State of Charge Centralized Estimation of Road Condition Information Based on Fuzzy Sunday Algorithm

Abstract

:1. Introduction

1.1. Background

1.2. Related Works

1.3. Advantages and Innovations

1.4. The Article’s Structure

2. Descriptions of Datasets and Model

2.1. Experimental Data

2.2. Experimental Model Construction

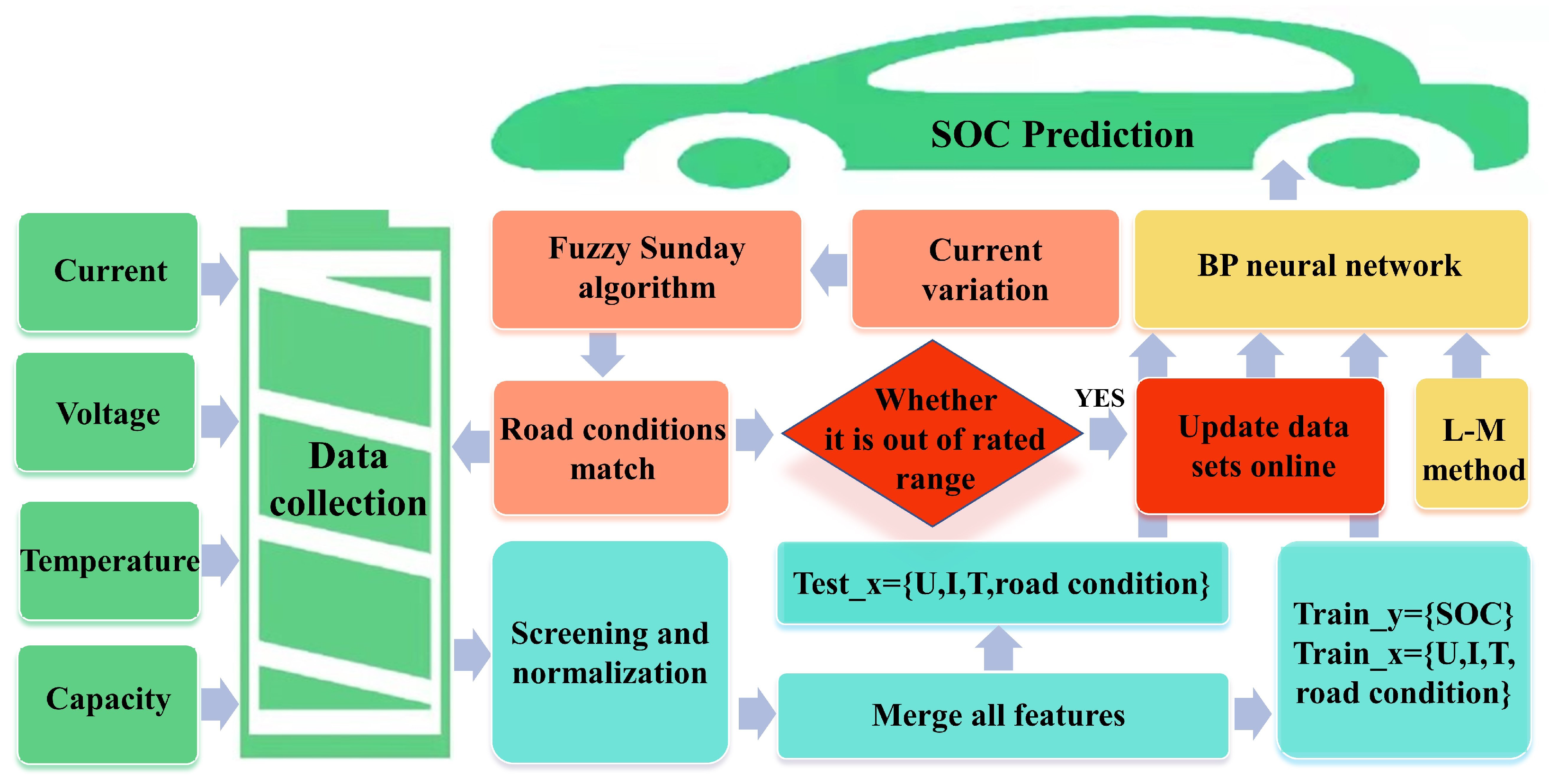

2.2.1. Model Overview

2.2.2. Improved Fuzzy Sunday Algorithm

| Algorithm 1 Whether the road conditions match (Sunday). |

Ensure:

|

2.2.3. Backpropagation Neural Network

3. Experimental Verification

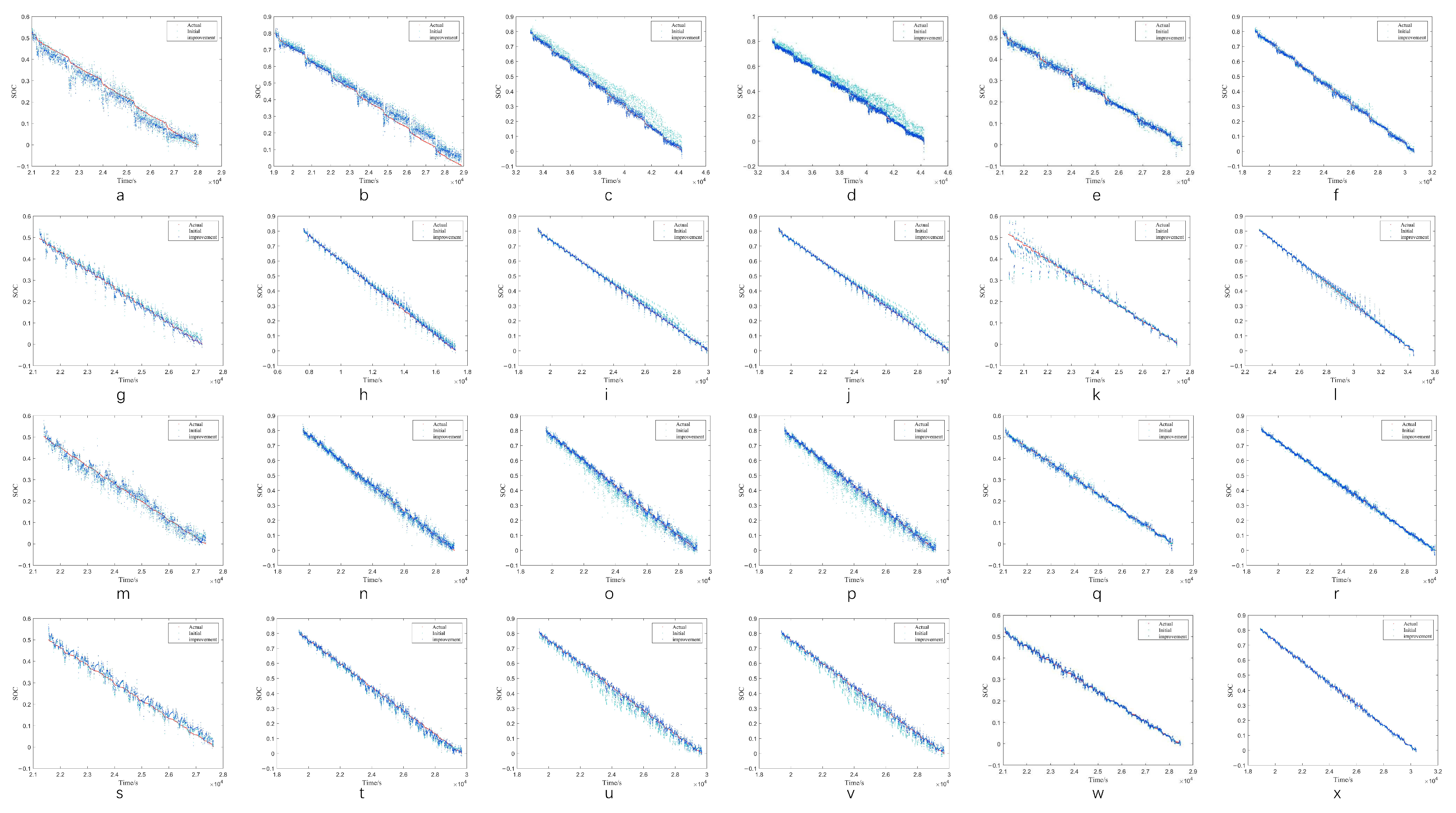

3.1. Experiment and Error Analysis

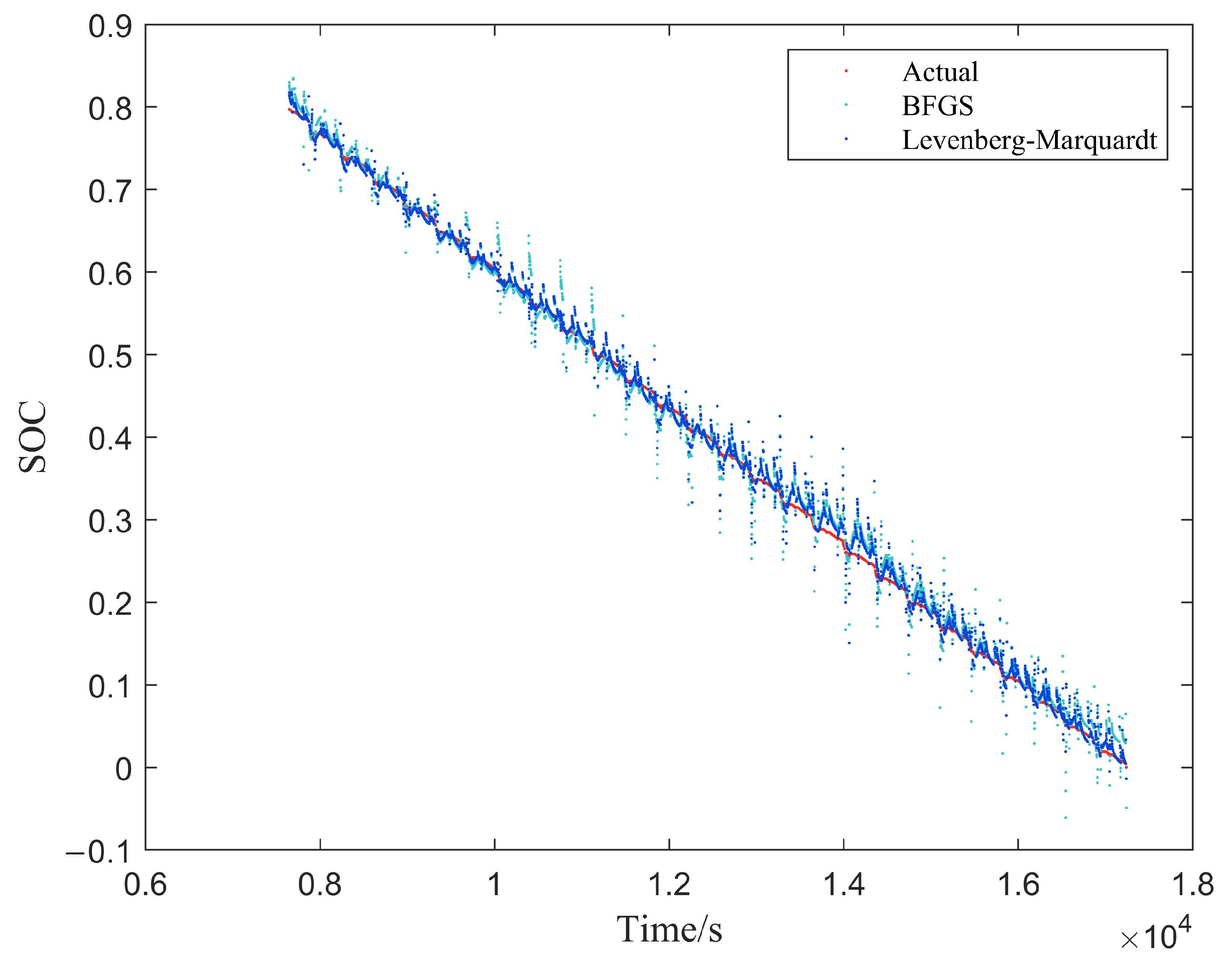

3.2. Analysis of the Training Algorithm

4. Discussion

4.1. Estimation Strategies for Unknown Road Conditions

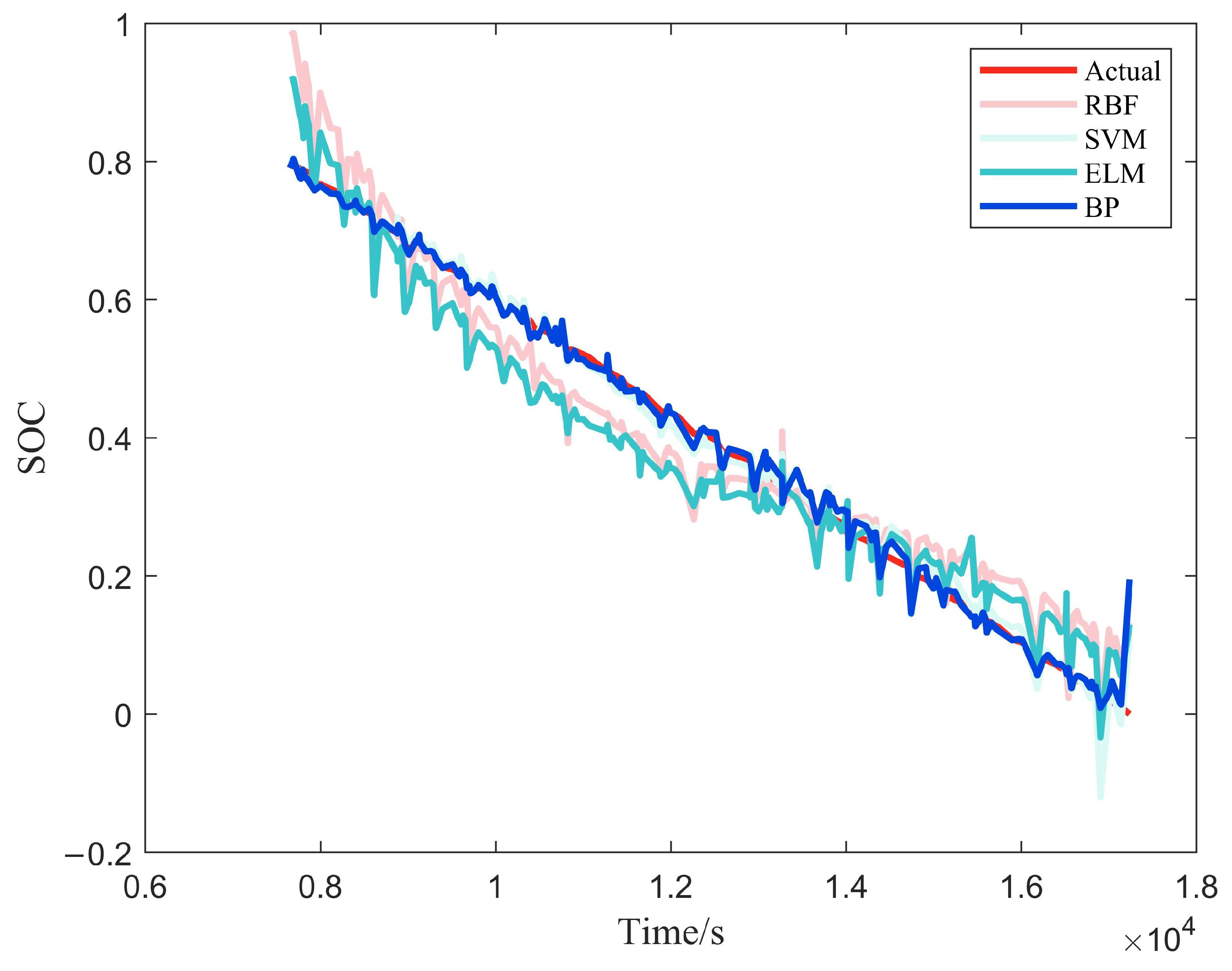

4.2. Comparison with Other SOC Models

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SOC | state of charge |

| LIBs | lithium-ion batteries |

| BPNN | backpropagation neural network |

| L–M | Levenberg–Marquardt |

| DST | dynamic stress test |

| FUDS | Federal Urban Driving Schedule |

| US06 | A type of federal test procedure |

| BJDST | Beijing dynamic stress test |

| MAE | Mean absolute error |

| MSE | Mean square error |

| RMSE | Root mean square error |

| BFGS | quasi-Newton method |

References

- Stampatori, D.; Raimondi, P.P.; Noussan, M. Li-ion batteries: A review of a key technology for transport decarbonization. Energies 2020, 13, 2638. [Google Scholar] [CrossRef]

- Yu, W.; Chao, W.; Xingsheng, G. Research on fault diagnosis method for over-discharge of power lithium battery. In Theory, Methodology, Tools and Applications for Modeling and Simulation of Complex Systems; Springer: Singapore, 2016; pp. 308–314. [Google Scholar]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Ng, K.S.; Moo, C.; Chen, Y.; Hsieh, Y. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Appl. Energy 2009, 86, 1506–1511. [Google Scholar] [CrossRef]

- Weng, C.; Sun, J.; Peng, H. A unified open-circuit-voltage model of lithium-ion batteries for state-of-charge estimation and state-of-health monitoring. J. Power Sources 2014, 258, 228–237. [Google Scholar] [CrossRef]

- He, Z.; Yang, Z.; Cui, X.; Li, E. A method of state-of-charge estimation for EV power lithium-ion battery using a novel adaptive extended kalman filter. IEEE Trans. Veh. Technol. 2020, 69, 14618–14630. [Google Scholar] [CrossRef]

- Sun, D.; Yu, X.; Zhang, C.; Wang, C.; Huang, R. State of charge estimation for lithium-ion battery based on an intelligent adaptive unscented Kalman filter. Int. J. Energy Res. 2020, 44, 11199–11218. [Google Scholar] [CrossRef]

- Lai, X.; Yi, W.; Zheng, Y.; Zhou, L. An all-region state-of-charge estimator based on global particle swarm optimization and improved extended kalman filter for lithium-ion batteries. Electronics 2018, 7, 321. [Google Scholar] [CrossRef] [Green Version]

- Ye, M.; Guo, H.; Cao, B. A model-based adaptive state of charge estimator for a lithium-ion battery using an improved adaptive particle filter. Appl. Energy 2017, 190, 740–748. [Google Scholar] [CrossRef]

- Lipu, H.; Hannan, M.A.; Hussain, A.; Ayob, A.; Saad, M.H.; Muttaqi, K.M. State of charge estimation in lithium-ion batteries: A neural network optimization approach. Electronics 2020, 9, 1546. [Google Scholar] [CrossRef]

- Rivera-Barrera, J.P.; Muñoz-Galeano, N.; Sarmiento-Maldonado, H.O. SoC Estimation for Lithium-ion Batteries: Review and Future Challenges. Electronics 2017, 6, 102. [Google Scholar] [CrossRef] [Green Version]

- Cheng, A.; Wang, Y. A Novel State of Charge Estimation Method of Batteries Using Recurrent Neural Networks. In Proceedings of the 2018 International Conference on Network, Communication, Computer Engineering (NCCE 2018), Chongqing, China, 26–27 May 2018. [Google Scholar]

- Liu, Z.; Dang, X.; Jing, B.; Ji, J. A novel model-based state of charge estimation for lithium-ion battery using adaptive robust iterative cubature kalman filter. Electr. Power Syst. Res. 2017, 177, 105951. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Chen, X. A novel framework for lithium-ion battery state of charge estimation based on Kalman filter Gaussian process regression. Int. J. Energy Res. 2021, 45, 13238–13249. [Google Scholar] [CrossRef]

- Xie, F. A novel battery state of charge estimation based on the joint unscented kalman filter and support vector machine algorithms. Electr. Power Syst. Res. 2020, 8, 7935–7953. [Google Scholar] [CrossRef]

- Wang, C.; Fan, X.; Zhang, X.; Gao, L.; Liu, H. An evaluation method of li-ion batteries state of charge based on irvm and verified by simulation. Appl. Electron. Tech. 2018, 44, 127–130. [Google Scholar]

- Wan, X.; Yang, B.; Fan, Z. Improved Sunday Pattern Matching Algorithm. Appl. Electron. Tech. 2009, 35, 125–126. [Google Scholar]

- Alicherry, M.; Muthuprasanna, M.; Kumar, V. High Speed Pattern Matching for Network IDS/IPS. In Proceedings of the 2006 IEEE International Conference on Network Protocols, Santa Barbara, CA, USA, 12–15 November 2006; pp. 187–196. [Google Scholar]

- Baeza-Yates, R.; Gonnet, G.H. A New Approach to Text Searching. Commun. ACM 1992, 35, 74–82. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Chen, C.; Pecht, M. State of charge estimation for li-ion batteries using neural network modeling and unscented kalman filter-based error cancellation. Int. J. Electr. Power Energy Syst. 2014, 62, 783–791. [Google Scholar] [CrossRef]

- Hunt, G. Usabc Electric Vehicle Battery Test Procedures Manual; Office of Scientific & Technical Information Technical Reports; United States Department of Energy: Washington, DC, USA, 1996.

- Jiang, F.; Yang, J.; Cheng, Y.; Zhang, X.; Yang, Y.; Gao, K.; Peng, J.; Huang, Z. An aging-aware soc estimation method for lithium-ion batteries using xgboost algorithm. In Proceedings of the 2019 IEEE International Conference on Prognostics and Health Management (ICPHM), San Francisco, CA, USA, 17–20 June 2019. [Google Scholar]

- Song, S.; Zhang, X.; Gao, D.; Jiang, F.; Wu, Y.; Huang, J.; Gong, Y.; Liu, B.; Huang, Z. A hierarchical state of charge estimation method for lithium-ion batteries via xgboost and kalman filter. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020. [Google Scholar]

- Al-Gabalawy, M.; Hosny, N.S.; Dawson, J.A.; Omar, A.I. State of charge estimation of a li-ion battery based on extended kalman filtering and sensor bias. Int. J. Energy Res. 2021, 45, 6708–6726. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Shen, W.; Lu, J. State-of-charge estimation of lifepo4 batteries in electric vehicles: A deep-learning enabled approach. Appl. Energy 2021, 291, 116812. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Qin, Y.; Adams, S.; Yuen, C. Transfer learning-based state of charge estimation for lithium-ion battery at varying ambient temperatures. IEEE Trans. Ind. Inform. 2021, 17, 7304–7315. [Google Scholar] [CrossRef]

- Sunday, D.M. A very fast substring search algorithm. Commun. ACM 1990, 33, 132–142. [Google Scholar] [CrossRef]

- Yufang, F.; Houqing, L.; Hong, Y. Study on fault diagnosis model based on bp neural network. Comput. Eng. Appl. 2019, 55, 24–30. [Google Scholar]

- Marquardt, D.W. An algorithm for least-squares estimation of non-linear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Gavin, H.P. The Levenberg–Marquardt Algorithm for Nonlinear Least Squares Curve-Fitting Problems; Department of Civil and Environmental Engineering, Duke University: Duke, NC, USA, 2019; Volume 19. [Google Scholar]

| Condition | DST | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature | 0 | 25 | 45 | |||||||||

| State | 50 | 80 | 50 | 80 | 50 | 80 | ||||||

| Improve | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes |

| MAE | 2.60 × 10 | 2.80 × 10 | 2.92 × 10 | 2.48 × 10 | 2.78 × 10 | 9.74 × 10 | 2.79 × 10 | 9.76 × 10 | 8.76 × 10 | 7.37 × 10 | 8.04 × 10 | 7.00 × 10 |

| MSE | 1.20 × 10 | 1.27 × 10 | 1.31 × 10 | 1.01 × 10 | 1.61 × 10 | 1.72 × 10 | 1.63 × 10 | 1.79 × 10 | 1.56 × 10 | 1.03 × 10 | 1.36 × 10 | 8.68 × 10 |

| RMSE | 3.35 × 10 | 3.56 × 10 | 3.61 × 10 | 3.17 × 10 | 4.02 × 10 | 1.31 × 10 | 4.04 × 10 | 1.34 × 10 | 1.25 × 10 | 1.01 × 10 | 1.17 × 10 | 9.32 × 10 |

| Condition | FUDS | |||||||||||

| Temperature | 0 | 25 | 45 | |||||||||

| State | 50 | 80 | 50 | 80 | 50 | 80 | ||||||

| Improve | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes |

| MAE | 1.42 × 10 | 1.17 × 10 | 1.37 × 10 | 8.93 × 10 | 1.20 × 10 | 5.02 × 10 | 1.22 × 10 | 5.06 × 10 | 1.51 × 10 | 1.20 × 10 | 5.80 × 10 | 7.67 × 10 |

| MSE | 3.59 × 10 | 2.54 × 10 | 3.63 × 10 | 1.88 × 10 | 3.08 × 10 | 5.56 × 10 | 3.20 × 10 | 5.68 × 10 | 9.12 × 10 | 6.41 × 10 | 9.01 × 10 | 1.78 × 10 |

| RMSE | 1.89 × 10 | 1.60 × 10 | 1.91 × 10 | 1.37 × 10 | 1.76 × 10 | 7.46 × 10 | 1.79 × 10 | 7.54 × 10 | 3.02 × 10 | 2.53 × 10 | 9.50 × 10 | 1.34 × 10 |

| Condition | US06 | |||||||||||

| Temperature | 0 | 25 | 45 | |||||||||

| State | 50 | 80 | 50 | 80 | 50 | 80 | ||||||

| Improve | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes |

| MAE | 1.93 × 10 | 1.81 × 10 | 1.53 × 10 | 1.27 × 10 | 2.56 × 10 | 1.28 × 10 | 2.65 × 10 | 1.27 × 10 | 6.74 × 10 | 6.00 × 10 | 5.97 × 10 | 5.29 × 10 |

| MSE | 6.31 × 10 | 5.28 × 10 | 4.30 × 10 | 2.99 × 10 | 1.30 × 10 | 2.93 × 10 | 1.43 × 10 | 2.91 × 10 | 9.37 × 10 | 6.13 × 10 | 7.54 × 10 | 4.93 × 10 |

| RMSE | 2.51 × 10 | 2.30 × 10 | 2.07 × 10 | 1.73 × 10 | 3.61 × 10 | 1.71 × 10 | 3.78 × 10 | 1.71 × 10 | 9.68 × 10 | 7.83 × 10 | 8.68 × 10 | 7.02 × 10 |

| Condition | BJDST | |||||||||||

| Temperature | 0 | 25 | 45 | |||||||||

| State | 50 | 80 | 50 | 80 | 50 | 80 | ||||||

| Improve | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes |

| MAE | 1.66 × 10 | 1.86 × 10 | 1.74 × 10 | 1.30 × 10 | 2.49 × 10 | 1.11 × 10 | 2.55 × 10 | 1.12 × 10 | 5.00 × 10 | 5.02 × 10 | 4.53 × 10 | 4.69 × 10 |

| MSE | 4.04 × 10 | 4.90 × 10 | 5.34 × 10 | 3.16 × 10 | 1.23 × 10 | 2.32 × 10 | 1.29 × 10 | 2.29 × 10 | 4.41 × 10 | 4.37 × 10 | 3.58 × 10 | 3.76 × 10 |

| RMSE | 2.01 × 10 | 2.21 × 10 | 2.31 × 10 | 1.78 × 10 | 3.51 × 10 | 1.52 × 10 | 3.60 × 10 | 1.51 × 10 | 6.64 × 10 | 6.61 × 10 | 5.98 × 10 | 6.13 × 10 |

| Improve | No | Yes | ||||

|---|---|---|---|---|---|---|

| Error | MAE | MSE | RMSE | MAE | MSE | RMSE |

| Summary | 1.65 × 10 | 6.73 × 10 | 2.59 × 10 | 1.07 × 10 | 2.70 × 10 | 1.64 × 10 |

| FUDS | 2.14 × 10 | 3.60 × 10 | 3.19 × 10 | 1.37 × 10 | 2.01 × 10 | 2.05 × 10 |

| DST | 1.17 × 10 | 3.60 × 10 | 1.90 × 10 | 7.84 × 10 | 2.01 × 10 | 1.42 × 10 |

| US06 | 1.65 × 10 | 6.69 × 10 | 2.59 × 10 | 1.09 × 10 | 2.38 × 10 | 1.54 × 10 |

| BJDST | 1.59 × 10 | 6.25 × 10 | 2.50 × 10 | 1.02 × 10 | 2.10 × 10 | 1.45 × 10 |

| Method | L–M | BFGS |

|---|---|---|

| MAE | 1.07 × 10 | 1.40 × 10 |

| MSE | 2.70 × 10 | 3.84 × 10 |

| RMSE | 1.64 × 10 | 1.96 × 10 |

| Method | Add | Not Added | Add and Update |

|---|---|---|---|

| MAE | 2.19 × 10 | 2.32 × 10 | 1.19 × 10 |

| MSE | 5.08 × 10 | 1.15 × 10 | 4.00 × 10 |

| RMSE | 2.58 × 10 | 3.40 × 10 | 2.00 × 10 |

| Time consuming/s | 0.197 | 0.086 | 0.516 |

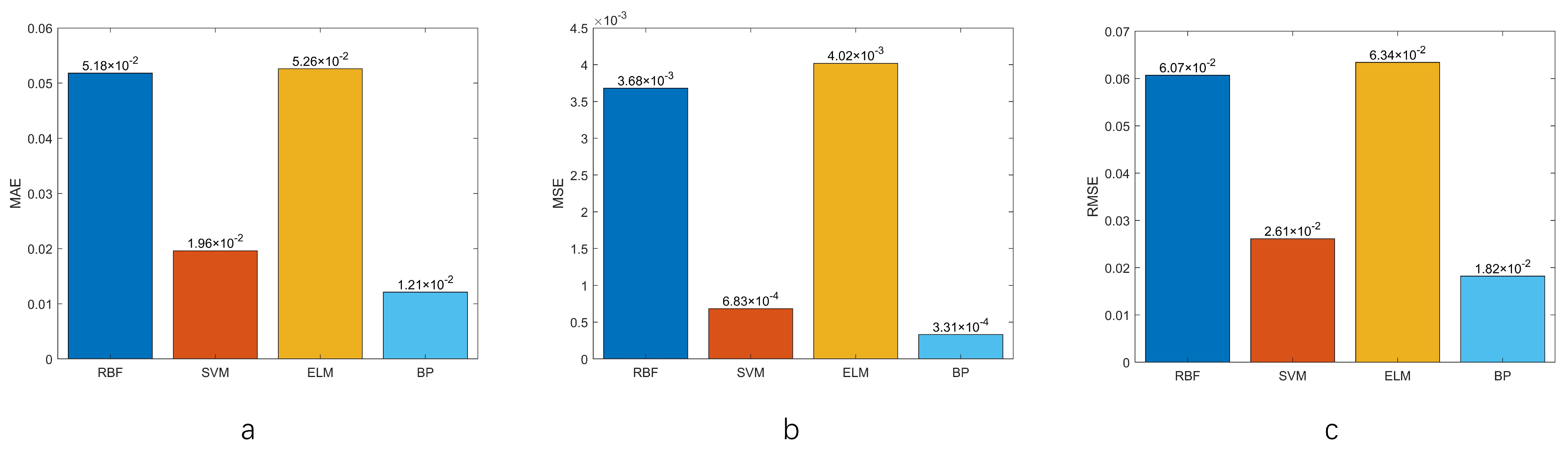

| Algorithm | RBF | SVM | ELM | BP |

|---|---|---|---|---|

| MAE | 5.18 × 10 | 1.96 × 10 | 5.26 × 10 | 1.21 × 10 |

| MSE | 3.68 × 10 | 6.83 × 10 | 4.02 × 10 | 3.31 × 10 |

| RMSE | 6.07 × 10 | 2.61 × 10 | 6.34 × 10 | 1.82 × 10 |

| Time consuming/s | 6.241 | 2.378 | 0.006 | 0.173 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Lin, B.; Wang, M.; Zhang, J.; Zhang, W.; Lu, Y. State of Charge Centralized Estimation of Road Condition Information Based on Fuzzy Sunday Algorithm. Energies 2022, 15, 2853. https://doi.org/10.3390/en15082853

Hu J, Lin B, Wang M, Zhang J, Zhang W, Lu Y. State of Charge Centralized Estimation of Road Condition Information Based on Fuzzy Sunday Algorithm. Energies. 2022; 15(8):2853. https://doi.org/10.3390/en15082853

Chicago/Turabian StyleHu, Jingwei, Bing Lin, Mingfen Wang, Jie Zhang, Wenliang Zhang, and Yu Lu. 2022. "State of Charge Centralized Estimation of Road Condition Information Based on Fuzzy Sunday Algorithm" Energies 15, no. 8: 2853. https://doi.org/10.3390/en15082853

APA StyleHu, J., Lin, B., Wang, M., Zhang, J., Zhang, W., & Lu, Y. (2022). State of Charge Centralized Estimation of Road Condition Information Based on Fuzzy Sunday Algorithm. Energies, 15(8), 2853. https://doi.org/10.3390/en15082853