Bioethanol Production in Poland in the Context of Sustainable Development-Current Status and Future Prospects

Abstract

1. Introduction

2. Materials and Methods

3. Bioethanol and Sustainable Development—The Ecological, Social and Economic Order

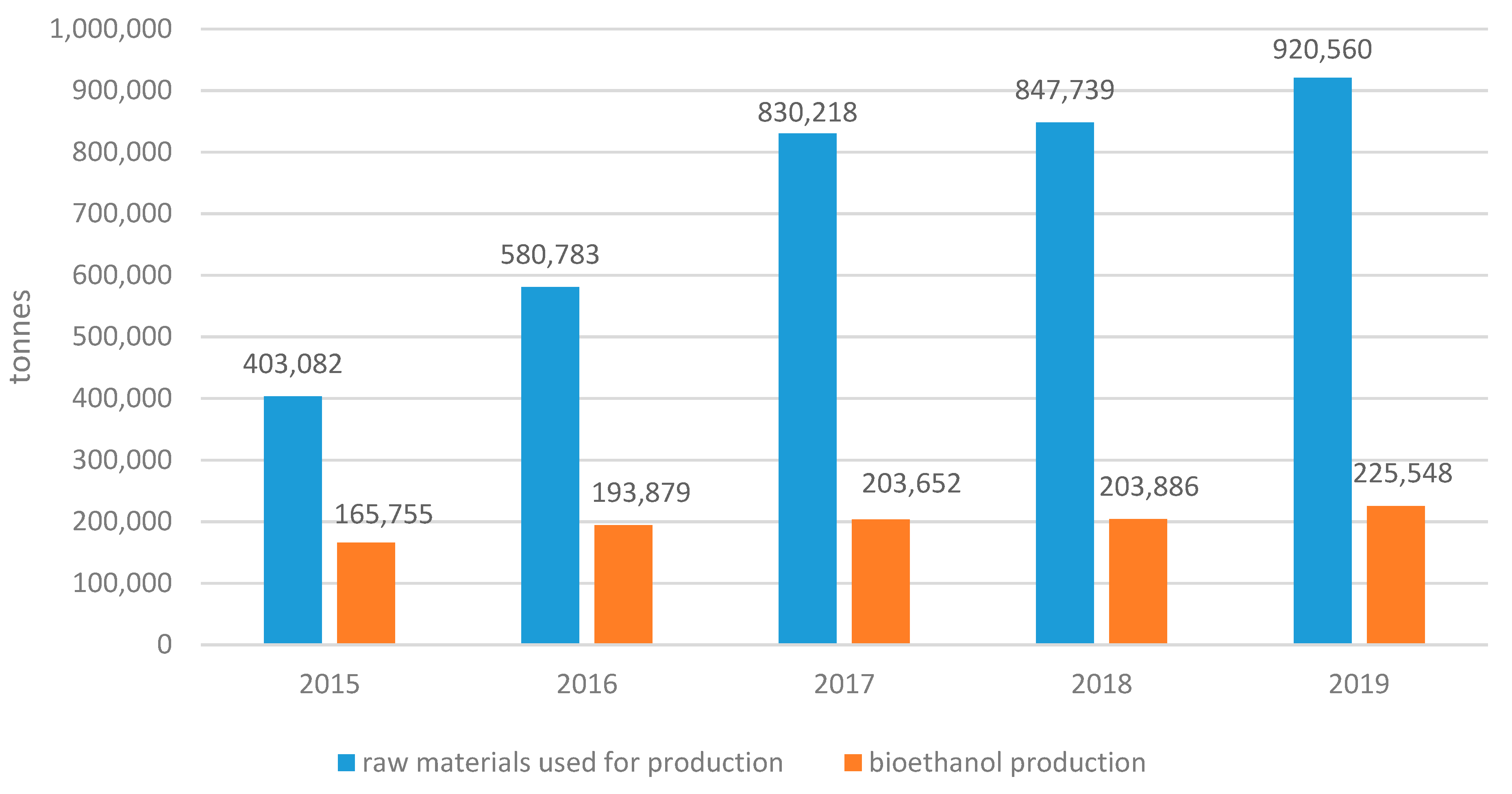

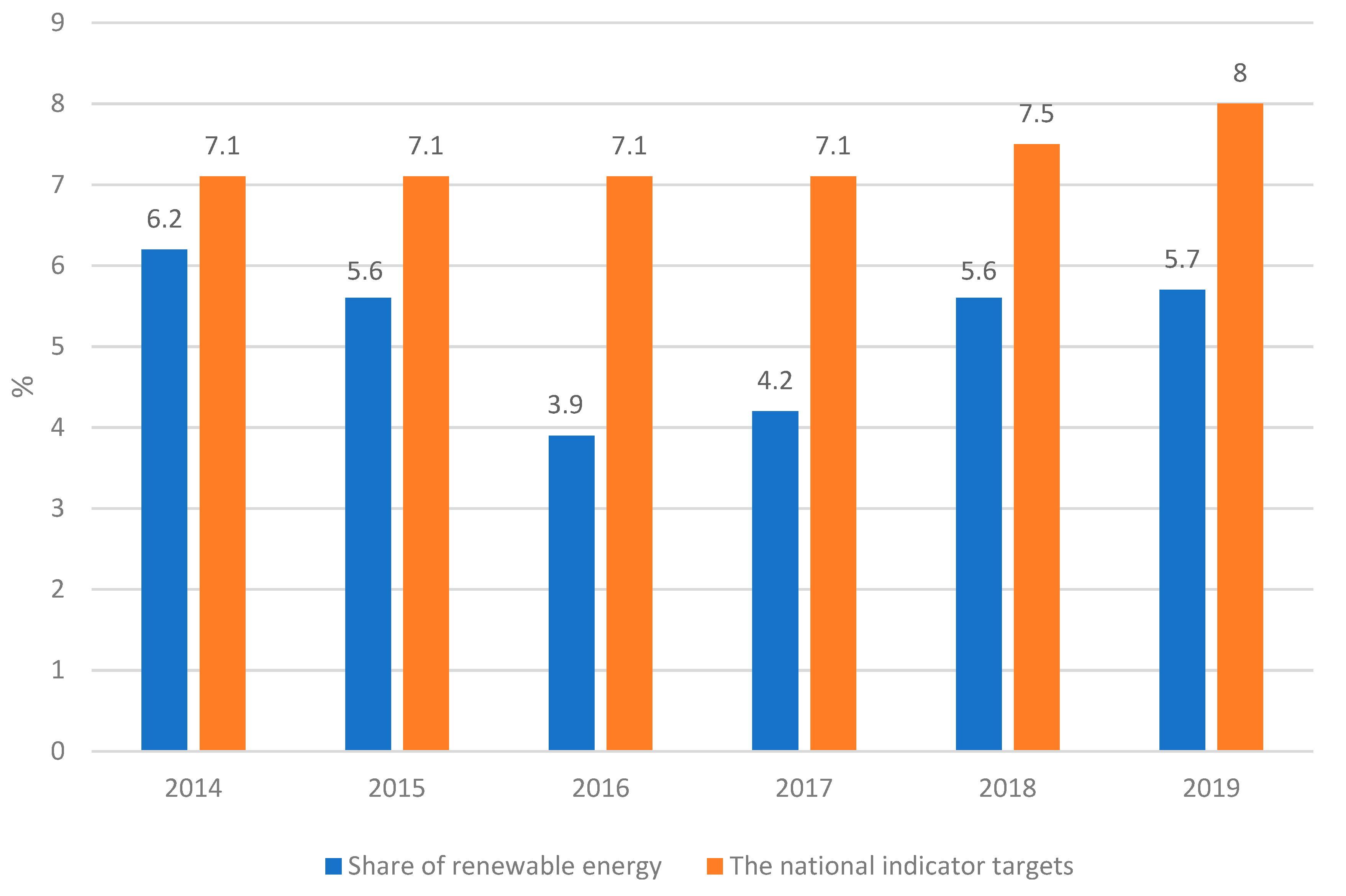

4. Bioethanol Market in Poland—Legal Regulations, Production Volume, Raw Materials and Characteristics of the Main Producers

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klikocka, H.; Kasztelan, A.; Zakrzewska, A.; Wyłupek, T.; Szostak, B.; Skwaryło-Bednarz, B. The energy efficiency of the production and conversion of spring triticale grain into bioethanol. Agronomy 2019, 9, 423. [Google Scholar] [CrossRef]

- Sharma, G.; Kaur, M.; Punj, S.; Singh, K. Biomass as a sustainable resource for value-added modern materials: A review. Biofuels Bioprod. Biorefin. 2020, 14, 673–695. [Google Scholar] [CrossRef]

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol production from agricultural wastes: An overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- Sekoai, P.T.; Ouma, C.N.M.; Du Preez, S.P.; Modisha, P.; Engelbrecht, N.; Bessarabov, D.G.; Ghimire, A. Application of nanoparticles in biofuels: An overview. Fuel 2019, 237, 380–397. [Google Scholar] [CrossRef]

- Mohapatra, S.; Ray, R.C.; Ramachandran, S. Bioethanol From Biorenewable Feedstocks: Technology, Economics, and Challenges. In Bioethanol Prod. Food Crops; Academic Press: Cambridge, MA, USA, 2019; pp. 3–27. [Google Scholar]

- Wicki, L. Development of biofuels production from agricultural raw materials. Int. Sci. Conf. Rural. Dev. 2017, 502–508. [Google Scholar] [CrossRef]

- Amigun, B.; Petrie, D.; Görgens, J. Economic risk assessment of advanced process technologies for bioethanol production in South Africa: Monte Carlo analysis. Renew. Energy 2011, 36, 3178–3186. [Google Scholar] [CrossRef]

- Deenanath, E.D.; Iyuke, S.; Rumbold, K. The bioethanol industry in Sub-Saharan Africa: History, challenges, and prospects. Biomed. Res. Int. 2012, 416491. [Google Scholar] [CrossRef]

- Adewuyi, A. Challenges and prospects of renewable energy in Nigeria: A case of bioethanol and biodiesel production. Energy Rep. 2020, 6, 77–88. [Google Scholar] [CrossRef]

- Tao, J.; Yu, S.; Wu, T. Review of China’s bioethanol development and a case study of fuel supply, demand and distribution of bioethanol expansion by national application of E10. Biomass Bioenergy 2011, 35, 3810–3829. [Google Scholar] [CrossRef]

- Jiang, D.; Hao, M.; Fu, J.; Liu, K.; Yan, X. Potential bioethanol production from sweet sorghum on marginal land in China. J. Clean. Prod. 2019, 220, 225–234. [Google Scholar] [CrossRef]

- Di Donato, P.; Finore, I.; Poli, A.; Nicolaus, B.; Lama, L. The production of second generation bioethanol: The biotechnology potential of thermophilic bacteria. J. Clean. Prod. 2019, 233, 1410–1417. [Google Scholar] [CrossRef]

- Hoang, T.-D.; Nghiem, N. Recent Developments and Current Status of Commercial Production of Fuel Ethanol. Fermentation 2021, 7, 314. [Google Scholar] [CrossRef]

- Renewable Fuels Association Database. Available online: https://ethanolrfa.org/statistics/annual-ethanol-production (accessed on 9 June 2021).

- Sharma, B.; Larroche, C.; Dussap, C.G. Comprehensive assessment of 2G bioethanol production. Bioresour. Technol. 2020, 313, 123630. [Google Scholar] [CrossRef] [PubMed]

- Pacini, H.; Silveira, S. Consumer choice between ethanol and gasoline: Lessons from Brazil and Sweden. Energy Policy 2011, 39, 6936–6942. [Google Scholar] [CrossRef]

- de Souza Abud, A.K.; de Farias Silva, C.E. Bioethanol in Brazil: Status, challenges and perspectives to improve the production. In Bioethanol Production Food Crops; Academic Press: Cambridge, MA, USA, 2019; pp. 417–443. [Google Scholar]

- Gumienna, M.; Lasik, M.; Czarnecki, Z.; Szambelan, K. Applicability of inconventional energy raw materials in ethanol production. Acta Sci. Pol. Technol. Aliment. 2009, 8, 17–24. [Google Scholar]

- Dzikuć, M.; Adamczyk, J.; Piwowar, A. Problems associated with the emissions limitations from road transport in the Lubuskie Province (Poland). Atmos. Environ. 2017, 160, 1–8. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Gazda-Grzywacz, M.; Zarębska, K. Research and Prospects for the Development of Alternative Fuels in the Transport Sector in Poland: A Review. Energies 2020, 13, 2988. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Folęga, P. Impact of road transport means on climate change and human health in Poland. Promet-Traffic Transp. 2019, 31, 195–204. [Google Scholar] [CrossRef][Green Version]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. R. Soc. 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Roy, P.; Dutta, A. Life Cycle Assessment (LCA) of Bioethanol Produced From Different Food Crops: Economic and Environmental Impacts. In Bioethanol Production Food Crops; Academic Press: Cambridge, MA, USA, 2019; pp. 385–399. [Google Scholar]

- Lovett, J.C.; Hards, S.; Clancy, J.; Snell, C. Multiple objectives in biofuels sustainability policy. Energy Environ. Sci. 2011, 4, 261–268. [Google Scholar] [CrossRef]

- Mączyńska, J.; Kupczyk, A. Conventional biofuels in respects of sustainable development. Ekonomia i Środowisko 2018, 1, 170–180. [Google Scholar]

- Mohr, A.; Raman, S. Lessons from first generation biofuels and implications for the sustainability appraisal of second generation biofuels. Energy Policy 2013, 63, 114–122. [Google Scholar] [CrossRef] [PubMed]

- Lydgate, E.B. Biofuels, sustainability, and trade-related regulatory chill. J. Int. Econ. Law 2012, 15, 157–180. [Google Scholar] [CrossRef]

- Ackrill, R.; Kay, A. EU biofuels sustainability standards and certification systems–how to seek WTO-compatibility. J. Agric. Econ. 2011, 62, 551–564. [Google Scholar] [CrossRef]

- Endres, J.M. Clearing the air: The meta-standard approach to ensuring biofuels environmental and social sustainability. Va. Environ. Law J. 2010, 28, 73–120. [Google Scholar]

- Scarlat, N.; Dallemand, J.F. Recent developments of biofuels/bioenergy sustainability certification: A global overview. Energy Policy 2011, 39, 1630–1646. [Google Scholar] [CrossRef]

- Bracco, S. Effectiveness of EU biofuels sustainability criteria in the context of land acquisitions in Africa. Renew. Sustain. Energy Rev. 2015, 50, 130–143. [Google Scholar] [CrossRef]

- Skowroń, J.; Golimowski, W. Produkcja biopaliw: Priorytetowy kierunek badań naukowych. Podstawy i Metod. Oceny Sr. Pr. 2015, 2, 5–15. (In Polish) [Google Scholar] [CrossRef]

- Slade, R.; Bauen, A.; Shah, N. The greenhouse gas emissions performance of cellulosic ethanol supply chains in Europe. Biotechnol. Biofuels 2009, 2, 15. [Google Scholar] [CrossRef]

- Soimakallio, S.; Koponen, K. How to ensure greenhouse gas emission reductions by increasing the use of biofuels?–Suitability of the European Union sustainability criteria. Biomass Bioenergy 2011, 35, 3504–3513. [Google Scholar] [CrossRef]

- Börjesson, P. Good or bad bioethanol from a greenhouse gas perspective–what determines this? Appl. Energy 2009, 86, 589–594. [Google Scholar] [CrossRef]

- Hattori, T.; Morita, S. Energy crops for sustainable bioethanol production; which, where and how? Plant Prod. Sci. 2010, 13, 221–234. [Google Scholar] [CrossRef]

- Rai, M.; Ingle, A.P.; Pandit, R.; Paralikar, P.; Biswas, J.K.; da Silva, S.S. Emerging role of nanobiocatalysts in hydrolysis of lignocellulosic biomass leading to sustainable bioethanol production. Catal. Rev. 2019, 61, 1–26. [Google Scholar] [CrossRef]

- Kumar, M.N.; Ravikumar, R.; Thenmozhi, S.; Kumar, M.R.; Shankar, M.K. Choice of pretreatment technology for sustainable production of bioethanol from lignocellulosic biomass: Bottle necks and recommendations. Waste Biomass Valorization 2019, 10, 1693–1709. [Google Scholar] [CrossRef]

- Yao, F.; Tian, D.; Shen, F.; Hu, J.; Zeng, Y.; Yang, G.; Zhang, Y.; Deng, S.; Zhang, J. Recycling solvent system in phosphoric acid plus hydrogen peroxide pretreatment towards a more sustainable lignocellulose biorefinery for bioethanol. Bioresour. Technol. 2019, 275, 19–26. [Google Scholar] [CrossRef]

- Mushlihah, S.; Husain, D.R.; Langford, A.; Tassakka, A.C.M.A. Fungal pretreatment as a sustainable and low cost option for bioethanol production from marine algae. J. Clean. Prod. 2020, 265, 121763. [Google Scholar]

- Daroch, M.; Geng, S.; Wang, G. Recent advances in liquid biofuel production from algal feedstocks. Appl. Energy 2013, 102, 1371–1381. [Google Scholar] [CrossRef]

- Szufa, S.; Dzikuć, M.; Adrian, Ł.; Romanowska-Duda, Z.; Lewandowska, W.; Marcza, M.; Błaszczak, A.; Piwowar, A. Torrefaction of oat straw to use as solid biofuel, an additive to organic fertilizers for agriculture purposes and activated carbon–TGA analysis, kinetics. E3S Web Conf. 2020, 154, 02004. [Google Scholar] [CrossRef]

- Ntaikou, I.; Antonopoulou, G.; Lyberatos, G. Biohydrogen production from biomass and wastes via dark fermentation: A review. Waste Biomass Valorization 2010, 1, 21–39. [Google Scholar] [CrossRef]

- Nagarajan, D.; Chang, J.S.; Lee, D.J. Pretreatment of microalgal biomass for efficient biohydrogen production–Recent insights and future perspectives. Bioresour. Technol. 2020, 302, 122871. [Google Scholar] [CrossRef]

- Yi, W.; Nadeem, F.; Xu, G.; Zhang, Q.; Joshee, N.; Tahir, N. Modifying crystallinity, and thermo-optical characteristics of Paulownia biomass through ultrafine grinding and evaluation of biohydrogen production potential. J. Clean. Prod. 2020, 269, 122386. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Ong, H.C.; Cheah, M.Y.; Chen, W.H.; Yu, K.L.; Mahlia, T.M.I. Sustainability of direct biodiesel synthesis from microalgae biomass: A critical review. Renew. Sustain. Energy Rev. 2019, 107, 59–74. [Google Scholar] [CrossRef]

- Smuga-Kogut, M. Znaczenie produkcji biopaliw w Polsce na przykładzie bioetanolu. Autobusy 2015, 6, 202–205. (In Polish) [Google Scholar]

- Kupczyk, A.; Szlachta, J. Polski potencjał produkcyjny bioetanolu w kontekście uwarunkowań Dyrektywy 2003/30/EC. Probl. Ekol. 2007, 11, 154–156. (In Polish) [Google Scholar]

- Piwowar, A. Produkcja biokomponentów i biopaliw ciekłych w Polsce–tendencje rozwoju i regionalne zróżnicowanie. Ann. PAAAE 2015, XVII, 196–200. (In Polish) [Google Scholar]

- Jarosz, Z.; Faber, A. Zmiany w rozwoju sektora biopaliw płynnych. Ann. PAAAE 2016, XVIII, 110–116. (In Polish) [Google Scholar]

- National Support Centre for Agriculture Database. Available online: http://www.kowr.gov.pl/odnawialne-zrodla-energii/biokomponenty-i-biopaliwa (accessed on 7 June 2021).

- Statistic Poland Database. Available online: https://stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/rolnictwo/rolnictwo-w-2020-roku,3,17.html (accessed on 18 March 2022).

- Rynek Zbóż. Analizy Rynkowe 2021, p. 61. (In Polish). Available online: http://ierigz.waw.pl/publikacje/analizy-rynkowe/rynek-zboz (accessed on 25 January 2022).

- Bujoczek, L.; Bujoczek, M.; Zięba, S. How much, why and where? Deadwood in forest ecosystems: The case of Poland. Ecol. Indic. 2021, 121, 107027. [Google Scholar] [CrossRef]

- Pacini, H.; Assunção, L.; Van Dam, J.; Toneto, R., Jr. The price for biofuels sustainability. Energy Policy 2013, 59, 898–903. [Google Scholar] [CrossRef]

- Energy from Renewable Sources in 2018, Statistic Poland 2018, Warsaw, 2019, p. 34. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/energia-ze-zrodel-odnawialnych-w-2018-roku,3,13.html (accessed on 10 June 2021).

- Available online: http://www.popihn.pl/raporty2.php (accessed on 10 June 2021).

- Energy from Renewable sources in 2020. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/energia-ze-zrodel-odnawialnych-w-2020-roku,3,15.html (accessed on 19 March 2022).

- Kupczyk, A.; Mączyńska, J.; Sikora, M.; Tucki, K.; Zieleziński, T. Stan i perspektywy oraz uwarunkowania prawne funkcjonowania sektorów biopaliw transportowych w Polsce. Rocz. Nauk. Ekon. Rol. I Rozw. Obsz. Wiej. 2017, 104, 39–55. (In Polish). Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/energia-ze-zrodel-odnawialnych-w-2018-roku,3,13.html (accessed on 10 June 2021). [CrossRef]

- Szewczyk, M.; Tłuczak, A. Bioethanol production-opportunities and threats for agriculture in Opolskie Province. Ann. PAAAE 2010, 6, 168–172. [Google Scholar]

- Smuga-Kogut, M.; Szymanowska, D.; Markiewicz, R.; Piskier, T.; Kobus-Cisowska, J.; Cielecka-Piontek, J.; Schöne, H. Evaluation of the potential of fireweed (Epilobium angustifolium L.), European goldenrod (Solidago virgaurea L.), and common broom (Cytisus scoparius L.) stems in bioethanol production. Energy Sci. Eng. 2020, 8, 3244–3254. [Google Scholar] [CrossRef]

- Gray, K.A.; Zhao, L.; Emptage, M. Bioethanol. Curr. Opin. Chem. Biol. 2006, 10, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Cerazy-Waliszewska, J.; Jeżowski, S.; Łysakowski, P.; Waliszewska, B.; Zborowska, M.; Sobańska, K.; Ślusarkiewicz-Jarzina, A.; Białas, W.; Pniewski, T. Potential of bioethanol production from biomass of various Miscanthus genotypes cultivated in three-year plantations in west-central Poland. Ind. Crops Prod. 2019, 141, 111790. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first-and second-generation sugar-based feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Toor, M.; Kumar, S.S.; Malyan, S.K.; Bishnoi, N.R.; Mathimani, T.; Rajendran, K.; Pugazhendhi, A. An overview on bioethanol production from lignocellulosic feedstocks. Chemosphere 2020, 242, 125080. [Google Scholar] [CrossRef]

- Nosecka, B.; Szczepaniak, I. Przetwórstwo owoców i warzyw w Polsce-stan obecny i perspektywy rozwoju. Przemysł Spożywczy 2019, 73, 2–10. (In Polish) [Google Scholar] [CrossRef]

- Kut, A.; Demiray, E.; Ertuğrul Karatay, S.; Dönmez, G. Second generation bioethanol production from hemicellulolytic hydrolyzate of apple pomace by Pichia stipitis. Energy Sources Part A Recovery Util. Environ. Effects 2020, 42, 1–12. [Google Scholar] [CrossRef]

- ORLEN Will Invest in the Production of New Generation Bioethanol. Available online: https://www.orlen.pl/pl/o-firmie/media/komunikaty-prasowe/2021/grudzien/ORLEN-zainwestuje-w-produkcje-bioetanolu-nowej-generacji (accessed on 10 January 2022).

- Kozłowska, A.; Kozłowski, K.; Skawiński, W.; Kapka-Skrzypczak, L. Effect of pollutants emissions from biofuels on the environment and human health. Public Health 2020, 55, 45–55. (In Polish) [Google Scholar]

- Who Was Subsidized for Biofuels? Available online: https://www.gramwzielone.pl/bioenergia/1140/kto-dostal-dotacje-na-biopaliwa (accessed on 17 March 2022).

- Puricelli, S.; Casadei, S.; Bellin, T.; Cernuschi, S.; Faedo, D.; Lonati, G.; Rossi, T.; Grosso, M. The effects of innovative blends of petrol with renewable fuels on the exhaust emissions of a GDI Euro 6d-TEMP car. Fuel 2021, 294, 120483. [Google Scholar] [CrossRef]

- Godzisz, K.; Dzikuć, M.; Kułyk, P.; Piwowar, A.; Kuryło, P.; Szufa, S. Selected Determinants of Sustainable Transport in the Context of the Development of a Low-Carbon Economy in Poland. Energies 2021, 14, 5418. [Google Scholar] [CrossRef]

- Dzikuć, M.; Miśko, R.; Szufa, S. Modernization of the Public Transport Bus Fleet in the Context of Low-Carbon Development in Poland. Energies 2021, 14, 3295. [Google Scholar] [CrossRef]

| Region | 2015 | 2016 | 2017 | 2018 | 2019 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Billion L | % | Billion L | % | Billion L | % | Billion L | % | Billion L | % | |

| USA | 56.05 | 57.5 | 58.34 | 58.9 | 60.32 | 59.8 | 60.91 | 56.1 | 59.72 | 54.3 |

| Brazil | 27.25 | 27.9 | 25.59 | 25.8 | 25.29 | 25.1 | 30.32 | 27.9 | 32.44 | 29.5 |

| European Union | 5.25 | 5.4 | 5.21 | 5.3 | 5.30 | 5.3 | 5.41 | 5.0 | 5.45 | 5.0 |

| China | 3.08 | 3.2 | 3.20 | 3.2 | 3.26 | 3.2 | 3.97 | 3.7 | 3.41 | 3.1 |

| Canada | 1.65 | 1.7 | 1.65 | 1.7 | 1.78 | 1.8 | 1.82 | 1.7 | 1.89 | 1.7 |

| India | 0.74 | 0.8 | 1.04 | 1.1 | 0.79 | 0.8 | 1.51 | 1.4 | 2.01 | 1.8 |

| Thailand | 1.26 | 1.3 | 1.21 | 1.2 | 1.40 | 1.4 | 1.48 | 1.4 | 1.59 | 1.4 |

| Argentina | 0.80 | 0.8 | 1.00 | 1.0 | 1.10 | 1.1 | 1.10 | 1.0 | 1.10 | 1.0 |

| Rest of World | 1.48 | 1.5 | 1.48 | 1.9 | 1.57 | 1.6 | 2.08 | 1.9 | 2.27 | 2.1 |

| Total | 96.08 | 100.0 | 98.72 | 100.0 | 100.80 | 100.0 | 108.60 | 100.0 | 109.87 | 100.0 |

| Environmental | Economic | Social |

|---|---|---|

| Renewable character | Creating additional demand for agricultural raw materials and waste | Rural development, agricultural subsidies |

| Lower oil production | Waste management from agricultural production and other areas of agribusiness, development of advanced conversion technologies | Reorientation of public awareness. |

| Limiting environmental devastation and climate change | Development of trade in biofuels and derivatives | Security of energy supply |

| Specification | 2010 | 2015 | 2018 | 2019 |

|---|---|---|---|---|

| Total sowings | 10,366 | 10,753 | 10,829 | 10,898 |

| Cereals | 7597 | 7512 | 7806 | 7891 |

| Potatoes | 375 | 292 | 291 | 303 |

| Sugar beet | 206 | 180 | 239 | 242 |

| Rapeseed and colza | 945 | 947 | 845 | 875 |

| Other | 1243 | 1822 | 1648 | 1587 |

| Specification | 2015/16 | 2016/17 | 2017/18 | 2018/19 | 2019/20 |

|---|---|---|---|---|---|

| Cultivation area (thousand ha) | 670 | 594 | 562 | 645 | 665 |

| Yields (tonnes per hectare) | 4.71 | 7.32 | 7.15 | 5.99 | 5.62 |

| Production (thousand tonnes) | 3156 | 4343 | 4022 | 3864 | 3734 |

| Total domestic consumption (thousand tonnes) | 3046 | 3787 | 4100 | 4133 | 3755 |

| Consumption for industrial purposes (thousand tonnes) | 612 | 727 | 776 | 817 | 816 |

| Export (thousand tonnes) | 718 | 1674 | 1194 | 1334 | 1666 |

| Specification | Amount of Used Raw Material | Amount of Produced Biocomponent | ||||||

|---|---|---|---|---|---|---|---|---|

| Raw Materials 1 | Raw Materials 2 | A Biocomponent 3 | A Biocomponent 4 | |||||

| (Tonnes) | (%) | (Tonnes) | (%) | (Tonnes) | (%) | (Tonnes) | (%) | |

| 2018 | 672,192.25 | 79.29 | 175,547.06 | 20.71 | 197,620.03 | 96.93 | 6,265.79 | 3.07 |

| 2019 | 625,245.85 | 67.92 | 295,314.50 | 32.08 | 213,144.31 | 94.50 | 12,403.55 | 5.50 |

| No. | Company | Annual Capacity (Million L) |

|---|---|---|

| 1 | BIOAGRA S.A. | 210.00 |

| 2 | DESTYLACJE POLSKIE Sp. z o.o. | 150.00 |

| 3 | HGBS FINANSE S.A. | 95.00 |

| 4 | BGW Sp. z o.o. | 90.00 |

| 5 | GRUPA AWW Spółka z ograniczoną odpowiedzialnością Spółka komandytowa | 70.00 |

| 6 | WRATISLAVIA-BIODIESEL S.A. | 70.00 |

| 7 | BIOETANOL AEG Sp. z o.o. | 39.00 |

| 8 | CARGILL POLAND Sp. z o.o. | 35.00 |

| 9 | “Komers International” Sp. z o.o. | 32.00 |

| 10 | ARCTICA POLAND Sp. z o.o. | 16.00 |

| 11 | IMA POLSKA S.A. | 16.00 |

| 12 | Podlaskie Gorzelnie SURWIN Sp. z o.o. | 12.00 |

| 13 | Grupa Producencka AGRO-ŻABICE Sp. z o.o. | 4.40 |

| Total | 839.40 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piwowar, A.; Dzikuć, M. Bioethanol Production in Poland in the Context of Sustainable Development-Current Status and Future Prospects. Energies 2022, 15, 2582. https://doi.org/10.3390/en15072582

Piwowar A, Dzikuć M. Bioethanol Production in Poland in the Context of Sustainable Development-Current Status and Future Prospects. Energies. 2022; 15(7):2582. https://doi.org/10.3390/en15072582

Chicago/Turabian StylePiwowar, Arkadiusz, and Maria Dzikuć. 2022. "Bioethanol Production in Poland in the Context of Sustainable Development-Current Status and Future Prospects" Energies 15, no. 7: 2582. https://doi.org/10.3390/en15072582

APA StylePiwowar, A., & Dzikuć, M. (2022). Bioethanol Production in Poland in the Context of Sustainable Development-Current Status and Future Prospects. Energies, 15(7), 2582. https://doi.org/10.3390/en15072582