An Update on the Electronic Connection Issues of Low Power SWTs in AC-Coupled Systems: A Review and Case Study

Abstract

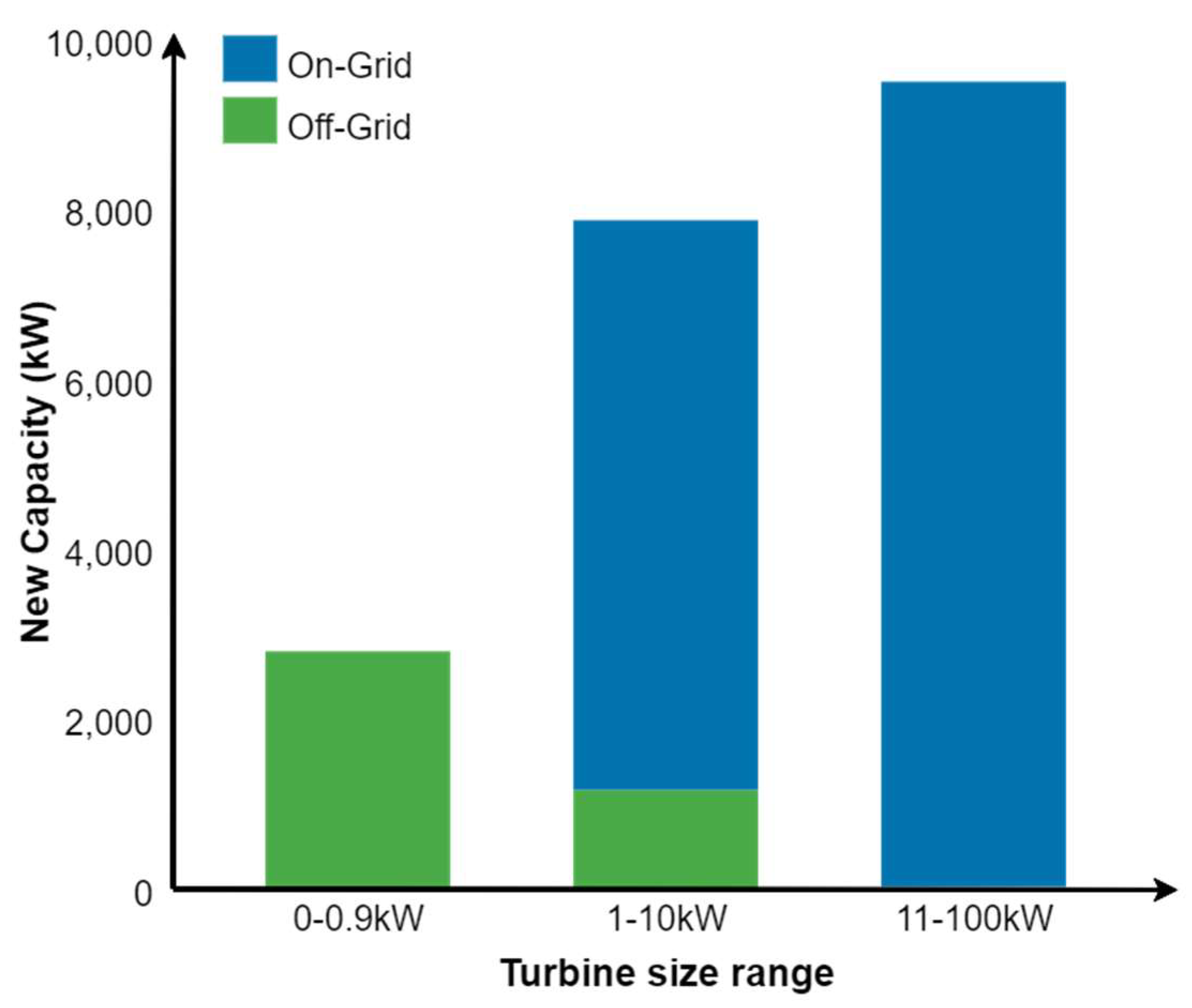

:1. Introduction

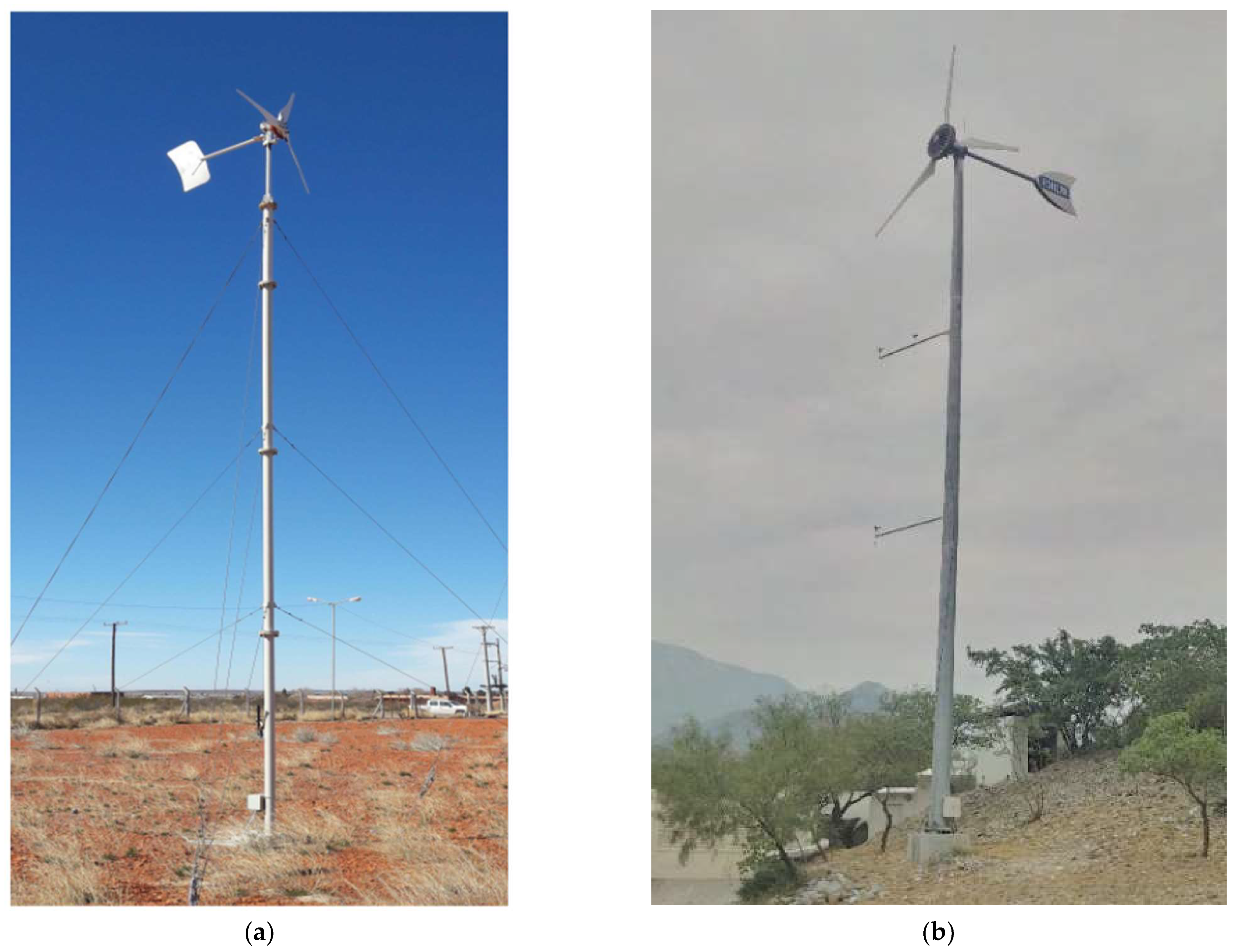

Configuration of the System under Review and Introduction to the Case Study

2. Requirements for Applying Grid Connection in Each Component of a SWT

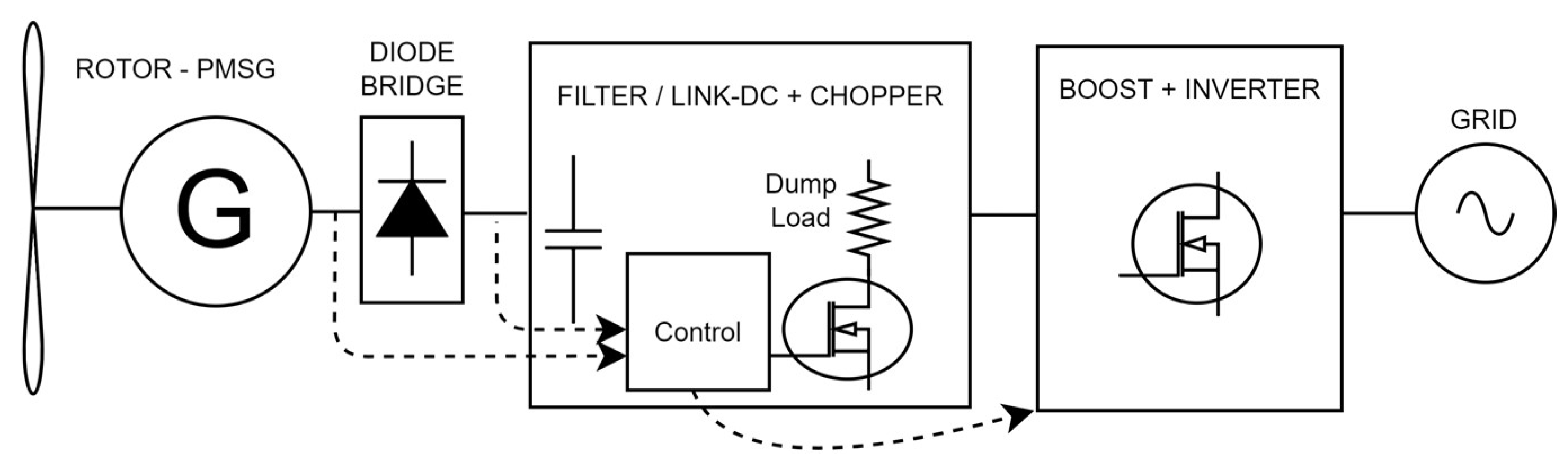

2.1. The Inverter for the Grid Connection

2.1.1. Inverters Designed Specifically for SWT Applications

2.1.2. General Purpose Photovoltaic (PV) Inverters

- -

- Frequency drop—power regulation in AC-coupled microgrids: in the case of AC-coupled microgrids, it is common to use frequency drop in order to regulate the power generated by the inverter [14]. Based on the frequency variation, the generator-side inverter will move the working point of the PV generator, changing the working voltage so that the current is adjusted to the desired value. However, as this characteristic is different for a SWT, this regulation might not work as expected.

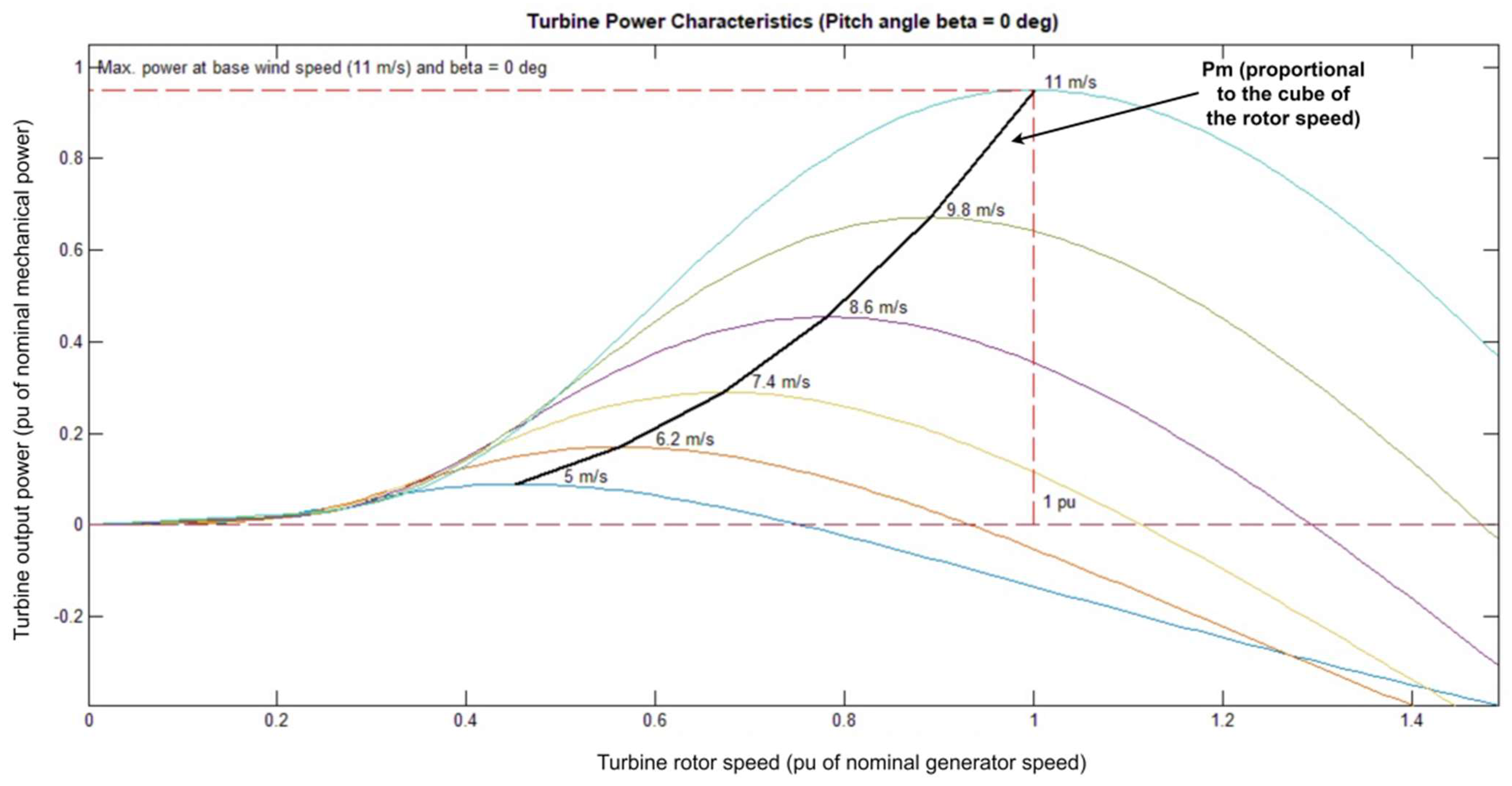

- -

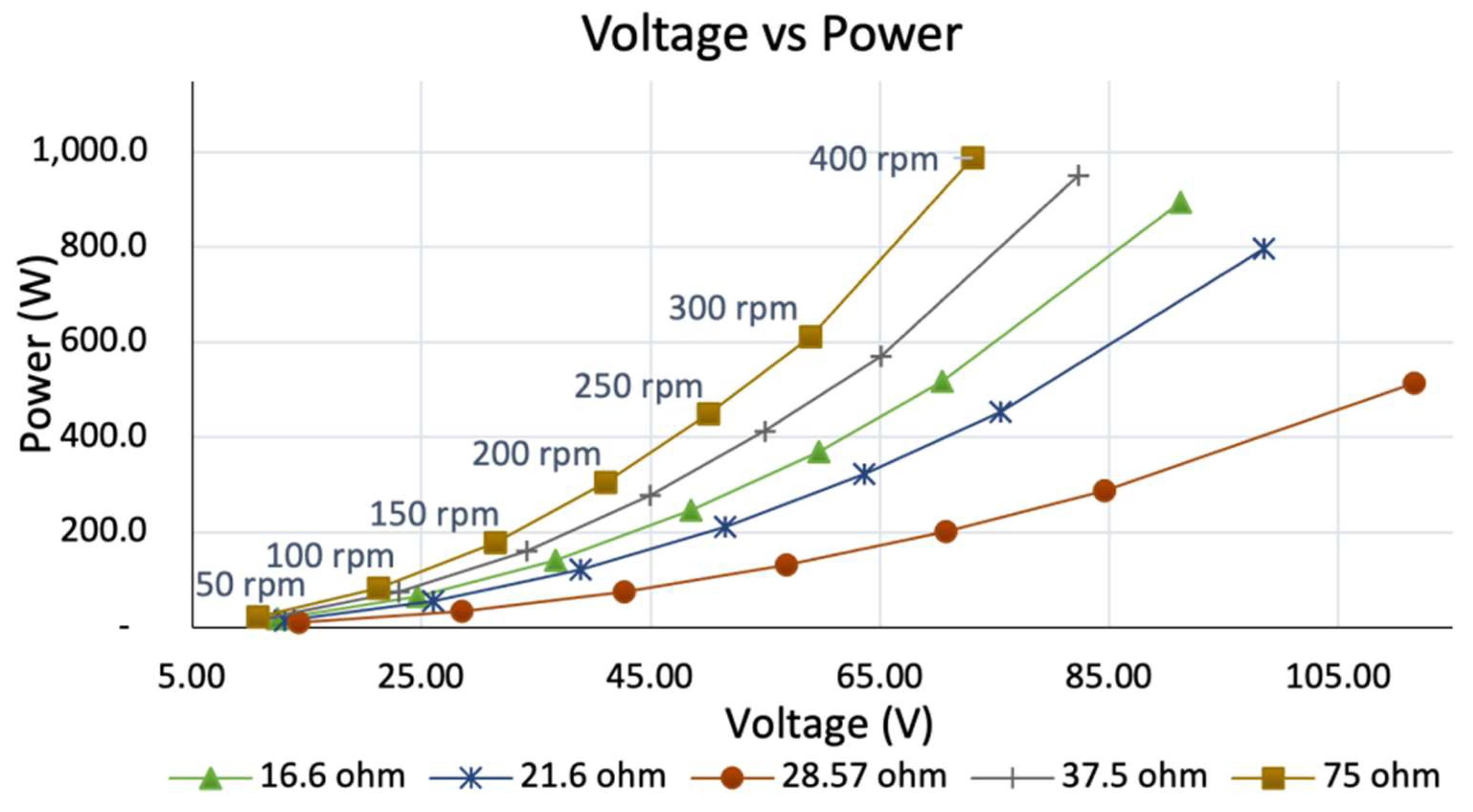

- Maximum Power Point Tracking (MPPT): in the same way, the inverter will move the working point of the PV generator to track for the maximum power point, changing the working voltage according to the PV’s I–V curve. However, as this characteristic is different for a SWT, this regulation might not work as expected either. The variability in wind speeds creates a challenge for turbine control, because the aerodynamic efficiency of the turbine rotor is related to maintaining an optimal relationship between current wind speed and rotational speed [12]. Sudden gusts of wind can also cause an increase in the fatigue load on turbine components that might reduce the lifetime of the turbine.

- -

- Time response: PV generation has no inertia, whereas SWT generation does. This means that the two methods will have different time responses, which might affect the correct functioning of the converter.

- -

- Waiting time: the time until the inverter starts producing, usually in the tens of seconds (during which the generator is unloaded). The inverter control routines may cause periods of disconnection from the grid, which are allowable for PV applications, but which might result in conditions that compromise the integrity of the SWT due to situations where there might be high voltage and overspeed in the wind turbine, requiring an overvoltage device.

- -

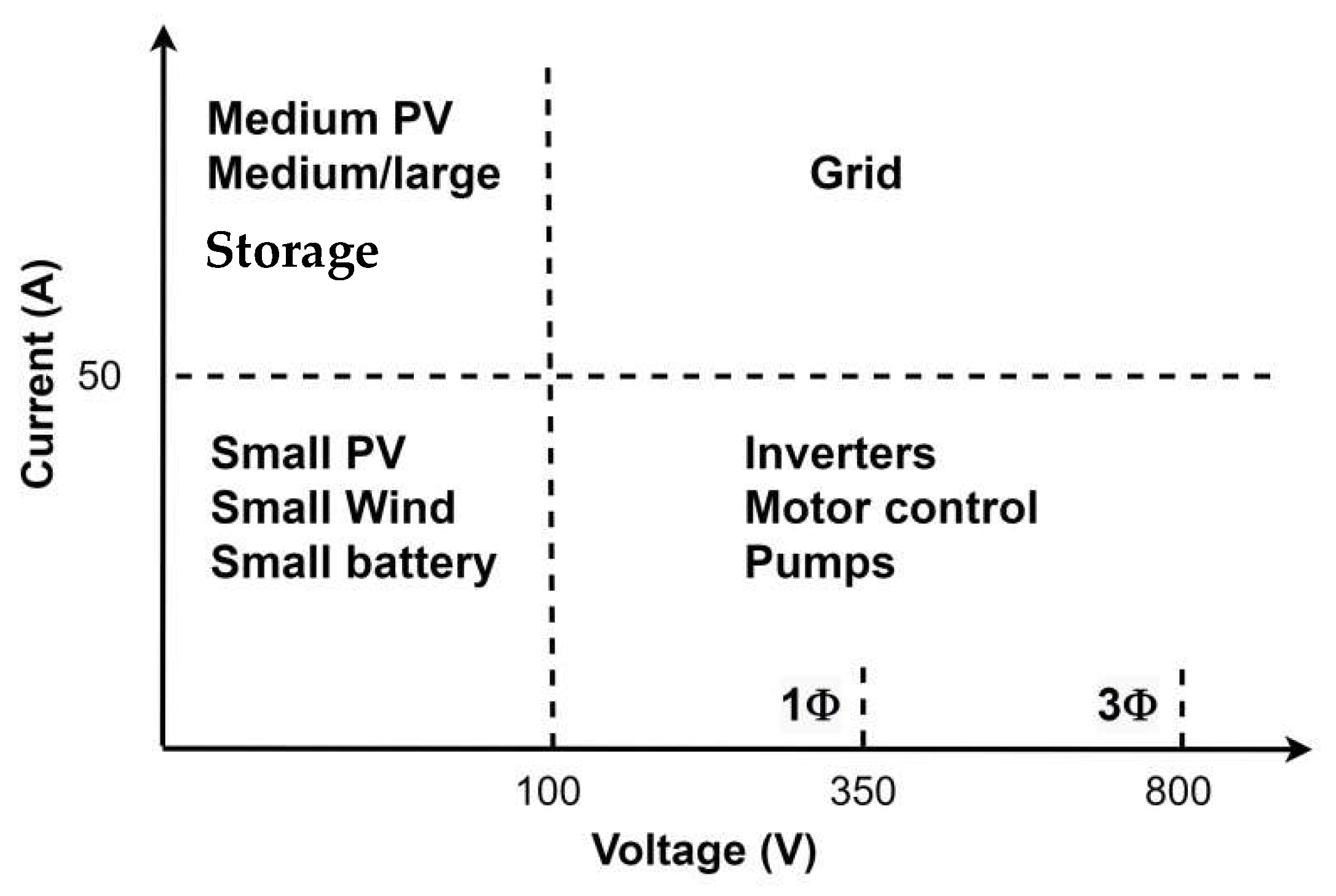

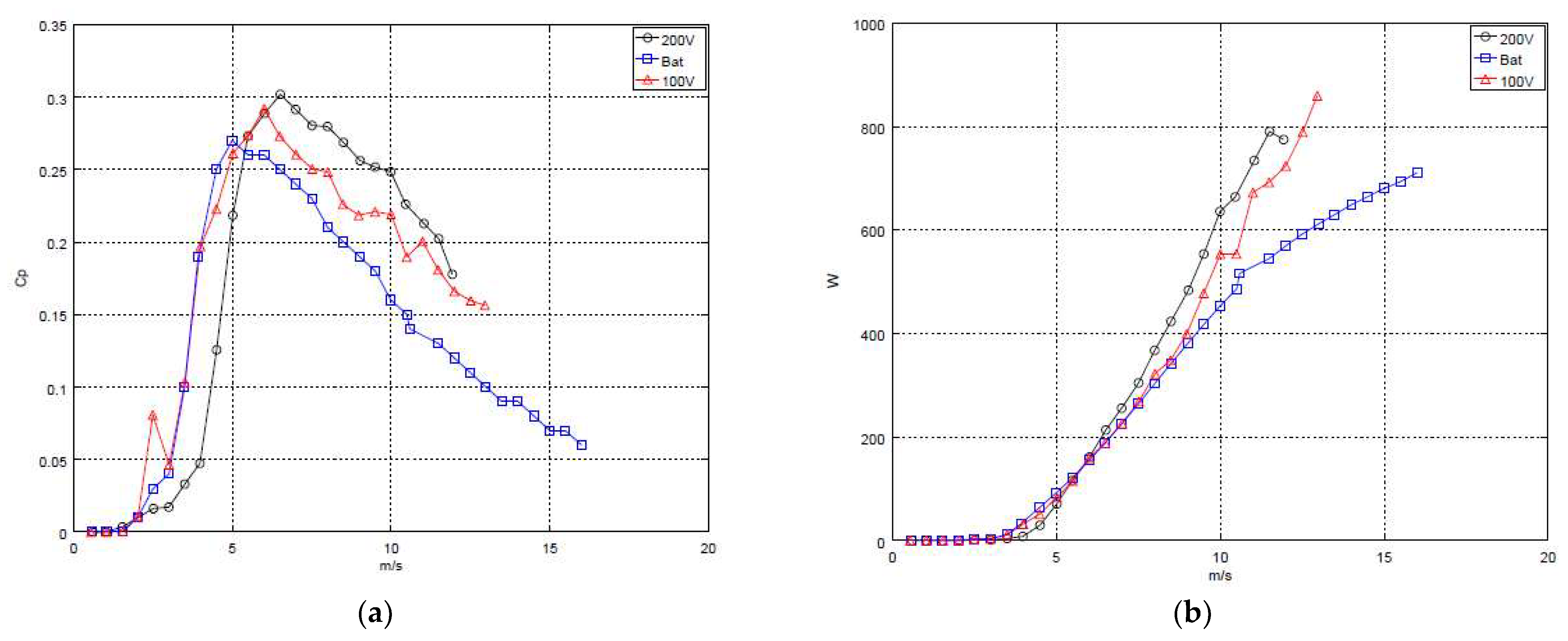

- High DC voltages: in Figure 5 it is shown that inverters for grid-connected power generation usually work with voltages higher than 100 V, up to hundreds of volts [15]. SWTs designed for battery charging applications usually use 12, 24 or 48 V as nominal voltages, which are far from the voltage range used for grid connection. This effect means that some adaptation will be needed for voltage matching, either at the SWT’s generator or at the power converter, or both.

- -

- Outages: in grid-connected systems, outages have to be considered. In IEC 61400-2 standard [16], it is stated that “Electrical network outages shall be assumed to occur 20 times per year. An outage of up to 24 h shall be considered a normal condition”. This fact equally necessitates overvoltage protection for the SWT, and adds the need for it to be able to work in continuous mode.

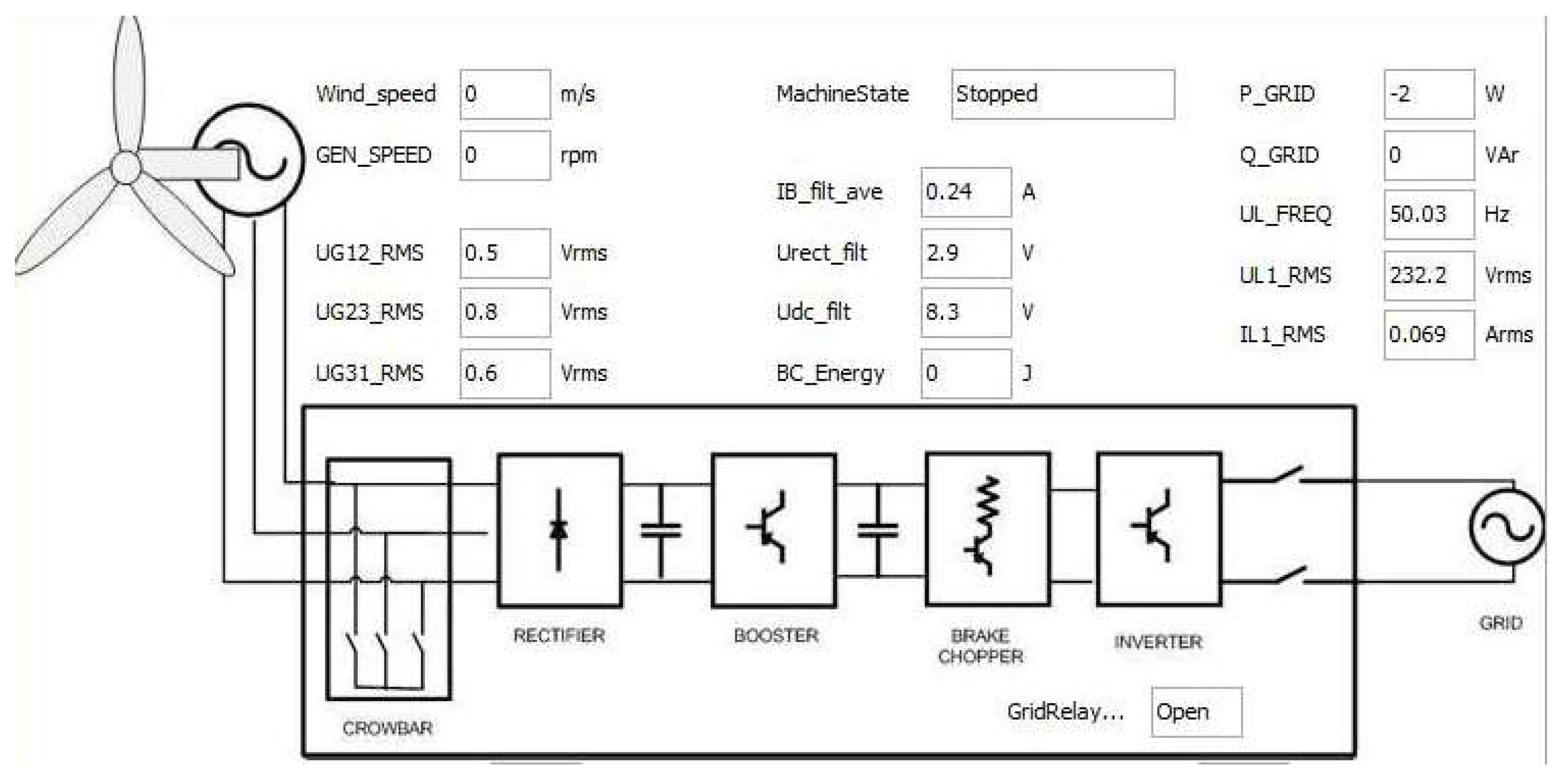

2.1.3. The Inverter in the Case Study

2.2. The Power Controller

2.2.1. Overvoltage Protection

- It is mandatory: as derived from analysis of the effects on the PV inverter (2.1.2), it is mandatory to have an overvoltage protection device for the times when there is no load connected to the SWT, such as an outage in a grid-connected SWT.

- It has to be able to work in a continuous mode: also derived from the referred analysis; grid power outages may last up to 24 h in normal conditions, which can be considered continuous mode operation for the overvoltage device.

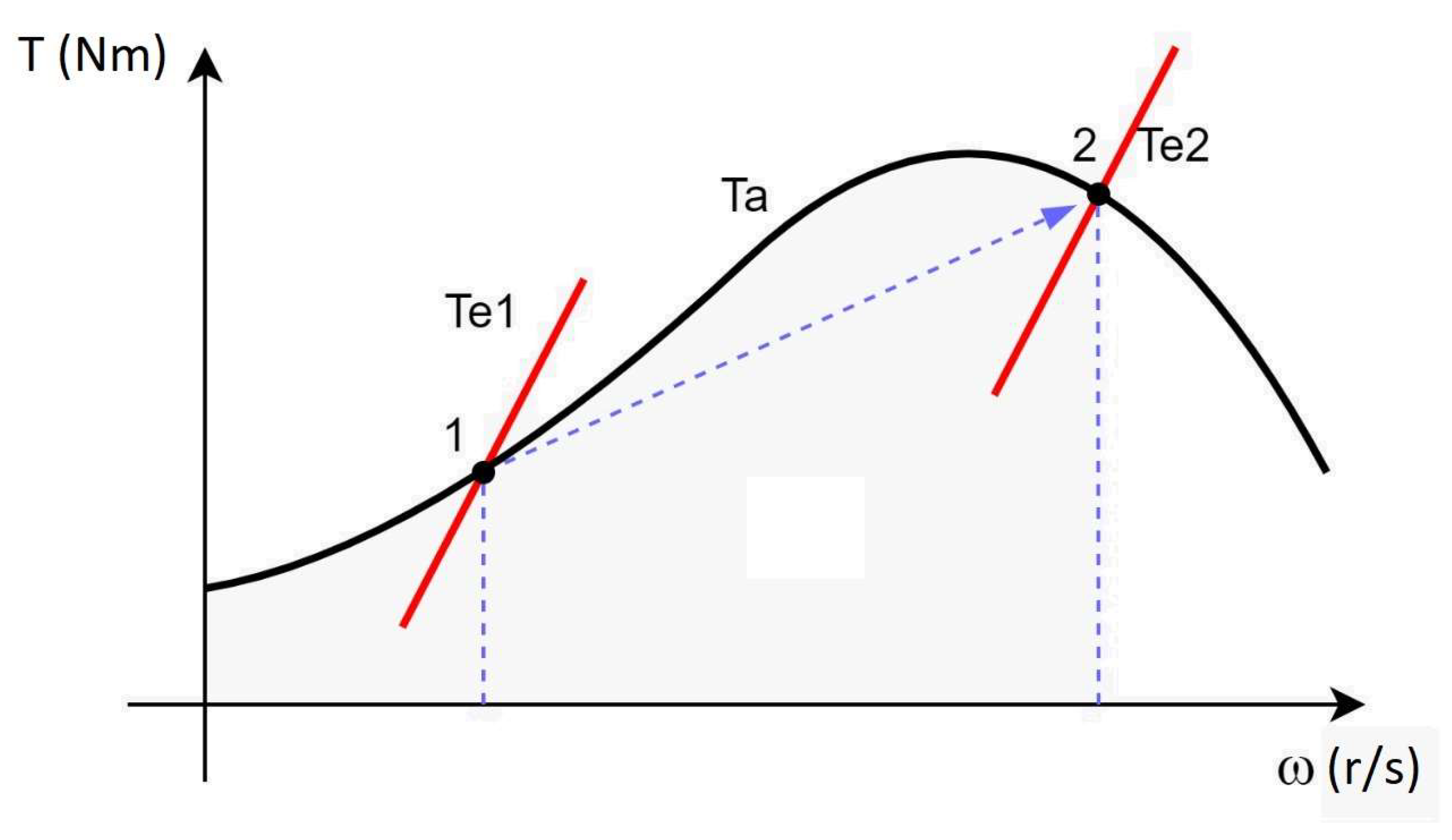

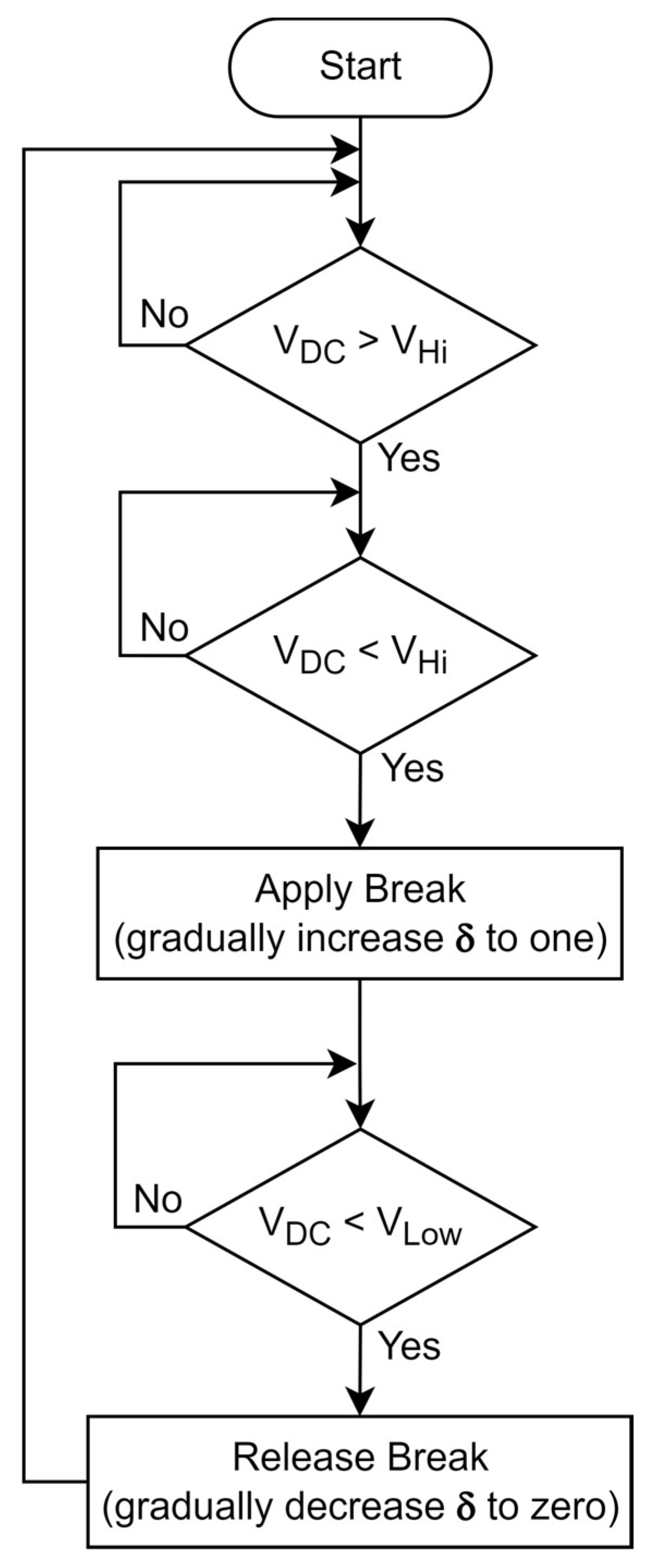

- These electronic overvoltage protection devices are common for SWT battery-charging applications, where there is a stable voltage reference from the battery and the voltage variations are slow and small, as the battery maintains voltage stability. This is not the case in grid-connected turbines: in the case of an inverter waiting time, for example, the SWT will be open-loaded and the DC voltage might change abruptly if the wind is high enough at that moment. In that case, it is possible that the control algorithm of the electronic overvoltage protection device will try to diminish the rotational speed sharply, delivering a (relatively) large amount of power to the resistive load. This action will produce a sudden brake in the SWT, with corresponding fatigue loads. This might be thought of as an emergency system, but will certainly highly decrease the lifetime of the SWT if it is used as a normal condition.

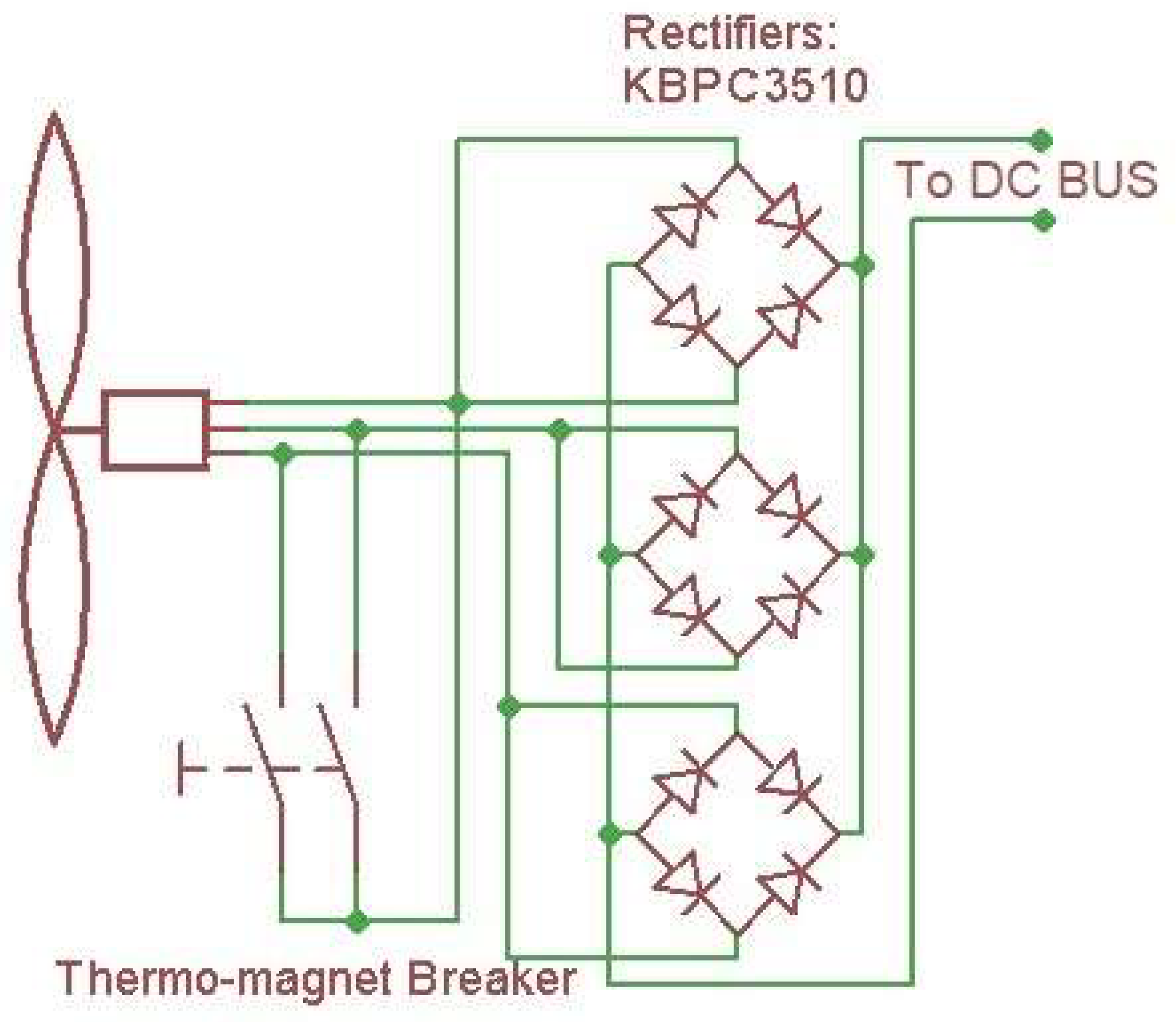

2.2.2. Controllers for Wind Turbines: Rectifiers

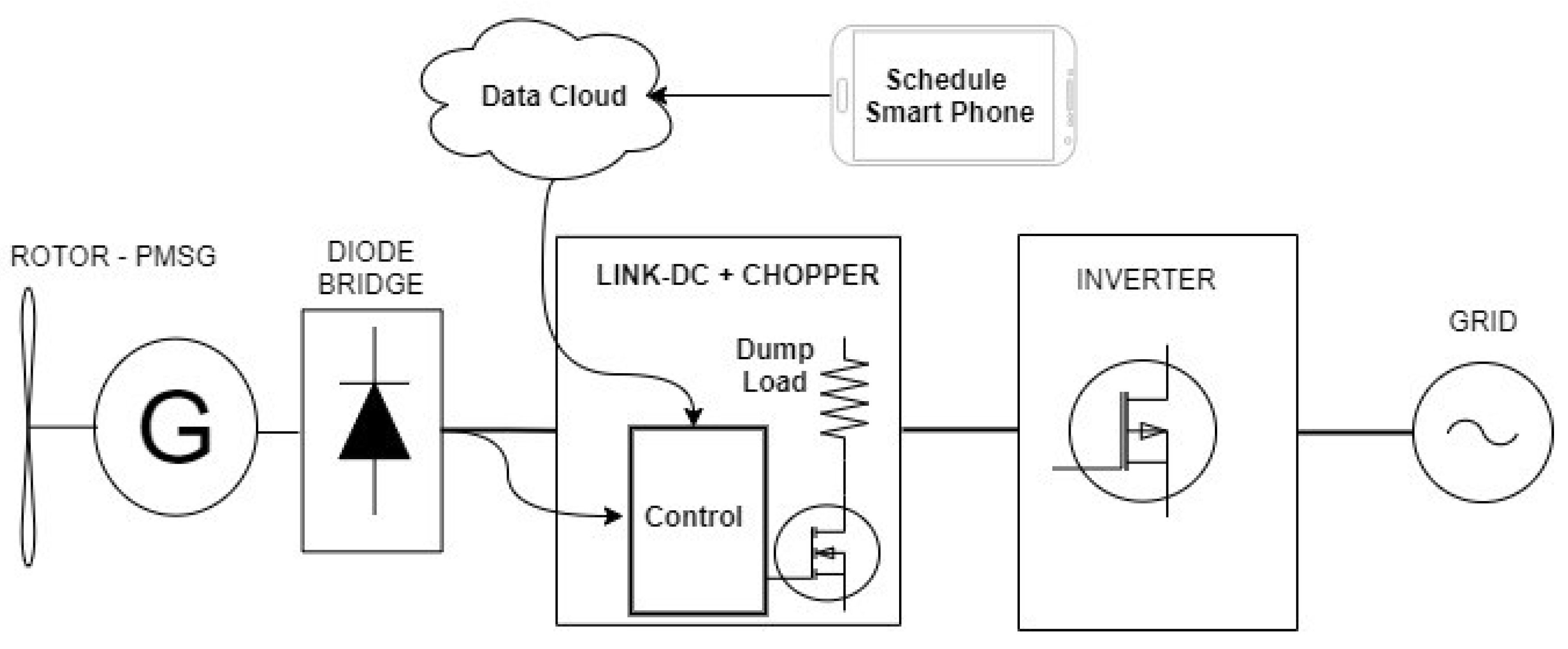

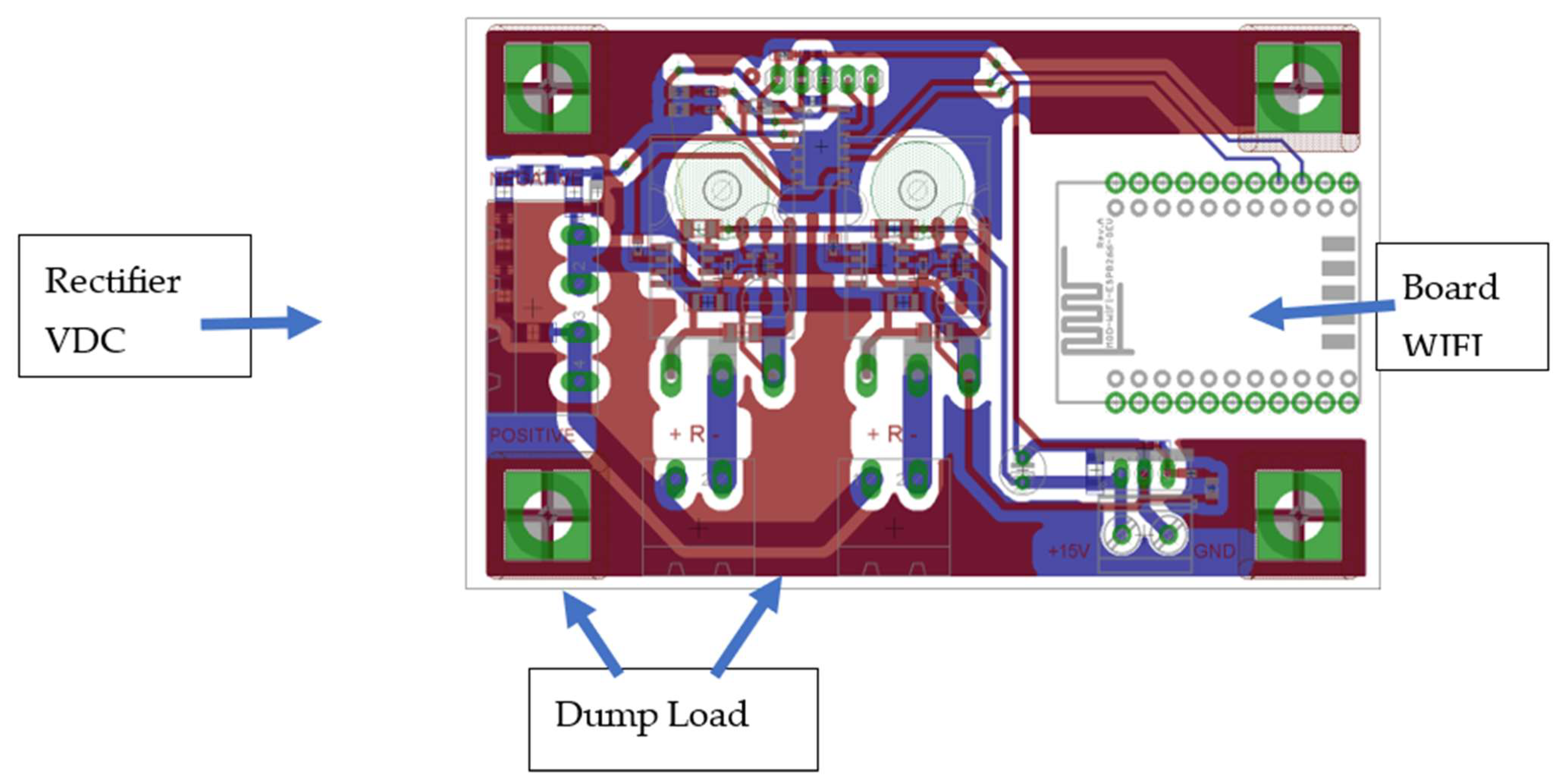

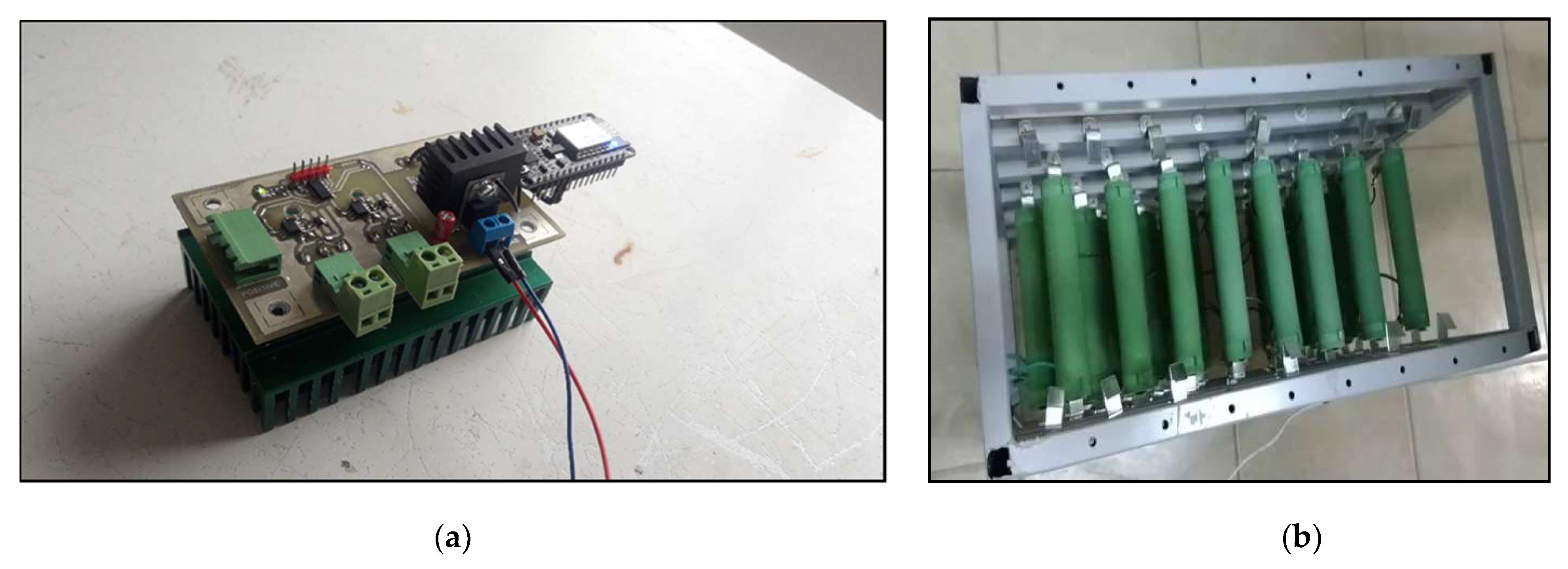

2.2.3. The Power Control in the Case Study

2.3. The Generator

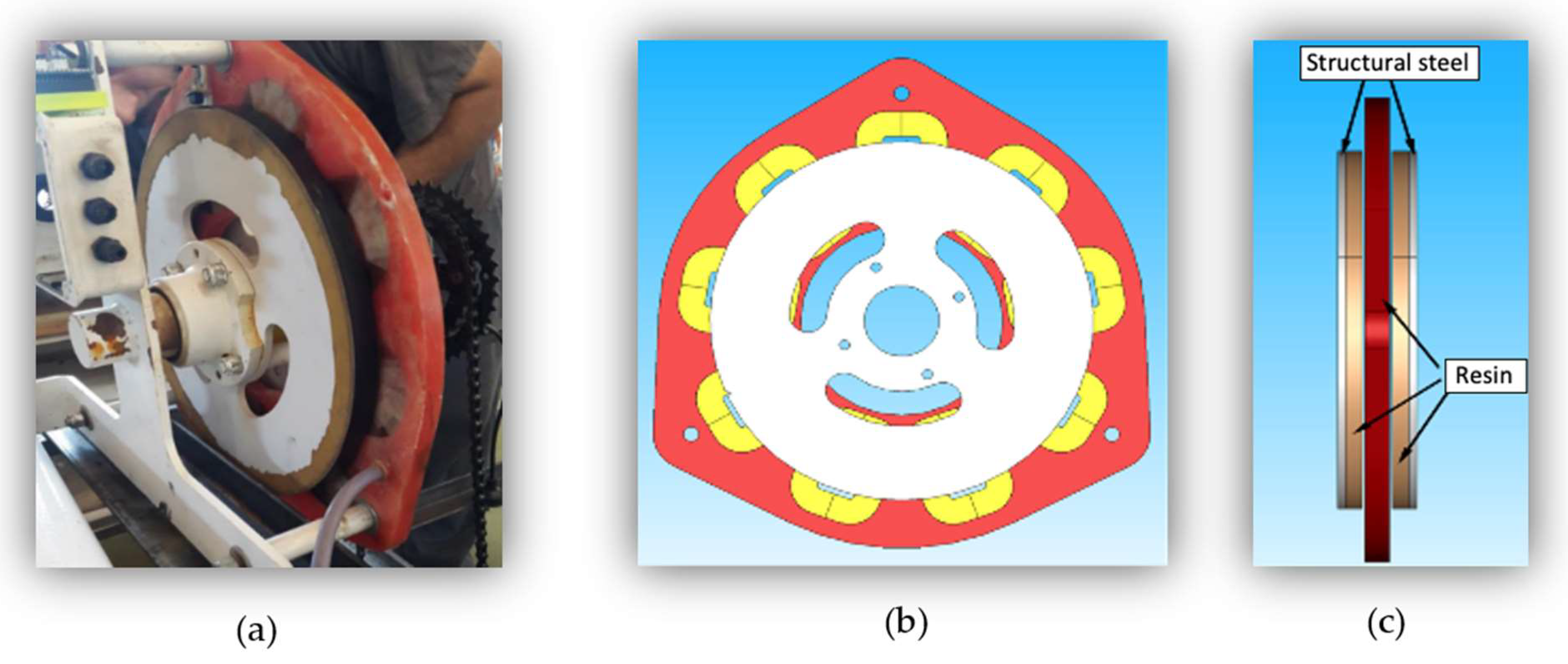

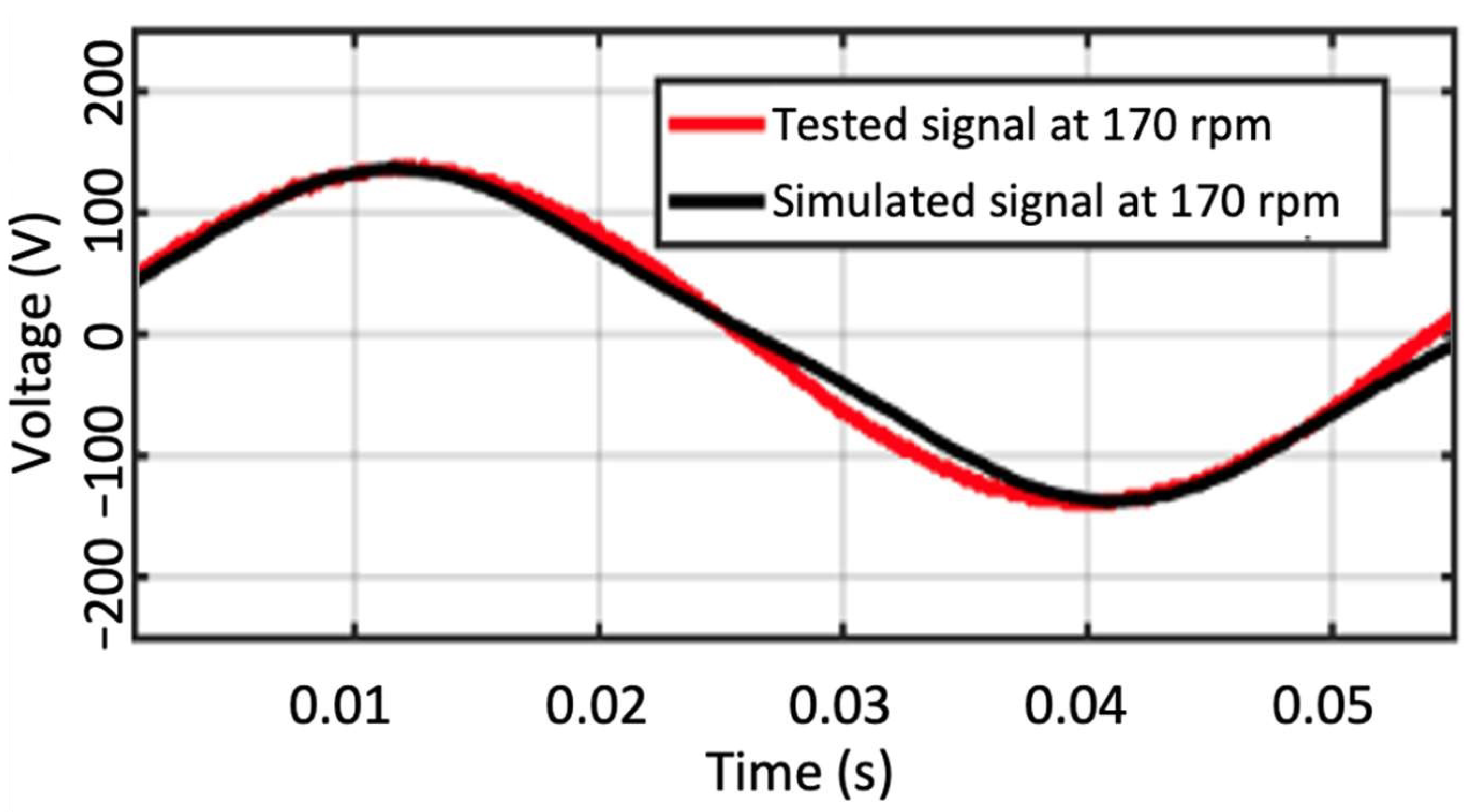

The Generator in the Case Study

2.4. A Short List of SWTs Below 5 kW and Their Main Characteristics for Grid Connection Capacity

- Generator: PMSG technology dominates. The number of pole pairs is quite high to avoid the need for a gearbox. The output voltage of the generator is higher than 200 V.

- Overvoltage protection device: the chopper plus dump load is always present; other devices (either mechanical or electronic) are also present in some models.

- Braking system: usually, the overvoltage protection device is also used as a braking system.

- Controller: some of the models include a MPPT controller.

3. A Review of Existing Options for Overvoltage Protection

- -

- Proprietary products, i.e., manufactured in-house and used exclusively by manufacturers of SWTs;

- -

- Off-the-shelf products existing at a commercial level, i.e., equipment manufactured by electronic equipment manufacturers, and which can be used in different wind turbine models;

- -

- Free or open source designs, i.e., designs that are available in the literature and/or on the Internet, and that allow anyone to manufacture them.

3.1. Proprietary Devices

3.2. Commercially Available Devices

3.2.1. PowerOne Turbine Controller

3.2.2. Morningstar TriStar Turbine Controller

3.2.3. Voltsys Wind Turbine Controller

3.2.4. Midnite Controller

3.3. Freely Available Designs

3.3.1. Wind Empowerment

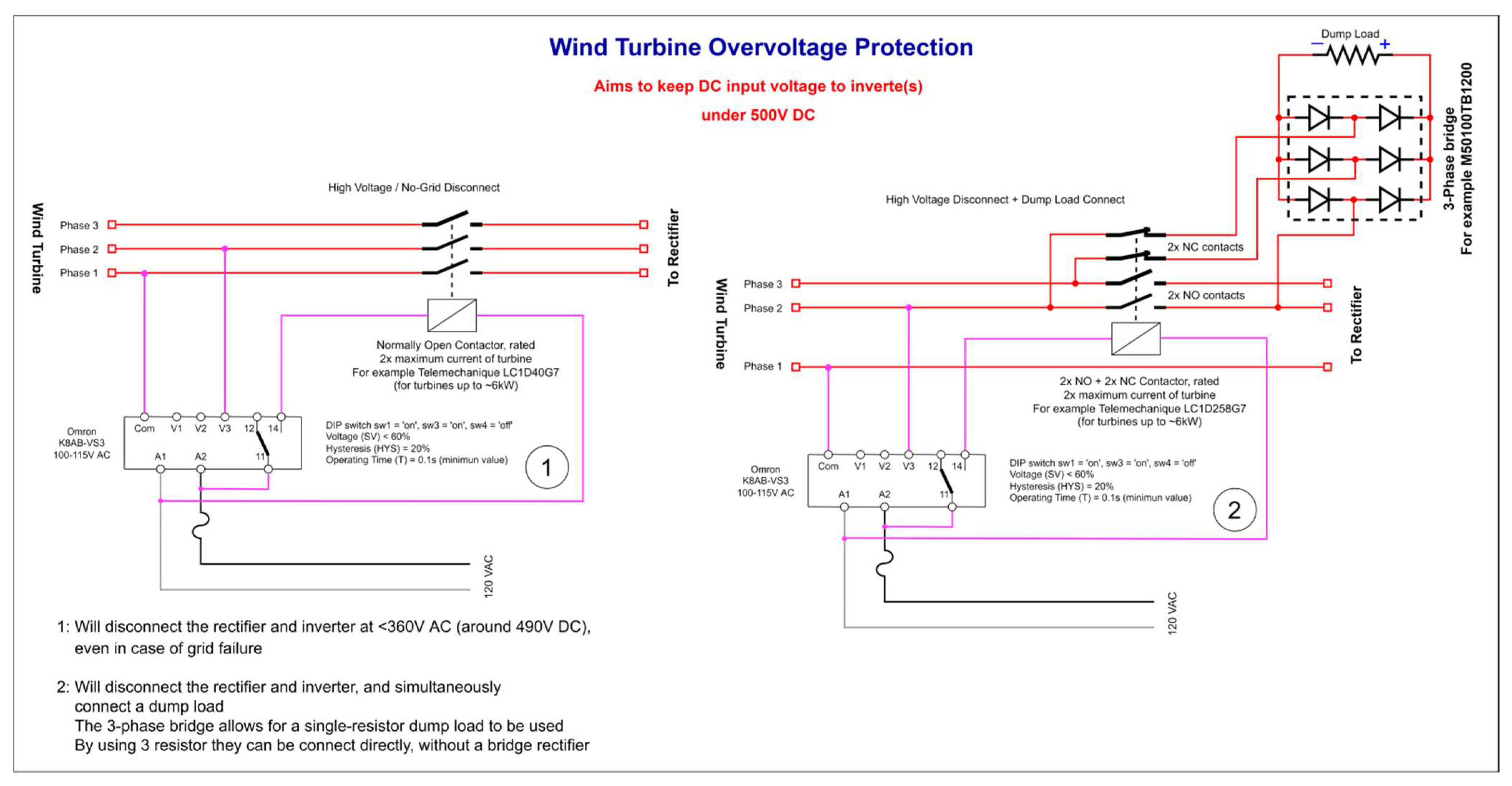

3.3.2. Overvoltage Relay Protection

4. An Open Source Proposal for Overvoltage Protection for a 1 kW SWT: A Case Study and Preliminary Field Results

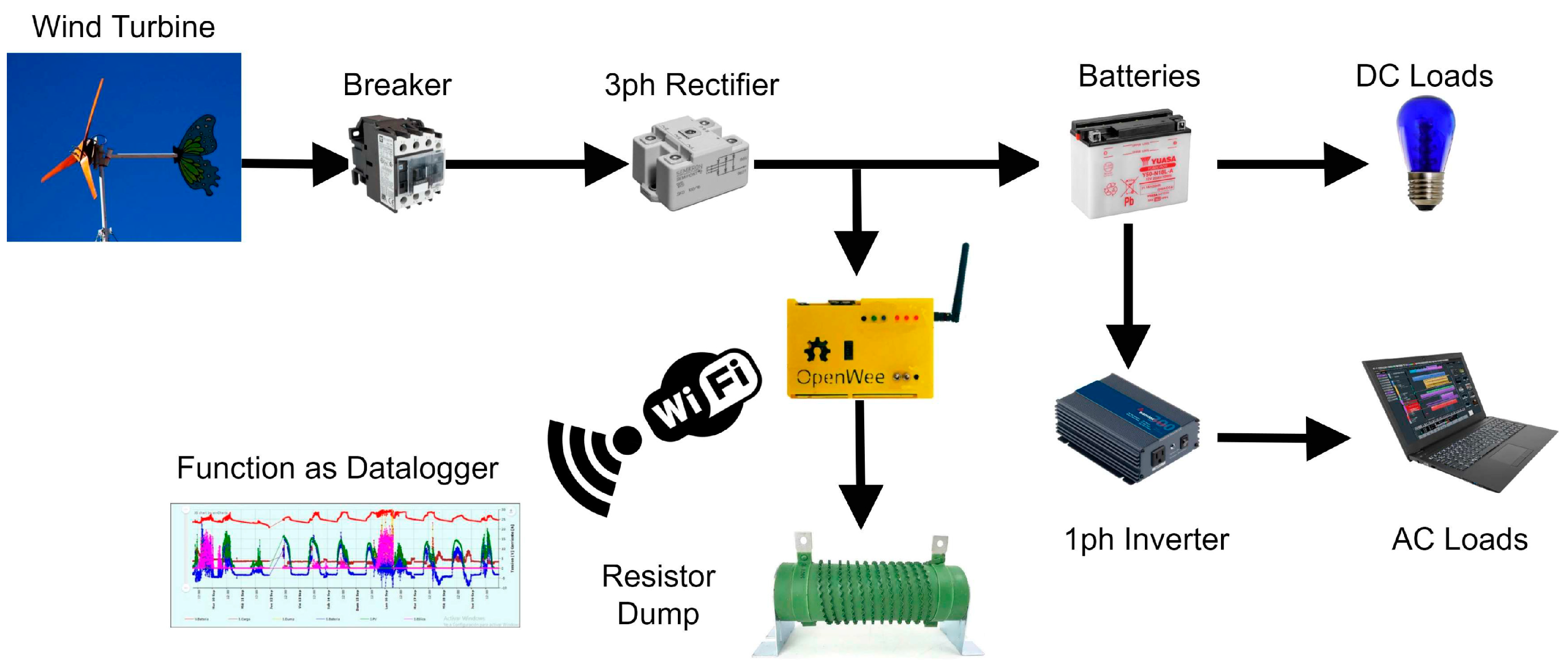

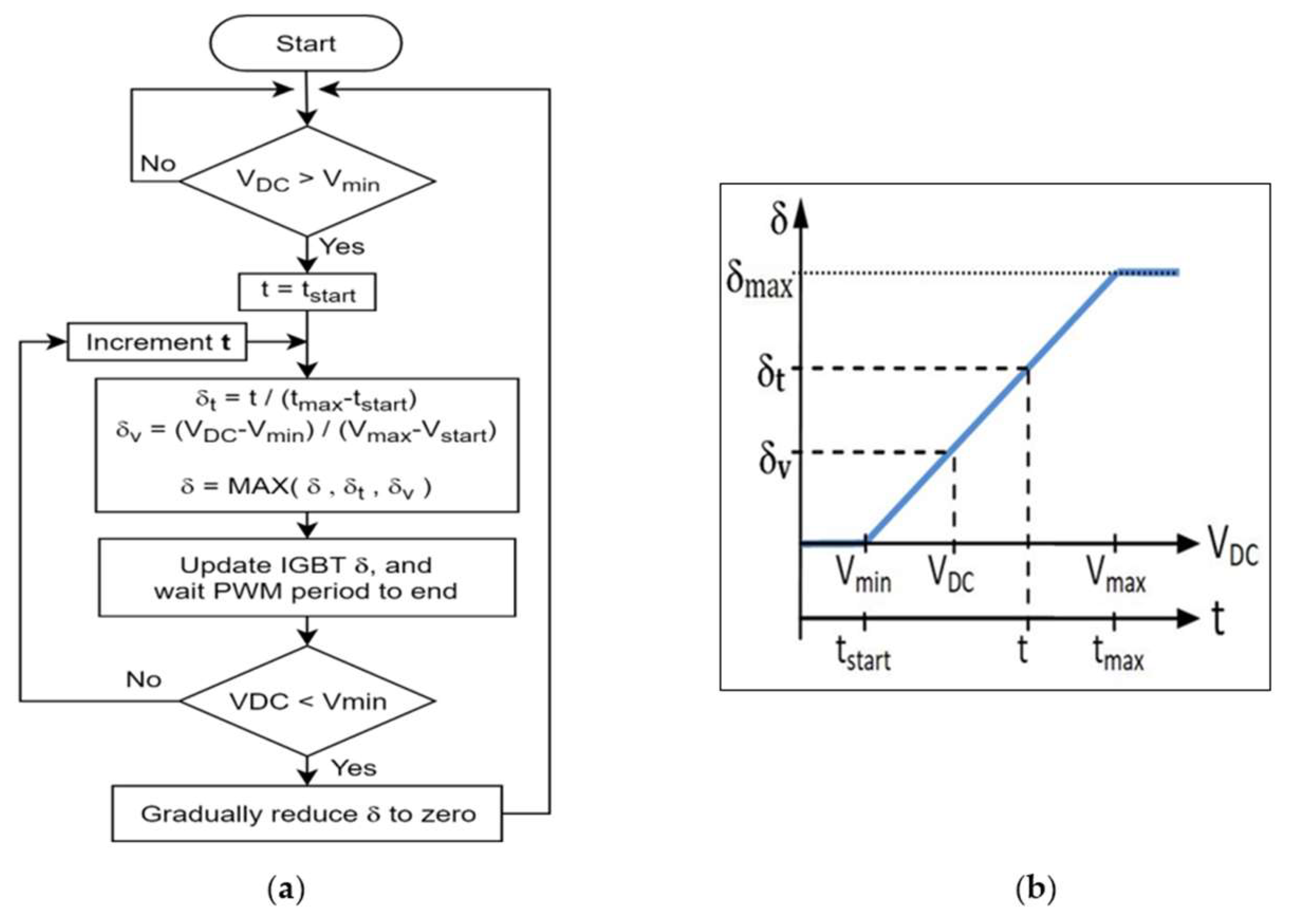

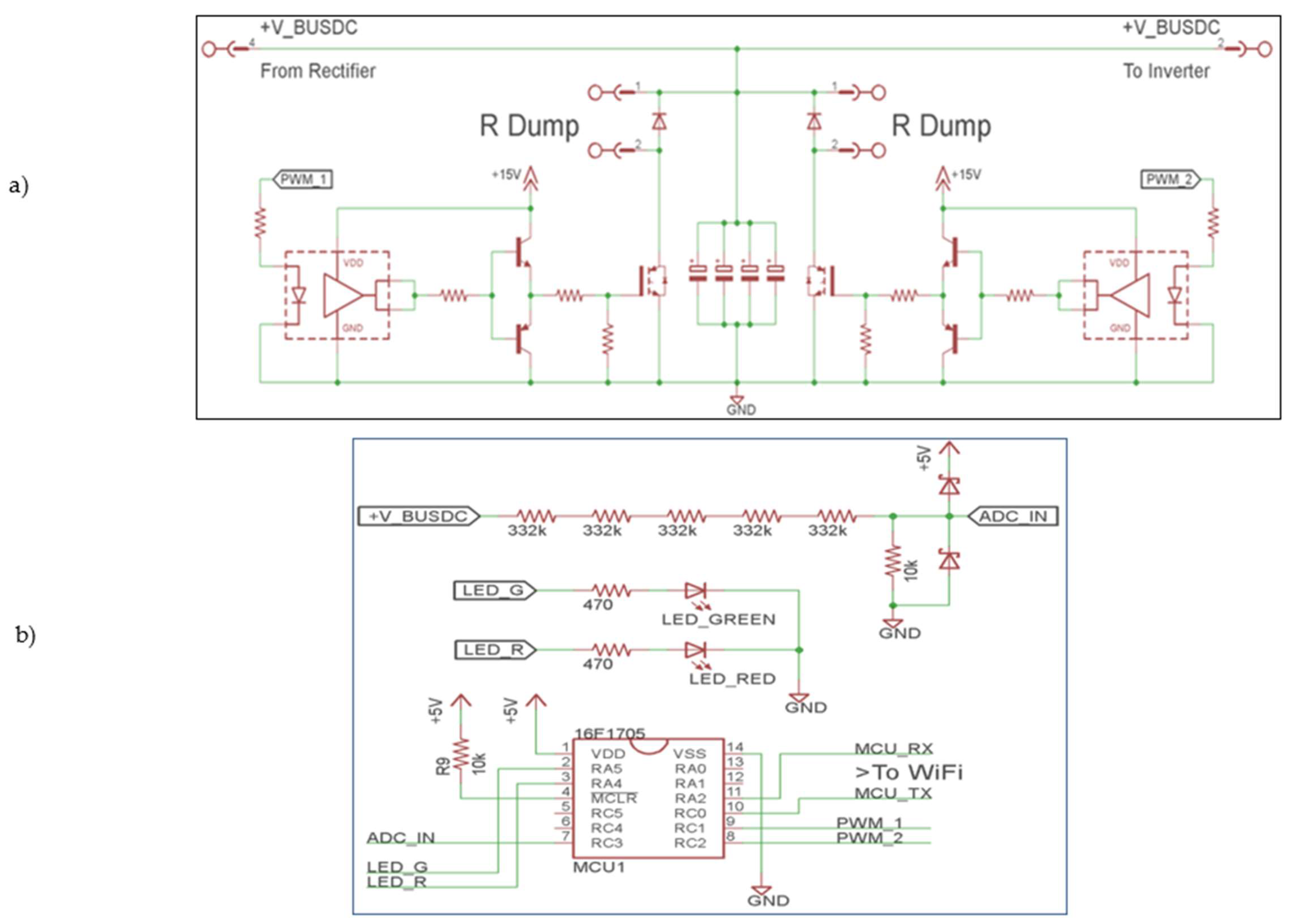

4.1. Proposed Solution for Overvoltage

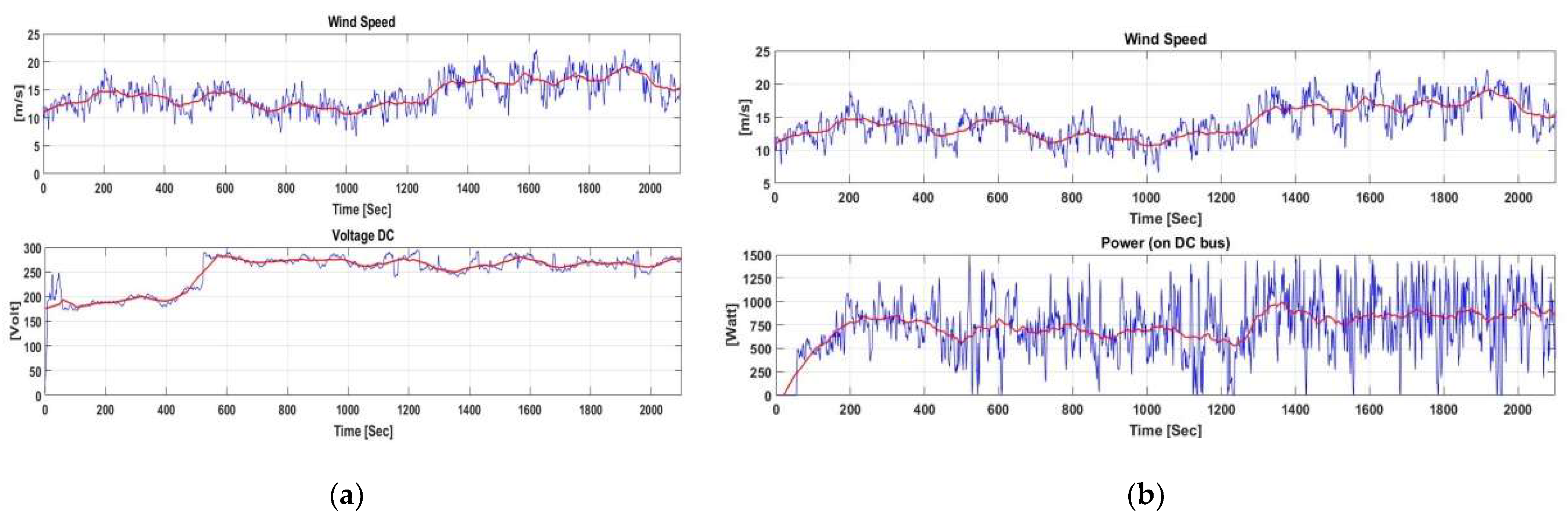

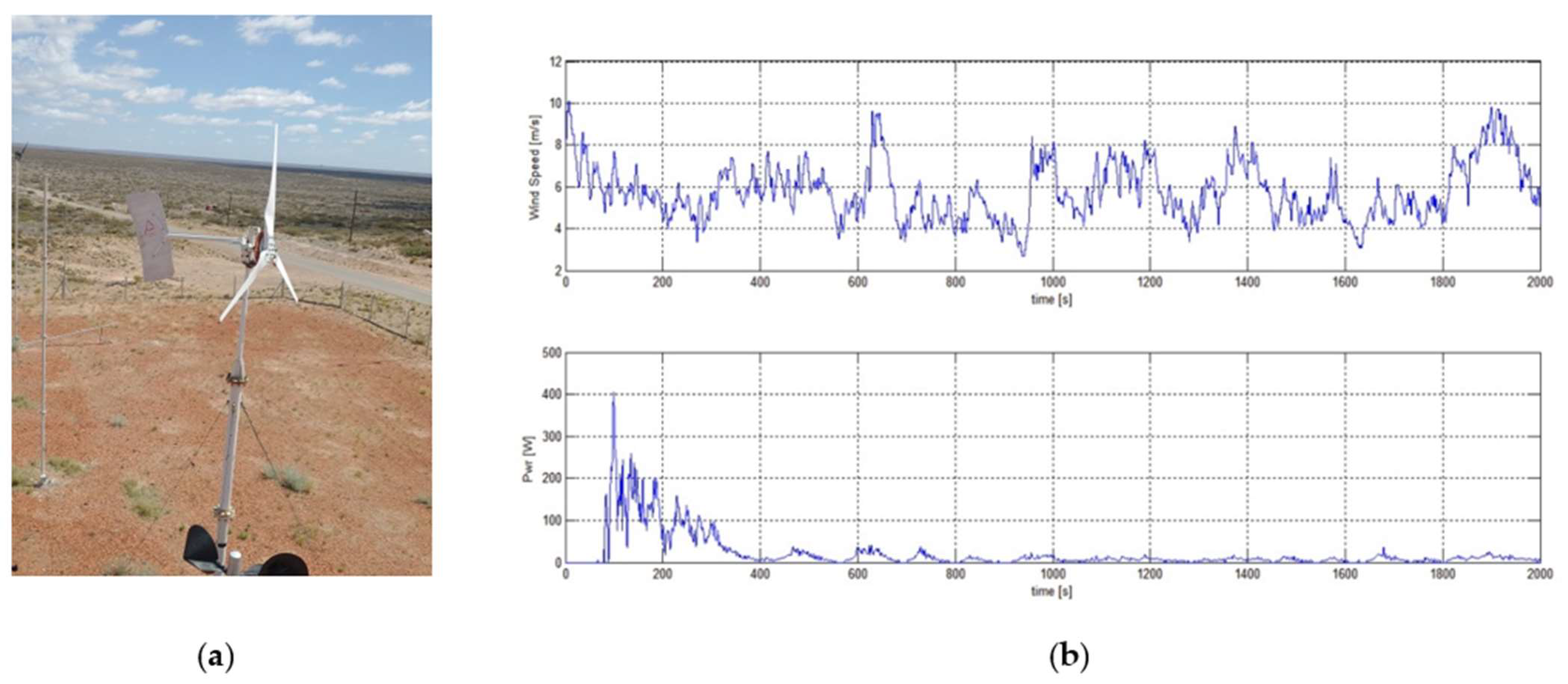

4.2. Experimental Prototype and Field Evaluation

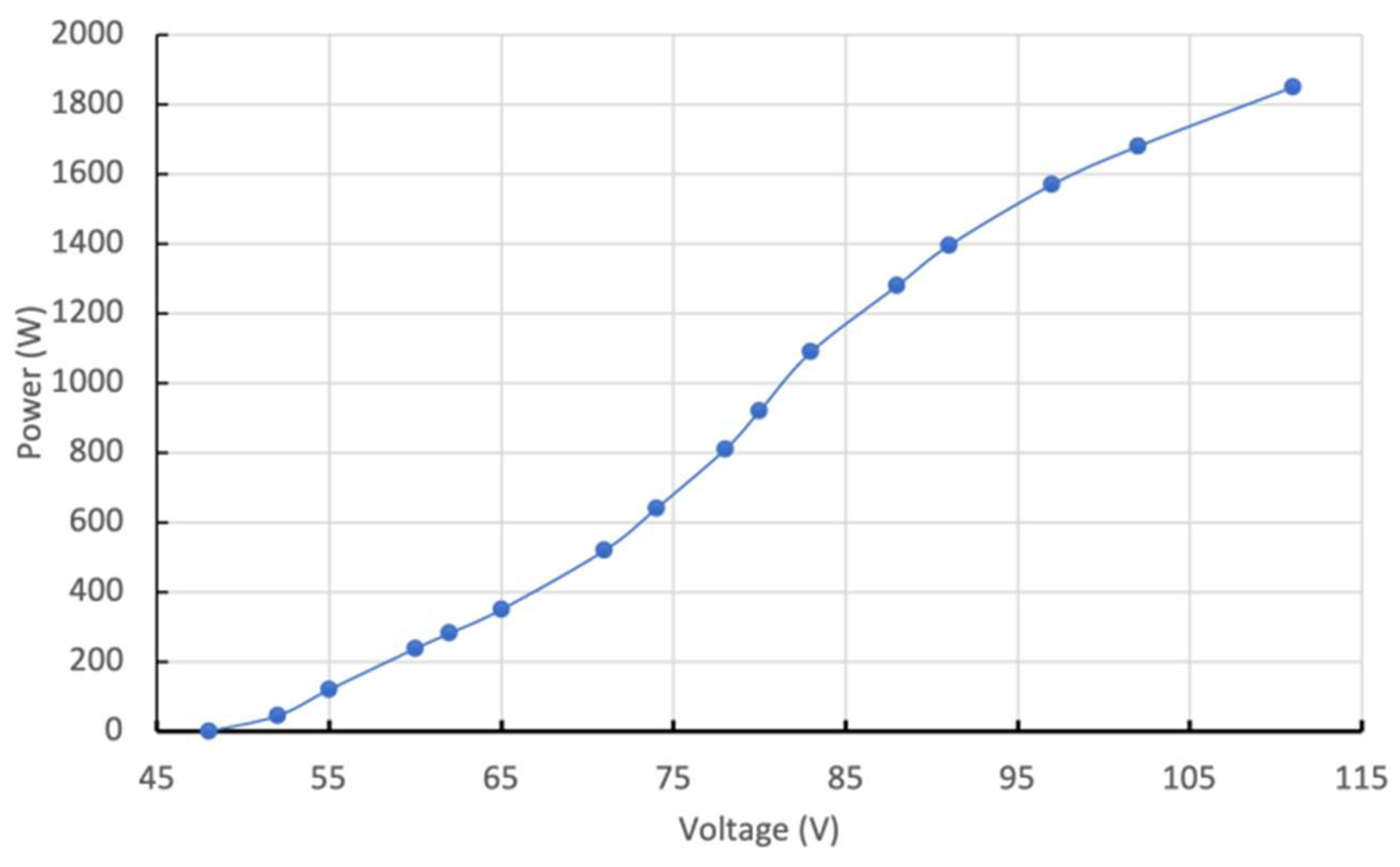

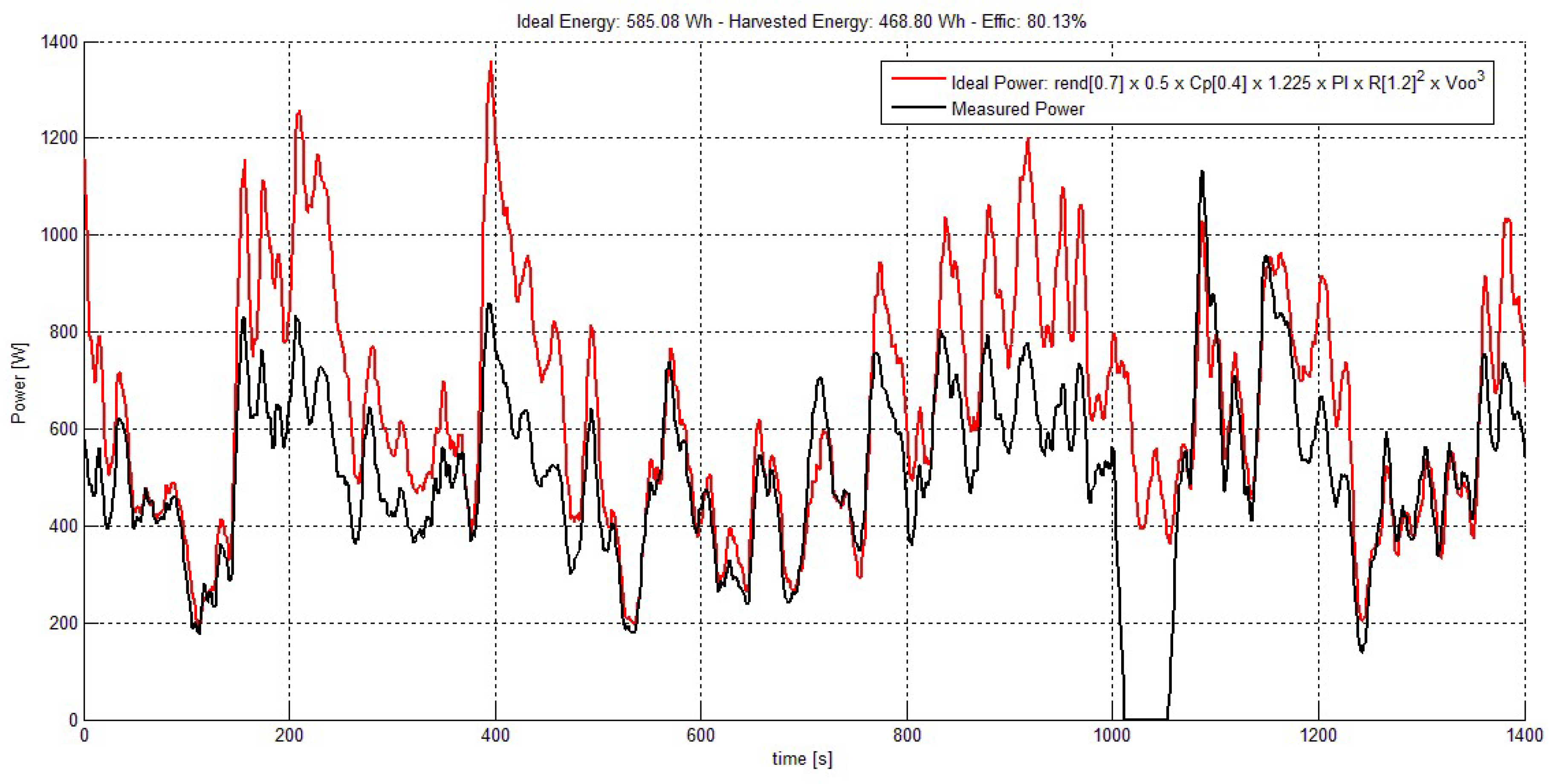

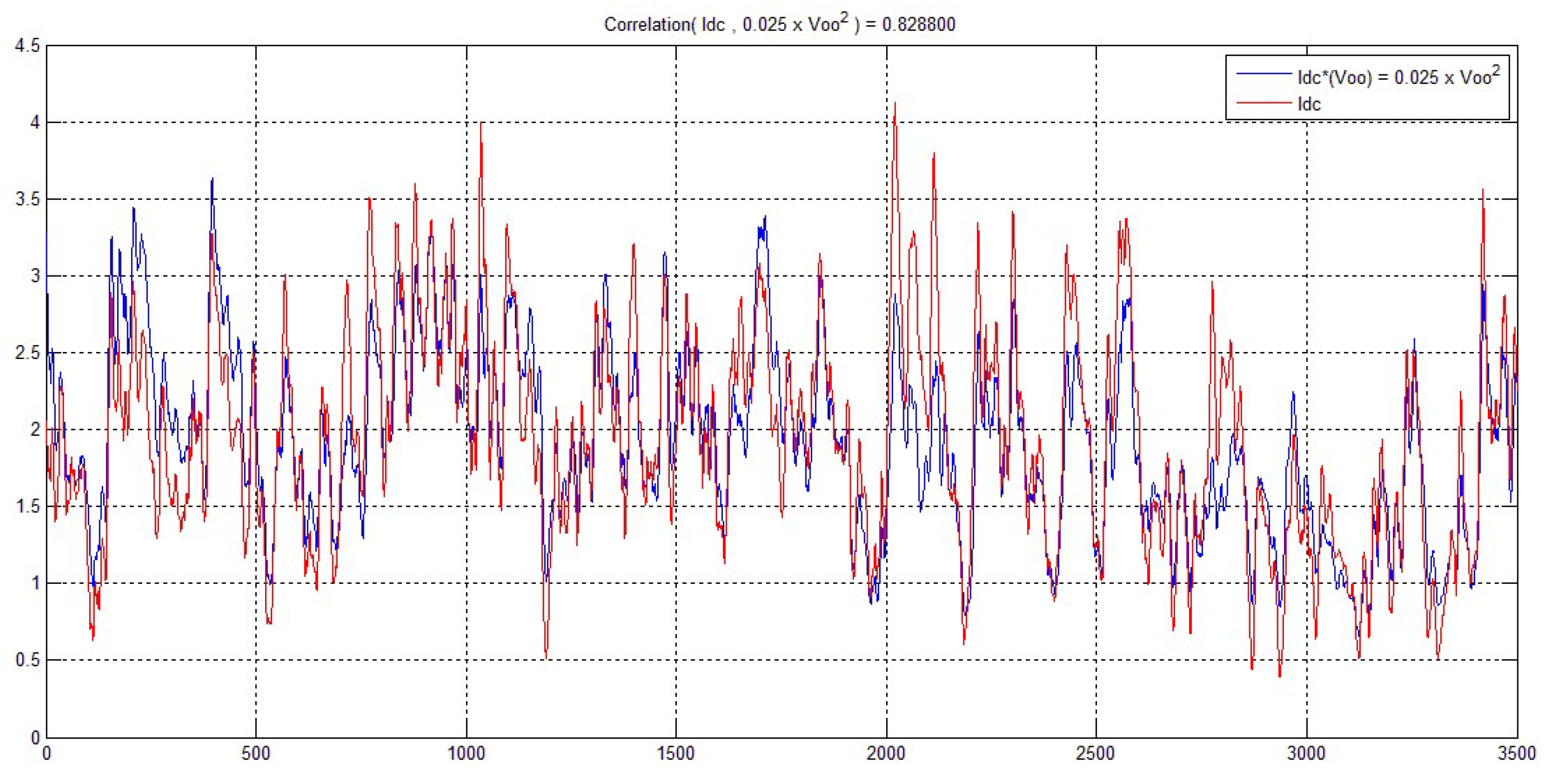

4.2.1. Analysis of Energy Performance

4.2.2. Proposed Energy Improvement When Using a Solar Inverter

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wind Energy—The Facts; Earthscan: London, UK, 2009; ISBN 978184407710.

- Bloomberg and SEforALL, 2020. State of the Global Mini-Grids Market Report. 2020. Available online: https://www.seforall.org/system/files/2020-06/MGP-2020-SEforALL.pdf (accessed on 3 July 2021).

- Small Wind Turbines Optimization and Market Promotion Project Web Page. Available online: http://swtomp.ciemat.es/ (accessed on 29 December 2021).

- 2013 Small Wind World Report Update; WWEA: Bonn, Germany, 2013.

- Arribas, L.; García Barquero, C.; Avia, F.; Zappa, A.; Duzdevich, J.P.; Amadío, M.; de la Cruz, J.; Zamora, A.; Karlson, T. Sample Survey Results. Deliverable 1.2, SWTOMP Project. Available online: http://projects.ciemat.es/documents/1349819/4792266/Deliverable+1.2+final.pdf/26b9b1e9-40a7-4214-b611-b71594e0b3d4 (accessed on 29 December 2021).

- Alsop, A.; Eales, A.; Sumanik-Leary, J.; Persson, J.; Ruiz Almeyda, I. Small Wind for Rural Development in the Global South: Assessing the Market. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), Santa Clara, CA, USA, 8–11 September 2022. [Google Scholar]

- Resolution 349/2021 from the Argentinian Ministry of Economy: Contracting of the Design, Construction and Initial Operation of Five Photovoltaic and Wind Generation Plants with Storage, Integrated to a Mini Grid within the PERMER Program. Available online: https://www.boletinoficial.gob.ar/detalleAviso/primera/243511/20210426 (accessed on 29 December 2021). (In Spanish).

- Law 27424 (2018) to Promote the Generation of Energy from Renewable Sources for Self-Consumption and the Injection of Surpluses into the Grid in Argentina. Available online: https://www.argentina.gob.ar/economia/energia/generacion-distribuida (accessed on 29 December 2021). (In Spanish).

- Arifujjaman, M.; Iqbal, M.T.; Quaicoe, J.E. Performance Comparison of Grid Connected Small Wind Energy Conversion Systems. Wind. Eng. 2009, 33, 1–18. [Google Scholar] [CrossRef]

- de Freitas, T.R.; Menegáz, P.J.; Simonetti, D.S. Rectifier topologies for permanent magnet synchronous generator on wind energy conversion systems: A review. Renew. Sustain. Energy Rev. 2016, 54, 1334–1344. [Google Scholar] [CrossRef]

- Arifujjaman, M.; Iqbal, M.T.; Quaicoe, J.E. Power Electronics Reliability Comparison of Grid Connected Small Wind Energy Conversion Systems. Wind. Eng. 2011, 35, 93–110. [Google Scholar] [CrossRef]

- Wood, D. Small Wind Turbines: Analysis, Design and Application; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Bialasiewicz, J.T. Furling control for small wind turbine power regulation. In Proceedings of the 2003 IEEE International Symposium on Industrial Electronics, Rio de Janeiro, Brazil, 9–11 June 2003. [Google Scholar]

- Rocabert, J.; Luna, A.; Blaabjerg, F.; Rodríguez, P. Control of Power Converters in AC Microgrids. IEEE Trans. Power Electron. 2012, 27, 4734–4749. [Google Scholar] [CrossRef]

- Villa, L.F.L. Wind Empowerment and Open-Source Power Electronics: Creating a Fully Bottom-Up Technology Suit for Rural Electrification. 4th International Conference on Small and Medium Wind Energy, On-Line. 2020. Available online: https://www.youtube.com/watch?v=rwPP25KDQFU&list=PL9vuawmFXuGkyknlx79dwRTBClufwBlxB&index=17 (accessed on 29 December 2021).

- IEC 61400-2 Ed.3; Wind Turbines–Part 2: Small Wind Turbines. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- OMNIK New Energy. User Manual OMNIKSOL-1k-TL2-M. Available online: https://www.merkasol.com/WebRoot/StoreLES/Shops/62387086/5B3C/8760/EA84/A0C7/FC53/0A0C/6D09/F34A/UserManual_OMNIK_1k_1.5k-TL2-M_EN_V1.2.pdf (accessed on 29 December 2021).

- Removed from Solar Industry Directory Note. Available online: https://www.enfsolar.com/omnik (accessed on 29 December 2021).

- OMNIK Portal Web Page. Available online: https://www.omnikportal.net/ (accessed on 29 December 2021).

- Wang, H.; Nayar, C.; Su, J.; Ding, M. Control and Interfacing of a Grid-Connected Small-Scale Wind Turbine Generator. IEEE Trans. Energy Convers. 2011, 26, 428–434. [Google Scholar] [CrossRef]

- Kassem, A.M.; Abdelaziz, A.Y. BFA optimization for voltage and frequency control of a stand-alone wind generation unit. Electr. Eng. 2015, 97, 313–325. [Google Scholar] [CrossRef]

- Rezkallah, M.; Sharma, S.; Chandra, A.; Singh, B. Implementation and control of small-scale hybrid standalone power generation system employing wind and solar energy. In Proceedings of the 2016 IEEE Industry Applications Society Annual Meeting, Portland, OR, USA, 2–6 October 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Mardal, A. Power regulation oppotunities for small wind turbines. In Proceedings of the 4th International Conference on Small and Medium Wind Energy, Folkecenter, Denmark, 23–26 November 2020. [Google Scholar]

- Fredericks, A.F.; Devries, I.D. Design of an auto-braking regulator for a small wind generator. In Proceedings of the AFRICON 2007, Windhoek, South Africa, 26–28 September 2007; pp. 1–5. [Google Scholar] [CrossRef]

- Chinchilla, M. Control de un Sistema de Generación Eólica de Velocidad Variable con Generador Síncrono Multipolar de Imanes Permanentes Acoplado a Red. Ph.D. Thesis, Universidad Carlos III, Madrid, Spain, 2001. (In Spanish). [Google Scholar]

- Anvir, A.A.; Merabet, A.; Beguenane, R. Real-Time Control of Active and Reactive Power for Doubly Fed Induction Generator (DFIG)-Based Wind Energy Conversion System. Energies 2015, 8, 10389–10408. [Google Scholar] [CrossRef] [Green Version]

- Ackermann, T. Wind Power in Power Systems; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 0470012676. [Google Scholar]

- Polinder, H. Overview of and trends in wind turbine generator systems. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011. [Google Scholar]

- Urtasun, A.; Sanchis, P.; Martín, I.S.; López, J.; Marroyo, L. Modeling of small wind turbines based on PMSG with diode bridge for sensorless maximum power tracking. Renew. Energy 2013, 55, 138–149. [Google Scholar] [CrossRef] [Green Version]

- Piggott, H. How to Build a WIND TURBINE. May 2003. Available online: https://www.scoraigwind.com/pirate%20oldies/Hugh%20Piggott%20Axial-flow%20PMG%20wind%20turbine%20May%202003.pdf (accessed on 29 December 2021).

- Augustin, A.; Pop, F.; Jurca, C.; Oprea, M.; Chirca, S.; Breban, S.; Radulescu, M.M. Axial-flux vs. radial-flux permanent-magnet synchronous generators for micro-wind turbine application. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013. [Google Scholar]

- Available online: https://stcharger.com.ar/ (accessed on 29 December 2021).

- Available online: http://www.ebhsa.com.ar/energia-renovable/alternativa-economica---wintec-1500 (accessed on 29 December 2021).

- Skystream 3.7 Product Technical Specifications. Available online: https://shop.solardirect.com/pdf/wind-power/skystream-specs.pdf (accessed on 29 December 2021).

- Available online: https://sd-windenergy.com/small-wind-turbines/sd3-3kw-wind-turbine/ (accessed on 29 December 2021).

- Available online: www.ennera.com (accessed on 29 December 2021).

- Available online: https://www.fortiswindenergy.com/montana/ (accessed on 29 December 2021).

- Available online: https://www.renugen.co.uk/content/medium_wind_turbine_brochures/50_030_001_C_MANUAL_windspot_3.5_y_1.5_Manual.pdf (accessed on 29 December 2021).

- Available online: https://www.enair.es/en/small-wind-turbines/e70pro (accessed on 29 December 2021).

- Available online: www.invap.com.ar (accessed on 29 December 2021).

- Available online: http://www.potenciaindustrial.com.mx/es/productos/turbina-eolica-colibri.html (accessed on 29 December 2021).

- Matsui, Y.; Sugawara, A.; Sato, S.; Takeda, T.; Ogura, K. Braking Circuit of Small Wind Turbine Using NTC Thermistor under Natural Wind Condition. In Proceedings of the 2007 7th International Conference on Power Electronics and Drive Systems, Bangkok, Thailand, 27–30 November 2007; pp. 910–915. [Google Scholar] [CrossRef]

- Sugawara, A.; Yamamoto, K.; Yoshimi, T.; Sato, S.; Tsurumaki, A.; Ito, T. Research for Electric Brake Using NTC Thermistors on Micro Wind Turbine. In Proceedings of the 2006 12th International Power Electronics and Motion Control Conference, Portoroz, Slovenia, 30 August–1 September 2006; pp. 1597–1601. [Google Scholar] [CrossRef]

- Muljadi, E.; Forsyth, T.; Butterfield, C.P. Soft-Stall Control Versus Furling Control for Small Wind Turbine Power Regulation; Technical Report; National Renewable Energy Lab.: Golden, CO, USA, 1998. Available online: http://www.osti.gov/scitech/biblio/661575 (accessed on 29 December 2021).

- Hui, J.C.Y.; Bakhshai, A.; Jain, P.K. An Energy Management Scheme with Power Limit Capability and an Adaptive Maximum Power Point Tracking for Small Standalone PMSG Wind Energy Systems. IEEE Trans. Power Electron. 2015, 31, 4861–4875. [Google Scholar] [CrossRef]

- Dalala, Z.; Zahid, Z.U.; Lai, J. New overall control strategy for wind energy conversion systems in MPPT and stall regions. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 2412–2419. [Google Scholar] [CrossRef]

- Chen, J.; Chen, J.; Gong, C. New Overall Power Control Strategy for Variable-Speed Fixed-Pitch Wind Turbines Within the Whole Wind Velocity Range. IEEE Trans. Ind. Electron. 2013, 60, 2652–2660. [Google Scholar] [CrossRef]

- Lumbreras, C.; Guerrero, J.M.; Garcia, P.; Briz, F.; Reigosa, D.D. Control of a Small Wind Turbine in the High Wind. IEEE Trans. Power Electron. 2015, 31, 6980–6991. [Google Scholar] [CrossRef]

- Power One. Aurora Wind Box Interface. Installation and Operator’s Manual. 2009. Available online: https://alternateenergycompany.com/pdf/powerone/PowerOne_pvi-7200-wind_interface.pdf (accessed on 29 December 2021).

- ABB Wind Interface Web Page. Available online: https://new.abb.com/power-converters-inverters/wind-turbines/small-wind/legacy-small-wind-inverters-old/wind-interface-15-kw-25-kw (accessed on 29 December 2021).

- Available online: https://www.solar-electric.com/lib/wind-sun/TriStar%20MPPT%20150V%20and%20600V%20Wind%20Charging%20Control%20Info.pdf (accessed on 29 December 2021).

- Available online: https://www.voltsys.com/ (accessed on 29 December 2021).

- Available online: http://www.folkecenterevents.net/pages/5th-Small-Wind-Conference-2021.html#Speakers (accessed on 29 December 2021).

- Available online: https://www.solarpowerworldonline.com/2020/03/fimer-finalizes-acquisition-of-abb-solar-inverter-business/ (accessed on 29 December 2021).

- Available online: https://midnitesolar.com/productPhoto.php?product_ID=320&productCatName=Wind%20and%20Hydro&productCat_ID=25&sortOrder=1&act=pc (accessed on 29 December 2021).

- Gangneux, C. Designing Your Own Charge Controller; Wind Empowerment, Ti’éole and Wisions; 2017; Available online: https://docplayer.net/60777447-Designing-your-own-charge-controller.html (accessed on 29 December 2021).

- Wind Turbine Overvoltage Protection. Available online: https://s1.solacity.com/docs/Wind%20Turbine%20Overvoltage%20Protection.pdf (accessed on 29 December 2021).

- Catuogno, G.; Villa, L.; Alinei, J.; Catuogno, C. Open source Hardware Technology, a sustainable solution to achieve energy for all the global south. In Proceedings of the VIII International Conference on Sustainable Development (ICSD2020), New York, NY, USA, 21–22 September 2020. [Google Scholar]

- Villa, L. Mid-Term Report–SEPS CALL. Modula Power to the People Project. Technical Report. 2016. Available online: https://www.researchgate.net/publication/308012118_MID-TERM_REPORT_-_SEPS_CALL_MODULAR_POWER_TO_THE_PEOPLE_PROJECT_EXECUTIVE_SUMMARY (accessed on 29 December 2021). [CrossRef]

- Bianchi, F. Wind Turbine Control Systems; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Wu, B. Power Conversion and Control of Wind Energy Systems; John Wiley and Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- CYTED’s Distributed Wind Generation (REGEDIS) Network Web Page. Available online: https://www.cyted.org/es/regedis (accessed on 29 December 2021).

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Phases | 3 | Voltage THD | 7.1% |

| Poles | 12 | Power | 1 kW |

| Phase Inductance | 0.0407 H | Phase Voltage | 75 Vrms |

| Phase Resistance | 11.6 ohm | Torque | 23.21 Nm |

| PM Flux | 1.2 T (neodymium) | Angular speed | 400 rpm |

| Turns per coil | 355 | Efficiency | 73% |

| SWT | Generator | Overvoltage/Overspeed | Braking System | Controller | Website | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mechanic | Electronic | |||||||||||||||

| Manufacturer | Model | Rated Power (W) | Number of Pole Pairs | Type | Voltage (Nominal, V) | Furling | Centrifugal | Chopper + Dump Load | MPPT (+ grid) | Electronic | Mechanic | Electro magnetic Brake | MPPT | Passive Mechanical Pitch Control | Stall | |

| ST Charger | ST1100 | 600 | 3 | Asynch. | autofurl | x | x | [32] | ||||||||

| EBH | Wintec1500 | 1800 | 7 | PMG | autofurl | x | x | x | [33] | |||||||

| XZERES | Skystream3.7 | 2400 | 21 | PMG | x | x | x | x | x | [34] | ||||||

| SD wind energy | SD3 | 3000 | PMG | x | x | [35] | ||||||||||

| ENNERA | Windera S | 3200 | PMG | x | x | x | x | x | [36] | |||||||

| Fortis | Montana | 3400 | 9 | PMG | 48–500 | x | x | [37] | ||||||||

| SONKYO | WINDSPOT | 3500 | PMG | x | x | x | x | x | x | [38] | ||||||

| Enair | 70 PRO | 4000 | 15 | PMG | 225 | x | x | x | x | [39] | ||||||

| INVAP | IVS4500 | 4500 | 8 | PMG | 450 | autofurl | x | x | x | x | [40] | |||||

| Potencia Industrial | Hummingbird 5 kW (Colibrí 5 kW) | 5000 | PMG | 0–450 VDC | x | x | [41] | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bufanio, R.; Arribas, L.; de la Cruz, J.; Karlsson, T.; Amadío, M.; Zappa, A.E.; Marasco, D. An Update on the Electronic Connection Issues of Low Power SWTs in AC-Coupled Systems: A Review and Case Study. Energies 2022, 15, 2082. https://doi.org/10.3390/en15062082

Bufanio R, Arribas L, de la Cruz J, Karlsson T, Amadío M, Zappa AE, Marasco D. An Update on the Electronic Connection Issues of Low Power SWTs in AC-Coupled Systems: A Review and Case Study. Energies. 2022; 15(6):2082. https://doi.org/10.3390/en15062082

Chicago/Turabian StyleBufanio, Rubén, Luis Arribas, Javier de la Cruz, Timo Karlsson, Mariano Amadío, Andrés Enrique Zappa, and Damián Marasco. 2022. "An Update on the Electronic Connection Issues of Low Power SWTs in AC-Coupled Systems: A Review and Case Study" Energies 15, no. 6: 2082. https://doi.org/10.3390/en15062082

APA StyleBufanio, R., Arribas, L., de la Cruz, J., Karlsson, T., Amadío, M., Zappa, A. E., & Marasco, D. (2022). An Update on the Electronic Connection Issues of Low Power SWTs in AC-Coupled Systems: A Review and Case Study. Energies, 15(6), 2082. https://doi.org/10.3390/en15062082