1. Introduction

The subject of the research presented in this article is the supply of liquefied natural gas (LNG) and the risks associated with its handling. LNG is a gas mixture of hydrocarbons in the following proportions: methane 87–99 mol%, ethane 0.1–5.5 mol%, propane 0–4 mol%, butane 0–2.5 mol%, nitrogen 0.02–1 mol%, and traces of sulfur (less than four ppmv) and CO

2 (50 ppmv) [

1]. For this reason, the transport of LNG fuel is included in the transport of hazardous substances that may affect human life, the environment, and financial aspects of society. Other logistic operations, in particular LNG reloading, can also be dangerous. The main risks associated with this include fires and explosions, which may occur from leaks and spills in ignition sources [

2]. An essential aspect in this situation is the presence of ignition. Mokhatab et al. [

1] emphasize that in the event of failure to ignite, LNG quickly evaporates and spreads without harmful effects on the environment (when diluted below the ignition limit). However, in the event of ignition, LNG presents four potential fire-risk scenarios: vapor cloud flash fire, jet fire, pool fire, and vapor cloud explosion.

For this reason, the literature emphasizes that in the event of failure to ignite, LNG quickly evaporates and spreads without harmful effects on the environment (when diluted below the ignition limit). There are numerous publications on risk assessment related to the transport and handling of LNG and the safety of its storage. According to the literature review [

2,

3], these publications have been systematically growing in the last decade.

Poland is currently in a phase of energy transformation in transport. This transformation consists of a gradual departure from traditional energy carriers and instead favors alternative fuels. Liquefied natural gas (LNG) is currently of particular interest among these fuels. Many publications by Polish authors emphasize numerous benefits related to the development of this fuel sector in Poland (including [

4]). The growing interest in this fuel is also confirmed by various reports, including [

5]. According to this report, in 2020, the increase in the amount of LNG delivered by sea was recorded as 9.7% compared to 2019. The report also indicated that the ongoing energy transformation of Poland would also result in a dynamic increase in demand for LNG. The importance of this fuel for the stability of the country’s power system will also increase [

5]. For this reason, it is expected that the number of logistic operations related to the handling of LNG fuel transport by water will increase in the coming years.

Poland’s critical liquefied natural gas installation is the LNG terminal in Świnoujście. This terminal is one of the most critical investments implemented in Poland in recent years. Its operation aims to improve the security of gas fuel supplies to Poland, allowing LNG to be received by sea from any direction [

5]. Most of the LNG from the terminal in Świnoujście is delivered to customers via the gas network. The liquefied gas is additionally reloaded to cisterns adapted for LNG transport. All reloading processes are carried out following [

6] instructions. This manual has also become the starting point for identifying potential adverse events during logistic operations related to LNG deliveries at the terminal.

According to Animah and Shafiee [

3], the risk analysis process in the LNG sector is crucial to ensuring health, safety, security, and business success. Therefore, this article aims to present a method of assessing the human risk factor occurring during the logistic handling of LNG deliveries at a port terminal and its implementation for a selected LNG terminal in Poland. Fuzzy logic methodology was used to assess the risk due to the lack of access to specific historical data on identified events. The analysis considers general procedures related to LNG deliveries and specific reloading conditions occurring at the Polish gas terminal under study. Hence, the main contributions of this study are:

Development of a risk assessment method for reloading operations in the process of LNG deliveries based on the guidelines of the manual [

6], using the fuzzy logic concept;

Identification of adverse events caused by the human factor based on applicable regulations/standards of LNG cargo handling and interviews with experts;

Estimation of the value of risk assessment parameters based on the knowledge of experts, taking into account the specificity of the operation of the Polish gas terminal in Świnoujście;

Identify existing limitations of the proposed solution and constraints to its implementation.

Section 2 presents a literature review on transportation and logistics services for LNG terminal delivery. Following this,

Section 3 presents the authors’ approach to the risk analysis approach, including the research and computational part.

Section 4 presents the characteristics of the terminal in Świnoujście, which is the subject of the research that allows taking into account the specificity of local logistics conditions. The obtained results are presented in

Section 5 and a discussion on the conducted literature review is presented in

Section 6. At the end of the article,

Section 7 presents the conclusions of the conducted research.

2. Literature Review

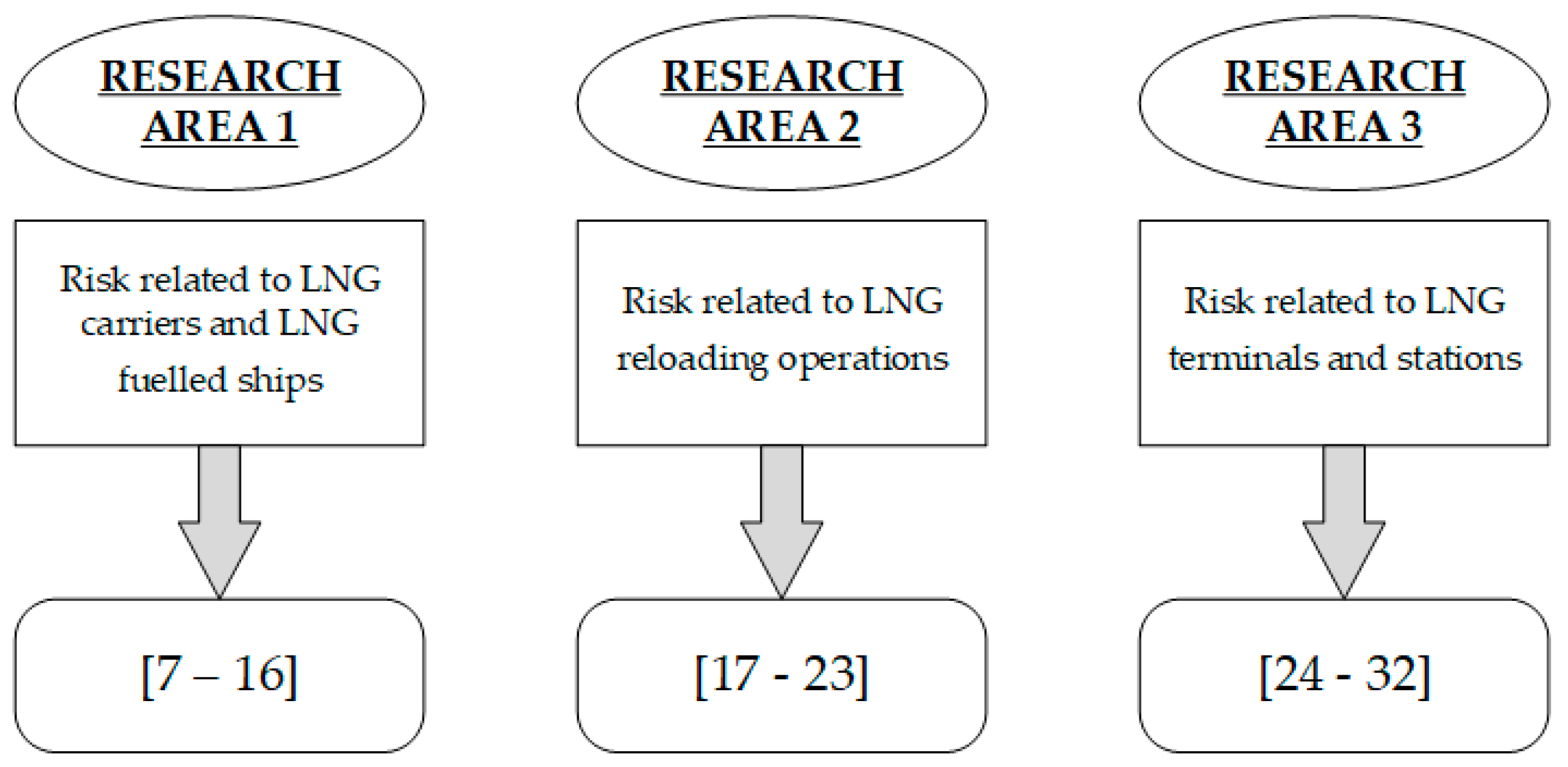

This literature review shows that risk research most often relates to three areas in LNG-related transport and reloading operations. These areas are presented in

Figure 1. The most significant publications are then distinguished for each area, presented in

Table 1,

Table 2 and

Table 3.

Among the studies in research Area 1, ten publications deserve attention, presented in

Table 1. These publications present various approaches to the risk assessment related to LNG carriers’ transport or using LNG-powered ships for transport. These articles propose new technics and modifications to the already known methods of identifying and assessing the risk of adverse events. The presented results of the analysis usually refer to such adverse events as accidents, fires, and explosions.

Table 1.

Literature review for research Area 1—Risk related to LNG carriers and LNG-fueled ships.

Table 1.

Literature review for research Area 1—Risk related to LNG carriers and LNG-fueled ships.

| Ref. No. | Problem Investigated | Method Used |

|---|

| [7] | The high-level, generic risk analysis related to the operation of LNG carriers | Formal

Safety Assessment (FSA) |

| [8] | The proactive model for risk evaluation for harbor maneuvers where an LNG tanker and escorting tugs are involved | Bayesian Belief Network (BBN) |

| [9] | LNG spill risk assessments in an LNG carrier system, such as a containment system | Combination of the FSA methodology and fuzzy evidential reasoning (FER) |

| [10] | Fire and explosion risk assessment on LNG-powered ships | DOW method, BLEVE model, and VCE model |

| [11] | A new approach to risk analysis that integrates Fuzzy Evidence Inference (FER), Fault Tree Analysis (FTA) techniques, and a risk matrix. The aim is to conduct a quantitative risk analysis in LNG carrier operations under uncertainty/limited information conditions. | Risk matrix and fuzzy evidential reasoning (FER) method and Fault Tree Analysis (FTA) |

| [12] | The risk assessment of excess pressure in fuel storage tanks on LNG-fueled ships | Dynamic process simulation combined with the Monte Carlo method |

| [13] | The risk assessment of accidents in the system of an LNG (Liquefied Natural Gas) carrier anchoring safely | Bayesian Network (BN) |

| [14] | The quantitative risk assessment of LNG-fueled vessels for potential leakage, including hazard identification and frequency analysis, accident scenario analysis, and consequence simulation | Integrated Event Tree Analysis (ETA) and computational fluid dynamics (CFD) |

| [15] | The risk analysis model for the hull girder collapse of a membrane liquefied natural gas (LNG) carrier after grounding | BBN |

| [16] | Process of risk assessment for LNG-powered ships during locking, based on the integrated QRA model and the interaction between the locked environment and the risk characterization of LNG-powered ships | HAZOP analysis, LOPA analysis, and CFD model simulation |

From the point of view of the research conducted, significant publications are articles from Area 2. The research presented in this case relates to the risk related to LNG’s reloading (loading and unloading). The related logistic operations are analyzed in the ship-transshipment terminal/port systems and ship-to-ship transshipment systems. The number of publications in Area 2 is much smaller than in Area 1. This may be because this subject is associated with transport operations in many publications, described in Area 1.

Table 2 presents the articles considered particularly important in the conducted research.

Table 2.

Literature review for research Area 2—Risk related to LNG reloading operations.

Table 2.

Literature review for research Area 2—Risk related to LNG reloading operations.

| Ref. No. | Problem Investigated | Method Used |

|---|

| [17] | The risk analysis of an LNG export loading operation at a jetty. The analysis takes into account the interaction between the vessel crew and the land-based operators | BN |

| [18] | The risk-based method to analyze the failure scenarios and associated consequences that may happen during the cargo handling operation of an LNG carrier | FTA and cause–consequence diagram |

| [19] | The use of the fuzzy TOPSIS approach for the risk assessment of LNG ships during loading and offloading at terminals | Fuzzy-TOPSIS |

| [20] | The risk analysis of LNG carriers’ operations aims to define the most critical pieces of equipment for avoiding LNG leakage during loading and unloading operations. | Cause–consequence diagram and BN |

| [21] | The identification of potential risks of LNG bunkering and critical factors in determining the extent of the safety exclusion zone of LNG-bunkering stations for ships | Bespoke IQRA software |

| [22] | Applying STPA (System Theoretic Process Analysis) for Liquefied Natural Gas (LNG) ship-to-ship transfer systems | System Theoretical Process Analysis (STPA) |

| [23] | Human error risk assessment method for the LNG-bunkering sector | The cognitive reliability and error analysis method (CREAM),

Fuzzy—BN |

The last area of the literature review concerns LNG terminals and stations. Publications on the topic mainly concern assessing the risk of explosion in the terminal area, which is carried out for specific real cases. The primary purpose of the analysis is to determine a safe zone. Some of the presented publications focus on using the results of risk analyses to develop guidelines for designing safe terminals and stations.

Table 3 presents selected publications from Area 3.

Table 3.

Literature review for research Area 3—Risk related to LNG terminals and stations.

Table 3.

Literature review for research Area 3—Risk related to LNG terminals and stations.

| Ref. No. | Problem Investigated | Method Used |

|---|

| [24] | The quantitative risk assessment method for safe terminal design and avoiding public disasters focuses on the material properties of LNG pumps. | API and ASME quantitative risk evaluation method |

| [25] | The comparative risk assessment of four different pipe-in-pipe alternatives for loading line design of an LNG liquefaction offshore jetty system | ETA and PHAST simulation software |

| [26] | Risk assessment method for an LNG terminal, based on the Bayesian-LOPA methodology. | Bayesian–LOPA |

| [27] | Identification, screening, and prioritization for various sources of risk in processes carried out in LNG terminals based on a selected terminal in Mexico. | - |

| [28] | A risk prediction model based on information diffused theory. The information diffusion theory estimates the number of LNG terminal station risk predictions. | Information diffusion theory |

| [29] | The computational fluid dynamics simulations (CFD) were conducted for the two potential hazards, LNG flammable vapor dispersion and LNG pool fire radiation, respectively, to evaluate the exclusion zones. The CFD model has the considered hazards’ spatial and temporal distribution in a complex spill scenario. | CFD |

| [30] | The integrated risk assessment framework for Liquefied Natural Gas (LNG) terminals. | Parameter estimation, ETA and FTA |

| [31] | The risk analysis related to the problems of safety and security linked to the use of new and alternative technologies for LNG regasification, like an offshore LNG terminal. | ETA and PHAST software |

| [32] | The fuzzy-based FMECA approach to an LNG unloading facility in an LNG terminal located in south India. | Fuzzy FMECA |

In addition to the studies mentioned above on LNG transport and reloading, the studies presented in [

33] deserve attention. The authors of this publication point out that in the case of LNG bunkering, the literature has proposed several methods to support risk management. Most of the techniques presented focus on identifying, analyzing, and controlling potential accidents as part of health and safety or technical reliability analysis, without correlation of risk with natural entities. Moreover, this is the main reason for formulating the approach based on the systematic study of the role of stakeholders and the threats and opportunities they generate for the organization [

33].

The growing popularity of LNG in transport increases research interest in topics related to its transport and handling safety. This is confirmed by the increasingly often published research results, which were presented in the above literature review. The analysis of these publications indicates the need to develop various approaches (methods) to assess the risk associated with LNG and consider the specificity of the operation of a given facility handling LNG reloading in the research. For this reason, the research results presented in this article, which describe the proposed approach to risk assessment and its implementation for the operating conditions of the selected LNG terminal, are consistent with the research currently being developed in this area.

3. Materials and Methods

A risk assessment aims to identify adverse event scenarios that may disrupt the logistic process of LNG deliveries carried out at sea reloading times and, in critical situations, cause injuries and deaths. The results obtained in the analysis should support decision-making processes related to the preparation of safe and interference-resistant logistic operations and enable continuous improvement of the applicable procedures related to LNG reloading.

In the case of risk analysis for LNG terminals with a short operational period, estimating the basic quantitative parameters to calculate the risk level is complicated. This is mainly due to the lack of historical data that can be referred to in the analysis. For this reason, the fuzzy logic concept was used to determine the values of the probability parameters and effects of the occurrence of each of the analyzed scenarios and estimate the value of the risk level.

In the bunkering process, the crew’s handling is crucial [

23]. Based on a risk assessment based on the Bowtie model [

34], it was found that human error can: (1) contribute to the causes of a hazardous event; (2) be the direct triggering event or even the sole triggering event for a hazardous event; (3) be related to the safety barriers of potential consequences. For this reason, the proposed risk assessment for logistic handling of LNG deliveries in sea terminals includes two stages of analysis: (1) qualitative analysis based on the

Terminal Operation Manual [

6], elements of Human Factor Analysis and Classification System (HFACS), brainstorming with experts, and analysis of “what-if“; (2) quantitative analysis using the concept of fuzzy logic in risk assessment. A team of experts should participate in both stages of the analysis. This team should include representatives of:

Science—people actively researching topics related to water transport, risk analysis and management, fuel supply chains; the experts should have a minimum of a doctoral degree;

Management and engineering staff employed at the selected LNG terminal, who have extensive knowledge of the procedures and principles of the terminal’s operation, the technical infrastructure used, and the crew handling the delivered cargo; they must have a minimum of five years of experience in this position

Officers managing LNG carriers who participate in LNG deliveries and have operational knowledge of the transport and bunkering process; They must have a minimum of five years of experience in this position.

The proposed method assumes that the opinions of individual experts are of equal weight.

The research procedure includes a qualitative and quantitative analysis characterized in

Section 3.1 and

Section 3.2.

3.1. Methodology of Qualitative Analysis

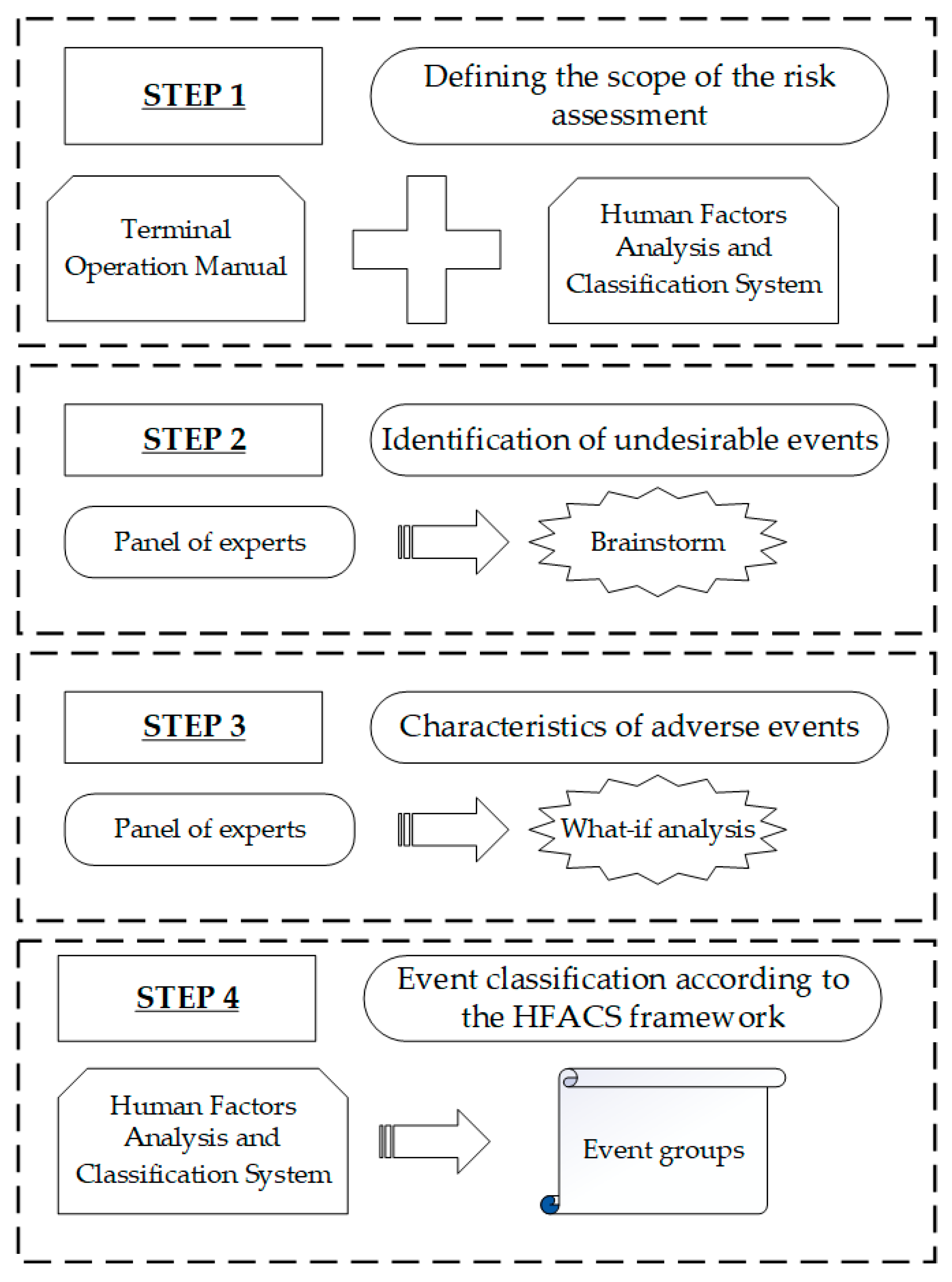

The qualitative analysis focuses primarily on identifying and describing possible adverse event scenarios during the logistic service of LNG carriers at the sea terminal. This analysis consists of four steps of the procedure, which are presented in

Figure 2.

Identification of potential adverse events as early as possible is part of the manual [

6] in force since 2020, containing a list of basic procedures and procedures related to the operation of terminals: from access, through approach, operational and emergency procedures, and legal regulations. The identified scenarios of adverse events in the proposed approach focus on people involved in servicing the LNG carrier at the terminal. Therefore, the reference point in the analytical procedure should be the groups of events distinguished under the HFACS method. This method, developed by Wiegmann and Shappell [

35], was initially used to identify threats in air transport. However, it has found its application in the risk assessment of human errors and other transport systems (e.g., in railways [

36]). This method distinguishes four groups of causes of adverse events: (1) organizational influences, (2) supervisory factors, (3) preconditions for unsafe acts, and (4) unsafe acts. The characteristics of the distinguished groups are the starting point for brainstorming among experts and for “what-if” analysis.

The research procedure related to the qualitative analysis was carried out following the procedure presented in

Figure 2. The identification of adverse events was carried out by a team of experts based on brainstorming. Then, each event was characterized by a description of the causes and effects of its occurrence. To prepare these characteristics, the experts used the “what-if” analysis technique, recommended, among other things, by the ISO 3100: 2018 standard [

37]. The defined adverse event scenarios were then classified according to the HFACS structure. By using the HFACS framework as a guide, policymakers can, in the following steps, better prepare process improvement actions to mitigate the risks involved. A quantitative risk analysis is carried out for such ordered adverse event scenarios.

3.2. Methodology of Quantitative Analysis

The concept of risk in the analyzed scenarios described by Kaplan and Garrick is as follows [

38]:

where:

R—the function of risk;

S—description of analyzed scenario;

P—the probability of a scenario occurrence;

C—the consequences of a scenario or damage caused by an occurrence scenario;

N—the number of possible scenarios.

Note the notation in Equation (1). It is about using the phrase “Probability” (P). The term used does not mean the probability is compliant with the mathematical definition, i.e., in the range from 0 to 1. However, the likelihood of the scenario is expressed by the frequency of its occurrence (range from 1 to 10). The same field was used for the consequences of the analyzed scenarios.

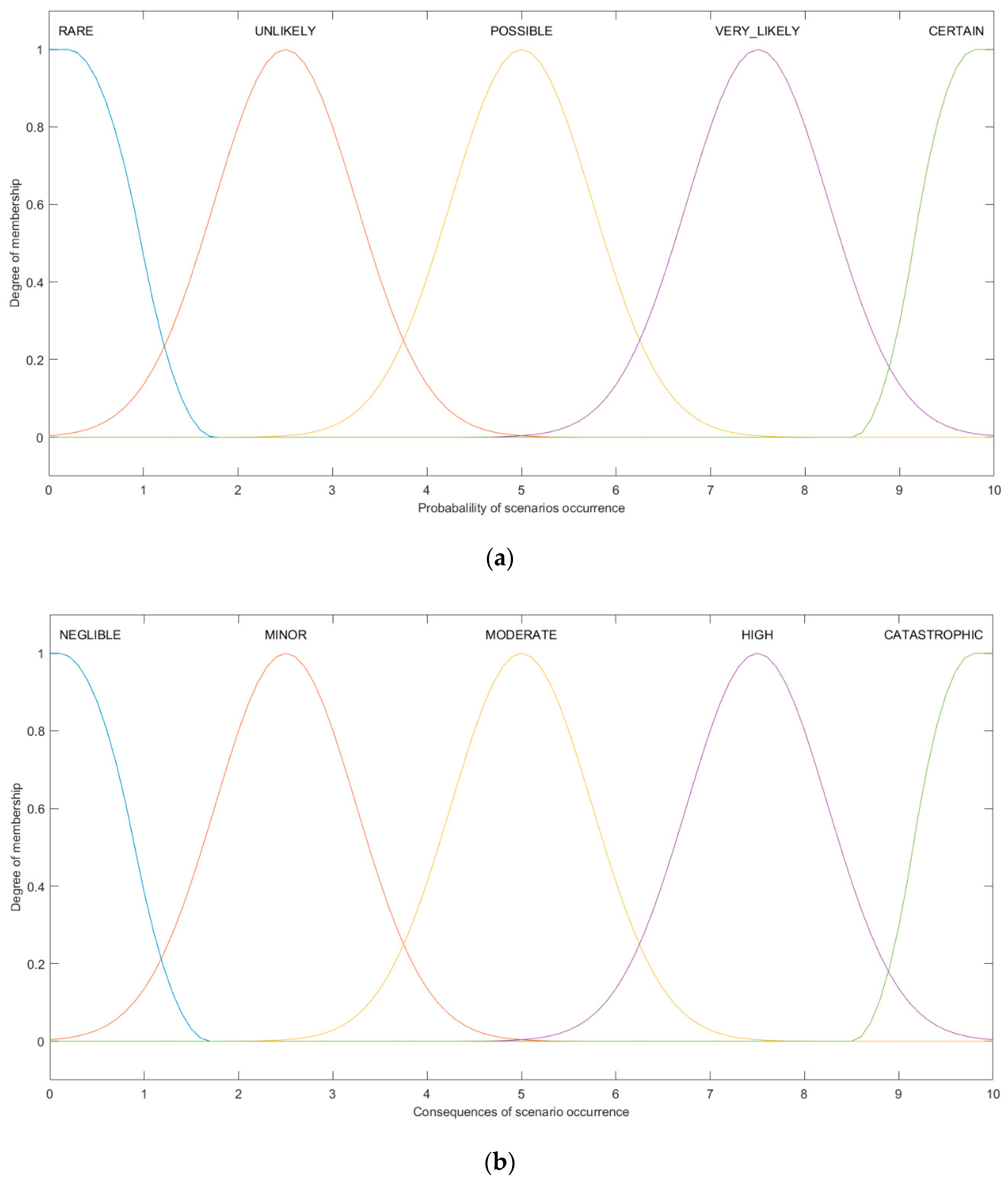

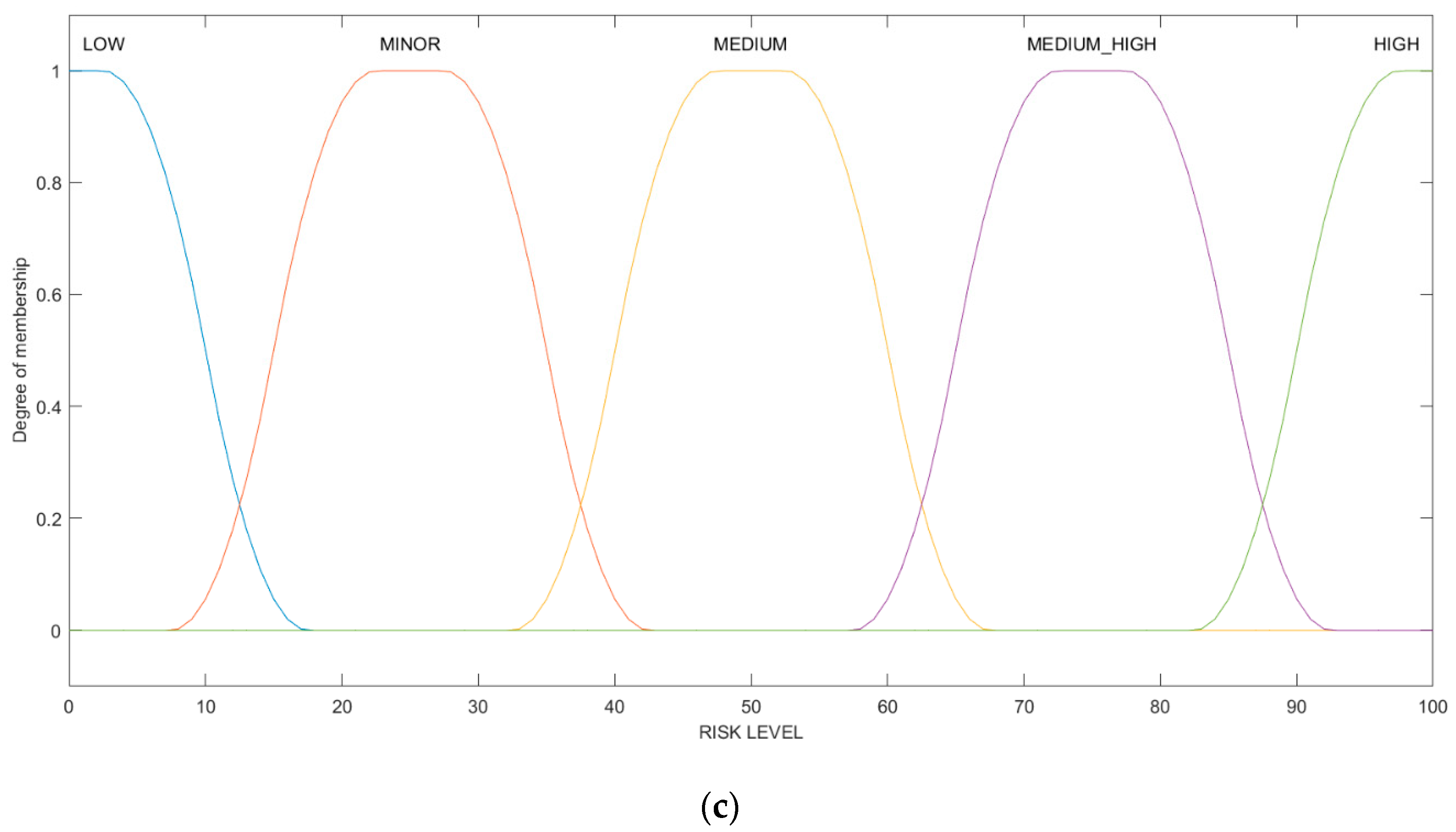

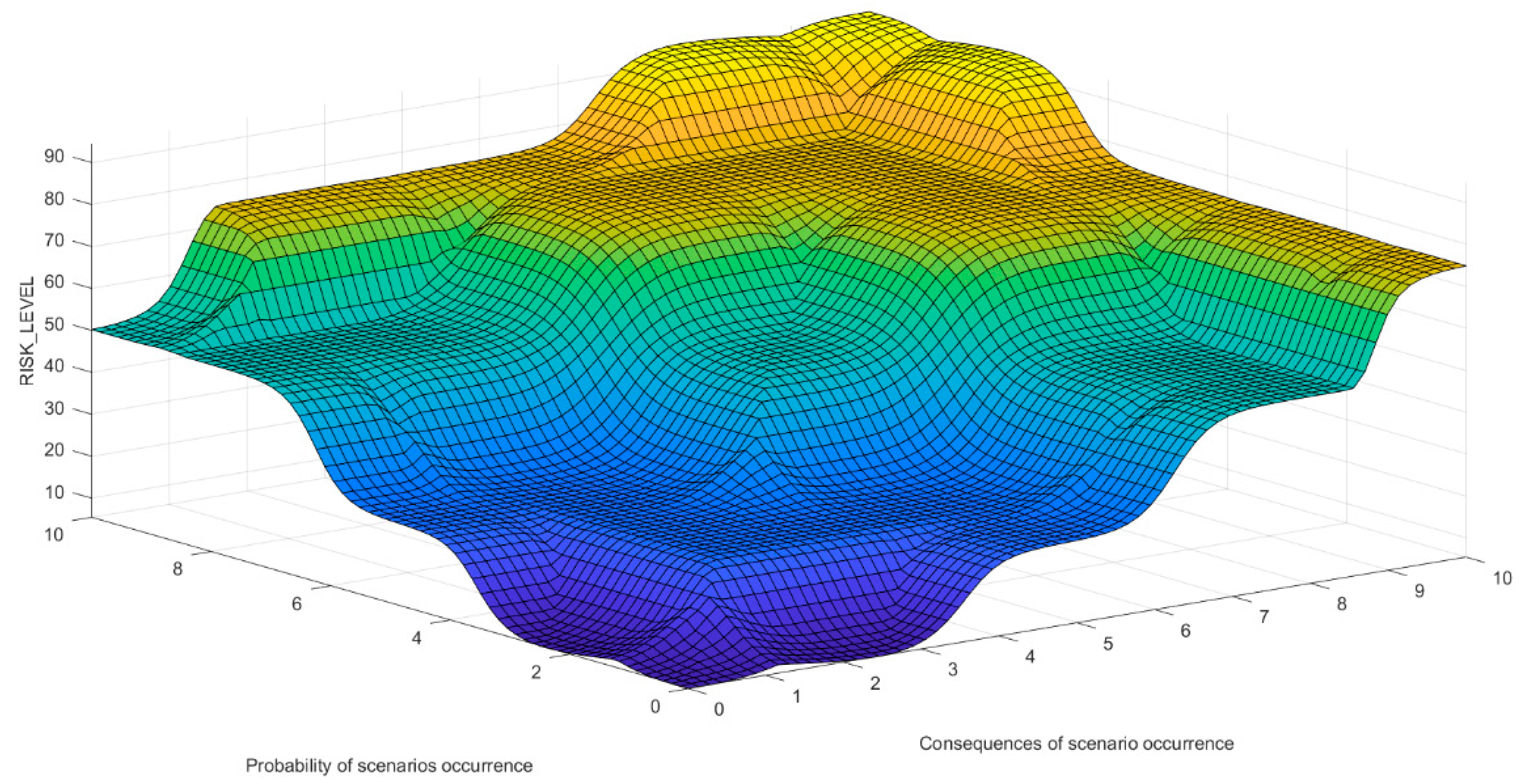

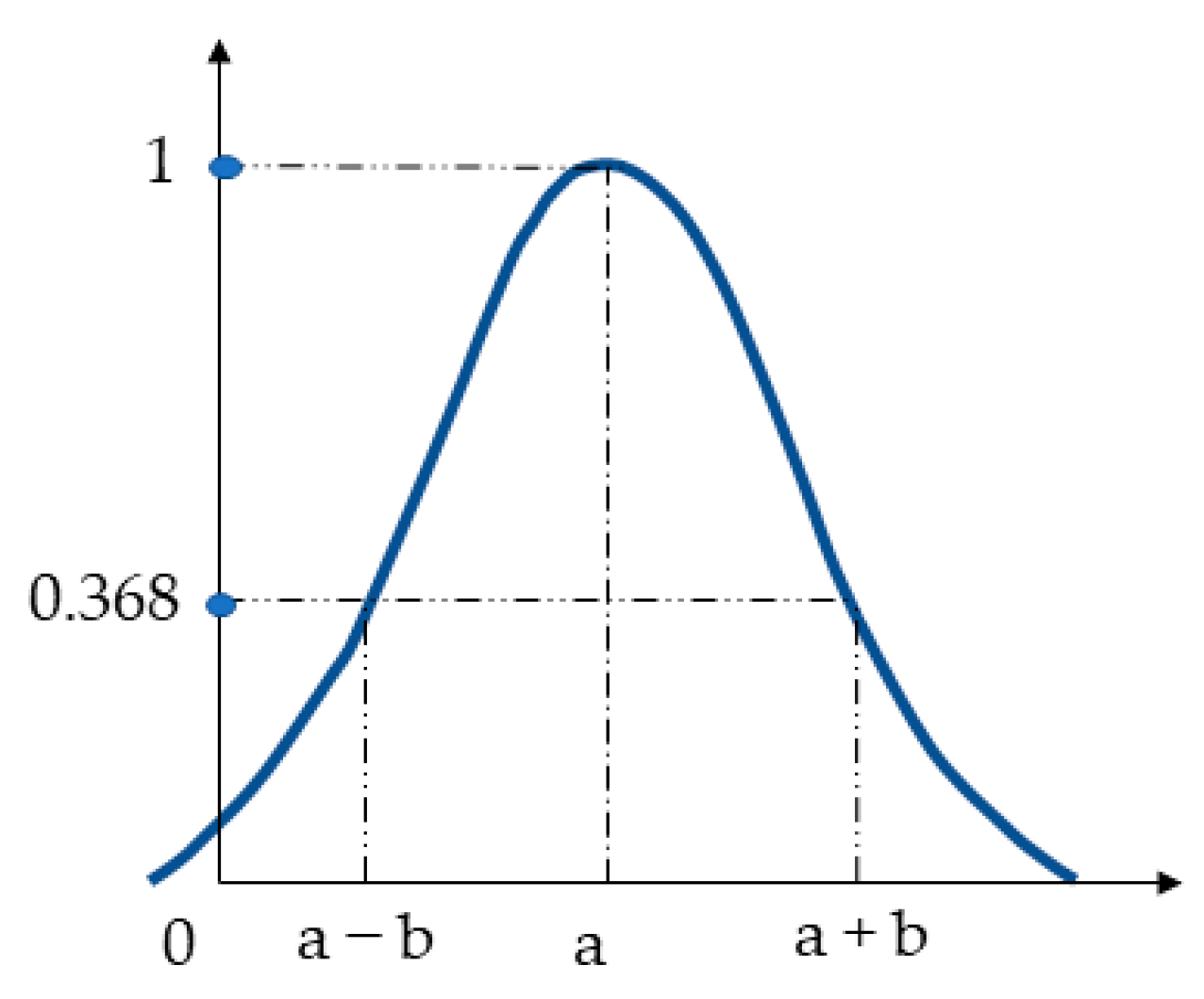

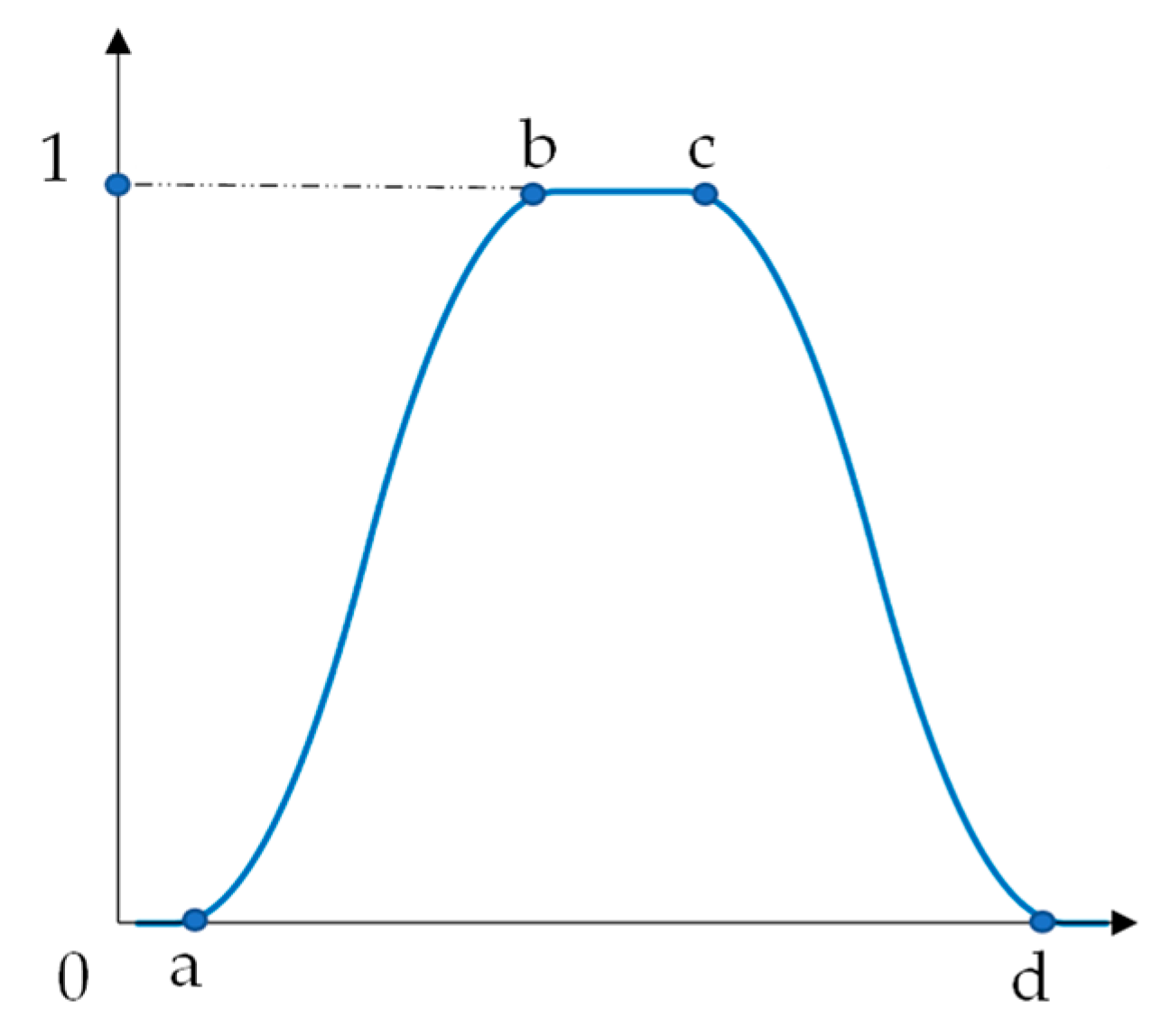

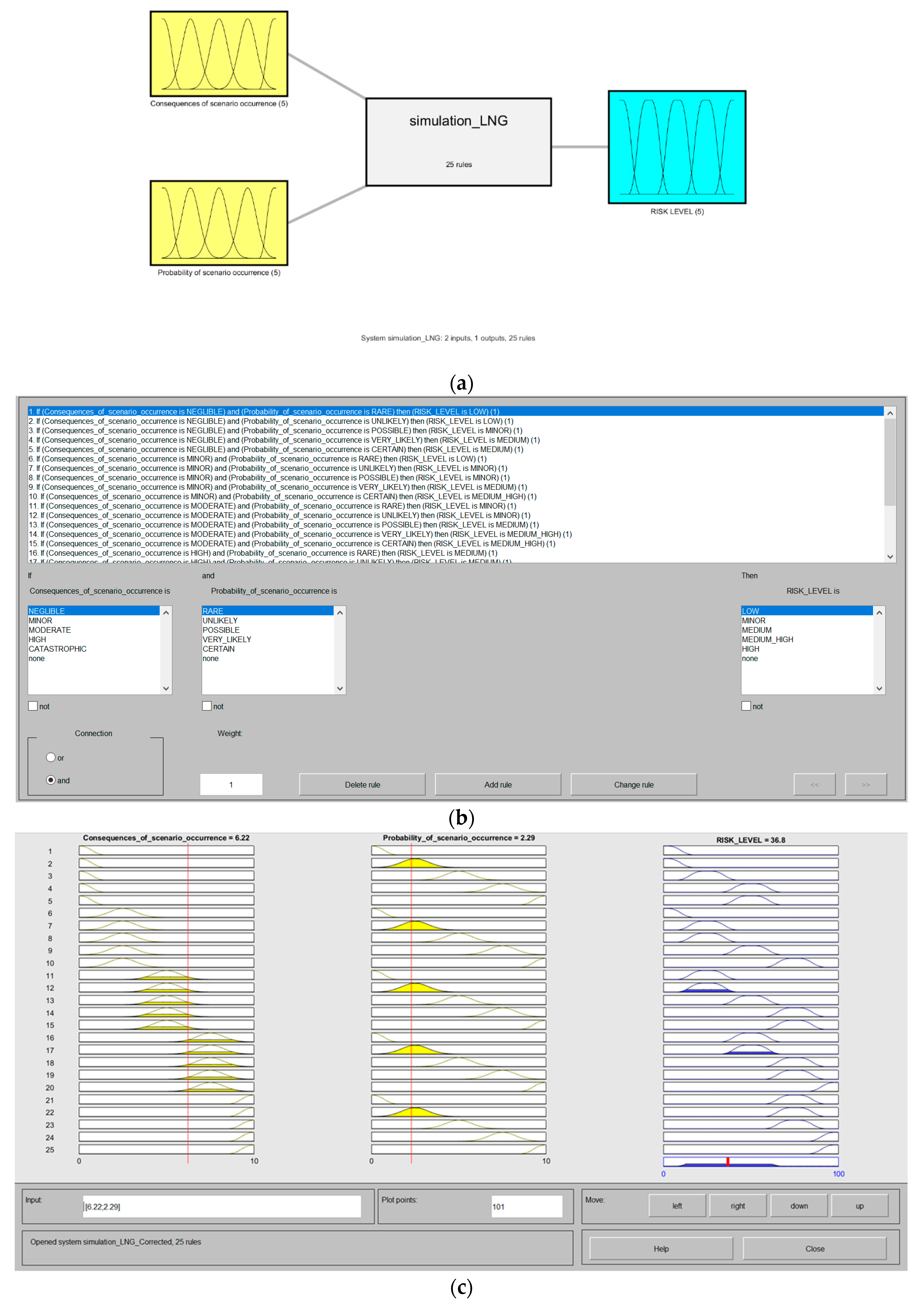

The adopted shape of the membership function (MF) in the analyzed problem requires explanation. Initially, the authors decided to use triangles. However, after the analysis, which generated a risk surface, many “inactive” areas were observed on the surface (horizontal boxes with a constant value of the risk-level indicator). Additionally, there was a spike in the risk-level indicator in some areas. Considering the above factors and how the model works in MATLAB (version R2021b), the input membership functions would be represented by Gaussian curves and the so-called Pi curves. The obtained results of the model performance confirmed the correctness of the adopted concept. Another issue requiring explanation is why the authors decided to use the predefined MAMDANI model in MATLAB. Systems that use the MAMDANI algorithm use data that are both input and output fuzzy sets. When analyzing the output signal range, the assumption is made that the range should be chosen to contain the cumulative minimum and maximum values of all output membership functions. To confirm the correctness of the selection of the input membership functions, in the section presenting the results and the plot of the risk surface, the dependencies of the input signals on the obtained values of the risk level are also presented.

Expert knowledge was used to assess the probability and impact of each scenario reliably. Linguistic variables were used to collect expert opinions. Collected data were then used with the fuzzy set theory. According to the assumptions of the fuzzy theory, the risk parameters indicated in [

1] are treated as a fuzzy number (FN) and its function (the so-called membership function—MF). Membership functions can take many forms. The choice of the shape of the membership function for a given fuzzy set is highly subjective and depends on the researcher’s experience in his work with fuzzy sets. Gaussian MF (likelihood and consequences) and Pi MF (index of risk) were used in the analysis.

The pair represent the Gaussian FN

FnGauss = (

a,

b), and its MF is given by (2):

The graphic presentation/interpretation of Gaussian FN is shown in

Figure 3.

Pi FN, defined as

FnPi = (

a,

b,

c,

d), has its MF given by (3):

A graphic interpretation of Pi FN and its MF is shown in

Figure 4.

In the presented scheme: a and d are the limits of the fuzzy number FnPi (upper and lower), and b and c are the modal values of FnPi.

In order to obtain the risk level, an aggregation operation is performed. The expert opinions obtained are used for this. One of the methods [

39] is to use the arithmetic mean aggregation operator. Aggregation is an operator defined in the Gaussian set of fuzzy numbers (

a1,

b1), (

a2,

b2), … (

an,

bn);

n is the number of experts. The result of the activities is the obtained pair in the form (

x,

y) according to Equation (4):

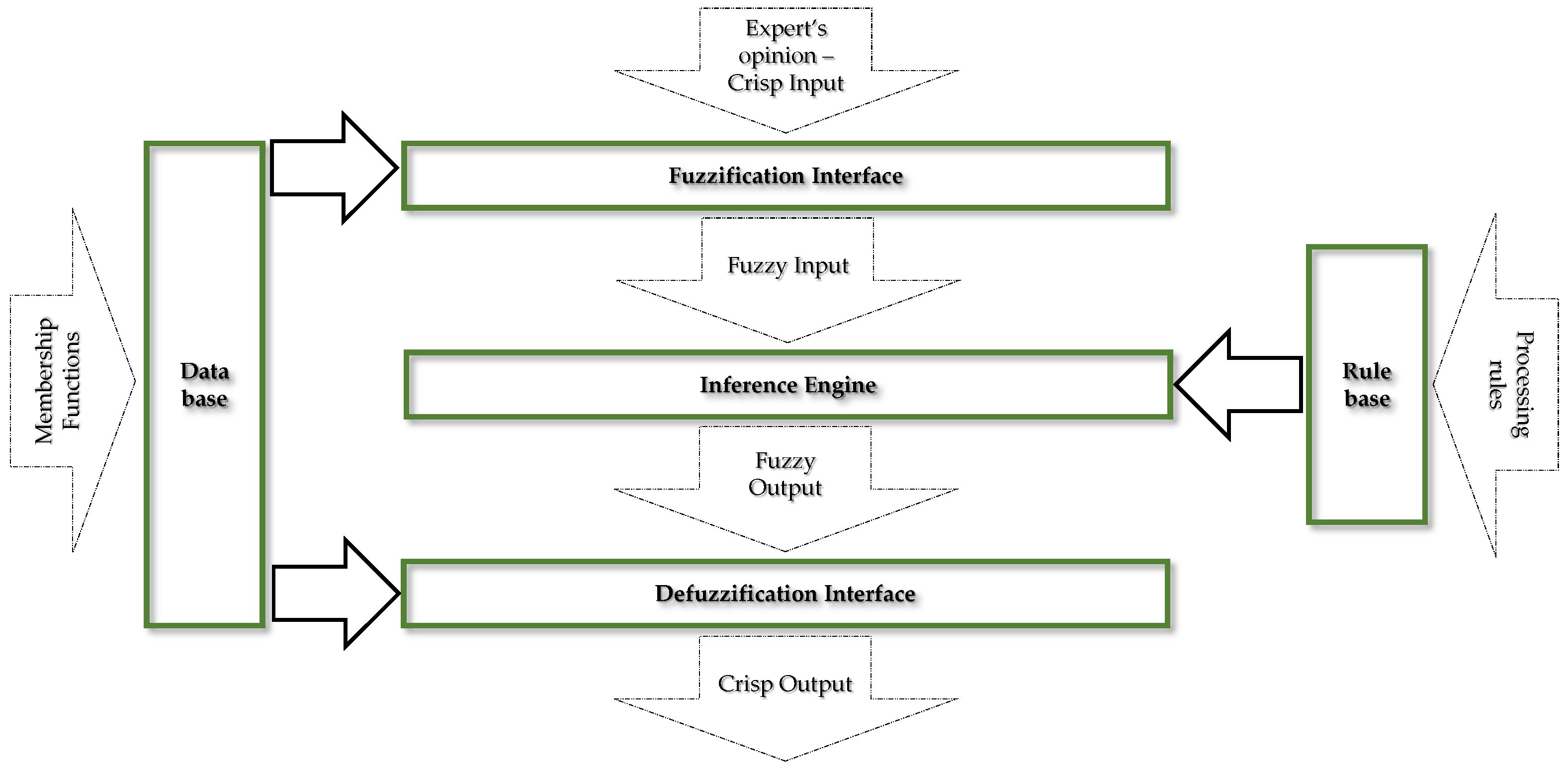

The next element is risk quantification. This process is based on using the MAMDANI fuzzy model [

40]. The mechanism used in the model is an interpretation of the Zadeh method [

41]. In line with Zadeh’s assumptions, building the model includes four phases: the fuzzification process, creating the knowledge base, building the FIS, and the process of defuzzification [

42].

Figure 5 presents the described approach used in solving the research problem.

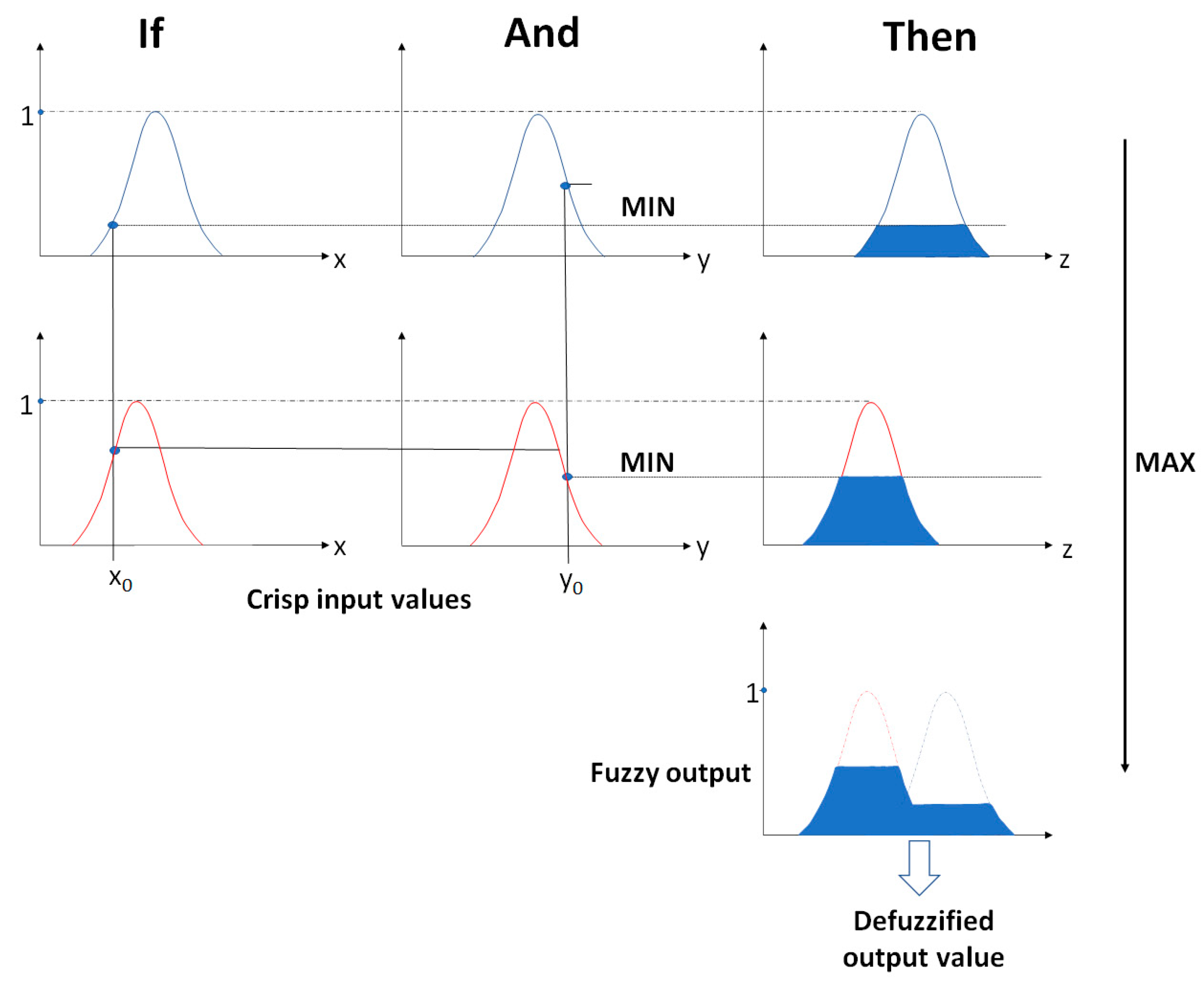

As already mentioned, the fuzzification process uses two types of fuzzy numbers: Gaussian and Pi. The FIS (Fuzzy Inference System) of the MAMDANI model used uses two types of operators: MIN and MAX operators. The MIN operator is used in conjunction and implication operations. MAX—for fuzzy aggregation results. The operation of FIS using the described operators for the solved problem is shown in

Figure 6.

The final stage is the defuzzification process. Its goal is to transform the fuzzy output signal into a crisp output signal. This method follows the approach described, for example, in [

43,

44]. The output value is defined by Equation (5) [

42]:

In Equation (5):

z*—defuzzified output;

—the aggregated output Gaussian membership function;

—the aggregated output Pi membership function;

z—the universe of discourse.

The defuzzification process consists of several steps. The first one consists in fuzzifying the input parameters. The next is the transformation (conversion) of experts’ linguistic evaluations into assigned fuzzy numbers. The final stage is the calculation of the value of the risk index (based on values input parameters) using the MAMDANI algorithm. The input and output parameters representing the adopted language scales are shown in

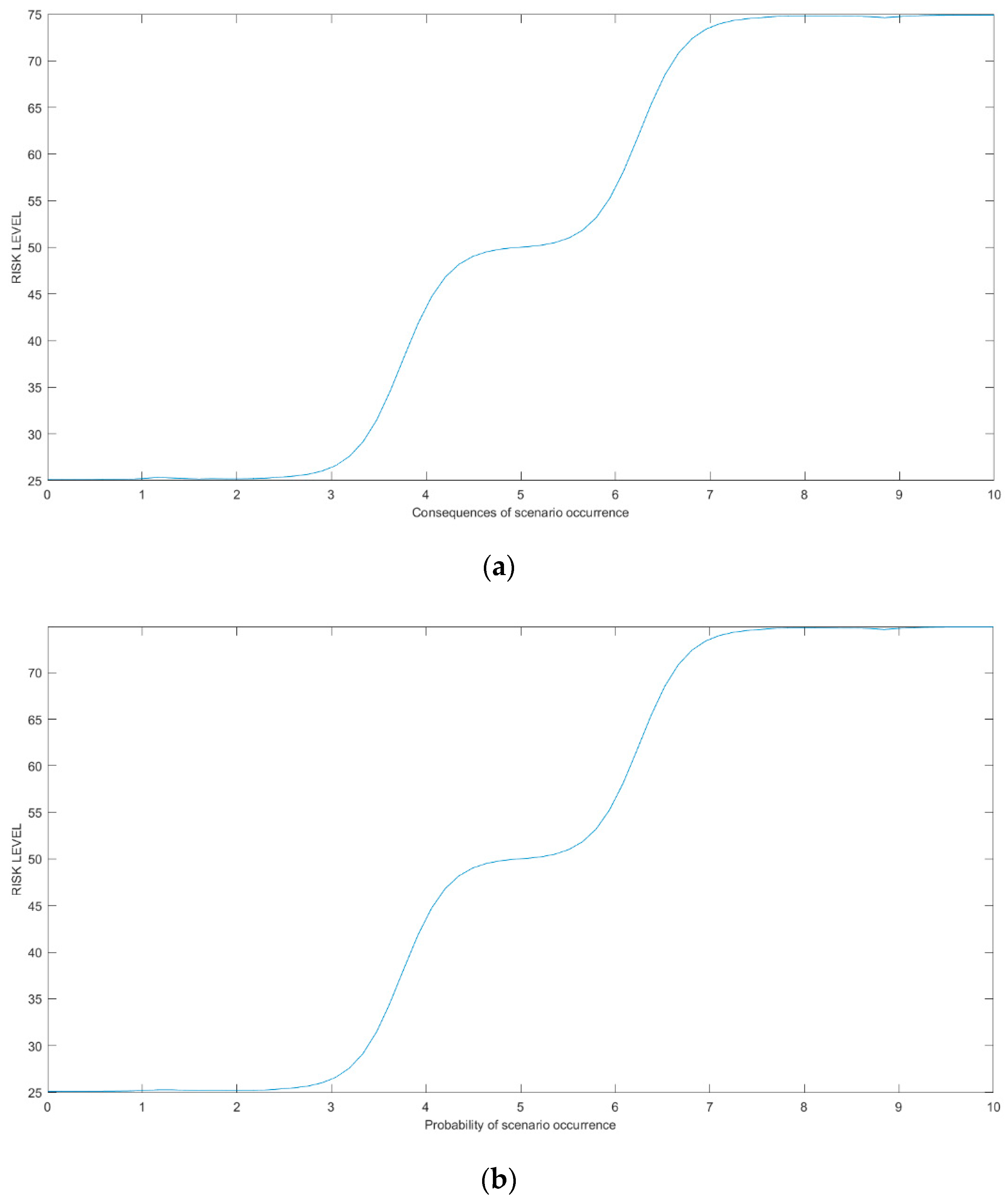

Figure 7 (

Table 4,

Table 5 and

Table 6).

Table 4.

Probability of scenario occurrence.

Table 4.

Probability of scenario occurrence.

| Adopted Scale | Description | Fuzzy Value |

|---|

| CERTAIN (P5) | It occurs with every or almost every transshipment | (8.5, 10, 10, 10) |

| VERY LIKELY (P4) | It occurs at least every 6 transshipments | (0.75, 7.5) |

| POSSIBLE (P3) | It occurs at least every 12 transshipments | (0.75, 5) |

| UNLIKELY(P2) | It occurs no more than once in 24 transshipments | (0.75, 2.5) |

| RARE (P1) | It probably never will but can happen | (0, 0, 0, 1.5) |

Table 5.

Consequences of scenario occurrence.

Table 5.

Consequences of scenario occurrence.

| Adopted Scale | Description | Fuzzy Value |

|---|

| CATASTROPHIC (C5) | Permanent damage to infrastructure, loss of health and life of employees and residents | (8.5, 10, 10, 10) |

| HIGH (C4) | Permanent damage to infrastructure, loss of health and life of employees | (0.75, 7.5) |

| MODERATE (C3) | Severe infrastructure damage, injured workers | (0.75, 5) |

| MINOR (C2) | Infrastructure damage resulting in longer downtimes (extended reloading time) | (0.75, 2.5) |

| NEGLIGIBLE (C1) | No significant impact on the safety and duration of the transshipment process | (0, 0, 0, 1.5) |

Table 6.

Value of risk index.

Table 6.

Value of risk index.

| Adopted Scale | Description | Fuzzy Value |

|---|

| HIGH (RL5) | The possibility of a given event occurring is highly probable, and the consequences are associated with the crew’s loss of life or health. The impact on the surroundings is very high. | (82.5, 97.5, 100, 100) |

| MEDIUM HIGH (RL4) | A sure or almost certain likelihood—negligible consequences, or an unlikely likelihood—critical consequences. | (57.5, 72.5, 77.5, 92.5) |

| MEDIUM (RL3) | The event is almost certain—minor consequences. High consequences with unlikely probability. Significant impact on the level of services provided. | (32.5, 47.5, 52.5, 67.5) |

| MINOR (RL2) | The occurrence of an event is possible—minor/no significant consequences. Possible impact on the reduction of the level of logistics service | (7.5, 22.5, 27.5, 42.5) |

| LOW (RL1) | It is almost impossible for an event to occur. The consequences are negligible. No impact on the surroundings | (0, 0, 2.5, 17.5) |

Figure 7.

The shape of membership functions: (a) probability of the scenario occurrence; (b) consequences of the scenario occurrence; (c) risk level.

Figure 7.

The shape of membership functions: (a) probability of the scenario occurrence; (b) consequences of the scenario occurrence; (c) risk level.

The final step was to define the rules for processing the model engine by building a rule base (IF-THEN). The proposed database, containing a total of 25 rules, is presented in

Table 7.

The engine of the model, i.e., the fuzzy inference module (FIS), is responsible for analyzing a set of fuzzy rules, and the results of applying these rules are interpreted using the MAMDANI algorithm (

Figure 8). To calculate the risk level, the defuzzification process of the fuzzy set uses Equation (4).

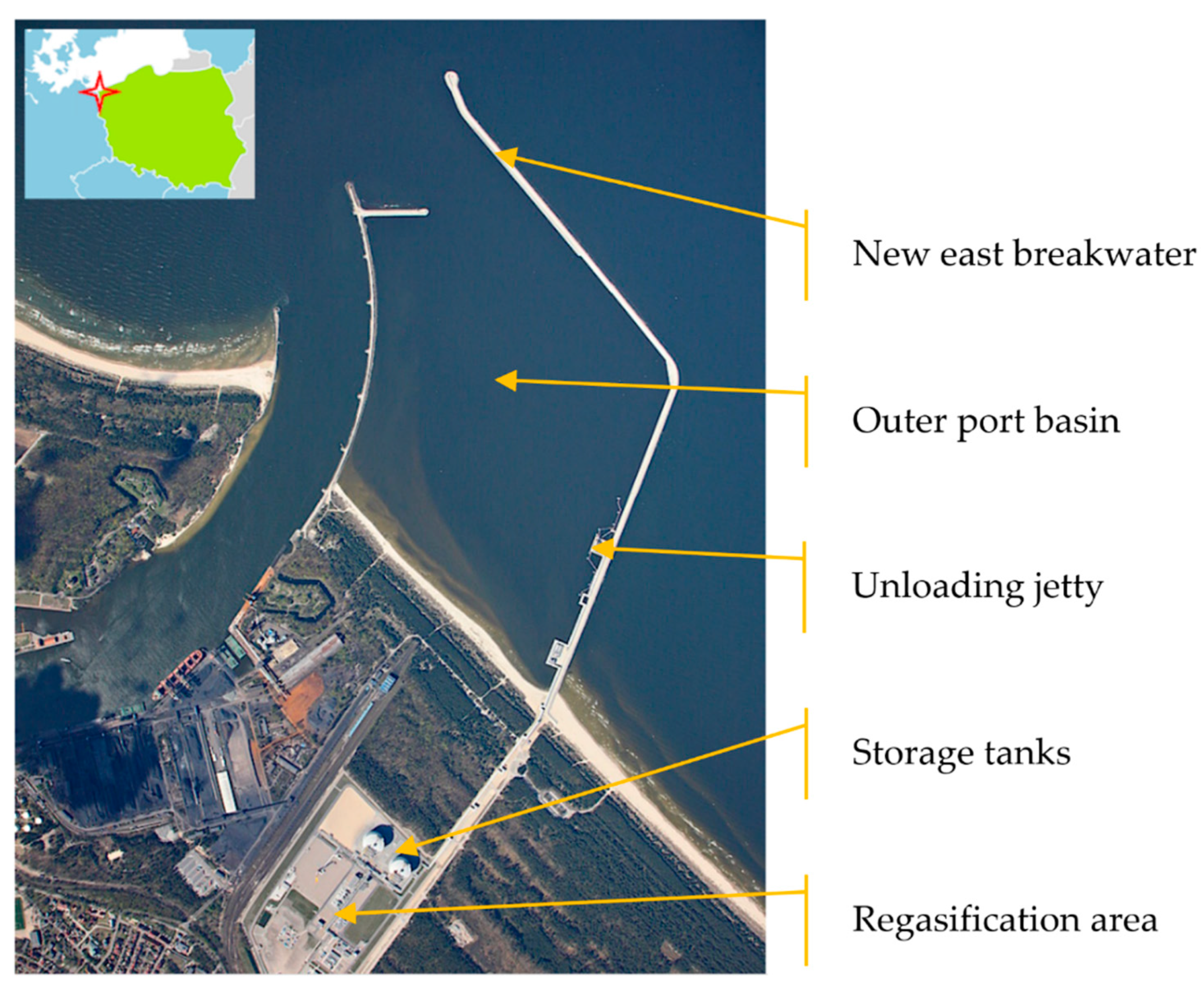

4. Description of LNG Terminal in Świnoujście

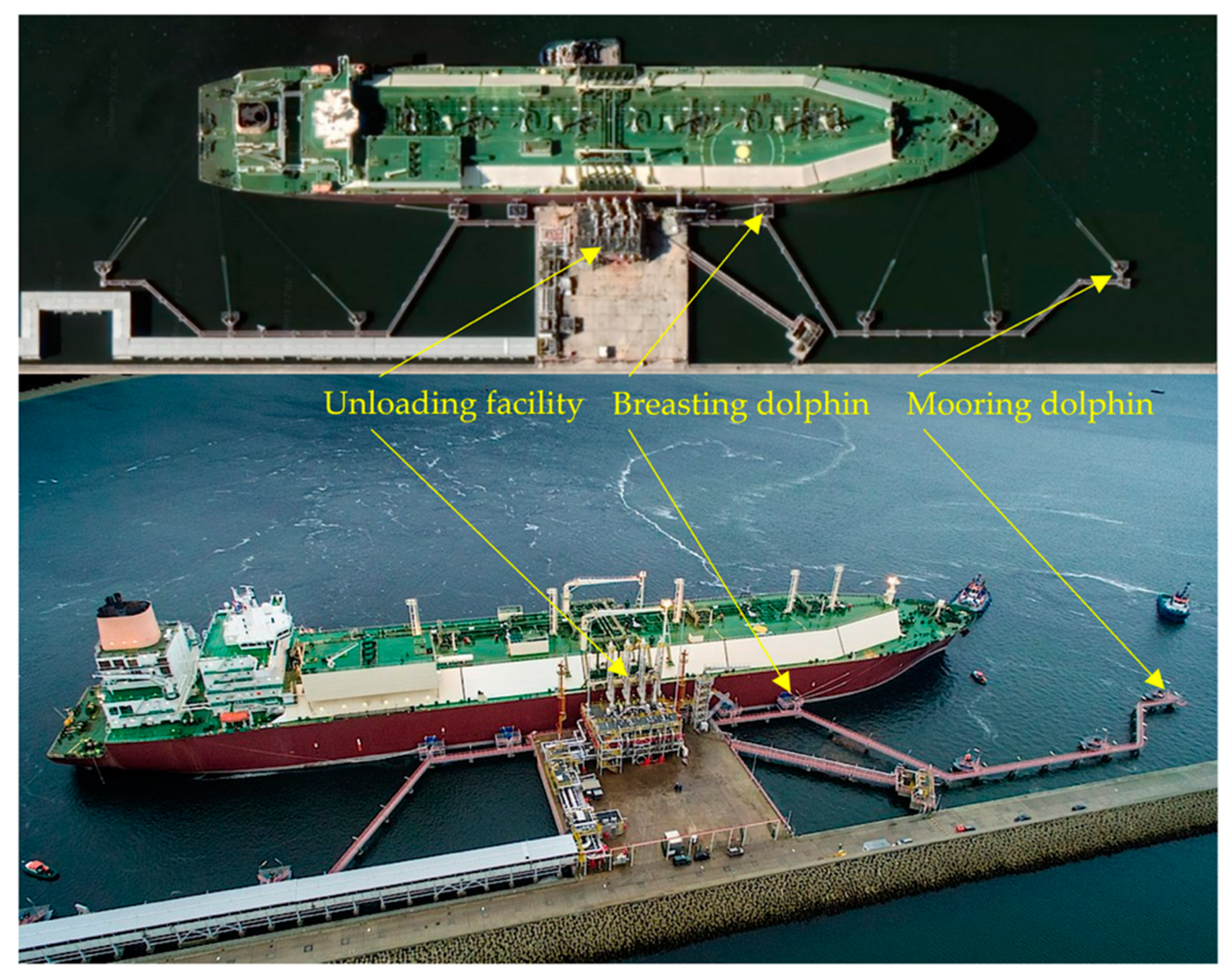

The terminal is located on the west end of the Polish coastline, in the southernmost part of the Baltic Sea—Pomeranian Bay, next to the estuary of Świna river, at the outer port of Świnoujście (

Figure 9).

The approach fairway has a minimum width of 200 m, and depth, also in an outer port basin, is 14.5 m. Therefore, the Port Regulations allows entry and maneuvering of a vessel with a maximum draught of 12.5 m, length of 320 m and breadth of 51 m. This is why, most often, deliveries are made by Q-flex gas carriers. The typical Q-flex LNG carrier is 315 m in length, 50 m in breadth, 12.5 m in draught, and a capacity of about 200,000 cubic meters of LNG.

The unloading jetty consists of four breasting and six mooring dolphins equipped with 22 quick-release mooring hooks (

Figure 10). The unloading facility is located on the main platform of the jetty, which includes three arms to transfer liquified natural gas from the ship to the storage tank and one arm for vapor return.

The safety of LNG carrier operations on the approach and in the outer port depends on weather conditions. Strong winds can cause interruptions to work or the need to anchor at the roadstead. In an average year, there are 13 days with winds exceeding 10 m/s, mostly from east, northeast, and north directions.

The maximum wave heights on the approach fairway are as follow:

2 m, at a distance more significant than 46 km from the entrance to the outer port at the boundary wind speed of 25 m/s;

1 m, at a distance between 15 and 46 km from the entrance to the outer port at the boundary wind speed of 10 m/s;

0.6 m, up to 15 km from the entrance to the outer port at the boundary wind speed of 10 m/s.

The maximum value of minimum water levels on the approach fairway and the outer port, referred to as the “Amsterdam 500” system, is 480 cm. The observations carried out between 2011 and 2014 indicate that the mean water level equals 509 cm and the probability that the level drops below 480 cm is less than 5% [

46].

The currents are strongly related to wind force and direction. At the outer port entrance, the maximum current velocity is 1.0 m/s and decreases to 0.5 m/s at a distance of 15 km and zero from 46 km.

The primary purpose of the LNG terminal in Świnoujście is to diversify sources of natural gas for the national grid. The liquified gas is delivered by LNG carriers, transferred to two storage tanks of 160,000 cubic meters each, and injected into the grid after regasification. A relatively small amount of LNG is shipped inland by truck cisterns to supply local grids or specific facilities. The terminal’s future activity will also include the transfer of LNG from land tanks to bunker ships or smaller LNG carriers. Today’s regasification capability is 5.0 bln cubic meters per year, and in 2024 it will increase to 8.3 bln, which is more than half of total gas consumption in Poland.

The terminal must be constantly supplied with liquified natural gas to achieve the primary purpose. During the first five years of operation, 130 LNG carriers were unloaded, which is about two vessels per month. To reach the first level, 5 bln cubic meters of natural gas from four LNG carriers are needed, and by the 2024 level—six or more if we include reselling of LNG. Therefore, the service of LNG carriers is not a daily routine, and the reception of LNG is one of the most critical moments during the terminal operation. During this period, two different systems have to be connected and co-operated to transfer an enormous amount of fuel as a cryogenic liquid in a relatively short time. Therefore, each gas carrier must conduct the compatibility study in compliance with the “Authorisation Procedure for LNG Vessels Arriving at the LNG terminal in Świnoujście” [

47]. Only those vessels confirmed by the study are admitted to arrive and unload.

Within 24 h after departure from the loading port, the ship’s master is obligated to submit a notice of departure to the terminal operator. Then, notification of arrival should be submitted seven days and subsequently 96, 72, 48, 24, 12, and 6 h before arrival, according to the estimated arrival time to the terminal. The reception operations can be divided into three phases: the approach to the terminal, the transfer of LNG, and leaving the terminal.

We can consider that the first phase begins when the LNG carrier is passing the N-1 buoy, which means 43 km from the entrance. From this point, the vessel should proceed with the assistance of two pilots and the passive assistance of a tug. At a distance of 26 km from the entrance, the LNG carrier may obtain permission to enter the port as long as [

48]:

Wind speed is less than 12.5 m/s;

Wave heights do not exceed 1.5 m;

Water level guarantees 2 m of under keel clearance;

The speed of the current, within a distance of 2 km before breakwater heads, does not exceed 0.26 m/s;

Visibility is at least 3 km.

The LNG carrier has to use active tug assistance with connected stern tow if permission is granted. When the vessel approaches 6 km, another tug must be connected with a bow tow, and fire-fighting vessel assistance must be provided. The following two tugs have to join the LNG carrier at a distance of 2 km to the outer port entrance as ordered by the pilot. In addition, all other vessels navigating in the vicinity of the Świnoujście port must not disturb the LNG carrier. When the gas carrier enters the outer port of Świnoujście, it has to rotate to the moor starboard side. The maximum approach transverse speed and angle are respectively 0.05 m/s and 2°. The first phase is completed when the LNG carrier is alongside the berth, all mooring lines are hooked and secured by the linesmen team, and the gangway is in place.

During the whole stay of the LNG carrier alongside the berth, the pilot must be present on board, and the assistance of two tugs and a fire-fighting vessel has to be kept.

At the beginning of the second phase, “the LNG unloading procedure and pre-discharge” meeting occur. The meeting attended by the master of the ship, the chief officer, and on the part of the terminal, the loading master, involves the [

48]:

Confirmation of the unloading schedule;

Exchange of any required information concerning the system and equipment of the Ship and the Terminal;

Arrangement of all cargo data and requirements concerning the unloading;

Arrangement of the D1011-PIC-12 BOG vapor return controller set point;

Carrying out of a safety inspection aboard (by the loading master or a person indicated by him and carrier’s duty officer or a person indicated by him) confirming that all safety requirements have been met before the unloading operation.

Filling a “Ship Shore Safety Checklist, SSSCL” or an equivalent document [

49].

After filling in the SSSCL, consent to connect the unloading arms is issued. The connection shall be carried out after the arm operators have ensured no contamination exists inside the manifold, that the ship’s crew has correctly installed adequate unloading filters, and that the vapor return (BOG) arm is connected and disconnected from the last one.

When the arms are connected, leak and pressure tests are executed, and measurement devices are also checked. The whole unloading line, which includes the arms and pipes leading to storage tanks, has to be cooled down. This produces a significant amount of LNG vapor; therefore, the BOG handling system is to be configured. The emergency shut-down procedure is tested before and after cooling down the unloading line. When the tests’ results are positive, the unloading of LNG can be commenced. The design unloading rate equals 12,000 m3/h with a ship manifold pressure of 4.5 bar, which shall not be exceeded. During the unloading, the pressure and temperature in the ship’s tanks and storage tanks are controlled by the actual discharge rate and amount of vapor return. Cargo is sampled with appropriate intervals to calculate the amount and composition of LNG.

When LNG discharging is completed, the unloading line is drained, purged with nitrogen, and the final measurement is taken. Following this, the post-discharge meeting is arranged to evaluate the unloading operation propose improvements for the next deliveries. After solutions to all issues and problems regarding safety and communications, the LNG carrier receives approval for further calls. At the end of the second phase, the unloading arms are disconnected, post-discharge documentation is prepared, and the vessel waits for permission to leave.

The last phase of reception operations begins when the LNG carrier obtains permission to depart from the port. The hydrometeorological conditions must be as follows:

Wind speed—less than 12.5 m/s;

Wave height—less than 1.5 m;

Visibility—minimum 3 km;

Current speed beyond breakwater heads—less than 0.26 m/s.

Similar assistance from pilots, tugs, and fire-fighting vessels is required when gas carriers leave the LNG terminal [

48].

5. Results

The proposed risk assessment method at the LNG terminal in Świnoujście is characterized in

Section 4. Representatives of all groups of experts attended the research procedure indicated in the description of the research methodology in

Section 3. Experts participated in the entire research procedure on identification and characteristics of adverse event scenarios and at the stage of quantitative analysis related to the estimation of fuzzy values for risk parameters—the probability and effects of the analyzed adverse events.

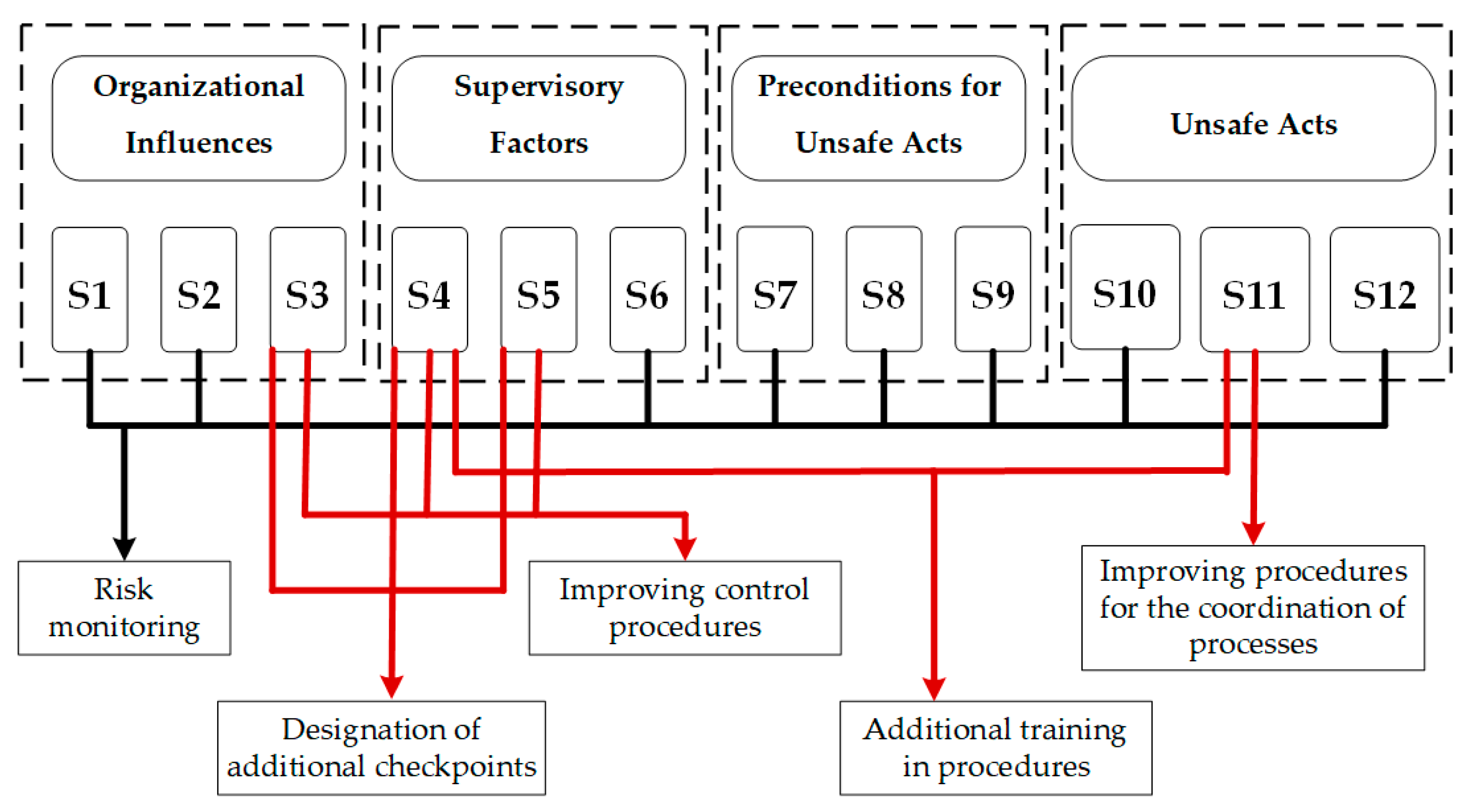

Based on the qualitative analysis, 12 adverse event scenarios were identified, then classified according to the groups defined in the HFACS analysis. Together with the assignment to the appropriate groups, these scenarios are presented in

Table 8.

A quantitative analysis was performed for defined adverse event scenarios following the assumptions presented in

Section 3, Materials and Methods. As a result of the conducted procedure, the value of the risk indicator for each of the identified scenarios was estimated. The final results are presented in

Table 9 and

Figure 11 and

Figure 12.

Table 9.

The obtained results of the risk assessment for all analyzed scenarios.

Table 9.

The obtained results of the risk assessment for all analyzed scenarios.

| Scenario | P (Fuzzy) | P (Crisp) | C (Fuzzy) | C (Crisp) | Risk Level |

|---|

| S1 | P2 | 2.45 | 5.43 | C3 | 26.1 |

| S2 | P2 | 2.43 | 5.27 | C3 | 25.6 |

| S3 | P2 | 2.04 | 6.11 | C4 | 36.7 |

| S4 | P2 | 2.29 | 6.22 | C4 | 36.8 |

| S5 | P2 | 2.33 | 6.15 | C4 | 35.1 |

| S6 | P2 | 2.45 | 4.78 | C3 | 25.2 |

| S7 | P2 | 2.77 | 5.56 | C3 | 27.3 |

| S8 | P2 | 2.31 | 4.88 | C2 | 25.2 |

| S9 | P2 | 2.50 | 4.75 | C3 | 25.2 |

| S10 | P2 | 2.17 | 5.88 | C3 | 29.6 |

| S11 | P1 | 1.78 | 6.22 | C4 | 36.7 |

| S12 | P2 | 2.47 | 5.89 | C3 | 29.9 |

Figure 11.

Risk surface generated in MATLAB.

Figure 11.

Risk surface generated in MATLAB.

Figure 12.

Influence of the course of input functions on the obtained risk index value: (a) the consequence function of the scenario; (b) the probability function of the scenario.

Figure 12.

Influence of the course of input functions on the obtained risk index value: (a) the consequence function of the scenario; (b) the probability function of the scenario.

According to the ISO 31,000: 2018 standard [

37], the final risk assessment stage is evaluation. At this stage, the level of risk accepted by decision-makers is determined, which is then the basis for determining the directions of further actions regarding a given adverse event scenario. In the analyzed case, the level of risk acceptance was determined by experts at a relatively low level (compare, among other things, [

50,

51]), as the acceptance threshold was indicated for the value of RL = 30. This is mainly due to the high level of risk to the health and life of the terminal crew and the surrounding community in the event of undesirable phenomena related to LNG reloading. This fact means that decision-makers are ready to take measures to prevent the occurrence of potential adverse event scenarios and monitor regularly occurring threats, even at a relatively low-risk index.

As a result of the evaluation procedure, four scenarios were identified, the risk index of which exceeded the acceptable level of acceptance. These scenarios include S3, S4, S5, and S11. It is necessary to take immediate actions to reduce the current level of risk concerning these events.

Figure 13 shows the individual groups for the analyzed event scenarios, along with an indication of the recommended courses of action depending on the estimated risk index.

The directions of action presented in the figure are only a guide for decision-makers who, based on the results of the presented analyses, are obliged to take further steps related to the management of the existing risk for the studied area.

6. Discussion

The issues related to the transport and reloading of LNG deliveries to sea terminals are the subject of many publications, confirmed by the presented literature reviews [

2,

3]. Due to the threat to the life and health of people involved in the supply process, research devoted to developing risk assessment methods that can be used to improve people, procedures, and technical infrastructure is of particular importance. For this reason, our proposed risk assessment method is primarily focused on human error that may be the cause of adverse events defined following the HFACS analysis. Thanks to its framework, it is possible to classify the analyzed scenarios, which will streamline the process of planning and introducing changes aimed at improving the servicing of LNG supplies.

Elsayed et al. [

19] noted that estimating the size of risk parameters in qualitative analysis is still a challenge for researchers despite many different techniques and models for assessing the risk related to LNG transmission. A detailed quantitative analysis is only possible if sufficient information can estimate quantitative failure frequency and/or associated accident consequences. For terminals that have been in operation for a short time, such historical data is usually not available. In such a situation, one can use the data on adverse events from other terminals or use the knowledge and experience of experts. Using historical data from other terminals may lead to incorrect conclusions. Each terminal functions according to its procedures. They are prepared based on global guidelines for servicing LNG deliveries and consider the specificity of local conditions. Each of the terminals also has its own resources at its disposal, including human resources, planning, organizing, and control of their work. The frequency and effects of a given adverse event may be incomparable between individual terminals. Therefore, the risk index for the same event scenarios may differ significantly in the assessment prepared for different ports.

For this reason, it seems more reasonable to use expert knowledge in the assessment. For the proposed approach, we chose the concept of fuzzy logic, which allows using the advantages of the quantitative approach in risk analysis, for which we lack historical data. In this case, however, the proper selection of experts for the research team is significant. For this reason, the members of such a team should include specialists who know both the methodology of risk assessment preparation and people involved in the delivery process at various levels of its implementation. The composition of such a team proposed by us, described in

Section 3, meets the above condition.

The proposed risk assessment method was verified based on the selected terminal in Poland. The obtained results allowed for a positive assessment of its application in this case by decision-makers. A significant benefit is taking the local operating conditions into account, thanks to an internal document describing the procedures in force at the analyzed terminal. At the same time, however, basing the qualitative analysis on the internal instruction of conduct may suggest that the presented approach is not universal and corresponds only to the needs of a given port. We want to emphasize that the primary document for conducting a risk analysis is the HFACS framework to meet these accusations. At the same time, the Terminal Operation Manual is a reference point for the characteristics of the identified adverse event scenarios. Therefore, they conduct a qualitative analysis for the selected port using a local document describing the applicable rules of conduct, the non-observance of which may lead to specific adverse events.

The use of the assumptions of the HFACS analysis in the proposed method causes researchers to focus primarily on human errors made by the crew. For this reason, the lack of targeting the risks associated with the technical infrastructure used may be considered a limitation of the proposed approach. However, the condition of this infrastructure depends on the adopted maintenance strategy, the effectiveness of which can also be related to the risk related to human errors. For this reason, it can be concluded that the inability to apply the proposed approach to the assessment of the infrastructure used will mainly refer to the risk associated with the limited financial resources of the enterprise and erroneous strategic decisions.

7. Conclusions

The development of alternative energy sources, including LNG as a low-emission fuel, has led to the development of global and local supply chains serving this type of fuel. In Poland, a sea terminal has been established to serve LNG deliveries. The number of transshipments related to the logistic service of tankers increases every year. The increasing number of units served increases the risk associated with logistics operations. In particular, human errors made by the crew involved in the service process may be dangerous. For this reason, a risk assessment method has been proposed for the logistic handling of LNG supplies, which is primarily focused on adverse events caused by the actions of participants involved in the analyzed process.

The proposed approach is universal while also considering the specificity of the solutions in force in the port under assessment. This is possible thanks to the simultaneous qualitative analysis of the HFACS framework and local instructions on procedures for the logistic service of ships delivering LNG. Thanks to the use of the fuzzy logic concept, it is also possible to determine quantitative values for risk indicators with a simultaneous lack of available historical data. However, the achievement of the intended effect strongly depends on the proper selection of members of the team of experts who participate in the critical stages of the research procedure. To obtain high-quality results, the composition of such a team of experts was proposed, whose representatives represent different points of view and have different knowledge about the LNG supply process. Thanks to this, the risk assessment performed is interdisciplinary and may consider a wide range of analyzed issues. In the approach presented in the article, the rule of not differentiating the opinions of individual experts was adopted. Therefore, in further research, it is worth analyzing the impact of assigning weights to the opinions of selected groups of experts participating in the risk assessment

The results obtained in the evaluation procedure should constitute the basis for improving the procedures in force at the terminal and the improvement of employees’ competencies. The decisions of the management staff regarding the organization of the logistic service of LNG deliveries should also be supported, with particular emphasis on the increasing number of deliveries. Time pressure, fatigue, and stress caused by the increased number of actions taken may contribute to the crew’s increased mistakes. Appropriate crew and system preparation to intensify the ongoing maintenance operations may be crucial for a safe and efficient LNG-reloading system. Therefore, the analysis results should help decision-makers eliminate the identified risks or support the resilience of logistic processes to possible adverse events.