A Systematic Review of the Design and Heat Transfer Performance of Enhanced Closed-Loop Geothermal Systems

Abstract

:1. Introduction

- (1)

- What types of CLGSs were investigated in previous studies? What types of research, designs, and methods were applied in previous studies that evaluate their performance?

- (2)

- What are the key performance parameters and which of their sensitivity-analysis variables were evaluated in the previous literature?

- (3)

- Can alternative working fluids such as CO2 be utilized in CLGSs? How do their heat transfer performances compare with H2O?

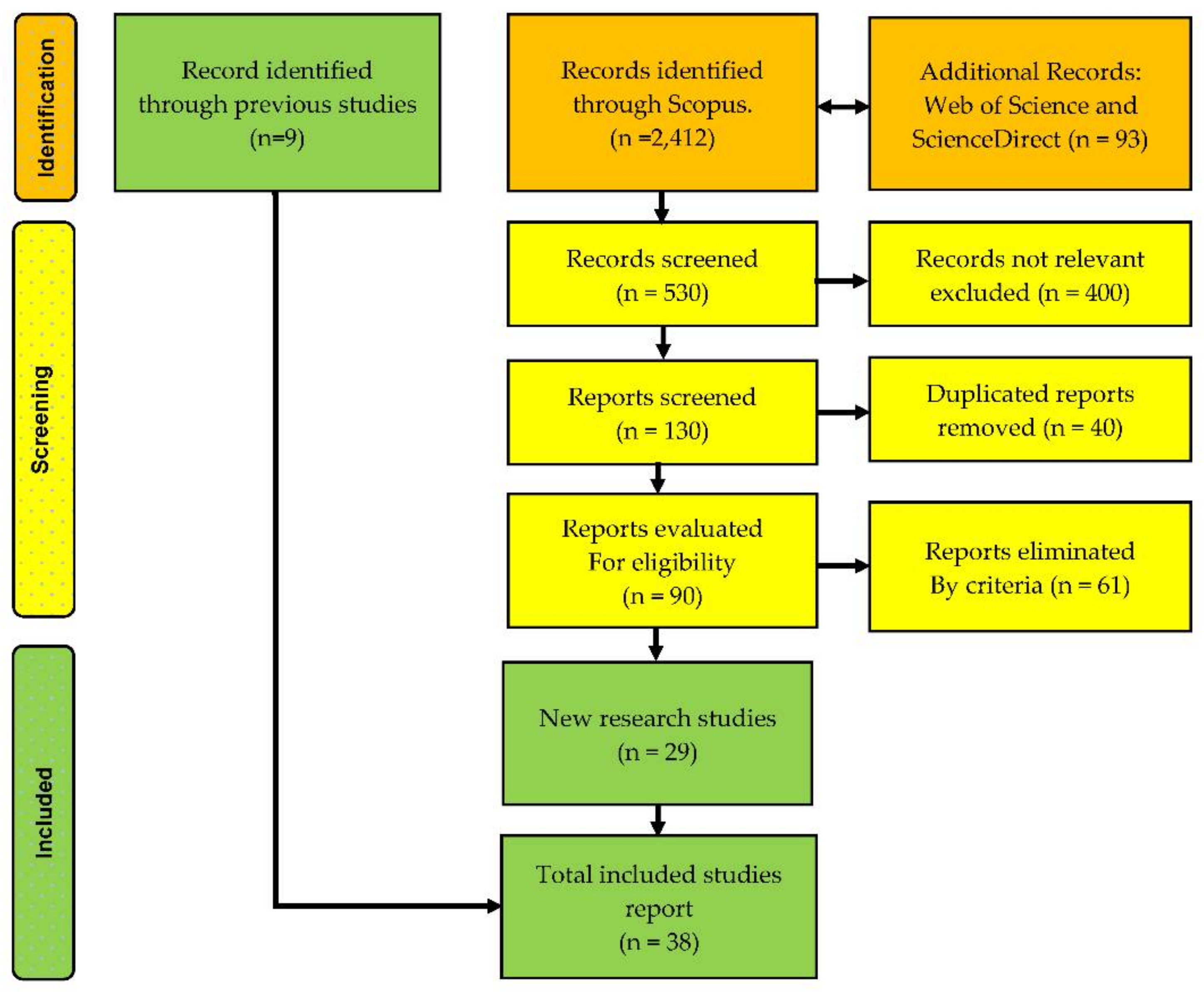

2. Methodology

2.1. Search of Literature

2.2. Data Analysis

3. Results

3.1. General Findings

3.2. The Design, Modeling, and Heat Transfer Performance of CLGSs

3.2.1. Design and Methods of Modeling of CLGSs

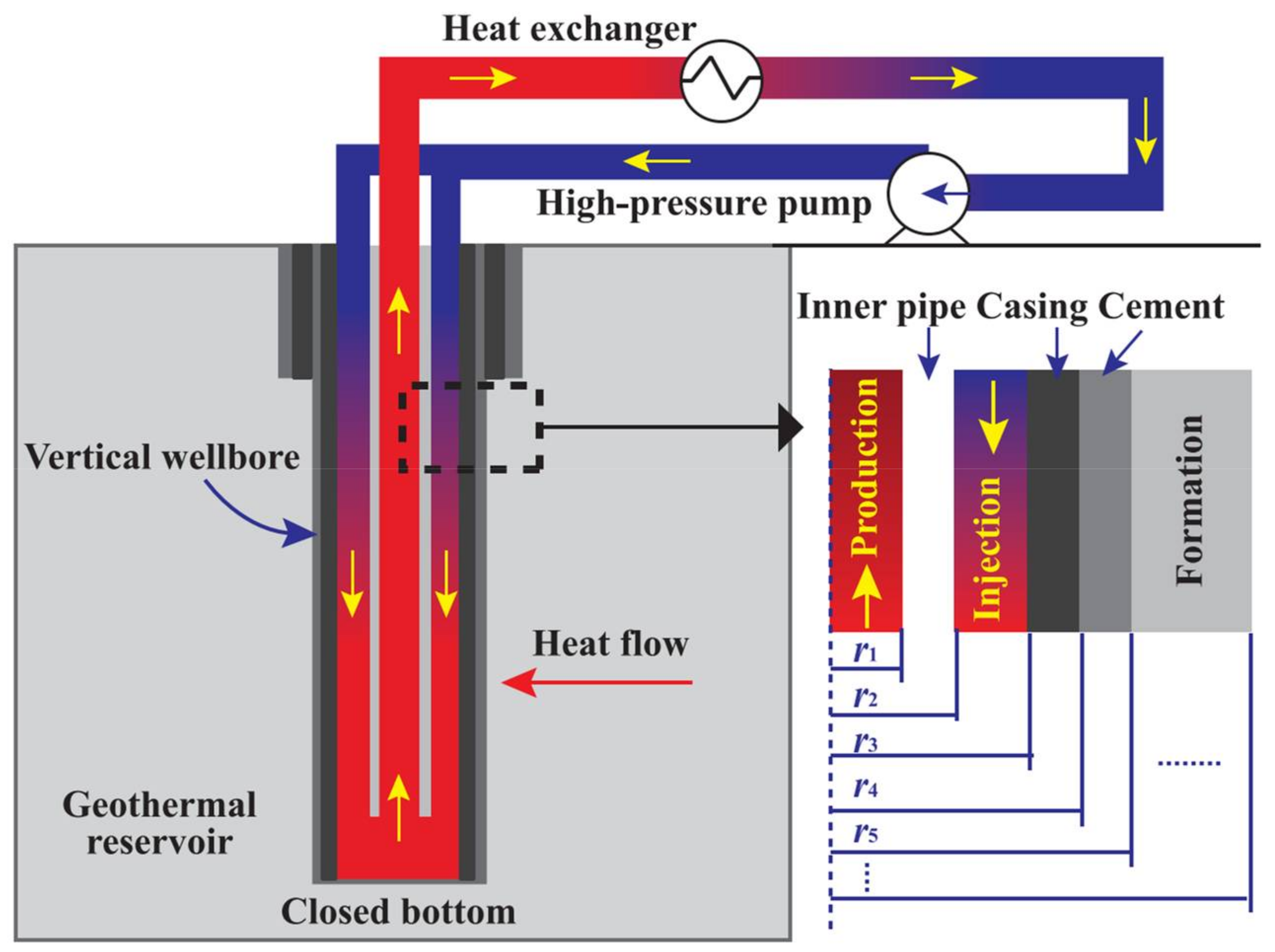

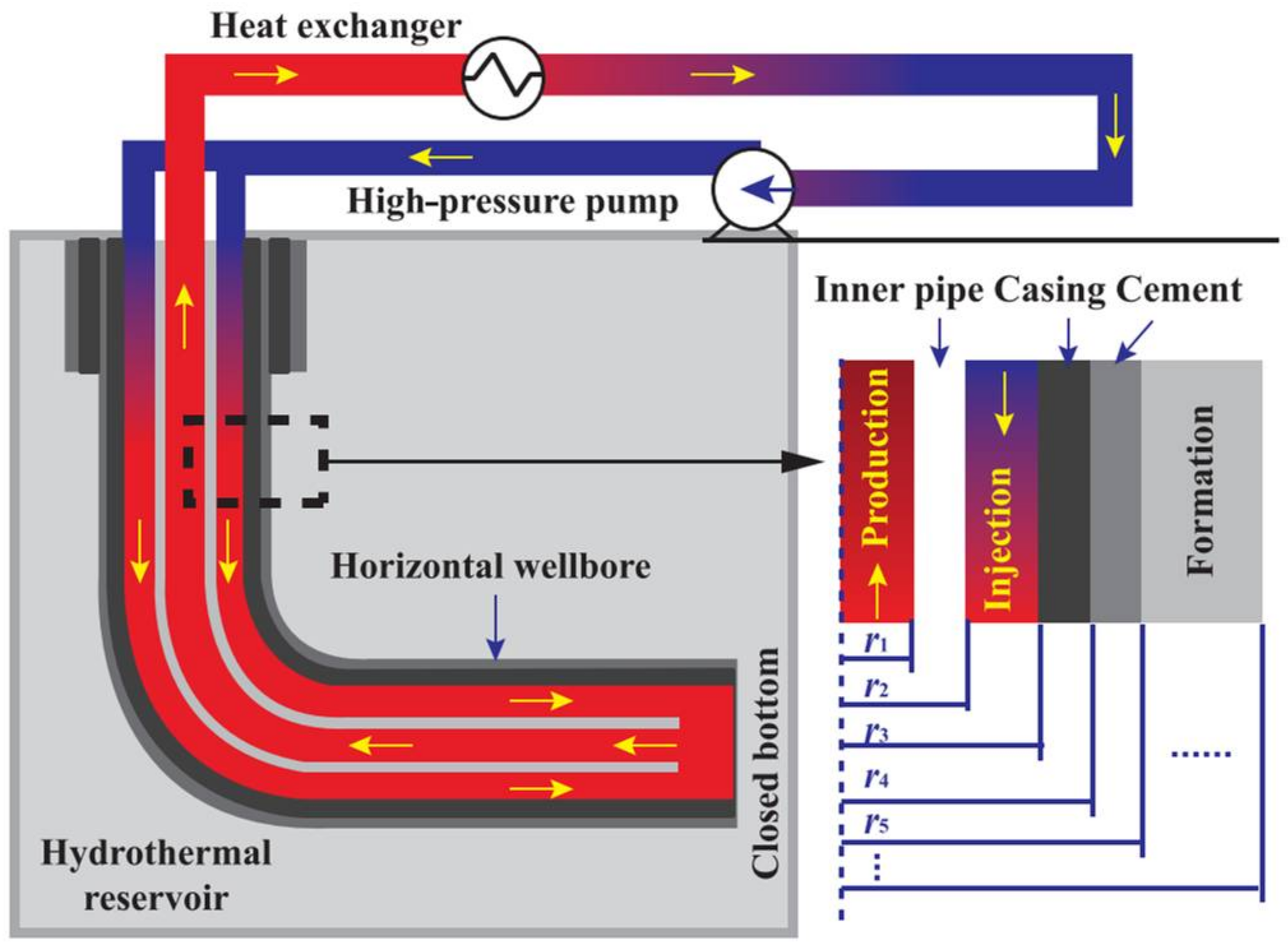

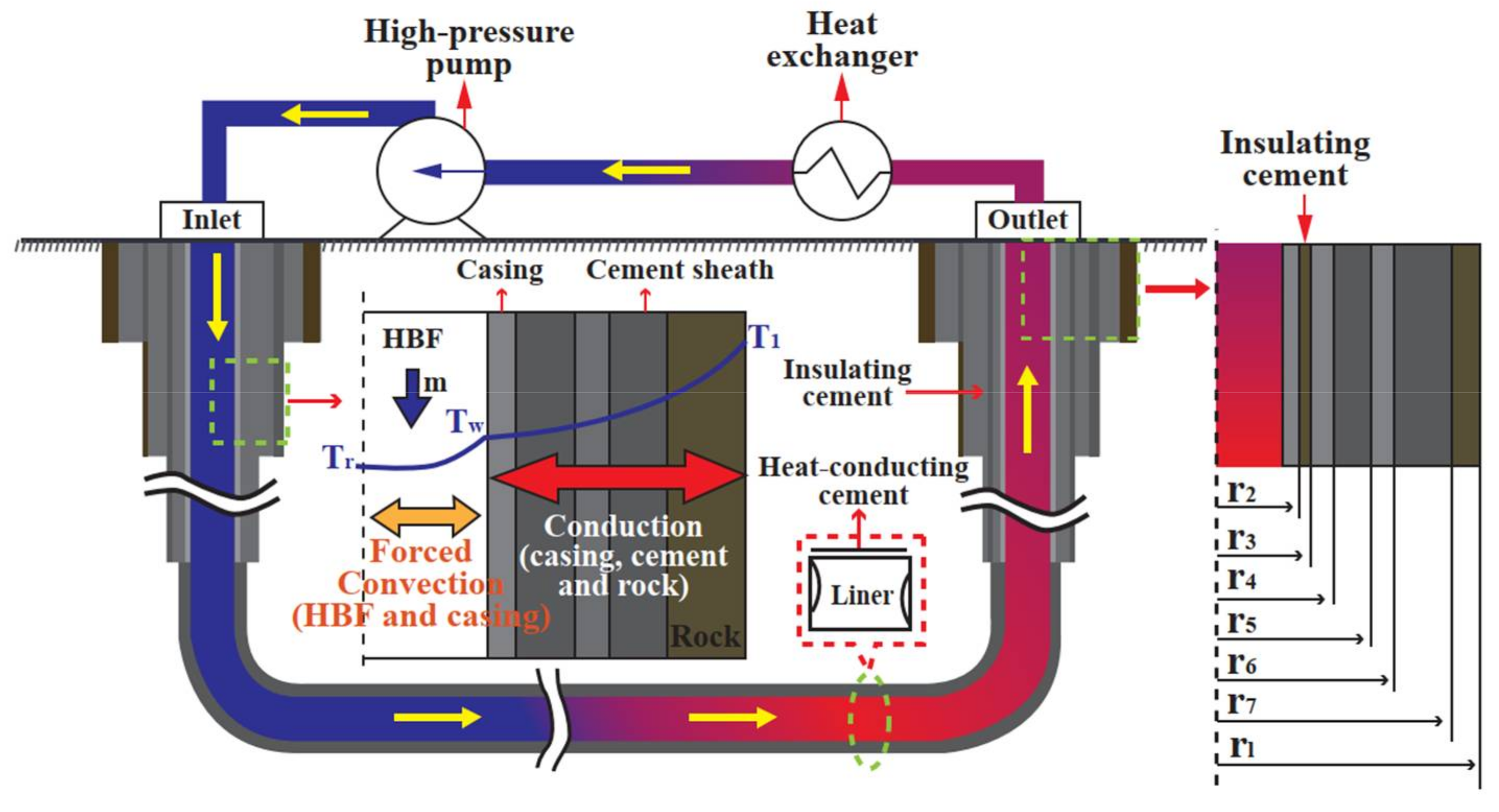

Design of Closed-Loop Geothermal Systems (CLGS)

CLGSs Models

| Reference | CLGS Type | di (mm) | Di (mm) | Depth (m) | Horizontal Length (m) |

|---|---|---|---|---|---|

| Song et al. [27] | UCLGS | 142.9 | 216.8 | 3500 | - |

| Nalla et al. [28] | CCLGS | 76.2 | 311 | 5593 | - |

| Kujawa et al. [29] | CCLGS | 60.3 | 244.5 | 3950 | - |

| Bu et al. [30] | CCLGS | 34 | 244.5 | 4000 | - |

| Focaccia and Tinti [31] | CCLGS | 40 | - | - | - |

| Yekoladio et al. [32] | CCLGS | 50–300 | - | - | - |

| Templeton et al. [33] | CCLGS | 40/80 | 150/196 | - | - |

| Wight and Bennett [34] | CCLGS | - | 244.5 | 4200 | - |

| Le Lous et al. [35] | CCLGS | 114 | 235 | 5000 | - |

| Noorollahi et al. [36] | CCLGS | 60.3 | 146.05 | 4200 | - |

| Alimonti and Soldo [37] | CCLGS | 77.9/88.9 | 150.4/177.8 | 6100 | - |

| Mokhtari et al. [38] | CCLGS | - | - | 1015.4 1574 | - |

| Caulk and Tomak [39] | CCLGS | 120 | 180 | 1500 | - |

| Sun et al. [40] | CCLGS-H | 152 | 250 | 1500 | - |

| Song et al. [25] | CCLGS | 200 | 384 | 5000 | - |

| Shi et al. [41] | CCLGS | 150 | 340 | - | - |

| Renaud et al. [42] | CCLGS | 75 | 219 | 2070 | - |

| Ghoreishi-Madiseh et al. [43] | CCLGS | 50 | 384 | 100 | - |

| Zhang et al. [44] | CCLGS | 62 | 114.3 | 1800 | - |

| Sun et al. [45] | CCLGS-H | 76 | 219 | 3800 | 3000 |

| Wang et al. [46] | CCLGS-H | 76 | 158 | 2000 | 2000 |

| Yu et al. [47] | CCLGS | 62 | 125 | 5000 | - |

| Yildirim et al. [48] | CCLGS | 127 | 203 | 2500 | - |

| Dai et al. [49] | CCLGS | 110 | - | 2070 | - |

| Hu et al. [50] | CCLGS | 76.2 | 188 | 3500 | - |

| Wang et al. [51] | CCLGS-H | 76 | 224.5 | 4350 | 1850 |

| Hu et al. [52] | CCLGS | 120 | 200 | 2000 | - |

| Kalmár et al. [53] | CCLGS | 73 | 114.3 | - | - |

| He et al. [54] | CCLGS | 62 | 139 | 2800 | 1900 |

| Wang et al. [26] | CCLGS-H | 76 | 224.5 | 2900 | 1900 |

| Wang et al. [55] | CCLGS-H | 76 | 224.5 | 2355 | 2300 |

| Pokhrel et al. [56] | CCLGS | 103.8 | 161.7 | - | - |

| Sun et al. [57] | UCLGS | 142.9 | 216.8 | 5000 | 5000 |

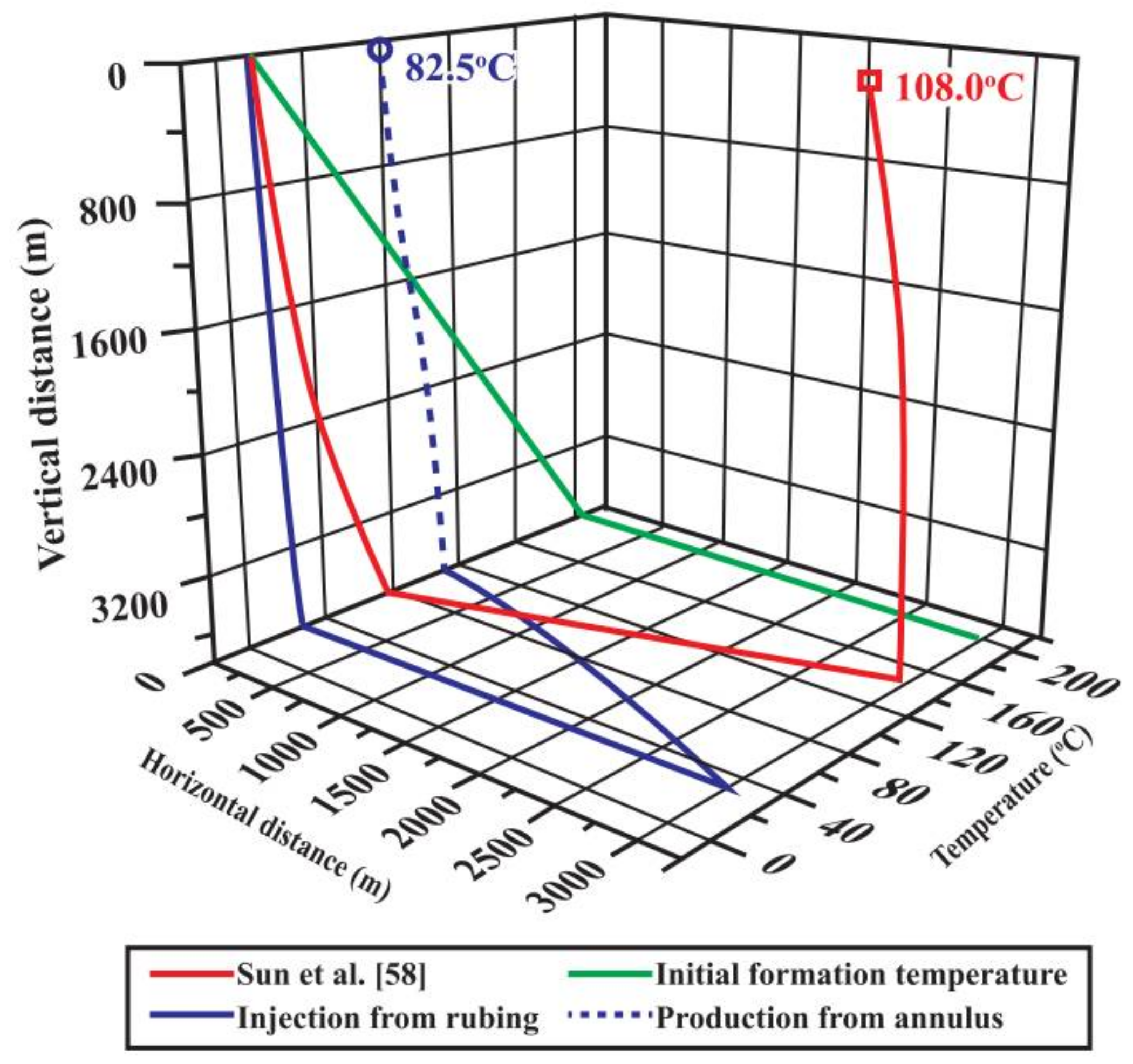

| Sun et al. [58] | UCLGS | 76 | 89 | 3800 | 3000 |

| Yuan et al. [59] | UCLGS | 156 | - | 4000 | 4000 |

| Ghavidel et al. [60] | UCLGS | 200–400 | - | - | 2000 |

| Fallah et al. [61] | UCLGS | 311.15 | 317.88 | 7000/10,000 | 7000/5000 |

| Zhang et al. [62] | UCLGS | 147 | 189 | 2000 | 2000 |

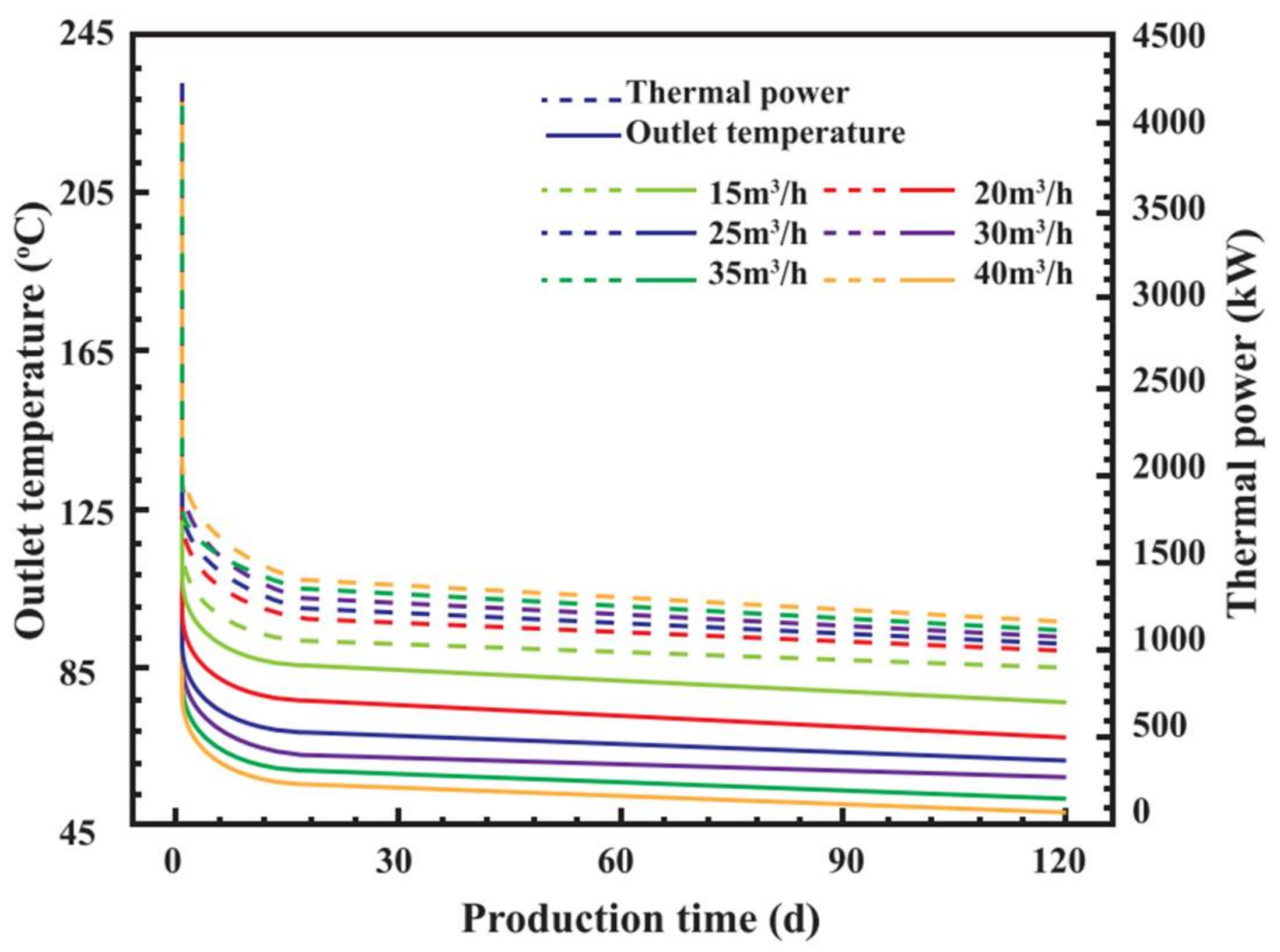

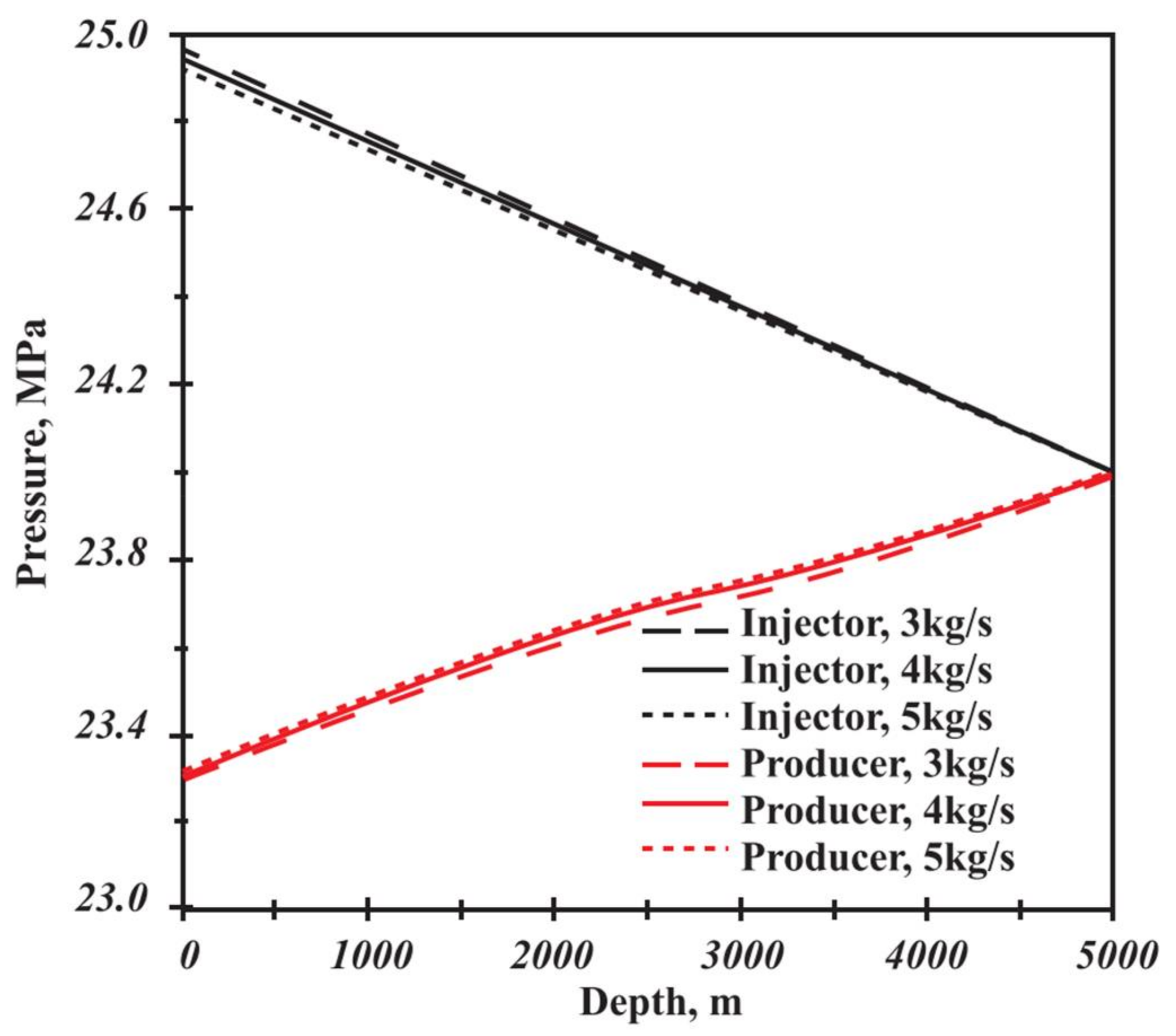

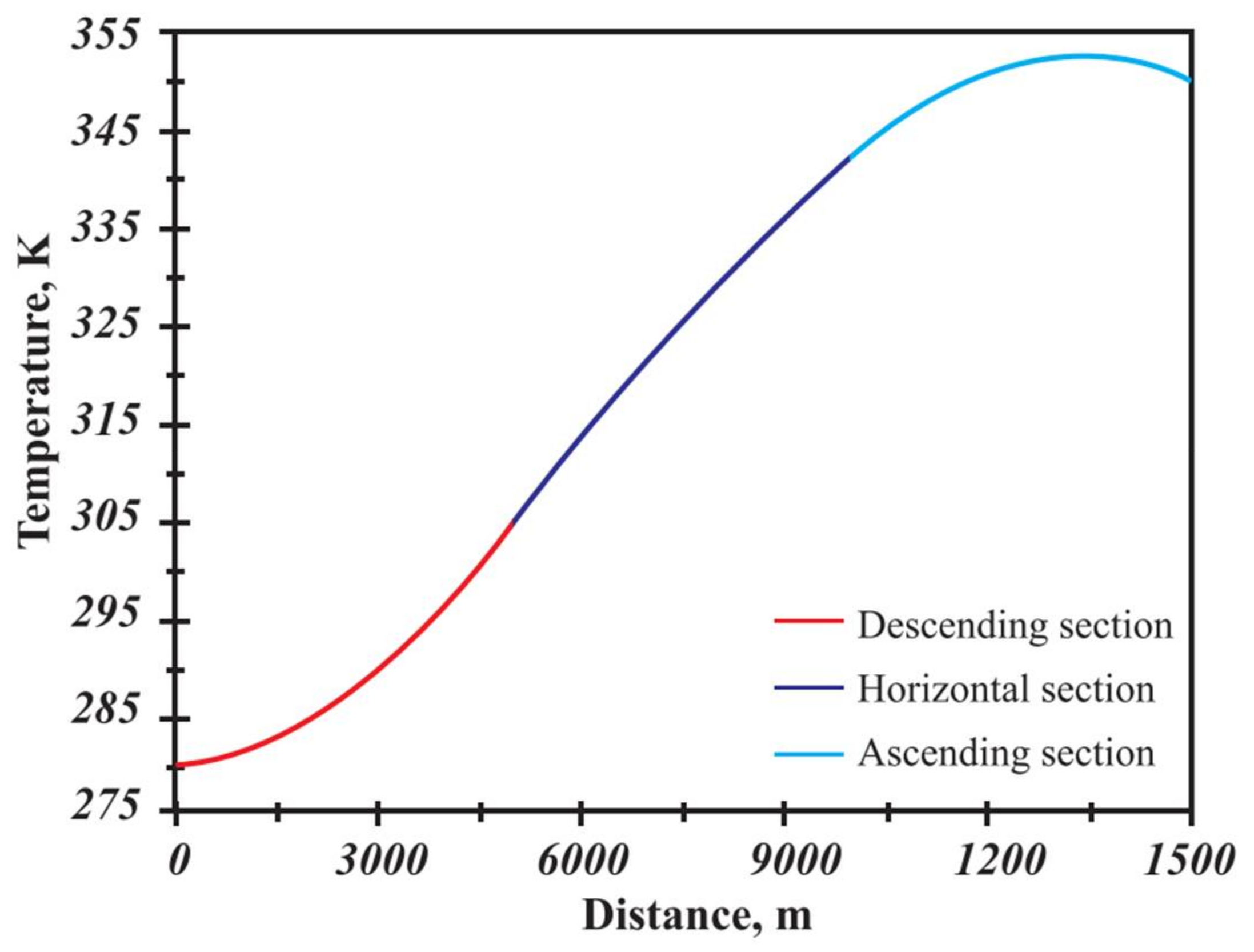

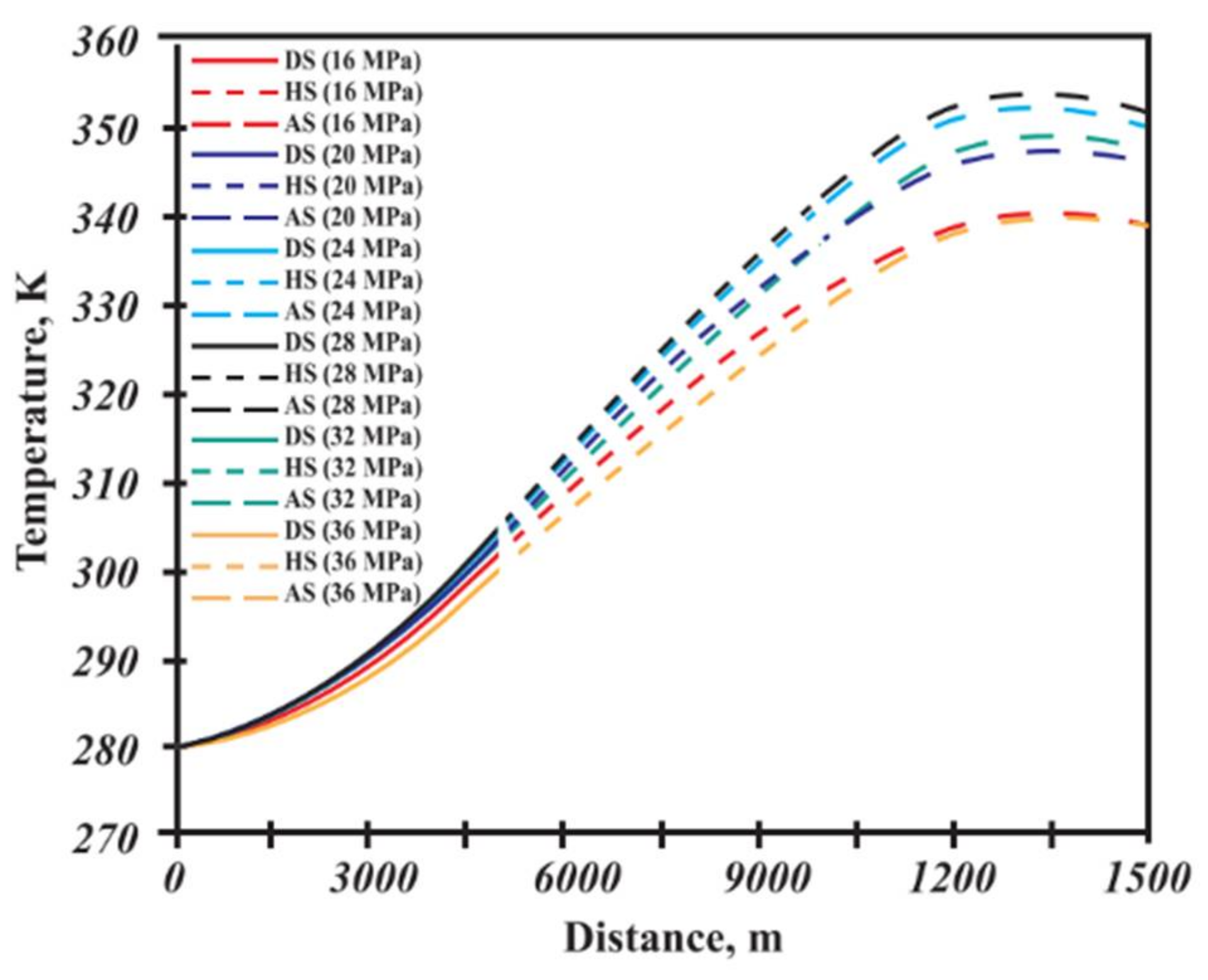

3.2.2. Heat Transfer Performance of CLGSs

Heat Transfer Performance of CCLGSs

Heat Transfer Performance of UCLGSs

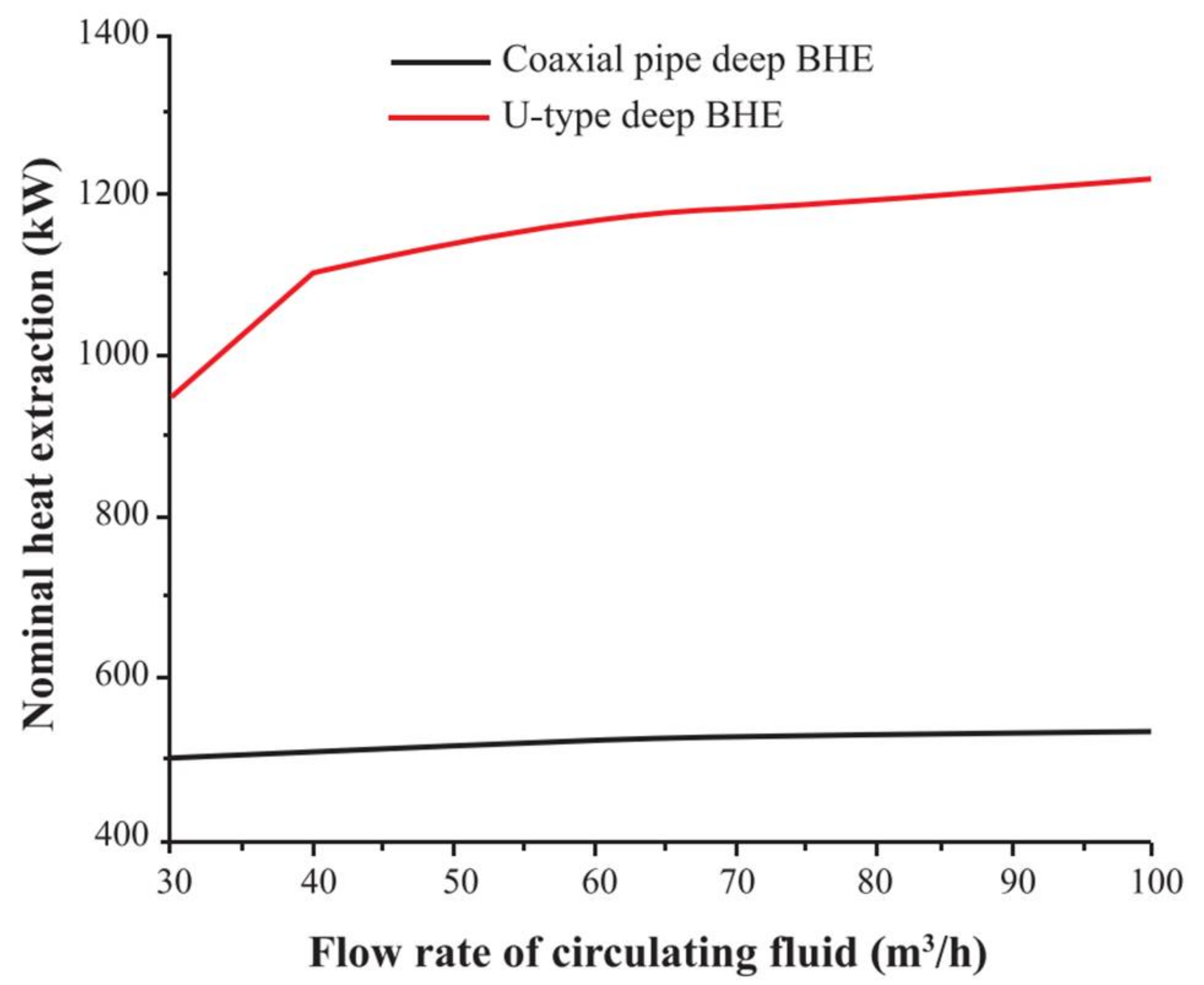

Comparison of CCLGS and UCLGS

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency: World Energy Outlook 2021. Revised Version October 2021 Report. Available online: https://www.iea.org/weo (accessed on 16 November 2021).

- Lu, S.M. A global review of enhanced geothermal system (EGS). Renew. Sustain. Energy Rev. 2018, 81, 2902–2921. [Google Scholar] [CrossRef]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Tester, J.W.; Anderson, B.J.; Batchelor, A.S.; Blackwell, D.D.; Di Pippo, R. The Future of Geothermal Energy-Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; Massachusetts Institute of Technology, DOE Contract DE-AC07-05ID14517 Final Report 2006. Available online: https://energy.mit.edu/research/future-geothermal-energy/ (accessed on 20 October 2021).

- Pruess, K. Enhanced geothermal systems (EGS) using CO2 as working fluid—A novel approach for generating renewable energy with simultaneous sequestration of carbon Karsten. Geothermics 2006, 35, 351–367. [Google Scholar] [CrossRef] [Green Version]

- Pruess, K. On production behavior of enhanced geothermal systems with CO2 as working fluid. Energy Convers. Manag. 2008, 49, 1446–1454. [Google Scholar] [CrossRef] [Green Version]

- Atrens, A.D.; Gurgenci, H.; Rudolph, V. Electricity generation using a carbon-dioxide thermosiphon. Geothermics 2010, 39, 161–169. [Google Scholar] [CrossRef]

- Randolph, J.B.; Saar, M.O. Combining geothermal energy capture with geologic carbon dioxide sequestration. Geophys. Res. Lett. 2011, 38, 10. [Google Scholar] [CrossRef] [Green Version]

- Biagi, J.; Agarwal, R.; Zhang, Z. Simulation and optimization of enhanced geothermal systems using CO2 as a working fluid. Energy 2015, 86, 627–637. [Google Scholar] [CrossRef]

- Guo, T.; Gong, F.; Wang, X.; Lin, Q.; Qu, Z.; Zhang, W. Performance of enhanced geothermal system (EGS) in fractured geothermal reservoirs with CO2 as working fluid. Appl. Therm. Eng. 2019, 152, 215–230. [Google Scholar] [CrossRef]

- Song, W.; Wang, C.; Du, Y.; Shen, B.; Chen, S.; Jiang, Y. Comparative analysis on the heat transfer efficiency of supercritical CO2 and H2O in the production well of enhanced geothermal system. Energy 2020, 205, 118071. [Google Scholar] [CrossRef]

- Wang, X.; Levy, E.K.; Pan, C.; Romero, C.E.; Banerjee, A.; Rubio-Maya, C.; Pan, L. Working fluid selection for organic Rankine cycle power generation using hot produced supercritical CO2 from a geothermal reservoir. Appl. Therm. Eng. 2019, 149, 1287–1304. [Google Scholar] [CrossRef]

- Gładysz, P.; Sowiżdżał, A.; Miecznik, M.; Pająk, L. Carbon dioxide-enhanced geothermal systems for heat and electricity production: Energy and economic analyses for central Poland. Energy Convers. Manag. 2020, 220, 113142. [Google Scholar] [CrossRef]

- Mohan, A.R.; Turaga, U.; Subbaraman, V.; Shembekar, V.; Elsworth, D.; Pisupati, S.V. Modeling the CO2-based enhanced geothermal system (EGS) paired with integrated gasification combined cycle (IGCC) for symbiotic integration of carbon dioxide sequestration with geothermal heat utilization. Int. J. Greenh. Gas Control. 2015, 32, 197–212. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Deng, S.; Zhao, J.; Wang, J.; Sun, T.; Yan, J. Performance and economic assessments of integrating geothermal energy into coal-fired power plant with CO2 capture. Energy 2017, 119, 278–287. [Google Scholar] [CrossRef]

- Pan, C.; Romero, C.E.; Levy, E.K.; Wang, X.; Rubio-Maya, C.; Pan, L. Fully coupled wellbore-reservoir simulation of supercritical CO2 injection from fossil fuel power plant for heat mining from geothermal reservoirs. J. CO2 Util. 2018, 27, 480–492. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.; Zhang, Q.; Xu, G.; Gao, Y.; Yang, Y.; Liu, T.; Wang, M. Thermodynamic analysis of an improved CO2-based enhanced geothermal system integrated with a coal-fired power plant using boiler cold-end heat recovery. Appl. Therm. Eng. 2018, 135, 10–21. [Google Scholar] [CrossRef]

- Vulin, D.; Muhasilović, L.; Arnaut, M. Possibilities for CCUS in medium temperature geothermal reservoir. Energy 2020, 200, 117549. [Google Scholar] [CrossRef]

- Pan, S.Y.; Gao, M.; Shah, K.J.; Zheng, J.; Pei, S.L.; Chiang, P.C. Establishment of enhanced geothermal energy utilization plans: Barriers and strategies. Renew. Energy 2019, 132, 19–32. [Google Scholar] [CrossRef]

- Baek, H.; Chung, J.B.; Yun, G.W. Differences in public perceptions of geothermal energy based on EGS technology in Korea after the Pohang earthquake: National vs. local. Technol. Forecast. Soc. Change 2021, 172, 121027. [Google Scholar] [CrossRef]

- Alimonti, C.; Soldo, E.; Bocchetti, D.; Berardi, D. The wellbore heat exchangers: A technical review. Renew. Energy 2018, 123, 353–381. [Google Scholar] [CrossRef]

- Sun, F.; Yao, Y.; Li, G. Literature review on a U-shaped closed loop geothermal energy development system. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 2794–2806. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Song, X.; Wang, G.; Shi, Y.; Li, R.; Xu, Z.; Zheng, R.; Wang, Y.; Li, J. Numerical analysis of heat extraction performance of a deep coaxial borehole heat exchanger geothermal system. Energy 2018, 164, 1298–1310. [Google Scholar] [CrossRef]

- Wang, G.; Song, X.; Song, G.; Shi, Y.; Yu, C.; Xu, F.; Ji, J.; Song, Z. Analyzes of thermal characteristics of a hydrothermal coaxial closed-loop geothermal system in a horizontal well. Int. J. Heat Mass Transf. 2021, 180, 121755. [Google Scholar] [CrossRef]

- Song, X.; Shi, Y.; Li, G.; Shen, Z.; Hu, X.; Lyu, Z.; Zheng, R.; Wang, G. Numerical analysis of the heat production performance of a closed loop geothermal system. Renew. Energy 2018, 120, 365–378. [Google Scholar] [CrossRef]

- Nalla, G.; Shook, G.M.; Mines, G.L.; Bloomfield, K.K. Parametric sensitivity study of operating and design variables in wellbore heat exchangers. Geothermics 2005, 34, 330–346. [Google Scholar] [CrossRef] [Green Version]

- Kujawa, T.; Nowak, W.; Stachel, A.A. Utilization of existing deep geological wells for acquisitions of geothermal energy. Energy 2006, 31, 650–664. [Google Scholar] [CrossRef]

- Bu, X.; Ma, W.; Li, H. Geothermal energy production utilizing abandoned oil and gas wells. Renew. Energy 2012, 41, 80–85. [Google Scholar] [CrossRef]

- Focaccia, S.; Tinti, F. An innovative Borehole Heat Exchanger configuration with improved heat transfer. Geothermics 2013, 48, 93–100. [Google Scholar] [CrossRef]

- Yekoladio, P.J.; Bello-Ochende, T.; Meyer, J.P. Design and optimization of a downhole coaxial heat exchanger for an enhanced geothermal system (EGS). Renew. Energy 2013, 55, 128–137. [Google Scholar] [CrossRef] [Green Version]

- Templeton, J.D.; Ghoreishi-Madiseh, S.A.; Hassani, F.; Al-Khawaja, M.J. Abandoned petroleum wells as sustainable sources of geothermal energy. Energy 2014, 70, 366–373. [Google Scholar] [CrossRef]

- Wight, N.M.; Bennett, N.S. Geothermal energy from abandoned oil and gas wells using water in combination with a closed wellbore. Appl. Therm. Eng. 2015, 89, 908–915. [Google Scholar] [CrossRef]

- Le Lous, M.; Larroque, F.; Dupuy, A.; Moignard, A. Thermal performance of a deep borehole heat exchanger: Insights from a synthetic coupled heat and flow model. Geothermics 2015, 57, 157–172. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Pourarshad, M.; Jalilinasrabady, S.; Yousefi, H. Numerical simulation of power production from abandoned oil wells in Ahwaz oil field in southern Iran. Geothermics 2015, 55, 16–23. [Google Scholar] [CrossRef]

- Alimonti, C.; Soldo, E. Study of geothermal power generation from a very deep oil well with a wellbore heat exchanger. Renew. Energy 2016, 86, 292–301. [Google Scholar] [CrossRef]

- Mokhtari, H.; Hadiannasab, H.; Mostafavi, M.; Ahmadibeni, A.; Shahriari, B. Determination of optimum geothermal Rankine cycle parameters utilizing coaxial heat exchanger. Energy 2016, 102, 260–275. [Google Scholar] [CrossRef]

- Caulk, R.A.; Tomac, I. Reuse of abandoned oil and gas wells for geothermal energy production. Renew. Energy 2017, 112, 388–397. [Google Scholar] [CrossRef] [Green Version]

- Sun, F.; Yao, Y.; Li, G.; Li, X. Performance of geothermal energy extraction in a horizontal well by using CO2 as the working fluid. Energy Convers. Manag. 2018, 171, 1529–1539. [Google Scholar] [CrossRef]

- Shi, Y.; Song, X.; Wang, G.; McLennan, J.; Forbes, B.; Li, X.; Li, J. Study on wellbore fluid flow and heat transfer of a multilateral-well CO2 enhanced geothermal system. Appl. Energy 2019, 249, 14–27. [Google Scholar] [CrossRef]

- Renaud, T.; Verdin, P.; Falcone, G. Numerical simulation of a Deep Borehole Heat Exchanger in the Krafla geothermal system. Int. J. Heat Mass Transf. 2019, 143, 118496. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Kuyuk, A.F.; Rodrigues de Brito, M.A. An analytical model for transient heat transfer in ground-coupled heat exchangers of closed-loop geothermal systems. Appl. Therm. Eng. 2019, 150, 696–705. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Li, G.; Guo, X.; Wang, G.; Shi, Y.; Peng, C.; Tan, Y. Performance analysis of a downhole coaxial heat exchanger geothermal system with various working fluids. Appl. Therm. Eng. 2019, 163, 114317. [Google Scholar] [CrossRef]

- Sun, X.; Liao, Y.; Wang, Z.; Sun, B. Geothermal exploitation by circulating supercritical CO2 in a closed horizontal wellbore. Fuel 2019, 254, 115566. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Cui, G.; Kang, J.; Ren, S. Geothermal development and power generation by circulating water and isobutane via a closed-loop horizontal well from hot dry rocks. Renew. Energy 2019, 136, 909–922. [Google Scholar] [CrossRef]

- Yu, H.; Li, Q.; Sun, F. Numerical simulation of CO2 circulating in a retrofitted geothermal well. J. Pet. Sci. Eng. 2019, 172, 217–227. [Google Scholar] [CrossRef]

- Yildirim, N.; Parmanto, S.; Akkurt, G.G. Thermodynamic assessment of downhole heat exchangers for geothermal power generation. Renew. Energy 2019, 141, 1080–1091. [Google Scholar] [CrossRef]

- Dai, C.; Li, J.; Shi, Y.; Zeng, L.; Lei, H. An experiment on heat extraction from a deep geothermal well using a downhole coaxial open loop design. Appl. Energy 2019, 252, 113447. [Google Scholar] [CrossRef]

- Hu, X.; Banks, J.; Wu, L.; Liu, W.V. Numerical modeling of a coaxial borehole heat exchanger to exploit geothermal energy from abandoned petroleum wells in Hinton, Alberta. Renew. Energy 2020, 148, 1110–1123. [Google Scholar] [CrossRef]

- Wang, G.; Song, X.; Shi, Y.; Yulong, F.; Yang, R.; Li, J. Comparison of production characteristics of various coaxial closed-loop geothermal systems. Energy Convers. Manag. 2020, 225, 113437. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, T.; Feng, B.; Yuan, Y.; Li, F.; Feng, G.; Jiang, Z. Thermal and fluid processes in a closed-loop geothermal system using CO2 as a working fluid. Renew. Energy 2020, 154, 351–367. [Google Scholar] [CrossRef]

- Kalmár, L.; Medgyes, T.; Szanyi, J. Specifying boundary conditions for economical closed loop deep geothermal heat production. Energy 2020, 196, 117068. [Google Scholar] [CrossRef]

- He, Y.; Jia, M.; Li, X.; Yang, Z.; Song, R. Performance analysis of coaxial heat exchanger and heat-carrier fluid in medium-deep geothermal energy development. Renew. Energy 2021, 168, 938–959. [Google Scholar] [CrossRef]

- Wang, G.; Song, X.; Shi, Y.; Yang, R.; Yulong, F.; Zheng, R.; Li, J. Heat extraction analysis of a novel multilateral-well coaxial closed-loop geothermal system. Renew. Energy 2021, 163, 974–986. [Google Scholar] [CrossRef]

- Pokhrel, S.; Sasmito, A.P.; Sainoki, A.; Tosha, T.; Tanaka, T.; Nagai, C.; Ghoreishi-Madiseh, S.A. Field-scale experimental and numerical analysis of a downhole coaxial heat exchanger for geothermal energy production. Renew. Energy 2022, 182, 521–535. [Google Scholar] [CrossRef]

- Sun, F.; Yao, Y.; Li, G.; Li, X. Geothermal energy development by circulating CO2 in a U-shaped closed loop geothermal system. Energy Convers. Manag. 2018, 174, 971–982. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Z.; Liao, Y.; Sun, B.; Gao, Y. Geothermal energy production utilizing a U-shaped well in combination with supercritical CO2 circulation. Appl. Therm. Eng. 2019, 151, 523–535. [Google Scholar] [CrossRef]

- Yuan, W.; Chen, Z.; Grasby, S.E.; Little, E. Closed-loop geothermal energy recovery from deep high enthalpy systems. Renew. Energy 2021, 177, 976–991. [Google Scholar] [CrossRef]

- Ghavidel, A.; Gracie, R.; Dusseault, M.B. Transient heat transfer in a horizontal well in hot dry rock—Model, solution, and response surfaces for practical inputs. Appl. Therm. Eng. 2021, 195, 117158. [Google Scholar] [CrossRef]

- Fallah, A.H.; Gu, Q.; Chen, D.; Ashok, P.; van Oort, E. Globally scalable geothermal energy production through managed pressure operation control of deep closed-loop well systems. Energy Convers. Manag. 2021, 236, 114056. [Google Scholar] [CrossRef]

- Zhang, W.; Li, W.; Sørensen, B.R.; Cui, P.; Man, Y.; Yu, M.; Fang, Z. Comparative analysis of heat transfer performance of coaxial pipe and U-type deep borehole heat exchangers. Geothermics 2021, 96, 102220. [Google Scholar] [CrossRef]

| Database | Search String |

|---|---|

| Scopus | TITLE-ABS-KEY(“closed loop *” OR “closed-loop *” OR “borehole *” OR “bore hole” AND geothermal) |

| Science Direct | “closed loop” OR “closed-loop” OR “borehole” OR “bore hole” AND geothermal |

| Web of Science | TS = (“closed loop *” OR “closed-loop*” OR “borehole *” OR “bore hole” AND geothermal) |

| Journal Name | Number of Articles |

|---|---|

| Renewable Energy | 13 |

| Geothermics | 5 |

| Energy | 5 |

| Applied Thermal Engineering | 5 |

| Energy Conversion and Management | 4 |

| Applied Energy | 2 |

| Heat and Mass Transfer | 2 |

| Fuel | 1 |

| Journal of Petroleum Science and Engineering | 1 |

| Country Name | Publication Number | Publication Year |

|---|---|---|

| China | 19 | 2012, 2018, 2019, 2020, 2021 |

| USA | 4 | 2005, 2015, 2017, 2021 |

| Canada | 3 | 2019, 2020, 2021 |

| Italy | 2 | 2013, 2016 |

| Iran | 2 | 2015, 2016 |

| Turkey | 1 | 2019 |

| Hungary | 1 | 2020 |

| Qatar | 1 | 2014 |

| France | 1 | 2015 |

| South Africa | 1 | 2013 |

| Iceland | 1 | 2019 |

| Japan | 1 | 2021 |

| Poland | 1 | 2006 |

| Reference | CLGS Type | Numerical Method | Software |

|---|---|---|---|

| Song et al. [27] | UCLGS | FDM | - |

| Nalla et al. [28] | CCLGS | - | - |

| Kujawa et al. [29] | CCLGS | - | - |

| Bu et al. [30] | CCLGS | FVM | - |

| Focaccia and Tinti [31] | CCLGS | - | - |

| Yekoladio et al. [32] | CCLGS | - | - |

| Templeton et al. [33] | CCLGS | FEM | FlexPDE |

| Wight and Bennett [34] | CCLGS | - | - |

| Le Lous et al. [35] | CCLGS | FEM | FFEFLOW |

| Noorollahi et al. [36] | CCLGS | FVM | Ansys |

| Alimonti and Soldo [37] | CCLGS | - | - |

| Mokhtari et al. [38] | CCLGS | - | - |

| Caulk and Tomak [39] | CCLGS | FEM | Comsol |

| Sun et al. [40] | CCLGS-H | FDM | - |

| Song et al. [25] | CCLGS | FDM | - |

| Shi et al. [41] | CCLGS | FEM | Comsol |

| Renaud et al. [42] | CCLGS | FVM | Ansys |

| Ghoreishi-Madiseh et al. [43] | CCLGS | FVM | Ansys |

| Zhang et al. [44] | CCLGS | FEM | Comsol |

| Sun et al. [45] | CCLGS-H | FDM | - |

| Wang et al. [46] | CCLGS-H | FDM | - |

| Yu et al. [47] | CCLGS | FDM | - |

| Yildirim et al. [48] | CCLGS | FEM | Comsol |

| Dai et al. [49] | CCLGS | FVM | - |

| Hu et al. [50] | CCLGS | FEM | Comsol |

| Wang et al. [51] | CCLGS-H | FEM | Comsol |

| Hu et al. [52] | CCLGS | FVM | T2Well |

| Kalmár et al. [53] | CCLGS | FDM | - |

| He et al. [54] | CCLGS | _ | - |

| Wang et al. [26] | CCLGS-H | FEM | Comsol |

| Wang et al. [55] | CCLGS-H | FEM | Comsol |

| Pokhrel et al. [56] | CCLGS | FVM | Ansys |

| Sun et al. [57] | UCLGS | FDM | - |

| Sun et al. [58] | UCLGS | FDM | - |

| Yuan et al. [59] | UCLGS | FDM | - |

| Ghavidel et al. [60] | UCLGS | FEM | Comsol |

| Fallah et al. [61] | UCLGS | FDM | - |

| Zhang et al. [62] | UCLGS | FDM | - |

| Reference | Heat Transfer Parameter Sensitivity Analysis Variable | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | Qr | DP/P | Pth | H | q | t | Tgrd | Kins | Pin | Tin | d | Fluid | Lhor | Kres | Ws | |

| Song et al. [27] | √ | √ | √ | √ | √ | √ | ||||||||||

| Nalla et al. [28] | √ | √ | ||||||||||||||

| Kujawa et al. [29] | √ | √ | √ | √ | ||||||||||||

| Bu et al. [30] | √ | √ | √ | √ | ||||||||||||

| Focaccia and Tinti [31] | √ | √ | √ | √ | ||||||||||||

| Yekoladio et al. [32] | √ | √ | ||||||||||||||

| Templeton et al. [33] | √ | √ | √ | √ | √ | |||||||||||

| Wight and Bennett [34] | √ | √ | √ | |||||||||||||

| Le Lous et al. [35] | √ | √ | √ | √ | ||||||||||||

| Noorollahi et al. [36] | √ | √ | √ | |||||||||||||

| Alimonti and Soldo [37] | √ | √ | √ | √ | √ | |||||||||||

| Mokhtari et al. [38] | √ | √ | √ | √ | ||||||||||||

| Caulk and Tomak [39] | √ | √ | √ | √ | ||||||||||||

| Sun et al. [40] | √ | √ | √ | √ | √ | √ | ||||||||||

| Song et al. [25] | √ | √ | √ | √ | √ | |||||||||||

| Shi et al. [41] | √ | √ | √ | √ | √ | |||||||||||

| Renaud et al. [42] | √ | √ | √ | √ | ||||||||||||

| Ghoreishi-Madiseh et al. [43] | √ | √ | √ | |||||||||||||

| Zhang et al. [44] | √ | √ | √ | √ | √ | √ | ||||||||||

| Sun et al. [45] | √ | √ | √ | √ | √ | √ | ||||||||||

| Wang et al. [46] | √ | √ | √ | √ | √ | √ | √ | |||||||||

| Yu et al. [47] | √ | √ | √ | √ | √ | √ | ||||||||||

| Yildirim et al. [48] | √ | √ | √ | √ | √ | |||||||||||

| Dai et al. [49] | √ | √ | √ | √ | ||||||||||||

| Hu et al. [50] | √ | √ | √ | √ | ||||||||||||

| Wang et al. [51] | √ | √ | √ | |||||||||||||

| Hu et al. [52] | √ | √ | √ | √ | √ | |||||||||||

| Kalmár et al. [53] | √ | √ | √ | √ | √ | |||||||||||

| He et al. [54] | √ | √ | √ | √ | ||||||||||||

| Wang et al. [26] | √ | √ | √ | √ | ||||||||||||

| Wang et al. [55] | √ | √ | √ | √ | √ | |||||||||||

| Pokhrel et al. [56] | √ | √ | √ | √ | ||||||||||||

| Sun et al. [57] | √ | √ | √ | √ | √ | √ | ||||||||||

| Sun et al. [58] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| Yuan et al. [59] | √ | √ | √ | √ | √ | √ | ||||||||||

| Ghavidel et al. [60] | √ | √ | √ | |||||||||||||

| Fallah et al. [61] | √ | √ | √ | √ | √ | |||||||||||

| Zhang et al. [62] | √ | √ | √ | √ | √ | √ | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budiono, A.; Suyitno, S.; Rosyadi, I.; Faishal, A.; Ilyas, A.X. A Systematic Review of the Design and Heat Transfer Performance of Enhanced Closed-Loop Geothermal Systems. Energies 2022, 15, 742. https://doi.org/10.3390/en15030742

Budiono A, Suyitno S, Rosyadi I, Faishal A, Ilyas AX. A Systematic Review of the Design and Heat Transfer Performance of Enhanced Closed-Loop Geothermal Systems. Energies. 2022; 15(3):742. https://doi.org/10.3390/en15030742

Chicago/Turabian StyleBudiono, Andres, Suyitno Suyitno, Imron Rosyadi, Afif Faishal, and Albert Xaverio Ilyas. 2022. "A Systematic Review of the Design and Heat Transfer Performance of Enhanced Closed-Loop Geothermal Systems" Energies 15, no. 3: 742. https://doi.org/10.3390/en15030742

APA StyleBudiono, A., Suyitno, S., Rosyadi, I., Faishal, A., & Ilyas, A. X. (2022). A Systematic Review of the Design and Heat Transfer Performance of Enhanced Closed-Loop Geothermal Systems. Energies, 15(3), 742. https://doi.org/10.3390/en15030742