Abstract

This article aims to describe the current state of research on plastic waste management as a circular economy practice at the end of the supply chain. The methodological strategy chosen was a systematic literature review. The articles selected from the Web of Science and Scopus databases were screened, and the research corpus consisted of 201 articles published in journals between 2014 and 2021. The results present 13 study categories, showing topics such as pyrolysis, business models, Industry 4.0, and energy generation. The insertion of Industry 4.0 technologies is still in its initial stages, comprising mainly the generation of inputs to reuse waste for 3D printers’ materials. Regarding energy generation, the insertion of processes such as pyrolysis for fuel generation stands out. The proposed discussion in this article suggests a circular ecosystem in which wastes follow a reuse flow according to their properties; incineration can be an option depending on the stage and benefits generated from the removal of plastic waste from the ecosystem. The highlighted issue is the scalability of the developed processes in the research, which is only possible if the state, universities, and civil society integrate efforts in the construction of a circular ecosystem infrastructure for waste management.

1. Introduction

Concerning generated waste, it is estimated that each person produces an average of 1.3 kg of solid waste per day. Although this situation in itself is alarming the impact may worsen, because the projection is that after the year 2100 waste generation will reach its peak, where 11 million tons of waste could be produced per day [1]. Corroborating the above ideas, ECYCLE [2] indicates that a small town with only ten thousand inhabitants could produce about ten tons of waste daily. In this context, it is necessary to create solutions to mitigate the impacts arising from a linear flow of waste that causes new virgin materials to be inserted for the generation of products [3,4].

This being the case, the opportunity arises to discuss the adoption of a circular economy perspective [5,6], this one being aimed at processes that link industrial ecology to waste management [7,8]. Industrial ecology is used to analyze stages of the production processes of goods and services from the point of view of nature, trying to mimic a natural system to conserve the reuse of resources [7]. In a circular economy, the search for the well-being of individuals and the preservation of the planet’s resources become relevant factors, especially when discussing production and consumption systems based on technical and biological cycles [6,9]. Silva et al. [10] point out that production and consumption routines in a circular economy should be thought about from the perspective of an economic system analogous to biological ecosystems.

Therefore, the linear economy model of taking, making, and discarding must be replaced by the circular economy model, which is restorative and regenerative. The basic principles of a circular economy include optimizing resources and minimizing system risks [11]. A circular economy promotes reuse and encourages industrial symbiosis, transforming the by-products of an industry or waste arising from consumption into raw material that will be reinserted into the supply chain [4]. Thus, an industry cannot be seen as a separate system, as the integration between the biological and technical systems causes decisions about production and consumption to take into account inputs and outputs in a circular and integrated manner [12,13]. The objective of a circular economy is to ensure that materials remain for as long as possible in the production and consumption processes, because even in more efficient supply chain systems there will always be waste generation, which must be eliminated or mitigated by symbiotic relationships with other chain actors [10,14].

Waste draws attention to how plastic is perceived as a great villain [15]. Around the world, barriers are created for the use of plastic, including in bags, straws, etc. The global production of plastics reached 322 million tons in 2015, and in a report by the European Commission [16] it was estimated that this number will double in the next 20 years. In the EU, the plastics sector generated a turnover of EUR 340 billion in 2015. On average, 25.8 million tons of waste are produced in Europe, of which only less than 30% is collected for recycling [16]. Calero et al. [17] highlight that, in the world, plastic waste represents an important fraction of municipal solid waste, with 29.1 million tons of plastics being introduced into the municipal waste stream in the EU annually, of which approximately 25% is still deposited in landfills.

Questions about the reintroduction of plastic into the supply chain are often based on an economic view related to easy and cheap access to virgin materials [18]. However, we realize that this perspective is sometimes short-sighted, as it does not take into account externalities that are contemplated in a circular economy perspective. In the situation of combating the COVID-19 pandemic, the benefits of plastic properties were made apparent, as pointed out by De Sousa [19]. We can say that properties such as sealability, ease of cleaning, and transport are beneficial in daily routines and adverse situations such as COVID-19. Thus, the discussion cannot be conducted in a Manichean way about the life span of plastic waste, but instead towards what we can do to responsibly reinsert it into the same supply chain or other ones. A Manichean discussion is based on a dualistic vision of good and evil, which does not take into account the inherent complexity of reality in the management of plastic waste.

Despite this perspective there are actions aimed at banning plastics, as can be seen in a message from the World Economic Forum [20], which highlights that 170 countries have committed to significantly reduce the use of plastics by 2030. The problem here is not reducing plastic but instead dealing with its life cycle. It should be stressed that because plastic materials are versatile and light, they are widely used in the packaging, construction, automotive, and food industries, among others. In Europe, according to PlasticsEurope [21], plastics production reached nearly 62 Mt in 2018, with plastic packaging being by far the largest plastics end-use market in Europe, with a 40% share. Additionally, according to PlasticsEurope [21], only a third of post-consumer plastic waste in Europe is collected for recycling.

As highlighted by Calero et al. [17], plastic waste represents an important fraction of urban solid waste in most developed countries in the world. The authors indicate that 29.1 million tons of plastics are introduced annually into the EU municipal waste stream. Lameh et al. [22] highlight that the production of recycled plastic is not economically competitive yet. This situation is different from other waste, such as aluminum, which demonstrates a positive accounting based on economic values related to the waste transaction. In this sense, advances in dealing with plastic waste are often not particularly perceived as beneficial, which is the opposite to actions by public and private actors to ban it, which are popularly attractive.

Although the above situation is not an essential condition for conducting research, it ends up influencing in some way the incentives of the private sector and the conduct of public policies. Calero et al. [17] point out three possible actions to support the recycled plastics market: (i) set taxes on the use of virgin plastics; (ii) introduce campaigns on the environmental benefits of using recycled plastics; and (iii) encourage the production of recycled plastics. Another action we advocate for is to think about the creation of a symbiotic economic system based on the assumptions of a circular economy. Therefore, it is necessary to analyze and develop a network of activities that generate inputs and outputs that are aware of their collaboration with the entire supply chain, in addition to clearly including public managers, researchers, and consumers [6,23,24].

Based on what has been presented, this research aims to describe how the management of plastic waste is presented in research that contemplates a circular economy at the end of the supply chain. The methodological strategy chosen to achieve this goal and answer the research question was a systematic literature review (SLR). The justification for this choice is given by the role of an SLR in helping to map and assess a specific intellectual structure to develop a body of knowledge [25,26]. An SLR is a methodological procedure that uses the literature as its main data source. This article contributes to the understanding in line with the knowledge presented by De Sousa [27].

2. Materials and Methods

The research presented here adopted an SLR as the method with which to understand the convergence of two relevant themes. The first theme is related to the management of plastic waste and the second one is a circular economy. An SLR differs from traditional narrative reviews in that it adopts a systematized scientific process that is replicable and transparent [25]. In this sense, its use is justified by minimizing the bias in the construction of a theoretical corpus and enabling an audit trail of the decisions and procedures applied [28]. An SLR also differs from bibliometric studies in its more qualitative bias, as content analysis procedures are applied to categorize the research corpus based on the critical and reflective reading [25].

The realization of this SLR followed the phases of the procedure prescribed by Pollock and Berge [26]: clarify research goals and objectives; seek relevant research; collect data; assess the quality of studies; synthesize the evidence; and interpret the findings. The phases and activities presented here are intended to ensure rigor and robustness in this type of research and guarantee its reliability. The first phase was determined by the question that guides this research: “How is plastic waste management presented in research that contemplate the circular economy at the end of the supply chain?” Thus, the Web of Science and Scopus databases were used as the research sources. The bases adopted are justified by incorporating the main journals, authors, and contents in the areas of administration, engineering, computer science, and the environment, among others relevant to the field of study of this research.

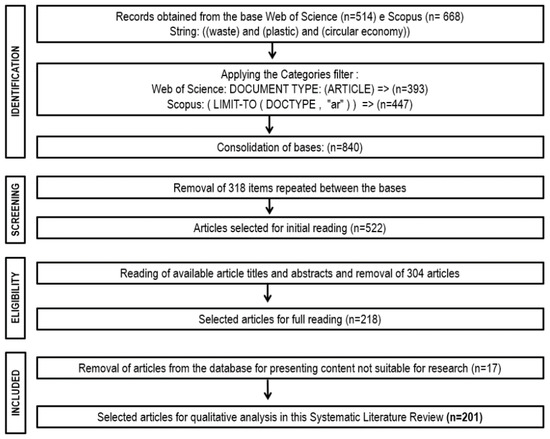

The string used to perform the searches was ((waste) AND (plastic) AND (circular AND economy)). The survey was carried out on 15 May 2021. The use of the Boolean operator “AND” allowed for control in the construction of the research base. Boolean operators were applied whilst taking into account the intersection of the research areas studied. It is noteworthy that no temporal filter was applied to make it possible to map the entire production on the themes studied. The application of the aforementioned search string brought results that underwent analysis and screening, as shown in Figure 1. In this phase, we also followed the prescriptions of Pollock and Berge [26], which determine a four-step flow for the construction of the analysis corpus.

Figure 1.

Search results in data sources. Source: adapted from Pollock and Berge [26].

Identification was the first step where the search string was defined. The second step was the screening of the results, which aims to delimit the base of articles corresponding to the research proposal. In the third step the eligibility criteria were applied, where the base was evaluated according to the inclusion and exclusion criteria. Finally, the corpus of analysis was constituted, thus composing the sample base of articles. The filter that was applied to both databases defined the inclusion only of articles published in academic journals, excluding articles presented in conferences or books, among other mediums, from the database.

The inclusion criteria applied were: (i) dealing with plastic waste management in the context of a circular economy, which comprises recycling, reusing, remanufacturing, and reducing; (ii) dealing with the management of plastic waste at the end of the supply chain; and (iii) dealing with models and techniques that allow the reusing of waste for reinsertion through recycling, reduction, remanufacturing, and reuse. Following these criteria, some examples of articles that were removed from the base were articles that dealt with production processes to eliminate waste in the use of raw materials for production at the beginning of the chain; articles that dealt with legal aspects or norms only in a descriptive way; and articles that did not deal with plastic waste as a focus of study, but with waste in a generic way.

After the constitution of the database, the selected articles were treated with the aid of electronic spreadsheets in Microsoft Excel software. This software made it possible to perform data analysis and present the results from the combination of quantitative information by frequency analysis, as well as qualitative information by categorizing the content of articles. This phase of the research also allowed us to present a relevant descriptive analysis of the study carried out.

The last phase of this research was an analysis via the in-depth reading of the corpus, consisting of 201 articles. A careful reading of the articles allowed for the categorization of content, which enabled a grouping of findings and the comparison of categories. The activities applied in this last phase are in line with the prescriptions of Pollock and Berge [26] in phases to synthesize the evidence and interpret the findings. Although some quantitative treatments have been applied, in this research we prioritized the qualitative analysis of the articles to constitute a matrix that could represent the findings of this study.

3. Results and Discussion

This section presents the results of this SLR after carrying out the collection and analysis processes. Initially, the mapping of the articles that constituted the research corpus is presented. Next, the categories highlighted after an in-depth analysis of the contents of the articles are presented.

3.1. Mapping of Articles

The articles selected in the Web of Science and Scopus databases were screened, and the research corpus consisted of 201 articles (Table 1). The articles that underwent an in-depth analysis allowed us to understand how studies on plastic waste management incorporate issues related to a circular economy at the end of the supply chain.

Table 1.

Temporal analysis of journals and articles.

The 201 articles analyzed are temporally located between 2014 and 2021, as shown in Table 1. We emphasize that the database consisted of 99 journals, and, for presentation purposes, we included in Table 1 only the journals with three or more articles published on the subject. For the purpose of counting the articles per year, we inform that the last two lines represent the sum of taking into account the 99 journals searched. A relevant aspect is that no time filter was applied, demonstrating that the circular economy theme applied to plastic waste management is still incipient but has shown significant growth.

Important evidence in the data analysis is that after China officially banned plastic waste imports in January 2018 [29] the number of articles published increased significantly. We can say that interest in the subject is directly in line with changes in the global scenario, including EU policies on waste management and circular economies. Actions to promote ecodesign and eliminate landfills are evident in publications on public policies and private initiative actions in the EU.

Table 1 also demonstrates that the four journals with the most published articles, Waste Management (24 articles), Resources, Conservation and Recycling (18 articles), Journal of Cleaner Production (17 articles), and Sustainability (15 articles), together represent 37% of the research corpus. Furthermore, it is possible to observe that the journals that constituted this corpus were distributed over several fields of study, such as management, engineering, chemistry, and technology, among others. This result allows us to infer that the themes studied here can be considered interdisciplinary, because even after analyzing the intersection of the two themes in the articles the studies transit through several areas. In this sense, it is possible to state that the complexity of promoting the circular economy in plastic waste management requires integrating different knowledge and social actors.

The methodological procedures identified in the analyzed articles are presented in Table 2. The most evident method was laboratory experiments, followed by case studies, theoretical articles, and statistical modeling. A relevant aspect in the analysis of the articles is the delimitation of studies in experiments to understand, for example, the addition of material in a process or changes in steps in a procedure, among other small-scale controlled activities. Even when the articles are about case studies, the analysis of a specific situation predominates, such as the analysis of the product’s life cycle, which is present in 29 of the 48 articles corresponding to this category.

Table 2.

Analysis of applied methods.

The methodological procedures used and the results found in the articles point to a considerable gap in the scalability of the application of the knowledge generated from the research. Studies conducted in laboratory environments often had many restrictions on their practical application to scale. We point out that this is one of the points that should be strongly explored by companies and governments, as conducting, through fostering studies, the advancement of the scalability of the solutions generated could contribute to improving society in general.

The continuity of research is another relevant aspect in the analysis of the selected articles. Based on the articles, most authors contribute only one or two articles. However, despite the pattern detected and the limitations of the analyzed database, some names are highlighted, such as Thomas Fruergaard Astrup (six articles), Joshua M. Pearce (five articles), Roland Pomberg (five articles), Giorgia Faraca (five articles), and Renato Sarc (four articles). This leads us to consider that, in the 201 articles analyzed, these authors are important nodes for plastic waste management studies. Therefore, it can be inferred that perhaps there is a lack of a greater incentive on the part of public and private agents for research to continue.

On the other hand, it can also be said that in many cases the authors were involved conveniently in the research, which the researcher had no intention of continuing from the beginning. This situation concerning methods and researchers is worrying given the complexity involved in waste management in general. Regardless of the contributions that a survey can make to the practical and academic community, a survey is often just a building block in an ocean of activities and processes. Each advance or revision counts, as long as they are treated continuously. As already pointed out, the case here is to think of an ecosystem that can promote the convergence of knowledge that will contribute to the scalability of solutions.

After mapping the metadata of the articles that constituted the research corpus, the researchers proceeded to an in-depth analysis of the content of each article. The reading and categorization of the contents led to classifying the articles into 13 categories, as shown in Table 3.

Table 3.

Study categories of articles.

The 13 categories found comprise an abstraction obtained from the reading of the articles. It is important to clarify here that the process of the initial analysis of the articles was individual; then, for the selection of the categories, the researchers of this research were inquired. The categorization process was carried out through the discussion and establishment of a consensus on which of the constituted categories each of the articles adhered to the most. In the next section, the categories will be discussed in order to explain the findings of this research.

3.2. Analysis and Discussion of the Categories Found

Based on the reading of the articles, the researchers sought to understand the focus that each one of them presented. It should be noted that the same article can be in more than one category depending on the way the research was presented. The first category, by the number of articles published, was the one dealing with mechanical processes (37) with which to recycle, reuse, remanufacture, and reduce plastic waste at the end of the supply chain.

Articles related to mechanical processes discussed, among other topics: wet mechanical processing [30,31,32]; the identification and classification of waste in mechanical processes [33,34]; the recirculation of post-consumer and industrial bio-based plastic waste through mechanical recycling [4]; the technical–economic evaluation of the mechanical recycling of post-consumer plastic packaging waste [35,36,37]; and the analysis of material properties during and after the mechanical recycling process [38,39]. A relevant aspect in the analysis of the articles is that although we are developing other processes, mechanical processes are still, in many cases, the most adequate solution or complementary to other initiatives, such as in “Advancing Plastic Recycling by Wet-Mechanical Processing of Mixed Waste Fractions” by Schwabl, Bauer, and Lehner [30]. Here, we can reinforce the need to gain scale for new opportunities to incorporate waste circularly.

Regarding the category with the second most amount of articles, assessment and prediction models, there is the search for creating statistical models that help in the projection of landfill capacity [40]; the projection of volumes and waste flows in the future [41,42,43,44]; and product life cycle assessments [45,46], among others. Articles in this category present contributions mainly to the flow, saturation, and quality of materials, as well as their properties. Additionally, it is worth noting that the articles in this category are based on case studies, theoretical models, or laboratory experiments.

The third category is pyrolysis/thermal cracking, which comprises 30 articles. These articles deal with the comparison of pyrolysis with other processes related, among other aspects, with physicochemical properties [8,47,48]; simulations of the performance of solar thermal energy for applications in pyrolysis [22]; and the production of fuel, bitumen, solvents, and polystyrene [49,50,51,52]. In this category, technical and cost-related issues still make scalability unfeasible, which leads to the aforementioned point of the need to encourage research to allow for process improvement and applicability due to the wide range of opportunities.

Additionally, with 30 articles, the biodegradable plastics category features articles that deal with the separation of bioplastics from other waste [4], processing and composting [53,54,55], the benefits of bioplastics [56], and the reuse of bioplastics [57,58]. The main issues related to bioplastics are still in their separation from other materials, a topic common to other categories, in addition to their reuse and not simply composting.

The upcycling/downcycling category presented 24 articles, and according to the researchers’ analysis it is difficult to differentiate between the two types of cycles due to a simple economic evaluation [59,60]. A relevant aspect in discussions about value is the scarcity or not of a good, its value and utility, in addition to the ability to mitigate negative externalities arising not only from the first production cycle but from new cycles using the same material, which can be evaluated as upcycling. This is a controversial issue, as some articles treat the use of a certain amount of PET bottles to build houses as upcycling [60,61]. However, the effort and benefits generated can be questioned. Articles dealt with the reuse of waste in the composition of other materials [38,62,63] and graphene nanosheets [64], among other applications.

In the addition of materials for depolymerization category 21 articles were found. In this category, the articles dealt with the mixture of different materials or catalysts for reprocessing in a new production cycle [65,66,67]. The articles show studied materials’ properties, recyclability rates, and post-treatment application opportunities, among other aspects.

In the extending producer/consumer responsibility category, 19 studies were found. This category discusses the extent of post-production and post-consumption responsibilities, which aim to stimulate a circular economy. A positive aspect in this regard is that recommendations not only occur through negative reinforcement to take responsibility through legislation and fees [68], but also with positive reinforcement, such as credibility gains, emotional rewards, and legitimacy [18,59,69].

The ecodesign category had 16 articles, being treated as a way to reduce and reuse waste in post-production and post-consumption [36,70], technical issues [71], and learning about ecodesign [72,73] as well as packaging design [74,75,76].

In the plastic electronic waste category, 11 articles were found that dealt with the complexity of separating plastics from other materials and contaminants, such as flame retardants and catalysts [77,78], using this type of waste for the manufacturing of other materials, such as plastic wood [79], recycling feasibility studies [80], and the transformation of waste into energy by incineration [81]. This category draws attention not for the number of articles but for the research opportunities, given the volume of this type of waste in a digitized society.

In the Industry 4.0 category 11 articles were found in the research corpus. A relevant aspect is that this category has become a largely researched topic in several areas. Researchers try to understand the changes caused by topics such as big data, cloud computing, artificial intelligence, and the Internet of Things, among others, in societies in constant transformation. Despite this, nine out of the eleven articles here specifically deal with the recycling of plastic waste to transform it into an input for 3D printers [53,82,83]. Regarding the use of plastic waste as an input for 3D printers, these articles were considered as adhering to the Industry 4.0 category because somehow this process of materials reintroduction influences the equipment and production of these printers. The other two articles deal with a blockchain system with multi-sensors and artificial intelligence [84] in addition to a plastic waste processing technique based on a combination of a logarithmic sorting process and color plus high-resolution near-infrared (NIR) sensors [85]. Van Engelshoven et al. [85] describe logarithmic sorting as a developed mathematical analysis that is applied to ease the effort in sorting materials, in principle, to be logarithmic rather than linear.

In the construction category nine articles were found. The articles deal with processing plastic waste to transform it into bituminous pavement [86,87] and concrete composites [88,89]. The articles studied here demonstrate the great potential for gains by inserting plastic waste to mitigate environmental impacts and the quality of the products generated.

In the business model category, seven articles were found that dealt with recycling incentives for consumers and producers [90,91,92,93], transactions between different public and private actors [94], and theoretical studies on barriers and opportunities [95]. The business model category presents several opportunities, but it is still very incipient. An interesting aspect is a comparison between developed and developing countries, as the interest in financial incentives in the former cause less impact than business models geared towards awareness.

In the energy generation category, seven articles were found dealing with how to transform waste into energy through incineration [17,81], as well as comparing the gains of reusing waste in a new production cycle or incinerating it [56,96]. The articles also deal with the insertion of processes such as pyrolysis for fuel generation [97,98].

4. Research Propositions and Opportunities

An important insight from the analyzed articles is that landfills and recycling centers must be rethought in their concepts. Collection, selection, and processing points should be understood as “Circular Economy Industrial Units”. Our understanding here is not only of a new nomenclature but of a concept that symbiotically determines a point of facilitation for the flow of waste in a circular fashion. In this way, various social actors from the public and private sectors, or even from the non-governmental sector, could synergistically think of a circular ecosystem where waste, after leaving the factories of products and their respective packaging, can be received, sorted, or even processed for a destination in another link of the chain.

A relevant aspect when thinking about this ecosystem is the evidence of many small companies participating in a circular waste chain. Institutions that collect and process waste often have a limited capacity to interact with large producer organizations, or even participate more actively with public agents or consumers. In this context integrating agents are needed, which could be public actors, such as local politicians, or consortia of companies that could organically absorb the responsibility for managing or facilitating this ecosystem. At this point, we realize that the performance of many agents in this type of supply chain is often only through the commercial transaction of waste, which is the focus of business models based on the generation of some financial return [95].

The separation of materials is a great challenge, but it is also urgent to gain scale from the various ideas presented in these studies. Thus, producers, consumers, and other agents, such as public managers and recyclers, can better understand their roles and responsibilities by thinking symbiotically about a circular ecosystem. As Dijkstra, van Beukering, and Brouwer [95], as well as Ma, Park, and Moultrie [69], pointed out, fragmentation by actions related to laws and taxes does not bring as many benefits as engagement and awareness.

In this sense, actions to build a sustainable ecosystem must be thought of taking into account the externalities arising from the non-reuse of waste. The solutions should not only be aesthetic, such as using PET bottles to manufacture a house, which often do not consider scalability. Assessing the value generated from reuse is not a simple task, as can be seen in predictive and evaluative models [41,42,43,44], as not only should the monetary value of the products created after recycling be considered; the costs of inserting virgin inputs into the same chain should also be considered [18,45,46].

Regarding bioplastics, the discussion must be deepened so as not to fall into the trap of superficial assessments. We understand that the contribution of plastics to a circular economy is precisely in their properties, which can be better explored when considered within an ecosystem. Some examples are sewage treatment or the reuse of plastic waste from electronics in power generation systems, as presented in the studies by Calero et al. [17] and Butturi et al. [81]. Composting is still relevant when changing processes or interrupting supply flows. The same goes for incineration, as the volume of waste and the diversity of materials makes any fragmented view generate benefits in a more limited perspective but much more harm when compared to the environmental macrosystem.

The scalability problem raised can also be understood as a lack of interest by public and private agents. In this sense, the insertion and awareness of consumers in the ecosystem is inevitable [18,59,69]. The creation of fees or purposeful legislation is not enough [18,45], as the institutionalization of behaviors must be understood as something long-term. Although this reasoning is not new, it is often seen as a demonization of plastic without necessarily discussing its properties and opportunities. An example of this aspect can be seen when reading the articles, as a large part of them builds an argumentative line mimicked from information about plastic waste in the oceans. This is a discussion that needs to be further developed and consider the specifics of each study. A complex and multifaceted topic such as plastic waste and a circular economy cannot continue with a mimicked isomorphic perspective that becomes common sense.

5. Final Remarks

At the end of this research, it is possible to say that the categories raised can contribute to a better understanding of what is being researched in plastic waste management at the end of the supply chain. As pointed out, topics such as pyrolysis, business models, and Industry 4.0 are still incipient, especially the latter two, which apparently depend less on technical knowledge and more difficult-to-access equipment than the former. It is noted that the insertion of the theme Industry 4.0 into waste management is an opportunity both from a research point of view, as well as contributions to society in general. The use of technologies such as cloud computing, artificial intelligence, and the Internet of things could bring significant benefits in the operationalization, forecasting, and control of waste flows. Another option is to use blockchains in new business models to implement a circular economy in waste management.

We emphasize that the discussion about banning or reducing the use of plastic is often evident, but it is important to distinguish where only ideological discussions take place that distance themselves from rationality based on facts. The gains arising from advances in the circular insertion of plastics and their waste into the economy are many, in addition to the benefits of their properties, which in the case of food products could be incorporated into the vision of “packing as a service” [99]. In this sense, it is noted how much plastics helped in the pandemic situation caused by COVID-19, not only for their ability to seal and protect but also for their reuse. Another example that can be discussed is the use of recycled plastic in the mobility industry. We can try to understand better how much energy efficiency has been gained by inserting plastic into cars, trucks, buses, or even scooters.

A very important aspect evident in this research is the requirement to use interdisciplinarity to seek solutions for constructing of a circular plastic waste ecosystem. The integration of various areas of knowledge, such as political science, chemistry, and engineering, among others, helps to understand this ecosystem. Studies that deal only with a fragment of a complex system, such as this one, bring great contributions but do not allow its scalability. In this sense, we emphasize the importance of creating interdisciplinary centers fostered by public and private agents. As highlighted above, a certain lack of continuity in the surveys was evident, which may be the result of the lack of incentives or integration strategies.

Regarding the limitations of this study, we can say that the complexity of the theme makes the analysis of the research corpus a challenge. The knowledge required to understand the research corpus ranges from sociology and political science to understand social relations, the right to understand tax and legal aspects, as well as engineering and chemistry to understand waste processing. Despite this, if on the one hand this complexity becomes a limitation, on the other hand it presents opportunities for collaborative actions in an interdisciplinary way. Another limitation is the use of words for the search strategy, as the inclusion of words that also refer to studies that include plastic, such as PVC, PE, and PET, among others, could considerably increase the database and make the qualitative analysis of the articles unfeasible. We therefore suggest that new articles can delimit the search for one of the cited elements.

Author Contributions

Conceptualization, L.F.d.S., M.H.C.R., E.D.R.S.G. and D.d.M.C.; methodology, L.F.d.S., M.H.C.R., E.D.R.S.G. and D.d.M.C.; validation, L.F.d.S., M.H.C.R., E.D.R.S.G. and P.R.d.C.; formal analysis, L.F.d.S., M.H.C.R., E.D.R.S.G. and P.R.d.C.; investigation, L.F.d.S., M.H.C.R. and E.D.R.S.G.; resources, L.F.d.S., M.H.C.R., E.D.R.S.G. and P.R.d.C.; writing—original draft preparation, L.F.d.S., M.H.C.R. and D.d.M.C.; writing—review and editing, L.F.d.S., M.H.C.R., E.D.R.S.G. and P.R.d.C.; supervision, L.F.d.S., E.D.R.S.G. and D.d.M.C.; project administration, L.F.d.S., M.H.C.R., E.D.R.S.G. and P.R.d.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported in Brazil by CAPES—Coordination of Personnel Improvement for Higher Education: Code 001 and CNPQ—National Council for Scientific and Technological Development.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All raw data regarding the surveys in this paper can be found at https://docs.google.com/spreadsheets/d/1uoZ-VoWheM4t73hEQCjI7LkyNjtmOF5j/edit?usp=sharing&ouid=108544789876807678548&rtpof=true&sd=true (accessed on 24 January 2022).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Stromberg, J. When Will We Hit Peak Garbage? Smithsonian.com. 2013. Available online: http://www.smithsonianmag.com/science-nature/when-will-we-hit-peak-garbage-7074398/ (accessed on 9 September 2021).

- ECYCLE. O que São Resíduos Sólidos Urbanos (RSUs), Quais Seus Impactos e Como Amenizá-los? 2019. Available online: https://www.ecycle.com.br/component/content/article/63/3129-residuos-solidos-urbanos-conceito-definicao-lixo-atividades-domesti-cas-poluicao-contaminacao-perigosos-impactos-danos-ambiental-social-economico-cidades-coleta-seletiva-materiais-selecao-classificacao-destinaca-descarte-reciclagem-tratamento-gerenciamento.html (accessed on 9 September 2021).

- Appolloni, A.; D’Adamo, I.; Gastaldi, M.; Santibanez-Gonzalez, E.D.; Settembre-Blundo, D. Growing e-waste management risk awareness points toward new recycling scenarios: The view of the Big Four’s youngest consultants. Environ. Technol. Innov. 2021, 23, 101716. [Google Scholar] [CrossRef]

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. Recirculation potential of post-consumer/industrial bio-based plastics through mechanical recycling—Techno-economic sustainability criteria and indicators. Polym. Degrad. Stab. 2021, 183, 109217. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nat. News 2016, 531, 435. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ellen MacArthur Foundation Reuse: Rethinking Packaging. 2019. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/Reuse.pdf (accessed on 9 September 2021).

- Korhonen, J. Industrial ecology in the strategic sustainable development model: Strategic applications of industrial ecology. J. Clean. Prod. 2004, 12, 809–823. [Google Scholar] [CrossRef]

- Manahan, S.E. Industrial Ecology: Environmental Chemistry and Hazardous Waste; Routledge: Oxfordshire, UK, 2017. [Google Scholar]

- Jeswani, H.; Krüger, C.; Russ, M.; Horlacher, M.; Antony, F.; Hann, S.; Azapagic, A. Life cycle environmental impacts of chemical recycling via pyrolysis of mixed plastic waste in comparison with mechanical recycling and energy recovery. Sci. Total Environ. 2021, 769, 144483. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.F.; Guevara, A.J.H.; Gonzalez, E.D.S.; Oliveira, P.S.G. Evolution toward environment sustainable behavior: Search for survival in the plastic industry in Brazil. Environ. Dev. Sustain. 2019, 21, 1291–1320. [Google Scholar] [CrossRef]

- Joachimiak-Lechman, K.; Garstecki, D.; Konopczyński, M.; Lewandowska, A. Implementation of Life Cycle Based Tools in the Circular Economy Context—Case Study of Plastic Waste. Sustainability 2020, 12, 9938. [Google Scholar] [CrossRef]

- Erkman, S. Industrial ecology: A new perspective on the future of the industrial system. Swiss Med. Wkly. 2001, 131, 531–538. [Google Scholar]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Resnitzky, M.H.C.; Grander, G.; da Silva, L.F.; Gonzalez, E.D.R.S. Innovation projects of packaging recycling to a circular economy. Sustain. Oper. Comput. 2021, 2, 115–121. [Google Scholar] [CrossRef]

- Hake, S.; Damgir, R.; Awsarmal, P. Utilization of Plastic waste in Bitumen Mixes for Flexible Pavement. Transp. Res. Procedia 2020, 48, 3779–3785. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. European Commission 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52018DC0028&from=PT (accessed on 22 January 2022).

- Calero, M.; Godoy, V.; Quesada, L.; Martín-Lara, M.Á. Green strategies for microplastics reduction. Curr. Opin. Green Sustain. Chem. 2021, 100442. [Google Scholar] [CrossRef]

- Bassi, S.A.; Boldrin, A.; Faraca, G.; Astrup, T.F. Extended producer responsibility: How to unlock the environmental and economic potential of plastic packaging waste? Resour. Conserv. Recycl. 2020, 162, 105030. [Google Scholar] [CrossRef]

- de Sousa, F.D.B. Pros and Cons of Plastic during the COVID-19 Pandemic. Recycling 2020, 5, 27. [Google Scholar] [CrossRef]

- World Economic Forum. As Canada Bans Bags and More, This is What’s Happening with Single-Use Plastics Around the World. 2020. Available online: https://www.weforum.org/agenda/2020/10/canada-bans-single-use-plastics/ (accessed on 9 September 2021).

- Plastics Europe. Plastics–The Facts 2019. An Analysis of European Plastics Production, Demand and Waste Data. 2019. Available online: https://www.plasticseurope.org/application/files/9715/7129/9584/FINAL_web_version_Plastics_the_facts2019_14102019.pdf (accessed on 9 September 2021).

- Lameh, M.; Abbas, A.; Azizi, F.; Zeaiter, J. A simulation-based analysis for the performance of thermal solar energy for pyrolysis applications. Int. J. Energy Res. 2021, 45, 15022–15035. [Google Scholar] [CrossRef]

- Trokanas, N.; Cecelja, F.; Raafat, T. Semantic approach for pre-assessment of environmental indicators in Industrial Symbiosis. J. Clean. Prod. 2015, 96, 349–361. [Google Scholar] [CrossRef] [Green Version]

- Conti, D.D.M.; Guevara, A.J.D.H.; Heinrichs, H.; Silva, L.F.; Quaresma, C.C.; Beté, T.D.S. Governança colaborativa para a transição da sustentabilidade nas cidades. URBE Rev. Bras. Gestão Urbana 2019, 13, 138–156. [Google Scholar] [CrossRef] [Green Version]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Pollock, A.; Berge, E. How to do a systematic review. Int. J. Stroke 2018, 13, 138–156. [Google Scholar] [CrossRef]

- de Sousa, F.D.B. Management of plastic waste: A bibliometric mapping and analysis. Waste Manag. Res. 2021, 0734242X21992422. [Google Scholar] [CrossRef]

- Cook, D.J.; Mulrow, C.D.; Haynes, R.B. Systematic Reviews: Synthesis of Best Evidence for Clinical Decisions. Ann. Intern. Med. 1997, 126, 376–380. [Google Scholar] [CrossRef]

- Ncube, L.; Ude, A.; Ogunmuyiwa, E.; Zulkifli, R.; Beas, I. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Schwabl, D.; Bauer, M.; Lehner, M. Advancing Plastic Recycling by Wet-Mechanical Processing of Mixed Waste Fractions. Processes 2021, 9, 493. [Google Scholar] [CrossRef]

- Selina, M.; Markus, B.; Daniel, S.; Renato, S. Wet-mechanical processing of a plastic-rich two-dimensional-fraction from mixed wastes for chemical recycling. Waste Manag. Res. 2021, 39, 731–743. [Google Scholar] [CrossRef] [PubMed]

- Kranzinger, L.; Pomberger, R.; Schwabl, D.; Flachberger, H.; Bauer, M.; Lehner, M.; Hofer, W. Output-oriented analysis of the wet mechanical processing of polyolefin-rich waste for feedstock recycling. Waste Manag. Res. 2018, 36, 445–453. [Google Scholar] [CrossRef]

- Woidasky, J.; Moesslein, J.; Wendler, P.; Kirchenbauer, D.; Wacker, D.; Gao, G.; Lang-Koetz, C. Identification and Sorting of Polymers in a Circular Economy Using Fluorescent Tracer Materials. Chem. Ing. Tech. 2020, 92, 441–451. [Google Scholar] [CrossRef] [Green Version]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in EU: Process efficiencies, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Cappucci, G.M.; Avolio, R.; Carfagna, C.; Cocca, M.; Gentile, G.; Scarpellini, S.; Ferrari, A.M. Environmental life cycle as-sessment of the recycling processes of waste plastics recovered by landfill mining. Waste Manag. 2020, 118, 68–78. [Google Scholar] [CrossRef]

- Möllnitz, S.; Feuchter, M.; Duretek, I.; Schmidt, G.; Pomberger, R.; Sarc, R. Processability of Different Polymer Fractions Re-covered from Mixed Wastes and Determination of Material Properties for Recycling. Polymers 2021, 13, 457. [Google Scholar] [CrossRef]

- Möllnitz, S.; Küppers, B.; Curtis, A.; Khodier, K.; Sarc, R. Influence of pre-screening on down-stream processing for the pro-duction of plastic enriched fractions for recycling from mixed commercial and municipal waste. Waste Manag. 2021, 119, 365–373. [Google Scholar] [CrossRef] [PubMed]

- Wielgosiński, G.; Czerwińska, J.; Szufa, S. Municipal Solid Waste Mass Balance as a Tool for Calculation of the Possibility of Implementing the Circular Economy Concept. Energies 2021, 14, 1811. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, C.; Li, F.; Liu, H.; Yang, J. Stocks and flows of polyvinyl chloride (PVC) in China: 1980–2050. Resour. Conserv. Recycl. 2019, 154, 104584. [Google Scholar] [CrossRef]

- Olatayo, K.I.; Mativenga, P.T.; Marnewick, A.L. Comprehensive evaluation of plastic flows and stocks in South Africa. Resour. Conserv. Recycl. 2021, 170, 105567. [Google Scholar] [CrossRef]

- Pincelli, I.P.; Júnior, A.B.D.C.; Matias, M.S.; Rutkowski, E.W. Post-consumer plastic packaging waste flow analysis for Brazil: The challenges moving towards a circular economy. Waste Manag. 2021, 126, 781–790. [Google Scholar] [CrossRef] [PubMed]

- Vingwe, E.; Towa, E.; Remmen, A. Danish Plastic Mass Flows Analysis. Sustainability 2020, 12, 9639. [Google Scholar] [CrossRef]

- Moretti, C.; Hamelin, L.; Jakobsen, L.G.; Junginger, M.H.; Steingrimsdottir, M.M.; Høibye, L.; Shen, L. Cradle-to-grave life cycle assessment of single-use cups made from PLA, PP and PET. Resour. Conserv. Recycl. 2021, 169, 105508. [Google Scholar] [CrossRef]

- Schwarz, A.E.; Ligthart, T.N.; Bizarro, D.G.; De Wild, P.; Vreugdenhil, B.; van Harmelen, T. Plastic recycling in a circular economy; determining environmental performance through an LCA matrix model approach. Waste Manag. 2021, 121, 331–342. [Google Scholar] [CrossRef]

- Antelava, A.; Jablonska, N.; Constantinou, A.; Manos, G.; Salaudeen, S.A.; Dutta, A.; Al-Salem, S.M. Energy Potential of Plastic Waste Valorization: A Short Comparative Assessment of Pyrolysis versus Gasification. Energy Fuels 2021, 35, 3558–3571. [Google Scholar] [CrossRef]

- Canopoli, L.; Fidalgo, B.; Coulon, F.; Wagland, S. Physico-chemical properties of excavated plastic from landfill mining and current recycling routes. Waste Manag. 2018, 76, 55–67. [Google Scholar] [CrossRef] [Green Version]

- Mangesh, V.; Tamizhdurai, P.; Krishnan, P.S.; Narayanan, S.; Umasankar, S.; Padmanabhan, S.; Shanthi, K. Green energy: Hydroprocessing waste polypropylene to produce transport fuel. J. Clean. Prod. 2020, 276, 124200. [Google Scholar] [CrossRef]

- Faussone, G.C. Transportation fuel from plastic: Two cases of study. Waste Manag. 2018, 73, 416–423. [Google Scholar] [CrossRef] [PubMed]

- Gracida-Alvarez, U.R.; Winjobi, O.; Sacramento-Rivero, J.C.; Shonnard, D.R. System Analyses of High-Value Chemicals and Fuels from a Waste High-Density Polyethylene Refinery. Part 1: Conceptual Design and Techno-Economic Assessment. ACS Sustain. Chem. Eng. 2019, 7, 18254–18266. [Google Scholar] [CrossRef]

- Joshi, C.A.; Seay, J.R. Total generation and combustion emissions of plastic derived fuels: A trash to tank approach. Environ. Prog. Sustain. Energy 2019, 39. [Google Scholar] [CrossRef]

- Román-Ramírez, L.A.; Powders, M.; McKeown, P.; Jones, M.D.; Wood, J. Ethyl lactate production from the catalytic depoly-merisation of post-consumer poly (lactic acid). J. Polym. Environ. 2020, 28, 2956–2964. [Google Scholar] [CrossRef]

- McKeown, P.; Kamran, M.; Davidson, M.G.; Jones, M.D.; Román-Ramírez, L.A.; Wood, J. Organocatalysis for versatile polymer degradation. Green Chem. 2020, 22, 3721–3726. [Google Scholar] [CrossRef]

- Kawashima, N.; Yagi, T.; Kojima, K. Pilot-Scale Composting Test of Polylactic Acid for Social Implementation. Sustainability 2021, 13, 1654. [Google Scholar] [CrossRef]

- Bucknall, D.G. Plastics as a materials system in a circular economy. Philos. Trans. R. Soc. A 2020, 378, 20190268. [Google Scholar] [CrossRef]

- Platnieks, O.; Barkane, A.; Ijudina, N.; Gaidukova, G.; Thakur, V.K.; Gaidukovs, S. Sustainable tetra pak recycled cellulose/Poly(Butylene succinate) based woody-like composites for a circular economy. J. Clean. Prod. 2020, 270, 122321. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Kulikowska, D.; Bernat, K. Effect of Bio-Based Products on Waste Management. Sustainability 2020, 12, 2088. [Google Scholar] [CrossRef] [Green Version]

- Lonca, G.; Lesage, P.; Majeau-Bettez, G.; Bernard, S.; Margni, M. Assessing scaling effects of circular economy strategies: A case study on plastic bottle closed-loop recycling in the USA PET market. Resour. Conserv. Recycl. 2020, 162, 105013. [Google Scholar] [CrossRef]

- Adefila, A.; Abuzeinab, A.; Whitehead, T.; Oyinlola, M. Bottle house: Utilising appreciative inquiry to develop a user acceptance model. Built Environ. Proj. Asset Manag. 2020, 10, 567–583. [Google Scholar] [CrossRef]

- Allam, Z.; Jones, D.S. Towards a Circular Economy: A Case Study of Waste Conversion into Housing Units in Cotonou, Benin. Urban Sci. 2018, 2, 118. [Google Scholar] [CrossRef] [Green Version]

- Tafreshi, S.N.M.; Omran, M.P.; Rahimi, M.; Dawson, A. Experimental investigation of the behavior of soil reinforced with waste plastic bottles under cyclic loads. Transp. Geotech. 2020, 26, 100455. [Google Scholar] [CrossRef]

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; García-Muñoz, R.A. Incorporation of recycled high-density polyethylene to polyethylene pipe grade resins to increase close-loop recycling and Underpin the circular economy. J. Clean. Prod. 2020, 276, 124081. [Google Scholar] [CrossRef]

- Karakoti, M.; Pandey, S.; Jangra, R.; Dhapola, P.S.; Singh, P.K.; Mahendia, S.; Abbas, A.; Sahoo, N.G. Waste plastics derived graphene nanosheets for supercapacitor application. Mater. Manuf. Process. 2020, 36, 171–177. [Google Scholar] [CrossRef]

- Tramis, O.; Garnier, C.; Yus, C.; Irusta, S.; Chabert, F. Enhancement of the fatigue life of recycled PP by incorporation of recycled opaque PET collected from household milk bottle wastes. Waste Manag. 2021, 125, 49–57. [Google Scholar] [CrossRef]

- Nunes, B.F.S.; Oliveira, M.C.; Fernandes, A.C. Dioxomolybdenum complex as an efficient and cheap catalyst for the reductive depolymerization of plastic waste into value-added compounds and fuels. Green Chem. 2020, 22, 2419–2425. [Google Scholar] [CrossRef]

- Mumladze, T.; Yousef, S.; Tatariants, M.; Kriūkienė, R.; Makarevicius, V.; Lukošiūtė, S.I.; Denafas, G. Sustainable approach to recycling of multilayer flexible packaging using switchable hydrophilicity solvents. Green Chem. 2018, 20, 3604–3618. [Google Scholar] [CrossRef]

- Shin, S.-K.; Um, N.; Kim, Y.-J.; Cho, N.-H.; Jeon, T.-W. New Policy Framework with Plastic Waste Control Plan for Effective Plastic Waste Management. Sustainability 2020, 12, 6049. [Google Scholar] [CrossRef]

- Ma, X.; Park, C.; Moultrie, J. Factors for eliminating plastic in packaging: The European FMCG experts’ view. J. Clean. Prod. 2020, 256, 120492. [Google Scholar] [CrossRef]

- Berwald, A.; Dimitrova, G.; Feenstra, T.; Onnekink, J.; Peters, H.; Vyncke, G.; Ragaert, K. Design for Circularity Guidelines for the EEE Sector. Sustainability 2021, 13, 3923. [Google Scholar] [CrossRef]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical emptiability of dairy product packaging and its environmental implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef] [PubMed]

- Radusin, T.; Nilsen, J.; Larsen, S.; Annfinsen, S.; Waag, C.; Eikeland, M.S.; Pettersen, M.K.; Fredriksen, S.B. Use of recycled materials as mid layer in three layered structures-new possibility in design for recycling. J. Clean. Prod. 2020, 259, 120876. [Google Scholar] [CrossRef]

- Gall, M.; Steinbichler, G.; Lang, R.W. Learnings about design from recycling by using post-consumer polypropylene as a core layer in a co-injection molded sandwich structure product. Mater. Des. 2021, 202, 109576. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Voigt, S.; Walter, D.; Fullana-I-Palmer, P. Improving the production chain with LCA and eco-design: Application to cosmetic packaging. Resour. Conserv. Recycl. 2019, 151, 104475. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Sustainability design of plastic packaging for the Circular Economy. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Foschi, E.; Zanni, S.; Bonoli, A. Combining Eco-Design and LCA as Decision-Making Process to Prevent Plastics in Packaging Application. Sustainability 2020, 12, 9738. [Google Scholar] [CrossRef]

- Shi, P.; Wan, Y.; Grandjean, A.; Lee, J.-M.; Tay, C.Y. Clarifying the in-situ cytotoxic potential of electronic waste plastics. Chemosphere 2020, 269, 128719. [Google Scholar] [CrossRef]

- Suponik, T.; Franke, D.; Nuckowski, P.; Matusiak, P.; Kowol, D.; Tora, B. Impact of Grinding of Printed Circuit Boards on the Efficiency of Metal Recovery by Means of Electrostatic Separation. Minerals 2021, 11, 281. [Google Scholar] [CrossRef]

- Sommerhuber, P.F.; Wang, T.; Krause, A. Wood–plastic composites as potential applications of recycled plastics of electronic waste and recycled particleboard. J. Clean. Prod. 2016, 121, 176–185. [Google Scholar] [CrossRef]

- Wagner, F.; Peeters, J.; De Keyzer, J.; Janssens, K.; Duflou, J.; Dewulf, W. Towards a more circular economy for WEEE plastics—Part B: Assessment of the technical feasibility of recycling strategies. Waste Manag. 2019, 96, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Butturi, M.A.; Marinelli, S.; Gamberini, R.; Rimini, B. Ecotoxicity of Plastics from Informal Waste Electric and Electronic Treatment and Recycling. Toxics 2020, 8, 99. [Google Scholar] [CrossRef]

- DePalma, K.; Walluk, M.; Murtaugh, A.; Hilton, J.; McConky, S.; Hilton, B. Assessment of 3D printing using fused deposition modeling and selective laser sintering for a circular economy. J. Clean. Prod. 2020, 264, 121567. [Google Scholar] [CrossRef]

- Garmulewicz, A.; Holweg, M.; Veldhuis, H.; Yang, A. Disruptive Technology as an Enabler of the Circular Economy: What Potential Does 3D Printing Hold? Calif. Manag. Rev. 2018, 60, 112–132. [Google Scholar] [CrossRef]

- Chidepatil, A.; Bindra, P.; Kulkarni, D.; Qazi, M.; Kshirsagar, M.; Sankaran, K. From trash to cash: How blockchain and multi-sensor-driven artificial intelligence can transform circular economy of plastic waste? Adm. Sci. 2020, 10, 23. [Google Scholar] [CrossRef] [Green Version]

- Van Engelshoven, Y.; Wen, P.; Bakker, M.; Balkenende, R.; Rem, P. An Innovative Route to Circular Rigid Plastics. Sustainability 2019, 11, 6284. [Google Scholar] [CrossRef] [Green Version]

- Celauro, C.; Teresi, R.; Graziano, F.; La Mantia, F.P.; Protopapa, A. Preliminary Evaluation of Plasmix Compound from Plastics Packaging Waste for Reuse in Bituminous Pavements. Sustainability 2021, 13, 2258. [Google Scholar] [CrossRef]

- Anwar, M.; Shah, S.; Alhazmi, H. Recycling and Utilization of Polymers for Road Construction Projects: An Application of the Circular Economy Concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Tahir, M.M. Towards Sustainable Concrete Composites through Waste Valorisation of Plastic Food Trays as Low-Cost Fibrous Materials. Sustainability 2021, 13, 2073. [Google Scholar] [CrossRef]

- Mondal, M.; Bose, B.; Bansal, P. Recycling waste thermoplastic for energy efficient construction materials: An experimental investigation. J. Environ. Manag. 2019, 240, 119–125. [Google Scholar] [CrossRef] [PubMed]

- Roche Cerasi, I.; Sánchez, F.V.; Gallardo, I.; Górriz, M.Á.; Torrijos, P.; Aliaga, C.; Franco, J. Household plastic waste habits and attitudes: A pilot study in the city of Valencia. Waste Manag. Res. 2021, 39, 679–689. [Google Scholar] [CrossRef] [PubMed]

- Šuškevičė, V.; Kruopienė, J. Improvement of Packaging Circularity through the Application of Reusable Beverage Cup Reuse Models at Outdoor Festivals and Events. Sustainability 2021, 13, 247. [Google Scholar] [CrossRef]

- Cottafava, D.; Riccardo, L.E.; Cristian, D.A. From flow to stock. new circular business models for integrated systems: A case study on reusable plastic cups. Procedia Environ. Sci. Eng. Manag. 2019, 6, 81–94. [Google Scholar]

- Horvath, B.; Mallinguh, E.; Fogarassy, C. Designing Business Solutions for Plastic Waste Management to Enhance Circular Transitions in Kenya. Sustainability 2018, 10, 1664. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Chen, W.-Q.; Jiang, D.; Zhang, C.; Ma, Z.; Ren, Y.; Shi, L. Evolution of the global polyethylene waste trade system. Ecosyst. Heal. Sustain. 2020, 6. [Google Scholar] [CrossRef] [Green Version]

- Dijkstra, H.; van Beukering, P.; Brouwer, R. Business models and sustainable plastic management: A systematic review of the literature. J. Clean. Prod. 2020, 258, 120967. [Google Scholar] [CrossRef]

- Thunman, H.; Vilches, T.B.; Seemann, M.; Maric, J.; Vela, I.C.; Pissot, S.; Nguyen, H.N. Circular use of plastics-transformation of existing petrochemical clusters into thermochemical recycling plants with 100% plastics recovery. Sustain. Mater. Technol. 2019, 22, e00124. [Google Scholar] [CrossRef]

- Curtzwiler, G.W.; Schweitzer, M.; Li, Y.; Jiang, S.; Vorst, K.L. Mixed post-consumer recycled polyolefins as a property tuning material for virgin polypropylene. J. Clean. Prod. 2019, 239, 117978. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ulgiati, S. Circular economy transition in Italy. Achievements, perspectives and constraints. J. Clean. Prod. 2019, 243, 118360. [Google Scholar] [CrossRef]

- Chen, Z.; Tan, A. Exploring the circular supply chain to reduce plastic waste in singapore. LogForum 2021, 17, 271–286. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).