Breakup Mechanism of a Jet in the L-Shape Crossflow of a Gas Turbine Combustor

Abstract

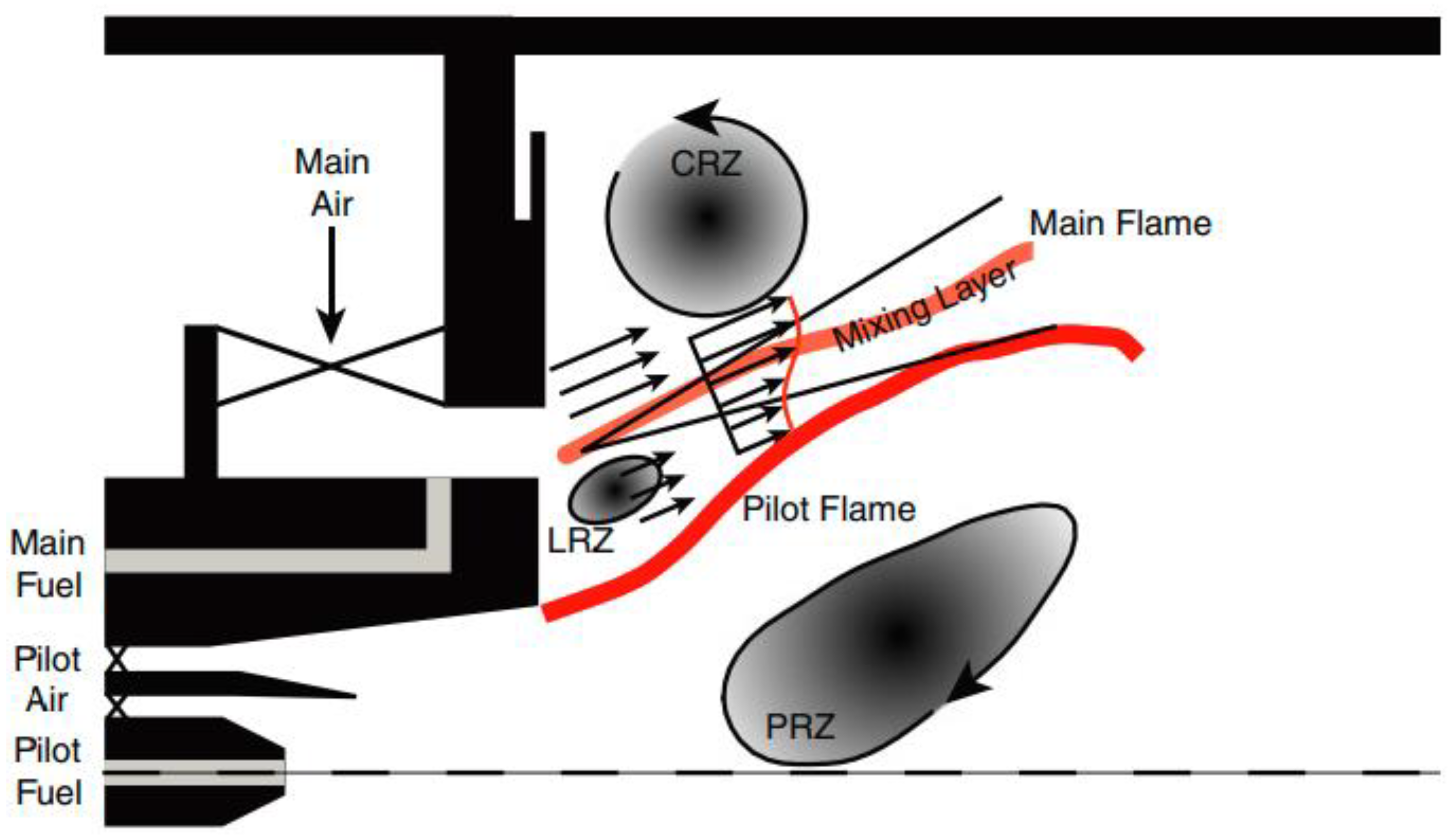

:1. Introduction

2. Setup and Methods

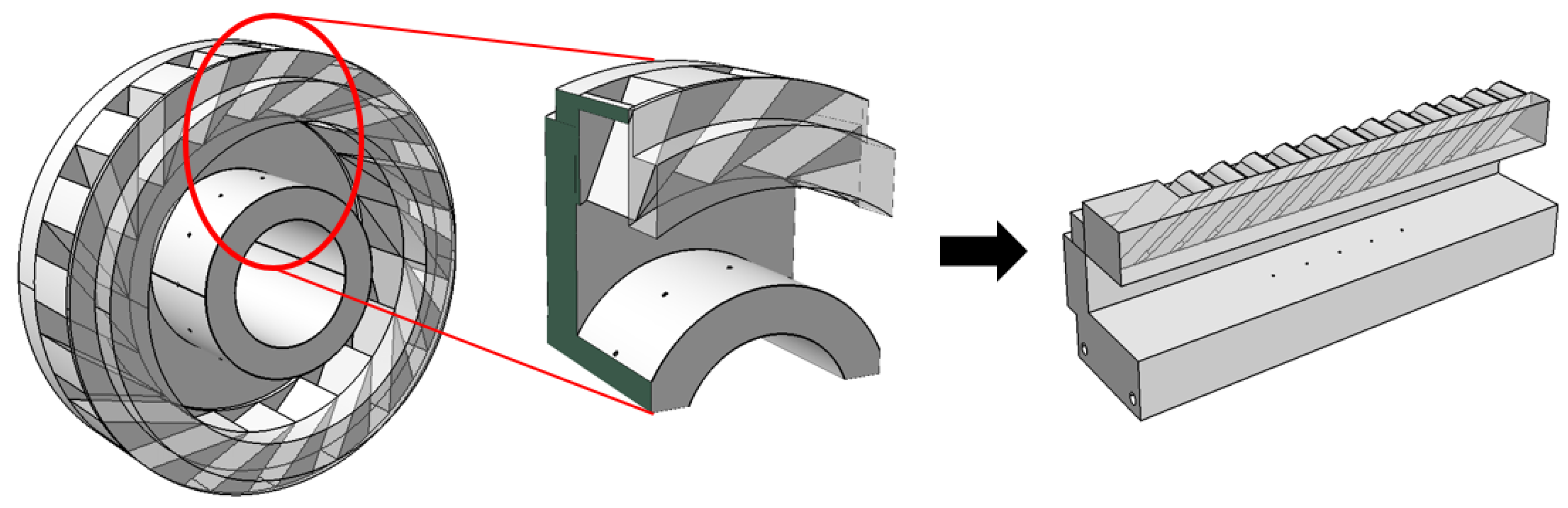

2.1. Design of L-Shape Channel

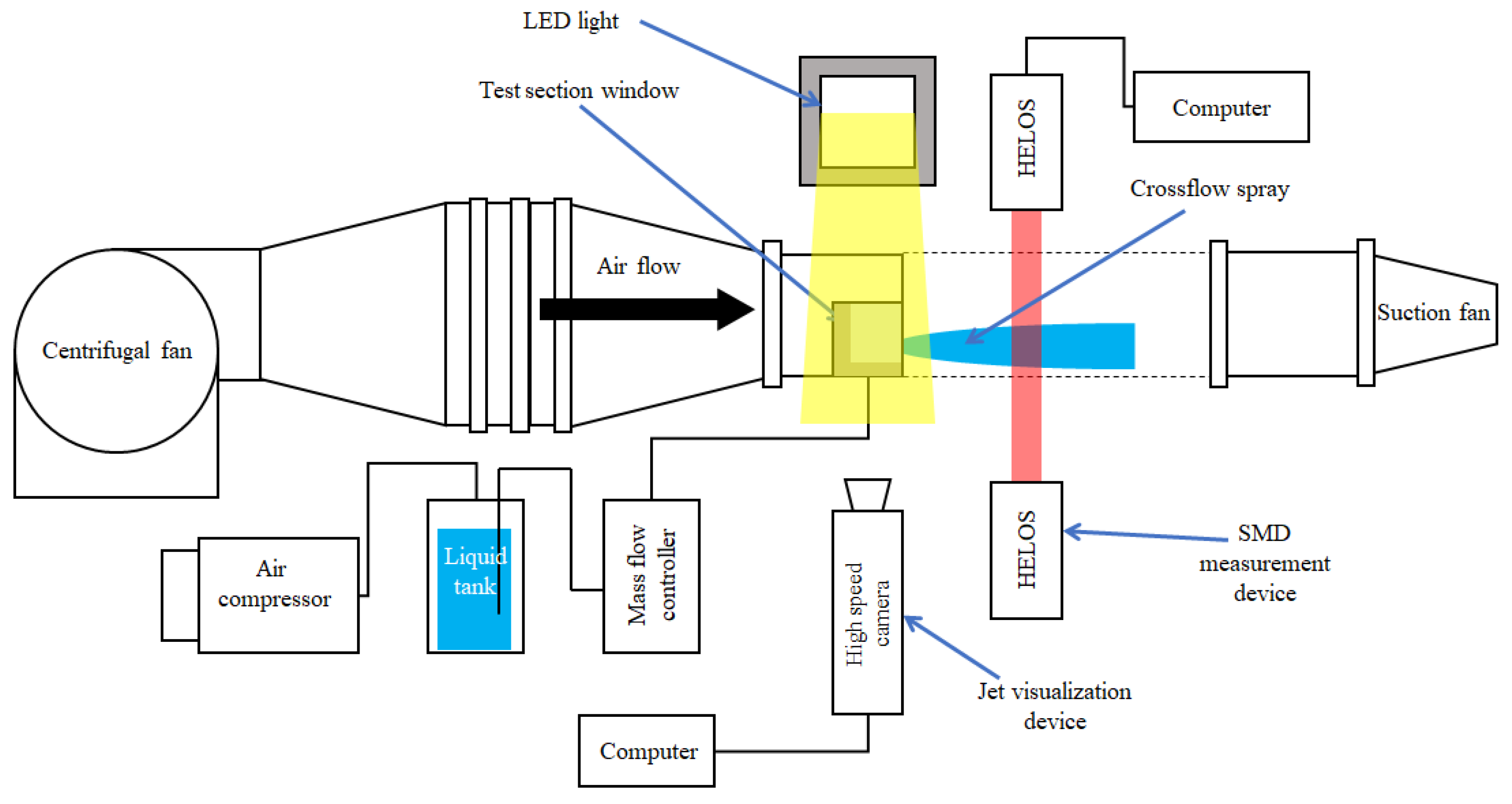

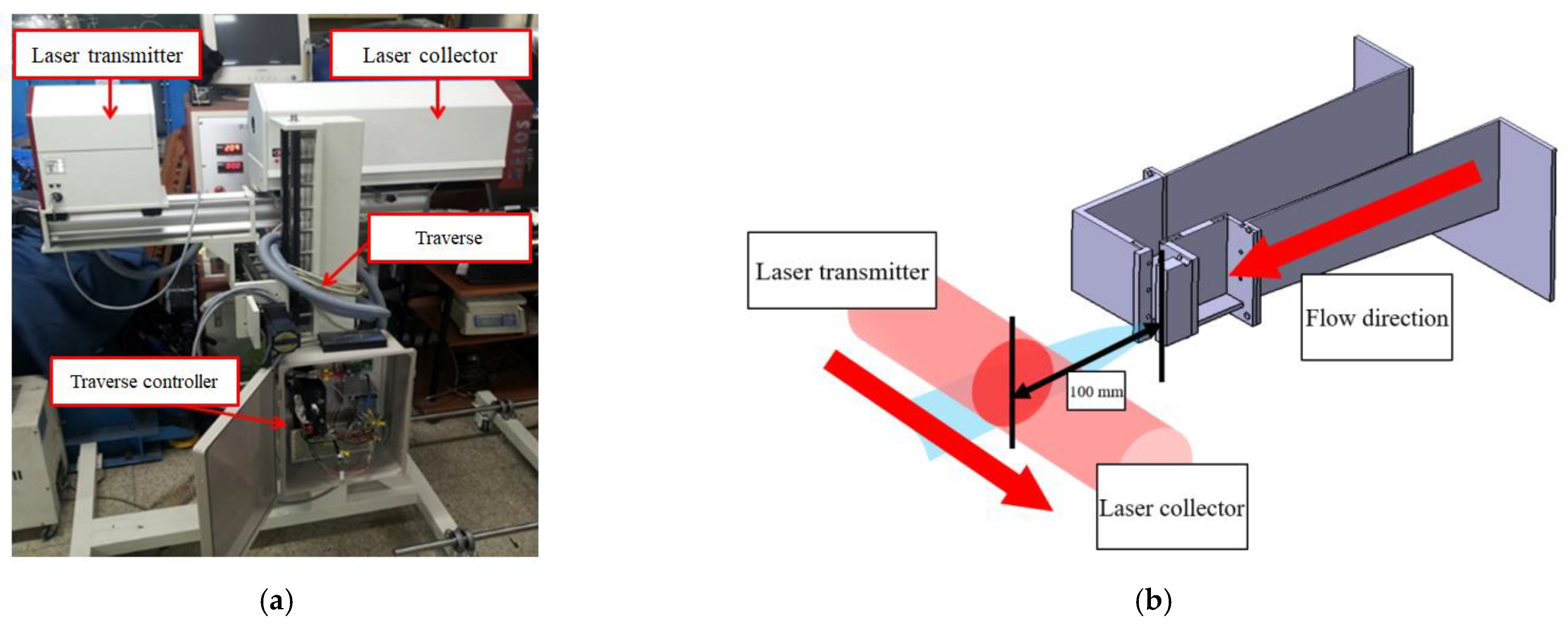

2.2. Experimental Setup

2.3. Non-Dimensional Parameters and Experimental Conditions

3. Results

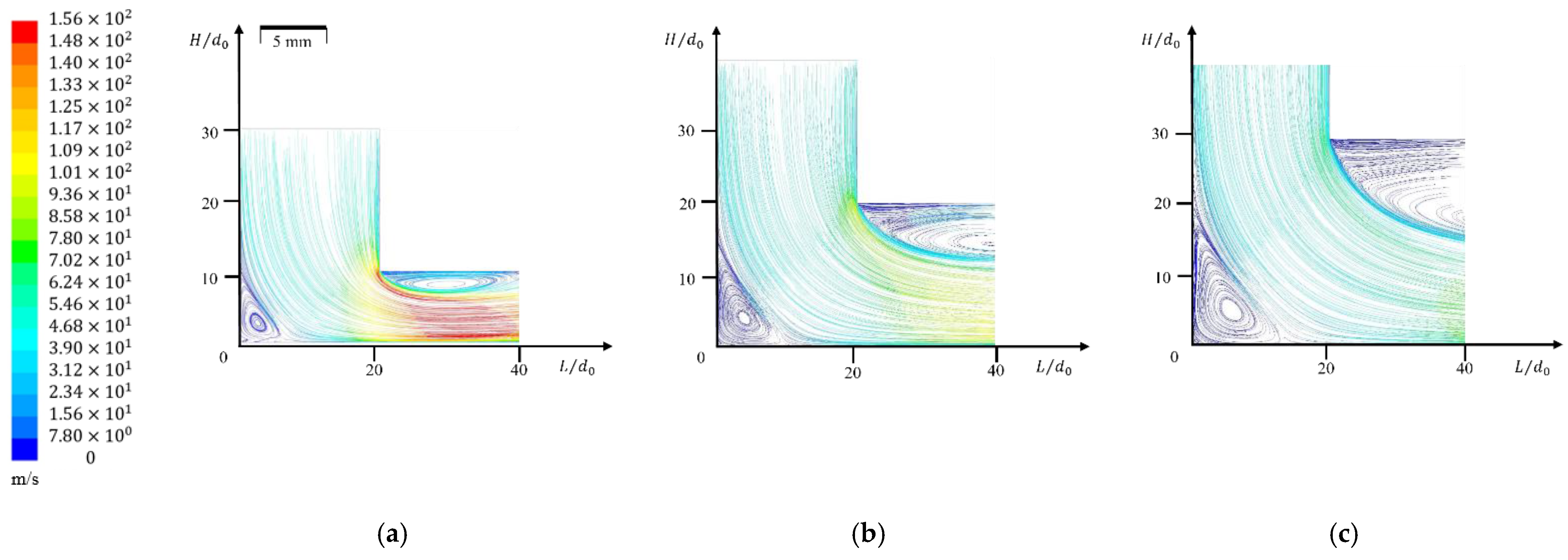

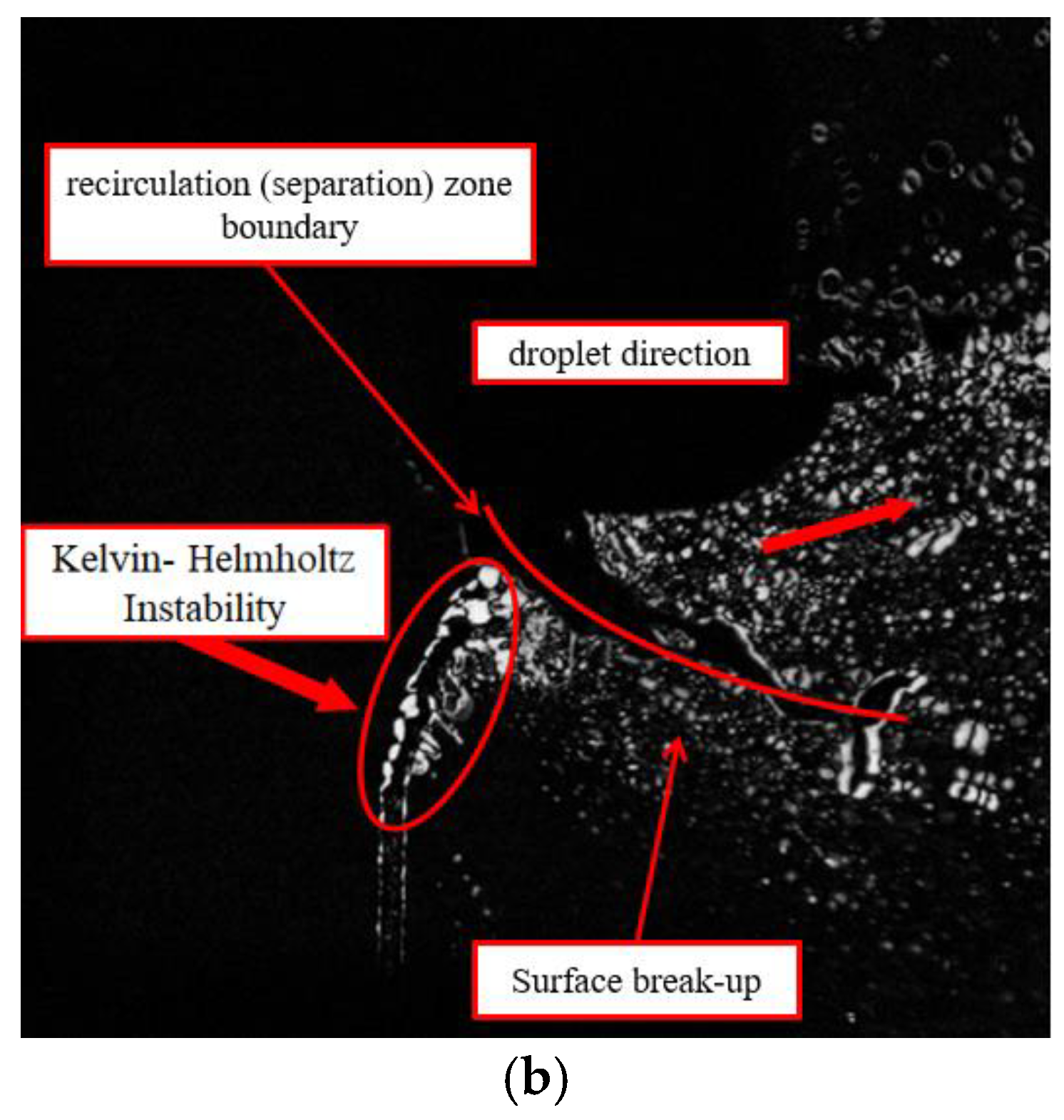

3.1. Flow Characteristics in the L-Shape Channel

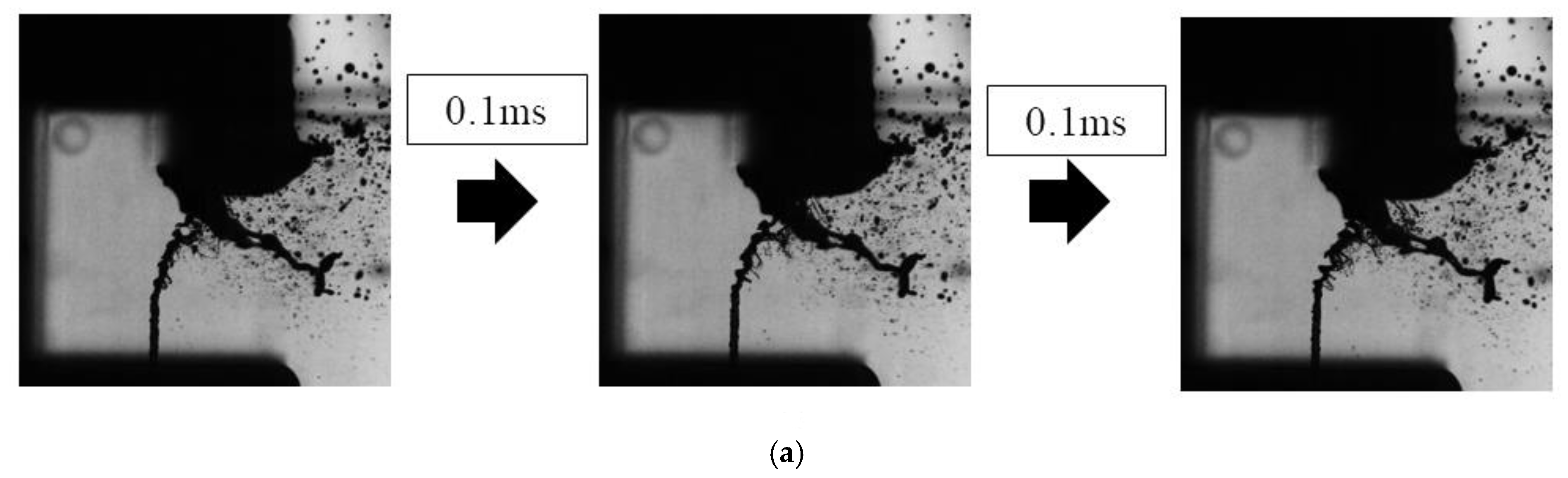

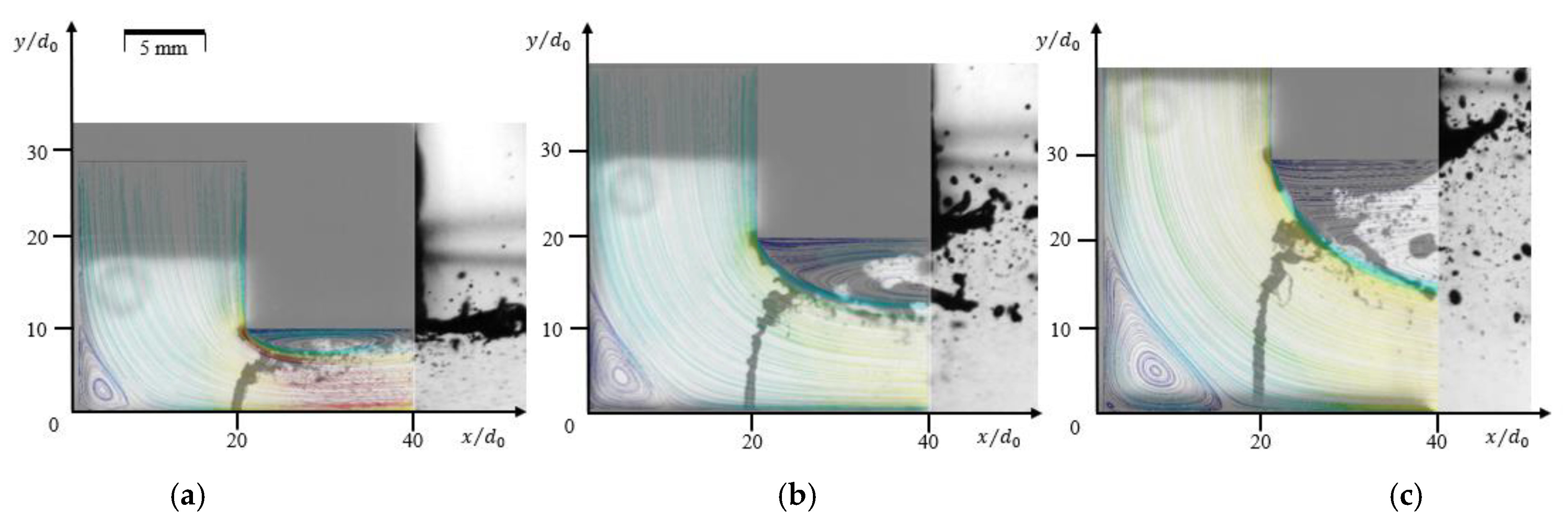

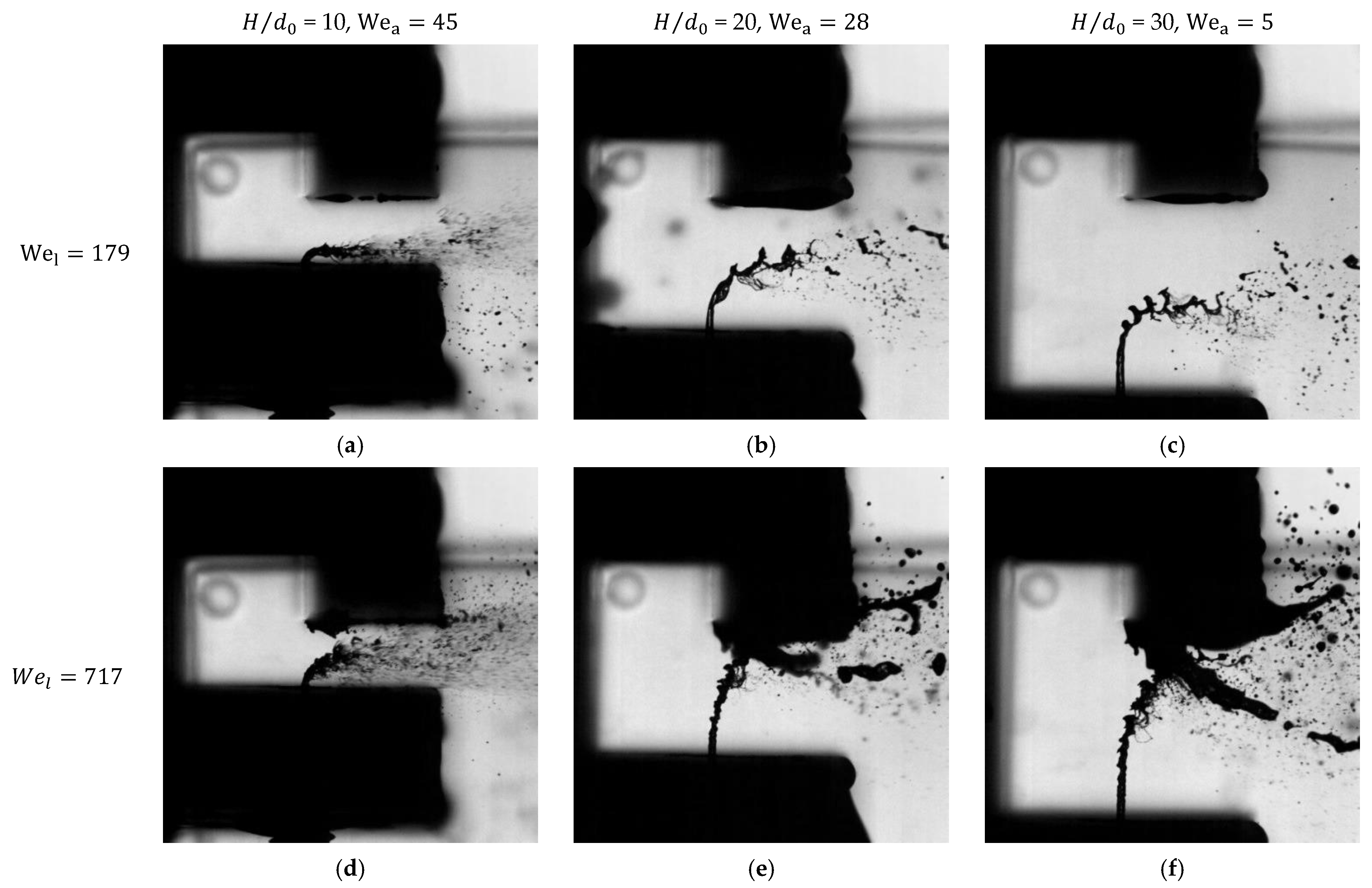

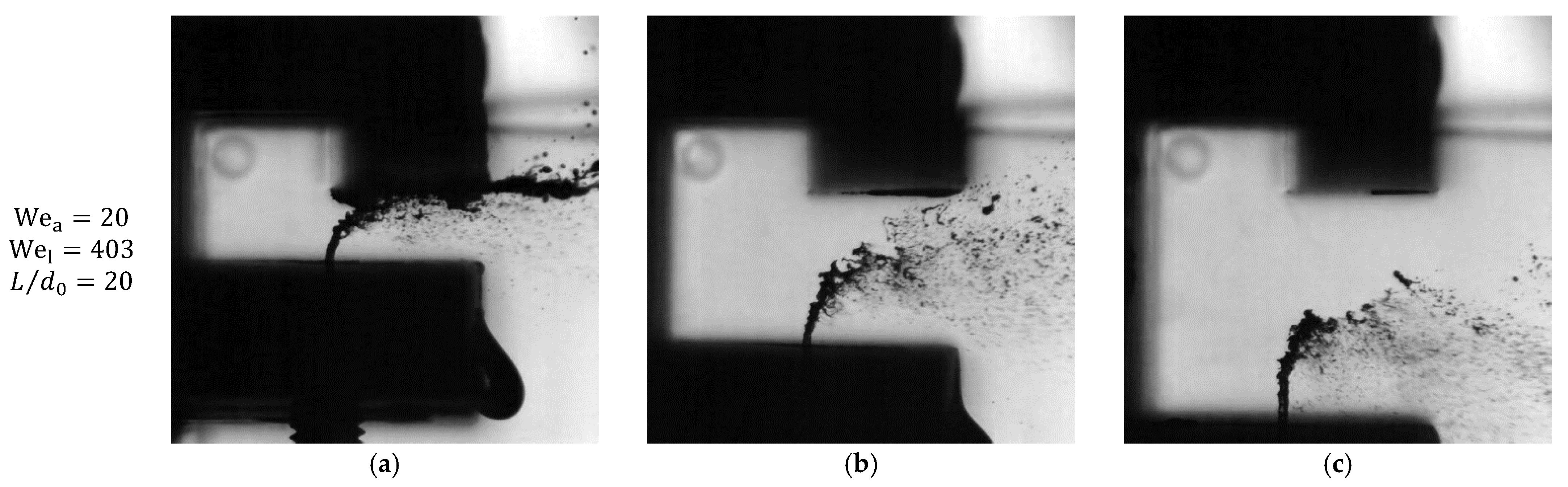

3.2. Macroscopic Jet Characteristics

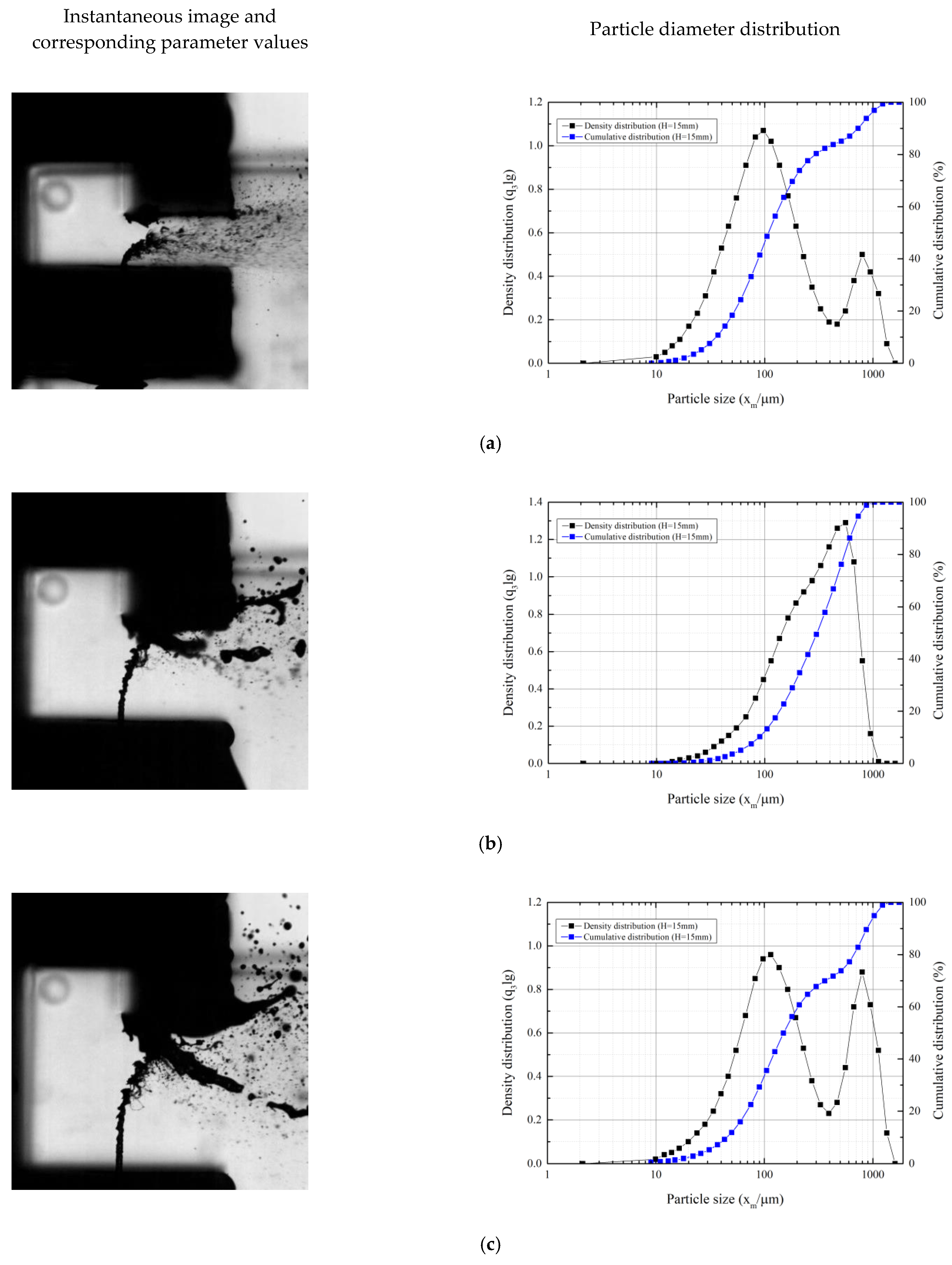

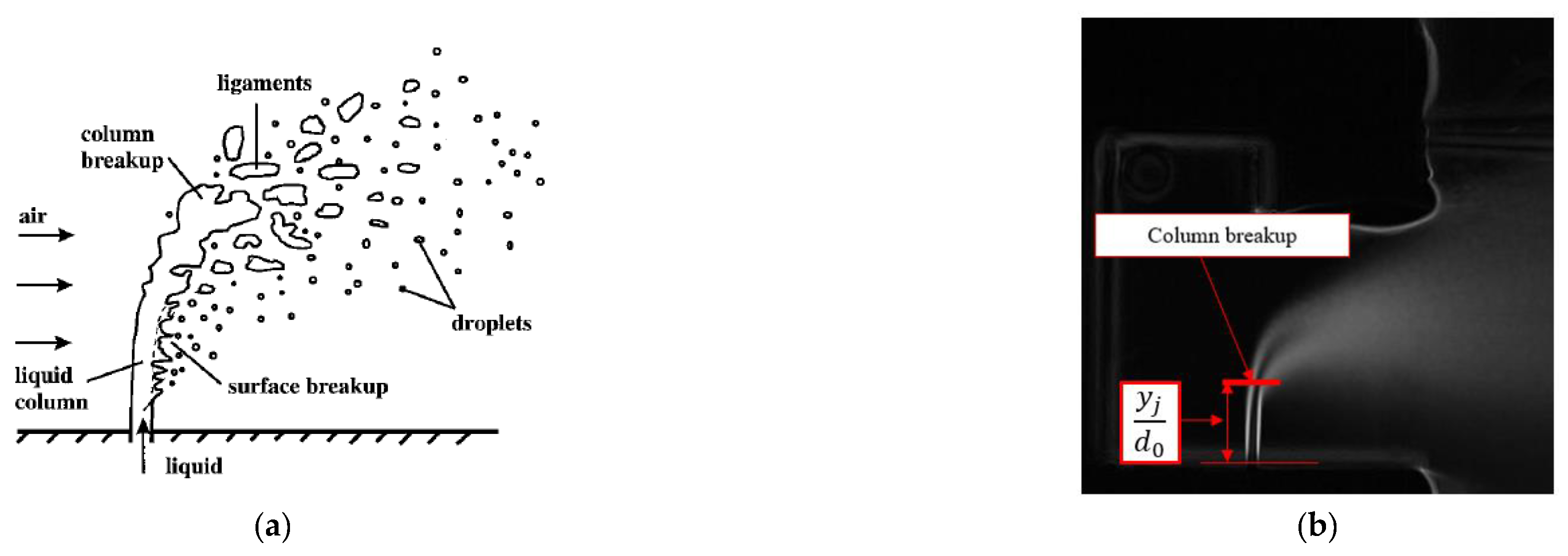

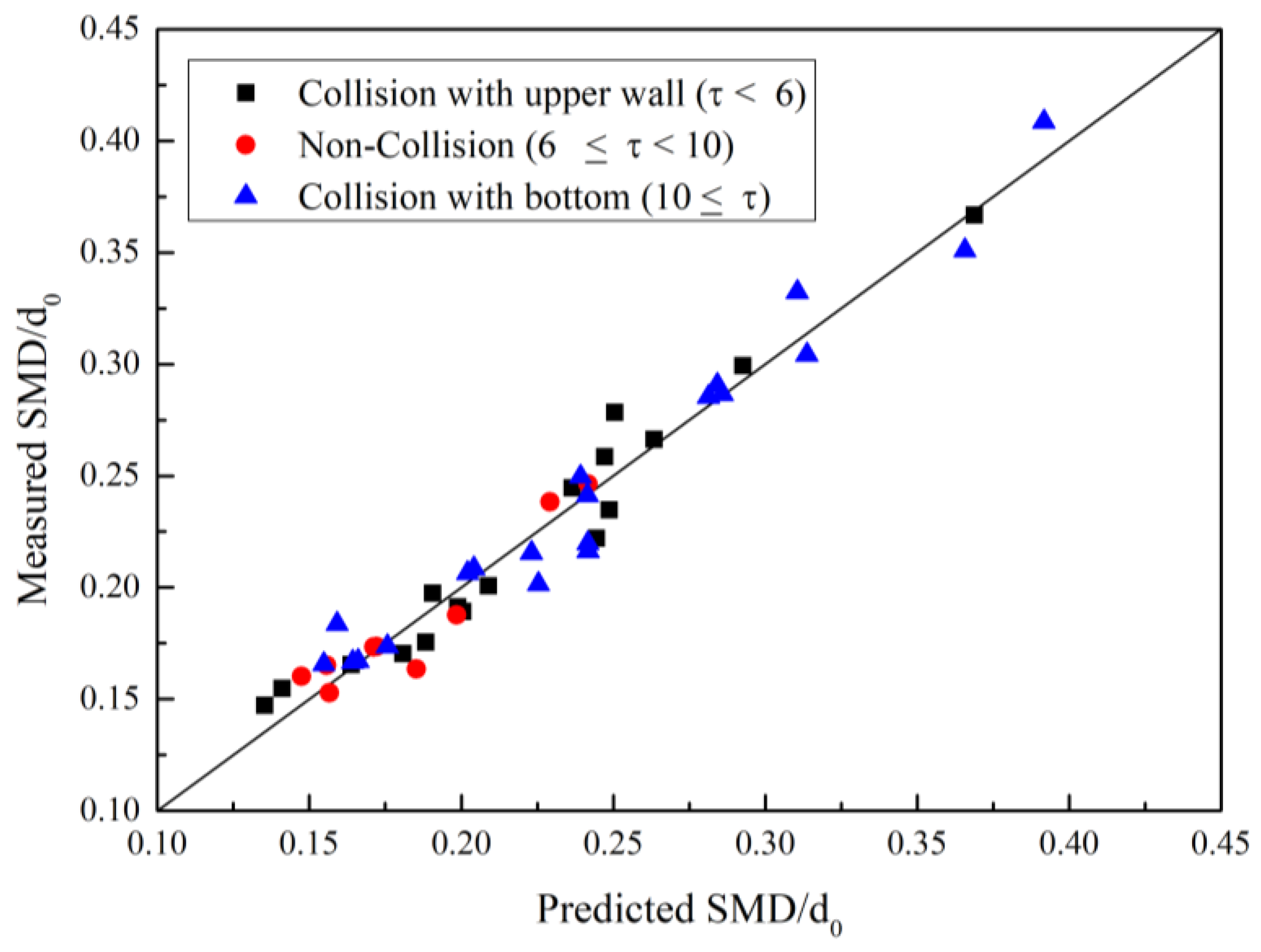

3.3. Effects of Jet Breakup Mechanism on Droplet Sizes

3.4. Generalization of Effects of Breakup Mechanisms on Atomization

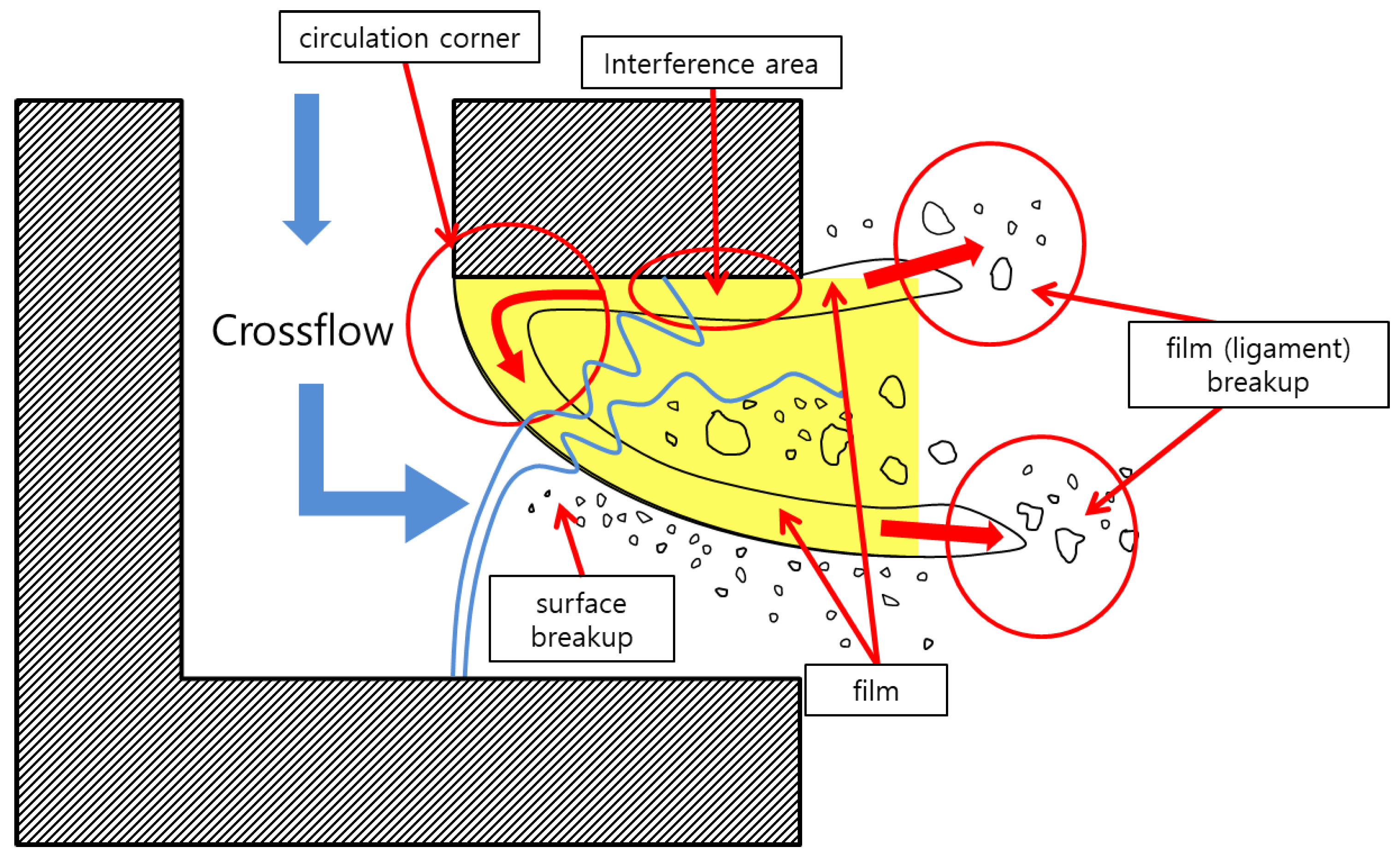

- (1)

- Mechanism 1: Collision with the upper wall,

- (2)

- Mechanism 2: JICF without collision,

- (3)

- Mechanism 3: Collision with the bottom wall,

4. Discussion and Conclusions

- (1)

- An L-shape channel was manufactured to simulate a JICF inside a radial swirler.

- (2)

- In the L-shape channel, the jet characteristics were determined by the dimensionless numbers We and Re, but in addition, the atomization characteristics changed via the geometric dimensionless variables and , and this affected the size of the separation area.

- (3)

- There were three types of jet breakup mechanisms inside the L-shape channel: (1) a general JICF mechanism, (2) jet collision via and , and (3) the formation of ligaments or a film via the jet collision, recirculation, and accumulation of droplets.

- (4)

- The new dimensionless number τ was introduced through experiment data correlation, and the jet breakup mechanisms presented in (3) were described in three ranges of τ:

- τ < 6, When the jet collides with the upper wall, the colliding droplet inevitably forms a ligament or film due to the recirculation area. The droplet size distribution creates a bimodal distribution.

- 6 ≤ τ < 10, The general JICF mechanism is dominant, and no jet collision occurs.

- 10 ≤ τ, Droplets collide with the bottom of the channel. According to the wall interaction of the droplets, it is possible for the droplet size distribution to create a bimodal distribution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lefebvre, A.H. Gas Turbine Combustion; CRC press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Dhanuka, S.K.; Temme, J.E.; Driscoll, J.F.; Mongia, H.C. Vortex-shedding and mixing layer effects on periodic flashback in a lean premixed prevaporized gas turbine combustor. Proc. Combust. Inst. 2009, 32, 2901–2908. [Google Scholar] [CrossRef]

- Crocker, D.S.; Nickolaus, D.A.; Smith, C.E. Piloted Airblast Lean Direct Fuel Injector. U.S. Patent 6,272,840, 14 August 2001. [Google Scholar]

- Liu, Y.; Sun, X.; Sethi, V.; Nalianda, D.; Li, Y.G.; Wang, L. Review of modern low emissions combustion technologies for aero gas turbine engines. Prog. Aerosp. Sci. 2017, 94, 12–45. [Google Scholar] [CrossRef] [Green Version]

- Brandt, D.; Wesorick, R. GE Gas Turbine Design Philosophy; Technical Report; GER-3434; General Electric: Boston, MA, USA, 1994. [Google Scholar]

- Dhanuka, S.K.; Temme, J.E.; Driscoll, J.F. Unsteady aspects of lean premixed prevaporized gas turbine combustors: Flame-flame interactions. J. Propuls. Power 2011, 27, 631–641. [Google Scholar] [CrossRef]

- Hsieh, S.y.; Hsiao, G.; Li, S.C.; Mongia, H. Air-Assisted Fuel Injector for Mixer Assembly of a Gas Turbine Engine Combustor. U.S. Patent 7,464,553, 16 December 2008. [Google Scholar]

- Cowell, L.H.; Rajput, A.; Rawlins, D.C. Development of a Dual-Fuel Injection System for Lean Premixed Industrial Gas Turbines. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: Birmingham, UK, 1996; Volume 78743, p. V003T06A034. [Google Scholar]

- Lefebvre, A.H. Lean Premixed/Prevaporized Combustion; Number NASA-CP-2016; Workshop: Cleveland, OH, USA, 1977. [Google Scholar]

- Foust, M.; Thomsen, D.; Stickles, R.; Cooper, C.; Dodds, W. Development of the GE aviation low emissions TAPS combustor for next generation aircraft engines. In Proceedings of the 50th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; p. 936. [Google Scholar]

- Ingebo, R.D.; Foster, H.H. Drop-Size Distribution for Cross Current Breakup of Liquid Jets in Airstreams; Technical Report; National Advisory Committee for Aeronautics: Cleveland, OH, USA, 1957.

- Ingebo, R.D. Capillary and Acceleration Wave Breakup of Liquid Jets in Axial-Flow Airstreams; Technical Report; National Advisory Committee for Aeronautics: Cleveland, OH, USA, 1981.

- Song, J.; Cary Cain, C.; Guen Lee, J. Liquid jets in subsonic air crossflow at elevated pressure. J. Eng. Gas Turbines Power 2015, 137, 041502. [Google Scholar] [CrossRef]

- Ingebo, R.D. Penetration of Drops into High-Velocity Airstreams; National Aeronautics and Space Administration: Cleveland, OH, USA, 1967.

- Schetz, J.; Kush, E., Jr.; Joshi, P. Wave phenomena in liquid jet breakup in a supersonic crossflow. AIAA J. 1980, 18, 774–778. [Google Scholar] [CrossRef]

- Wu, P.K.; Kirkendall, K.A.; Fuller, R.P.; Nejad, A.S. Breakup processes of liquid jets in subsonic crossflows. J. Propuls. Power 1997, 13, 64–73. [Google Scholar] [CrossRef]

- Yates, C.L. Liquid Injection into a Supersonic Stream; Technical report; Aero Propulsion Lab: Dayton, OH, USA, 1972. [Google Scholar]

- Kush Jr, E.A.; Schetz, J.A. Liquid jet injection into a supersonic flow. AIAA J. 1973, 11, 1223–1224. [Google Scholar] [CrossRef]

- Baranovsky, S.; Schetz, J. An Experimental Investigation of Methods to Increase the Liquid Jet Penetration into Supersonic Flow; Interim Report Virginia Polytechnic Inst. and State Univ: Fort Belvoir, VA, USA, 1978. [Google Scholar]

- Nejad, A.; Schetz, J. Effects of viscosity and surface tension on a jet plume in supersonic crossflow. AIAA J. 1984, 22, 458–459. [Google Scholar] [CrossRef]

- Reichenbach, R.; Horn, K. Investigation of injectant properties on jet penetration in a supersonic stream. AIAA J. 1971, 9, 469–472. [Google Scholar] [CrossRef]

- Bolszo, C.D.; McDonell, V.G.; Gomez, G.A.; Samuelsen, G.S. Injection of water-in-oil emulsion jets into a subsonic crossflow: An experimental study. At. Sprays 2014, 24, 303–348. [Google Scholar] [CrossRef] [Green Version]

- Tan, Z.P. Experimental Study of Spray-Formation Processes in Twin-Fluid Jet-in-Crossflow at Jet-Engine Operating Conditions. PhD Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2017. [Google Scholar]

- Tan, Z.P. The physics of twin-fluid jet-in-crossflow at atmospheric and jet-engine operating conditions. Phys. Fluids 2019, 31, 045106. [Google Scholar] [CrossRef]

- Barata, J.; Silva, A. Numerical study of impinging droplets through a crossflow. In Proceedings of the 40th Thermophysics Conference, Seattle, WA, USA, 23–26 June 2008; p. 3923. [Google Scholar]

- Makida, M.; Yamada, H.; Kurosawa, Y.; Yamamoto, T.; Matsuura, K.; Hayashi, S. Preliminary Experimental Research to Develop a Combustor for Small Class Aircraft Engine Utilizing Primary Rich Combustion Approach. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, 8–11 May 2006, Barcelona, Spain; ASME: Barcelona, Spain, 2006; Volume 42363, pp. 835–842. [Google Scholar]

- Johnson, S.M. Venturi Nozzle Effects on Fuel Drop Size and Nitrogen Oxide Emissions; Technical Report; National Advisory Committee for Aeronautics: Cleveland, OH, USA, 1982.

- Shin, D. A Study on the Spray Characteristics of Pre-filming Air blast Injector with Venturi Shape Design for Gas Turbine Combustor. Master’s Thesis, Korea Aerospace University, Goyang, Korea, 2018. [Google Scholar]

- Stouffer, S.; Ballal, D.; Zelina, J.; Shouse, D.; Hancock, R.; Mongia, H. Development & combustion performance of high pressure WSR and TAPS combustor. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NY, USA, 10–13 January 2005; p. 1416. [Google Scholar]

- Huang, Y.; Yang, V. Dynamics and stability of lean-premixed swirl-stabilized combustion. Prog. Energy Combust. Sci. 2009, 35, 293–364. [Google Scholar] [CrossRef]

- Winterfeld, G.; Eickhoff, H.; Depooter, K. Fuel injectors. Chapter 3. In Design of Modern Gas Turbine Combustors; Academic Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Gupta, A.K.; Lilley, D.G.; Syred, N. Swirl Flows; Royal Turnbridge Wells: Kent, UK, 1984. [Google Scholar]

- Huang, Y.; Wang, S.; Yang, V. Flow and flame dynamics of lean premixed swirl injectors. Prog. Astronaut. Aeronaut. 2005, 210, 213. [Google Scholar]

- Beer, J.M.; Chigier, N.A. Combustion Aerodynamics; Krieger Publishing Company: Malabar, FL, USA, 1983. [Google Scholar]

- Etheridge, C. Mars SoLoNOx: Lean Premix Combustion Technology in Production. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: The Hague, The Netherlands, 1994; Volume 78859, p. V003T06A013. [Google Scholar]

- Choi, M.H.; Shin, D.S.; Radhakrishnan, K.; Son, M.; Koo, J. Spray Characteristics of Jet According to Position of Injector Hole in Crossflow. J. Korean Soc. Propuls. Eng. 2018, 22, 88–96. [Google Scholar] [CrossRef]

- Choi, M.H. The Effect of Radial Swirler Geometry and Spray Condition on Jet in Crossflow. Master’s Thesis, Korea Aerospace University, Goyang, Korea, 2018. [Google Scholar]

- Madden, P. CAEP Combustion Technology Review Process and CAEP NOx Goals; CAEP Publication: Fergus Falls, MN, USA, 2014. [Google Scholar]

- Davis, D.W. On the Behavior of a Shear-Coaxial Jet, Spanning Sub-to Supercritical Pressures, with and without an Externally Imposed Transverse Acoustic Field; Technical Report; The Pennsylvania State University: Philadelphia, PA, USA, 2006. [Google Scholar]

- Davis, D.; Chehroudi, B. Shear-coaxial jets from a rocket-like injector in a transverse acoustic field at high pressures. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 758. [Google Scholar]

- Leong, M.Y.; McDonell, V.G.; Samuelsen, G.S. Effect of ambient pressure on an airblast spray injected into a crossflow. J. Propuls. Power 2001, 17, 1076–1084. [Google Scholar] [CrossRef]

- Leong, M.; Smugeresky, C.; McDonell, V.; Samuelsen, G. Rapid liquid fuel mixing for lean-burning combustors: Low-power performance. J. Eng. Gas Turbines Power 2001, 123, 574–579. [Google Scholar] [CrossRef] [Green Version]

- Leong, M.Y. Mixing of an Airblast-Atomized Fuel Spray Injected in to a Crossflow of Air. Ph.D. Thesis, University of California, Irvine, CA, USA, 2017. [Google Scholar]

- Saha, A.; Lee, J.D.; Basu, S.; Kumar, R. Breakup and coalescence characteristics of a hollow cone swirling spray. Phys. Fluids 2012, 24, 124103. [Google Scholar] [CrossRef] [Green Version]

- Harari, R.; Sher, E. Bimodal drop size distribution behavior in plain-jet airblast atomizer sprays. At. Sprays 1998, 8, 349–362. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; McDonell, V.G. Atomization and Sprays; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Lorenzetto, G.; Lefebvre, A.H. Measurements of drop size on a plain-jet airblast atomizer. AIAA J. 1977, 15, 1006–1010. [Google Scholar] [CrossRef]

- Lefebvre, A.H. The prediction of Sauter mean diameter for simplex pressure-swirl atomisers. At. Spray Technol. 1987, 3, 37–51. [Google Scholar]

- Rizkalla, A.; Lefebvre, A.H. The influence of air and liquid properties on airblast atomization. J. Fluids Eng. 1975, 97, 316–320. [Google Scholar] [CrossRef]

- El-Shanawany, M.S.; Lefebvre, A.H. Airblast atomization: Effect of linear scale on mean drop size. J. Energy 1980, 4, 184–189. [Google Scholar] [CrossRef]

- Lefebvre, A.H. Airblast atomization. Prog. Energy Combust. Sci. 1980, 6, 233–261. [Google Scholar] [CrossRef]

- Fraser, R.; Dombrowski, N.; Routley, J. The production of uniform liquid sheets from spinning cups. Chem. Eng. Sci. 1963, 18, 315–321. [Google Scholar] [CrossRef]

- Rizk, N.K.; Lefebvre, A.H. The Influence of Liquid Film Thickness on Airblast Atomization. J. Eng. Power 1980, 102, 706–710. [Google Scholar] [CrossRef]

| Parameter | Crossflow (Air) | Fuel (Liquid) |

|---|---|---|

| ρ (kg/ | 1.21 | 1006 |

| σ ( | - | 7.28 |

| μ ) | 1.85 | 8.90 |

| P (atm) | 1 | |

| T ( | 20 | |

| V ) | 27–80 | 5–15 |

| Re | 1100–2700 | 2800–5700 |

| We | 6–55 | 180–720 |

| MFR | 3–192 | |

| ALR (air/liquid ratio) | 20–51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, M.H.; An, J.; Koo, J. Breakup Mechanism of a Jet in the L-Shape Crossflow of a Gas Turbine Combustor. Energies 2022, 15, 3360. https://doi.org/10.3390/en15093360

Choi MH, An J, Koo J. Breakup Mechanism of a Jet in the L-Shape Crossflow of a Gas Turbine Combustor. Energies. 2022; 15(9):3360. https://doi.org/10.3390/en15093360

Chicago/Turabian StyleChoi, Myeung Hwan, Jeongwoo An, and Jaye Koo. 2022. "Breakup Mechanism of a Jet in the L-Shape Crossflow of a Gas Turbine Combustor" Energies 15, no. 9: 3360. https://doi.org/10.3390/en15093360

APA StyleChoi, M. H., An, J., & Koo, J. (2022). Breakup Mechanism of a Jet in the L-Shape Crossflow of a Gas Turbine Combustor. Energies, 15(9), 3360. https://doi.org/10.3390/en15093360