Abstract

Exhaustion of fossil fuel resources, shrinking forest areas, with accompanying deterioration of their quality and striving (also of the society) to make forests perform their ecological function, with simultaneous development and propagation of the biomass conversion technologies—all of this necessitates research of forest biomass diversification. It is a consequence of the fact that its properties and composition depend not only on the genus but also on the plant organ, and they each time determine its usability as a raw biomaterial in a wide range of thermal, physical, or chemical conversion processes. This study reviewed and analysed selected qualitative and quantitative features of forest dendromass, taking into account the genus and a plant organ/morphological part, followed by a group of trees (coniferous and deciduous) and without the latter differentiation. The study involved an analysis of data covering 15 selected qualitative-quantitative features of forest dendromass within three main and nine additional plant organs/morphological parts and 21 genera (5 coniferous and 16 deciduous) typical of the temperate climate.

1. Introduction

Owing to photosynthesis, on which all life on Earth is founded [1], five to eight times more energy has been accumulated in biomass than man consumes from all sources. The global forest resources alone produce 65 billion mg of dry plant biomass, with nearly 1200 EJ of primary energy accumulating in it. It is estimated that it is four times the global demand for this type of energy [2]. The current climate changes result, among other things, from the widespread use of fossil fuels, which are running out. In order to prevent these phenomena, they have to be replaced with renewable energy sources (RES), including biomass. An increase in the share of RES in the energy acquisition structure helps to stem the growth of greenhouse gas emissions into the atmosphere and to reduce the pollution caused by fossil fuel combustion [3]. Due to its widespread presence, easy accessibility, and neutrality with respect to CO2 emissions, biomass combustion does not increase that gas concentration in the atmosphere. Moreover, biomass energy potential is renewed continuously by natural processes and/or by human activity. This makes biomass used increasingly often in various power technologies, which are in constant development [4,5,6,7]. Together with waste, biofuels account for approximately 50% of the global primary energy supply [8], which is of particular importance to the European Union, which plans to achieve at least a 32% share of RES by 2030 [9].

Currently, various biomass sources are sought that would be acceptable for use and suitable for commonly applied conversion technologies [3]. However, to use biomass as an energy feedstock, it is necessary to know its energy equivalent [10], which ranges from 17 to 21 MJ kg−1 (higher heating value—HHV) for dry wood, which makes wood a competitor for fossil fuels [11]. It is all the more so that trees achieve high thickness and give a high biomass yield after some time [12], and their material base in some regions or sub-regions is large, providing the main potential for biofuel production increase [13,14]. Dendromass provides more energy than herbaceous plants [15], and it is not becoming less important as an energy feedstock despite the technology development [16]. Dendromass consists mainly of bark, wood, and green material, such as twigs, leaves, with bark accounting for 5–15% of coniferous dendromass, wood for 70–80%, and green biomass for 10–15%. The proportions for deciduous dendromass are as follows: bark, 5–20%; wood, 60–75%; green biomass, 15–20% [17]. The diversity of biomass composition affects the variability of its thermophysical properties, upon which the choice of the relevant energy generation technology is based in the case of fuels [2]. For example, the lower heating value (LHV), which is the major parameter in fuel quality assessment, is extremely labile in biomass, which is a consequence of the complexity of the biomass chemical composition, which affects its properties. [6,18]. The biomass chemical composition is believed to be responsible for biomass LHV deviations [18], not omitting the impact of the moisture content, which is of key importance [19].

Regarding wood biomass, its effective use as an energy feedstock is associated not only with the knowledge LHV of the systematic genera but also LHV of its morphological parts/organs. The amount of the accumulated energy that can be acquired is diverse and depends on the amount and the chemical structure of dendromass produced by a specific tree species [10]. Compared to grasses or perennial plants, wood biomass contains more lignin in general. The LHV of dry biomass is higher, and the content of ash and problematic elements, such as K, Na, Cl, Si, S, are generally lower. All of these features favour dendromass use in thermo-chemical conversion processes [20]. Additionally, the LHV of aquatic plants is lower than land-based plants, and it is lower in deciduous trees than in coniferous trees [21,22]. LHV changes depending on the moisture content, the content of individual chemical components, and similarly, on the biofuel elemental composition. The dry matter of forest biofuels consists of 48–52% of carbon, 6–7% of hydrogen, 38–42% of oxygen, and 0.5–5% of ash and nitrogen. It is noteworthy that only carbon and hydrogen had an impact on the heating value, while oxygen, nitrogen, and ash practically did not [22].

Given the non-uniformity of the dendromass composition, with the simultaneous exhaustion of the fossil fuel resources, forest area shrinking (and deterioration of its condition), as well as striving (also of the society) for a transition to forests performing ecological functions [23,24], studies need to be taken up covering the diversity of the thermophysical properties and elemental composition of that bioenergy feedstock. This is especially so since the chemical composition of forest trees is not only affected by the systematic genus but also by the plant organ, morphological part, age, time of acquisition, origin, and environmental conditions of growth. All of these factors determine LHV [2,5,25]. Therefore, studying this issue will contribute to the more effective use of dendromass as a feedstock in thermal or chemical conversion processes and to more effectively manage the environment in the context of solid biomass acquisition.

Therefore, the research problem taken up in this review was to present selected qualitative-quantitative forest dendromass features of key importance with respect to the conversion, considering the systematic genus and the organ/morphological part. Secondly, an analysis was conducted of the dendromass thermophysical properties and chemical composition diversity in view of the plant organ/morphological part and systematic genus and, depending on the tree group, according to the traditional classification into coniferous and deciduous trees. Subsequently, the same analysis was performed without differentiation into a group of trees. Therefore, the aim of this study was to review, present and analyse the scientific papers on these issues published to date. A comparison was made between different plant organs/morphological parts of the most common systematic genera of coniferous and deciduous trees in the temperate climate zone. Moreover, answers to the following questions were sought: (1) Which dendromass, coniferous or deciduous, has a more favourable composition? (2) Which of these groups is more diverse with respect to a given feature between different genera? (3) Is the diversity of a feature within a genus between different plant organs greater than the diversity of the feature within an organ, but from the pool of different systematic genera?

2. Materials and Methods

2.1. The Method for Data Collection and Analysis

The study involved a review of published papers with respect to the elemental composition, thermophysical and chemical properties of dendromass. The search was conducted using the following tools: Science Direct, Scopus, MDPI, Google Scholar, WoS, Research Gate, and other sources. The search focused on original papers, scientific articles, monographs, reports, conference materials, and brief communiques issued between 2000 and 2021. A total of 221 scientific papers were identified [2,4,6,9,10,17,18,21,22,23,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190,191,192,193,194,195,196,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212,213,214,215,216,217,218,219,220,221,222,223,224,225,226,227,228,229,230,231,232,233,234,235,236], the majority of which were published in English (216), but also in Chinese (2), Slovak (2), and Latvian (1). The papers were analysed in terms of proximate analysis, thermophysical properties, and composition (with respect to the chemical compounds and elementary composition/ultimate analysis) of different genera systematic dendromass and diverse plant organs/morphological parts. Information was collected on the qualitative-quantitative features of dendromass from various locations but covered the most common genera in the temperate climate zone.

The review produced material on the qualitative and quantitative parameters for individual tree organs/morphological parts of different genera, of both coniferous trees (Pinopsida) and deciduous trees, that was gathered with Microsoft Excel for Microsoft 365 MSO (setup.exe version: 16.0.14326.20384). The data included 21 genera of trees, including five coniferous ones: pine Pinus spp., spruce Picea spp., fir Abies spp. (with Abies batavorum—a synonym of Cunninghamia lanceolata), larch Larix spp., douglas fir Pseudotsuga spp., and 16 deciduous ones: birch Betula spp., beech Fagus spp., Prunus spp. (only including bird cherry Prunus padus and black cherry Prunus serotina), oak Quercus spp., hornbeam Carpinus spp., ash Fraxinus spp., maple Acer spp., linden Tilia spp., alder Alnus spp., locust Robinia spp., poplar Populus spp., willow Salix spp., Aesculus sp. (only including horse chestnut Aesculus hippocastanum), chestnut Castanea sp. (only including sweet chestnut Castanea sativa), hazel Corylus spp., walnut tree Juglans sp. (only including edible walnut Juglans regia).

The selected data for these genera concerned one or more plant organs/morphological parts but within the following range: wood (as the central part of the cross-section of a trunk without bark, with the trunk denoting a lignified main sprout excluding the stump, the tree crown, and its apex); branch; twig; foliage; bark; seed husk and root. The cone and seed wing were selected for the coniferous trees, and fruit husk, fruit shell, and fruit for deciduous trees. The data were collected in such a way that each plant organ/morphological part was assigned to a suitable genus, according to the analysed paper, and to the qualitative-quantitative features reported in that paper. The collected features covered the following areas:

- –

- Thermophysical properties: higher heating value (HHV) and lower heating value (LHV);

- –

- Proximate analysis: moisture content (MC), volatile matter (VM), fixed carbon (FC), and ash (A);

- –

- Ultimate analysis/elementary composition: carbon (C), hydrogen (H), oxygen (O), nitrogen (N), and sulphur (S);

- –

- Selected chemical composition: cellulose, hemicellulose, lignin, and other extracts.

The data for individual genera were catalogued additionally with respect to the tree group to which they belonged, according to the traditional forestry classification (coniferous/deciduous). The combined listing was performed for the two groups and the results were provided without differentiation by type according to the traditional division in forestry, e.g., coniferous and/plus deciduous trees. The procedure was shown in Figure 1.

The results for individual organs of these genera are shown in Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8 and Table A9 presented in Appendix A, in which the minimum and maximum values were provided for each feature, the median, and the absolute mean deviation of the median.

2.2. Analysis of Data Agglomeration

A total of 201 scientific papers were selected for the agglomeration analysis. They were grouped based on keywords using VOSviewer software. The grouping was based on keyword co-occurrence. The minimum number of co-occurrences was three. Subsequently, the keywords were grouped into clusters, in which each occurred only once. The weights denoting the frequency of keyword occurrence in the publications were marked on a graph with circles. The larger the circle, the greater the weight and the higher the term occurrence frequency. Each cluster was marked with a different colour. Lines between keywords represented links. The closer they were to the keywords, the stronger their relationship and the more frequent the co-occurrence. The network visualisation and overlay visualisation maps were created in this manner. The keyword arrangement on the overlay visualisation map was the same as on the network visualisation map, whereas the colours of the keywords and links referred to the year when the article was published, which provided information on the keyword variability over time. The analysis was performed with the use of the clustering technique, and the association strength method was used for normalising the strength of the links between keywords.

2.3. Statistical Analysis

Three main organs: wood, branch (including branch and twig), and bark were chosen for the main statistical analysis. The collected data were analysed separately for coniferous and deciduous trees, and also without differentiation by type according to the traditional division in forestry. The analysis was performed with Statistica TIBCO Software Inc. (2017) (data analysis software system) version 13 and descriptive statistics were determined: N valid (abbreviation: N), average (); median (M); minimum value (Min.); maximum value (Max.); lower quartile (Q1); upper quartile (Q3); standard deviation (s); coefficient of variation (V). The results for individual chosen systematic genera were presented as the average arithmetic value () and average deviation from the average arithmetic value (d) obtained in Microsoft Excel. The data labels for all the series are shown in Table A10, Table A11, Table A12, Table A13, Table A14, Table A15, Table A16, Table A17, Table A18, Table A19, Table A20, Table A21, Table A22, Table A23 and Table A24 in Appendix A.

Additionally, the similarity analysis with respect to the country of origin was performed for the accumulated values for the main dendromass components, including cellulose, hemicellulose, and lignin, and for the values of the features which characterise the dendromass energy parameters, i.e., HHV, ash, and sulphur content. A multivariate cluster analysis (CA) was performed, agglomeration was applied by the Ward method, and Euclidean distances were used as the measure of distance. The significance of the cut-off point was adopted based on the Sneath criterion at 33%.

3. Results and Discussion

3.1. Number, Geographical Distribution, and Agglomeration of Publications

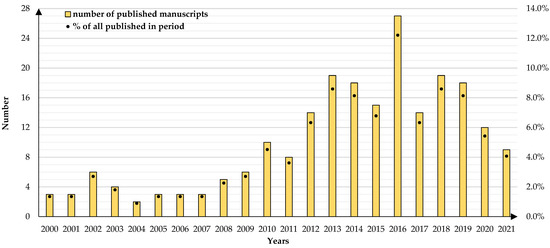

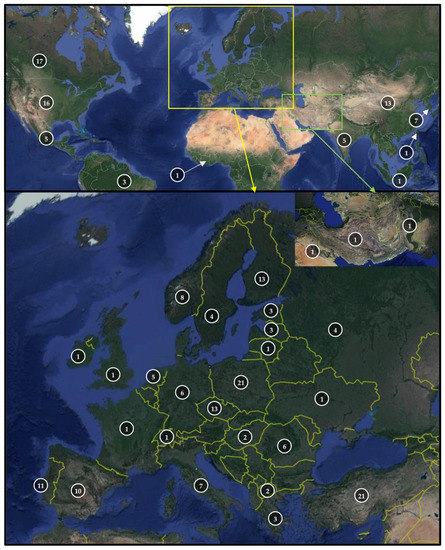

The manuscripts published between 2012 and 2020 accounted for over 70.6% of the total, with the greatest number of them (27) being published in 2016, which accounted for 12.2% of the 221 manuscripts under analysis (Figure 2). When broken down into countries, the largest number of manuscripts were published in Europe—148 (i.e., 67.0%), with manuscripts from Poland and Turkey dominating (21 each). The rest of the world was represented mainly by the USA, Canada, and China (17, 16, and 13 papers, i.e., 20.8% of the total, respectively). The number of manuscripts published in individual countries is shown in Figure 3.

Figure 2.

Number of published manuscripts in each year and the corresponding percentage.

Figure 3.

Number of published manuscripts from individual countries.

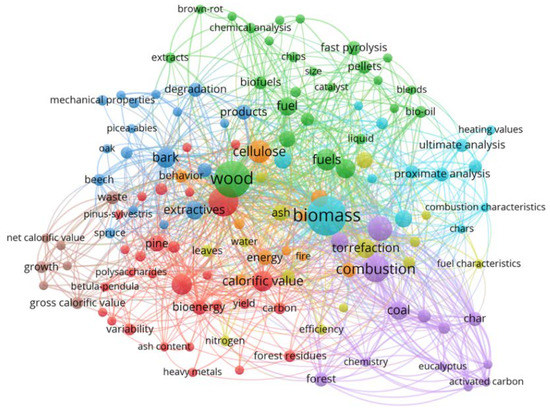

An analysis with VOSviewer produced 76 keywords, which were present in at least three papers (Figure 4). Biomass was the most frequent keyword (55 times). Other frequent keywords included: wood (47 times), lignin (31 times), combustion (25 times), pyrolysis (21 times), cellulose (18 times), fuels and fuel (16 and 12 times), calorific value, and chemical composition (15 times each). The other 56 keywords occurred fewer than 15 times.

Figure 4.

Network visualisation of papers selected for analysis.

Eight clusters were formed based on the keyword co-occurrence. The first cluster, marked in red, contained works that analysed mainly lignin, chemical composition, calorific value as well as works concerning biomass with respect to ethanol production, polysaccharide content, yield, wheat straw, high heating value, and forest residues. The second cluster, marked in green, contained papers devoted mainly to an analysis of wood with respect to fuel (and fuels), biofuels, fast pyrolysis, pellets, chips, and biochar, as well as papers on chemical analysis, extracts, bio-oil, liquid, and blends. The third cluster was marked in blue and contained mainly papers on analysis of bark, extractives, antioxidants, and products, as well as degradation, moisture, and mechanical properties. The fourth cluster was marked in yellow. The papers in this cluster dealt mainly with torrefaction, fuel characterisation, and elemental composition, ash, and water. The fifth cluster was marked in purple and the papers included in it dealt mainly with combustion, pyrolysis, coal, char, forest, and activated carbon. The sixth cluster was marked in turquoise. The main subjects within this cluster included biomass, proximate analysis, and ultimate analysis, higher heating value (HHV), combustion characteristic, and biomass fuel. The seventh cluster was marked in orange, and the main topic included the cellulose and hemicellulose content, kinetics, behaviour, and energy. The eighth cluster was marked in brown. It included papers whose keywords appeared less frequently and included waste, gross calorific value, as well as model and growth.

An analysis of the temporal variability of the keyword occurrence showed that the largest number of papers were published between 2010 and 2018 (Figure 5). It was also shown that the oldest papers were mainly in cluster eight, marked brown in Figure 4, where gross calorific value, model, and growth, as well as gasification from cluster seven (orange), were analysed. The largest number of papers covering the keywords of biomass and pyrolysis were published around the year 2013, whereas the papers on wood, lignin, combustion, and fuels were published slightly later, around 2015. The subject matter dealt with in the papers in 2016 still included fuel, bioenergy, but also bark, lignocellulosic biomass, and wood biomass. Newer papers in 2018 covered analyses of elemental composition, biofuel, extracts, antioxidants, forest residues, and logging residues.

Figure 5.

Overlay visualisation of papers selected for analysis.

3.2. Thermophysical Properties

3.2.1. Higher Heating Value (HHV)

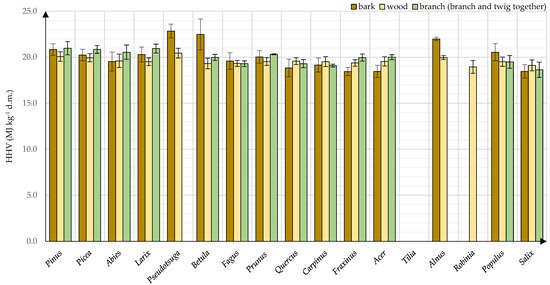

The mean wood HHV was 19.66 MJ kg−1 dry matter (d.m.) (Table 1). The mean HHV of coniferous wood was higher: 19.90 MJ kg−1 d.m. (Table 2) compared to deciduous wood, for which the mean level was 19.42 MJ kg−1 d.m. (Table 3). This was also confirmed by the median, which was 0.52 MJ kg−1 d.m. higher for coniferous wood. Moreover, although its sample was made up of much fewer genera than deciduous wood, coniferous wood was more diverse, which was indicated by a higher standard deviation and a larger variation coefficient (the values larger by 0.11 MJ kg−1 d.m. and 0.50 percentage points, respectively, compared to the values for deciduous wood). A quarter of the results for total wood were under 19.12 MJ kg−1 d.m., and ¾ of the results were above 20.05 MJ kg−1 d.m. The highest wood HHV among the genera under study was found for Pseudotsuga spp. at 20.45 MJ kg−1 d.m., and the lowest, for Robinia spp. at 18.95 MJ kg−1 d.m. (Figure 6, in Appendix A, Table A10). The highest diversity was observed in the Abies spp., while the lowest diversity was in the Alnus spp. (mean deviations: 0.73 and 0.21 kg−1 d.m., respectively).

Table 1.

Differentiation of the thermophysical properties and composition of wood without differentiation by type.

Table 2.

Differentiation of the thermophysical properties and composition of coniferous wood.

Table 3.

Differentiation of the thermophysical properties and composition of deciduous wood.

Figure 6.

Average value and average deviation of the higher heating value of organs of particular systematic genera trees.

According to Demirbas and Demirbas [74], HHV for coniferous wood was 20.3 MJ kg−1 d.m., and it was 19.5 MJ kg−1 d.m. for deciduous wood. The current study confirmed this relationship; coniferous wood HHV was higher than in deciduous wood. However, the difference was not the same—0.8 MJ kg−1, in the study by Demirbas and Demirbas [74], and 0.5 MJ kg−1 in the current study. Pretzsch [21] reported that HHV for coniferous trees is 20.4 MJ kg−1 d.m. and for deciduous 19.8 MJ kg−1 d.m., which shows an advantage of coniferous HHV. The higher HHV values [21] compared to the current results (Table 2 and Table 3) could be a consequence of the absence of a specific organ, for which these values were indicated; moreover, they are limited to Europe. Telmo [210] reported 20.5 MJ kg−1 d.m. for coniferous and 20.2 MJ kg−1 d.m. for deciduous wood.

The mean HHV for branches was 20.07 MJ kg−1 d.m. (Table 4). The mean HHV of coniferous branches was 20.87 MJ kg−1 d.m. (Table 5) and was higher compared to deciduous branches, for which the mean HHV was 19.54 MJ kg−1 d.m. (Table 6). This was confirmed by the median, which was 1.31 MJ kg−1 d.m. higher for coniferous branches. Greater diversity was observed for coniferous branches—the standard deviation was higher by 0.22 MJ kg−1 d.m., and the variability coefficient by 0.81 p.p. compared to the values for deciduous wood. A quarter of the results for the branches overall were not higher than 19.31 MJ kg−1 d.m., and ¾ of the results were not lower than 20.78 MJ kg−1 d.m. The highest branch HHV was noted for Pinus spp. at 20.98 MJ kg−1 d.m., and the lowest for Salix spp. at 18.63 MJ kg−1 d.m. (Figure 6, in Appendix A, Table A10). The greatest diversity was observed in the Salix spp., while the smallest was in the Padus spp. (mean deviations: 0.83 and 0.05 kg−1 d.m., respectively).

Table 4.

Differentiation of thermophysical properties and elemental composition of branches without differentiation by type.

Table 5.

Differentiation of thermophysical properties and elemental composition of coniferous branches.

Table 6.

Differentiation of thermophysical properties and elemental composition of deciduous branches.

The mean HHV for bark was 20.07 MJ kg−1 d.m. (Table 7). Moreover, its maximum value was 25.1 MJ kg−1 d.m., which is completely consistent with the findings of Feng [94]. The mean HHV for coniferous bark was 20.50 MJ kg−1 d.m. (Table 8), and it was higher than for deciduous bark, with a mean HHV of 19.79 MJ kg−1 d.m. (Table 9). The median was 1.10 MJ kg−1 d.m. larger for coniferous wood. Greater diversity was observed for deciduous tree bark—the standard deviation was higher by 0.66 MJ kg−1 d.m., and the variability coefficient by 3.55 p.p. A quarter of the results for the bark were not higher than 19.00 MJ kg−1 d.m., and ¾ of the results were not lower than 21.17 MJ kg−1 d.m. The highest HHV for bark was noted for Pseudotsuga spp. at 22.85 MJ kg−1 d.m., and the lowest was noted for Fraxinus spp. at 18.45 MJ kg−1 d.m. (Figure 6, in Appendix A, Table A10). The greatest diversity was observed in Betula spp., while the least diversity was in Alnus spp. (mean deviations: 1.68 and 0.19 kg−1 d.m., respectively).

Table 7.

Differentiation of thermophysical properties and elemental composition of bark without differentiation by type.

Table 8.

Differentiation of thermophysical properties and elemental composition of coniferous bark.

Table 9.

Differentiation of thermophysical properties and elemental composition of deciduous bark.

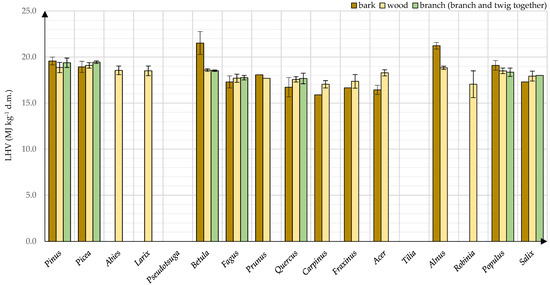

3.2.2. Lower Heating Value (LHV)

The mean wood LHV was 18.44 MJ kg−1 d.m., and it was 18.71 MJ kg−1 d.m. for branches and 19.36 MJ kg−1 d.m. for bark (Table 1, Table 3 and Table 7). The higher LHV (similarly to HHV) for bark compared to wood may have been caused by the chemical composition of these two plant organs—bark contains much more lignin (the heating value is based in 40% on lignin [122]) and extracts (Table 7), including resinous ones [94] whose HHV and, consequently, LHV, is higher compared to cellulose and hemicellulose (whose total and individual content is smaller compared to wood—Table 1 and Table 7). According to Rhen [196], HHV is 32.3–39.4 MJ kg−1 d.m. for extracts, 23.3–26.8 MJ kg−1 d.m. for lignin, 18.7–19.5 MJ kg−1 d.m. for cellulose, and 18.6 MJ kg−1 d.m. for holocellulose. Tekin et al. [237] conducted experiments and determined the HHV of acetone extract as 24.4, and of ether extract as 22.9 MJ kg−1 d.m. Kim et al. [238] report cellulose LHV to be 16.5, hemicellulose to be 13.9, and lignin to be 20.4 MJ kg−1 d.m., whereas according to Ma et al. [239], the respective values are: 15.4, 14.6, and 24.5 MJ kg−1 d.m. A similar analogy can be sought in the higher LHV for branches compared to wood, caused by the (diverse) bark content in the former.

Higher LHV for coniferous wood (18.85 MJ kg−1 d.m.) compared to deciduous wood (18.13 MJ kg−1 d.m.) is a consequence of higher lignin content in its chemical composition and a lower hemicellulose content (Table 2 and Table 3). Moreover, coniferous wood contains more carbon and, more importantly, more hydrogen (Section 3.4.1 and Section 3.4.2), which has a significant impact on the heating value. Picea spp. LHV was observed to be the highest—19.10 MJ kg−1 d.m. (Figure 7, in Appendix A Table A11), and that of Carpinus spp. to be the lowest—17.04 MJ kg−1 d.m. The greatest diversity was noted for Robinia wood (1.46 MJ kg−1 d.m.) and the least was for Betula spp. at 0.13 MJ kg−1 d.m.

Figure 7.

Average value and average deviation of the LHV of organs of particular systematic genera trees.

The branch LHV lay within the range of 17.10–20.23 MJ kg−1 d.m., with ¼ of the findings being not higher than 18.13 MJ kg−1 d.m., and ¾ not lower than 19.35 MJ kg−1 d.m. (Table 4). Coniferous and deciduous branches could not be compared as the sample of the latter comprised only one item (Table 6). However, our review revealed Picea spp. mean LHV to be the highest at 19.45 MJ kg−1 d.m., and that of Quercus spp. to be the lowest at 17.68 MJ kg−1 d.m. (Figure 7, in Appendix A Table A11).

The minimum LHV for bark was 15.60 MJ kg−1 d.m. and the maximum was 22.75 MJ kg−1 d.m. (Table 7). There was no considerable difference in the mean between the groups of trees (coniferous/deciduous) (19.34/19.37 MJ kg−1 d.m.) (Table 8 and Table 9). However, with the interquartile range being nearly four times smaller compared to deciduous wood, the median showed the coniferous wood LHV to be higher (19.53/18.72 MJ kg−1 d.m.). The advantage of the coniferous bark in this regard is expressed well in its chemical composition, as it contained more lignin and extracts (Table 8 and Table 9). The data-based LHV diversity between the genera under analysis is shown in Figure 7 and in Appendix A, Table A11. It is interesting to note that median LHV of the root (19.32 MJ kg−1 d.m.) was higher compared to that of wood (18.61 MJ kg−1 d.m.) (in Appendix A, Table A7).

3.3. Proximate Analysis

3.3.1. Moisture Content (MC)

The moisture content has a significant impact on the HHV and, consequently, on the LHV. With a constant sample mass, HHV decreases in proportion to the decreasing material mass at the expense of the increasing water share [29]. However, when the moisture content in a sample increases by 10% (which is also accompanied by a sample mass increase), then, according to the equations developed by Lunguleasa et al. [240], HHV decreases by 1.78–2.02 MJ kg−1, depending on the wood species. Furthermore, according to the equation proposed by Garcia et al. [23] based on HHV as ƒ (A, FC, M, C, O) → HHV decreases by 1.82 MJ kg−1 with a moisture content increase by each 10%. A 10% moisture content increase is followed by an LHV decrease of 1.83 [241] or 2 MJ kg−1 [19]. However, it is noteworthy that the LHV will be 0 MJ kg−1, at a moisture content of approximately 87%. The moisture content of 55% is the upper limit for effective energy generation [242].

The total moisture content in biomass can reach as much as 90% [243], whereas it lies in the following ranges for the dendromass samples under analysis: wood: 1.29–58.56% (Table 1); branches: 5.50–61.23% (Table 4); bark: 1.30–68.45% (Table 7); with variability coefficients of 100.19%, 59.10%, and 72.19%, respectively. This indicates a strong variability for bark and branches and very strong variability for wood. This is caused by bringing the moisture content to a specific level by drying in a laboratory, in the open air, or under a roof. The moisture content in fresh wood ranges from 35% to 60%; it was 20–25% in wood dried in the open air and 15–20% under a roof [122,244]. The moisture content spectrum includes the dry (moisture content of 20%), semi-dry (35%) and fresh (more than 35%) state [245]; for the laboratory conditions: air-dry (moisture content: 10–20%) [246] and dry (moisture content: approximately 0%) [247]. Biomass with a moisture content under 50% is used effectively for combustion [243], but wood with a moisture content of 5–20% is usually used as fuel [244]. The moisture content of wood used in small heating systems (e.g., in private houses) should not exceed 25% [122]. If it is higher, the combustion temperature will decrease below the optimum range, leading to increased heat loss, intensified emissions, and possible chimney damage. The maximum moisture content levels, as found in this study (Table 1, Table 4 and Table 7) are close to those provided in the literature, where the level for raw wood is 60%; for branches, 60%; and for bark, it is 70% [122]. The maximum moisture content level was found in one bark of the deciduous (68.45%) (in Appendix A, Table A4).

Incidentally, raw and moist forest residues stored on forest land for several months after tree felling can undergo enzymatic decomposition caused by microorganisms (rotting). This can reduce HHV/LHV by 1 MJ kg−1 d.m. [196]. On the other hand, drying can entail evaporation from dendromass of various amounts of high-LHV extracts as volatile organic compounds (e.g., terpenes), which can also decrease these thermophysical parameters [248]. Both of these processes may have affected the values of variables in this review.

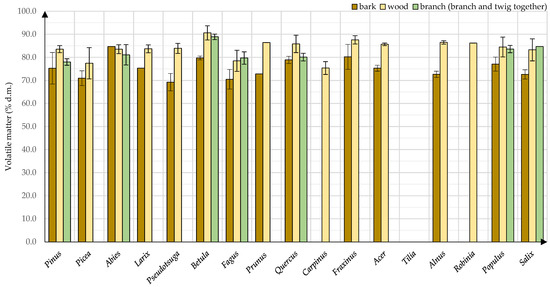

3.3.2. Volatile Matter (VM)

Volatile matter is determined as the percentage of gas (emission) from a biomass sample, which is released in an anaerobic environment (except moisture) at a normalised temperature (900 °C or 950 °C) [222,249]. Wood contains 80–85% of such matter, which makes it easily flammable [222]. The wood VM in the current study lay within a closed interval: 70.20–93.36% d.m. (Table 1), but the quartile range limits of 81.29–87.05% d.m. better reflected the values commonly determined for wood [222]. Moreover, the variability for the sample was low (6.18%) (Table 1). The occurrence of some values of out-of-Q1–Q3 range could be affected by decreased or elevated levels of ash and/or fixed carbon in individual samples (according to the equation VM = 1–FC–A for samples in a dry state). The mean VM content in coniferous wood was lower than in deciduous wood (84.34% and 82.46% d.m., respectively; median: 85.70% and 83.50% d.m., respectively) (Table 2 and Table 3), which was the correct difference given the structure of the conductive tissue in these two tree types. The mean diameters of vessels in deciduous wood are larger [250]. They act like macropores and are the least resistant paths for volatile substances during their emission. They determine the wood porosity and, combined with occlusions/tyloses, determine the ease of volatile substances leaving the wood structure during its “pyrolysis” (VM determination). Therefore, the VM levels in deciduous wood are higher. Volatile matter is first pushed out of the wood structure during the combustion process, and it is then burned in the gaseous state, leaving the fixed carbon (pyrolytic carbon) as burning later in the solid-state [251].

Bark contained less VM compared to wood (mean: bark 74.85%, wood 83.57% d.m.) (Table 1 and Table 7), with nearly the same diversity (bark 5.18%, wood 5.17% d.m.). This indicates a higher wood reactivity compared to bark [251], and, in consequence, a lower flash point [243], which is consistent with the findings of Wcisło and Labak [222] and Senelwa and Sims [251], who found the same interdependence even in the same tree age groups [222]. The mean VM level in branches was also higher—81.98% d.m. (Table 4). However, it was lower than in wood, which can be attributable to the share of bark in this organ. In this case, the diversity was the lowest (4.56% d.m.) (Table 4).

The volatile matter content diversity is a consequence of the difference in mean diameters of conductive elements (tracheids, vessels) between different genera and organs. The mean values and average deviations for the VM content in individual species and organs are shown in Appendix A in Figure A1 and Table A13.

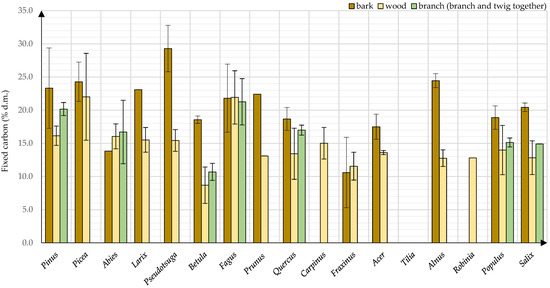

3.3.3. Fixed Carbon (FC)

The mean fixed carbon content in wood was 15.23% d.m. (Table 1), 20.91% d.m. in bark (Table 7), and 16.55% d.m. in branches. (Table 4). These values lie within an interval indicated for wood biomass, i.e., 6–25% [122]. Due to the lowest VM content, bark contained the highest FC levels, whereas it was medium in branches due to the presence of bark. In general, FC is the portion of carbon that is left after the VM is determined and the sum of moisture content and ash is deducted [252]. FC is the combustible solid carbon, which remains in the scorched biomass and includes elemental carbon and all the carbon residues produced during heating [243,252,253]. The FC content in biomass differs from elemental carbon (C) content, which can be observed in the data provided in Section 3.4.1 and which is a consequence of the fact that part of C is lost in hydrocarbons as VM [253]. Moreover, FC contains small amounts of H, O, N, and S, which are not removed with gas [252], which also affects the difference. The higher FC content in coniferous wood compared to deciduous wood (Table 2 and Table 3) is a consequence of the relationship described earlier in Section 3.3.2. If the matter conducting elements (vessels, tracheids) are less transparent (smaller perforation diameters), then the reactive volatile substances cannot easily escape their interior, which makes some of them deposit and join to form the solid carbon matrix (FC). This results in the higher FC content in coniferous wood. The lower FC content in wood (mean 15.23%) d.m. (Table 1) reflected a high VM content regardless of the ash content and showed that most wood is used in the gaseous form during the combustion process [251]. The same relationship was observed for bark and branches.

A higher FC content in branches and bark (Table 4 and Table 7) indicates their lower reactivity. On the other hand, an increase in the FC content entails an HHV increase [254], which manifests itself in the analysed data, because the highest mean LHV was determined for bark (Table 7), followed by branches (Table 4) and wood (Table 1), and the LHV increase in the presented order was accompanied by a simultaneous increase in the mean FC content. Extracts (other extracts in our review) contribute significantly to an increase in the FC content—a linear and positive correlation [255], which is also shown in the current study. Their content was the highest in bark, followed by branches and wood (Table 1, Table 4 and Table 7), owing to that the FC increase was observed in the same order (Section 3.5.4). The mean values and average deviations for the FC content for individual species and organs are shown in Appendix A in Figure A2 and Table A14.

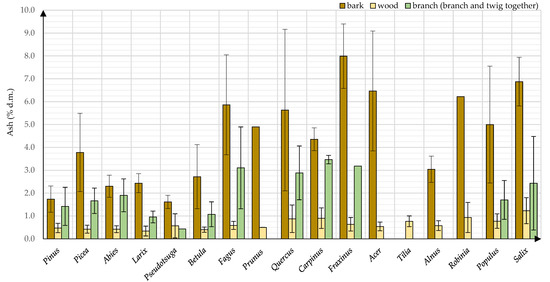

3.3.4. Ash (A)

Given the fact that minerals are essential to dendromass growth, many of them are absorbed through the root system in various concentrations, whereby they are found in extracts in mature dendromass [29,239,256]. In consequence, dendromass combustion produces non-flammable residue (ash), which is always alkaline in the case of dendromass, and it always tends to decrease the HHV [94,257]. It should be noted that an increase in the ash content in dendromass can result from soil pollution, chemical treatments, presence of rocks, plastic, or metals [257].

The minimum ash content in the analysed organs was 0.07%, and the maximum was 13.50% d.m. (Table 1, Table 4 and Table 7), which is consistent with the findings of Caillat and Vakkilainen [257], where the maximum ash content in some biomass kinds reached 20%. Telmo [210] reports that wood contains 0.3% of ash in d.m., whereas according to Kask et al. [122], the content lies within the range of 0.1–2% d.m., with no difference in the mean level between coniferous and deciduous trees [122]. The mean ash content in wood found in this study was 0.61% d.m. (median 0.47% d.m.), and the whole data distribution lay within the range of 0.07–2.70% d.m. (Table 1). The ash content in the bark was higher than in wood (4.05% d.m.) (Table 7), whereas the medium content was found in branches (1.93% d.m.) (Table 5). The higher mean ash content in bark compared to branches and wood may be caused by a higher content of lignin (Table 1, Table 4 and Table 7), which in extracted form contains ash (mean 2.87% d.m. [239]), while cellulose and hemicellulose contain only C, H, and O in a pure, non-extracted form [243]).

Coniferous wood contained less ash (mean 0.45% d.m.) (Table 2) than deciduous wood (0.70% d.m.) (Table 3). The same observations were made by Gbenga and Oluwatosin [258] and Alakangas [29]. This may be caused by a higher content of other extracts in deciduous wood (Section 3.5.4) and their different composition compared to coniferous wood—other extracts from deciduous wood may contain higher levels of ash-forming elements in the carbon structures (inseparable ash as fixed/tied salts [259]). The mean ash content in coniferous bark (2.67% d.m., Table 8) was also lower than in deciduous bark (4.83% d.m., Table 9), as in the study by Kask et al. [122].

The current study found that the lowest mean ash content is present in Larix spp. (0.34% d.m.), and the highest is in Fraxinus spp. (7.99% d.m.) (Figure 8, in Appendix A, Table A15).

Figure 8.

Average value and average deviation of the ash content of organs of particular systematic genera trees.

3.4. Ultimate Analysis/Elemental Composition

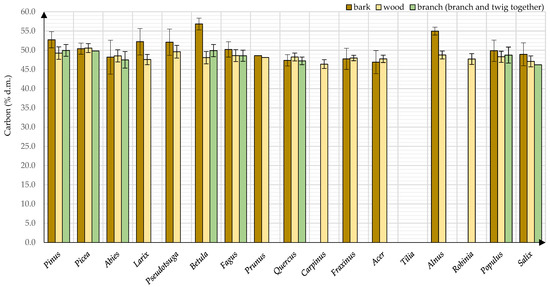

3.4.1. Carbon (C)

The C content in biomass has a considerable impact on HHV of organic substances and, in consequence, on the LHV because it is by oxidation of C that energy is released (E) [131]. Oxidation of 1 kg of pure carbon to CO2 results in the release of 32.8 MJ kg−1 E [22]. The highest mean content of C was found in bark at 51.49% d.m. (Table 7), whereas it was 48.53% d.m. in wood (Table 1) and 48.52% d.m. in branches (Table 4). This diversity is most probably caused by the lignin content, which contains approximately 58.7% d.m of carbon (cellulose 41.5% d.m.; and hemicellulose, 40.7% d.m.) [239]. This diversity is most probably caused by the lignin content, which contains approximately 58.7% d.m of carbon (cellulose 41.5% d.m.; and hemicellulose, 40.7% d.m.) [239]. The current study showed that bark contained the highest level of lignin, followed by branches and wood (Section 3.5.3). The same can be argued about a higher C content in coniferous wood (49.30% d.m.) (Table 2) compared to deciduous wood (47.99% d.m.) (Table 3)—the former contained more lignin, with a simultaneous lower hemicellulose content (Table 2 and Table 3). A higher C content in coniferous wood was found by Telmo [210], with a difference of 2%. The C content in wood lay within the interquartile range of 47.20–49.99% d.m., whereas a range of 49–51% d.m. is commonly indicated [122]. The minimum C content for the whole dendromass under analysis was 42.24% d.m. (wood, Table 1), whereas the maximum content was 62.42% d.m. (bark, Table 7). The highest diversity was observed for bark (3.89% d.m.), and the lowest was for wood (2.00% d.m.).

An analysis of the C content in various dendromass types showed that the highest C content was present in the bark of Betula spp. (56.82% d.m.), and the lowest was in branches of Salix spp. (46.20% d.m.) (Figure 9, in Appendix A, Table A16). The highest diversity was observed in the bark of Abies spp. (4.41% d.m., although some samples may have contained leaves, with consequent dispersion of the results), whereas it was the lowest in the wood of Fraxinus spp. (0.70% d.m.).

Figure 9.

Average value and average deviation of the carbon content of organs of particular systematic genera trees.

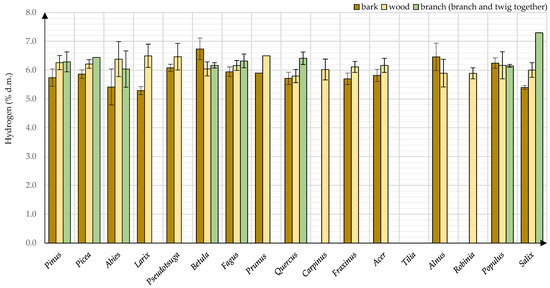

3.4.2. Hydrogen (H)

Hydrogen can be found in all organic compounds, and it has a considerable impact on the energy properties of biomass because the synthesis of hydrogen and oxygen produces a water molecule with the release of E, which directly contributes to the generation of the heat of combustion. The water formed by hydrogen oxidation collects the heat of the reaction, thereby decreasing the LHV [131]. Since the hydrogen:water ratio during hydrogen combustion in oxygen is 1:9, oxidation of 1 kg of H2 produces 8.937 kg of H2O, whose evaporation takes E from the reaction. When 142.2 MJ kg−1 E is released [22], 21.869 MJ kg−1 E is collected by water (the latent heat of water vapour: 2.447 MJ kg−1; water reference state: 1 bar and 25 °C [260]).

The highest mean H content was found in branches at 6.29% d.m. (Table 4), whereas it was the lowest in the bark at 6.01% d.m. (Table 7). Wood contained 6.17% d.m. of H (Table 1). This diversity is most probably caused by the lignin content, which contains approximately 5.43% d.m. of hydrogen (cellulose 5.97% d.m.; hemicellulose, 5.75% d.m.) [239]. The current study showed that bark contained the highest level of lignin, followed by branches and wood (Section 3.5.3). The higher H content in branches compared to wood may be caused by a higher content of other extracts (Section 3.5.4), which may also contain much more hydrogen compared to wood.

The higher H content in coniferous wood (6.33% d.m.) (Table 2) compared to deciduous wood (6.05% d.m.) (Table 3) may be caused by a higher content of other extracts richer simultaneously in H. A higher H content in coniferous wood was also reported by Telmo [210], with the difference being 0.1%. The H content in wood lay within the interquartile range of 5.98–6.30% d.m. (Table 1), whereas the range of 6.0–6.2% d.m. is commonly reported [122]. The minimum H content in the whole dendromass under analysis was 4.74% d.m. (bark, Table 7), whereas the maximum content was 9.70% d.m. (wood, Table 1). The highest diversity was observed for wood (0.55% d.m.), and the lowest was for branches (0.41% d.m.).

The highest H content among the dendromass under analysis was found in branches of Salix spp. (7.30% d.m.), and the lowest was in the bark of Larix spp. (5.29% d.m.). The highest diversity was observed in the branches and bark of Abies spp. (0.63% d.m., some samples of branches may have contained leaves), whereas it was the lowest in branches of Populus spp. (0.05% d.m.) (Figure 10, in Appendix A, Table A17).

Figure 10.

Average value and average deviation of the hydrogen content of organs of particular systematic genera trees.

3.4.3. Oxygen (O)

The O content may be important because of the temperature of decomposition initiation, which indicates the thermal stability of the biofuel organic part. The lower the O content in biomass, the lower the initial thermal decomposition temperature. It is 100–160 °C for wood and peat, with the temperatures being lower for wood [122]. The O content can be determined, but it is usually calculated in the following manner: O = 100—C, H, N, S, and A (% d.m.) [29], with C, H, and O combined accounting for approximately 99% d.m. of wood fuel [122]. It was calculated from this difference in the majority of the papers under analysis.

The highest mean content of O was found in wood (44.19% d.m.) (Table 1), whereas it was the lowest in bark (40.02% d.m.) (Table 7). Branches contained 42.91% d.m. of oxygen (Table 4). This diversity is most probably caused by the lignin content, which contains approximately 34.51% dry ashless mass of oxygen (cellulose, 52.48% d.a.m.; and hemicellulose, 53.49% d.a.m.) [239].

The higher O content in deciduous wood (44.50% d.m.) (Table 3) compared to coniferous wood (43.77% d.m.) (Table 2) could be attributed to a lower lignin content (Table 2 and Table 3). A higher O content in deciduous wood was found by Telmo [210], with a difference of 2%. The O content in wood lay within the interquartile range of 42.60–45.79% d.m., whereas a range of 38–42% d.m. is commonly reported [122]. The minimum O content for the whole dendromass under analysis was 33.39% d.m. (branches, Table 7), whereas the maximum content was 54.58% d.m. (wood, Table 1). According to this review, the highest diversity was observed in bark (3.75% d.m., Table 7), and the lowest was in wood (2.55% d.m.). The mean O content of each genus in the organs under analysis is shown in Appendix A in Figure A3 and Table A18.

3.4.4. Nitrogen (N)

Energy is released during the process of nitrogen oxidation to oxides (NOx). Nitrogen oxides react with water and produce nitric acids, with N present in them at different oxidation states. The reactions also affect the heating value, but to a lesser extent [131]. N and S emissions depend on the content of these two elements in the fuel and on the conditions of the thermal transformation. The majority of biofuels contain low levels of N and S [122].

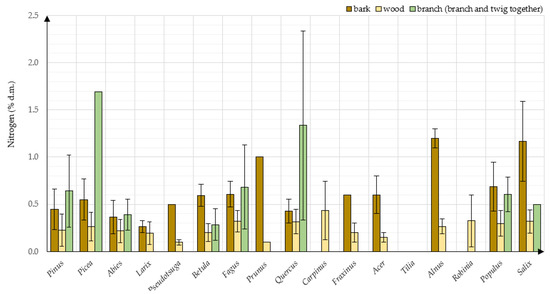

The mean N content was the highest in branches because some of them contained leaves (0.84% d.m.) (Table 4), with the mean N content in the foliage of 1.10% d.m. (in Appendix A, Table A8). It was the lowest in wood (0.25% d.m.) (Table 1). Bark contained 0.61% d.m. of N (Table 7). A higher N content in bark compared to wood can be justified by a higher content of other extracts (Table 1 and Table 7), which could also be richer in N compared to other extracts from wood.

A higher N content in deciduous wood (0.29% d.m.) (Table 3) compared to coniferous wood (0.21% d.m.) (Table 2) may be caused by a higher content of other extracts, which could also be richer in N. Telmo [210] points to the absence of a difference in N content between deciduous and coniferous wood.

The N content in wood lay within the interquartile range of 0.10–0.35% d.m. (Table 1), whereas the range of 0.1–0.4% d.m. is commonly reported [122]. The minimum N content for the whole dendromass under analysis was 0.01% d.m. (wood, Table 1), whereas the maximum content was 2.87% d.m. (branches, Table 7). The current analysis showed that the highest N content was in branches of Picea spp. (1.69% d.m.), and the lowest was in the wood of Pseudotsuga spp. and Padus spp. (both samples were 0.10% d.m.) (Figure 11, in Appendix A, Table A19).

Figure 11.

Average value and average deviation of the nitrogen content of organs of particular systematic genera trees.

3.4.5. Sulphur (S)

Sulphur (inorganic SO42− and organic chemically bonded with organic compounds) reacts with O2 during biomass combustion to form SO2. Some of the oxides are further oxidised to SO3, which reacts with water to form sulphuric (VI) acid [261]. Thermal decomposition first releases S from organic compounds, e.g., amino acids and proteins. Subsequently, S from the decomposition and transformation of inorganic sulphates is emitted [262].

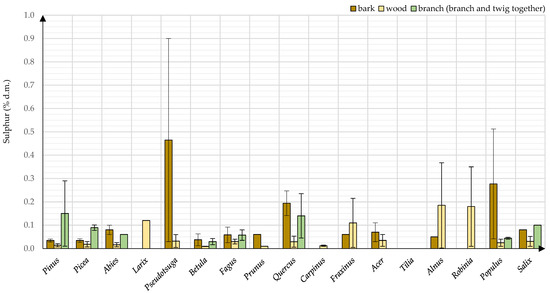

The highest mean content of S was found in bark (0.10% d.m.) (Table 7), and it did not deviate much from that in branches (0.09% d.m.) (Table 4). The lowest mean S content was found in wood (0.04% d.m.) (Table 1). This differentiation can be explained by the content of the other extracts, which should contain sulphur—the highest other extract content was found in bark, followed by branches and wood (Section 3.5.4).

The higher S content in deciduous wood (0.06% d.m.) (Table 3) compared to coniferous wood (0.02% d.m.) (Table 2) may be caused by a higher content of other extracts (Section 3.5.4), which should also be richer in S. Telmo [210] points to the absence of a difference in S content between these dendromass types.

The S content in wood lay within the interquartile range of 0.10–0.30% d.m. (Table 1), whereas the range of 0.01–0.05% d.m. is commonly reported [122]. The minimum S content in the whole dendromass under analysis was 0.01% d.m. (wood and bark, Table 1 and Table 7), whereas the maximum content was 0.92% d.m. (bark, Table 7). The findings of the current study show that the highest mean S content was found in Pseudotsuga spp. bark (0.465% d.m.), whereas the lowest content was found in the wood of Padus spp. and Betula spp. (0.010% d.m.) (Figure 12, in Appendix A, Table A20). Taking into account all tree organs, the maximum sulphur content was found in one deciduous bark (0.920% d.m.) (in Appendix A, Table A5).

Figure 12.

Average value and average deviation of the sulphur content of organs of particular systematic genera trees.

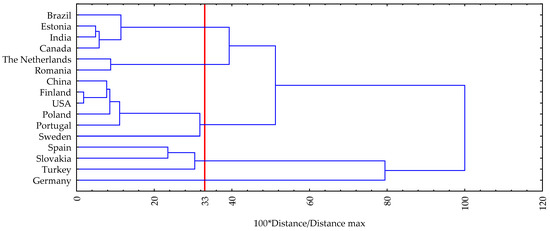

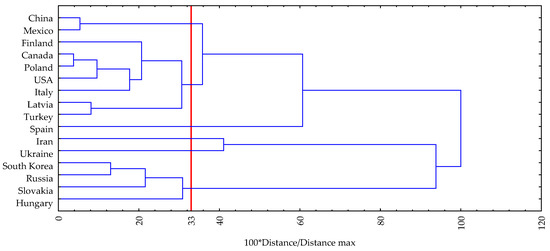

A cluster analysis based on the energy parameters of dendromass, i.e., HHV, ash content, and S content, revealed five areas (Figure 13). One distinct area covered Germany with HHV and ash content levels above average and lower sulphur content. The second group included The Netherlands and Romania, with the values of all the features below average. The third group included Canada, Brazil, India, and Estonia, and the HHV in it was higher, but the ash and sulphur contents were lower. The fourth group included Slovakia, Spain, and Turkey, and the HHV in it was lower, but the ash and sulphur contents were higher. The fifth group (the largest) included Sweden, Poland, China, Portugal, Finland, and the USA, and it had higher HHV, lower ash, and medium sulphur content. One can conclude that the dendromasses with the best energy features in the study were found in the countries in groups three and five.

Figure 13.

Cluster analysis for energy potential characteristic of dendromass in selected countries.

3.5. Selected Chemical Composition

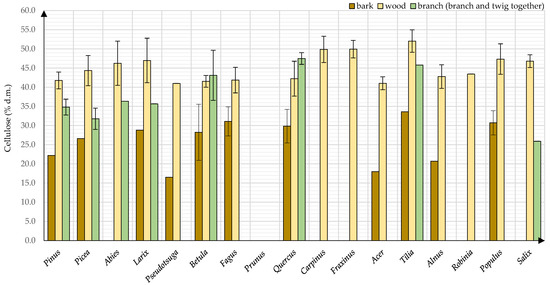

3.5.1. Cellulose

The minimum cellulose content in the dendromass under analysis was 16.20% d.m., and the maximum was 58.60% d.m., for bark and wood, respectively (Table 1 and Table 7). Its mean content in wood, branches, and bark was 44.22, 38.89, 28.18% d.m., respectively (Table 1 and Table 7). The quartile range for wood lay between 40.90% and 47.30% d.m. (Table 1), and it is generally accepted that cellulose content in wood ranges from 40% to 50% d.m. [34,39] or from 35% to 60% d.m. [122]. Deciduous wood contains more cellulose than coniferous wood [263], which is confirmed by the current study—the mean levels for deciduous and coniferous wood were 44.43% and 43.86% d.m., respectively (Table 2 and Table 3). Deciduous branches also contained more cellulose than coniferous ones (42.93% d.m. vs. 34.28% d.m.) (Table 5 and Table 6). This was also true for bark (29.02% d.m. vs. 23.53% d.m.) (Table 8 and Table 9). The cellulose content in coniferous wood lay within the range of 37.40–58.60% d.m. (Table 2), with the levels ranging from 33.90% to 54.95% d.m. in deciduous wood. (Table 3). It is widely accepted that cellulose content in coniferous wood ranges from 40% to 45% d.m. [122], and even from 40% to 60% [247]. The following ranges are reported for deciduous wood: 40–50% d.m. [122] and 35–55% [247].

The highest cellulose content was found in a one of Salix spp. root (60.00% d.m.) (in Appendix A, Table A3). However the current study found that the highest mean cellulose content was found in Tilia spp. wood (52.03% d.m.), and the lowest was in Pseudotsuga spp. bark (16.50% d.m.) (Figure 14, in Appendix A, Table A21).

Figure 14.

Average value and average deviation of the cellulose content of organs of particular systematic genera trees.

3.5.2. Hemicellulose

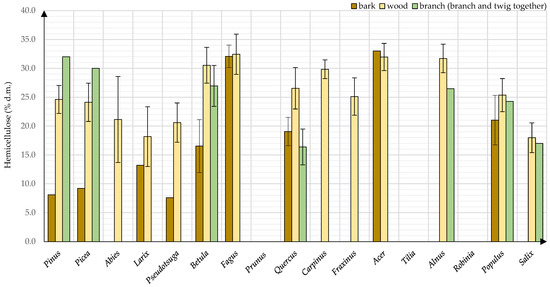

The minimum hemicellulose content in the dendromass under analysis was 7.60% d.m., and the maximum was 44.30% d.m., for bark (Table 7) and wood (Table 1), respectively. Its mean content in wood, branches, and bark was 26.43%, 24.04%, 19.72% d.m., respectively. The quartile range for wood lay between 22.80% and 30.17% d.m., and it is generally accepted that hemicellulose content in wood ranges from 20% to 35% d.m. [264] or from 20% to 30% d.m. [265]. Deciduous wood contains more hemicellulose than coniferous wood [263,264], which is confirmed by the current study—the mean levels for deciduous wood: 28.34% d.m. (Table 3), and 23.06% d.m. for coniferous wood. (Table 2). This was also true for bark (22.85% d.m. vs. 9.53% d.m.) (Table 5 and Table 6). In the case of branches, coniferous branches contained more hemicellulose (31.00% d.m. vs. 22.06% d.m.) (Table 5 and Table 6), which may have been caused by a larger proportion of branches with leaves in the leafy branch sample (leaves contained less hemicellulose than branches, and leaves of deciduous trees contained less hemicellulose than those of coniferous trees (Table A6 and Table A9 in Appendix A)). The hemicellulose content in coniferous wood lay within the range of 12.37–31.00% d.m. (Table 2), and 14.10–44.30% d.m. in deciduous wood. (Table 3). It is generally accepted that the hemicellulose content in coniferous wood ranges from 24% to 37% d.m. [122] or 7% to 15% [247], whereas in deciduous wood, it ranges from 22% to 40% d.m. [122] or from 19% to 21% [247].

The current analysis of various tree genera and organs shows that the highest mean hemicellulose content was found in Acer spp. bark (33.00% d.m.), and the lowest was in Pseudotsuga spp. bark (7.60% d.m.) (Figure 15, in Appendix A, Table A22).

Figure 15.

Average value and average deviation of the hemicellulose content of organs of particular systematic genera trees.

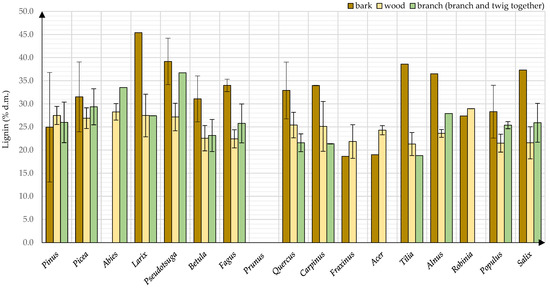

3.5.3. Lignin

The minimum lignin content in the dendromass under analysis was 13.10% d.m., and the maximum was 51.00% d.m., for bark in both cases (Table 7). Its mean content in wood, branches, and bark was 24.82%, 25.60%, 31.93% d.m., respectively. (Table 1, Table 4 and Table 7). The quartile range for wood lay between 21.80% and 27.75% d.m. (Table 1), whereas the generally accepted values lie in the ranges between 15% and 35% d.m. [264] or between 15% and 36% d.m. [265]. Coniferous wood contains more lignin than deciduous wood [263], which was confirmed by the current study—the mean level for coniferous wood was 27.32% d.m. (Table 2) and for deciduous wood, it was 23.15% d.m. (Table 3). This was also true for bark (33.12% d.m. vs. 31.65% d.m.) (Table 8 and Table 9) and branches (28.88% d.m. vs. 23.37% d.m.) (Table 5 and Table 6). The lignin content in coniferous wood lay within the interquartile range of 26.81–29.00% d.m. (Table 2), whereas ranges of 25–30% d.m. [122] and 25–35% [247] are commonly reported. The interquartile range for deciduous wood lay between 20.90% and 25.06% d.m. (Table 3), whereas the generally reported values ranged between 20% and 25% d.m. [122] or between 22% and 30% d.m. [247].

Taking into account all tree organs, the maximum lignin content was found in one bark (51.00% d.m.) (in Appendix A, Table A9). However the findings of the current study show that the highest mean lignin content was found in the bark of Larix spp. (45.40% d.m.), whereas the lowest was in the bark of Fraxinus spp. (18.64% d.m.) (Figure 16, in Appendix A, Table A23).

Figure 16.

Average value and average deviation of the lignin content of organs of particular systematic genera trees.

3.5.4. Other Extracts

Extracts (except cellulose, hemicellulose, and lignin) denote a heterogeneous group of chemical compounds, but the following can be identified in dendromass: terpenoids, tropolones, flavonoids, stilbenes, simple and complex phenols, waxes, pectins, mucilages, resins, starch, saponins, and proteins. They can be obtained with polar or non-polar solvents [263,266]. Other extracts account for a small portion of dendromass, but they have a considerable impact on the process of material digestion [266]; they can also increase the biomaterial heating value in the same way as, for example, resinous substances [94]. Other extracts include mainly intermediate metabolites (defence and energy reserve for trees) [263,266].

The minimum other extract content in the dendromass under analysis was 0.31% d.m., and the maximum was 32.10% d.m. for wood (Table 1) and bark (Table 7), respectively. Its mean content in wood, branches, and bark was 3.24%, 5.97%, 12.60% d.m., respectively (Table 1, Table 4 and Table 7). The content ranges for wood for the other extracts were between 0.31% and 9.00% d.m. (Table 1), whereas, in general, ranges from 1% to 10% d.m. [264], 2% to 10% d.m. [265], 4% to 10% d.m. [263] or 1% to 20% d.m. [122] are reported. Deciduous wood contains more other extracts than coniferous wood [263], which is confirmed by the current review—the mean levels for deciduous wood were 3.55% d.m. (Table 3), and 2.84% d.m. for coniferous wood (Table 2). For branches, coniferous ones contained more other extracts (6.68% d.m. vs. 5.26% d.m.), which may have been caused by a larger proportion of branches with leaves in the leafy branch sample (leaves contained fewer other extracts than branches themselves; in addition, leaves of coniferous trees contained more other extracts (Table A6 and Table A9 in Appendix A)). The bark of coniferous trees contained more other extracts compared to deciduous bark (14.33% d.m. vs. 12.06% d.m.) (Table 8 and Table 9). The other extract content lay within the range of 0.31–6.24% d.m. in coniferous wood (Table 2), and 0.72–9.00% d.m. in deciduous wood (Table 3). In general, the range of 7–9% is generally reported for coniferous wood and 8–15% for deciduous wood (for pectins and protective substances) [247].

The findings of the current study show that the highest other extract content was found in the bark of Fraxinus spp. (18.49% d.m.), whereas the lowest was in branches of Carpinus spp. (1.38% d.m.) (in Appendix A, Figure A4, and Table A24).

Cluster analysis was also carried out for the content of the main polymers, i.e., cellulose, hemicellulose, and lignin, which are particularly important in regard to the lignocellulosic biomass potential for the production of, among others, liquid biofuels (cellulose and hemicellulose) and other bioproducts (lignin). Biomass of the first group was represented by Spain, and it had the lowest content of all the components under analysis (Figure 17). Biomass in the second group, represented by Iran, contained higher levels of hemicellulose, lower cellulose content, and low lignin content. The third group was represented by Ukraine. The cellulose, hemicellulose, and lignin content were similar in these groups, but the mean cellulose content was lower in Iran than in Ukraine. Biomass in the fourth group, including China and Mexico, contained medium levels of the components under analysis, with the highest level of cellulose. Biomass in the fifth group, including Finland, the USA, Latvia, Canada, Poland, and Italy, also contained medium levels of the components under analysis, with the highest level of lignin. The highest content of cellulose and hemicellulose and the lowest content of lignin were found in the biomass in group 6, i.e., Russia, Slovakia, Hungary, and South Korea.

Figure 17.

Cluster analysis for the main chemical compounds in dendromass in selected countries.

4. Conclusions

An analysis was conducted of 221 scientific papers, from which data were isolated on the properties and composition (15 selected features) of 12 plant organs/morphological parts of dendromass (wood, branches, and bark were selected for the main analysis) among 21 genera, including 5 coniferous genera and 16 deciduous genera; of which 17 genera (5 coniferous and 12 deciduous genera) were chosen for the analysis of individual systematic genera.

Compared to bark, the HHV and LHV of wood were lower, as was the ash, FC, C, N, S, lignin, and other extract content. However, wood was superior in terms of the content of VM, H, O, cellulose, and hemicellulose. Medium levels of these features were found in branches (except HHV, C, H, and N, which, in some cases, could be caused by the presence of leaves or an increased bark content in part of a sample). Compared to deciduous wood, coniferous wood contained more FC, C, H, and lignin, and its HHV and LHV were higher. On the other hand, it contained less ash, VM, O, N, S, cellulose, hemicellulose, and extracts. However, one cannot state clearly which of these two groups of trees (coniferous or deciduous) produces biomass with more beneficial composition and properties. It should be noted that low levels of individual parameters may be advantageous in some conversion processes (and in some conditions), while the opposite may be true for others. Moreover, one must always make an assessment of the acceptable emissions or of the acceptable amount of produced residues in the individual process. Therefore, there is no single universal key that can be used to decide which dendromass group (coniferous/deciduous) will be better for conversion.

The diversity of mean HHV levels (as the resultant of the features under analysis) of the wood of individual genera was analysed in both groups (coniferous/deciduous). It was higher within the coniferous genera (standard deviation of 0.38) compared to the deciduous genera (0.26 MJ kg−1 d.m.). It was determined that the mean HHV diversity between the tree organs (wood, branches, and bark) of the most common genera in forests of Europe: Pinus spp., Picea spp., Fagus spp., Quercus spp., Betula spp., Abies spp. were 0.46, 0.49, 0.15, 0.37, 1.67 and 0.56 MJ kg−1 d.m., respectively. Furthermore, the mean HHV diversity between the organs of these six genera was 0.31 for wood, 0.75 for branches, and 1.29 MJ kg−1 d.m. for bark. This shows that the differentiation between the organs within one genus was not always greater than differentiation within one organ from the pool of different systematic genera. The cluster analysis showed that dendromass with the most favourable energy parameters analysed in this study was found in the following countries: Canada, Brazil, India, Estonia, Sweden, Poland, China, Portugal, Finland, and the USA. The highest cellulose and hemicellulose and the lowest lignin content were found in dendromass in Russia, Slovakia, Hungary, and South Korea.

The qualitative-quantitative data generated and presented in this paper can be used by other researchers, science centres, and companies to help them choose the optimum/ most efficient biomass from forest dendromass as feedstock for thermophysical or chemical conversion, or at least to identify specific raw biomaterials which can be included in studies of their efficiency in specific processing technologies. This review has shown that—to save time and costs—the starting raw material parameters in many experimental studies, for example, of biomass gasification or torrefaction, were set based on literature data, to which subsequently the parameters of obtained semi-finished or products were compared. In other studies, the starting parameters of a previously selected dendromass group were determined, with such a group being considerably narrowed down compared to mentioned studies (for the same reasons as mentioned above) and then the results were referred to them. In many experiments, the authors chose dendromass raw materials of different plant organs and genera in order to identify those most suitable for the individual process. The current review can make the choice easier, or at least facilitate a search for dendromass raw materials that are the most suitable for a specific conversion process. Moreover, the data presented in Appendix A may help to narrow down the search to specific genera. It is important given the ongoing studies aimed at improving the production efficiency not only for solid, liquid, and gas biofuels but also for obtaining bioproducts, biochemicals, and bioextracts from forest biomass.

In general, we have found that the genus and plant organ have an impact on forest dendromass properties and composition. However, the analysis did not show intercontinental differences, especially since dendromass obtained in Europe dominated in most samples. It is known that the impact of a geographic location is obvious, but it has to be determined in a more precise manner. Therefore, research is needed to be conducted on the same genus at the same time at different places/locations of the world, preferably in the same habitat, density, etc., and with the same genetic material if the same species are taken for the research.

Author Contributions

Conceptualization, M.J.S. and P.D.; methodology, M.J.S., P.D. and E.O.-Z.; validation, M.J.S., P.D., E.O.-Z., P.S. and M.K.; formal analysis, M.J.S., P.D., E.O.-Z. and P.S.; investigation, M.J.S., P.D. and E.O.-Z.; data curation, M.J.S. and P.D.; writing—original draft preparation, P.D., M.J.S. and E.O.-Z.; writing—review and editing, M.J.S., P.D., M.K., E.O.-Z. and P.S.; visualisation, P.D. and E.O.-Z.; supervision, M.J.S.; project administration, M.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

The results presented in this paper were obtained as part of a comprehensive study financed by the University of Warmia and Mazury in Olsztyn, Faculty of Agriculture and Forestry, Department of Genetics, Plant Breeding and Bioresource Engineering (grant No. 30.610.007–110). Project financially supported by the Minister of Education and Science under the program entitled “Regional Initiative of Excellence” for the years 2019-2022, Project No. 010/RID/2018/19, amount of funding 12.000.000 PLN.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

Paweł Stachowicz is a participant in the third edition program of the “Industrial doctorate” supported by the Ministry of Education and Science, contract number DWD/3/19/2019.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

In Figure A1, Figure A2, Figure A3 and Figure A4, we have presented the average value and average deviation of the volatile matter, fixed carbon, oxygen, and other extracts of organs of particular systematic genera trees in sequence.

For the number of obtained results greater than 1, in every Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, median and mean absolute deviation of the median were given. It is presented as follows: range of values closed on both sides (minimum value and maximum value), below in bracket median and mean absolute deviation of the median. In Table A10, Table A11, Table A12, Table A13, Table A14, Table A15, Table A16, Table A17, Table A18, Table A19, Table A20, Table A21, Table A22, Table A23 and Table A24, the average value (abbreviation ) and average deviation (d) were given. The information which literature positions we used during generating the data for manuscript elements, we have included in Table A25.

Figure A1.

Average value and average deviation of the volatile matter of organs of particular systematic genera trees.

Figure A2.

Average value and average deviation of the fixed carbon of organs of particular systematic genera trees.

Figure A3.

Average value and average deviation of the oxygen content of organs of particular systematic genera trees.

Figure A4.

Average value and average deviation of the contents of other extracts in the organs of particular systematic genera trees.

Table A1.

Thermophysical properties and proximate analyses of particular organs of various systematic genera of trees.

Table A1.

Thermophysical properties and proximate analyses of particular organs of various systematic genera of trees.

| Systematic Genus | Organ/ Morphological Part | Moisture (%) | Volatile Matter (% d.m.) | Fixed Carbon (% d.m.) | Ash (% d.m.) | HHV (MJ kg−1 d.m.) | LHV (MJ kg−1 d.m.) |

|---|---|---|---|---|---|---|---|

| Pinus spp. | wood | 7.12–55.00 (11.51; 16.47) | 81.50–85.80 (83.09; 1.54) | 14.00–18.00 (16.77; 1.41) | 0.17–1.14 (0.18; 0.40) | 18.89–21.60 (20.06; 0.51) | 17.50–19.88 (19.13; 0.54) |

| branch | 5.50–60.00 (10.81; 20.18) | 76.64–80.80 (77.67; 1.39) | 18.20–21.36 (20.18; 1.05) | 0.24–3.27 (1.00; 0.69) | 19.30–22.84 (20.88; 0.68) | 18.55–20.80 (19.29; 0.51) | |

| twig | - | 76.79 | 20.94 | 2.27 | 19.45–21.80 (20.95; 0.78) | - | |

| foliage | 9.59–55.00 (12.00; 15.14) | 72.40–79.40 (75.90; 3.50) | 18.70–26.10 (22.40; 3.70) | 1.40–4.72 (2.35; 0.70) | 20.00–23.00 (21.40; 0.66) | 20.08–21.04 (21.00; 0.22) | |

| bark | 5.50–55.00 (40.67; 17.95) | 70.10–85.54 (70.12; 5.15) | 14.24–28.82 (26.90; 4.86) | 0.27–3.10 (1.80; 0.57) | 19.20–21.90 (21.17; 0.59) | 18.23–20.30 (19.58; 0.42) | |

| cone | 8.00–10.39 (8.90; 0.80) | - | - | 0.60–3.40 (0.85; 0.73) | 19.09–21.60 (19.40; 0.84) | 17.85–20.30 (18.35; 0.73) | |

| seed wing | - | - | - | 1.70 | 20.57 | 19.38 | |

| seed husk | - | 72.20 | 27.20 | 0.60 | - | - | |

| root | - | - | - | 1.98 | 21.04 | 19.32–21.02 (20.17; 0.85) | |

| Picea spp. | wood | 6.40–55.00 (10.00; 17.97) | 70.20–85.50 (77.30; 6.77) | 14.20–28.90 (22.20; 6.55) | 0.16–0.92 (0.37; 0.17) | 18.78–21.10 (20.03; 0.43) | 18.40–19.79 (19.11; 0.30) |

| branch | 8.00–47.59 (27.47; 13.20) | - | - | 0.35–3.16 (1.44; 0.59) | 20.68–21.61 (21.08; 0.24) | 19.30–19.40 (19.35; 0.05) | |

| twig | 53.37–54.28 (53.82; 0.46) | - | - | 1.69–2.60 (1.84; 0.30) | 19.68 | 19.64 | |

| foliage | 8.00–55.00 (43.52; 13.14) | 77.78 | 19.90 | 1.91–8.16 (3.07; 1.47) | 20.15–21.25 (20.66; 0.27) | 19.19–19.95 (19.22; 0.20) | |

| bark | 8.00–58.73 (38.27; 20.81) | 64.60–75.20 (72.05; 3.13) | 21.00–30.20 (22.95; 2.53) | 1.33–9.51 (3.14; 155) | 18.72–21.81 (20.30; 0.62) | 17.50–20.00 (18.80; 0.56) | |

| cone | 8.00–12.54 (10.27; 2.27) | 80.92 | 17.48 | 0.93–5.32 (1.80; 0.94) | 18.91–21.10 (20.31; 0.67) | 16.96–19.90 (18.45; 0.92) | |

| seed wing | 6.40–55.00 (10.00; 17.97) | - | - | 1.40 | 20.38 | 19.20 | |

| root | 20.09 | - | - | 2.38 | - | 19.32–19.33 (19.325; 0.005) | |

| Abies spp. | wood | 3.70–14.40 (6.81; 3.49) | 80.84–88.79 (83.19; 1.82) | 10.90–18.38 (16.54; 1.72) | 0.23–0.82 (0.36; 0.14) | 18.10–21.20 (19.93; 0.65) | 17.46–19.29 (18.62; 0.45) |

| branch | 14.33 | 78.76–87.74 (83.25; 4.49) | 9.54–20.44 (14.99; 5.45) | 0.81–2.33 (1.38; 0.65) | 20.57–22.82 (20.68; 0.49). | - | |

| twig | - | 76.84 | 20.16 | 2.51–3.00 (2.76; 0.25) | 18.82–19.57 (19.19; 0.38) | - | |

| foliage | 9.67 | 75.28 | 18.08 | 3.95–6.00 (4.86; 0.80) | 20.78–21.50 (21.27; 0.30) | 20.47 | |

| bark | 10.83 | 84.67 | 13.84 | 1.33–2.65 (2.61; 0.33) | 18.50–21.31 (19.01; 0.58). | - | |

| cone | - | - | - | - | 21.16 | 19.86 | |

| Larix spp. | wood | 3.19–9.80 (8.16; 1.68) | 81.17–87.10 (83.24; 1.70) | 12.72–17.65 (16.18; 1.64) | 0.10–1.15 (0.24; 0.19) | 18.78–20.01 (19.77; 0.39) | 17.81–19.28 (18.20; 0.47) |

| branch | - | - | - | 0.70–1.21 (0.95; 0.25) | 20.14–21.46 (21.09; 0.49) | - | |

| foliage | - | - | - | 3.05 | 20.09–21.30 (20.10; 0.40) | - | |

| bark | 5.50–8.70 (7.10; 1.60) | 75.30 | 23.10 | 1.60–3.05 (2.54; 0.39) | 19.49–21.17 (20.27; 0.81) | - | |

| cone | 8.00 | - | - | 1.70–2.00 (1.85; 0.15) | 20.58–21.90 (21.24; 0.66) | 19.14–20.60 (19.28; 0.49) | |

| Pseudotsuga spp. | wood | 1.29–13.40 (10.70; 2.56) | 78.70–87.30 (84.20; 2.12) | 12.60–18.60 (15.40; 1.63) | 0.10–2.70 (0.30; 0.40) | 19.70–21.77 (20.37; 0.49) | - |

| branch | - | - | - | 0.43 | - | - | |

| foliage | - | - | - | 4.96 | - | 20.55 | |

| bark | 11.00 | 65.46–73.00 (69.23; 3.77) | 25.80–32.79 (29.30; 3.50) | 1.20–2.11 (1.70; 0.27) | 22.10–23.60 (22.85; 0.75) | - | |

| Betula spp. | wood | 5.50–50.00 (7.60; 11.52) | 86.00–93.36 (92.50; 2.45) | 6.26–12.80 (7.00; 2.18) | 0.18–0.70 (0.38; 0.11) | 18.02–19.94 (19.64; 0.52) | 18.10–19.06 (18.61; 0.13) |

| branch | 5.50–56.31 (41.55; 16.94) | 86.50–89.74 (89.69; 0.83) | 9.63–13.27 (9.95; 1.07) | 0.28–2.72 (1.04; 0.54) | 19.50–21.04 (19.93; 0.31) | 18.40–18.64 (18.54; 0.08) | |

| foliage | 43.10–60.20 (51.65; 8.55) | - | - | 2.90–7.50 (4.80; 0.89) | 19.75–21.98 (21.11; 0.56) | 18.50–19.77 (19.72; 0.25) | |

| bark | 6.24–50.00 (41.63; 14.59) | 78.50–80.60 (80.10; 0.70) | 17.80–19.40 (18.50; 0.53) | 1.14–12.70 (2.07; 1.08) | 20.20–25.09 (21.87; 1.59) | 18.67–22.75 (22.26; 1.15) | |

| root | - | - | - | - | - | 18.50–18.59 (18.55; 0.04) | |

| Fagus spp. | wood | 6.10–57.18 (10.07; 15.81) | 74.00–85.70 (75.60; 4.00) | 13.90–24.80 (24.50; 2.78) | 0.17–0.79 (0.59; 0.18) | 18.30–20.01 (19.23; 0.32) | 17.00–18.60 (17.67; 0.44) |

| branch | 41.17 | 80.53–82.90 (81.71; 1.19) | 18.46–26.50 (22.48; 4.02) | 1.06–1.93 (1.85; 0.29) | 18.80–19.64 (19.61; 0.28) | 17.51–18.00 (17.76; 0.25) | |

| twig | 61.23 | 75.67 | 18.83 | 5.18–5.50 (5.34; 0.16) | 19.03–19.42 (19.23; 0.20) | - | |

| foliage | 55.00–65.81 (58.51; 3.60) | - | - | 2.69–8.65 (5.96; 1.86) | 18.60–22.80 (20.76; 1.21) | 19.00–19.20 (19.10; 0.10) | |

| bark | 1.30–68.45 (43.13; 22.61) | 64.10–73.70 (73.60; 3.20) | 17.40–29.50 (18.50; 4.03) | 2.58–12.00 (5.00 2.11) | 18.39–21.96 (19.52; 0.89) | 16.70–18.28 (16.92; 0.53) | |

| fruit husk | 9.77 | - | - | 4.95 | 19.02 | 17.79 | |

| fruit | - | - | - | - | 23.08 | - | |

| Prunus spp. | wood | - | 86.40 | 13.10 | 0.50 | 19.11–19.95 (19.53; 0.42) | 17.69 |

| twig | - | - | - | - | 20.37 | - | |

| branch | - | - | - | - | 20.26 | - | |

| foliage | - | - | - | - | 21.90 | - | |

| bark | - | 72.80 | 22.40 | 4.90 | 18.07 | 19.36–20.71 (20.04; 0.68) | |

| Quercus spp. | wood | 4.92–58.56 (8.00; 8.82) | 78.10–90.55 (87.67; 3.60) | 6.75–21.40 (12.63; 3.78) | 0.20–2.40 (0.51; 0.52) | 18.70–20.05 (19.63; 0.37) | 17.00–18.30 (17.51; 0.27) |

| twig | 56.09 | 77.46 | 18.40 | 4.14–6.05 (5.10; 0.96) | 18.92–20.17 (19.30; 0.42) | - | |

| branch | 8.20–49.50 (36.41; 10.34) | 78.40–82.70 (80.82; 1.33) | 16.18–17.43 (16.34; 0.49) | 0.75–4.20 (2.26; 0.88) | 17.72–20.87 (19.24; 0.43) | 17.10–18.25 (17.68; 0.57) | |

| foliage | 9.10–53.72 (26.69; 18.86) | 72.00 | 24.19 | 3.50–11.66 (7.14; 2.44) | 17.09–21.28 (18.49; 0.95) | 15.85–19.23 (17.31; 0.85) | |

| bark | 5.60–62.28 (10.50; 10.90) | 77.20–81.80 (78.30; 1.55) | 16.10–20.50 (19.43; 1.47) | 0.30–13.50 (3.70; 3.38) | 16.50–20.70 (18.93; 0.96) | 15.60–18.29 (16.29; 0.90) | |

| fruit | 8.92–13.26 (11.90; 1.45) | 74.00–75.10 (74.55; 0.55) | 22.23–22.80 (22.52; 0.29) | 2.60–3.20 (2.62; 0.20) | 16.17–19.07 (17.37; 0.97) | 17.83 | |

| Carpinus spp. | wood | 6.50–51.83 (13.09; 16.38) | 72.58–78.14 (75.36; 2.78) | 12.63–17.39 (15.01; 2.38) | 0.44–1.80 (0.71; 0.39) | 19.06–20.61 (19.22; 0.44) | 16.40–17.50 (17.20; 0.36) |

| twig | 53.21–53.22 (53.22; 0.00) | - | - | 3.28–3.65 (3.47; 0.19) | 18.86–19.11 (18.99; 0.13) | - | |

| branch | - | - | - | - | 19.31 | - | |

| foliage | 38.70–49.06 (48.14; 3.45) | - | - | 4.32–13.10 (4.58; 2.93) | 16.28–18.95 (18.92; 0.89) | 15.27 | |

| bark | 55.04–56.39 (55.72; 0.68) | - | - | 3.87–5.10 (4.09–0.41) | 17.64–19.84 (19.56; 0.68) | 15.89 | |

| Fraxinus spp. | wood | 5.81–10.83 (7.60; 1.46) | 84.90–90.00 (87.84; 1.70) | 9.50–14.70 (10.46; 1.73) | 0.07–1.70 (0.53; 0.27) | 18.84–20.01 (19.20; 0.34) | 16.24–18.03 (17.80; 0.60) |

| twig | - | - | - | - | 20.17 | - | |

| branch | - | - | - | 3.18 | 19.38–20.33 (19.86; 0.48) | - | |

| foliage | 43.80 | - | - | 8.07–11.90 (9.99; 1.91) | 16.51–21.43 (17.88; 1.91) | 15.53 | |

| bark | - | 74.80–85.60 (80.20; 5.40) | 5.30–15.90 (10.60; 5.30) | 5.17–9.30 (8.74; 1.21) | 17.86–19.33 (18.30; 0.41) | 16.66 | |

| Acer spp. | wood | 6.80–55.00 (6.95; 12.08) | 85.10–86.20 (85.65; 0.55) | 13.30–13.90 (13.60; 0.30) | 0.30–1.00 (0.44; 0.17) | 18.60–20.49 (19.57; 0.50) | 17.95–18.62 (18.29; 0.34) |

| twig | - | - | - | - | 19.97–20.25 (20.11; 0.14) | - | |

| branch | - | - | - | - | 19.46–20.43 (19.93; 0.33) | - | |

| foliage | 36.80–55.00 (37.90; 6.07) | - | - | 12.40–19.40 (12.80; 2.33) | 16.05–21.05 (17.51; 1.60) | 13.48–19.07 (15.75; 1.80) | |

| bark | 55.00 | 74.00–76.60 (75.30; 1.30) | 15.60–19.40 (17.50; 1.90) | 4.00–10.40 (5.00; 2.13) | 17.14–19.74 (18.37; 0.66) | 15.94–16.93 (16.44; 0.50) | |

| Tilia spp. | wood | 6.70 | - | - | 0.53–1.00 (0.76; 0.24) | - | - |

| foliage | 37.60 | - | - | 11.80–18.90 (12.50; 2.37) | 17.31–17.40 (17.35; 0.04) | 14.21–19.44 (16.82; 2.62) | |

| Alnus spp. | wood | 4.50–50.00 (7.00; 11.53) | 85.70–87.55 (86.10; 0.62) | 10.87–13.90 (13.50; 1.01) | 0.30–1.30 (0.48; 0.21) | 19.62–20.44 (19.95; 0.21) | 18.45–19.14 (18.89; 0.15) |

| foliage | - | - | - | 4.80–5.40 (5.10; 0.30) | - | 19.78–20.57 (20.54; 0.26) | |

| bark | - | 71.30–74.00 (72.65; 1.35) | 23.40–25.50 (24.45; 1.05) | 1.95–4.60 (2.90; 0.56) | 21.73–22.27 (21.97; 0.18) | 20.69–21.57 (21.44; 0.32) | |

| Robinia spp. | wood | 7.00 | 86.19 | 12.80 | 0.33–2.50 (0.45; 0.56) | 18.31–19.99 (18.54; 0.56) | 15.59–18.50 (17.05; 1.46) |

| foliage | - | - | - | 4.90 | - | - | |

| bark | - | - | - | 6.22 | - | - | |

| Populus spp. | wood | 4.80–50.64 (6.79; 11.15) | 73.80–92.86 (86.00; 4.09) | 6.59–25.00 (12.60; 3.25) | 0.32–1.80 (0.59; 0.29) | 18.50–20.27 (19.68; 0.48) | 17.49–18.89 (18.67; 0.26) |

| branch | 8.37–42.34 (8.40; 11.32) | 82.00–85.20 (83.60; 1.60) | 14.46–15.80 (15.13; 0.67) | 0.30–4.00 (1.75; 0.84) | 18.41–21.12 (19.50; 0.70) | 17.90–18.81 (18.36; 0.46) | |