1. Introduction

Nuclear energy offers great potential to support a sustainable energy future, since it is currently the only available net-zero technology that can deliver 24/7 availability and adjustability while also producing the required massive amounts of on-demand, low carbon energy to make a net zero society viable. However, for large scale future deployment, it is vital to improve the sustainability of the technology, thus the fuel utilization, see [

1]. The key to achieving improved fuel utilization is a closed fuel cycle operation, as has already been demonstrated in fast reactor technology, but this will only be possible when the operation is based on plutonium as a fissile material [

2]. Fast reactors have always been planned to operate in a closed fuel cycle mode based on mixed oxide (MOX) fuel. However, for a long time, the only industrially operated fast reactor, BN-600, operated on pure uranium-based fuel. The follow up system, BN-800, was also started on uranium oxide fuel, but it is now gradually being converted to MOX fuel-based operation [

3]. However, for closing the fuel cycle with solid fuelled reactors, a complex and investment intensive fuel reprocessing process has to be installed to separate and access plutonium, often called ‘Plutonium Economy’. To avoid these challenges, we have proposed the iMAGINE concept: a highly innovative nuclear system which aims to use molten salt fast reactors in conjunction with an integrated salt clean-up system based on the principles of reverse reprocessing. The system is proposed to operate on spent nuclear fuel from light water reactors (LWRs) without prior reprocessing and has the potential to deliver waste management [

4] and power production [

5] in a single unified process, significantly more efficient than the classical closed fuel cycle approaches [

6]. In contrast to the above-mentioned solid fuel-based approaches and the recent approaches for transmutation in ADS [

7], this novel integrated approach offers the prospect of a single holistic solution, starting with transforming the spent fuel into the salt phase, as is done in the pre-processing stage of pyro reprocessing. The iMAGINE concept has the potential to deliver an innovative, resource efficient energy production system as well as a highly sustainable waste management process [

6,

8], creating a solution to the often criticised negative aspects of nuclear [

1]. This novel approach, which could be called “reverse” reprocessing, is completely different from other proposed molten salt reactor systems [

9,

10] and has been developed for iMAGINE with the aim of keeping all actinides in the salt to avoid proliferation issues, while separating only selected elements which prevent the reactor from long term operation. Following the study of the enriched uranium-based iMAGINE proposal in “A HELIOS based dynamic salt clean-up study for iMAGINE” [

11], this paper focusses on a Pu-started core, since for the UK, with its massive amount of already separated civil plutonium [

12], this approach could be the most interesting as a potential new strategy for the most efficient utilisation of plutonium. The codes, methods, and models as already described in [

11] have been used to assure comparability and to allow direct comparison of the effects.

This work will address the investigation of clean-up requirements for the Pu-started core and its comparison to the uranium core as a basis for planning the future applications of iMAGINE. Some general knowledge on this is already available through historic experience. Replacing the uranium-based core with a Pu-started core will improve the availability of neutrons for breeding due to the increased number of neutrons per fission in Pu. However, no significant difference in long term operation is to be expected, since the large difference in the material composition at the beginning will disappear rapidly. This is because the breeding process in a uranium-based fast reactor core will turn the fissile material composition into Pu. Nevertheless, it is essential to understand the differences to give consolidated advice in future discussions.

2. Background

The iMAGINE concept has been developed as a future nuclear energy system for the 21st century based on two visions, unlimited nuclear energy and zero waste nuclear.

The vision, unlimited nuclear energy, has been transformed into the mission to make available a closed fuel cycle operation to release a factor of 100 more energy out of already mined nuclear material, such as spent fuel and tailings; this will allow the creation of a significant amount of energy without the need to mine new resources. The aim is to utilise these already mined resources for energy production through advanced technology development without creating proliferation issues. The mission delivers, in addition, a significant improvement in resource security for all countries; those which have operated nuclear power plants in the past as well as newcomer countries. For the latter, the iMAGINE system could be started with enriched uranium and subsequently fed with the tailings accumulated through the enrichment process.

The vision, zero waste nuclear, reflects the aim of reducing the amount of waste produced per unit energy. This is realised by releasing almost all energy from the material which has already been mined, and ultimately also delivers towards the mission of unlimited nuclear energy. The aim is to reduce the waste per unit energy to 1% or lower, compared to the LWR open fuel cycle operation. This has to be achieved through the subsequent use of all fissile and fertile material for energy production, as well as by developing reasonable strategies for the selective removal of the required fission product, followed by delivering strategies for the use of fission products separated from the reactor instead of just declaring all fission products as waste.

Figure 1 depicts the position of iMAGINE in the nuclear system as it was defined earlier, with LWRs operating in open fuel cycle mode and the option of fast breeder reactors operating in closed fuel cycle mode for energy production (as well as potentially for waste management). iMAGINE offers the opportunity either to be seen as: (1) A waste management system where the spent nuclear fuel of LWRs is directly turned into the salt phase to be inserted into the reactor system. The attached salt clean-up, based on the principles of reverse reprocessing [

4,

6], only separates out fission products from the reactor; or (2) a closed fuel cycle system replacing the need for classical solid fuelled fast reactors and the required multi-recycling scheme [

5,

7] for massive, long term nuclear energy production. However, these seemingly alternate perspectives are only important for setting initial priorities, since the system intrinsically delivers on both visions. Only in the case of demand for very rapid delivery on the waste management target would a dedicated reprocessing system be required to concentrate the minor actinides, otherwise the process will take the time which will be required to harvest the energy of roughly 95% of the SNF; the uranium 238 which is still contained in the spent fuel of LWRs.

3. Code, Model and Methods

This section is based on the code, models, and methods section of [

11]. Compared to this recent publication, we have only amended this section to describe the specifics of the present study.

The HELIOS code system, version HELIOS 2.03, with an internal 173 group library [

13] has been used for the simulations. The code is a 2D spectral code with wide unstructured mesh capabilities, a transport solver based on the collision probability method [

14] and a newer extension based on the method of characteristics [

15]. The general model is based on the EVOL benchmark configuration [

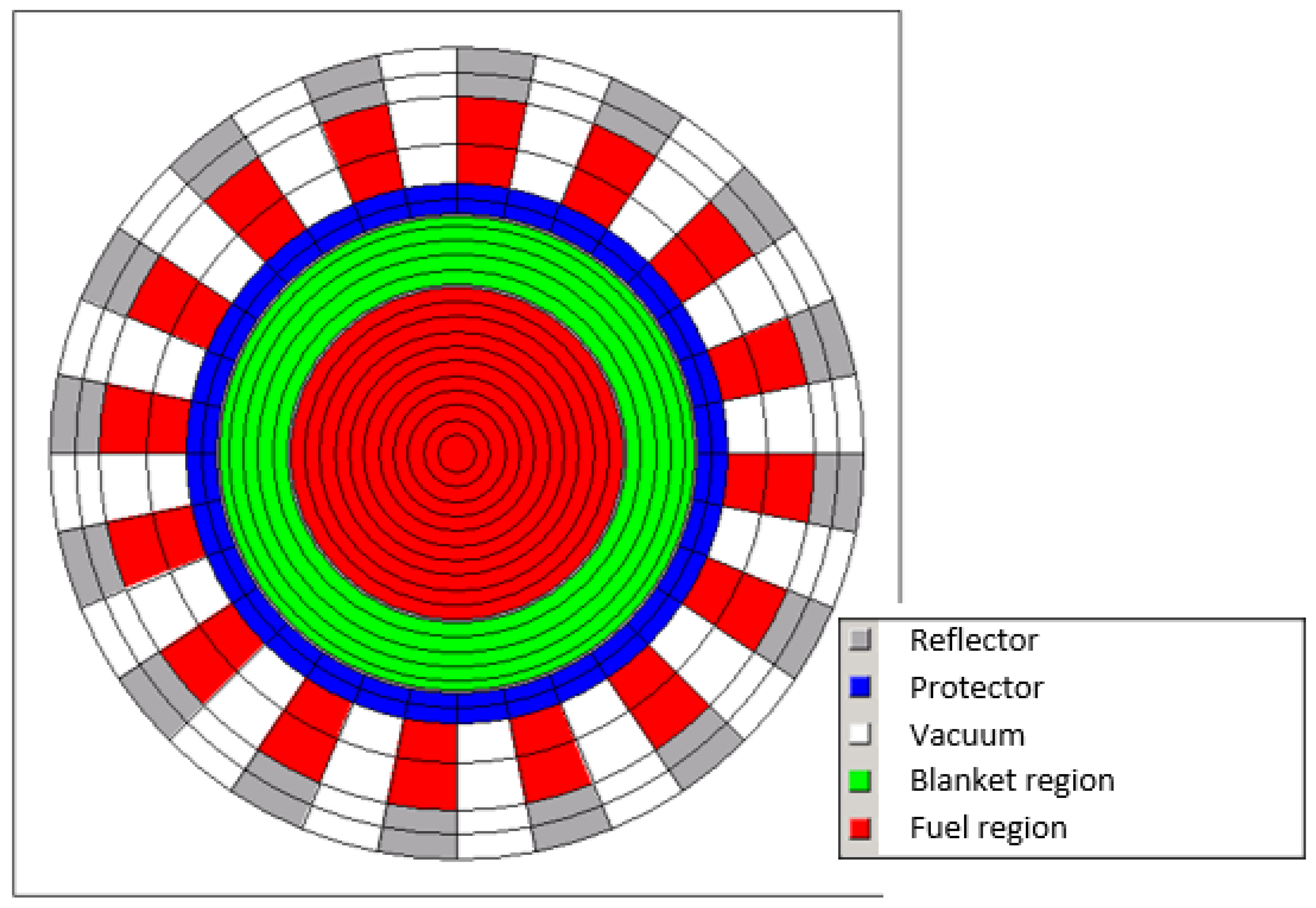

16] which has been transformed into a volume corrected 2D HELIOS model (see

Figure 2). The model has been adopted to reproduce the 3D structure and the relations between the different materials as closely as possible. Furthermore, the benchmark model has been extended to additionally represent the outer structures and the 16 heat exchanger pipe arrangement for a better representation of the real geometry. The leakage in the third dimension is introduced into the calculation through the insertion of a buckling correction available in HELIOS (BSQ: 0.00002). This value has been fixed by a comparison of 2D and 3D calculations within the EVOL benchmark exercises [

17]. Using this setting, a k

inf of ~1.005 is required to achieve a pseudo 3D k

eff of 1.0. Leakage in the radial direction is directly modelled through vacuum boundary conditions.

The salt system chosen as reference system for iMAGINE is based on NaCl–UCl

3–UCl

4, with the eutectic composition 42.5%–17.0%–40.5%. A more detailed discussion on the properties of the salt system and the rationale behind its choice is given in [

18]. The blanket area is filled with sodium, while the protector (the component used to shield the sensitive components such as pumps and heat exchangers) is based on B

4C. The starting reference model has a core size of 287.5 cm radius and a U-235 enrichment of 11.06%. This will be used for the comparison with the Pu-started core for which the dimensions and the fissile loading has to be determined using the Pu vector as given in

Table 1.

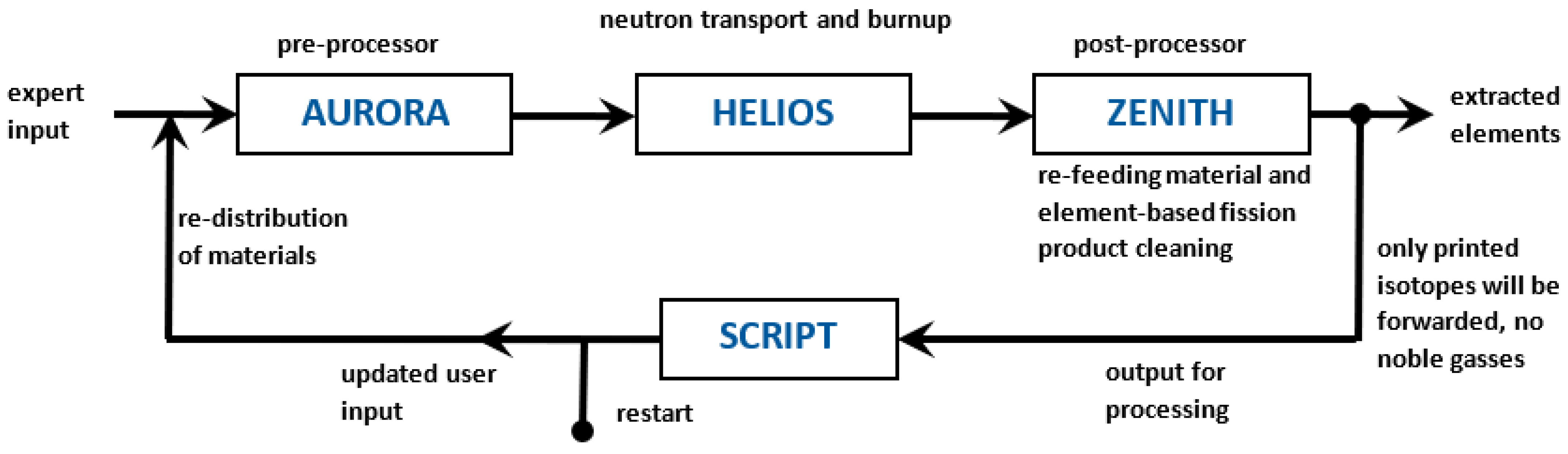

The HELIOS code is an industrial standard software which is designed to perform neutron transport and burn up calculations, and if requested, the cross-section preparation in the whole system or in defined calculation areas under the consideration of the boundary conditions set for the unit cell. Originally, HELIOS was developed to simulate solid structured fuel assemblies; thus, the possibility of online refuelling and reprocessing was not foreseen. To deal with these special molten salt reactor modelling requirements, a PYTHON script based on the special features of the HELIOS package has been developed [

20]. All input data, which does not change during the whole reactor operation, is stored in a so-called expert input. The changing material configuration is fed into the system through a user input which is re-written in every cycle using a PYTHON script. Within each of these cycles, five burnup steps are calculated through HELIOS. The expert input and the updated user input are merged in the pre-processor AURORA [

21], which creates the updated input for the HELIOS run used to determine the neutron flux distribution and material burnup. The results are finally evaluated at the end of each cycle in the post-processor ZENITH [

22] where it is decided which elements are reduced or increased and to what extent, along with the isotopes to be fed back into the next user input, which is created using the PYTHON script (see

Figure 3). Theoretically, it would be possible to simulate a molten salt reactor precisely by using small time steps in this calculation loop. In a real molten salt reactor (MSR), however, two different time scales based on two different processes can be observed for the salt clean-up; the helium bubbling for gaseous and volatile fission products with a comparably short acting time, and the online salt clean-up for the dissolved fission products with a significantly longer acting time. To improve the modelling of both procedures, a new strategy has been developed based on the use of a reduced burnup per cycle (10 GWd/tHM using five burnup steps in HELIOS). The cycle length coincides with full removal of the gaseous and volatile fission products (the elements 18, 35, 36, 53, 54, 85) which are not carried forward through ZENITH. In contrast, the dissolved fission products can be removed within ZENITH based on a cleaning efficiency, providing the opportunity to set this efficiency element-wise for all of the elements considered. The applied process allows the modelling of a dynamic salt clean-up, since the separation amount of the specific fission products is not set as a constant value, but instead relative to the accumulated amount of fission products in a specific clean-up stream. This leads to concentration dependent separation amounts in each step and the build-up of asymptotic fission product concentrations as described later. In addition, this approach also allows for allow changing the amount of clean-up streams as well as the individual separation efficiencies for each element during the calculation procedure.

The use of the aforementioned process has already been validated and used in several peer-reviewed publications [

20,

23,

24,

25]. However, the modelling and simulation quality will be significantly improved due to the new code version and the increased computational power which allows the use of the 173 energy group cross-section set instead of the 47 group set used in the earlier publications.

However, due to the characteristics of HELIOS, some approximations still have to be accepted. The absence of fuel salt movement leads to an undesirable burnup distribution during each calculation cycle, with the materials redistributed only on defining a new user input. HELIOS is an LWR code and an LWR spectrum is used for weighting the master libraries inside each energy group. However, this error will be significantly reduced compared to earlier publications, since the number of energy groups is tripled, leading to a significant reduction in the width of each energy group. Comparisons with other codes in the EVOL benchmark [

17], in a fast reactor isotope accumulation test against SERPENT [

26], as well as comparisons with SCALE/POLARIS [

18,

27] have shown good agreement. This is what is currently available in terms of modelling techniques and solvers; therefore, to judge the reliability of the results, a real reactor physics experiment for molten salt reactors would be required, as discussed in [

27].

The approximations and the use of the HELIOS code package seem to be adequate for the approximation level required for this kind of long-term investigation of isotope accumulation to support the development of a clean-up system. The results of the influence of different elements on the system criticality has been evaluated against earlier publications [

19,

28].

The accumulation of isotopes is evaluated through a series of calculations of the system using the dynamic calculation scheme described above.

This is followed by a more sophisticated evaluation of the effect of the partial removal of different fission product element combinations on the potential increase in criticality compared to the reference case, as well as the increase in the final burnup achievable through the removal of specific element combinations. The same approach is used to investigate the effect of initiating the fission product clean-up at different burnup levels and the effect of different separation efficiencies, representing different salt throughputs through the clean-up system. In the next step, the fission product removal is applied in a staggered way, where the clean-up of one additional fission product is initiated every time the criticality of the test system approaches unity. For some of the cases, the fission product accumulation of specific elements will be analysed in addition, to get a deeper insight into the influence of the clean-up system on the fission product accumulation and a potential asymptotic limit of accumulation. The study will be finished with the investigation of the opportunity to control the system by splitting a share of fuel salt from the operational system and replacing it with pure fertile salt. This could be a promising approach for creating the fuel required for a next of a kind system which would help to avoid the transient system adaption at the beginning of the operation.

4. Results and Discussion

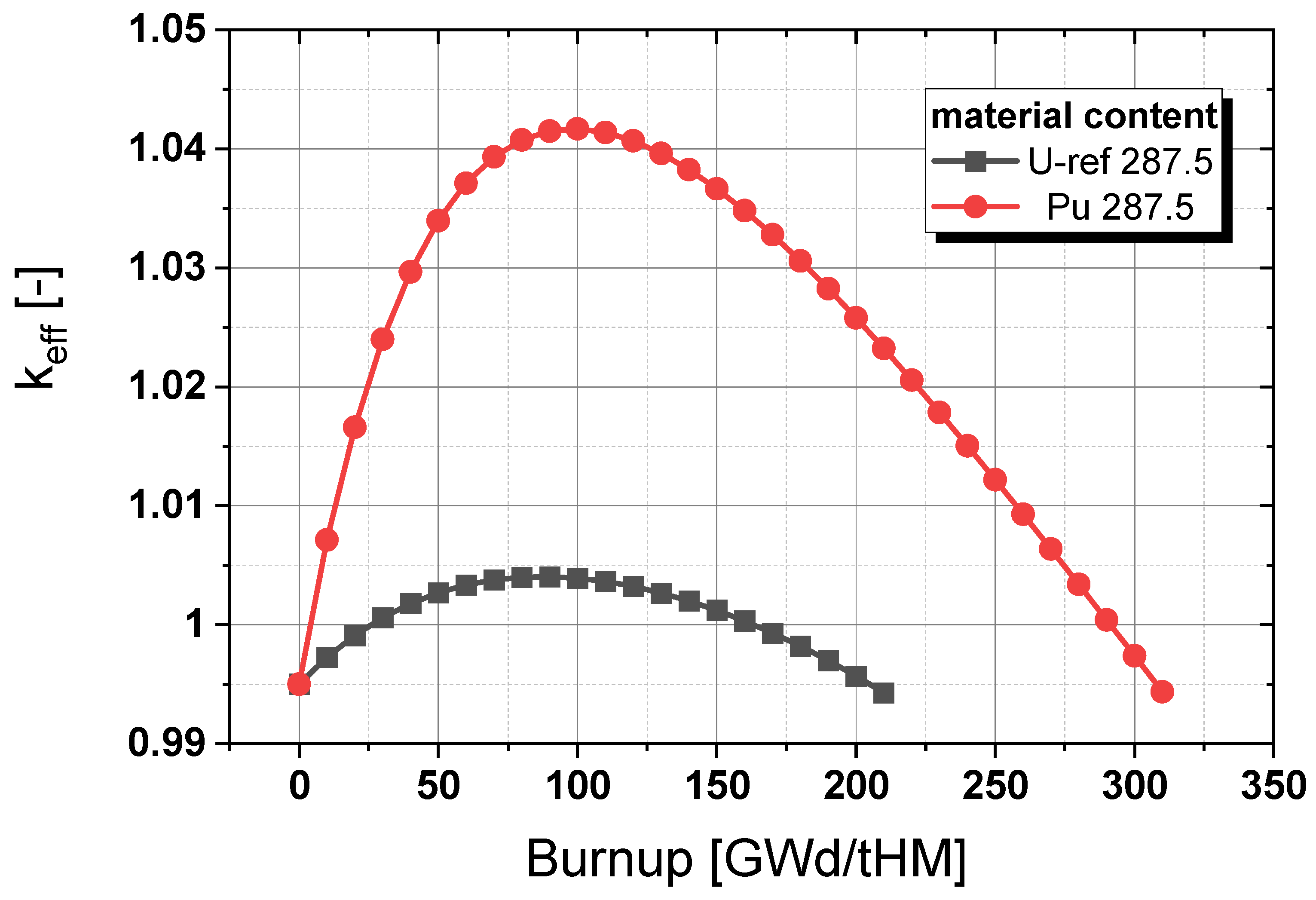

In the first step of the comparison for the molten salt fast reactor (MSFR) design, the Pu content in the core is adopted to achieve the same starting criticality value for the core with 287.5 cm radius. The calculated Pu content is 10.4% with the same core dimension to achieve the same starting value for criticality, see

Figure 4. The burnup curve shows that using the same reactor dimensions, the Pu-loaded core provides substantially more efficient breeding than the uranium-based start-up core, leading to an almost 4000 pcm higher peak criticality. Additionally, the achievable burnup before the clean-up would have to be initiated is roughly 50% higher. The original approach for the determination of the core size in the U ref. case was to keep the criticality between ±500 pcm to allow using fuel temperature control as promised in [

29]. To satisfy these limits, obviously, the core size has to be significantly reduced. In addition, it has to be mentioned that the final burnup for a case with such high criticality will not be completely correct, since a considerable number of neutrons will get lost due to normalisation and will thus not be available for breeding. A rough estimation of this effect showed that the breeding is underestimated by ~2.3% due to the normalisation. Based on this first outcome, the next step will be to determine a reactor core size which will fulfil the criterion of deviating within ±500 pcm from criticality throughout the observed operational period.

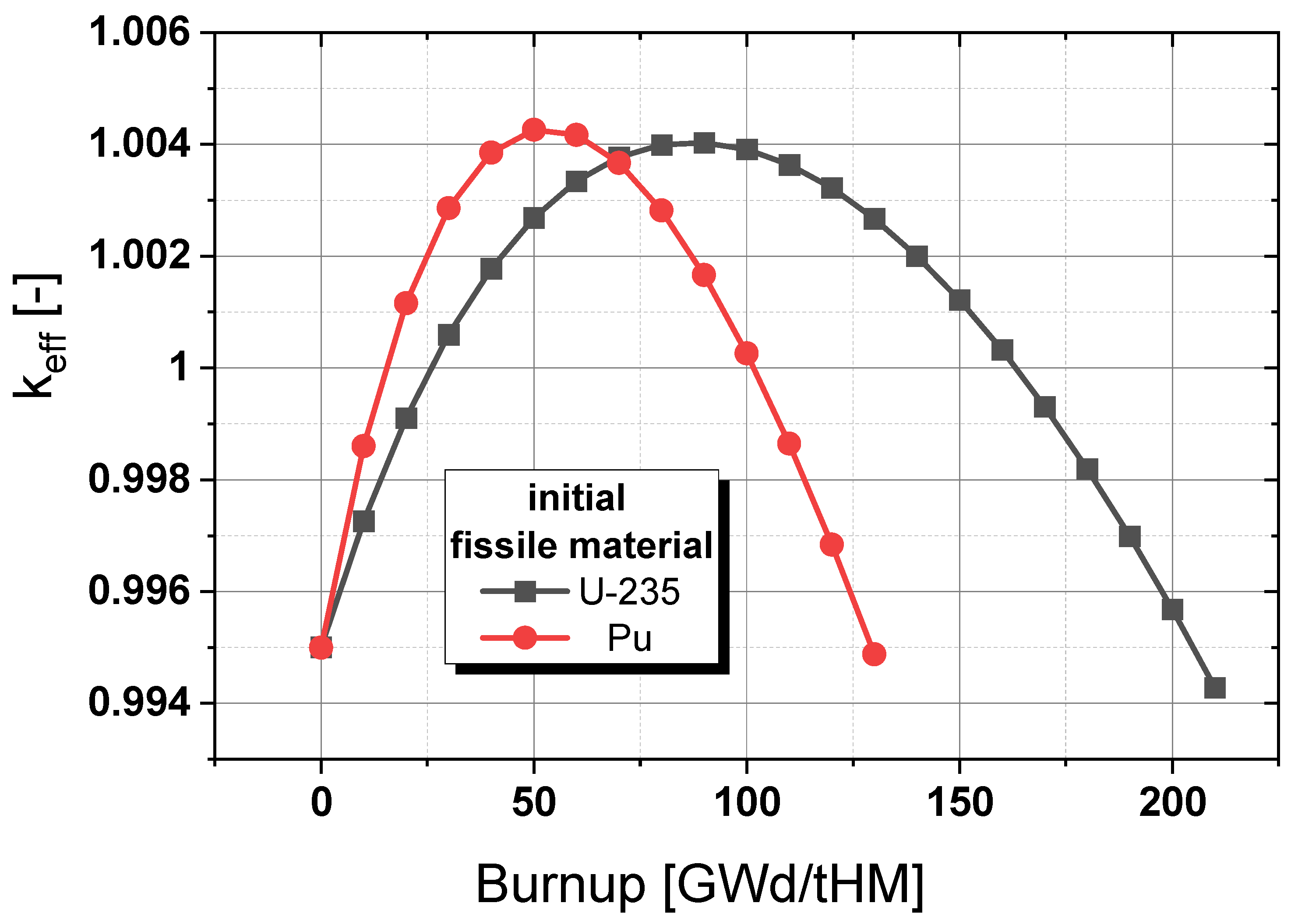

The considerably reduced core size, which stays within the defined limit, was 187 cm in radius with 11.67% Pu content in the core and leads to a breeding curve that delivers a comparable criticality change to the U reference case but with a reduction in the achievable burnup, see

Figure 5. This is equivalent to a 34% reduction in diameter, or more importantly a 58% reduction in core volume and thus, in fuel salt required for the first core loading. The plutonium balance indicates roughly a 52% reduction in the Pu demand for the start-up of the system. However, this comes with a drawback; the energy which can be extracted from the fuel before demanding the start of the salt clean-up system is 34% lower compared to the uranium reference fuel, due to the reduced achievable burnup (see

Figure 5). The achievable burnup without initiation of the clean-up system is ~130 GWd/tHM compared to more than 200 GWd/tHM, a decrease of ~35%. Combined with the reduced salt mass or volume in the core, the energy which can be harvested from the core is reduced to 35%. The major reason for the different behaviour of the Pu- and U-based cores is the change in the fissile material in the U-based core which turns slowly from a U-235 driven core to a Pu-239 driven core. This change leads to a substantial increase in the number of neutrons per fission, which enhances the breeding process considerably.

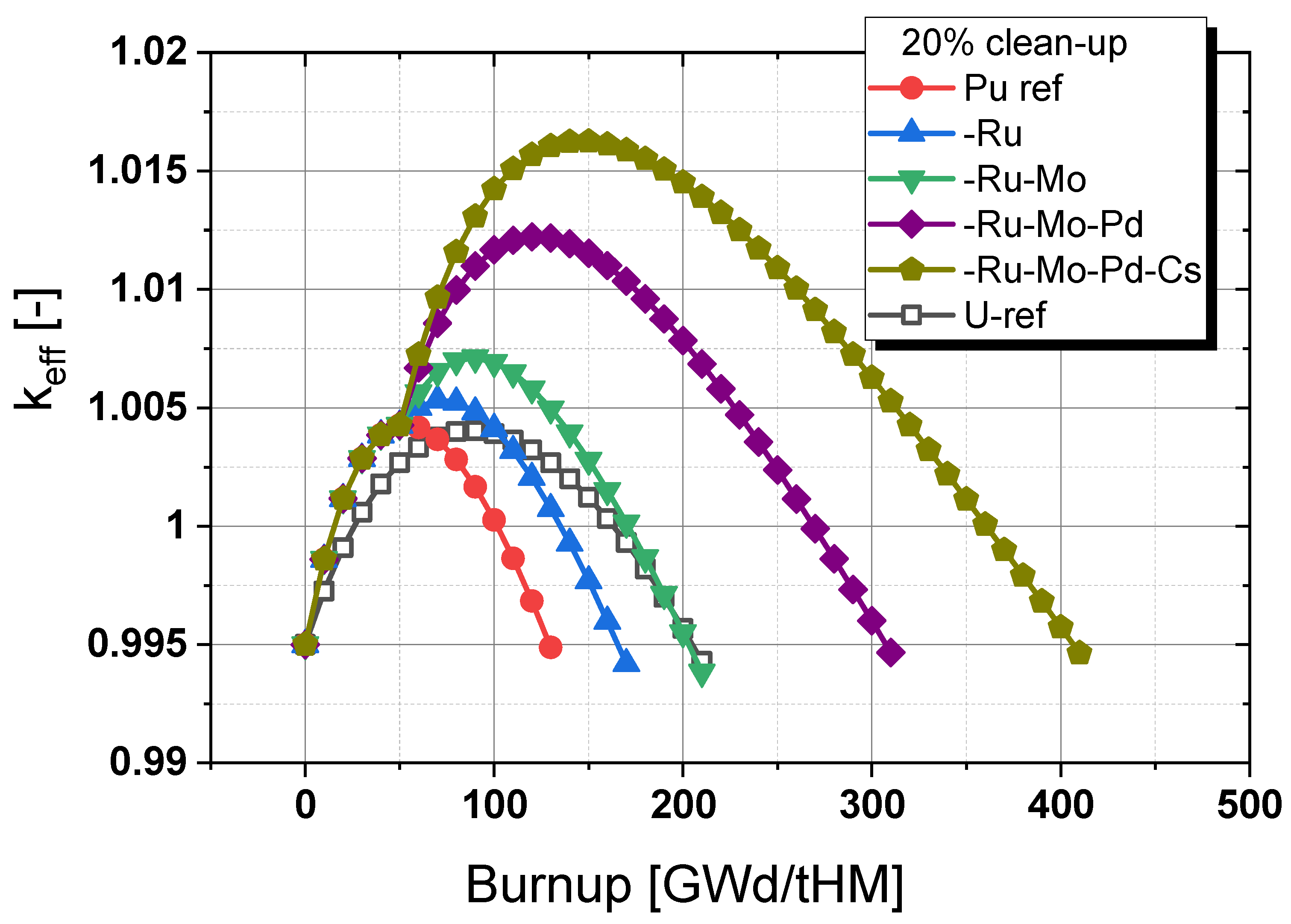

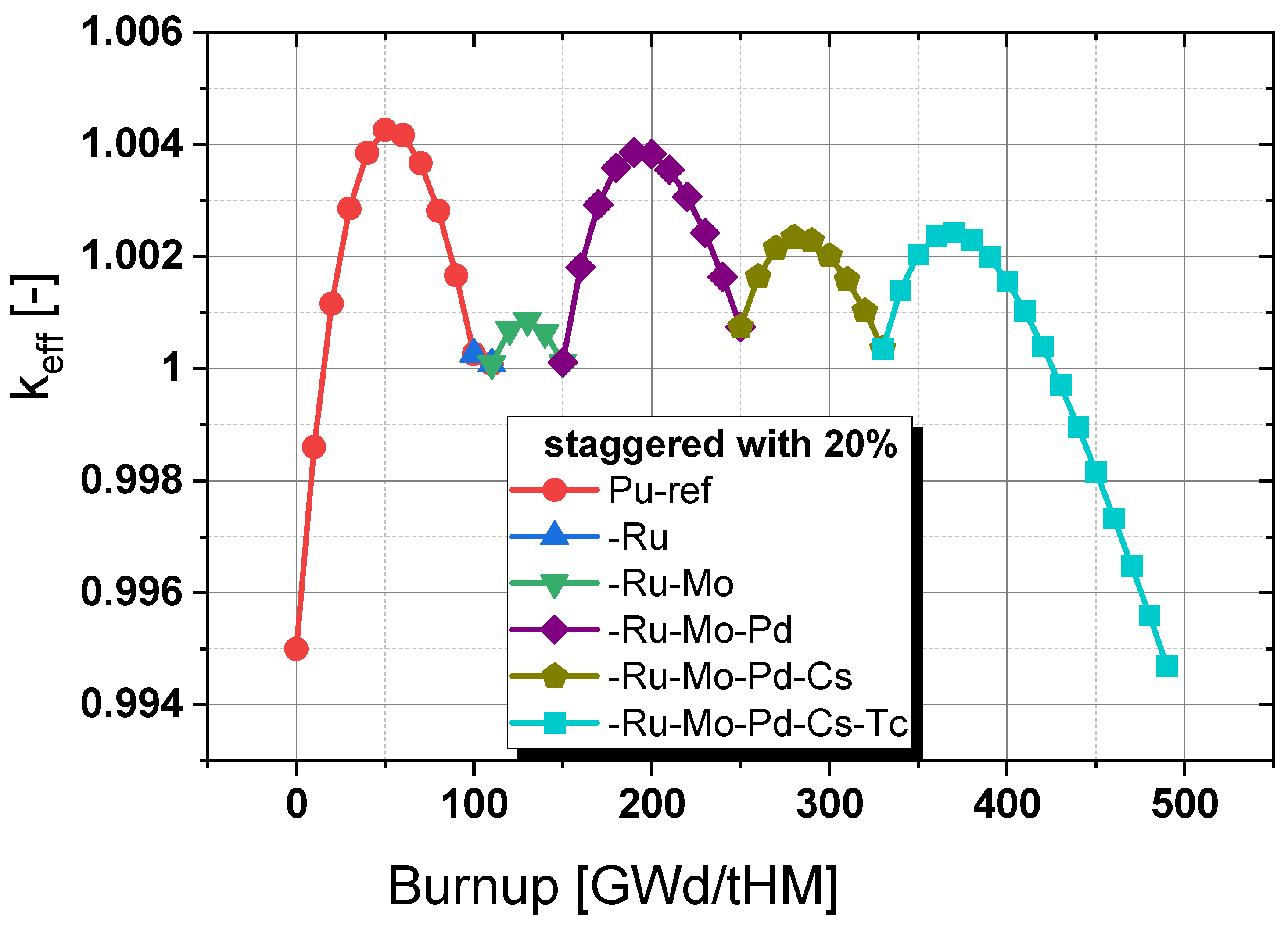

Adding different levels of salt clean-up (20% and 40%) to the operational schedule will help to extend the achievable burnup of the core, see

Figure 6 and Figure 8. The clean-up with desired efficiency was modelled, as described above, by splitting a stream of salt (20% or 40%) at the end of each calculation cycle (10 GWd/tHM), which is then cleaned of specific fission products. The initiation leads to a significant increase in the maximum criticality from ~426 pcm in the reference case to ~530 pcm after initiating the Ru clean-up, to slightly more than 700 pcm after the initiation of the Ru and Mo clean-up, to 1220 pcm if Pd is integrated to the clean-up and finally to ~1620 pcm when Ru, Mo, Pd, and Cs clean-up is initiated at 50 GWd/tHM.

The following increase in achievable burnup from the Pu reference case is observed with starting the clean-up system at a burnup of 50 GWd/tHM: ~40 GWd/tHM for only Ru, +~40 GWd/tHM integrating the clean-up of Mo, +~100 GWd/tHM integrating Pd to the clean-up, and +~100 GWd/tHM integrating Cs to the clean-up. The overall increase in the burnup when Ru, Mo, Pd, and Cs are integrated into the clean-up is from 130 GWd/tHM to almost 410 GWd/tHM. It becomes obvious here that for the Pu-started case, we would already need to initiate the clean-up of Ru and Mo to achieve a burnup comparable to the U ref. case.

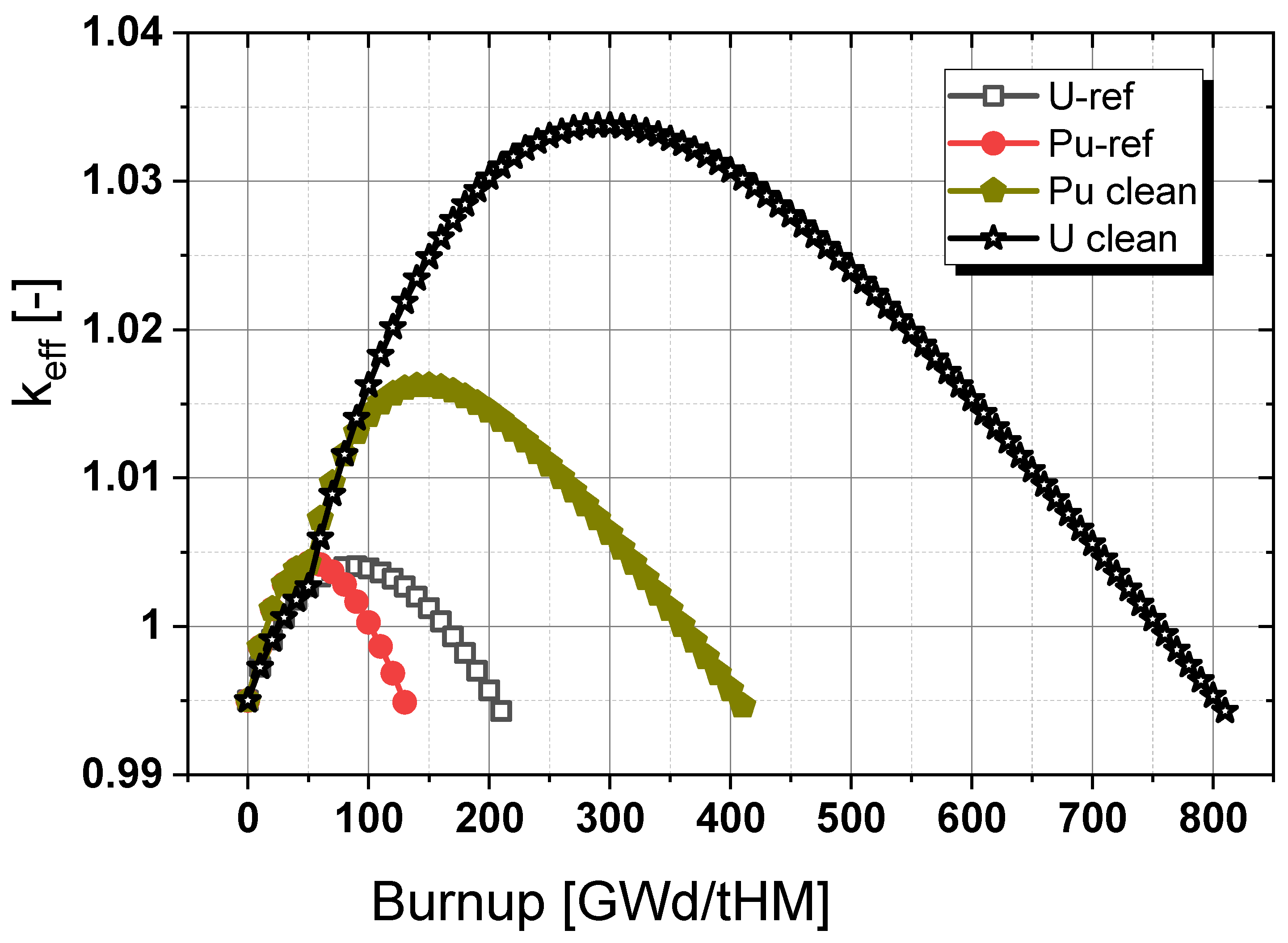

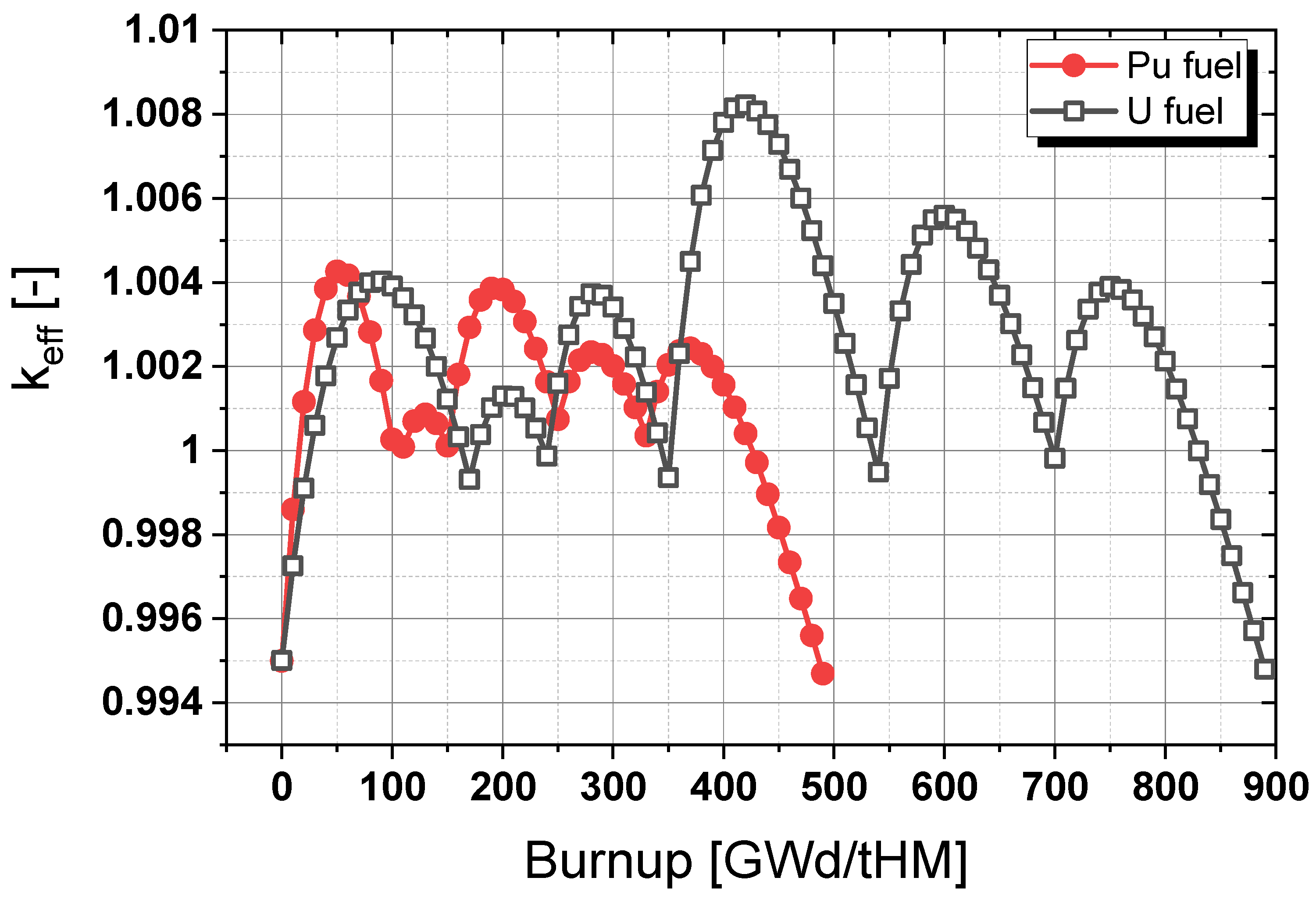

In comparison to the uranium-started case,

Figure 7 shows that the achievable burnup for the Pu-started case is not only significantly lower than the reference case, where the difference was 35%, but the effect becomes even more pronounced when considering the salt clean-up in the uranium- and plutonium-started cases. Here, the reduction was about 50%, which would become even higher if the k

eff normalisation effect is considered, since this normalisation becomes more pronounced with a higher maximum criticality. The k

eff normalisation effect is a mathematical artefact of the calculation procedure due to normalisation of the fission source by the criticality value, leading to an ‘artificial’ increase or decrease in the fission source. It is known that this effect can lead to ‘artificial’ results regarding breeding, especially in cases of very high or low criticality, as the above-mentioned normalisation of the fission source either creates artificial neutrons in the case of criticality less than unity, or it neglects a part of the neutron source in the case of criticality higher than unity. This leads to an over- and under-estimation of breeding in subcritical and supercritical systems, respectively. It should be mentioned here that the effect of criticality above unity is MSR specific, since criticality will/can probably be controlled through feeding and temperature effects [

29]. In classical solid fuelled reactors, the excess neutrons will have to be controlled away through absorption processes; thus, this mathematical approach will be permitted, since it replicates a real physical process. Thus, the k

eff normalisation effect is a potential source of misinterpretation of results in MSRs and has to be considered carefully. In general, the curves are comparable in their form, but the effect of the change in the fissile material in the uranium-started case leads to this significant difference in the achievable burnup which is still normalised on the fuel volume. Thus, the effect on the energy which can be extracted in a real reactor would have to be multiplied with the difference in core volume as given in the initial analysis.

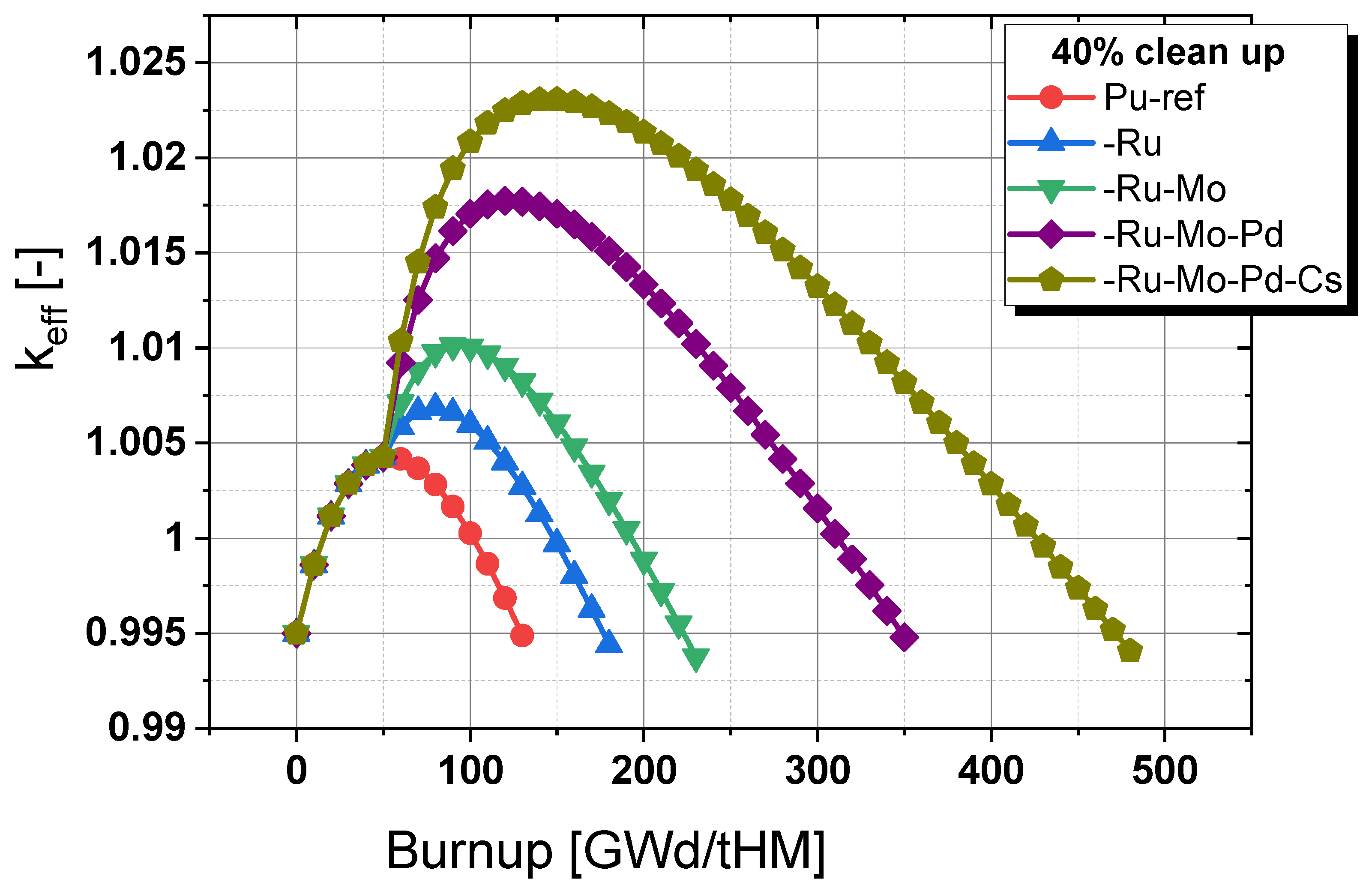

Next, the effect of doubling the clean-up rate to 40% was investigated, see

Figure 8. The increased clean-up leads to a significant increase in the maximum criticality from +426 pcm in the reference case to ~690 pcm (vs. 530 pcm for the standard 20% clean-up rate) after initiating Ru clean-up. It then rises to slightly more than 1000 pcm (vs. 710 pcm) after the initiation of the Ru and Mo clean-up. Following this, it rises to almost 1800 pcm (vs. 1220 pcm) if Pd is integrated to the clean-up and finally rises to ~2300 pcm (vs. 1624 pcm) when Ru, Mo, Pd, and Cs clean-up is initiated at 50 GWd/tHM. Doubling of the clean-up rate to 40% also helped to extend the achievable burnup of the core, see

Figure 8. This is reflected in the higher burnup where the following increases were achieved: +~50 GWd/tHM (vs. ~40 GWd/tHM) for only Ru clean-up; +~50 GWd/tHM (vs. ~40 GWd/tHM) when integrating the clean-up of Mo; +~120 GWd/tHM (vs. ~100 GWd/tHM) when integrating Pd into the clean-up; and +130 GWd/tHM (vs. ~100 GWd/tHM) when integrating Cs into the clean-up. Thus, the overall increase in achievable burnup when Ru, Mo, Pd, and Cs are integrated into the clean-up was from 130 GWd/tHM to almost 480 GWd/tHM instead of 410 GWd/tHM. In other words, doubling the clean-up rate from 20% to 40% leads to a less than 20% increase in the final achievable burnup, which shows that the effect is self-limiting.

A comparison of the average long-term fission product concentrations which will develop as a result of the increased throughput of the clean-up system is shown in

Figure 9. The main take-away message from this figure is that doubling the throughput will be disadvantageous for the chemical engineering. The clean-up system would have to work on roughly half as large concentrations, which will have a clear drawback on the efficiency of the chemical processes [

19]. Considering the associated cost of doubling the clean-up efforts and the increased challenges in the clean-up due to the lower concentrations of the elements to be separated, the effect is clearly not as strong as desired which raises a question regarding the optimal value.

From this discovery, some important outlooks can be developed regarding different potential reactor concepts, their efficiency and their breeding potential. Large uranium- and plutonium-based systems such as those investigated are characterised by a comparatively high number of neutrons per fission (>~2.7) due to the hard neutron spectrum and the high number of neutrons per fission produced in Pu-239. This offers a robust number of excess neutrons for breeding, since a fast reactor is typically relatively robust to fission product poisoning due to the low absorption cross-sections of the fission products in the fast spectrum. Two other important factors have to be considered in addition: a typical fast reactor core requires a significantly higher amount of fuel and the neutron leakage from the core is higher in a fast spectrum. From this we could have an outlook to thermal breeding which is typically delivered in the thorium–uranium cycle. U-233 releases ~2.3 neutrons per fission in the thermal breeder systems which is significantly lower than that of the fast reactors and thus leads to a lower breeding potential. In addition, the absorption cross-section of several fission products is much higher in the thermal spectrum. The only advantage in the thermal core will be the reduced neutron leakage compared to fast reactor cores thus lowering the amount of fuel required in the core. Based on these physical and technological observations, it can be postulated that the demand on the salt clean-up will be significantly higher for a thermal core, due to the reduced breeding potential, the lower amount of fuel in the core and the higher risk of fission product poisoning.

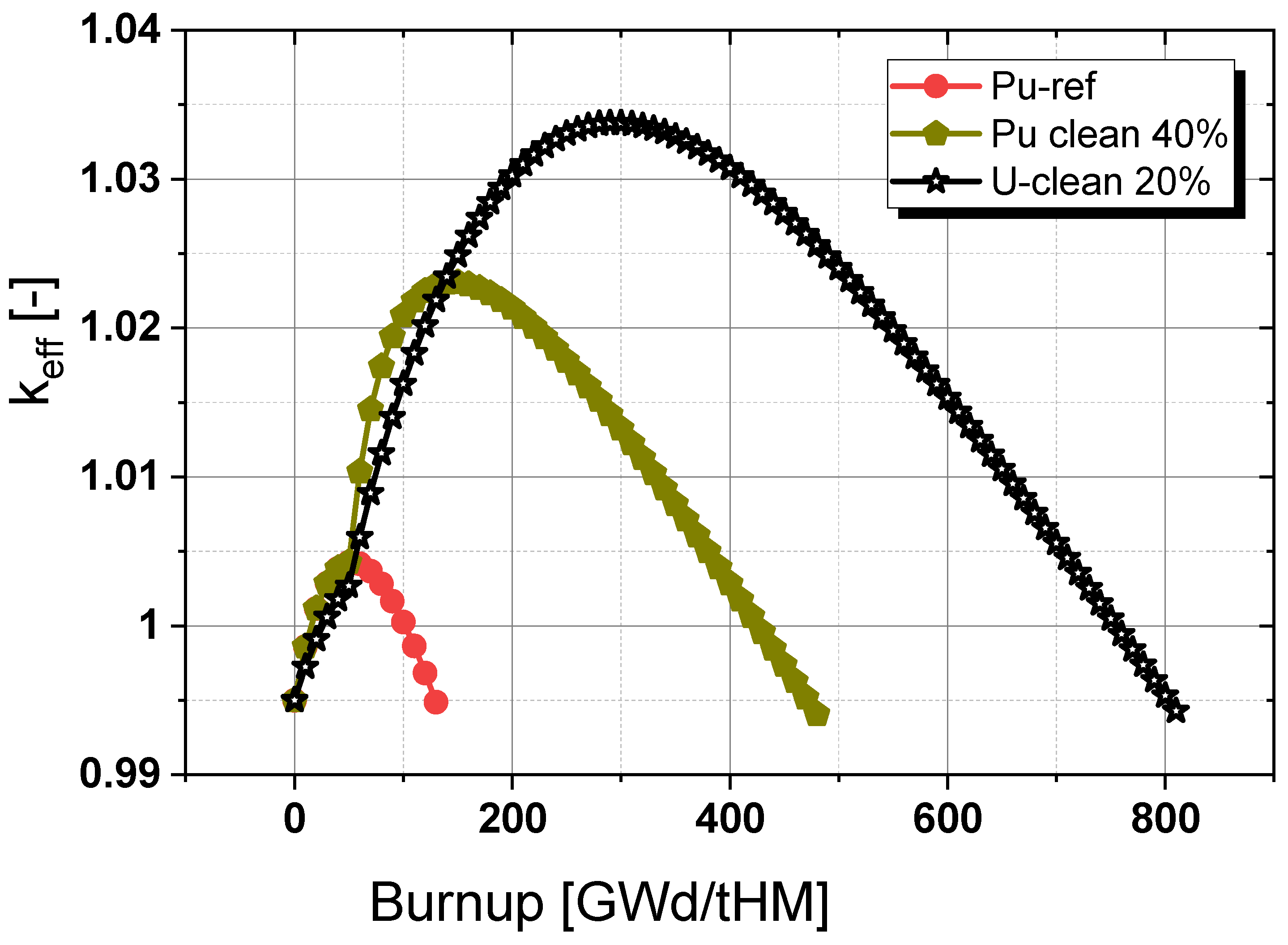

Coming back to the steps of the study, the detailed comparison between the uranium-started system with 20% clean-up and the Pu-started system with doubled throughput, see

Figure 10, indicates that the maximum of criticality of the Pu-based core is increased from ~1.016 to 1.023 (compare

Figure 10 with

Figure 7) by increasing the clean-up throughput, which leads to a lower content of fission products, as shown in

Figure 9. However, from this figure it becomes clear that doubling the throughput of the clean-up system leads to a limited gain of about 20% in the potential operational time. This is significantly lower than the potential operational time achievable in the uranium-started system due to the substantially larger system dimensions and the resulting higher salt volume. This is due to the progressive change in fissile material composition of the uranium-started system from primarily U-235 to Pu which produces a higher number of neutrons per fission.

Looking at the wider picture, some conclusions should be drawn here to complete the view. Taking the difference in the volume into account, the energy amount which can be produced in the Pu-started core will be only about a quarter of the amount of that of the U-started core. This needs some discussion. The Pu-started core is more attractive based on the amount of initially invested fissile material, since less than 50% of the initial salt is required compared to the uranium case. However, considering the economics of the overall system, the system cost will not differ significantly since the Pu-based core, although slightly smaller, would have a larger clean-up demand and finally in the long-term operation both systems will be fed using spent fuel or tailings which are low in cost.

Following the investigation of the increased throughput through the salt clean-up system, which shows an insufficient increase in the core lifetime, the next investigation will be to look into the effect of adding a new clean-up step for the element Tc and the potential for achieving a higher burnup [

11]. Additionally, the clean-up process with 20% throughput is now staged in a staggered manner such that the clean-up for an additional element is initiated at the step prior to the system criticality going below unity, see

Figure 11. The advantage of this approach is that the system achieves a criticality maximum of less than 1.005 leading to a more reliable result for the efficiency of the breeding process by minimising the influence of k

eff normalisation. A staggered initiation of additional elements in the clean-up process will allow a final burnup of almost 500 GWd/tHM, and the additional clean-up step delivers a burnup increase of ~80 GWd/tHM. This approach shows that it would not be necessary to have the technology for clean-up of all the elements at the same time. Progressive addition of clean-up approaches for elements lower on the clean-up list delivered in [

15] will allow extension of the core lifetime even if it is not initiated at an early stage of the core life. This opens promising opportunities for the long-term operation of the system with a stepwise increase in sophistication of the salt treatment technology.

However, comparing the plutonium-started system to the uranium-started system with staggered clean-up approach again shows that the uranium-started system will work for longer and will thus be more preferable, see

Figure 12. This choice becomes even more evident when considering that not all countries will have access to separated plutonium from operating a reprocessing facility such as is the case in the UK. These results further show that it is possible and more attractive to start iMAGINE with an enriched uranium-based fuel and accept the increased system size required for this system.

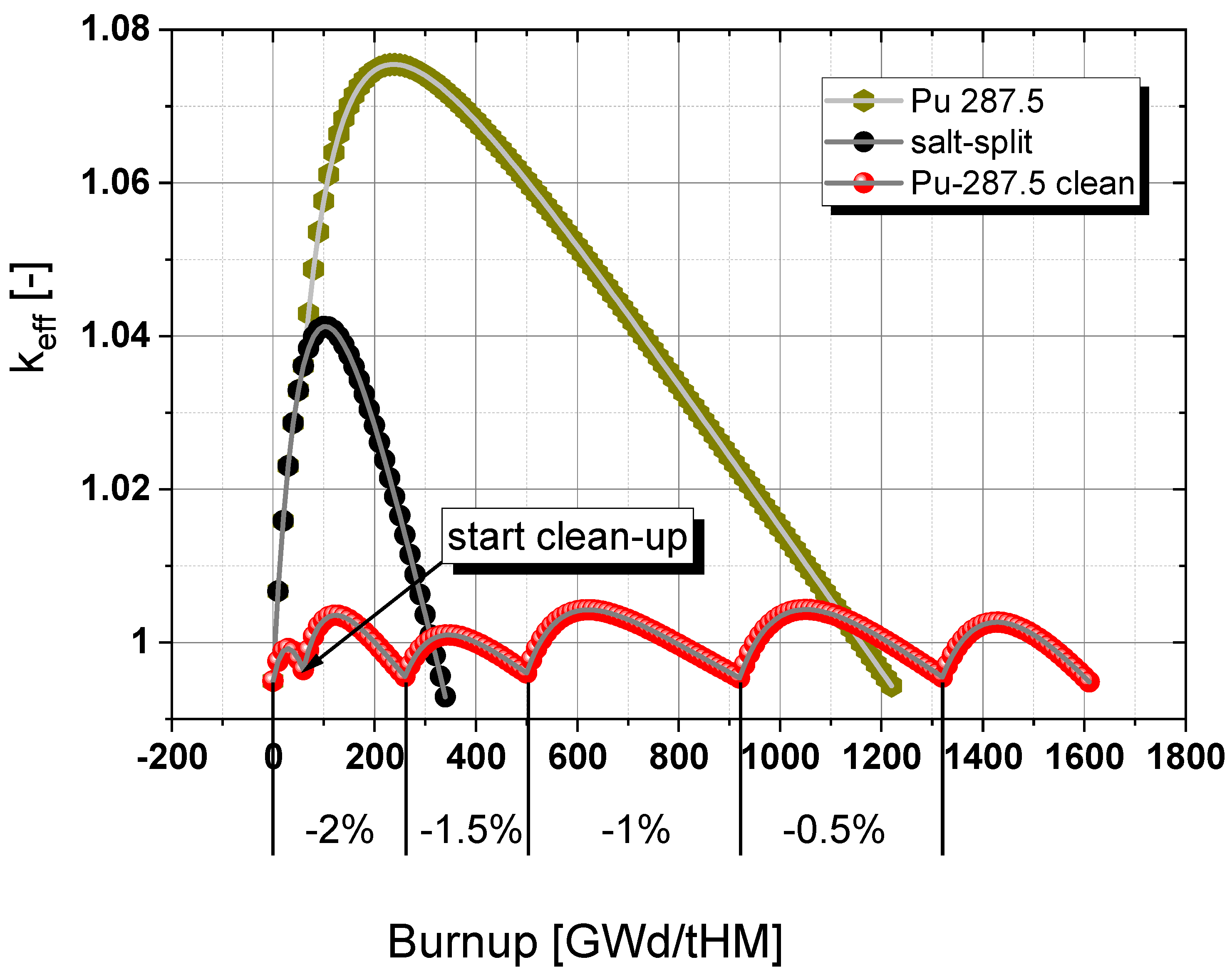

Evaluating the approaches from a technical point of view, it might be questionable to develop a new system with different sizes in parallel; a smaller one for the plutonium-started system and a larger one for the uranium-started system. This guides us to the question; how to design a plutonium-started system with the required criticality control using the same size as determined for the uranium-started system. One potential approach could be to use salt splitting as the operational reactivity control mechanism, where the salt amount split away from the system is replaced by UCl-based fuel manufactured from depleted uranium (tailings) or fertile salt. In this approach, the split away salt could be used for feeding the next reactor in the chain, avoiding the uranium enrichment process.

Figure 13 indicates the criticality curve for the 287.5 cm radius system filled with the required amount of plutonium to achieve the initial starting condition of k

eff = 0.995. The system without any additional clean-up would rise to a maximum criticality of ~1.04, before the effect of the fission product poisoning reduces the criticality, leading to a final achievable burnup of ~370 GWd/tHM. Starting the clean-up system after 50 GWd/tHM and separating Ru, Mo, Pd, and Cs with a throughput of 20% after every 10 GWd/tHM burnup would lead to a maximum criticality of ~1.075, and a final burnup of more than 1200 GWd/tHM. Salt splitting is applied by replacing a certain amount of the fuel by pure fertile salt while the amount split away at each step is progressively reduced from an initial value of 2% to 0 in steps of 0.5%. The burnup periods with the amounts of salt (in %) split away from the core are given at the bottom of

Figure 13. The red curve indicates the efficiency of the core reactivity control through this process, even if it is clear that in a real reactor operation the steps would need to be smaller. However, the approach does not only help to control excess core reactivity, it additionally increases the final burnup from ~1200 GWd/tHM to ~1600 GWd/tHM, and the split away salt amount would be sufficient to reproduce ~1.5 times the core. Thus, the salt would be sufficient to start one additional reactor and could feed another to 50%. The achievable burnup increase can be explained here with two mechanisms: (a) the inaccuracy of the breeding calculation due to the k

eff normalisation (this can be estimated to ~4% here); and (b) the withdrawal of a significant amount of fission products due to the salt splitting while fresh, clean breeding material is provided to the core. In general, the process seems to be highly promising since the reactivity control, needed regardless, would create the basis for the supply of fuel for future reactors. Concluding from these results and the discussion above in

Figure 10, it seems to be much more promising to rely on a larger core and use the salt splitting as a potential excess reactivity control instrument. On the one hand, this will allow the clean-up to work with higher fission product concentrations, while on the other hand, the improved breeding will help to provide new fuel as well as to keep the core critical for a substantially longer time. Thus, the core size may not be limited by maximum energy production but instead by the radioactive source term as a safety related parameter [

18].

5. Conclusions

Nuclear energy has the potential to play a very unique role in a sustainable energy future due to the fact that it is the only currently available technology capable of delivering a net-zero energy supply with assured 24/7 availability and controllability. In addition, nuclear technologies can deliver massive amounts of low carbon energy on demand based on already mined resources to support the urgent transition into a net-zero society. However, to deliver on the expected large-scale demand, significant innovation would be required in advanced reactor development to improve the handling/usage of the fuel within the fuel cycle, as well as in the waste management. The iMAGINE concept delivers exactly on these challenges [

30]. However, the core challenges are, on the one hand, to deliver self-sustained breeding and, on the other hand, to deliver a strictly demand driven salt clean-up process which is based on reverse reprocessing to avoid proliferation issues of the so-called plutonium economy. To develop and optimise this process, a substantial input from reactor physics into the solution of this multi-disciplinary challenge is required, which has been delivered in [

11]. The present work extends this insight by investigating a plutonium-started core in comparison with the previously investigated uranium-started core. The start-up of the reactor using Pu as a fissile material is an essential view for the UK due to the Pu stockpile and the demand for a positive management [

31].

The results provided help to optimise the parameters for the salt clean-up process by creating a deeper understanding of the differences which appear between a core started with enriched uranium and one started with plutonium as fissile material. The integrated model is used to investigate the effects of the initial fissile material on core size, achievable burnup, and long-term operation. Obviously, a Pu-started core can be much smaller, but with the consequence of a much lower target burnup before salt clean-up becomes necessary. Due to the significantly smaller fissile inventory, the power delivered before initiation of the clean-up is significantly lower. Different approaches were tested to achieve a higher burnup in the considerably smaller Pu driven core. The effects of different throughputs through the clean-up system on the concentration of fission products in the reactor salt and its consequences are discussed for general molten salt reactor design. The evaluations are supported by a first estimate of the effect or error caused by the keff normalisation for cases where higher criticality is achieved which, in a future molten salt reactor, could potentially be controlled with methods other than simply absorbing neutrons such as those in solid fuelled reactors. Finally, an analysis is presented on how a larger plutonium loaded core could be used to provide fuel for future reactors through fuel salt splitting as a method for controlling the excess core reactivity. The outcome is that one Pu-started reactor of the same size as a uranium-started core could deliver critical molten salt fuel for 1.5 new cores through the enhanced breeding as a positive side effect of this criticality control approach.

In general, this work proves the requirement for a dynamic modelling and simulation approach considering the interaction between the clean-up system and reactor operation. The results provided through such a modelling and simulation approach will form the basis for creating a deeper understanding of the operational behaviour, potential operational issues, and ultimately the safe operation of molten salt reactors. For the longer term, it will be one of the core challenges to develop a toolset for coupled multi-disciplinary operational analysis considering heat removal, the detailed modelling of some of the chemical processes, and the consideration of clean-up and feeding. Such a comprehensive tool would allow investigation of the role of feedback effects on the operation and load following behaviour of a molten salt reactor under constant criticality status, influenced by the integrated salt clean-up and the effects of the feeding streams.