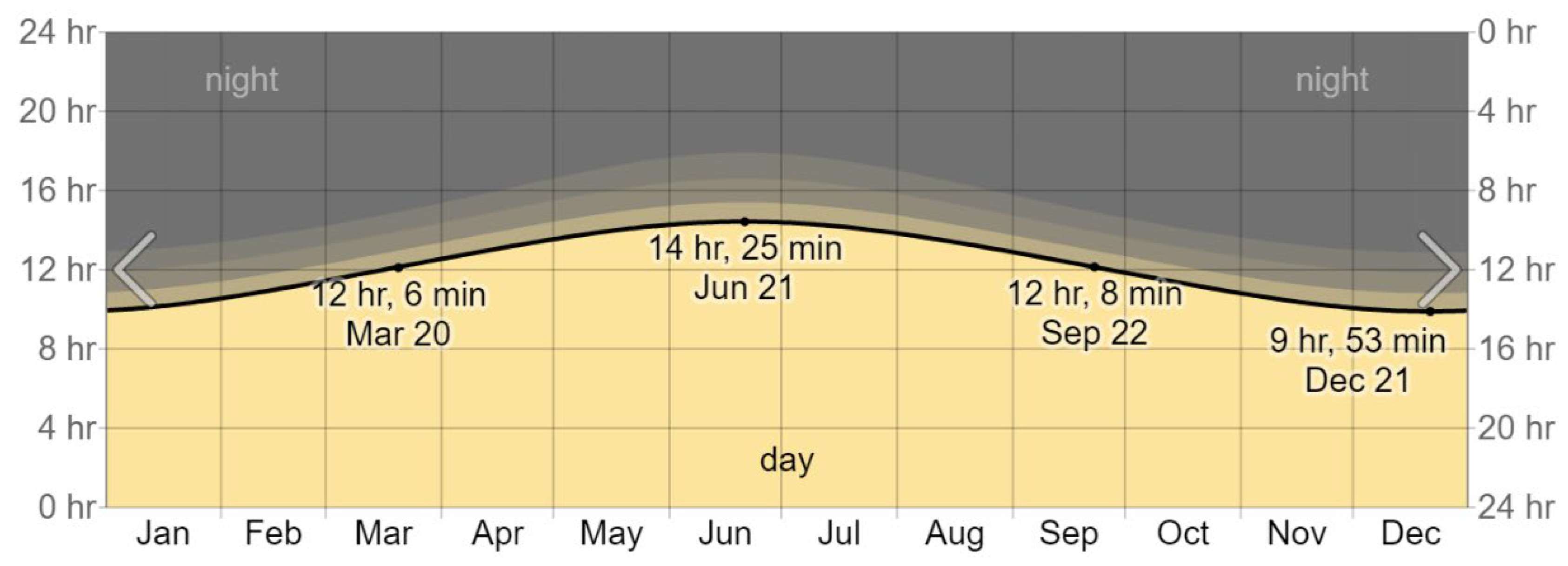

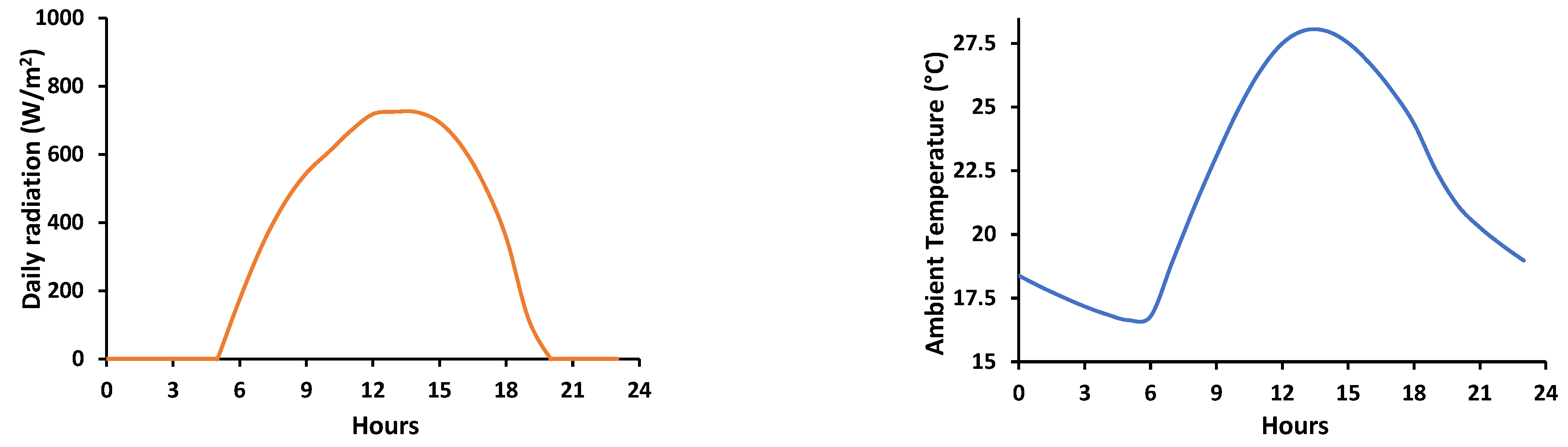

3.1. Meteorological Data of Test Month (June 2021)

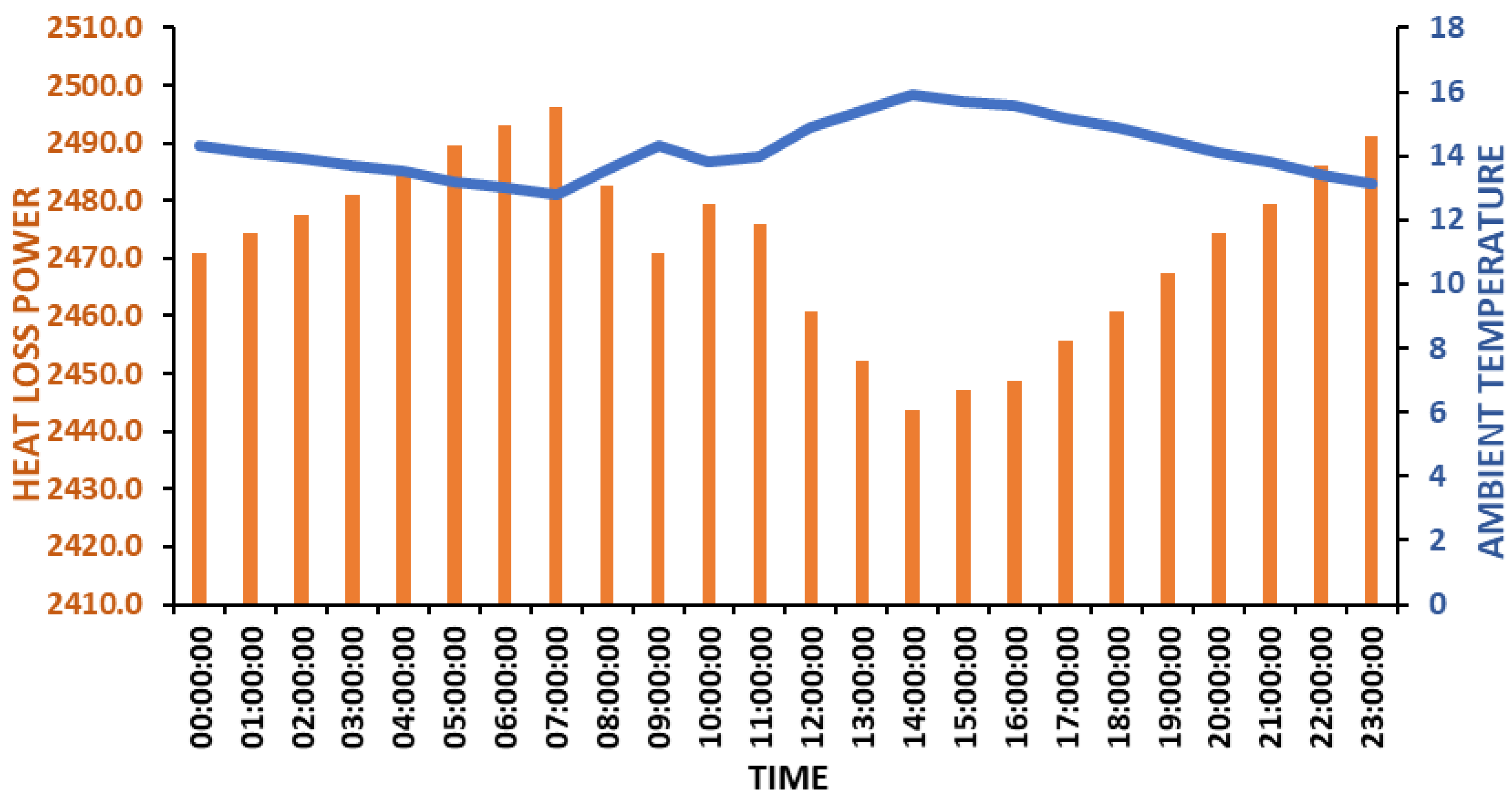

3.2. Solar System Performance

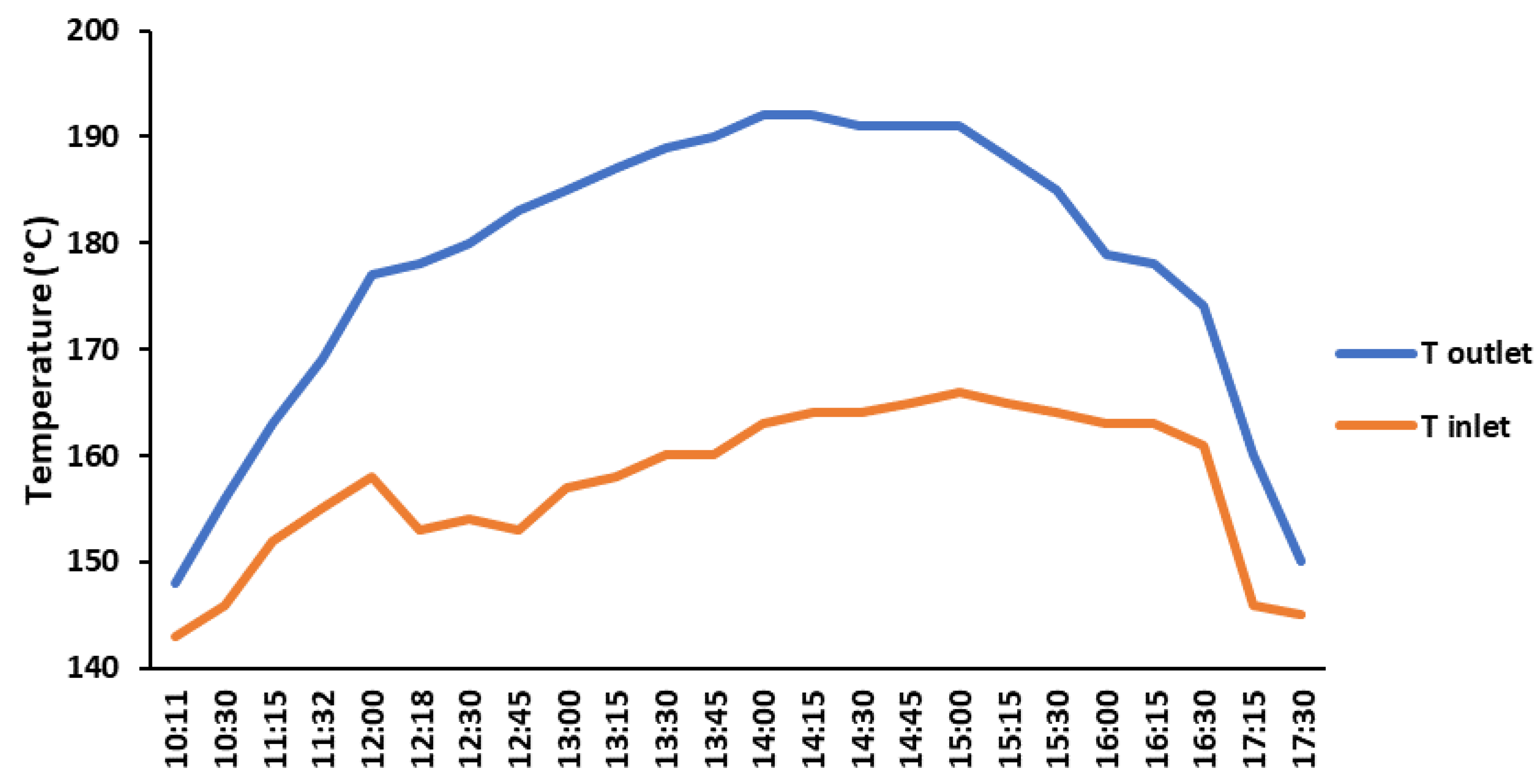

3.2.1. XCPC Collector

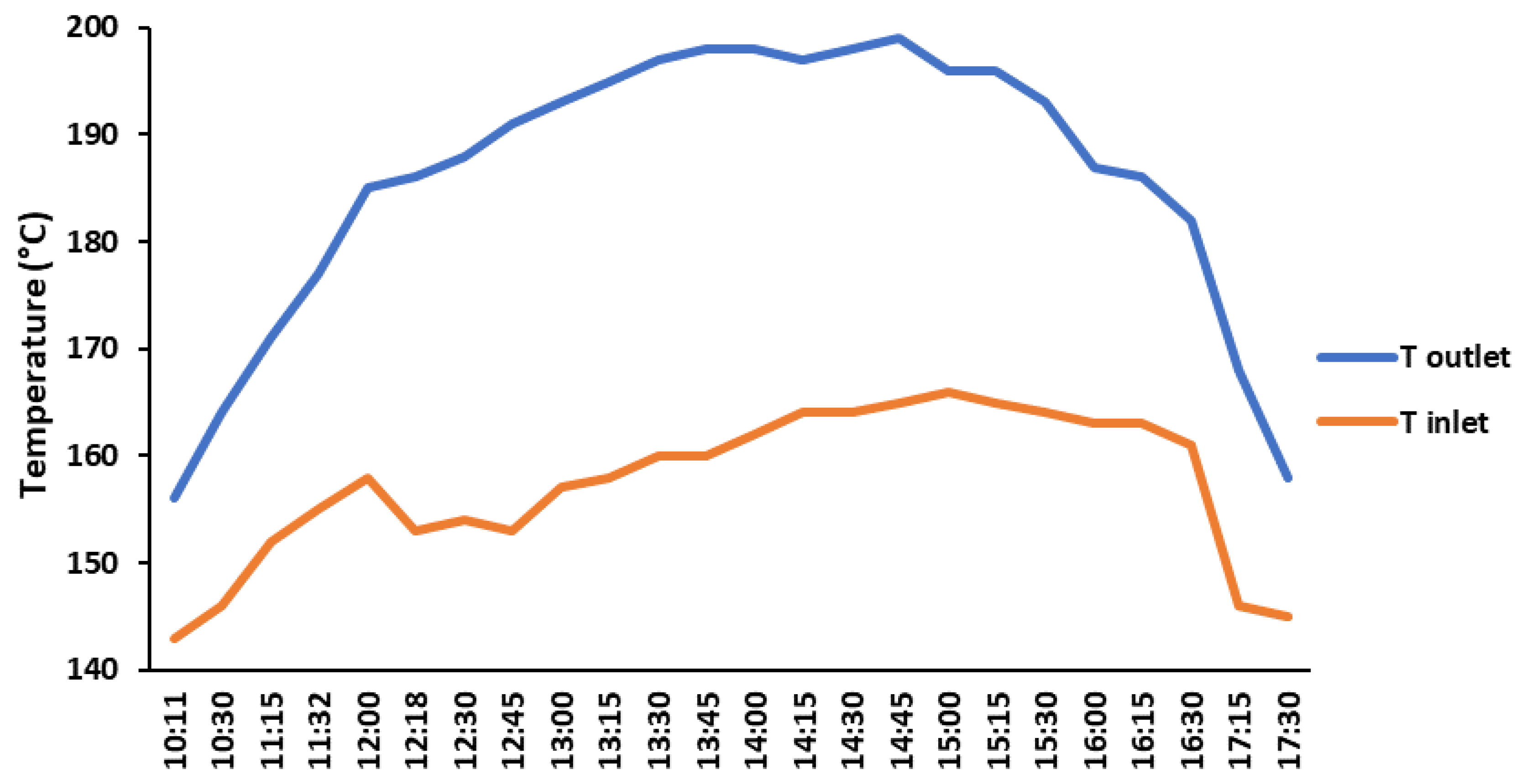

3.2.2. Parabolic Trough Collector

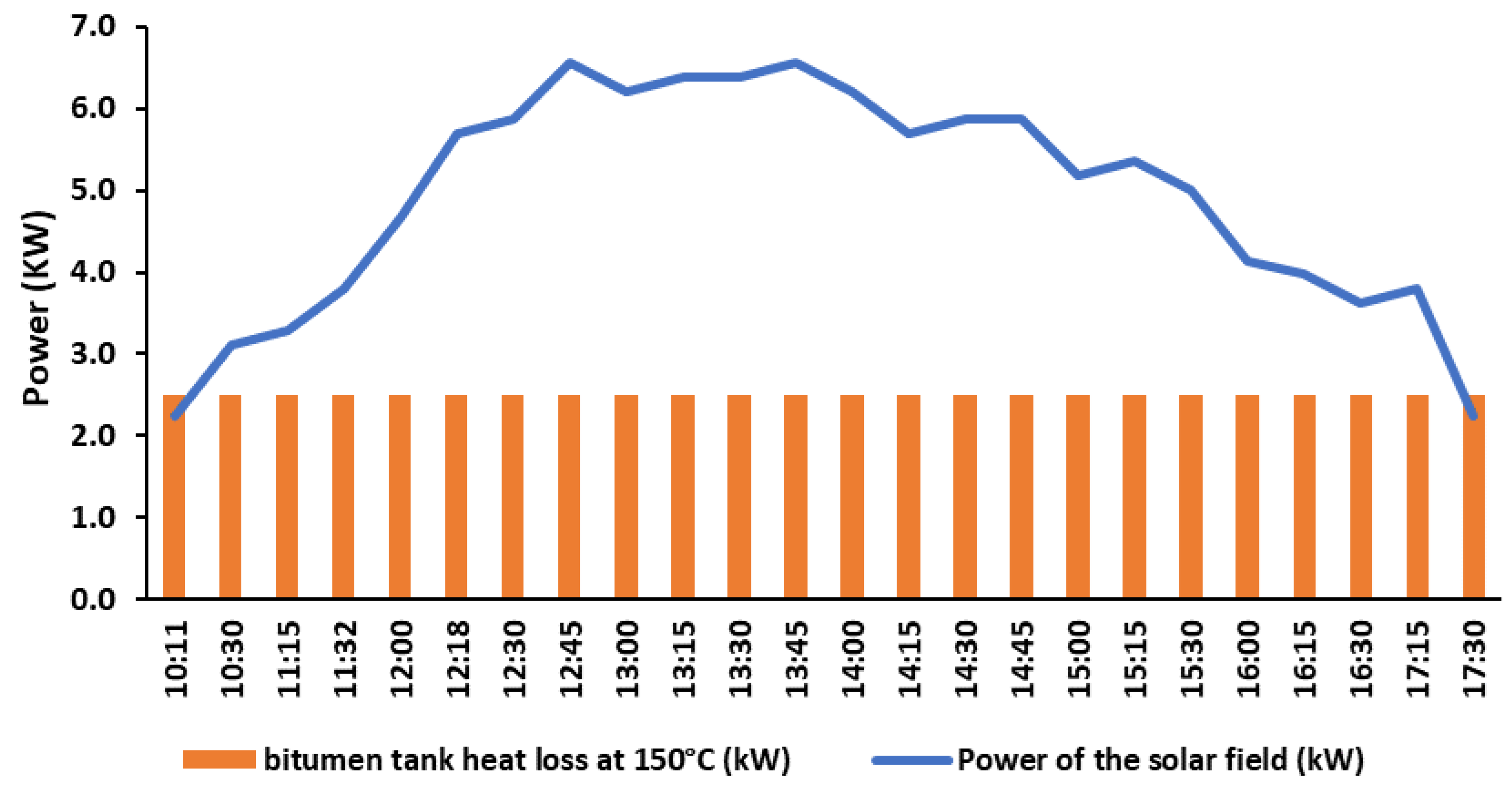

3.2.3. PV Solar Field

3.3. Physical Property Evaluation

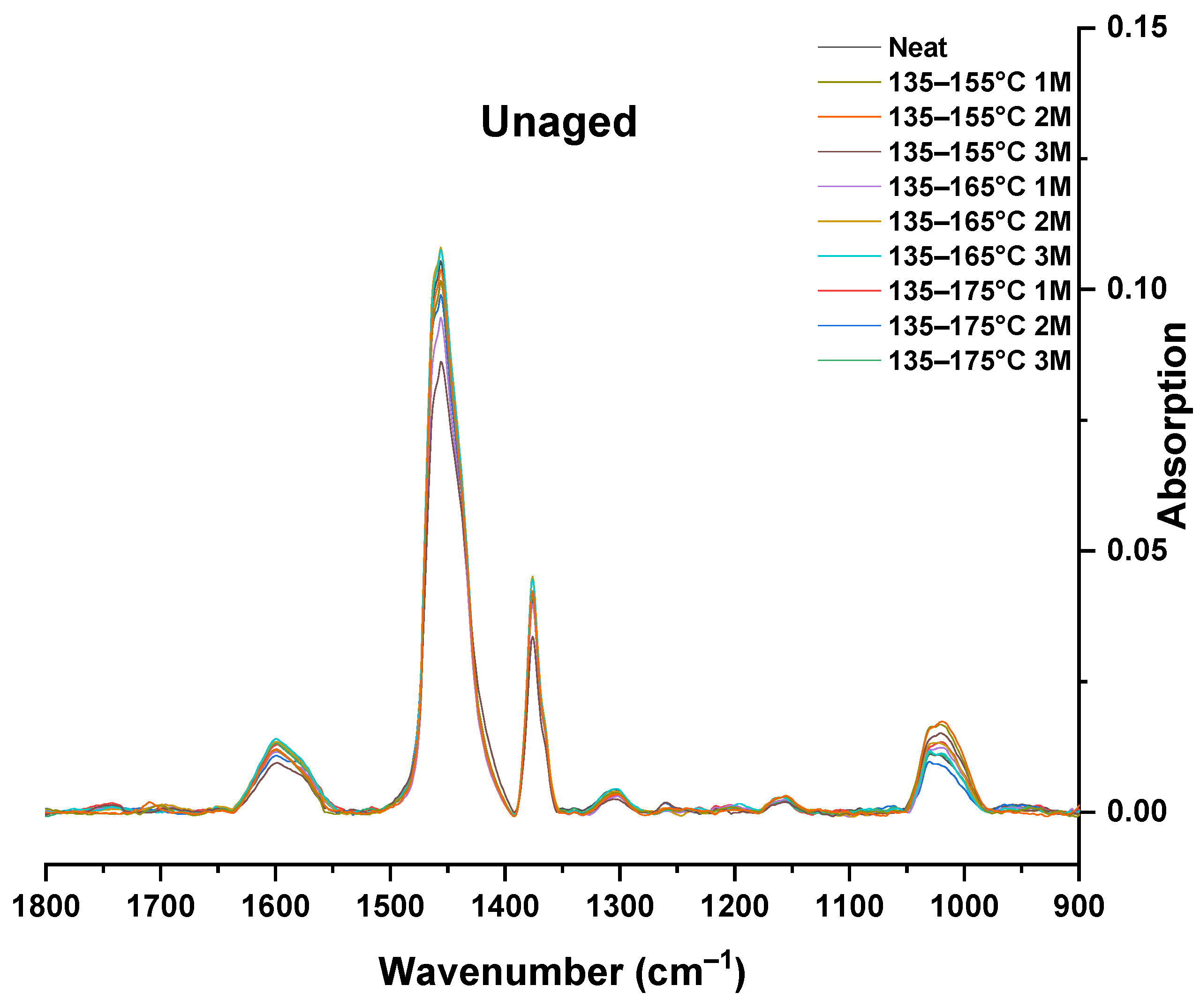

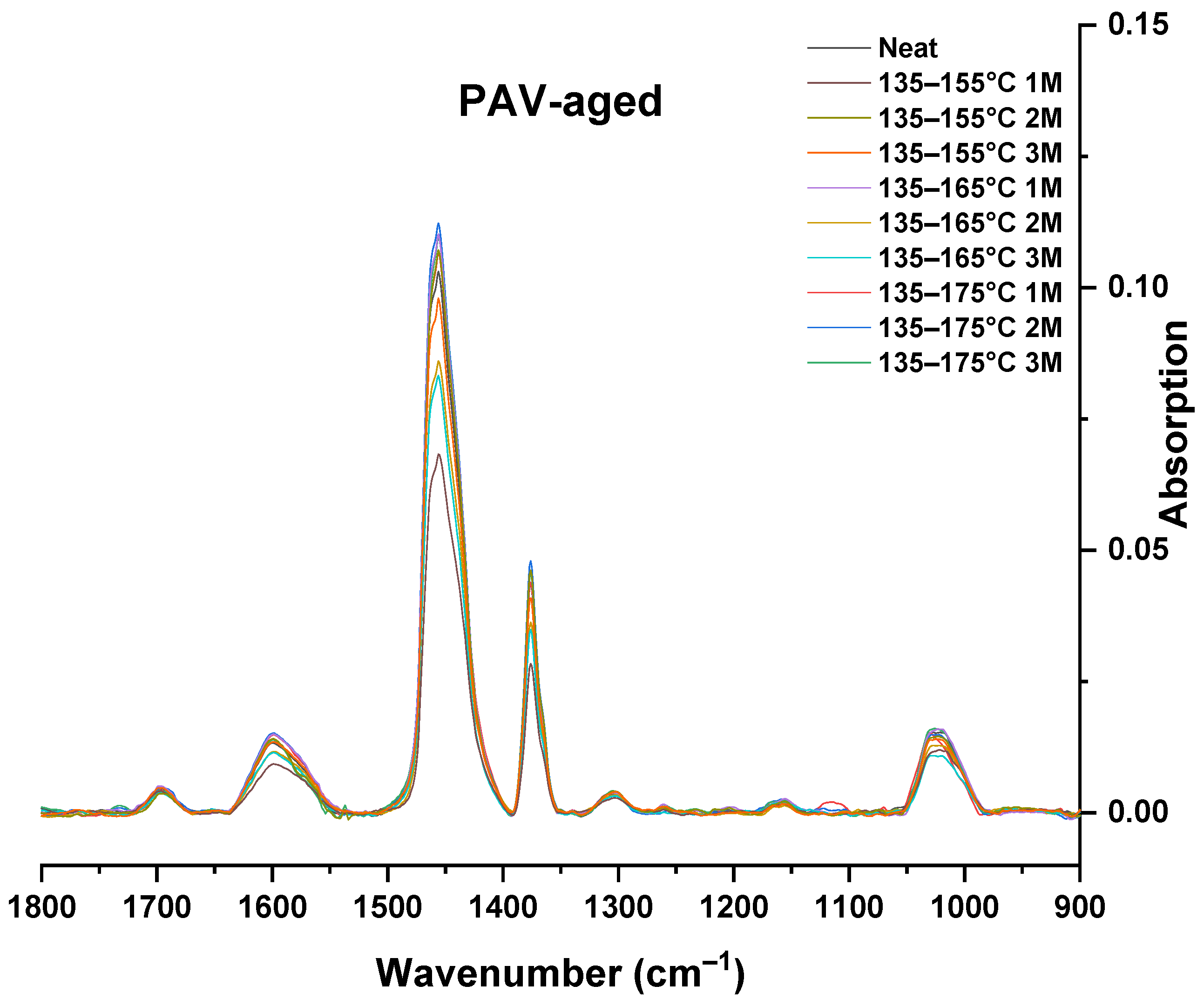

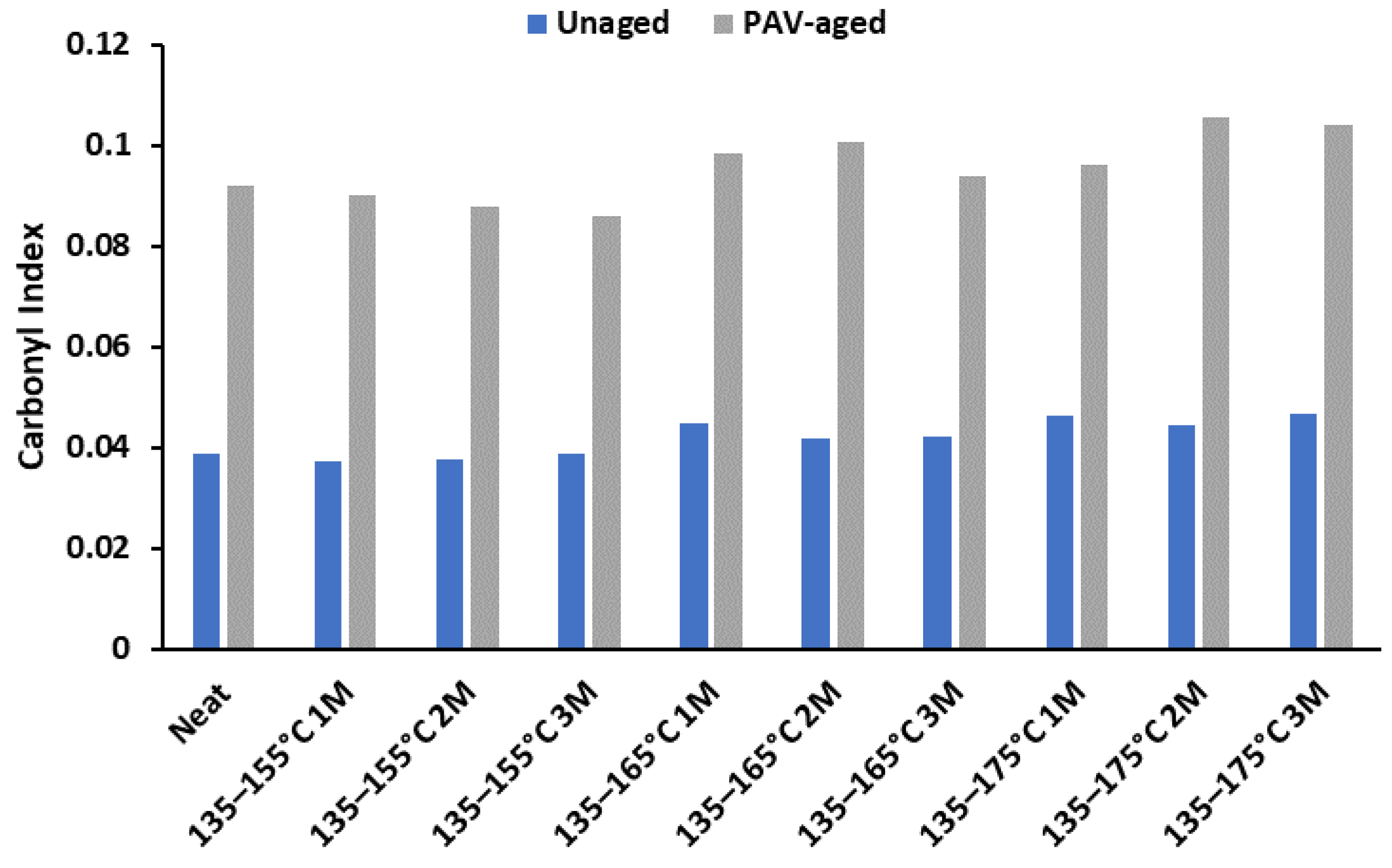

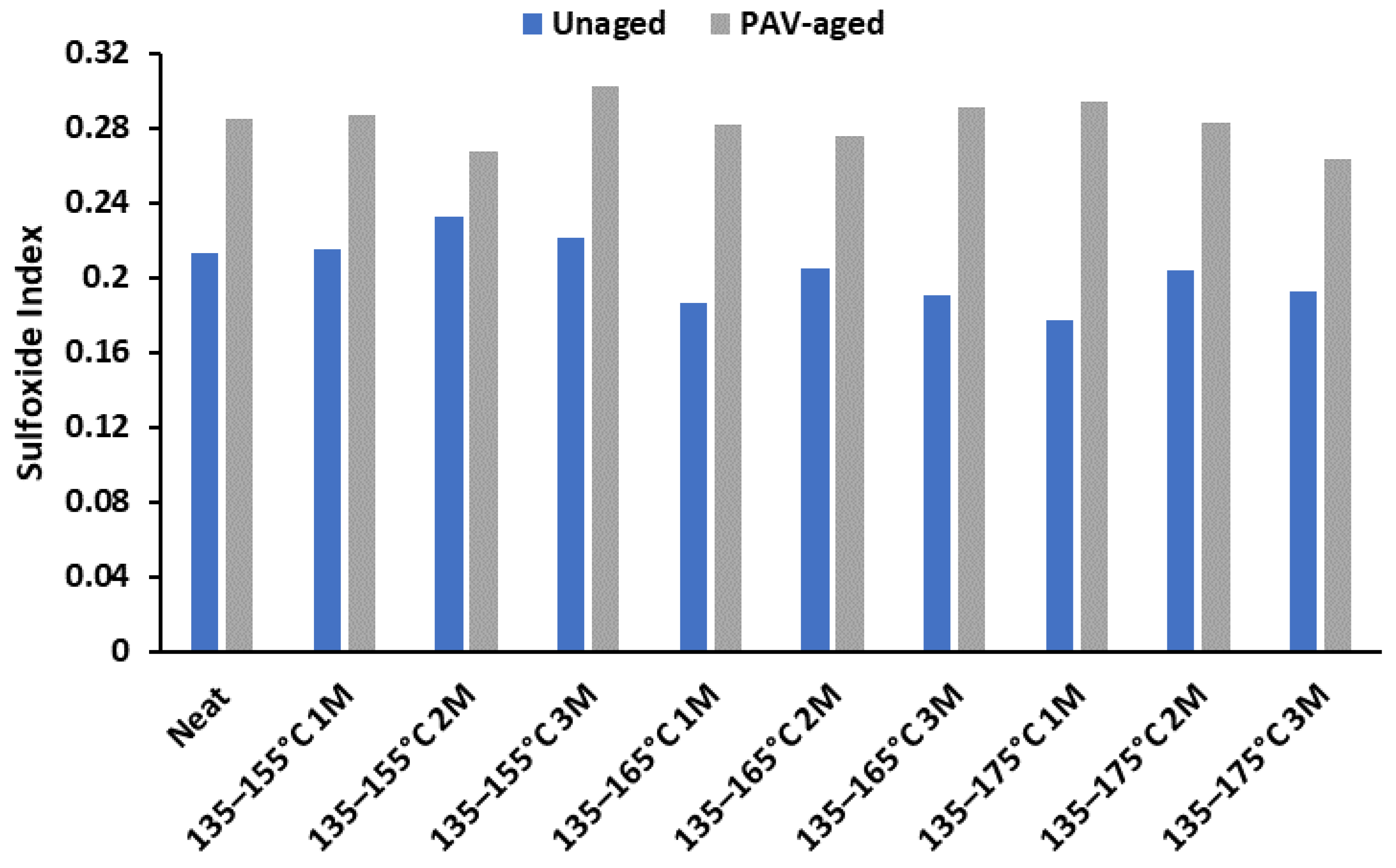

3.4. ATR-FTIR Analysis

3.5. DSR Analysis

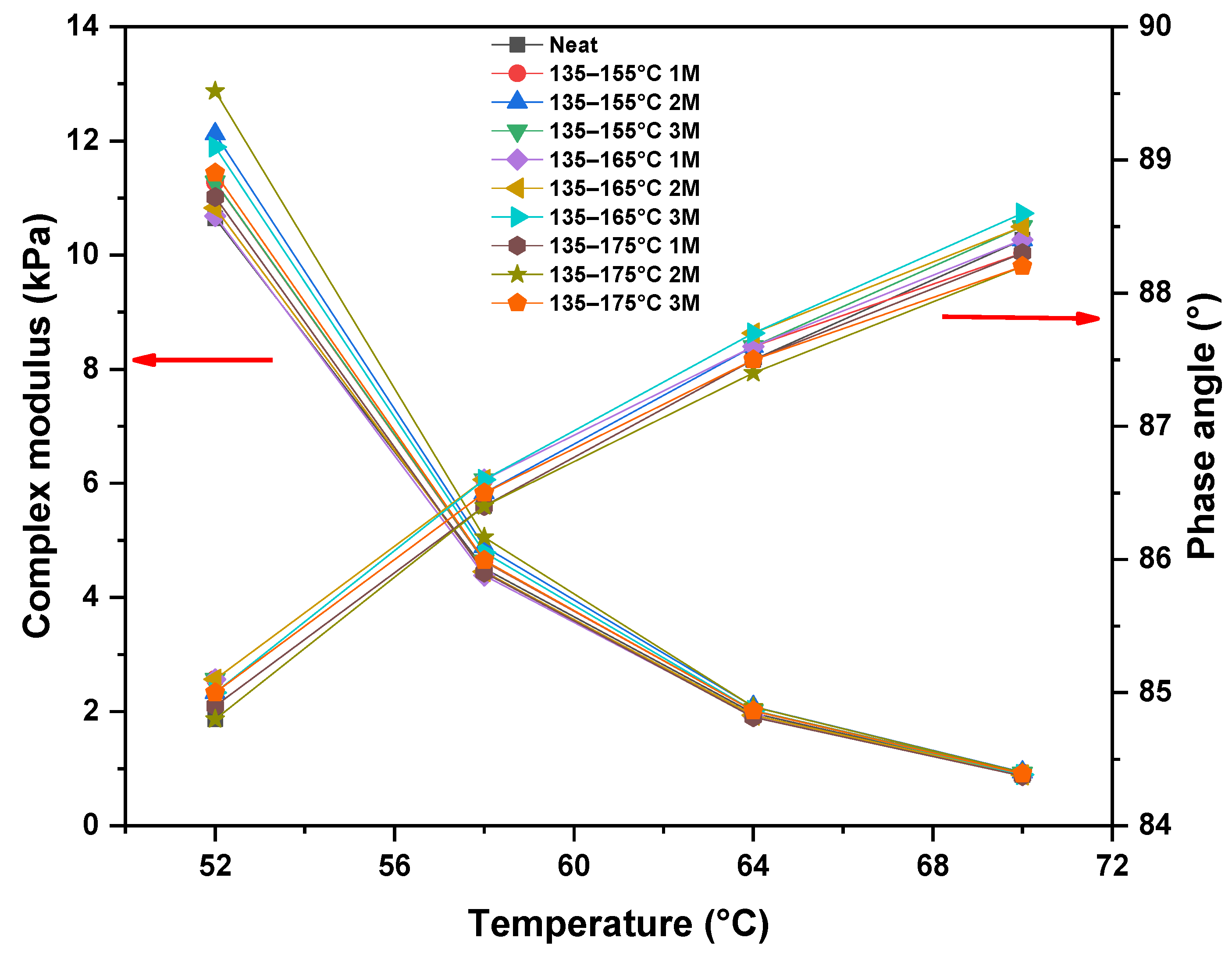

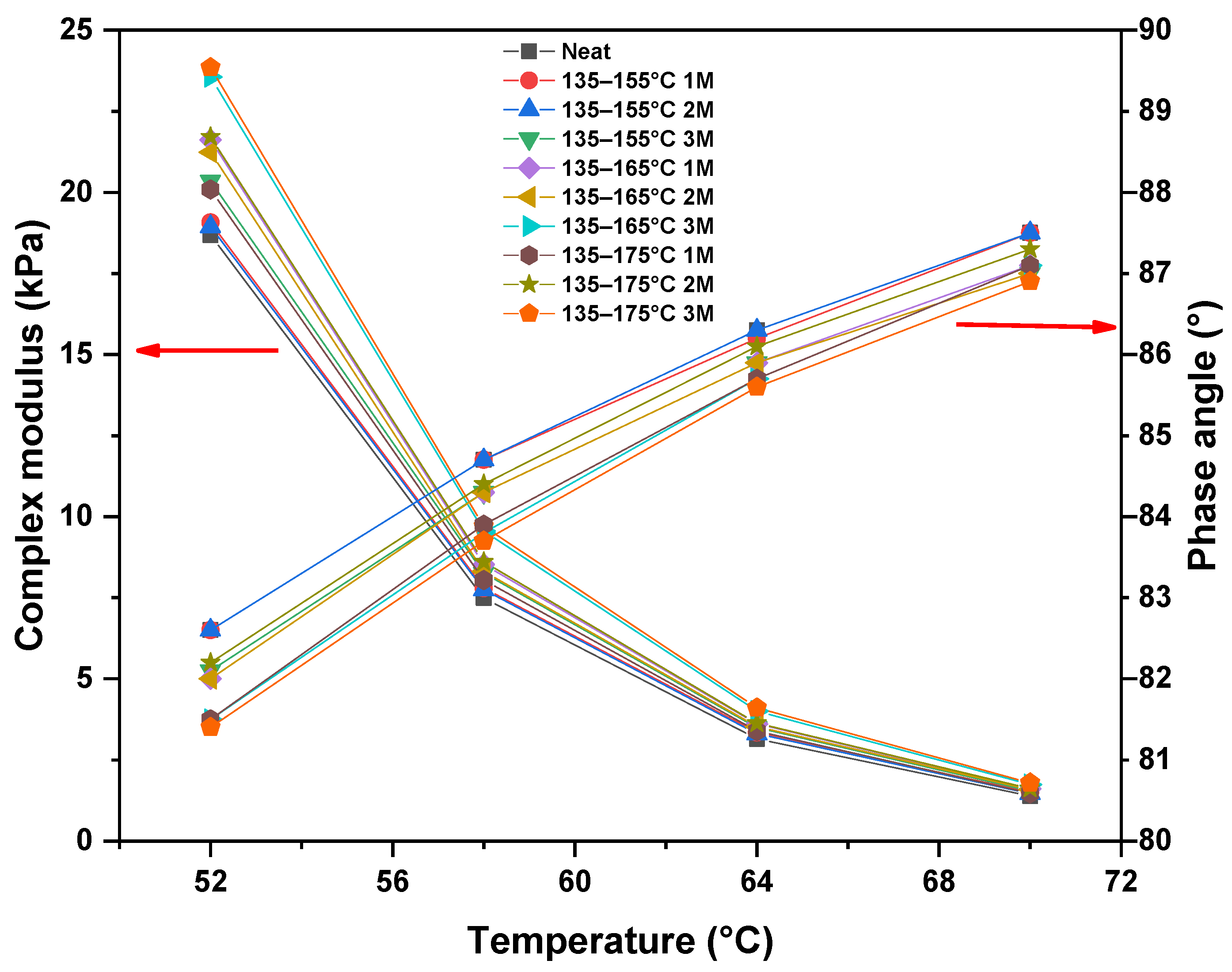

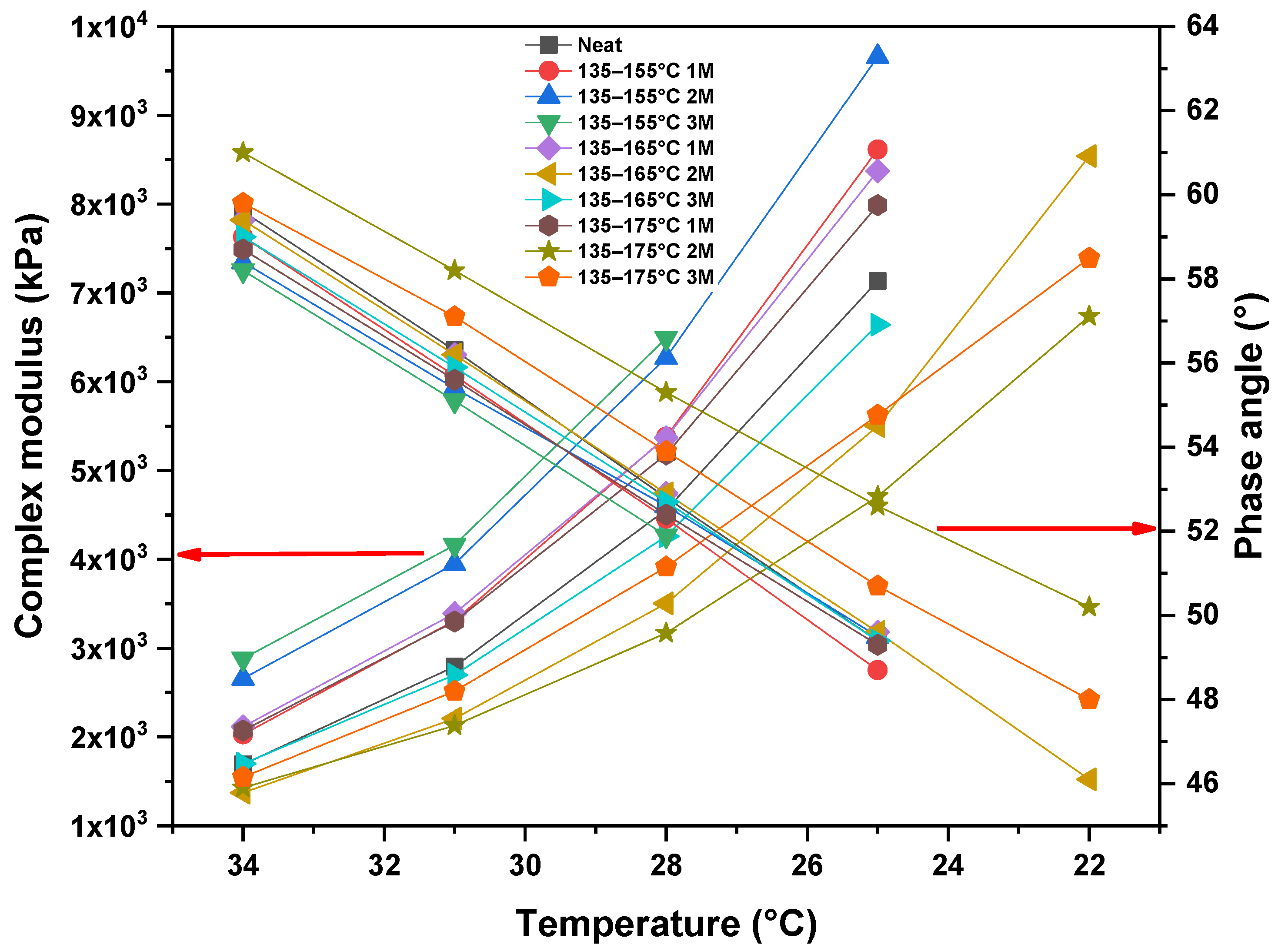

3.5.1. Complex Modulus and Phase Angle

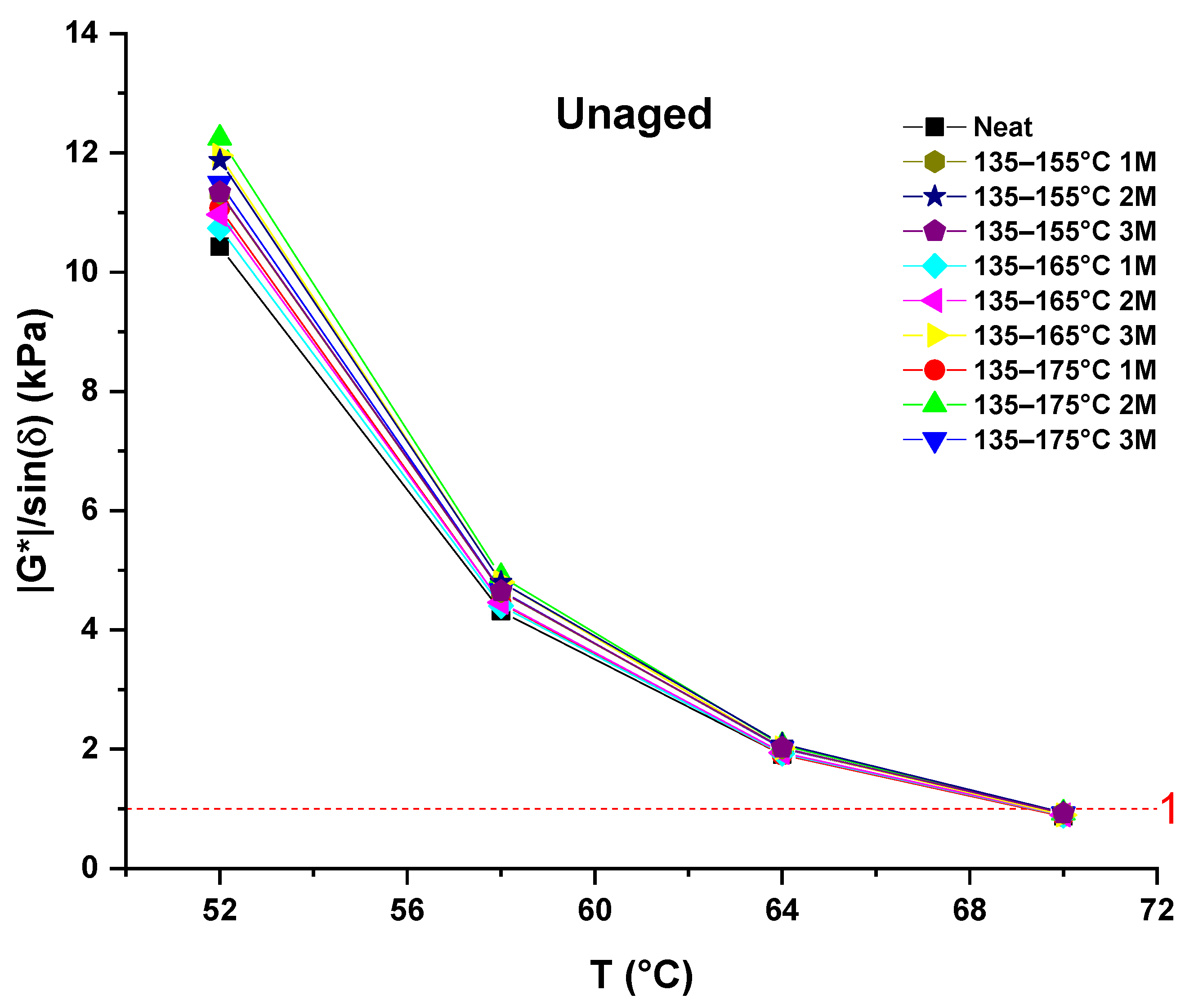

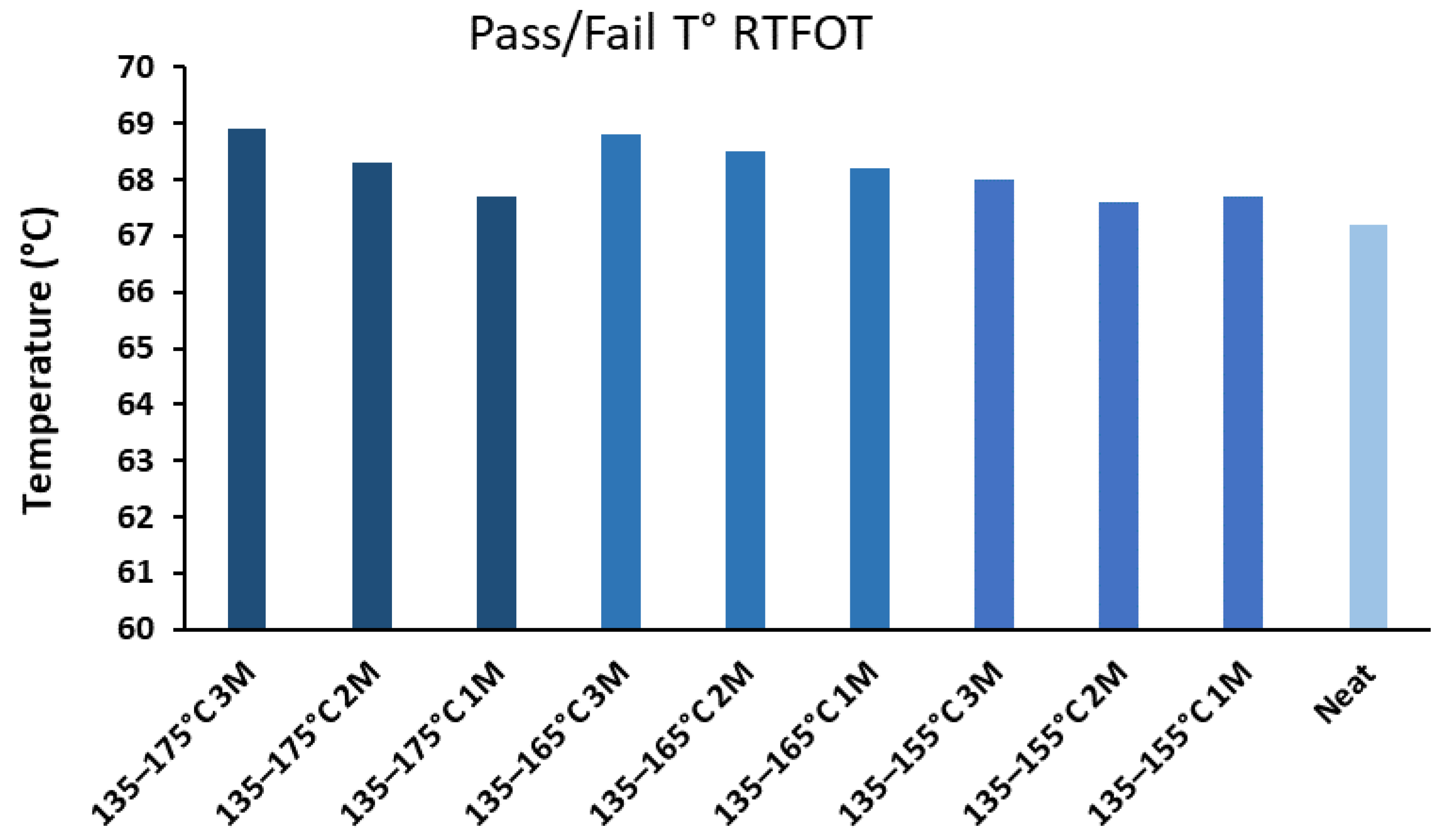

3.5.2. Rutting Factor

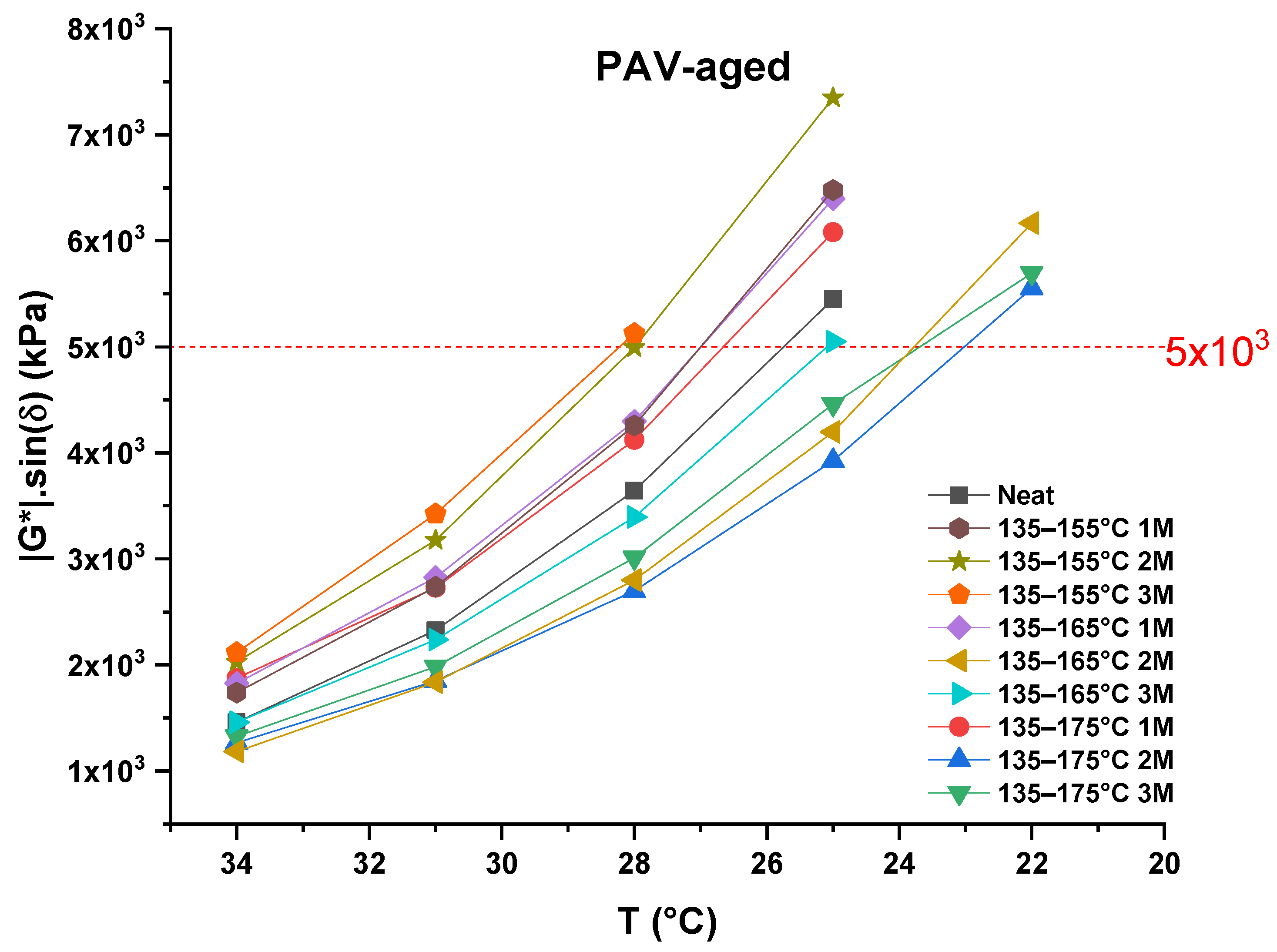

3.5.3. Fatigue Cracking Factor

4. Conclusions

- The FTIR results showed that the higher the storage temperature and the longer the storage duration, the greater the occurrence of oxidation.

- The DSR results showed that thermal fluctuations improved bitumen’s rutting resistance and fatigue cracking resistance. In addition, we found that storing 35/50 bitumen for one month at any tested temperature range (135–155 °C, 135–165 °C, or 135–175 °C) resulted in the same rheological performance in the long term. Moreover, longer storage periods led to more viscous behavior after long-term aging.

- We reached the following conclusions:

- The temperature fluctuations during bitumen heating have a positive impact on the rheological properties of 35/50 bitumen. This could be because the binder stays at lower temperatures most of the time (down to 135 °C) instead of being stored at a high temperature during the whole storage duration.

- However, high storage temperatures (>165 °C) with long storage periods augment the risk of oxidation. Hence, we recommend limiting the storage duration to a maximum of two months for storage temperatures lower than 165 °C and a maximum of one month for storage temperatures higher than 165 °C.

- Consequently, solar energy usage to maintain bitumen storage heat has proved to be a promising solution, resulting in impressive economic and environmental gains without compromising the quality of the stored binder.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

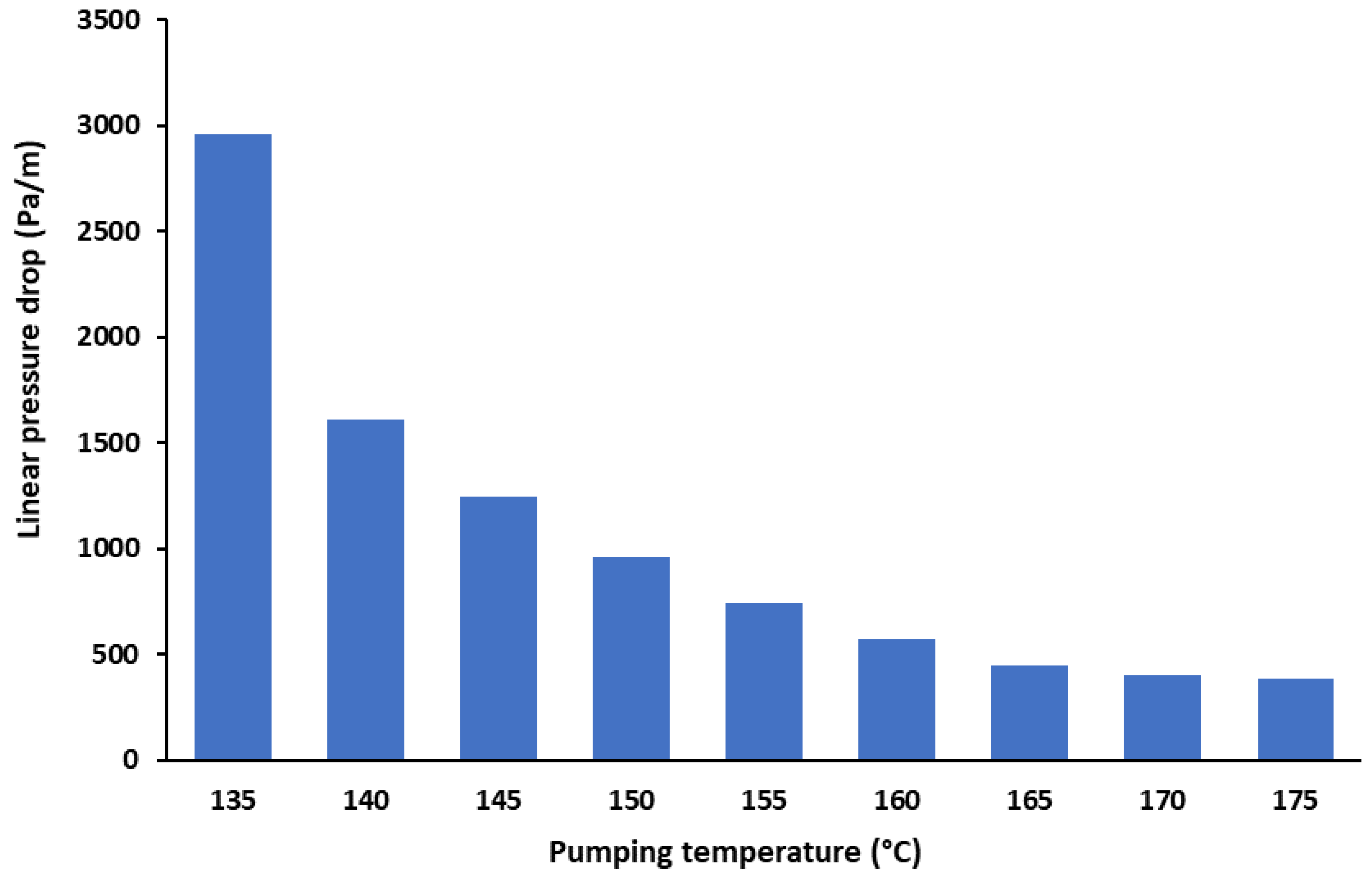

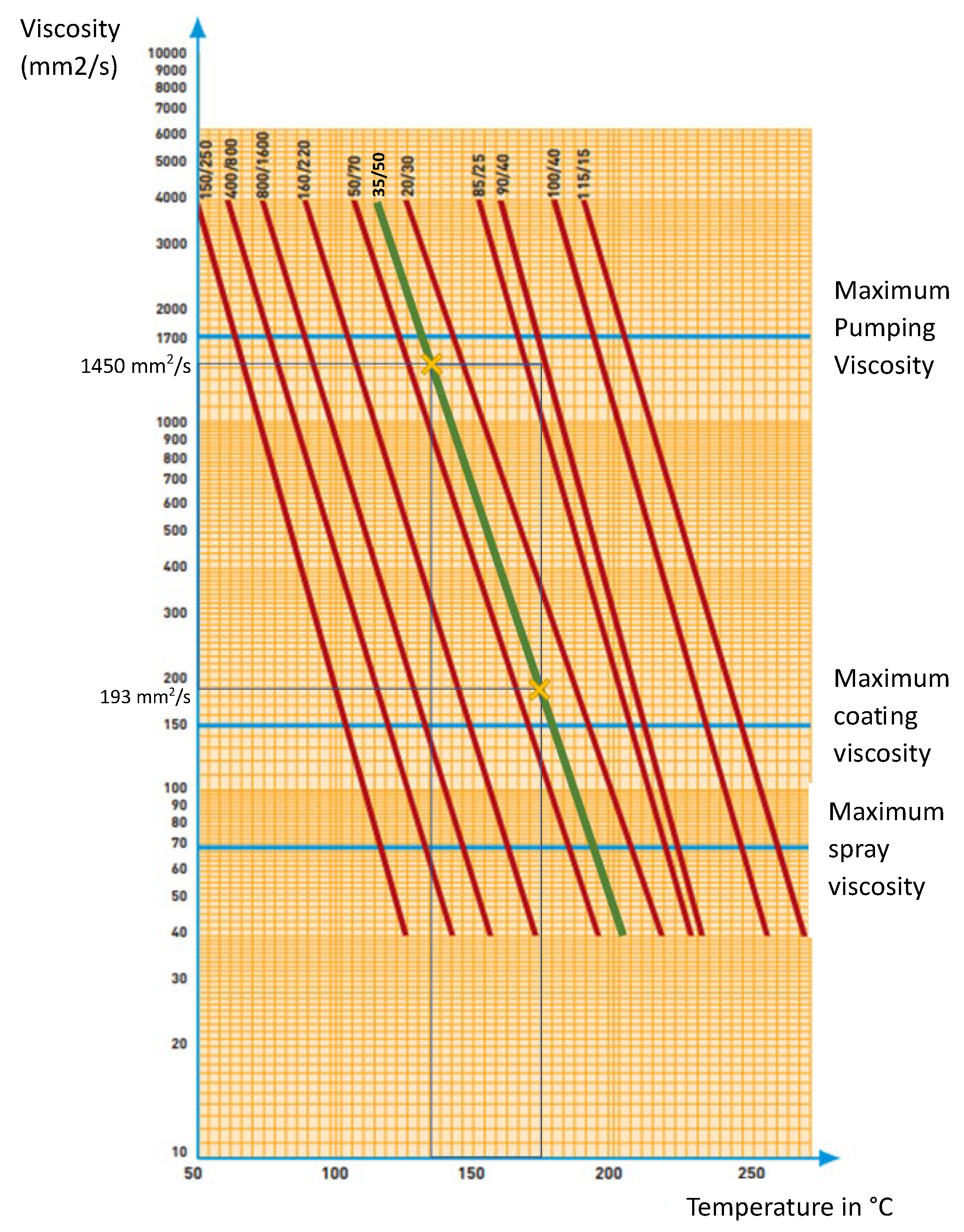

Impact of Bitumen Viscosity on the Pumping Power

- 𝜌x: density at application temperature X;

- 𝜌15: density at 15 °C in g/cm3;

- Δt: temperature difference (X-15), X ∈ (15,16…200).

- ρ is the density of the fluid (SI units: kg/m3);

- U is the flow speed (m/s);

- D is a characteristic linear dimension (m);

- μ is the dynamic viscosity of the fluid (Pa·s).

- is the linear pressure drop in Pa/m;

- is the head loss factor;

- is the internal diameter of the pipe in m;

- is the volume kinetic energy of the flow in Pa.

References

- Apeaning, R.W. Energy Efficiency and Management in Industries—A Case Study of Ghana’s Largest Industrial Area. Master’s Thesis, Linköping University, Linköping, Sweden, 2012. [Google Scholar]

- Turk, M. Substituting Natural Gas with Solar Energy in Industrial Heating Applications—A Multiple Case Study in Italy and Spain. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2021. [Google Scholar]

- Arachchige, U.; Wellwaththage, S.R.G. Solar Energy Technology. J. Res. Technol. Eng. 2020, 1, 67–75. [Google Scholar]

- Sing, C.K.L.; Lim, J.S.; Walmsley, T.G.; Liew, P.Y.; Goto, M.; Bin Shaikh Salim, S.A.Z. Time-Dependent Integration of Solar Thermal Technology in Industrial Processes. Sustainability 2020, 12, 2322. [Google Scholar] [CrossRef]

- Zahraoui, Y.; Basir Khan, M.R.; AlHamrouni, I.; Mekhilef, S.; Ahmed, M. Current Status, Scenario, and Prospective of Renewable Energy in Algeria: A Review. Energies 2021, 14, 2354. [Google Scholar] [CrossRef]

- IRENA Coalition for Action. Companies in Transition towards 100% Renewables: Focus on Heating and Cooling; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Shah, H. Integration of Solar Thermal Collectors in the Dairy Industry: A Techno-Economic Assessment. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2021. [Google Scholar]

- Fragnito, A.; Bianco, N.; Iasiello, M.; Mauro, G.M.; Mongibello, L. Experimental and numerical analysis of a phase change material-based shell-and-tube heat exchanger for cold thermal energy storage. J. Energy Storage 2022, 56, 105975. [Google Scholar] [CrossRef]

- Liu, C.; Yang, H. Multi-objective optimization of a concrete thermal energy storage system based on response surface methodology. Appl. Therm. Eng. 2022, 202, 117847. [Google Scholar] [CrossRef]

- Boquera, L.; Castro, J.R.; Pisello, A.L.; Fabiani, C.; D’Alessandro, A.; Ubertini, F.; Cabeza, L.F. Thermo-mechanical stability of supplementary cementitious materials in cement paste to be incorporated in concrete as thermal energy storage material at high temperatures. J. Energy Storage 2022, 54, 105370. [Google Scholar] [CrossRef]

- Kempener, R. Solar Heat for Industrial Processes. IEA-ETSAP and IRENA Technology Brief E21. 2015. Available online: etsap.org/web/Supply.asp,www.irena.org/Publications (accessed on 1 December 2022).

- Gosselar, J.; Johnson, M. Solar Thermal Energy for Industrial Uses, Issue Brief. Environmental and Energy Study Institute. 2011. Available online: www.eesi.org (accessed on 1 December 2022).

- Akar, S.; Kurup, P.; McTigue, J.; Boyd, M. Renewable Thermal Hybridization Framework for Industrial Process Heat Applications. In Proceedings of the 26th Annual SolarPACES Conference, Online, 28 September–2 October 2020. [Google Scholar]

- Schweiger, H.; Mendes, J.F.; Benz, N.; Hennecke, K.; Prieto, G.; Cusi, M.; Goncalves, H. The Potential of Solar Heat in Industrial Processes. A State of the Art Review for Spain and Portugal. In Proceedings of the EuroSun, Copenhagen, Denmark, 19–20 June 2000. [Google Scholar]

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Potential of Solar Energy Utilization for Process Heating in Paper Industry in India: A Preliminary Assessment; Energy Procedia. In Proceedings of the International Conference on Alternative Energy in Developing Countries and Emerging Economies, Bangkok, Thailand, 28–29 May 2015. [Google Scholar]

- Al-Hasnawi, H. Solar Heat in Industrial Processes—Integration of Parabolic Trough Solar Collectors in Dairy Plants and Pharmaceutical Plants. Master’s Thesis, Umeå University, Umeå, Sweden, 2016. [Google Scholar]

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Potential of Solar Industrial Process Heating in Dairy Industry in India and Consequent Carbon Mitigation. J. Clean. Prod. 2017, 140, 714–724. [Google Scholar] [CrossRef]

- Allouhi, A.; Agrouaz, Y.; Amine, M.B.; Rehman, S.; Buker, M.S.; Kousksou, T.; Jamil, A.; Benbassou, A. Design optimization of a multi-temperature solar thermal heating system for an industrial process. Appl. Energy 2017, 206, 382–392. [Google Scholar] [CrossRef]

- Korkua, S.K.; Khongtong, S.; Ray, P.K.; Thinsurat, K. Cleaner Potential for Natural Rubber Drying Process Using Microwave Technology Powered by Solar Energy. Energies 2022, 15, 6564. [Google Scholar] [CrossRef]

- Pérez, C.; Ponce, P.; Meier, A.; Dorantes, L.; Sandoval, J.O.; Palma, J.; Molina, A. S4 Framework for the Integration of Solar Energy Systems in Small and Medium-Sized Manufacturing Companies in Mexico. Energies 2022, 15, 6882. [Google Scholar] [CrossRef]

- Ahmed, J.; Kumar, L.; Abbasi, A.F.; El Haj Assad, M. Energy, Exergy, Environmental and Economic Analysis (4e) of a Solar Thermal System for Process Heating in Jamshoro, Pakistan. Energies 2022, 15, 8617. [Google Scholar] [CrossRef]

- ESTIF. Solar Industrial Process Heat—State of the Art, Key Issues for Renewable Heat in Europe; ESTIF: Brussels, Belgium, 2006. [Google Scholar]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Saidur, R. Solar process heat in industrial systems—A global review. Renew. Sustain. Energy Rev. 2018, 82, 2270–2286. [Google Scholar] [CrossRef]

- Ramaiah, R.; Shekar, K.S.S. Solar Thermal Energy Utilization for Medium Temperature Industrial Process Heat Applications—A Review. In Proceedings of the International Conference on Advances in Manufacturing, Karnataka, India, 2–3 March 2018; IOP Conference Series: Materials, Science, and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 376, p. 012035. [Google Scholar] [CrossRef]

- Luminosu, I.; Fara, L. Experimental research on bitumen preheating (fluidization) by using solar energy in passive mode. Int. J. Therm. Sci. 2009, 48, 209–217. [Google Scholar] [CrossRef]

- Luminosu, I.V.; De Sabata, C.T.; De Sabata, A.I. Solar Energy Based Industrial Applications at the “Politehnica” University of Timisoara. Thermal Sci. 2011, 15, 587–598. [Google Scholar] [CrossRef]

- Benvenuti, C.; Maranzana, M.; Pauletta, S. Bitumen Heating up to 180 °C by the SRB Solar Panel. In Proceedings of the 23rd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Lausanne, Switzerland, 14–17 June 2010; Favrat, D., Maréchal, F., Eds.; CreateSpace: Scotts Valley, CA, USA, 2011. [Google Scholar]

- Ship Plants. Available online: http://ship-plants.info/solar-thermal-plants (accessed on 1 December 2022).

- Ghazouani, M.; Bouya, M.; Benaissa, M.; Anoune, K.; Ghazi, M. Thermal energy management optimization of solar thermal energy system based on small parabolic trough collectors for bitumen maintaining on heat process. Sol. Energy 2020, 211, 1403–1421. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Alhasssan, H. Impact of Climate Change on Rheological Properties of Bitumen. Open J. Civ. Eng. 2020, 10, 93–104. [Google Scholar] [CrossRef][Green Version]

- Brown, S.F. Creep of Bituminous Aggregates. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 1795–1796. [Google Scholar] [CrossRef]

- Merbouh, M. Effect of thermal cycling on the creep-recovery behavior of road bitumen. Energy Procedia 2012, 18, 1106–1114. [Google Scholar] [CrossRef]

- Glaoui, B.; Merbouh, M.; Ven, M.; Chialleux, E.; Youcefi, A. How Thermal Fatigue Cycles Change the Rheological Behavior of Polymer-Modified Bitumen. Energy Procedia 2013, 36, 844–851, In Proceedings of the TerraGreen 13 International Conference 2013—Advancements in Renewable Energy and Clean Envi-ronment, Beirut, Lebanon, 15–17 February 2013. [Google Scholar] [CrossRef]

- Tahri, A.; Bouya, M.; Ghazouani, M.; Achak, O.; Chafik, T. Methodology for Efficient Bitumen Storage with Reduced Energy Consumption. Appl. Sci. 2021, 11, 9319. [Google Scholar] [CrossRef]

- Ghazouani, M.; Bouya, M.; Benaissa, M. Thermo-Economic and Exergy Analysis and Optimization of Small PTC Collectors for Solar Heat Integration in Industrial Processes. Renew. Energy 2020, 152, 984–998. [Google Scholar] [CrossRef]

- Articsolar. Available online: https://articsolar.com (accessed on 1 December 2022).

- Weather Spark. Available online: https://fr.weatherspark.com (accessed on 1 December 2022).

- Lombardi, B.; Kazziha, S. Bitume.Info: Aménager, Construire, Innover; Special Issue-1; Groupement Professionnel des Bitumes (GPB): Paris, France, 2005; p. 33. [Google Scholar]

- Błażejowski, K.; Olszacki, J.; Peciakowski, H. Bitumen Handbook, 6th ed.; ORLEN Asfalt: Płock, Poland, 2014. [Google Scholar]

- EN 12607-1:2014; Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under the Influence of Heat and Air. European Committee for Standardization: Brussels, Belgium, 2014. Available online: https://standards.iteh.ai/catalog/standards/cen/5e1f0c0a-99bc-4c99-a191-cf07c1482527/en-12607-1-2014 (accessed on 1 December 2022).

- EN 14769:2013; Bitumen and Bituminous Binders—Accelerated Long-Term Ageing Simulated by a Pressure Ageing Vessel (PAV), AFNOR, France. European Committee for Standardization: Brussels, Belgium, 2013. Available online: https://infostore.saiglobal.com/en-au/standards/nf-en-14769-2013-36667_saig_afnor_afnor_82014/ (accessed on 1 December 2022).

- EN 1426:2015; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization: Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/853455a7-1455-4f3e-a2b8-60d17bfdf3df/en-1426-2015 (accessed on 1 December 2022).

- EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point. Ring and Ball Method. European Committee for Standardization: Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/0edd2612-e3e1-43b4-b533-8debe5c55040/en-1427-2015 (accessed on 1 December 2022).

- Petersen, J.C.; Glacer, R. Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater. Pavement Des. 2011, 12, 795–819. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. AASHTO T 315. Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012. [Google Scholar]

- Anoune, K.; Laknizi, A.; Bouya, M.; Astito, A.; Ben Abdellah, A. Sizing a PV-Wind hybrid system using deterministic approach. Energy Convers. Manag. 2018, 169, 137–148. [Google Scholar] [CrossRef]

- Institut Français des Sciences et Techniques des Réseaux, de l’Aménagement et des Transports (IFSTTAR). French MLPC Method, No. 69 for Binders: Identification et Dosage des Fonctions Oxygénées Présentes dans les Liants Bitumineux—Analyse par Spectrométrie Infrarouge à Transformée de Fourier. 2010. Available online: https://www.ifsttar.fr/fileadmin/user_upload/editions/lcpc/MethodeDEssai/MethodeDEssai-LCPC-ME69.pdf (accessed on 1 December 2022).

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, J.; Qu, X.; Wang, C.; Oeser, M. Investigation of Bitumen Rheological Properties Measured at Different Rheometer Gap Sizes. Constr. Build. Mater. 2020, 265, 120287. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Omairey, E.L.; Al-Malaika, S.; Sheena, H. Influence of Anti-ageing Compounds on Rheological Properties of Bitumen. J. Clean. Prod. 2021, 318, 128559. [Google Scholar] [CrossRef]

- Wang, C.; Wang, P.; Li, Y.; Zhao, Y. Laboratory Investigation of Dynamic Rheological Properties of Tourmaline Modified Bitumen. Constr. Build. Mater. 2015, 80, 195–199. [Google Scholar] [CrossRef]

- Liley, C. Rutting: Causes, Prevention, and Repairs; Illinois Asphalt Pavement Association: Springfield, IL, USA, 2018. [Google Scholar]

- Moe, A.L.; Lee, Y.P.K.; Ho, N.Y.; Wang, X. Rutting and Cracking Performance of Asphalt Concrete Incorporating Plastic Waste and Crumb Rubber. In Road and Airfield Pavement Technology. In Proceedings of the 12th International Conference on Road and Airfield Pavement Technology, Colombo, Sri Lanka, 14–16 July 2021. [Google Scholar] [CrossRef]

- Ge, D.; Chen, S.; You, Z.; Yang, X.; Yao, H.; Ye, M.; Yap, Y.K. Correlation of DSR Results and FTIR’s Carbonyl and Sulfoxide Indexes: Effect of Aging Temperature on Asphalt Rheology. J. Mater. Civ. Eng. 2019, 31, 04019115. [Google Scholar] [CrossRef]

- EN 15326:2007; Bituminous Binders—Measurement of Density and Specific Gravity Capillary-Stoppered Pyknometer Method. European Committee for Standardization: Brussels, Belgium, 2007.

| Temperature Range | ΔT a | Number of Cycles | ||

|---|---|---|---|---|

| One Month | Two Months | Three Months | ||

| 135–155 °C | 20 °C | 30 | 60 | 90 |

| 135–165 °C | 30 °C | 20 | 40 | 60 |

| 135–175 °C | 40 °C | 15 | 30 | 45 |

| Functional Group | Bond Vibration | Absorption Wave Number (cm−1) |

|---|---|---|

| Carbonyls | C=O stretching | 1740–1690 |

| Aliphatic structures (Methyl) | CH3 asymmetric bending | 1460 |

| Branched aliphatic structures (Methylene) | CH3 symmetric bending | 1375 |

| Sulfoxides | S=O stretching | 1055–1030 |

| Condition | Acceptable Range of Two Test Results (d2s%) |

|---|---|

| Original Binder: G*/sinδ (kPa) | 6.4 |

| RTFO Residue: G*/sinδ (kPa) | 9.0 |

| PAV Residue: G*·sinδ (kPa) | 13.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahri, A.; Bouya, M.; Ghazouani, M.; Achak, O.; Chafik, T.; Azdi, K.E.; Boughanbour, S. Impact of Solar Energy Integration on the Rheological and Chemical Properties of Bitumen. Energies 2023, 16, 14. https://doi.org/10.3390/en16010014

Tahri A, Bouya M, Ghazouani M, Achak O, Chafik T, Azdi KE, Boughanbour S. Impact of Solar Energy Integration on the Rheological and Chemical Properties of Bitumen. Energies. 2023; 16(1):14. https://doi.org/10.3390/en16010014

Chicago/Turabian StyleTahri, Amina, Mohsine Bouya, Mokhtar Ghazouani, Ouafae Achak, Tarik Chafik, Khalid El Azdi, and Sanae Boughanbour. 2023. "Impact of Solar Energy Integration on the Rheological and Chemical Properties of Bitumen" Energies 16, no. 1: 14. https://doi.org/10.3390/en16010014

APA StyleTahri, A., Bouya, M., Ghazouani, M., Achak, O., Chafik, T., Azdi, K. E., & Boughanbour, S. (2023). Impact of Solar Energy Integration on the Rheological and Chemical Properties of Bitumen. Energies, 16(1), 14. https://doi.org/10.3390/en16010014