Rational Application of Electric Power Production Optimization through Metaheuristics Algorithm

Abstract

:1. Introduction

2. Problem Formulation

2.1. Mathematical Model of Generation by Solar Power Plant (g1)

- g1 = solar power plant

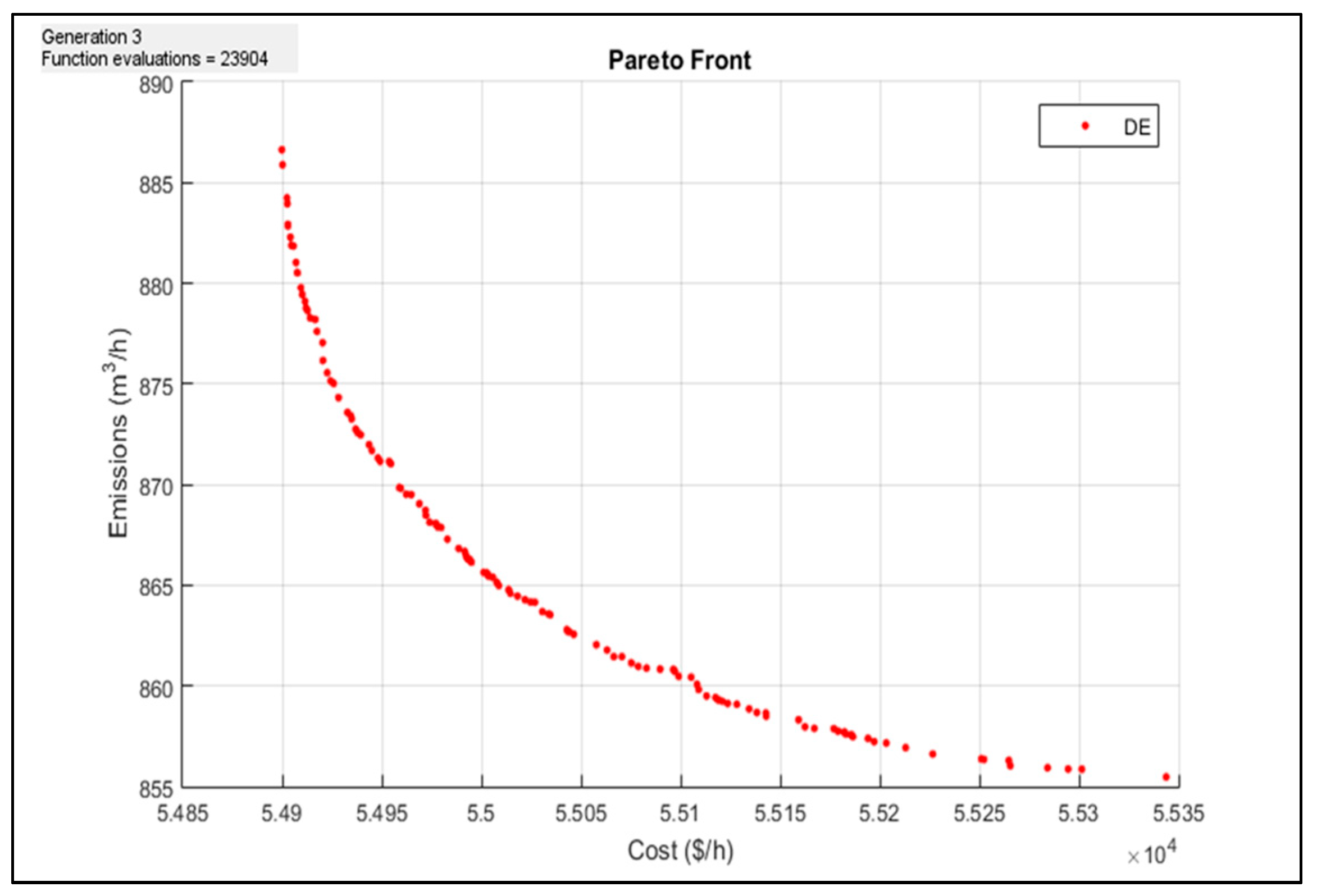

- Pgsj = generated power by the solar plant

- Prated = rated power;

- Tref = reference temperature;

- Tamb = room temperature;

- alpha = temperature coefficient; and

- Si = incident solar radiation.

2.2. Mathematical Model of Cost of Thermal Plants (f1)

2.3. Mathematical Model of Emissions of Thermal Plants (f2)

2.4. Economical Load Dispatch Constrains

2.4.1. Equal Power Constraints

2.4.2. Generation Constraint

2.5. Optimization Problem

2.6. Formulation of the Incremental Cost

- = incremental fuel cost;

- = actual incremental cost curve;

- = is an approximate (linear) incremental cost curve;

- = total power generation.

3. Optimization Technique

- ▪

- A new swarm intelligence optimization technique called the DA was proposed by [44]. This technique considers the proposal of binary and multi-objective versions. Dragonflies are small predators that hunt almost every small insect in nature. An interesting fact about dragonflies is their unique and rare swarming behavior. Dragonflies group together for two purposes: the first being hunting (static) and the second being migration (dynamic swarm). The hunting is in small groups. Dynamic swarms form large groups and travel long distances [44,45,46,47].

- ▪

- ○

- Separation is about preventing static collisions of individuals with other individuals in the neighborhood.

- ○

- The alignment indicates the similar speed of the individuals with that of other individuals in the neighborhood.

- ○

- Cohesion refers to the predisposition of individuals to move toward the center of mass in the neighborhood.

- ▪

- For DE, [48,49] proposed a new encoded evolution algorithm using a fluctuating point for global optimization and was nominated as DE algorithm. DE has four main stages: initialization, mutation, crossover, and selection. Many optimization guidelines should also be adjusted. These guidelines are bonded under the control guidelines of the common name. There are only three guidelines for the real control of the algorithm: the differential constant F (or mutation), crossover constant Cr, and population length Np. The remaining guideline dimensions of issue D measure optimization task difficulty, and generation maximum number (or iteration) Gen. This can be suited as an interruption condition, and low and high limit restrictions are variables that range a viable area [41,48,50].

- ▪

- Ant lion, the optimization technique of ant lion, is a stochastic research algorithm based on a recently developed population propounded by [52] to solve problems of restricted optimization engineering issues. ALO is inspired by the lifespan of ant lions (doodlebugs), which belong to the family Myrmeleontidae and the order Neuroptera (grid of insects with wings). This technique is a free algorithm of the grid and lacks a baseline for adjustment. Because ALO is a population-based algorithm, the avoidance of ideal places is inherently high. The ALO algorithm has a high probability of solving ideal place closeness because of the random loops and roulette swivels. The pursuit of space exploration in the ALO algorithm is guaranteed by random selection of ant lions and random loops of ants all around it, and the pursuit of space exploration is guaranteed by the adaptive shrinkage limits of ant lion traps [53]:

- ✓

- The ants random loop

- ✓

- Building traps

- ✓

- Ants entanglement with traps

- ✓

- Catching preys and

- ✓

- Traps restoration.

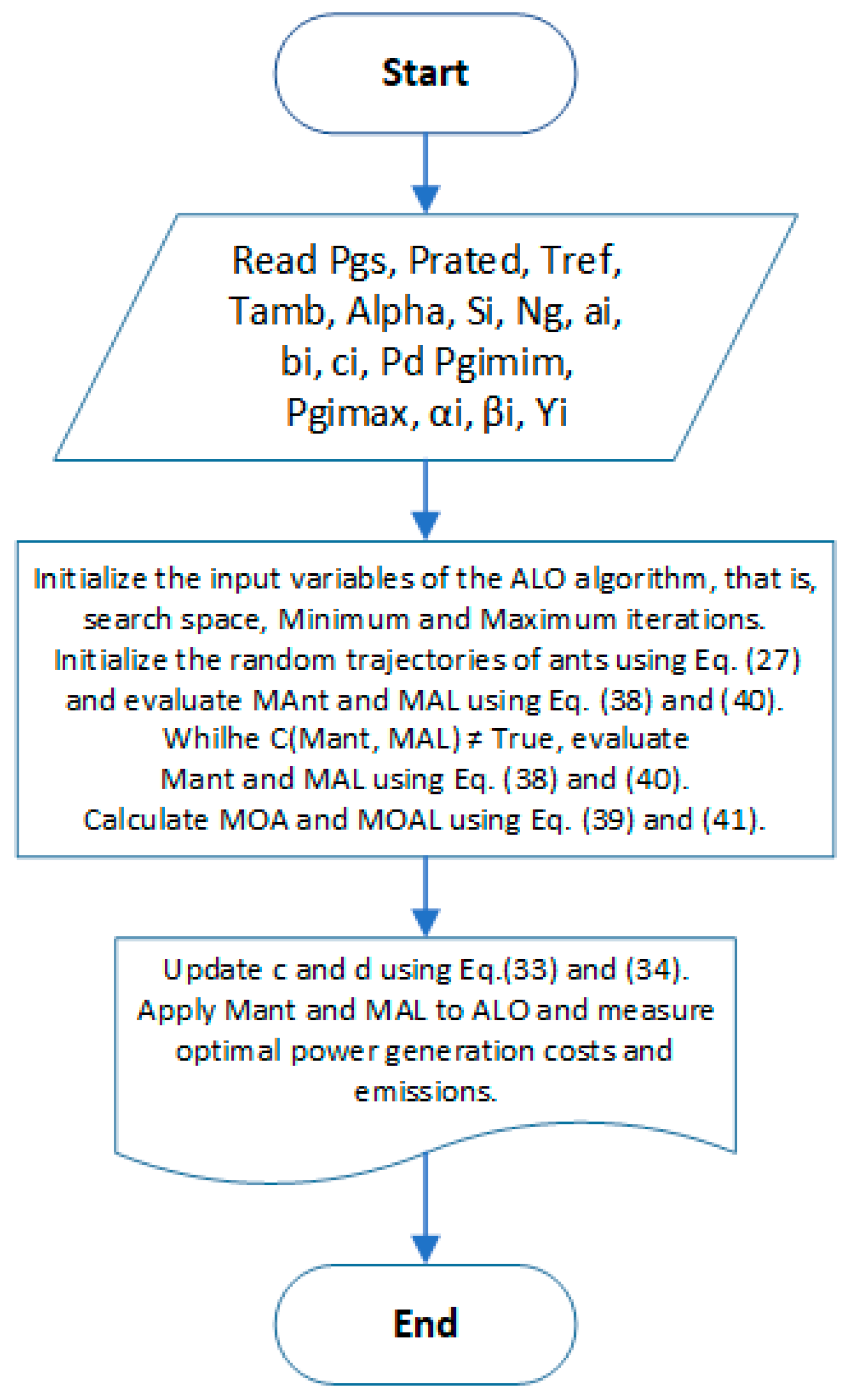

4. Applied Procedures to Solve the CEED Problem

- Step 1.

- The main agent of the ALO search, are characterized by the set of ants with random values.

- Step 2.

- The capacity value of each ant is evaluated using an objective function (Equation (15)) for each iteration.

- Step 3.

- The ants’ random paths through the search space are expected by the ant lion ant traps.

- Step 4.

- The position of the ants are evaluated in each iteration and the ones in the best position are relocated to capture the others.

- Step 5.

- The Lion ant is more agile, as it needs its position updated to catch the ant that becomes fitter.

- Step 6.

- An elite ant lion can affect the movement of the other ants, regardless of their displacement.

- Step 7.

- If a lion ant becomes better than the elite, then it is replaced by the new aptitude.

- Step 8.

- Steps 2 to 7 are repeated until the final parameter is satisfied.

- Step 9.

- The position and fitness coordinates of the elite ant lion are replicated as the best inferences for the overall optimization.

5. Case Study: IEEE 6-Units Test System and 13 Solar Plants

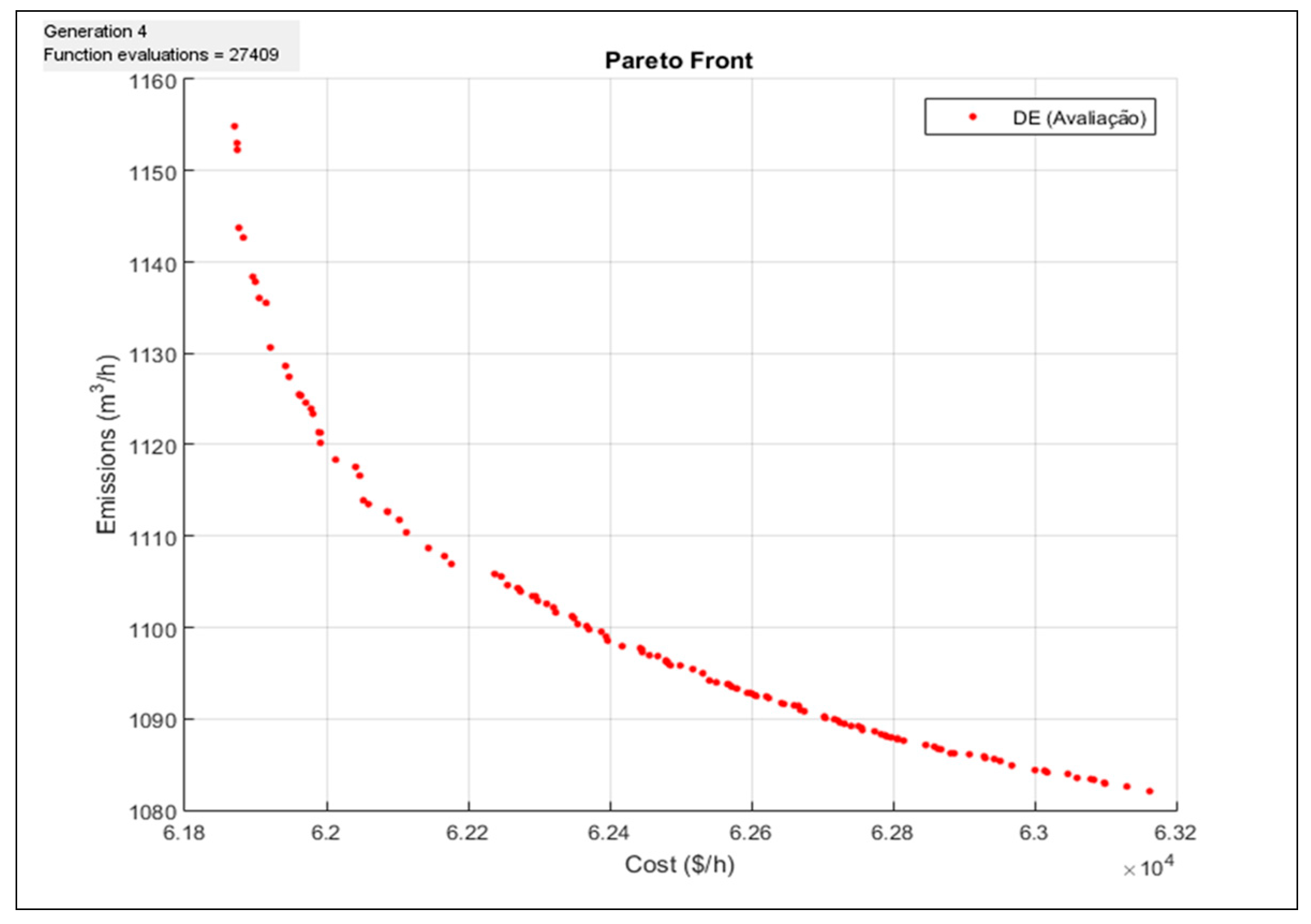

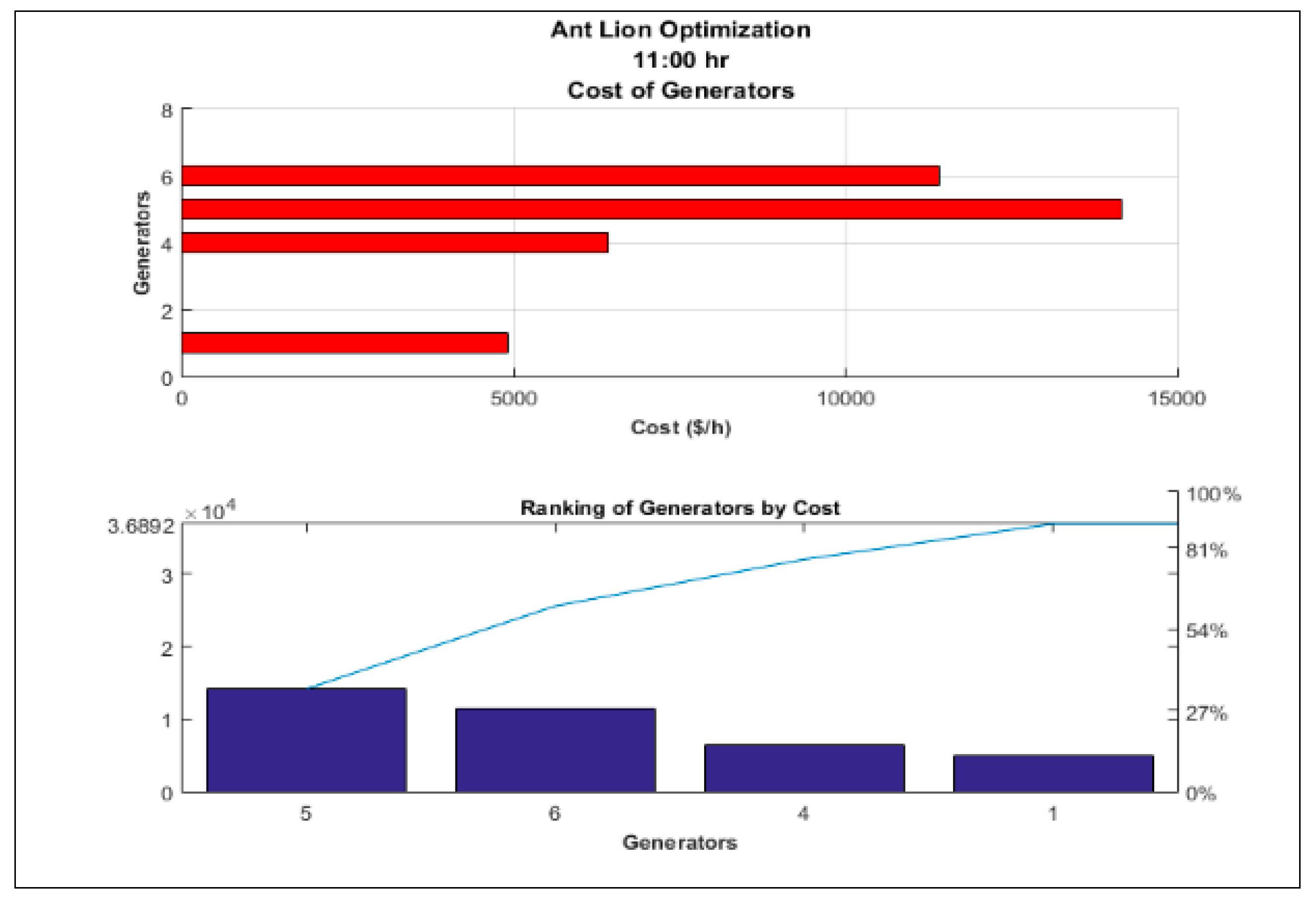

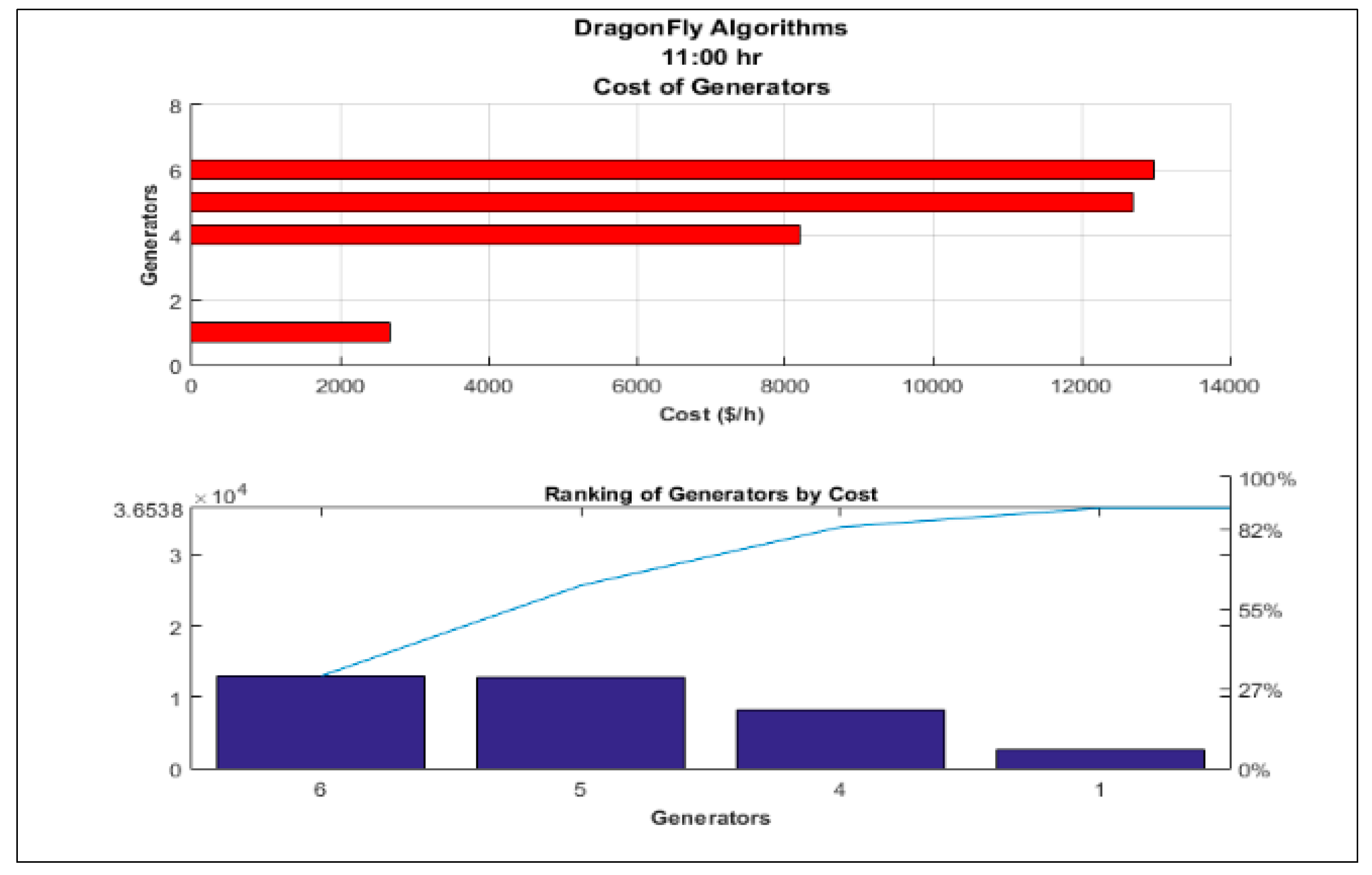

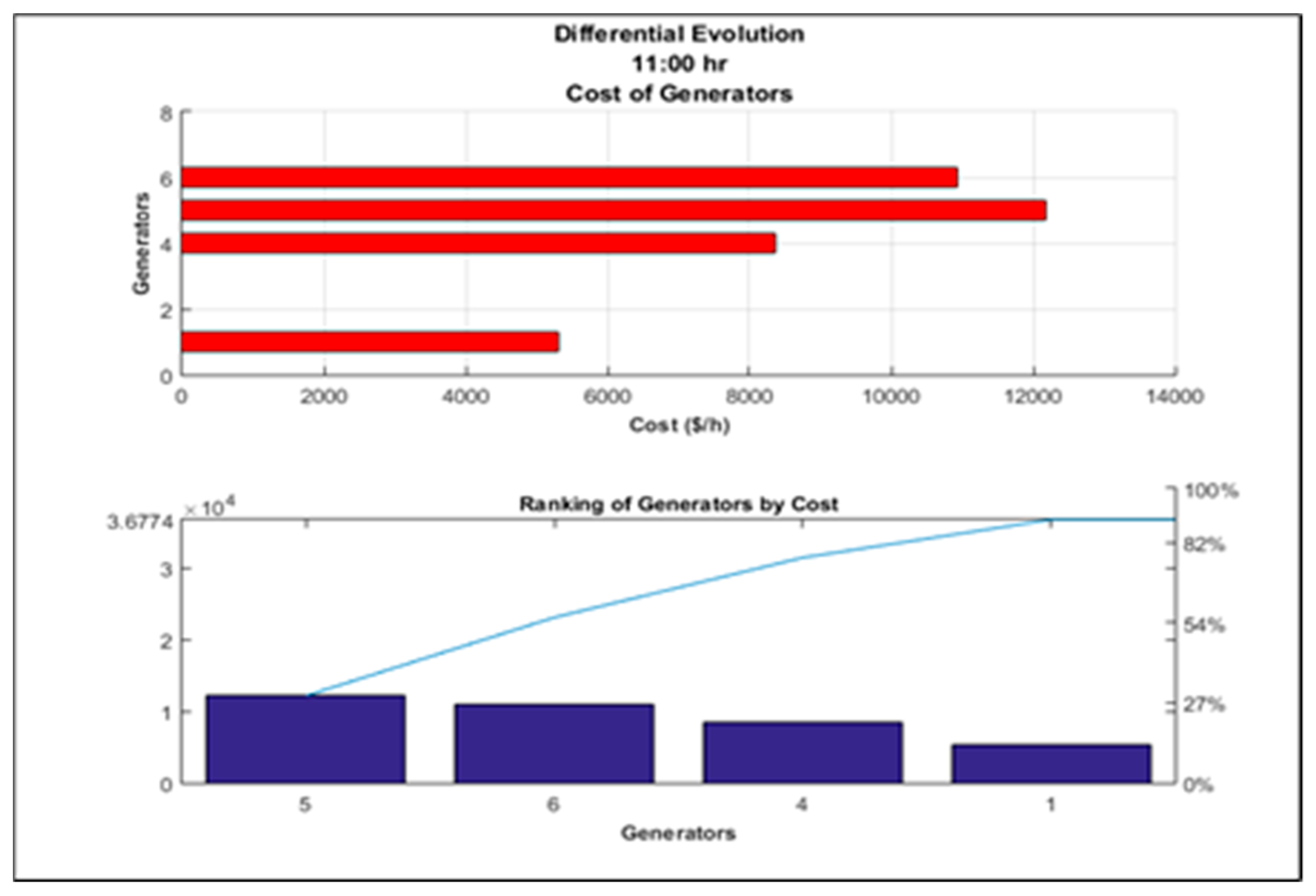

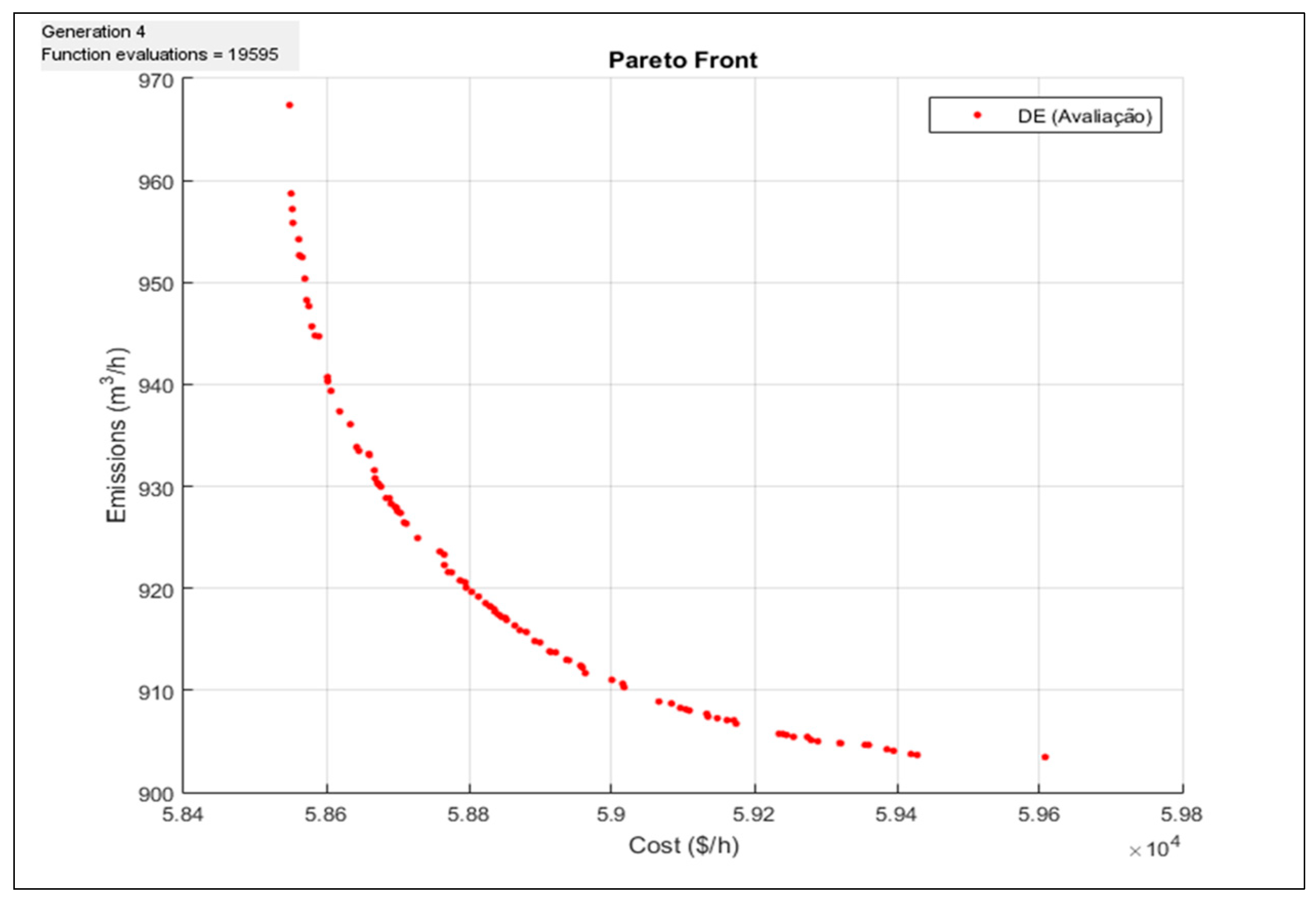

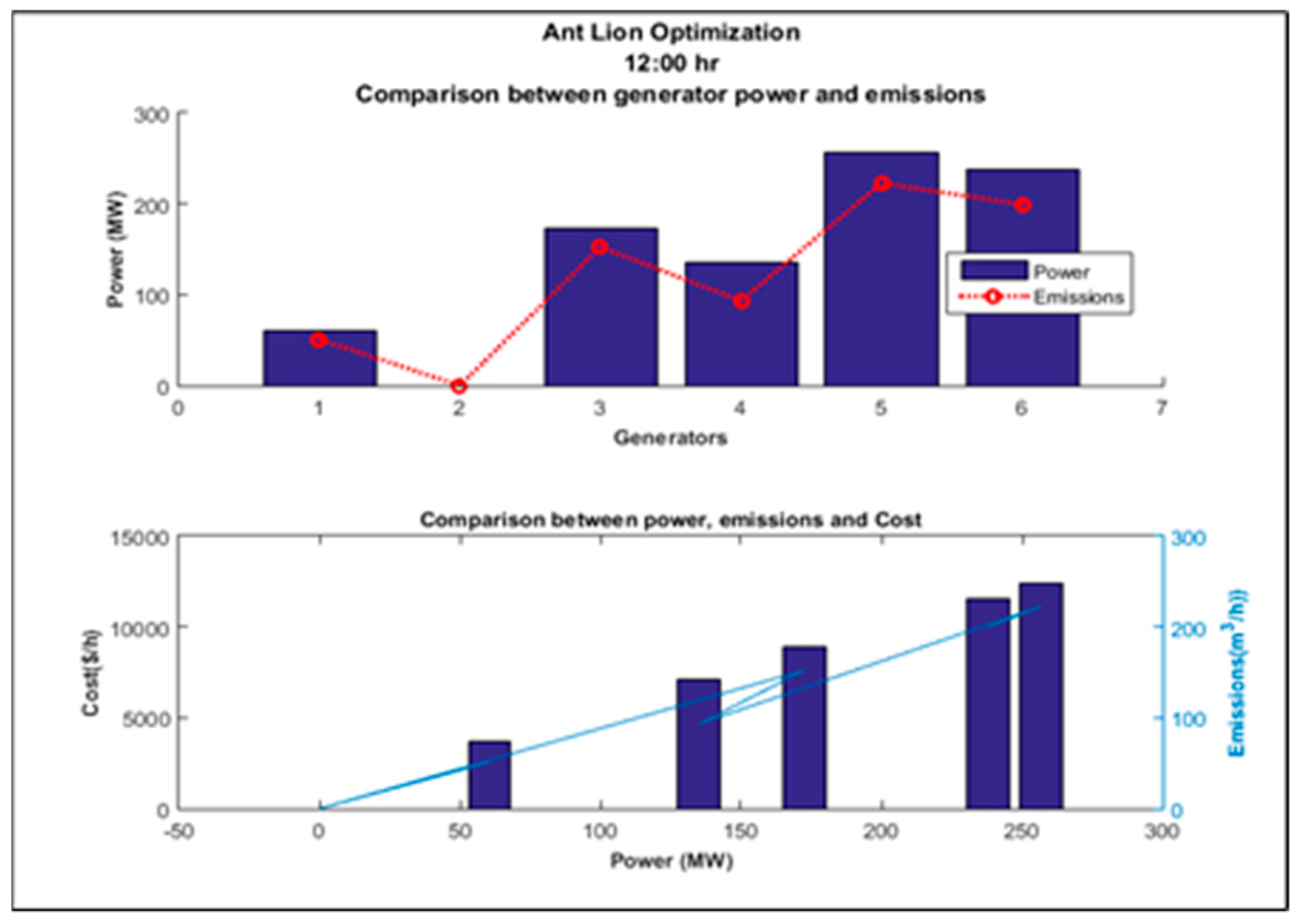

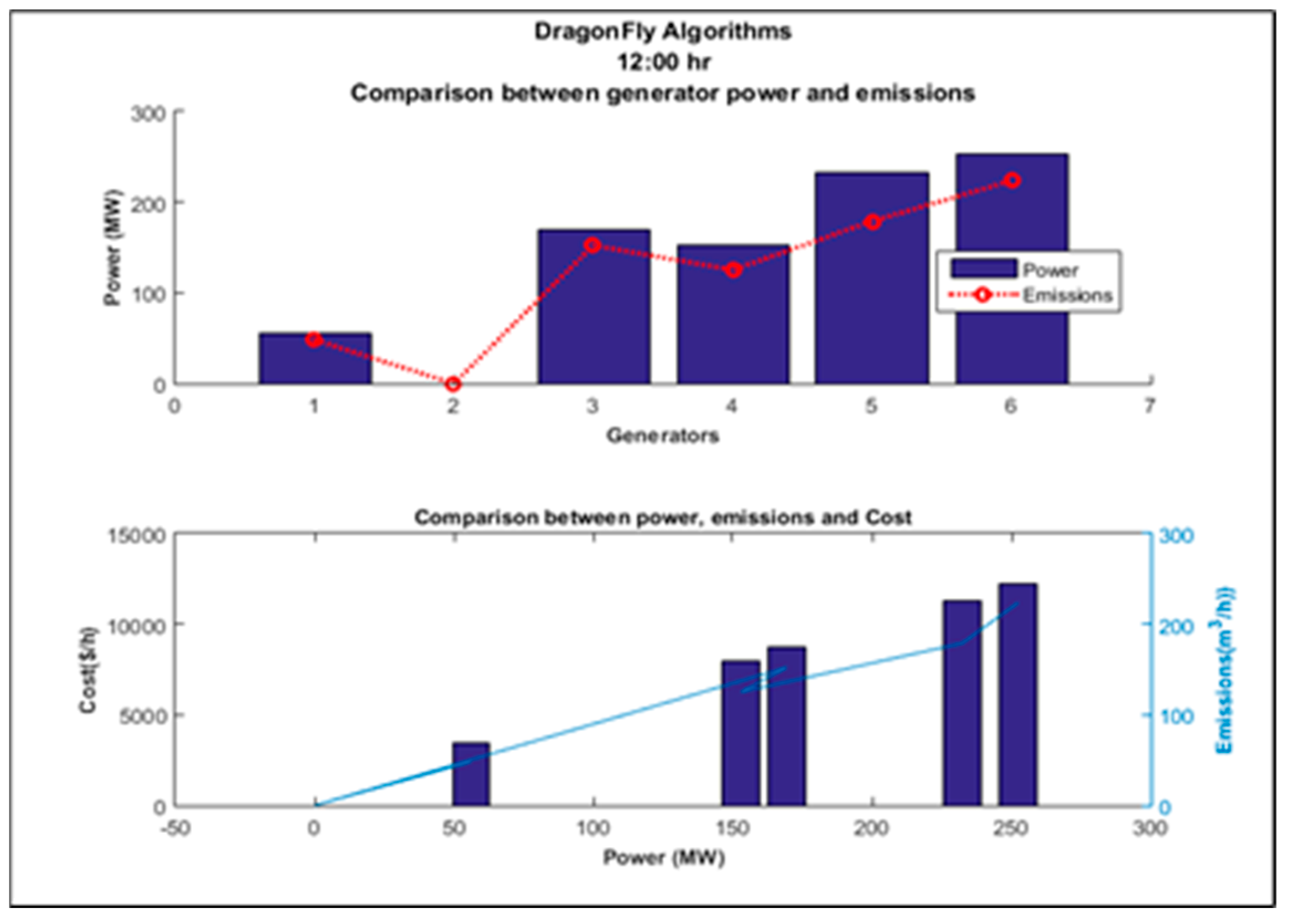

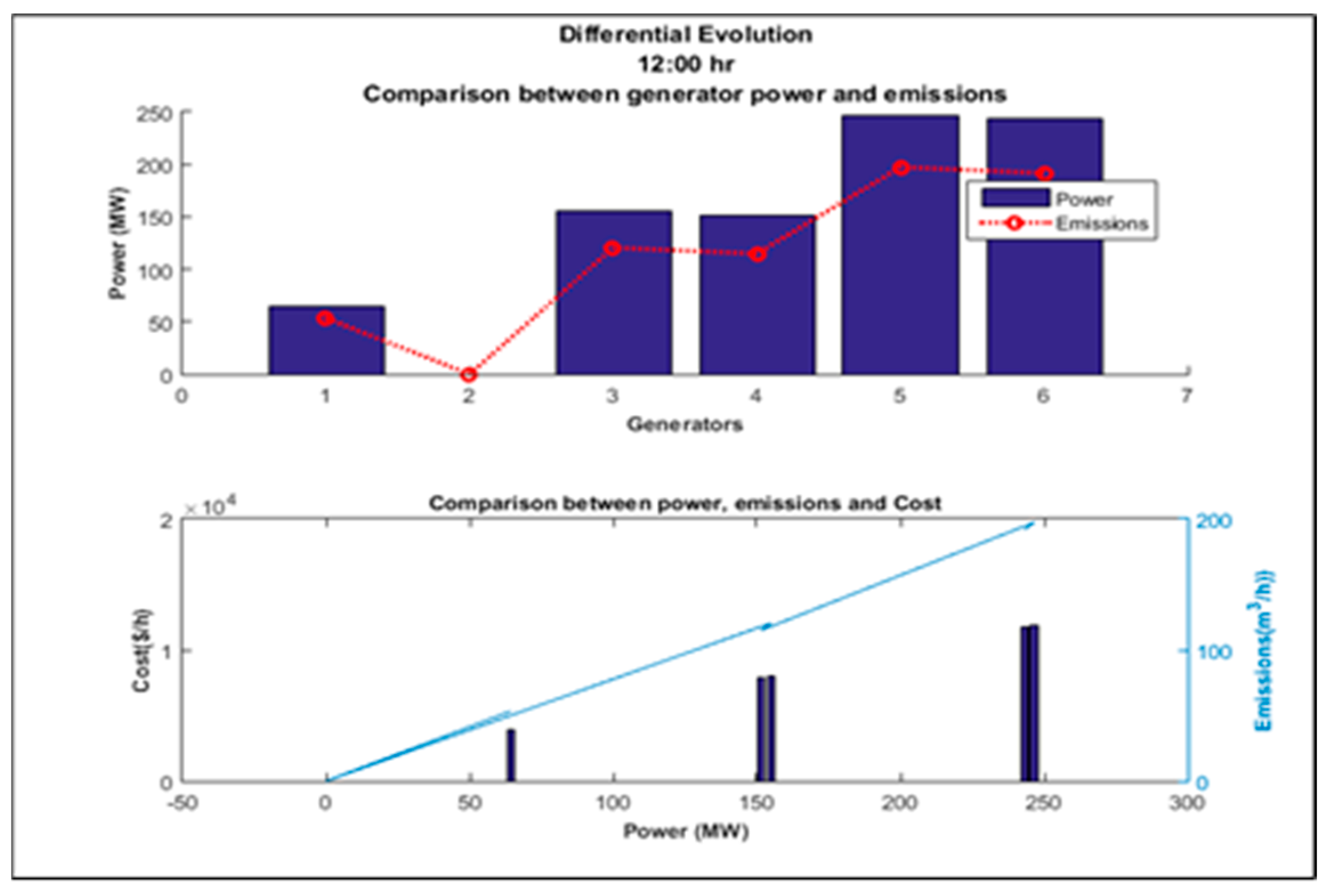

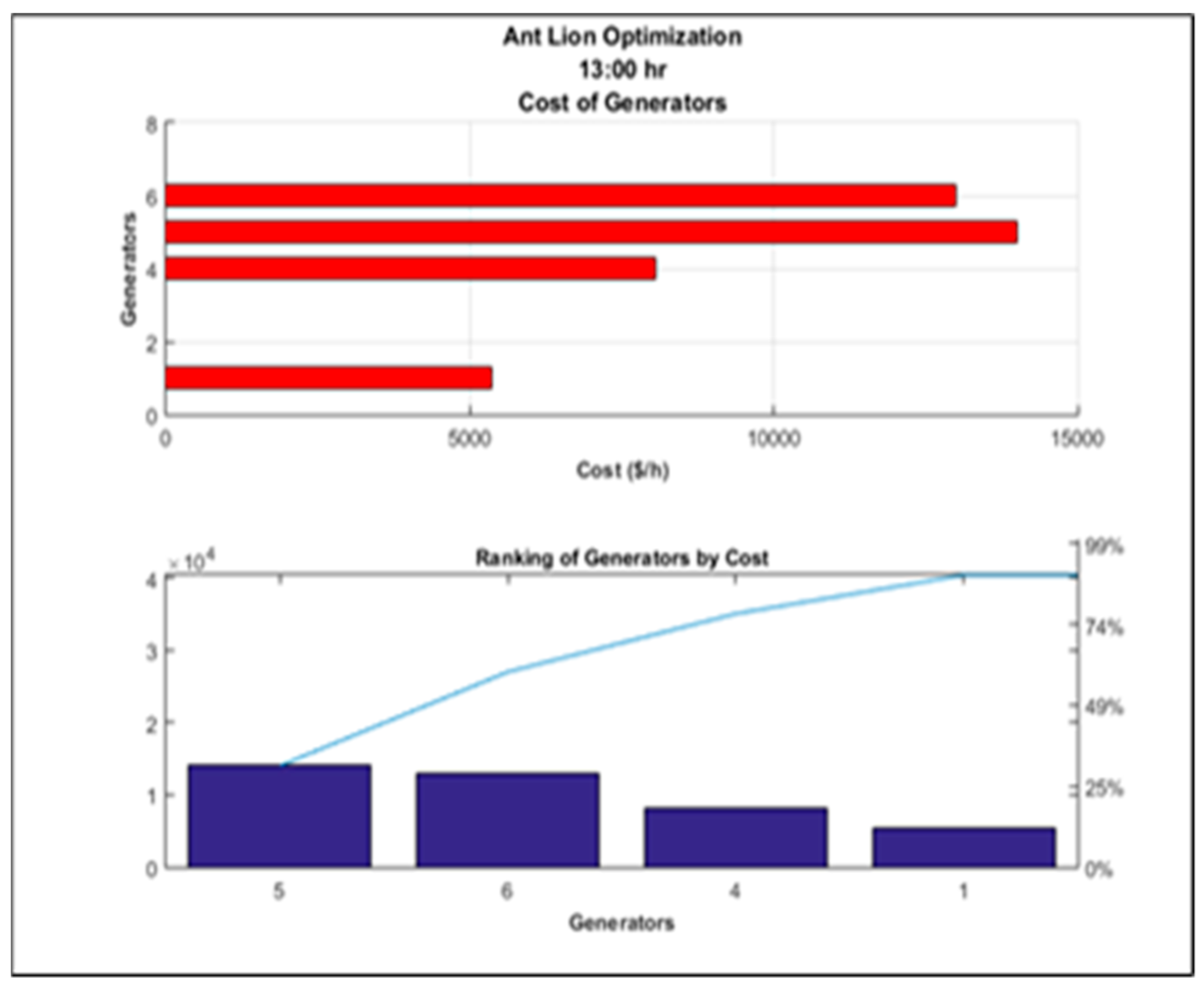

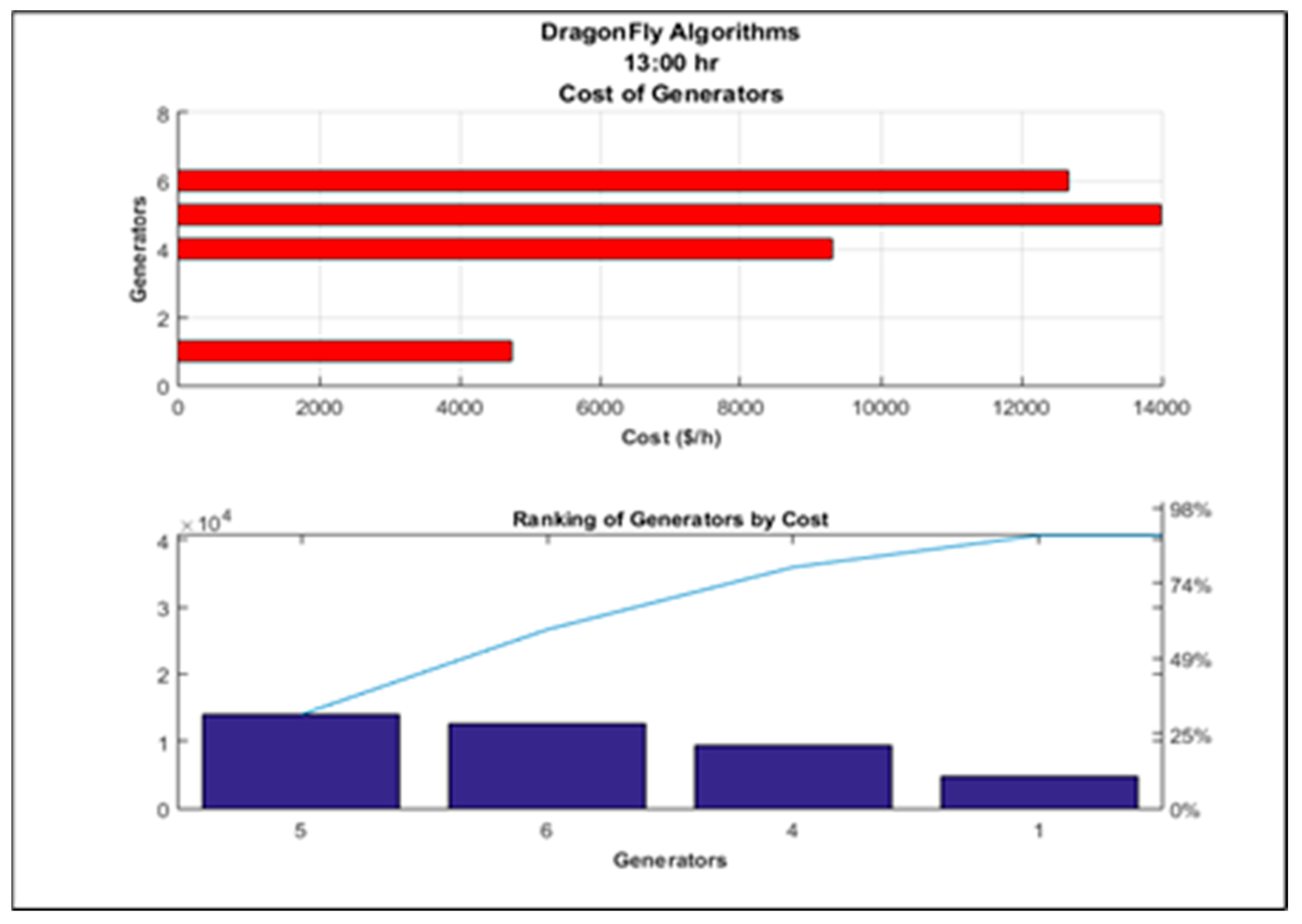

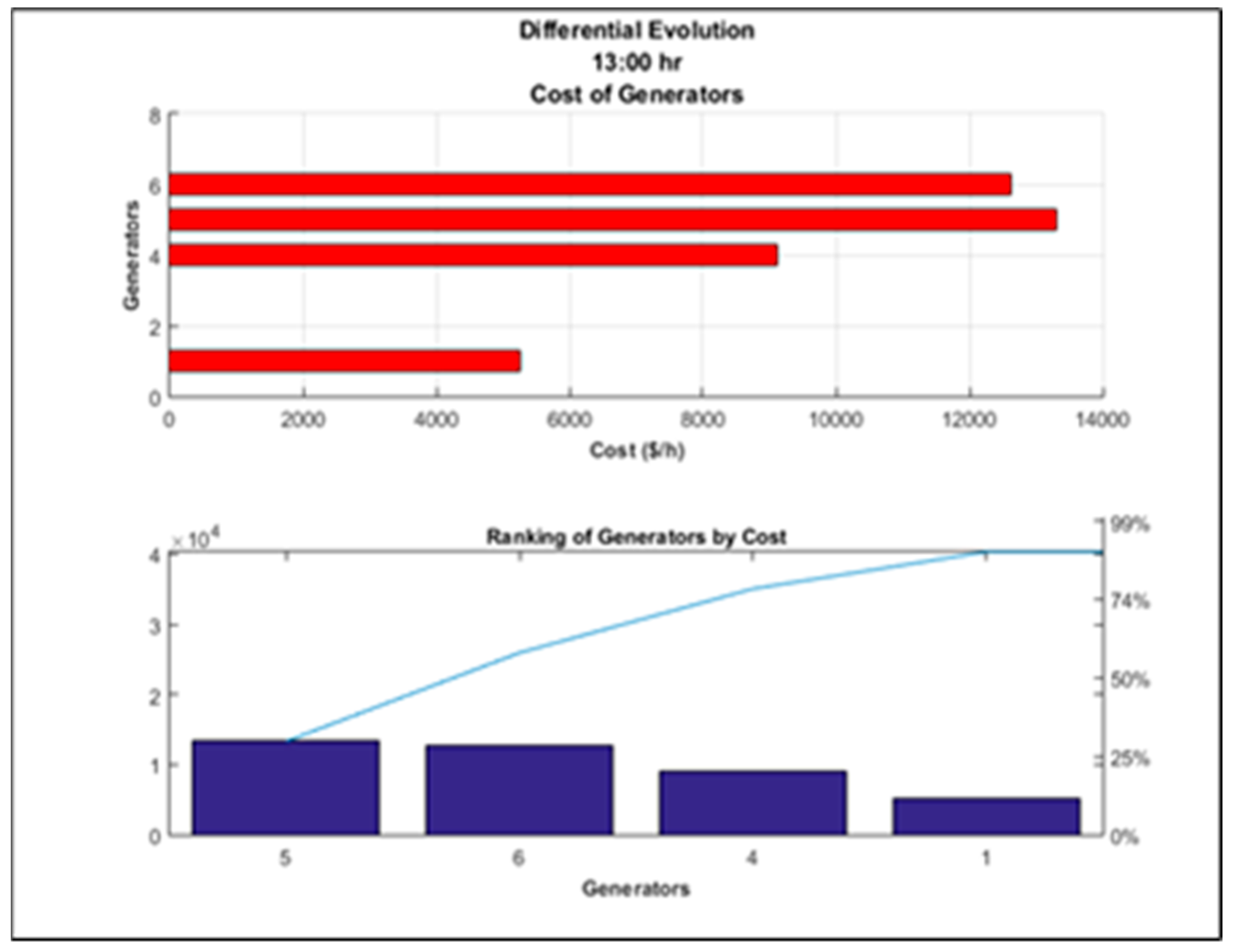

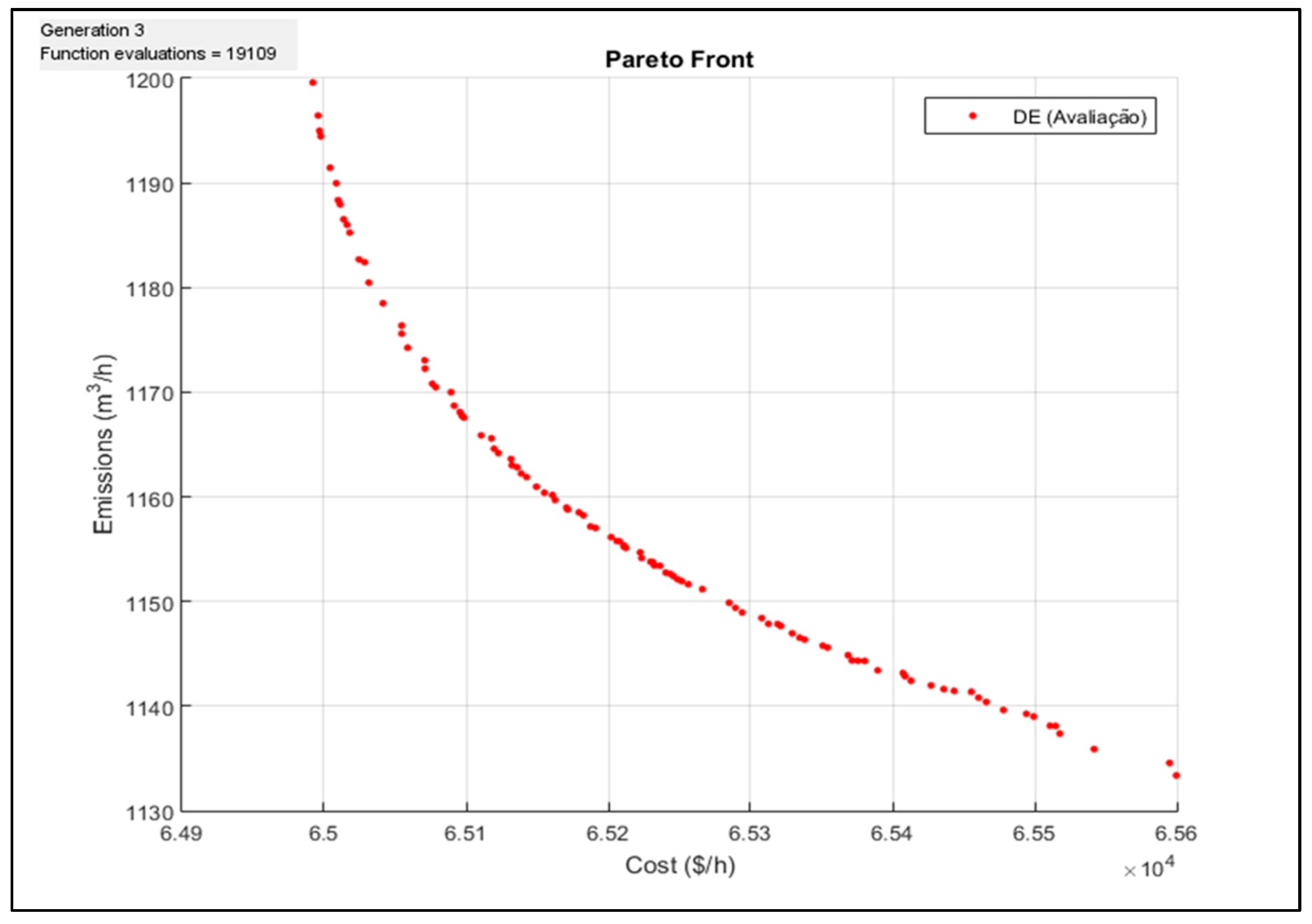

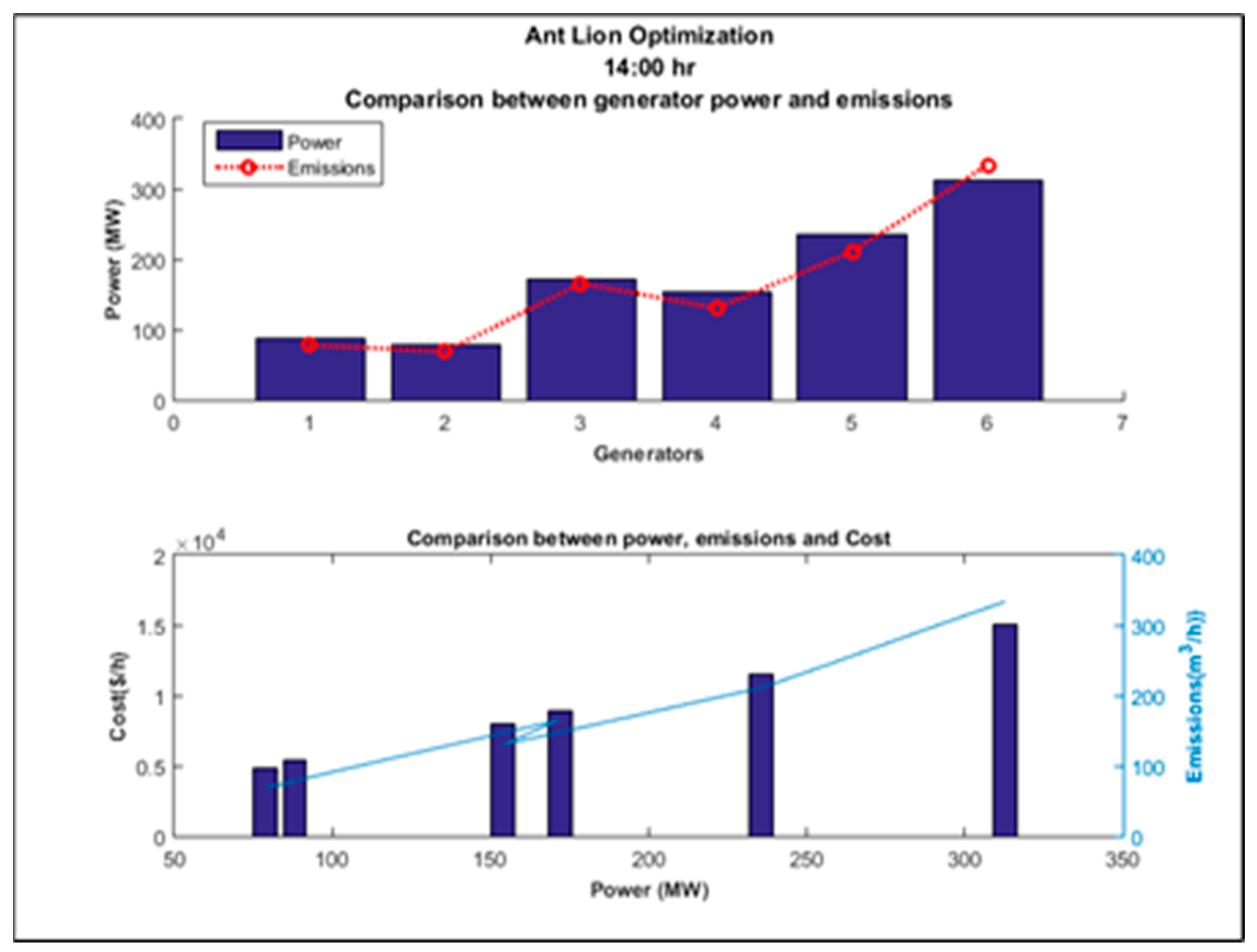

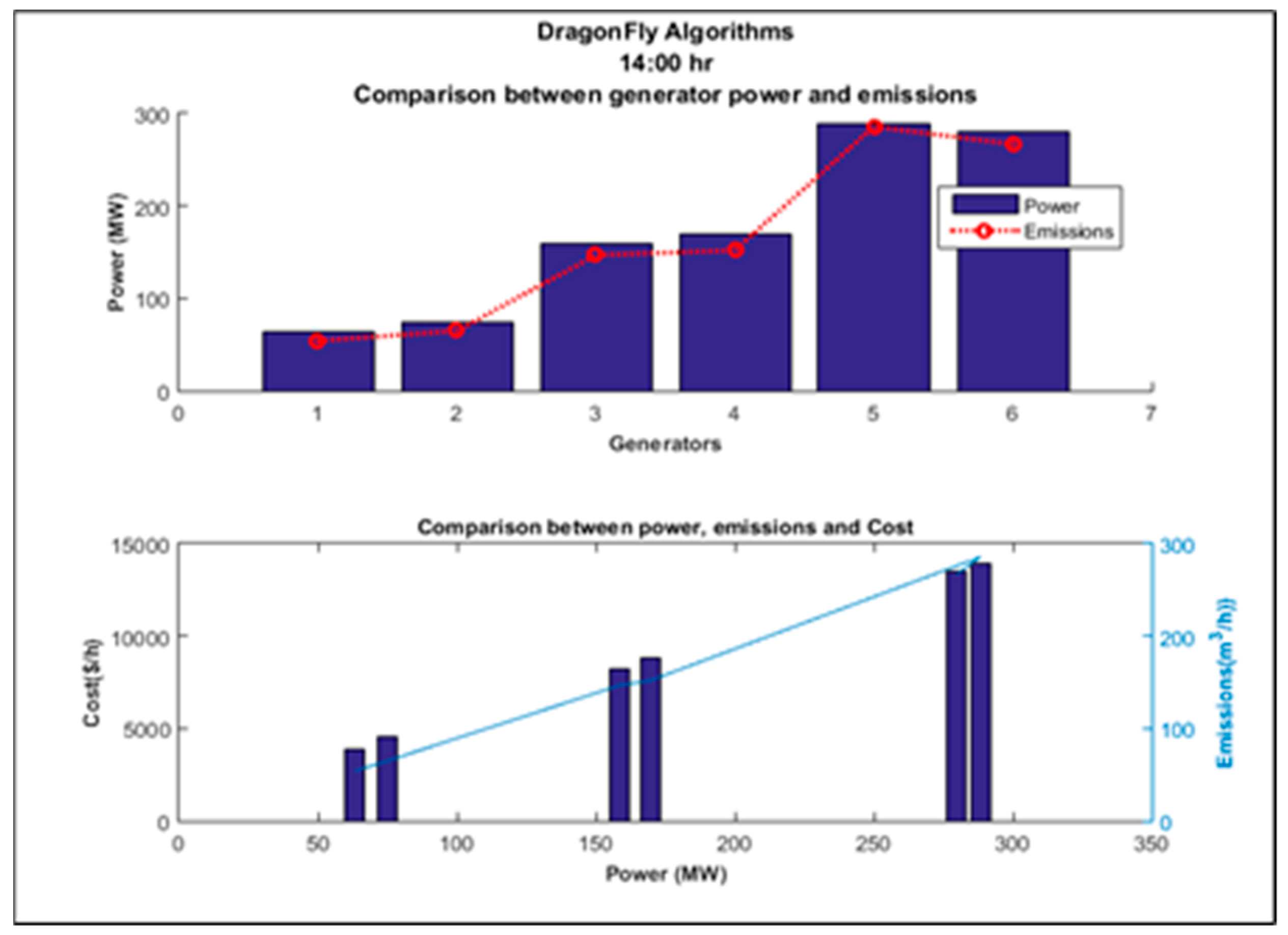

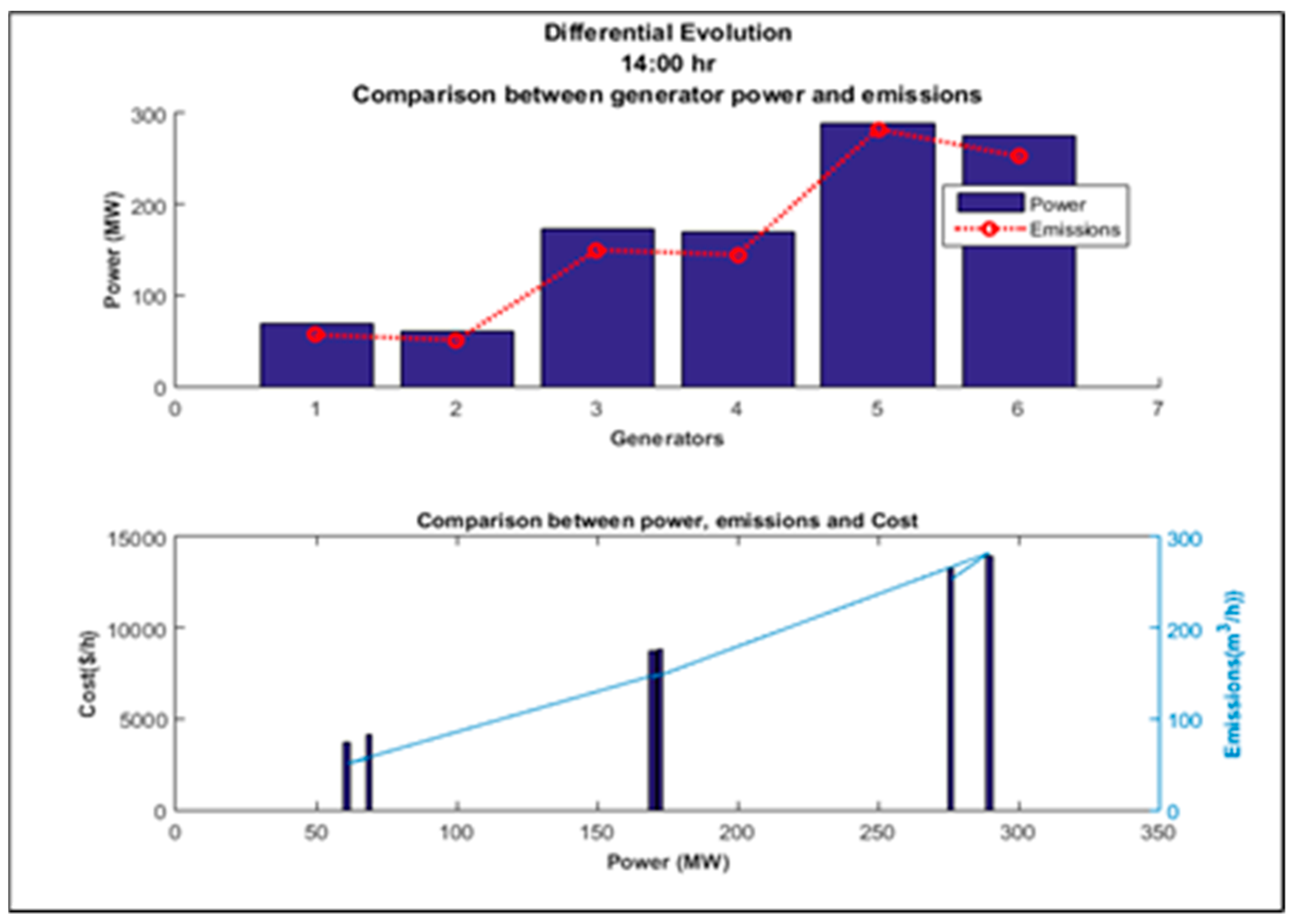

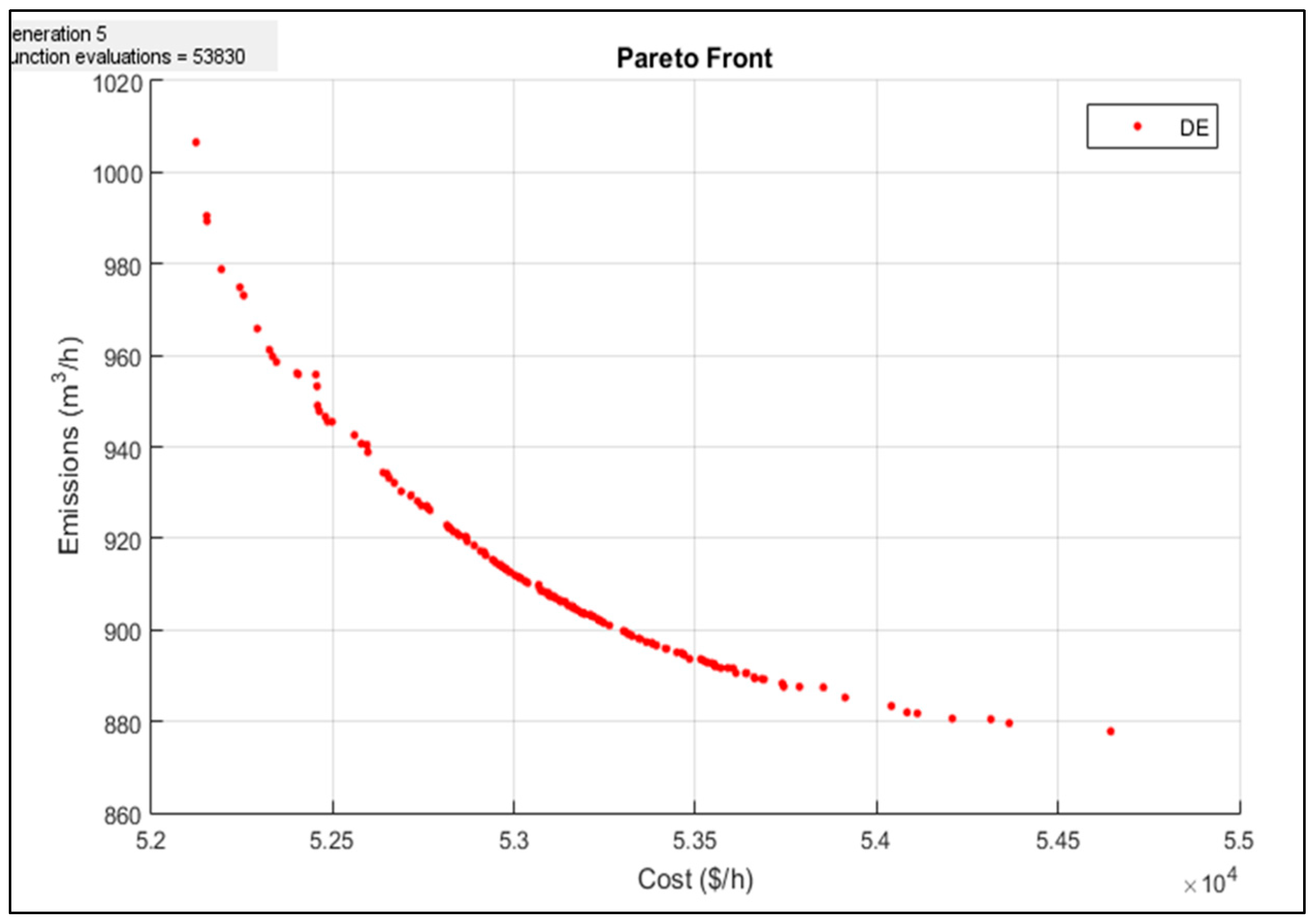

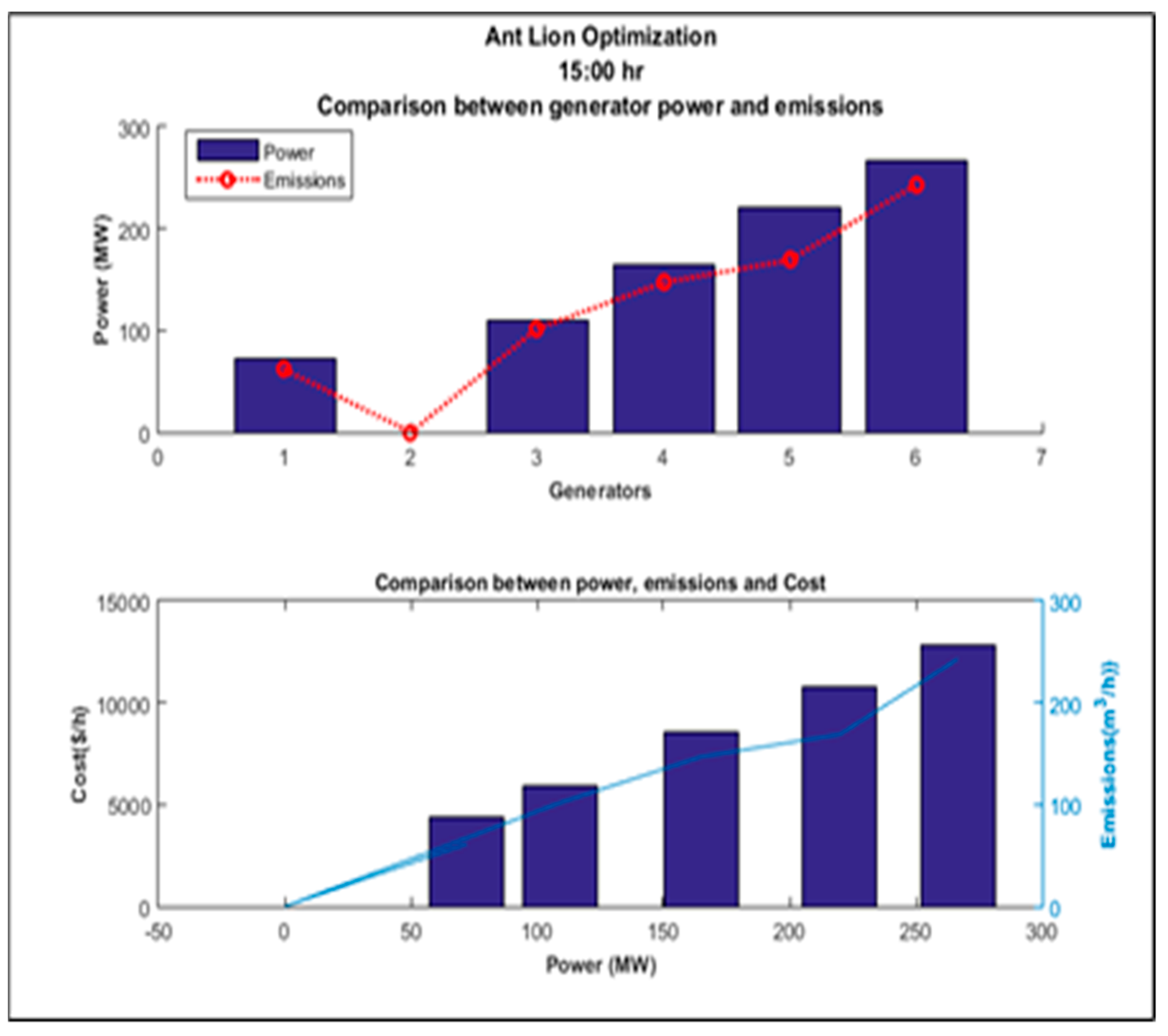

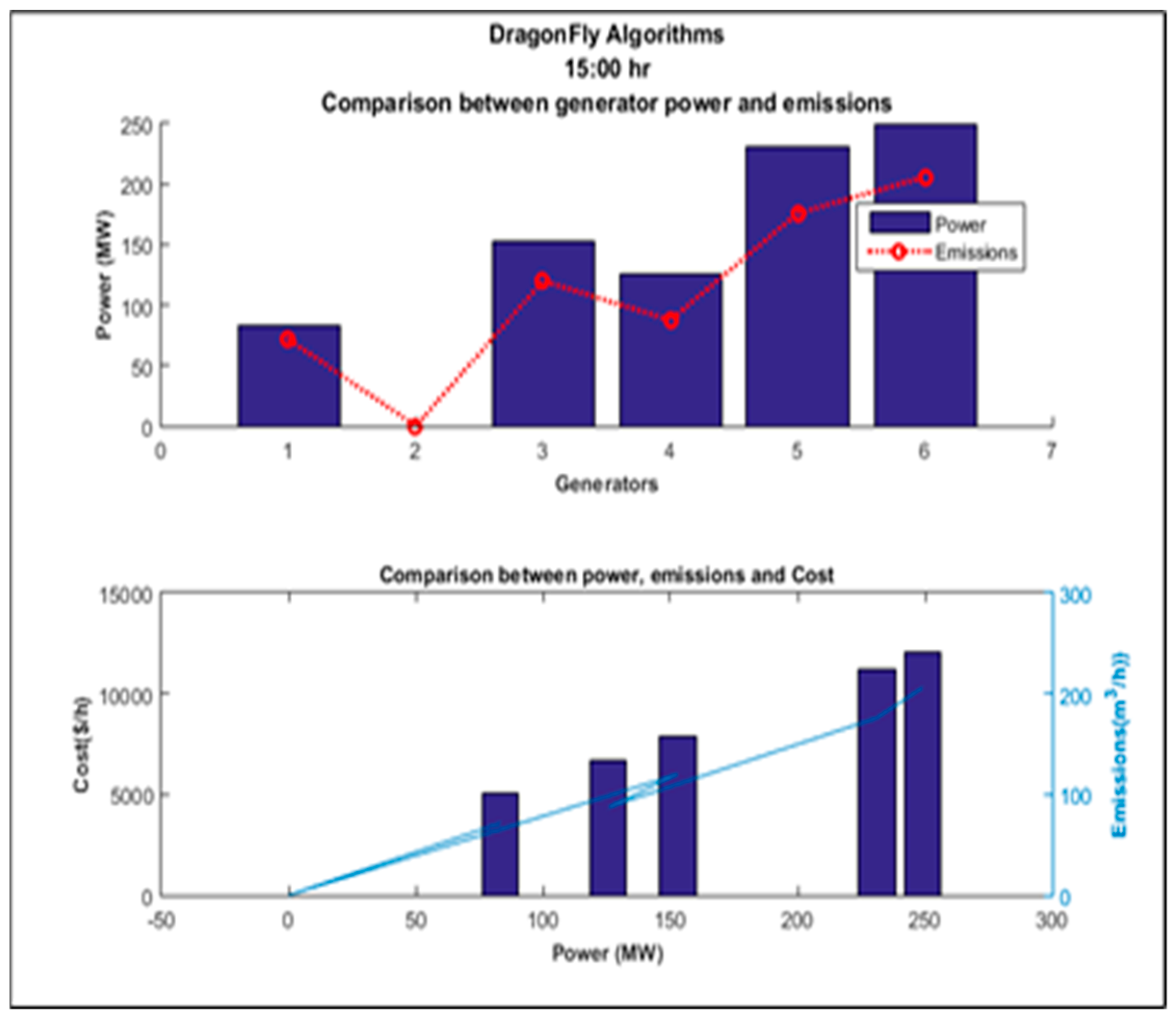

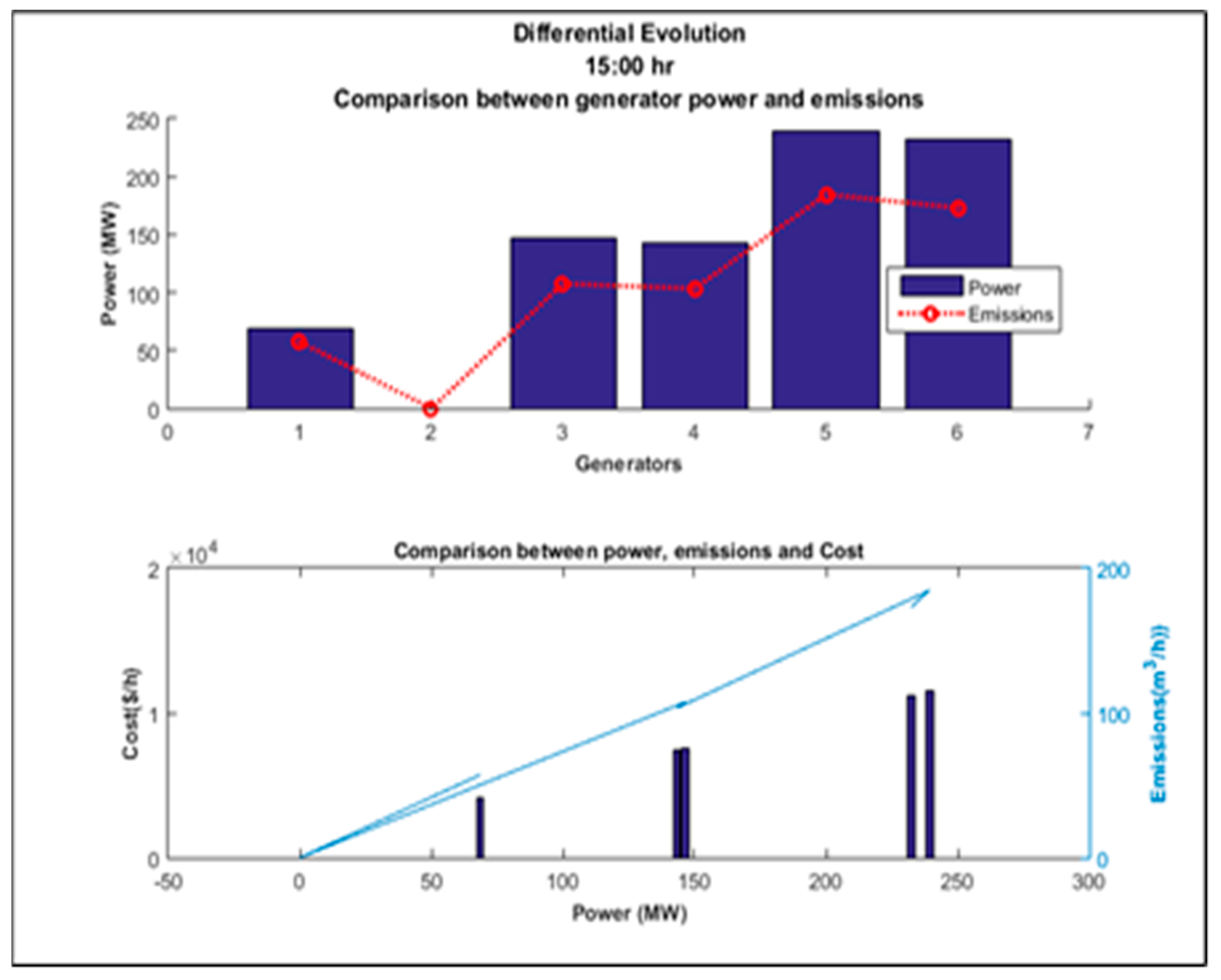

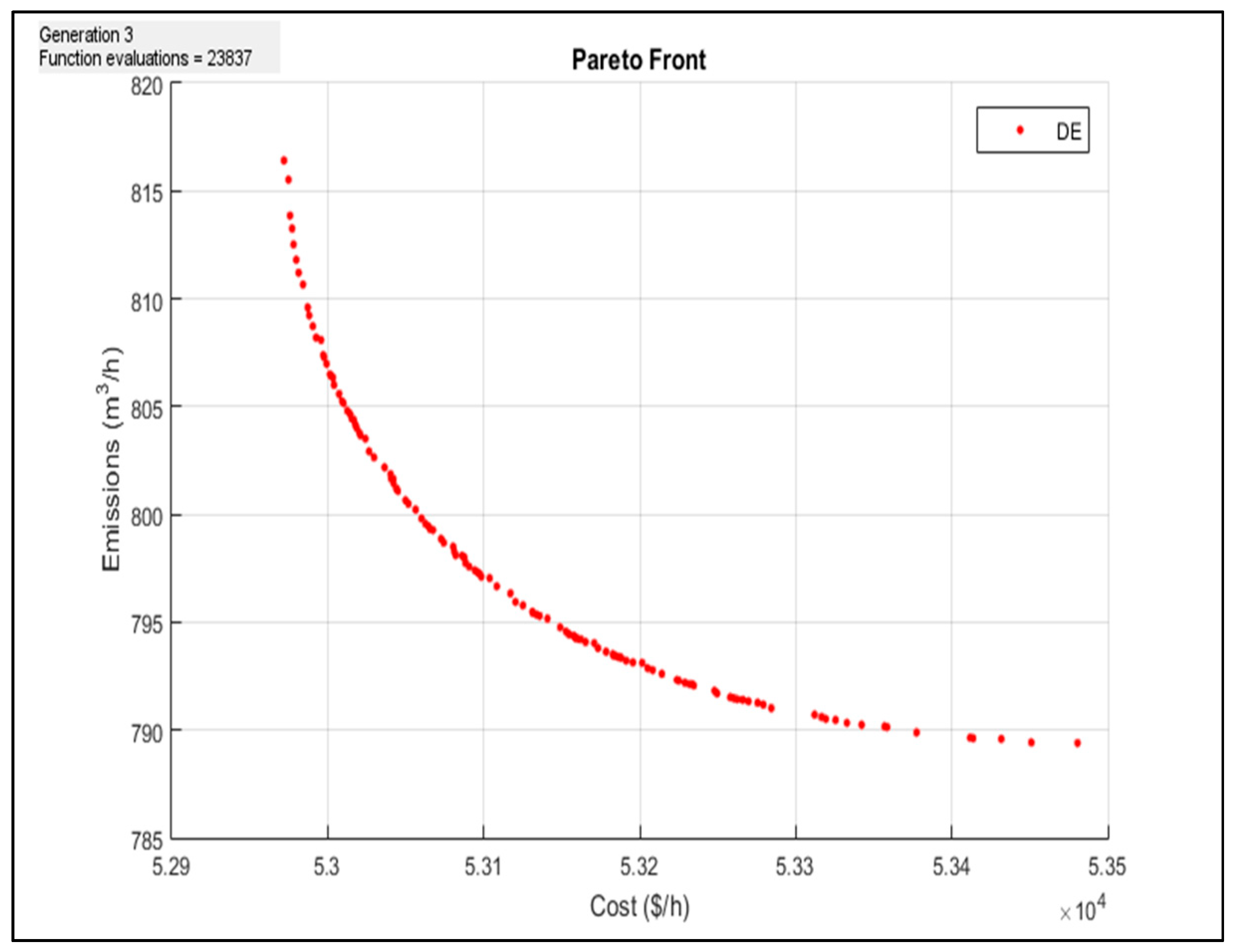

6. Analysis and Discussion of Results

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Panigrahi, T.K.; Sahoo, A.K.; Behera, A. A review on application of various heuristic techniques to combined economic and emission dispatch in a modern power system scenario. Energy Procedia 2017, 138, 458–463. [Google Scholar] [CrossRef]

- Younes, Z.; Alhamrouni, I.; Mekhilef, S.; Reyasudin, M. A memory-based gravitational search algorithm for solving economic dispatch problem in micro-grid. Ain. Shams. Eng. J. 2021, 12, 1985–1994. [Google Scholar] [CrossRef]

- Zhang, B.; Sudhoff, S.; Pekarek, S.; Swanson, R.; Flicker, J.; Neely, J.; Delhotal, J.; Kaplar, R. Prediction of Pareto-Optimal Performance Improvements in A Power Conversion System Using GaN Devices. In Proceedings of the 2017 IEEE 5th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Santa Ana Pueblo, NM, USA, 30 October–1 November 2017; pp. 80–86. [Google Scholar] [CrossRef]

- Goyal, S.K.; Singh, J.; Saraswat, A.; Kanwar, N.; Shrivastava, M.; Mahela, O.P. Economic Load Dispatch with Emission and Line Constraints using Biogeography Based Optimization Technique. In Proceedings of the 2020 International Conference on Intelligent Engineering and Management (ICIEM), London, UK, 17–19 June 2020; pp. 471–476. [Google Scholar] [CrossRef]

- Bai, Y.; Wu, X.; Xia, A. An enhanced multi-objective differential evolution algorithm for dynamic environmental economic dispatch of power system with wind power. Energy Sci. Eng. 2020, 9, 316–329. [Google Scholar] [CrossRef]

- Sarfi, V.; Niazazari, I.; Livani, H. Multiobjective Fireworks Optimization Framework for Economic Emission Dispatch in Microgrid. In Proceedings of the 2016 North American Power Symposium (NAPS), Denver, CO, USA, 18–20 September 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Dey, B.; Bhattacharyya, B.; Raj, S.; Babu, R. Economic emission dispatch on unit commitment-based microgrid system considering wind and load uncertainty using hybrid MGWOSCACSA. J. Electr. Syst. Inf. Technol. 2020, 7, 1–26. [Google Scholar] [CrossRef]

- Khan, N.A.; Awan, A.B.; Mahmood, A.; Razzaq, S.; Zafar, A.; Sidhu, G.A.S. Combined emission economic dispatch of power system including solar photo voltaic generation. Energy Convers. Manag. 2015, 92, 82–91. [Google Scholar] [CrossRef]

- Ma, H.; Yang, Z.; You, P.; Fei, M. Multi-objective biogeography-based optimization for dynamic economic emission load dispatch considering plug-in electric vehicles charging. Energy 2017, 135, 101–111. [Google Scholar] [CrossRef]

- Meziane, M.A.; Mouloudi, Y.; Draoui, A. Comparative study of the price penalty factors approaches for Bi-objective dispatch problem via PSO. Int. J. Electr. Comput. Eng. IJECE 2020, 10, 3343–3349. [Google Scholar] [CrossRef]

- Al-Betar, M.A.; Awadallah, M.A.; Krishan, M.M. A non-convex economic load dispatch problem with valve loading effect using a hybrid grey wolf optimizer. Neural Comput. Appl. 2019, 32, 12127–12154. [Google Scholar] [CrossRef]

- Elsayed, W.; El-Saadany, E.F.; Zeineldin, H.H.; Al-Sumaiti, A.S. Fast initialization methods for the nonconvex economic dispatch problem. Energy 2020, 201, 117635. [Google Scholar] [CrossRef]

- Zheng, M.; Wang, X.; Meinrenken, C.J.; Ding, Y. Economic and environmental benefits of coordinating dispatch among distributed electricity storage. Appl. Energy 2018, 210, 842–855. [Google Scholar] [CrossRef]

- Qin, Q.; Cheng, S.; Chu, X.; Lei, X.; Shi, Y. Solving non-convex/non-smooth economic load dispatch problems via an enhanced particle swarm optimization. Appl. Soft Comput. 2017, 59, 229–242. [Google Scholar] [CrossRef]

- Sharifi, S.; Sedaghat, M.; Farhadi, P.; Ghadimi, N.; Taheri, B. Environmental economic dispatch using improved artificial bee colony algorithm. Evol. Syst. 2017, 8, 233–242. [Google Scholar] [CrossRef]

- Reddy, A.S. Optimization of distribution network reconfiguration using dragonfly algorithm. J. Electr. Eng. 2016, 16, 10. [Google Scholar]

- Yıldız, B.S.; Yıldız, A.R. The Harris hawks optimization algorithm, salp swarm algorithm, grasshopper optimization algorithm and dragonfly algorithm for structural design optimization of vehicle components. Mater. Test. 2019, 61, 744–748. [Google Scholar] [CrossRef]

- dos Santos, E.S.; Nunes, M.V.A.; Júnior, J.D.A.B.; Nascimento, M.H.R.; Leite, J.C.; de Alencar, D.B.; de Freitas, C.A.O. Efficient use of the Generators for the Environmental Economic Dispatch from the energy system, including solar photovoltaic generation. Int. J. Innov. Educ. Res. 2021, 9, 9–34. [Google Scholar] [CrossRef]

- Qin, H.; Fan, P.; Tang, H.; Huang, P.; Fang, B.; Pan, S. An effective hybrid discrete grey wolf optimizer for the casting production scheduling problem with multi-objective and multi-constraint. Comput. Ind. Eng. 2019, 128, 458–476. [Google Scholar] [CrossRef]

- Santra, D.; Mukherjee, A.; Sarker, K.; Mondal, S. Dynamic economic dispatch using hybrid metaheuristics. J. Electr. Syst. Inf. Technol. 2020, 7, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Nascimento, M.H.R.; Junior, J.D.A.B.; De Freitas, C.A.O.; Moraes, N.M.; Leite, J.C. Analysis of the solution for the economic load dispatch by different mathematical methods and genetic algorithms: Case Study. ITEGAM-JETIA 2018, 4, 5–13. [Google Scholar] [CrossRef]

- Muhsen, D.H.; Nabil, M.; Haider, H.T.; Khatib, T. A novel method for sizing of standalone photovoltaic system using multi-objective differential evolution algorithm and hybrid multi-criteria decision making methods. Energy 2019, 174, 1158–1175. [Google Scholar] [CrossRef]

- Kuk, J.N.; Gonçalves, R.A.; Pavelski, L.M.; Venske, S.M.G.S.; de Almeida, C.P.; Pozo, A.T.R. An empirical analysis of constraint handling on evolutionary multi-objective algorithms for the Environmental/Economic Load Dispatch problem. Expert Syst. Appl. 2020, 165, 113774. [Google Scholar] [CrossRef]

- Bora, T.C.; Mariani, V.C.; Coelho, L.D.S. Multi-objective optimization of the environmental-economic dispatch with reinforcement learning based on non-dominated sorting genetic algorithm. Appl. Therm. Eng. 2019, 146, 688–700. [Google Scholar] [CrossRef]

- Moraes, N.M.; Bezerra, U.H.; Moya Rodriguez, J.L.; Nascimento, M.H.R.; Leite, J.C. A new approach to economic-emission load dispatch using NSGA II. Case study. Int. Trans. Electr. Energy Syst. 2018, 28, e2626. [Google Scholar] [CrossRef]

- Ogunmodede, O.; Anderson, K.; Cutler, D.; Newman, A. Optimizing design and dispatch of a renewable energy system. Appl. Energy 2021, 287, 116527. [Google Scholar] [CrossRef]

- Bustos, C.; Watts, D.; Olivares, D. The evolution over time of Distributed Energy Resource’s penetration: A robust framework to assess the future impact of prosumage under different tariff designs. Appl. Energy 2019, 256, 113903. [Google Scholar] [CrossRef]

- Adam, S.P.; Alexandropoulos, S.-A.N.; Pardalos, P.M.; Vrahatis, M.N. No Free Lunch Theorem: A Review. In Approximation and Optimization; Springer International Publishing: Cham, Switzerland, 2019; pp. 57–82. [Google Scholar] [CrossRef]

- Abido, M. A niched Pareto genetic algorithm for multiobjective environmental/economic dispatch. Int. J. Electr. Power Energy Syst. 2003, 25, 97–105. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Yuan, X.; Zhou, S. Environmental/economic power dispatch problem using multi-objective differential evolution algorithm. Electr. Power Syst. Res. 2010, 80, 1171–1181. [Google Scholar] [CrossRef]

- Mohamed, F.A.; Koivo, H.N. Online management of microgrid with battery storage using multiobjective optimization. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, Setubal, Portugal, 12–14 April 2007; pp. 231–236. [Google Scholar]

- Cervantes Rodriguez, C.R. Mecanismos Regulatorios, Tarifarios E Economicos Na Geração Distribuida: O Caso Dos Sistemas Fotovoltaticos Conectados a Rede. 2002. Available online: http://repositorio.unicamp.br/jspui/handle/REPOSIP/264941 (accessed on 14 March 2022).

- Basu, M. Economic environmental dispatch using multi-objective differential evolution. Appl. Soft Comput. 2011, 11, 2845–2853. [Google Scholar] [CrossRef]

- Deb, S.; Abdelminaam, D.S.; Said, M.; Houssein, E.H. Recent Methodology-Based Gradient-Based Optimizer for Economic Load Dispatch Problem. IEEE Access 2021, 9, 44322–44338. [Google Scholar] [CrossRef]

- Kamboj, V.K.; Bhadoria, A.; Bath, S.K. Solution of non-convex economic load dispatch problem for small-scale power systems using ant lion optimizer. Neural Comput. Appl. 2017, 28, 2181–2192. [Google Scholar] [CrossRef]

- Brini, S.; Abdallah, H.H.; Ouali, A. Economic dispatch for power system included wind and solar thermal energy. Leonardo J. Sci. 2009, 14, 204–220. [Google Scholar]

- Nwulu, N.; Xia, X. Multi-objective dynamic economic emission dispatch of electric power generation integrated with game theory based demand response programs. Energy Convers. Manag. 2015, 89, 963–974. [Google Scholar] [CrossRef]

- Wang, L.; Singh, C. Environmental/economic power dispatch using a fuzzified multi-objective particle swarm optimization algorithm. Electr. Power Syst. Res. 2007, 77, 1654–1664. [Google Scholar] [CrossRef]

- Huang, W.-T.; Yao, K.-C.; Chen, M.-K.; Wang, F.-Y.; Zhu, C.-H.; Chang, Y.-R.; Lee, Y.-D.; Ho, Y.-H. Derivation and Application of a New Transmission Loss Formula for Power System Economic Dispatch. Energies 2018, 11, 417. [Google Scholar] [CrossRef] [Green Version]

- Afandi, A.N. Thunderstorm algorithm for assessing thermal power plants of the integrated power system operation with an environmental requirement. Int. J. Eng. Technol. 2016, 8, 1102–1111. [Google Scholar]

- Nascimento, M.H.R.; Nunes, M.V.A.; Rodríguez, J.L.M.; Leite, J.C. A new solution to the economical load dispatch of power plants and optimization using differential evolution. Electr. Eng. 2017, 99, 561–571. [Google Scholar] [CrossRef]

- Dhamanda, A.; Dutt, A.; Prakash, S.; Bhardwaj, A.K. A traditional approach to solve economic load dispatch problem of thermal generating unit using MATLAB programming. Int. J. Eng. Res. Technol. 2013, 2, IJERTV2IS90218. [Google Scholar]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef] [Green Version]

- Mirjalili, S. Dragonfly algorithm: A new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems. Neural Comput. Appl. 2016, 27, 1053–1073. [Google Scholar] [CrossRef]

- Das, D.; Bhattacharya, A.; Ray, R.N. Dragonfly Algorithm for solving probabilistic Economic Load Dispatch problems. Neural Comput. Appl. 2020, 32, 3029–3045. [Google Scholar] [CrossRef]

- Meraihi, Y.; Ramdane-Cherif, A.; Acheli, D.; Mahseur, M. Dragonfly algorithm: A comprehensive review and applications. Neural Comput. Appl. 2020, 32, 16625–16646. [Google Scholar] [CrossRef]

- Reynolds, C.W. Flocks, herds and schools: A distributed behavioral model. In Proceedings of the 14th annual conference on Computer graphics and interactive techniques, Anaheim, CA, USA, 27–31 July 1987; pp. 25–34. [Google Scholar]

- Storn, R. Differrential evolution-a simple and efficient adaptive scheme for global optimization over continuous spaces. Tech. Rep. Int. Comput. Sci. Inst. 1995, 11. Available online: http://www.icsi.berkeley.edu/ftp/global/pub/techreports/1995/tr-95-012.pdf (accessed on 14 March 2022).

- Storn, R.; Price, K. Differential evolution–a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Roque, C.; Martins, P. Differential evolution for optimization of functionally graded beams. Compos. Struct. 2015, 133, 1191–1197. [Google Scholar] [CrossRef]

- Reddy, A.S.; Vaisakh, K. Shuffled differential evolution for large scale economic dispatch. Electr. Power Syst. Res. 2013, 96, 237–245. [Google Scholar] [CrossRef]

- Mirjalili, S. The Ant Lion Optimizer. Adv. Eng. Softw. 2015, 83, 80–98. [Google Scholar] [CrossRef]

- Mirjalili, S.; Jangir, P.; Saremi, S. Multi-objective ant lion optimizer: A multi-objective optimization algorithm for solving engineering problems. Appl. Intell. 2017, 46, 79–95. [Google Scholar] [CrossRef]

- Raju, M.; Saikia, L.C.; Sinha, N. Automatic generation control of a multi-area system using ant lion optimizer algorithm based PID plus second order derivative controller. Int. J. Electr. Power Energy Syst. 2016, 80, 52–63. [Google Scholar] [CrossRef]

- Refai, A.; Ebeed, M.; Kamel, S. Combined Economic and Emission Dispatch Analysis Using Lightning Attachment Procedure Optimizer. In Proceedings of the 2019 21st International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 17–19 December 2019. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Murphy, G.V.; Ndoye, M. A PSO Based Control Strategy for Combined Emission Economic Dispatch with Integrated Renewables. In Proceedings of the 52nd North American Power Symposium (NAPS), Tempe, AZ, USA, 11–14 April 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Trivedi, I.N.; Jangir, P.; Parmar, S.A. Optimal power flow with enhancement of voltage stability and reduction of power loss using ant-lion optimizer. Cogent Eng. 2016, 3, 1208942. [Google Scholar] [CrossRef]

- Manteaw, E.D.; Odero, N.A. Combined economic and emission dispatch solution using ABC_PSO hybrid algorithm with valve point loading effect. Int. J. Sci. Res. Publ. 2012, 2, 1–9. [Google Scholar]

| Machine No. | a ($/MW2h) | b ($/MW/h) | c ($/h) | Pmin (MW) | Pmax (MW) |

|---|---|---|---|---|---|

| 1 | 0.15247 | 38.53973 | 756.79886 | 10 | 125 |

| 2 | 0.10587 | 46.15916 | 451.32513 | 10 | 150 |

| 3 | 0.02803 | 40.39655 | 1049.32513 | 40 | 250 |

| 4 | 0.03546 | 38.30553 | 1243.5311 | 35 | 210 |

| 5 | 0.02111 | 36.32782 | 1658.5696 | 130 | 325 |

| 6 | 0.01799 | 38.27041 | 1353.27041 | 125 | 315 |

| Machine No. | α (kg/MW2 h) | β (kg/MW h) | (kg/h) |

|---|---|---|---|

| 1 | 0.00419 | 0.32767 | 13.85932 |

| 2 | 0.00419 | 0.32767 | 13.85932 |

| 3 | 0.00683 | −0.54551 | 40.2669 |

| 4 | 0.00683 | −0.54551 | 40.2669 |

| 5 | 0.00461 | −0.51116 | 42.89553 |

| 6 | 0.00461 | −0.51116 | 42.89553 |

| Plant | Prated (Mw) | Unit Rate ($/kw h) |

|---|---|---|

| 1 | 20 | 0.22 |

| 2 | 25 | 0.23 |

| 3 | 25 | 0.23 |

| 4 | 30 | 0.24 |

| 5 | 30 | 0.24 |

| 6 | 35 | 0.25 |

| 7 | 35 | 0.26 |

| 8 | 40 | 0.27 |

| 9 | 40 | 0.27 |

| 10 | 40 | 0.28 |

| 11 | 40 | 0.28 |

| 12 | 40 | 0.28 |

| 13 | 40 | 0.28 |

| Time | Global Solar Radiation (W/m2) | Power Demand (MW) | Temp. (°C) |

|---|---|---|---|

| 01:00 | 0 | 965 | 30 |

| 02:00 | 0 | 1142 | 29 |

| 03:00 | 0 | 1177 | 28 |

| 04:00 | 0 | 1198 | 28 |

| 05:00 | 5.4 | 1153 | 28 |

| 06:00 | 101 | 1136 | - |

| 07:00 | 253.7 | 1138 | 29 |

| 08:00 | 541.2 | 1060 | 31 |

| 09:00 | 530.4 | 1155 | 33 |

| 10:00 | 793.9 | 1244 | 34 |

| 11:00 | 1078 | 1088 | 35 |

| 12:00 | 1125.6 | 1240 | 36 |

| 13:00 | 1013.5 | 1135 | 37 |

| 14:00 | 848.2 | 1318 | 37 |

| 15:00 | 726.7 | 1074 | 37 |

| 16:00 | 654 | 1190 | 38 |

| 17:00 | 392.9 | 1276 | 38 |

| 18:00 | 215.1 | 1154 | 37 |

| 19:00 | 385 | 1333 | 35 |

| 20:00 | 0 | 1322 | 34 |

| 21:00 | 0 | 1269 | 34 |

| 22:00 | 0 | 1139 | 33 |

| 23:00 | 0 | 1202 | 32 |

| 00:00 | 0 | 1291 | - |

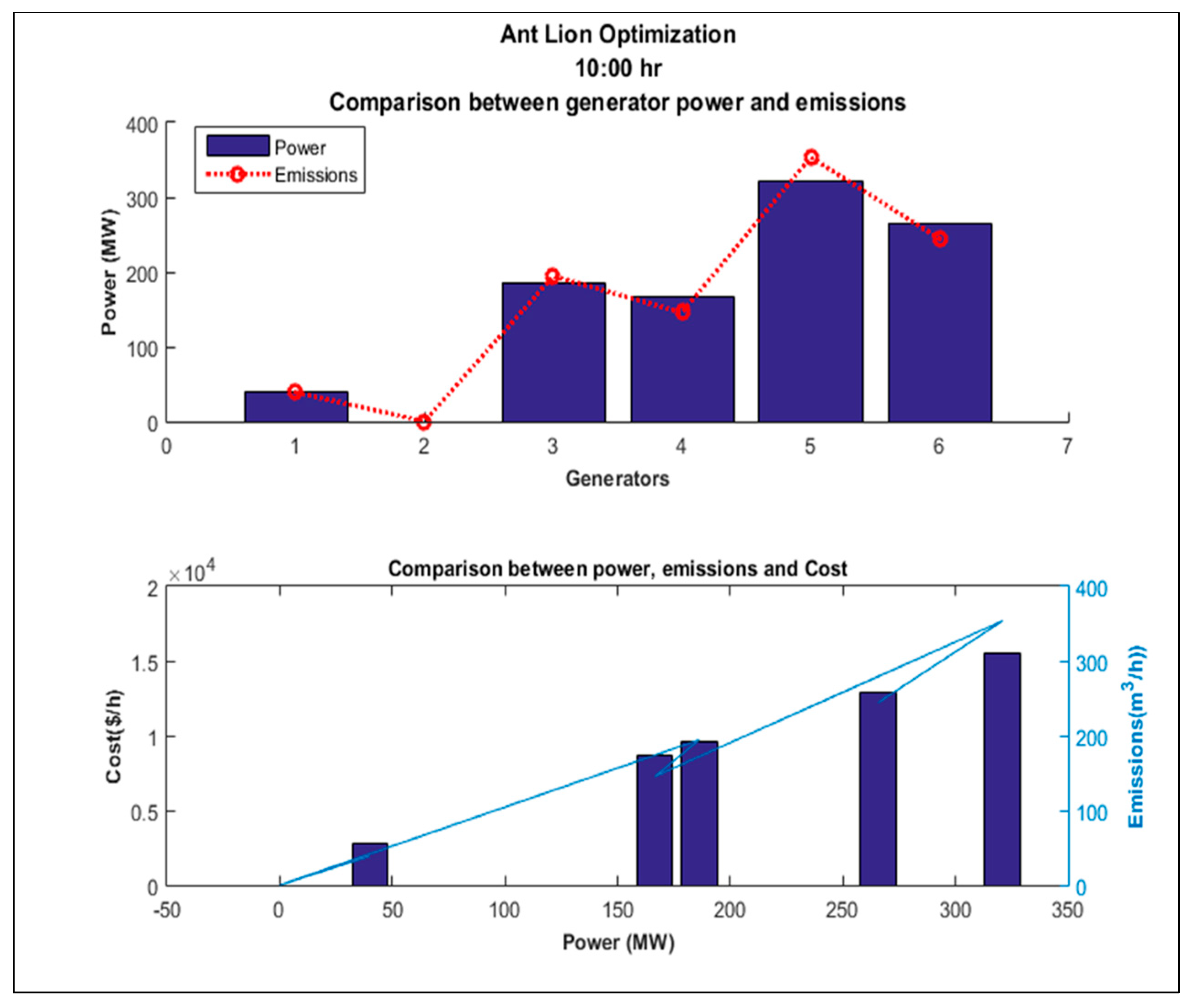

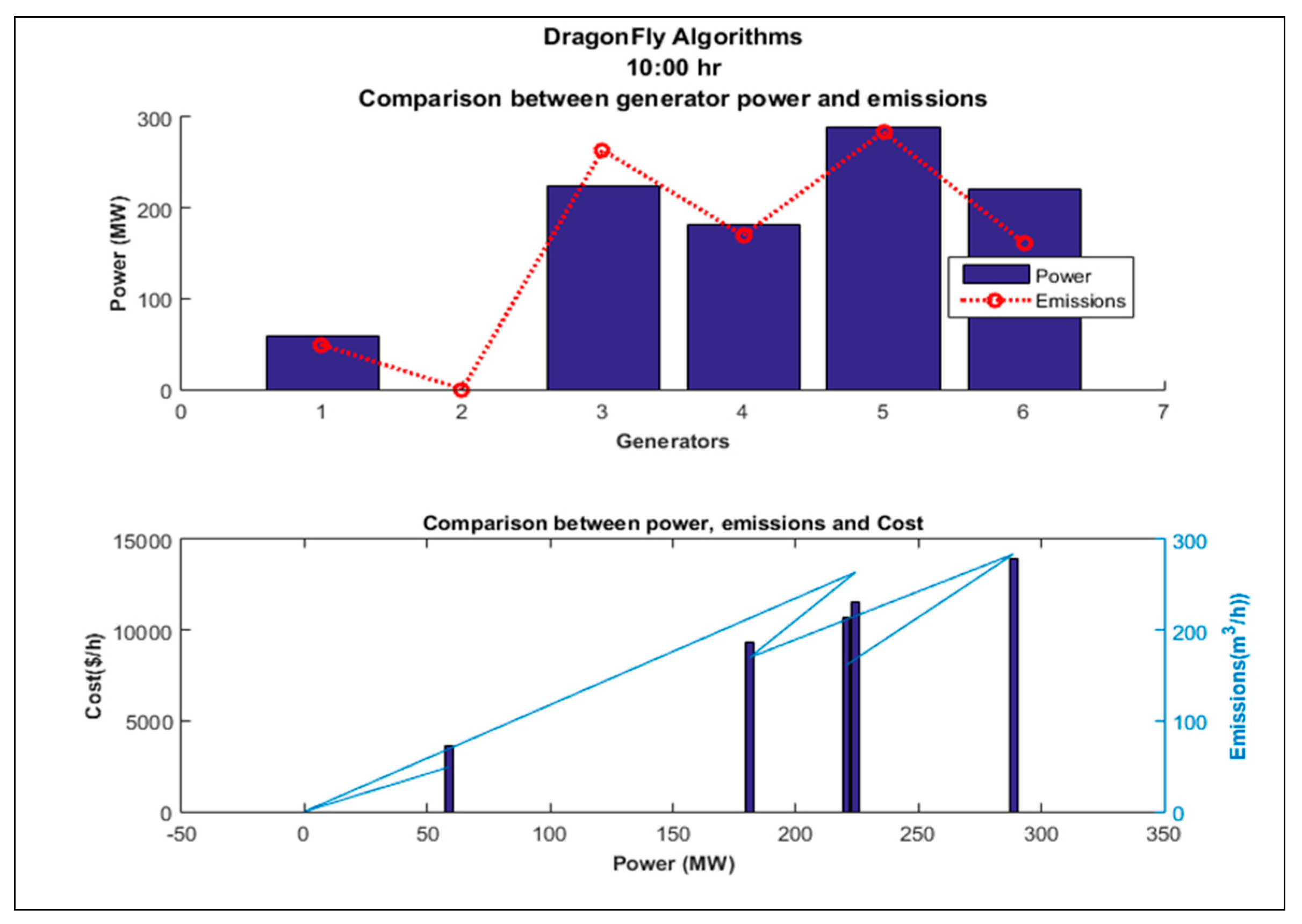

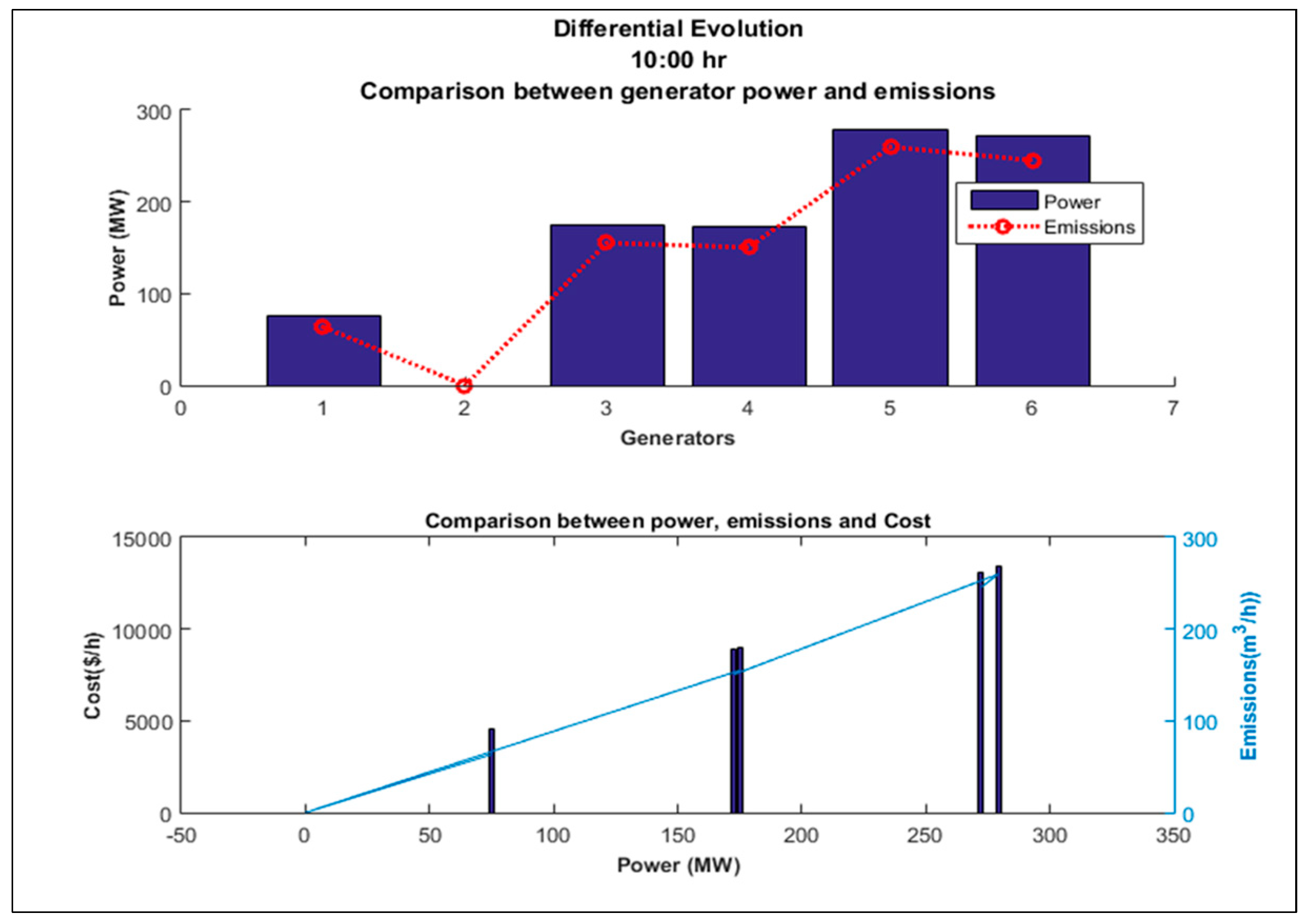

| The Simulation Presents the Results for Solar Power for 1244 MW at 10:00 A.M. UG | Khan [8] PSO | ALO | DA | DE |

|---|---|---|---|---|

| P1 (MW) | 120.4479 | 40.17953733 | 58.78230624 | 75.3254182 |

| P2 (MW) | 92.2947 | 0 | 0 | 0 |

| P3 (MW) | 155.8062 | 186.2565862 | 224.4173503 | 175.175433 |

| P4 (MW) | 76.4153 | 166.5931178 | 181.9118006 | 172.529459 |

| P5 (MW) | 257.9089 | 320.8753342 | 288.6447747 | 279.292715 |

| P6 (MW) | 302.2846 | 265.7177937 | 220.5766397 | 272.121335 |

| Total Thermal Power (MW) | 1005.1576 | 979.62 | 973.63 | 974.44 |

| Solar Power share (MW) | 238.825 | 269.644 | 269.644 | 269.644 |

| Total Power (MW) | 1243.9826 | 1249.27 | 1243.98 | 1244.09 |

| Fuel cost ($/h) | 52,626.00 | 49,337.05 | 49,126.17 | 49,027.83 |

| Emission Reduction | 19.20% | 21.58% | 21.69% | 21.67% |

| UG | Khan [8] PSO | ALO | DA | DE |

|---|---|---|---|---|

| P1 (MW) | 10.1062 | 79.3219763 | 41.52797 | 86.7820923 |

| P2 (MW) | 10 | 0 | 0 | 0 |

| P3 (MW) | 99.1 | 0 | 0 | 0 |

| P4 (MW) | 168.682 | 120.480886 | 157.301909 | 161.562873 |

| P5 (MW) | 235.8781 | 293.56174 | 262.569286 | 252.487176 |

| P6 (MW) | 246.7809 | 235.000594 | 269.032945 | 226.1967 |

| Total Thermal Power (MW) | 770.5472 | 728.37 | 730.43 | 727.03 |

| Solar Power share (MW) | 317.471 | 364.6572 | 364.6572 | 364.6572 |

| Total Power (MW) | 1088.0182 | 1093.02 | 1095.09 | 1091.69 |

| Fuel cost ($/h) | 39,426.00 | 36,891.78 | 36,537.91 | 36,774.07 |

| Emission Reduction | 29.18% | 33.36% | 33.30% | 33.40% |

| UG | Khan [8] PSO | ALO | DA | DE |

|---|---|---|---|---|

| P1 (MW) | 10.0000 | 60.5857502 | 56.0095473 | 64.3998993 |

| P2 (MW) | 10.2191 | 0 | 0 | 0 |

| P3 (MW) | 194.9316 | 172.74449 | 169.4236 | 155.009176 |

| P4 (MW) | 177.4014 | 135.063318 | 152.994586 | 151.431848 |

| P5 (MW) | 224.8683 | 256.93173 | 232.337102 | 246.627089 |

| P6 (MW) | 303.5647 | 238.005412 | 252.389297 | 243.248632 |

| Total Thermal Power (MW) | 920.9851 | 863.33 | 863.15 | 860.72 |

| Solar Power share (MW) | 319.1076 | 379.2137 | 379.2137 | 379.2137 |

| Total Power (MW) | 1240.0927 | 1242.54 | 1242.37 | 1239.983 |

| Fuel cost ($/h) | 46,762.00 | 43,635.43 | 43,690.57 | 43,393.47 |

| Emission Reduction | 25.73% | 30.52% | 30.52% | 30.58% |

| UG | Khan [8] PSO | ALO | DA | DE |

|---|---|---|---|---|

| P1 (MW) | 10.8593 | 87.5136189 | 76.5424528 | 85.1259115 |

| P2 (MW) | 118.1312 | 0 | 0 | 0 |

| P3 (MW) | 147.9272 | 0 | 0 | 0 |

| P4 (MW) | 186.3632 | 153.984147 | 179.975248 | 176.742446 |

| P5 (MW) | 150.7713 | 290.415925 | 290.251821 | 276.349213 |

| P6 (MW) | 221.0182 | 268.600735 | 261.928024 | 262.053767 |

| Total Thermal Power (MW) | 835.0704 | 800.51 | 808.70 | 800.27 |

| Solar Power share (MW) | 300.0974 | 340.056 | 340.056 | 340.056 |

| Total Power (MW) | 1135.1678 | 1140.57 | 1148.75 | 1140.33 |

| Fuel cost ($/h) | 44,136.00 | 40,408.16 | 40,689.57 | 40,322.38 |

| Emission Reduction | 26.44% | 29.81% | 29.60% | 29.82% |

| UG | Khan [8] PSO | ALO | DA | DE |

|---|---|---|---|---|

| P1 (MW) | 65.2834 | 88.0029047 | 63.3546866 | 68.7950098 |

| P2 (MW) | 97.2893 | 78.8123312 | 74.9684444 | 60.8853804 |

| P3 (MW) | 250 | 171.876892 | 158.668584 | 172.298593 |

| P4 (MW) | 107.6407 | 153.785556 | 169.725347 | 169.738537 |

| P5 (MW) | 252.7949 | 235.599762 | 288.435287 | 289.768452 |

| P6 (MW) | 297.7576 | 312.66407 | 279.817291 | 275.863726 |

| Total Thermal Power (MW) | 1070.7659 | 1040.74 | 1034.97 | 1037.35 |

| Solar Power share (MW) | 247.1655 | 284.5935 | 284.5935 | 284.5935 |

| Total Power (MW) | 1317.9314 | 1325.34 | 1319.56 | 1321.94 |

| Fuel cost ($/h) | 55,082.00 | 53,803.31 | 52,959.36 | 52,691.30 |

| Emission Reduction | 18.75% | 21.47% | 21.57% | 21.53% |

| UG | Khan [8] PSO | ALO | DA | DE |

|---|---|---|---|---|

| P1 (MW) | 82.7064 | 72.2365132 | 83.3714766 | 68.5854703 |

| P2 (MW) | 60.696 | 0 | 0 | 0 |

| P3 (MW) | 249.2579 | 109.101221 | 152.882149 | 146.602609 |

| P4 (MW) | 96.2554 | 164.950939 | 125.772343 | 143.316844 |

| P5 (MW) | 182.7257 | 219.94956 | 231.070386 | 239.300268 |

| P6 (MW) | 190.6486 | 266.531475 | 248.983057 | 232.386728 |

| Total Thermal Power (MW) | 862.29 | 832.77 | 842.08 | 830.19 |

| Solar Power share (MW) | 211.7604 | 243.827 | 243.827 | 243.827 |

| Total Power (MW) | 1074.0504 | 1076.60 | 1085.91 | 1074.02 |

| Fuel cost ($/h) | 45,057.00 | 42,554.83 | 42,856.77 | 41,985.64 |

| Emission Reduction | 19.72% | 22.65% | 22.45% | 22.70% |

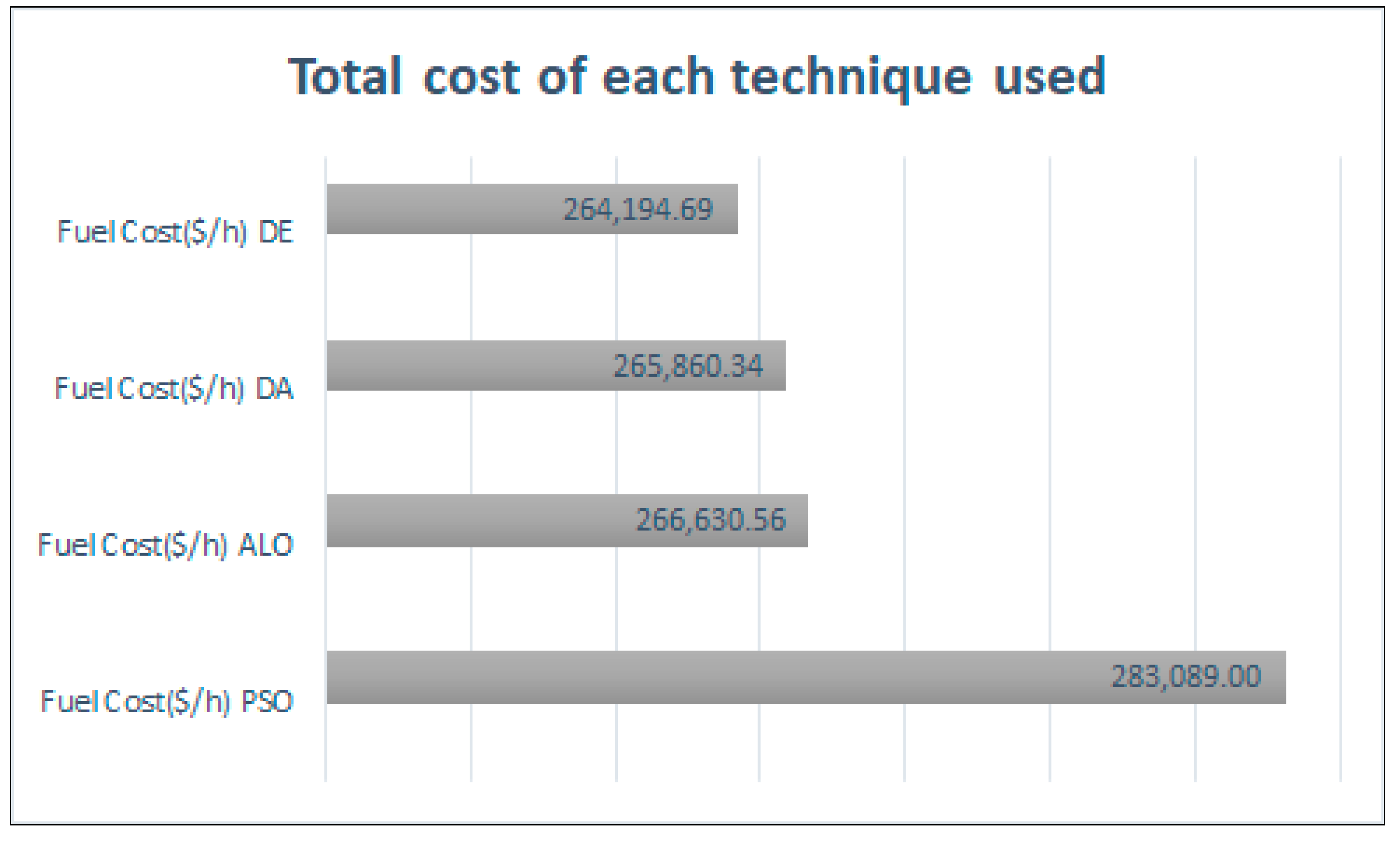

| Time Hours | PSO | ALO | DA | DE | |||

|---|---|---|---|---|---|---|---|

| Fuel Cost ($/h) | Fuel Cost ($/h) | Reduction % | Fuel Cost ($/h) | Reduction % | Fuel Cost ($/h) | Reduction % | |

| 10:00 | 52,626.00 | 49,337.05 | 6.25 | 49,126.17 | 6.65 | 49,027.83 | 6.84 |

| 11:00 | 39,426.00 | 36,891.78 | 6.43 | 36,537.91 | 7.33 | 36,774.07 | 7.33 |

| 12:00 | 46,762.00 | 43,635.43 | 6.69 | 43,690.57 | 6.57 | 43,393.47 | 7.20 |

| 13:00 | 44,136.00 | 40,408.16 | 8.45 | 40,689.57 | 7.81 | 40,322.38 | 8.64 |

| 14:00 | 55,082.00 | 53,803.31 | 2.32 | 52,959.36 | 3.85 | 52,691.30 | 4.34 |

| 15:00 | 45,057.00 | 42,554.83 | 5.55 | 42,856.77 | 4.88 | 41,985.64 | 6.82 |

| Total | 283,089.00 | 266,630.56 | 5.81 | 265,860.34 | 6.09 | 264,194.69 | 6.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, E.S.d.; Nunes, M.V.A.; Nascimento, M.H.R.; Leite, J.C. Rational Application of Electric Power Production Optimization through Metaheuristics Algorithm. Energies 2022, 15, 3253. https://doi.org/10.3390/en15093253

Santos ESd, Nunes MVA, Nascimento MHR, Leite JC. Rational Application of Electric Power Production Optimization through Metaheuristics Algorithm. Energies. 2022; 15(9):3253. https://doi.org/10.3390/en15093253

Chicago/Turabian StyleSantos, Eliton Smith dos, Marcus Vinícius Alves Nunes, Manoel Henrique Reis Nascimento, and Jandecy Cabral Leite. 2022. "Rational Application of Electric Power Production Optimization through Metaheuristics Algorithm" Energies 15, no. 9: 3253. https://doi.org/10.3390/en15093253

APA StyleSantos, E. S. d., Nunes, M. V. A., Nascimento, M. H. R., & Leite, J. C. (2022). Rational Application of Electric Power Production Optimization through Metaheuristics Algorithm. Energies, 15(9), 3253. https://doi.org/10.3390/en15093253