A Short Review on Thermoelectric Glazing for Sustainable Built Environment

Abstract

1. Introduction

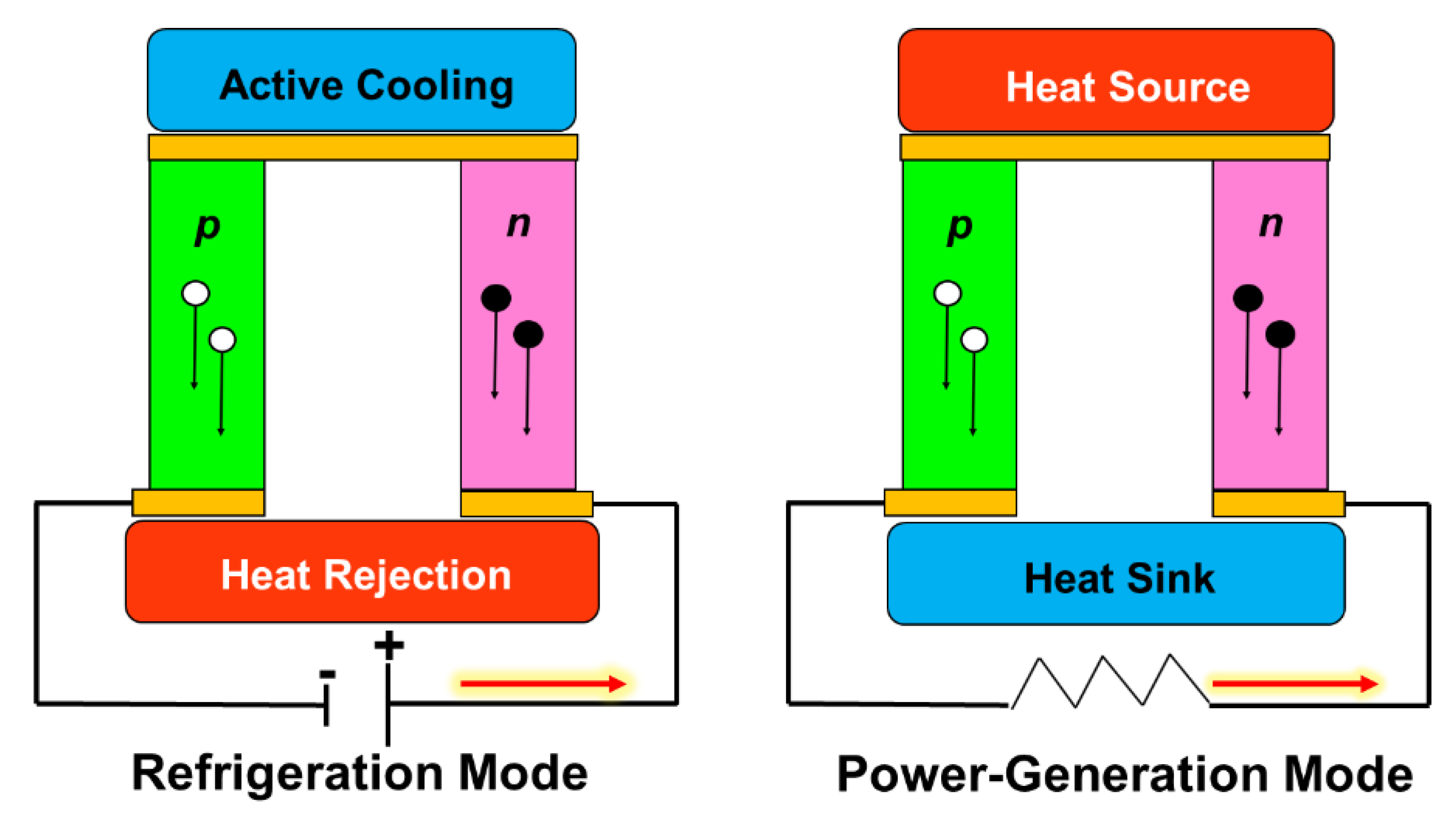

2. Overview of Thermoelectricity

Working Principle

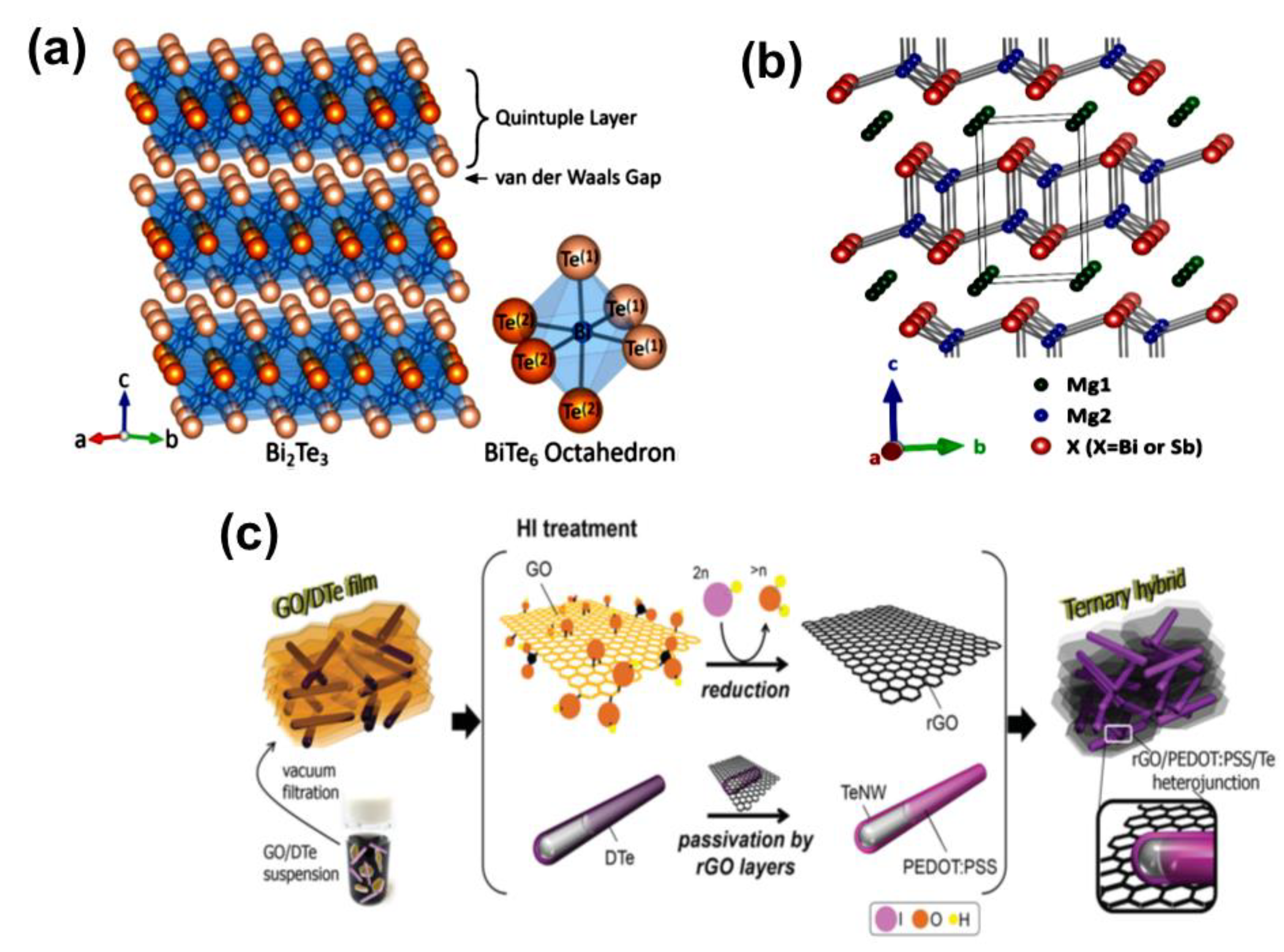

3. Suitable Materials for Thermoelectric Glazing

3.1. Low-Temperature Thermoelectric Materials

3.2. Transparent Thermoelectric Materials

3.3. Large-Scale Synthesis

4. Window Glazing

4.1. Low Heat Gain Glazing

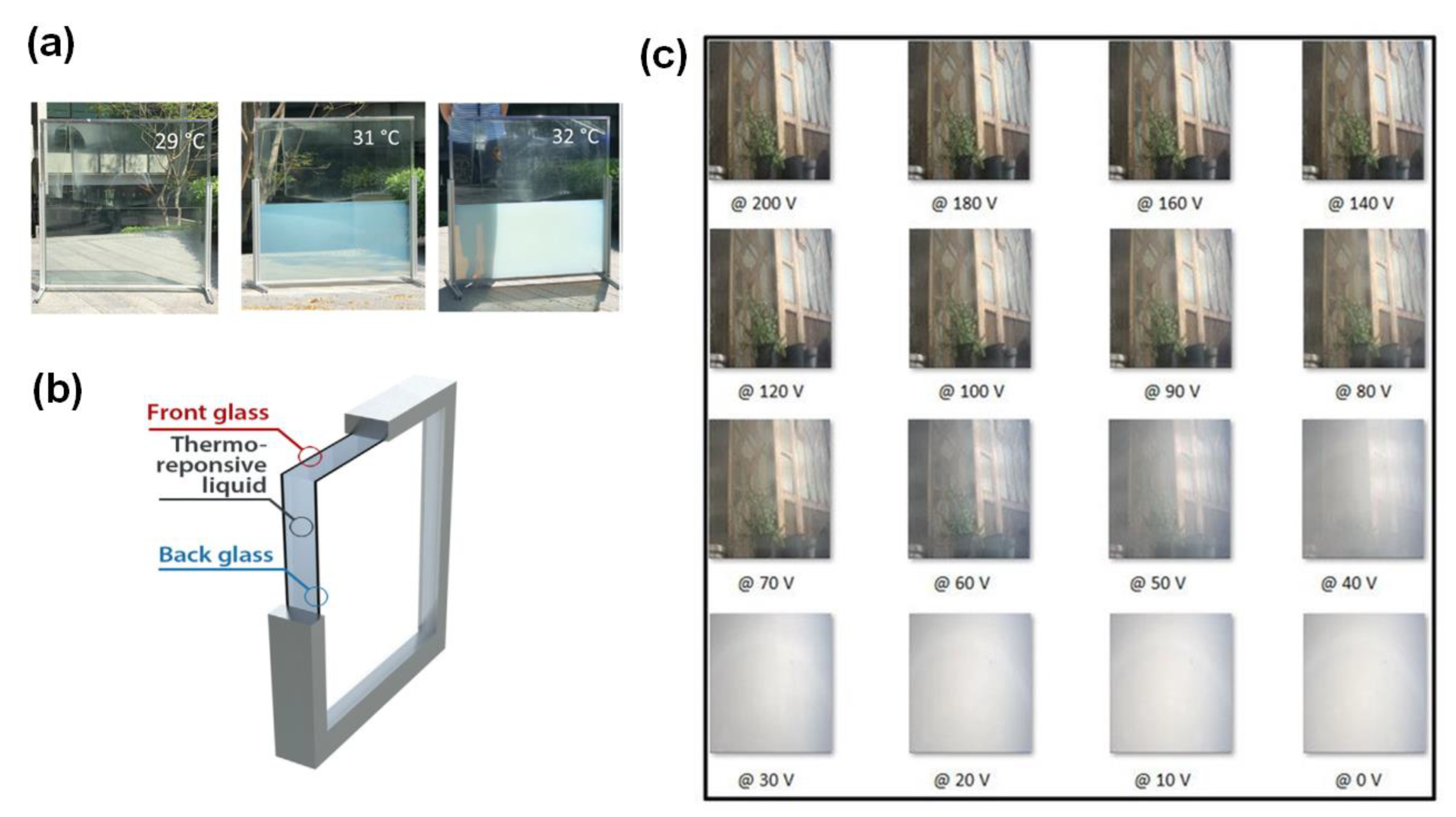

4.2. Smart Glazing

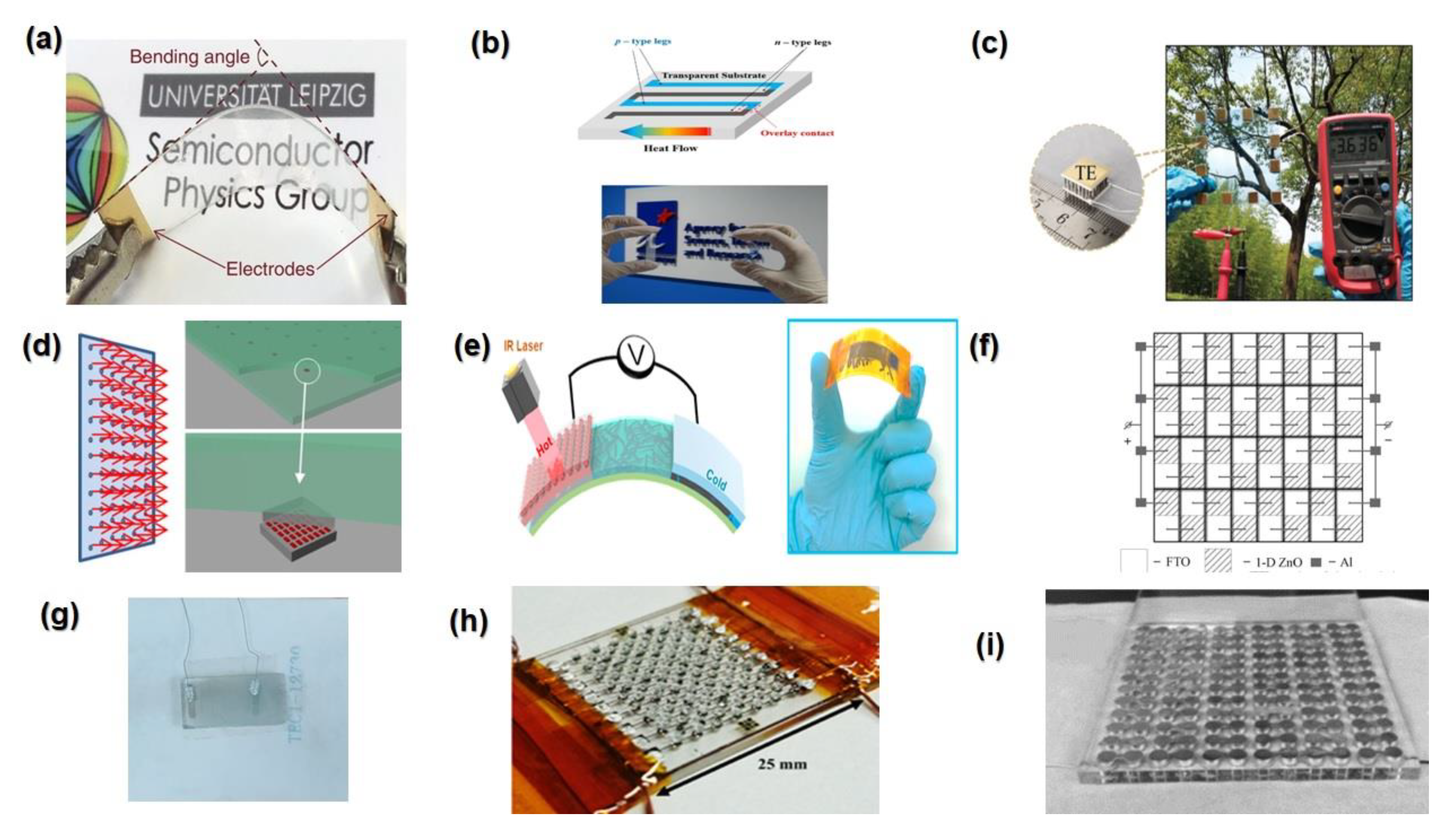

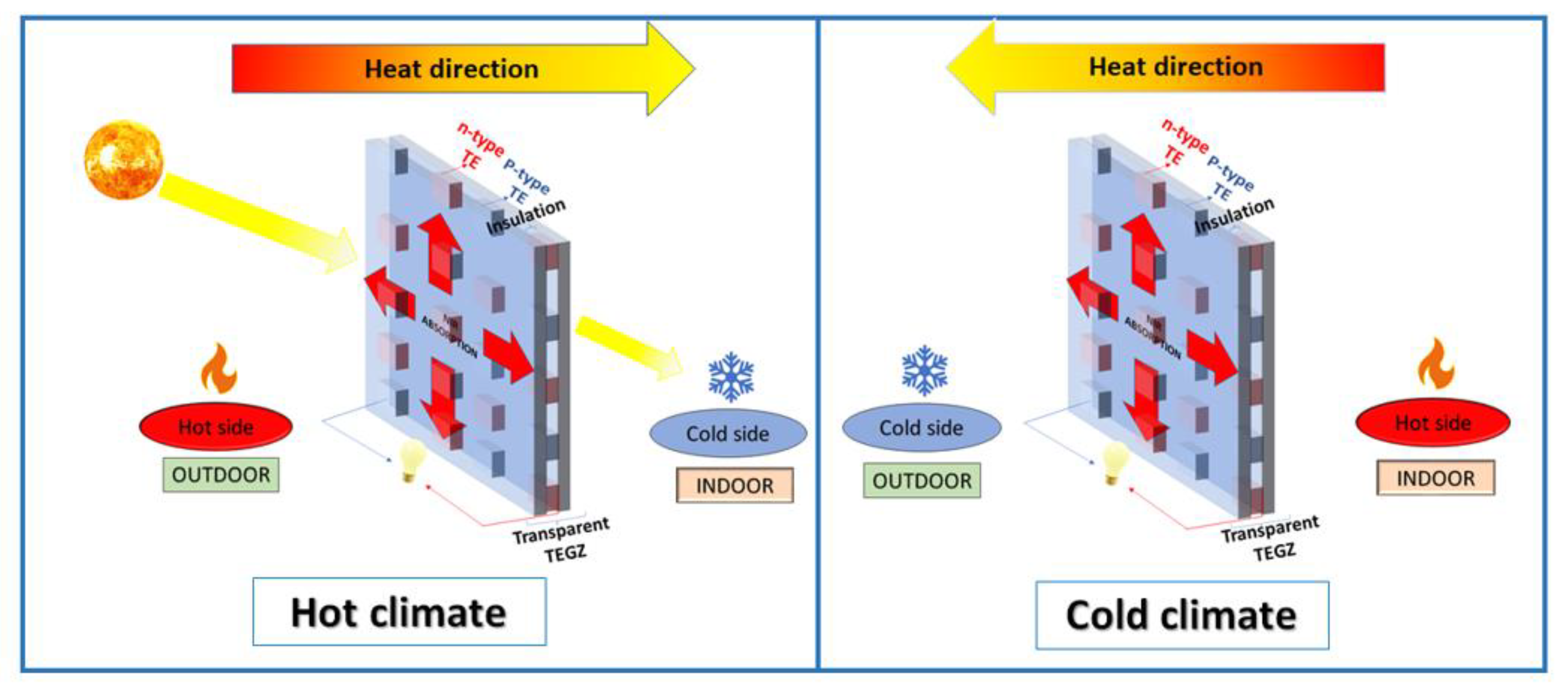

5. Thermoelectric Glazing System

6. Conclusions

7. Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| Specific Heat at constant volume | |

| e Isc | Carrier charge short circuit current |

| k | Thermal conductivity (W/m*K) |

| Electron thermal conductivity | |

| Lattice thermal conductivity | |

| L | Lorenz number |

| l | Phonons mean free path |

| Carrier density | |

| QH | Thermal energy (hot side) (J) |

| S | Seebeck coefficient |

| T | Temperature (K) |

| Tc | The temperature on the cold side |

| Th | The temperature on the hot side |

| V Voc | Voltage (V) The open circuit voltage |

| W | Power generated (W) |

| Average Sound velocity | |

| σ | Electrical conductivity (S/m) |

| μ | Carrier mobility |

| Abbreviations | |

| ATI | Active thermal insulators |

| CNT | Carbon nanotube |

| HC | Humidity-chromic |

| FEM | Finite element model |

| NWs | Nanowires |

| PF | Power factor |

| PANI | Polyaniline |

| PEDOT: PSS | Poly(3,4-ethylenedioxythiophene): poly (styrene sulfonate) |

| PDLC PGEC | Polymer-dispersed liquid crystals Phonon glass electron crystal |

| PTENG rGO | Photo-Thermoelectric Nanogenerator Reduced graphene oxide |

| TCOs | Transparent conductive oxides |

| TCM | Thermochromic materials |

| TC | Transition temperature |

| TE | Thermo electric |

| TEGs | Thermoelectric generators |

| TEGZ | Thermoelectric glazing |

| TENG | Thermoelectric nanogenerator |

| TIA | Transparent infrared absorbers |

| SWCNT | Single-wall carbon nanotube |

| ZT | Figure of merit |

References

- The Paris Agreement. Available online: https://www.un.org/en/climatechange/paris-agreement (accessed on 4 September 2022).

- UK Becomes First Major Economy to Pass Net Zero Emissions Law. Available online: https://www.gov.uk/government/news/uk-becomes-first-major-economy-to-pass-net-zero-emissions-law (accessed on 4 September 2022).

- Climate Change Targets: The Road to Net Zero? Available online: https://lordslibrary.parliament.uk/climate-change-targets-the-road-to-net-zero/ (accessed on 4 September 2022).

- Nieto, M. Whatever it Takes to Reach Net Zero Emissions around 2050 and Limit Global Warming to 1.5 c: The Cases of United States, China, European Union and Japan. BAFFI CAREFIN Cent. Res. Pap. 2022, 170, 1–25. [Google Scholar] [CrossRef]

- John, G.; Clements-Croome, D.; Jeronimidis, G. Sustainable building solutions: A review of lessons from the natural world. Build Environ. 2005, 40, 319–328. [Google Scholar] [CrossRef]

- GhaffarianHoseini, A.; Dahlan, N.D.; Berardi, U.; GhaffarianHoseini, A.; Makaremi, N.; GhaffarianHoseini, M. Sustainable energy performances of green buildings: A review of current theories, implementations and challenges. Renew. Sustain. Energy Rev. 2013, 25, 1–17. [Google Scholar] [CrossRef]

- Hee, W.; Alghoul, M.; Bakhtyar, B.; Elayeb, O.; Shameri, M.; Alrubaih, M.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Bahadori-Jahromi, A.; Rotimi, A.; Mylona, A.; Godfrey, P.; Cook, D. Impact of window films on the overall energy consumption of existing UK hotel buildings. Sustainability 2017, 9, 731. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; Li, C.; Boey, F.Y.C.; Long, Y. Liquid Thermo-Responsive Smart Window Derived from Hydrogel. Joule 2020, 4, 2458–2474. [Google Scholar] [CrossRef]

- Reducing Home Heat Loss Windows and Doors. Available online: https://energysavingtrust.org.uk/advice/windows-and-doors/ (accessed on 4 September 2022).

- Roy, A.; Ullah, H.; Alzahrani, M.; Ghosh, A.; Mallick, T.K.; Tahir, A.A. Synergistic Effect of Paraffin-Incorporated In2O3/ZnO Multifold Smart Glazing Composite for the Self-Cleaning and Energy-Saving Built Environment. ACS Sustain. Chem. Eng. 2022, 10, 6609–6621. [Google Scholar] [CrossRef]

- Klochko, N.; Klepikova, K.; Kopach, V.; Tyukhov, I.; Starikov, V.; Sofronov, D.; Khrypunova, I.; Zhadan, D.; Petrushenko, S.; Dukarov, S. Development of semi-transparent ZnO/FTO solar thermoelectric nanogenerator for energy efficient glazing. Sol. Energy 2019, 184, 230–239. [Google Scholar] [CrossRef]

- Mamur, H.; Dilmaç, Ö.F.; Begum, J.; Bhuiyan, M.R.A. Thermoelectric generators act as renewable energy sources. Cleaner Materials 2021, 2, 100030. [Google Scholar] [CrossRef]

- Witting, I.T.; Chasapis, T.C.; Ricci, F.; Peters, M.; Heinz, N.A.; Hautier, G.; Snyder, G.J. The thermoelectric properties of bismuth telluride. Adv. Electron. Mater. 2019, 5, 1800904. [Google Scholar] [CrossRef]

- Rowe, D.M. Thermoelectrics Handbook: Macro to Nano; CRC Press: Boca Raton, FL, USA, 2006; ISBN 1315220393. [Google Scholar]

- Ravindra, N.; Jariwala, B.; Bañobre, A.; Maske, A. Thermoelectrics: Fundamentals, Materials Selection, Properties, and Performance; Springer: Cham, Switzerland, 2018; ISBN 3319963414. [Google Scholar]

- El Oualid, S.; Kosior, F.; Dauscher, A.; Candolfi, C.; Span, G.; Mehmedovic, E.; Paris, J.; Lenoir, B. Innovative design of bismuth-telluride-based thermoelectric micro-generators with high output power. Energy Environ. Sci. 2020, 13, 3579–3591. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef]

- Vining, C.B. An inconvenient truth about thermoelectrics. Nat. Mater. 2009, 8, 83–85. [Google Scholar] [CrossRef]

- Shakouri, A. Recent developments in semiconductor thermoelectric physics and materials. Annu. Rev. Mater. Res. 2011, 41, 399–431. [Google Scholar] [CrossRef]

- Kim, E.B.; Dharmaiah, P.; Lee, K.-H.; Lee, C.-H.; Lee, J.-H.; Yang, J.-K.; Jang, D.-H.; Kim, D.-S.; Hong, S.-J. Enhanced thermoelectric properties of Bi0. 5Sb1. 5Te3 composites with in-situ formed senarmontite Sb2O3 nanophase. J. Alloys. Compd. 2019, 777, 703–711. [Google Scholar] [CrossRef]

- Inayat, S.B.; Rader, K.R.; Hussain, M.M. Manufacturing of Thermoelectric Nanomaterials (Bi0. 4Sb1. 6Te3/Bi1. 75Te3. 25) and Integration into Window Glasses for Thermoelectricity Generation. Energy Technol. 2014, 2, 292–299. [Google Scholar] [CrossRef]

- Zulkepli, N.; Yunas, J.; Mohamed, M.A.; Hamzah, A.A. Review of Thermoelectric Generators at Low Operating Temperatures: Working Principles and Materials. Micromachines 2021, 12, 734. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Heo, Y.-J.; Park, M.; Park, S.-J. Recent advances in organic thermoelectric materials: Principle mechanisms and emerging carbon-based green energy materials. Polymers 2019, 11, 167. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Li, A.; Hu, C.; He, B.; Yao, M.; Fu, C.; Wang, Y.; Zhao, X.; Felser, C.; Zhu, T. Demonstration of valley anisotropy utilized to enhance the thermoelectric power factor. Nat. Commun. 2021, 12, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Zakharchuk, K.V.; Tobaldi, D.M.; Xiao, X.; Xie, W.; Mikhalev, S.M.; Martins, J.F.; Frade, J.R.; Weidenkaff, A.; Kovalevsky, A.V. Synergistic effects of zirconium-and aluminum co-doping on the thermoelectric performance of zinc oxide. J. Eur. Ceram. Soc. 2019, 39, 1222–1229. [Google Scholar] [CrossRef]

- Sootsman, J.R.; Chung, D.Y.; Kanatzidis, M.G. New and old concepts in thermoelectric materials. Angew. Chem. Int. Ed. 2009, 48, 8616–8639. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Li, J.-W.; Jiang, F.; Xia, J.; Zhang, B.-P.; Li, J.-F.; Liu, W. Room-temperature thermoelectric materials: Challenges and a new paradigm. J. Materiomics. 2022, 8, 427–436. [Google Scholar] [CrossRef]

- Li, A.; Fu, C.; Zhao, X.; Zhu, T. High-Performance Mg3Sb2-x Bi x Thermoelectrics: Progress and Perspective. Research 2020, 2020, 1934848. [Google Scholar] [CrossRef] [PubMed]

- Zahid, F.; Lake, R. Thermoelectric properties of Bi2 Te3 atomic quintuple thin films. Appl. Phys. Lett. 2010, 97, 212102. [Google Scholar] [CrossRef]

- Fan, S.; Zhao, J.; Guo, J.; Yan, Q.; Ma, J.; Hng, H.H. p-type Bi0.4 Sb1.6 Te3 nanocomposites with enhanced figure of merit. Appl. Phys. Lett. 2010, 96, 182104. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef]

- Zhou, J.; Jin, C.; Seol, J.H.; Li, X.; Shi, L. Thermoelectric properties of individual electrodeposited bismuth telluride nanowires. Appl. Phys. Lett. 2005, 87, 133109. [Google Scholar] [CrossRef]

- El-Makaty, F.M.; Ahmed, H.K.; Youssef, K.M. Review: The effect of different nanofiller materials on the thermoelectric behavior of bismuth telluride. Mater. Des. 2021, 209, 109974. [Google Scholar] [CrossRef]

- Fan, S.; Zhao, J.; Yan, Q.; Ma, J.; Hng, H.H. Influence of nanoinclusions on thermoelectric properties of n-type Bi2Te3 nanocomposites. J. Electron. Mater. 2011, 40, 1018–1023. [Google Scholar] [CrossRef]

- Amatya, R.; Ram, R. Trend for thermoelectric materials and their earth abundance. J. Electron. Mater. 2012, 41, 1011–1019. [Google Scholar] [CrossRef]

- Chen, L.; Liu, R.; Shi, X. Thermoelectric Materials and Devices; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 0128184140. [Google Scholar]

- Kauzlarich, S.M.; Zevalkink, A.; Toberer, E.; Snyder, G.J. Chapter 1 Zintl Phases: Recent Developments in Thermoelectrics and Future Outlook. In Thermoelectric Materials and Devices; Iris Nandhakumar, N.M.W., Stephen, B., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2017; pp. 1–26. ISBN 2044-0774. [Google Scholar]

- Toberer, E.S.; May, A.F.; Snyder, G.J. Zintl Chemistry for Designing High Efficiency Thermoelectric Materials. Chem. Mater. 2010, 22, 624–634. [Google Scholar] [CrossRef]

- Mulla, R.; Rabinal, M.H.K. Copper sulfides: Earth-abundant and low-cost thermoelectric materials. Energy Technol. 2019, 7, 1800850. [Google Scholar] [CrossRef]

- Shi, X.; Sun, C.; Bu, Z.; Zhang, X.; Wu, Y.; Lin, S.; Li, W.; Faghaninia, A.; Jain, A.; Pei, Y. Revelation of Inherently High Mobility Enables Mg3Sb2 as a Sustainable Alternative to n-Bi2Te3 Thermoelectrics. Adv. Sci. 2019, 6, 1802286. [Google Scholar] [CrossRef]

- Pan, Y.; Yao, M.; Hong, X.; Zhu, Y.; Fan, F.; Imasato, K.; He, Y.; Hess, C.; Fink, J.; Yang, J. Mg 3 (Bi, Sb) 2 single crystals towards high thermoelectric performance. Energy Environ. Sci. 2020, 13, 1717–1724. [Google Scholar] [CrossRef]

- Shi, X.; Sun, C.; Zhang, X.; Chen, Z.; Lin, S.; Li, W.; Pei, Y. Efficient Sc-Doped Mg3.05–xScxSbBi Thermoelectrics Near Room Temperature. Chem. Mater. 2019, 31, 8987–8994. [Google Scholar] [CrossRef]

- Han, Z.; Gui, Z.; Zhu, Y.B.; Qin, P.; Zhang, B.-P.; Zhang, W.; Huang, L.; Liu, W. The Electronic Transport Channel Protection and Tuning in Real Space to Boost the Thermoelectric Performance of Mg3+δSb2-yBiy near Room Temperature. Research 2020, 2020, 1672051. [Google Scholar] [CrossRef]

- Barink, M.; Van den Berg, D.; Yakimets, I.; Giesen, P.; Van Dommelen, J.A.; Meinders, E. Flexible electronics: Prediction of substrate deformation during different steps of the lithography process. Microelectron. Eng. 2011, 88, 999–1005. [Google Scholar] [CrossRef]

- Du, Y.; Shen, S.Z.; Cai, K.; Casey, P.S. Research progress on polymer–inorganic thermoelectric nanocomposite materials. Prog. Polym. Sci. 2012, 37, 820–841. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Lee, T.-C.; Hsiao, Y.-S.; Lin, W.-K.; Whang, W.-T.; Chen, C.-H. Facile Synthesis of Diamino-Modified Graphene/Polyaniline Semi-Interpenetrating Networks with Practical High Thermoelectric Performance. ACS Appl. Mater. Interfaces 2018, 10, 4946–4952. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Du, D.; Guan, X.; Ouyang, J. Polymer films with ultrahigh thermoelectric properties arising from significant seebeck coefficient enhancement by ion accumulation on surface. Nano Energy 2018, 51, 481–488. [Google Scholar] [CrossRef]

- Choi, J.; Lee, J.Y.; Lee, S.S.; Park, C.R.; Kim, H. High-performance thermoelectric paper based on double carrier-filtering processes at nanowire heterojunctions. Adv. Energy Mater. 2016, 6, 1502181. [Google Scholar] [CrossRef]

- Ishibe, T.; Tomeda, A.; Watanabe, K.; Kikkawa, J.; Fujita, T.; Nakamura, Y. Embedded-ZnO Nanowire Structure for High-Performance Transparent Thermoelectric Materials. J. Electron. Mater. 2017, 46, 3020–3024. [Google Scholar] [CrossRef]

- Yang, Y.; Pradel, K.C.; Jing, Q.; Wu, J.M.; Zhang, F.; Zhou, Y.; Zhang, Y.; Wang, Z.L. Thermoelectric nanogenerators based on single Sb-doped ZnO micro/nanobelts. ACS Nano 2012, 6, 6984–6989. [Google Scholar] [CrossRef]

- Jood, P.; Mehta, R.J.; Zhang, Y.; Peleckis, G.; Wang, X.; Siegel, R.W.; Borca-Tasciuc, T.; Dou, S.X.; Ramanath, G. Al-doped zinc oxide nanocomposites with enhanced thermoelectric properties. Nano Lett. 2011, 11, 4337–4342. [Google Scholar] [CrossRef]

- Tomeda, A.; Ishibe, T.; Taniguchi, T.; Okuhata, R.; Watanabe, K.; Nakamura, Y. Enhanced thermoelectric performance of Ga-doped ZnO film by controlling crystal quality for transparent thermoelectric films. Thin Solid Film. 2018, 666, 185–190. [Google Scholar] [CrossRef]

- Pham, A.T.T.; Le, O.K.T.; Phan, T.T.T.; Van Hoang, D.; Nguyen, T.H.; Le, N.D.; Phan, T.B.; Tran, V.C. Enhancing transparent thermoelectric properties of Sb-doped ZnO thin films via controlled deposition temperature. Vacuum 2022, 202, 111137. [Google Scholar] [CrossRef]

- Wang, X.; Huang, X.; Wong, Z.M.; Suwardi, A.; Zheng, Y.; Wei, F.; Wang, S.; Tan, T.L.; Wu, G.; Zhu, Q. Gallium-Doped Zinc Oxide Nanostructures for Tunable Transparent Thermoelectric Films. ACS Appl. Nano Mater. 2022, 5, 8631–8639. [Google Scholar] [CrossRef]

- Klich, W.; Ohtaki, M. Thermoelectric properties of Mo-doped bulk In2O3 and prediction of its maximum. ZT Ceram. Int. 2021, 47, 18116–18121. [Google Scholar] [CrossRef]

- Brinzari, V.I.; Cocemasov, A.I.; Nika, D.L.; Korotcenkov, G.S. Ultra-low thermal conductivity of nanogranular indium tin oxide films deposited by spray pyrolysis. Appl. Phys. Lett. 2017, 110, 071904. [Google Scholar] [CrossRef]

- Korotcenkov, G.; Brinzari, V.; Cho, B. In2O3-based multicomponent metal oxide films and their prospects for thermoelectric applications. Solid State Sci. 2016, 52, 141–148. [Google Scholar] [CrossRef]

- Tchenka, A.; Agdad, A.; Mellalou, A.; Chaik, M.; el Haj, D.A.; Narjis, A.; Nkhaili, L.; Ibnouelghazi, E.; Ech-Chamikh, E. Spectroscopic Investigations and Thermoelectric Properties of RF-Sputtered ITO Thin Films. J. Electron. Mater. 2022, 51, 1401–1408. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, W.; Liu, D.; Zhang, Y.; Shi, P. Structural and electric response of ITO/In2O3 transparent thin film thermocouples derived from RF sputtering at room temperature. J. Mater. Sci. Mater. Electron. 2018, 29, 20253–20259. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, J.; Wang, W.; Zhang, Y.; Chen, B.; Shi, P. Effect of SiO2 buffer layer on thermoelectric response of In2O3/ITO thin film thermocouples. J. Alloys. Compd. 2022, 902, 163838. [Google Scholar] [CrossRef]

- Klochko, N.P.; Barbash, V.A.; Klepikova, K.S.; Kopach, V.R.; Tyukhov, I.I.; Yashchenko, O.V.; Zhadan, D.O.; Petrushenko, S.I.; Dukarov, S.V.; Lyubov, V.M.; et al. Use of biomass for a development of nanocellulose-based biodegradable flexible thin film thermoelectric material. Sol. Energy 2020, 201, 21–27. [Google Scholar] [CrossRef]

- Klochko, N.P.; Zhadan, D.O.; Klepikova, K.S.; Petrushenko, S.I.; Kopach, V.R.; Khrypunov, G.S.; Lyubov, V.M.; Dukarov, S.V.; Khrypunova, A.L. Semi-transparent copper iodide thin films on flexible substrates as p-type thermolegs for a wearable thermoelectric generator. Thin Solid Film. 2019, 683, 34–41. [Google Scholar] [CrossRef]

- Klochko, N.P.; Kopach, V.R.; Tyukhov, I.I.; Khrypunov, G.S.; Korsun, V.E.; Nikitin, V.O.; Lyubov, V.M.; Kirichenko, M.V.; Otchenashko, O.N.; Zhadan, D.O.; et al. Wet chemical synthesis of nanostructured semiconductor layers for thin-film solar thermoelectric generator. Sol. Energy 2017, 157, 657–666. [Google Scholar] [CrossRef]

- Coroa, J.; Morais Faustino, B.M.; Marques, A.; Bianchi, C.; Koskinen, T.; Juntunen, T.; Tittonen, I.; Ferreira, I. Highly transparent copper iodide thin film thermoelectric generator on a flexible substrate. RSC Adv. 2019, 9, 35384–35391. [Google Scholar] [CrossRef]

- Khademi, N.; Bagheri-Mohagheghi, M.; Shirpay, A. Bi-doped SnO2 transparent conducting thin films deposited by spray pyrolysis: Structural, electrical, optical, and photo-thermoelectric properties. Opt. Quant. Electron. 2022, 54, 130. [Google Scholar] [CrossRef]

- Bagheri-Mohagheghi, M.-M.; Shahtahmasebi, N.; Alinejad, M.R.; Youssefi, A.; Shokooh-Saremi, M. Fe-doped SnO2 transparent semi-conducting thin films deposited by spray pyrolysis technique: Thermoelectric and p-type conductivity properties. Solid State Sci. 2009, 11, 233–239. [Google Scholar] [CrossRef]

- Ferreira, M.; Loureiro, J.; Nogueira, A.; Rodrigues, A.; Martins, R.; Ferreira, I. SnO2 thin film oxides produced by rf sputtering for transparent thermoelectric devices. Mater. Today Proc. 2015, 2, 647–653. [Google Scholar] [CrossRef]

- Gao, L.; Wang, S.; Liu, R.; Zhai, S.; Zhang, H.; Wang, J.; Fu, G. The effect of Ni doping on the thermoelectric transport properties of CdO ceramics. J. Alloy. Compd. 2016, 662, 213–219. [Google Scholar] [CrossRef]

- Saha, B.; Thapa, R.; Chattopadhyay, K.K. Improvement of electrical and thermoelectric properties of CdO thin film by aluminum doping. In Proceedings of the International Workshop on Physics of Semiconductor Devices, Mumbai, India, 16–20 December 2007; pp. 423–426. [Google Scholar] [CrossRef]

- Spooner, K.B.; Ganose, A.M.; Scanlon, D.O. Assessing the limitations of transparent conducting oxides as thermoelectrics. J. Mater. Chem. A 2020, 8, 11948–11957. [Google Scholar] [CrossRef]

- Ponder, J.F., Jr.; Menon, A.K.; Dasari, R.R.; Pittelli, S.L.; Thorley, K.J.; Yee, S.K.; Marder, S.R.; Reynolds, J.R. Conductive, Solution-Processed Dioxythiophene Copolymers for Thermoelectric and Transparent Electrode Applications. Adv. Energy Mater. 2019, 9, 1900395. [Google Scholar] [CrossRef]

- Park, C.; Yoo, D.; Im, S.; Kim, S.; Cho, W.; Ryu, J.; Kim, J.H. Large-scalable RTCVD Graphene/PEDOT: PSS hybrid conductive film for application in transparent and flexible thermoelectric nanogenerators. RSC Adv. 2017, 7, 25237–25243. [Google Scholar] [CrossRef]

- Yang, Y.; Deng, H.; Fu, Q. Recent progress on PEDOT: PSS based polymer blends and composites for flexible electronics and thermoelectric devices. Mater. Chem. Front. 2020, 4, 3130–3152. [Google Scholar] [CrossRef]

- Dong, X.; Xiong, S.; Luo, B.; Ge, R.; Li, Z.; Li, J.; Zhou, Y. Flexible and Transparent Organic–Inorganic Hybrid Thermoelectric Modules. ACS Appl. Mater. Interfaces 2018, 10, 26687–26693. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, H.; Kim, S.; Son, W.; Cheong, I.W.; Kim, J.H. Transparent and flexible organic semiconductor nanofilms with enhanced thermoelectric efficiency. J. Mater. Chem. A 2014, 2, 7288–7294. [Google Scholar] [CrossRef]

- Ju, H.; Kim, J. Transparent and Hybrid Multilayer Films with Improved Thermoelectric Performance by Chalcogenide-Interlayer-Induced Transport Enhancement. ACS Appl. Mater. Interfaces 2019, 11, 35354–35361. [Google Scholar] [CrossRef]

- Weng, D.; Xu, F.; Li, X.; Li, S.; Li, Y.; Sun, J. Polymeric Complex-Based Transparent and Healable Ionogels with High Mechanical Strength and Ionic Conductivity as Reliable Strain Sensors. ACS Appl. Mater. Interfaces 2020, 12, 57477–57485. [Google Scholar] [CrossRef] [PubMed]

- Lan, J.; Li, Y.; Yan, B.; Yin, C.; Ran, R.; Shi, L.-Y. Transparent Stretchable Dual-Network Ionogel with Temperature Tolerance for High-Performance Flexible Strain Sensors. ACS Appl. Mater. Interfaces 2020, 12, 37597–37606. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, J.; Liu, J.; Hao, S.; Song, H.; Zhang, J. 3D Printable, Highly Stretchable, Superior Stable Ionogels Based on Poly(ionic liquid) with Hyperbranched Polymers as Macro-cross-linkers for High-Performance Strain Sensors. ACS Appl. Mater. Interfaces 2021, 13, 5614–5624. [Google Scholar] [CrossRef] [PubMed]

- Son, J.S.; Park, K.; Han, M.-K.; Kang, C.; Park, S.-G.; Kim, J.-H.; Kim, W.; Kim, S.-J.; Hyeon, T. Large-Scale Synthesis and Characterization of the Size-Dependent Thermoelectric Properties of Uniformly Sized Bismuth Nanocrystals. Angew. Chem. Int. Ed. Engl. 2011, 50, 1363–1366. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; We, J.H.; Cho, B.J. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 2014, 7, 1959–1965. [Google Scholar] [CrossRef]

- Chen, B.; Das, S.R.; Zheng, W.; Zhu, B.; Xu, B.; Hong, S.; Sun, C.; Wang, X.; Wu, Y.; Claussen, J.C. Inkjet Printing of Single-Crystalline Bi2Te3 Thermoelectric Nanowire Networks. Adv. Electron. Mater. 2017, 3, 1600524. [Google Scholar] [CrossRef]

- Matsuo, H.; Yoshitoku, K.; Saito, M.; Takahashi, H.; Terasaki, I.; Homma, T. Fabrication of ZnO-Based Thermoelectric Micro-Devices by Electrodeposition. J. Electrochem. Soc. 2018, 165, D417–D422. [Google Scholar] [CrossRef]

- Klochko, N.; Klepikova, K.; Kopach, V.; Tyukhov, I.; Zhadan, D.; Khrypunov, G.; Petrushenko, S.; Dukarov, S.; Lyubov, V.; Kirichenko, M. Semitransparent p-CuI and n-ZnO thin films prepared by low temperature solution growth for thermoelectric conversion of near-infrared solar light. Sol. Energy 2018, 171, 704–715. [Google Scholar] [CrossRef]

- Kaushik, N.; Saravanakumar, P.; Dhanasekhar, S.; Saminathan, R.; Rinawa, M.L.; Subbiah, R.; Sharma, R.; Kumar, P.M. Thermal analysis of a double-glazing window using a Nano-Disbanded Phase Changing Material (NDPCM). Mater. Today Proc. 2022, 62, 1702–1707. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, X.; Li, D.; Arıcı, M.; Yıldız, Ç.; Li, Q.; Zhang, S.; Jiang, W. Influence of sunspace on energy consumption of rural residential buildings. Sol. Energy 2020, 211, 336–344. [Google Scholar] [CrossRef]

- Shemelin, V.; Matuska, T.; Sourek, B.; Jirka, V. Energy savings potential from prismatic glass structure. In Proceedings of the 11th International Conference on Environmental Science and Development, Barcelona, Spain, 10–12 February 2020; EDP Sciences: Paris, France, 2020; p. 06004. [Google Scholar] [CrossRef]

- Katsura, T.; Memon, S.; Radwan, A.; Nakamura, M.; Nagano, K. Thermal performance analysis of a new structured-core translucent vacuum insulation panel in comparison to vacuum glazing: Experimental and theoretically validated analyses. Sol. Energy 2020, 199, 326–346. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Measured thermal & daylight performance of an evacuated glazing using an outdoor test cell. Appl. Energy 2016, 177, 196–203. [Google Scholar] [CrossRef]

- Tom, M.S.; Richard, E.C.; Fredric, A.B.; Dariush, K.A. Edge Conduction in Vacuum Glazing. In Proceedings of the Thermal Performance of the Exterior Envelopes of Buildings VI Conference, Clearwater Beach, FL, USA, 4–8 December 1995. [Google Scholar] [CrossRef]

- Mandal, C.; Donthula, S.; Far, H.M.; Saeed, A.M.; Sotiriou-Leventis, C.; Leventis, N. Transparent, mechanically strong, thermally insulating cross-linked silica aerogels for energy-efficient windows. J. Sol-Gel Sci. Technol. 2019, 92, 84–100. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F.; Zinzi, M. Aerogel glazing systems for building applications: A review. Energy Build. 2021, 231, 110587. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Advances in switchable and highly insulating autonomous (self-powered) glazing systems for adaptive low energy buildings. Renew. Energy 2018, 126, 1003–1031. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828. [Google Scholar] [CrossRef]

- Arnesano, M.; Pandarese, G.; Martarelli, M.; Naspi, F.; Gurunatha, K.L.; Sol, C.; Portnoi, M.; Ramirez, F.V.; Parkin, I.P.; Papakonstantinou, I.; et al. Optimization of the thermochromic glazing design for curtain wall buildings based on experimental measurements and dynamic simulation. Sol. Energy 2021, 216, 14–25. [Google Scholar] [CrossRef]

- Lei, Q.; Wang, L.; Xie, H.; Yu, W. Active-passive dual-control smart window with thermochromic synergistic fluidic glass for building energy efficiency. Build. Environ. 2022, 222, 109407. [Google Scholar] [CrossRef]

- Aburas, M.; Soebarto, V.; Williamson, T.; Liang, R.; Ebendorff-Heidepriem, H.; Wu, Y. Thermochromic smart window technologies for building application: A review. Appl. Energy 2019, 255, 113522. [Google Scholar] [CrossRef]

- Marchwiński, J. Study of electrochromic (EC) and gasochromic (GC) glazing for buildings in aspect of energy efficiency. Archit. Civ. Eng. Environ. 2021, 14, 27–38. [Google Scholar] [CrossRef]

- Roy, A.; Mallick, T.K.; Tahir, A.A. An optimal climate-adaptable hydrogel-filled smart window for the energy-saving built environment. J. Mater. Chem. C 2022, 10(41), 15474–15482. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, F.; Liu, Y.; Zhao, S.; Xu, Q.; Wang, S.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613. [Google Scholar] [CrossRef]

- Khaled, K.; Berardi, U. Current and future coating technologies for architectural glazing applications. Energy Build. 2021, 244, 111022. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, X.; Mi, Y.; Fan, F.; Xu, Q.; Zhao, H.; Wang, S.; Long, Y. Hydrogel smart windows. J. Mater. Chem. A 2020, 8, 10007–10025. [Google Scholar] [CrossRef]

- Bronnikov, S.; Kostromin, S.; Zuev, V. Polymer-dispersed liquid crystals: Progress in preparation, investigation, and application. J. Macromol. Sci. Phys. Part B 2013, 52, 1718–1735. [Google Scholar] [CrossRef]

- Saeed, M.H.; Zhang, S.; Cao, Y.; Zhou, L.; Hu, J.; Muhammad, I.; Xiao, J.; Zhang, L.; Yang, H. Recent advances in the polymer dispersed liquid crystal composite and its applications. Molecules 2020, 25, 5510. [Google Scholar] [CrossRef]

- Lami, M.; Al-naemi, F.; Alrashidi, H.; Issa, W. Quantifying of Vision through Polymer Dispersed Liquid Crystal Double-Glazed Window. Energies 2022, 15, 3196. [Google Scholar] [CrossRef]

- Karimov, K.S.; Fatima, N.; Qasuria, T.; Siddiqui, K.; Bashir, M.; Alharbi, H.; Alharth, N.; Al-Harthi, Y.; Amin, N.; Akhtaruzzaman, M. Innovative semitransparent photo-thermoelectric cells based on bismuth antimony telluride alloy. J. Alloys. Compd. 2020, 816, 152593. [Google Scholar] [CrossRef]

- Yang, C.; Souchay, D.; Kneiß, M.; Bogner, M.; Wei, H.; Lorenz, M.; Oeckler, O.; Benstetter, G.; Fu, Y.Q.; Grundmann, M. Transparent flexible thermoelectric material based on non-toxic earth-abundant p-type copper iodide thin film. Nat. Commun. 2017, 8, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Suwardi, A.; Lim, S.L.; Wei, F.; Xu, J. Transparent flexible thin-film p–n junction thermoelectric module. npj Flex. Electron. 2020, 4, 1–9. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, A.; Ai, X.; Liao, J.; Song, Q.; Reith, H.; Cao, X.; Fang, Y.; Schierning, G.; Nielsch, K. Transparent Power-Generating Windows Based on Solar-Thermal-Electric Conversion. Adv. Energy Mater. 2021, 11, 2101213. [Google Scholar] [CrossRef]

- He, S.; Li, Y.; Liu, L.; Jiang, Y.; Feng, J.; Zhu, W.; Zhang, J.; Dong, Z.; Deng, Y.; Luo, J. Semiconductor glass with superior flexibility and high room temperature thermoelectric performance. Sci. Adv. 2020, 6, eaaz8423. [Google Scholar] [CrossRef]

- Van Dessel, S.; Foubert, B. Active thermal insulators: Finite elements modeling and parametric study of thermoelectric modules integrated into a double pane glazing system. Energy Build. 2010, 42, 1156–1164. [Google Scholar] [CrossRef]

- He, M.; Lin, Y.-J.; Chiu, C.-M.; Yang, W.; Zhang, B.; Yun, D.; Xie, Y.; Lin, Z.-H. A flexible photo-thermoelectric nanogenerator based on MoS2/PU photothermal layer for infrared light harvesting. Nano Energy 2018, 49, 588–595. [Google Scholar] [CrossRef]

- Norouzi, M.; Kolahdouz, M.; Ebrahimi, P.; Ganjian, M.; Soleimanzadeh, R.; Narimani, K.; Radamson, H. Thermoelectric energy harvesting using array of vertically aligned Al-doped ZnO nanorods. Thin Solid Film. 2016, 619, 41–47. [Google Scholar] [CrossRef]

- Ito, Y.; Mizoshiri, M.; Mikami, M.; Kondo, T.; Sakurai, J.; Hata, S. Fabrication of thin-film thermoelectric generators with ball lenses for conversion of near-infrared solar light. Jpn. J. Appl. Phys. 2017, 56, 06GN06. [Google Scholar] [CrossRef]

- Murmu, P.P.; Shettigar, A.; Chong, S.V.; Liu, Z.; Goodacre, D.; Jovic, V.; Mori, T.; Smith, K.E.; Kennedy, J. Role of phase separation in nanocomposite indium-tin-oxide films for transparent thermoelectric applications. J. Mater. 2021, 7, 612–620. [Google Scholar] [CrossRef]

- Mokaripoor, E.; Bagheri-Mohagheghi, M.-M. Effect of very low to high Sb-doping on the structural, electrical, photo-conductive and thermoelectric properties of fluorine-doped SnO2 (FTO) thin films prepared by spray pyrolysis technique. J. Mater. Sci. Mater. Electron. 2016, 27, 2305–2314. [Google Scholar] [CrossRef]

- Kang, S.; Fu, Y.; Gu, H.; Lin, C. Chalcogenide glass for thermoelectric application. J. Non-Cryst. Solids: X 2022, 15, 100111. [Google Scholar] [CrossRef]

- Inayat, S.B.; Rader, K.R.; Hussain, M.M. Nano-materials enabled thermoelectricity from window glasses. Sci. Rep. 2012, 2, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Indab, M.B.L.; Ng, J.A.T.; Reyeg, L.A.F.P.; Tuppil, R.A.G.; Umali, R.; Manuel, M.C.E.; Cruz, J.C.D.; Tud, R.C. Design, Fabrication, and Testing of Thermoelectric Generators Integrated on a Residential Window Frame. In Proceedings of the 2021 IEEE International Conference on Automatic Control & Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 26 June 2021; pp. 197–202. [Google Scholar] [CrossRef]

- Inayat, S.B.; Hussain, M.M. Power generation from thermoelectric system-embedded Plexiglas for green building technology. Appl. Nanosci. 2013, 3, 335–342. [Google Scholar] [CrossRef]

- Energy Bills Support Factsheet. Available online: https://www.gov.uk/government/publications/energy-bills-support/energy-bills-support-factsheet-8-september-2022 (accessed on 11 November 2022).

| No. | System | Transparency | Thermoelectric Performance | Isolation System | Absorption System | Complexity | Scalability for Large Area | Materials | Ref |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Vertical cylinder-shaped TE cells | 25% transparent | Voc more than 4000 µv at 60 ΔT | Coolant system | Uses one layer of glasses instead of multilayers | Complicated design | Difficult to fabricate on large scale | Depends on rare elements | [111] |

| 2 | Single leg, γ-CuI thin films | 60–85% in the visible spectral range | ZT=0.21 at 300 K and power density of 2.4 mW cm−2 at ΔT = 50 K | - | - | Simple because it does not have isolation or absorption systems | Difficult to fabricate on large scale (sputtering) | Non-toxic and abundant earth elements | [112] |

| 3 | Transparent flexible thin-film p (PEDOT: PSS)–n (indium tin oxide) junction | 81% transparent | ZT = 0.30 for p-type and 0.29 for n-type at 450 K and power density of 2220 mWcm−2 at 80 K | - | - | Simple | Difficult to fabricate on large scale (spin coating and sputtering) | Non-toxic and abundant earth elements | [113] |

| 4 | Absorbant glass coupled with TEG | 88% transparent | The output voltage of ≈4 V within an area of 0.01 m2 | - | Cs0.33WO3 and resin | Simple | Large area of the glass can be covered for absorption by spray; however, it is difficult to scale TE material | Depends on rare elements | [114] |

| 5 | Active thermal isolator | - | It is an active thermal that produces heat rather than generating electricity | High isolation system by vacuum cavity | - | Complicated | Large area of the double-pane glass can be fabricated; however, it is difficult to scale TE material | Depends on rare elements | [116] |

| 6 | PTENG consisting of MoS2/PU photothermal film and Te/PEDOT TE layer | - | For area and at 20 °C temperature, the output voltage of 1.48 μV | The temperature difference arises from the horizontal distance between two thin-film electrodes | MoS2/PU photothermal film for harvesting environmental infrared (IR) light | Complicated | Large-scale films can be fabricated but need multi steps | Depends on rare element (Te) | [117] |

| 7 | ZnO/FTO TENG | Semi-transparent | The maximum output power= 60 pW. At 50 20 °C Voc = 0.24 Mv Isc = 1.1 μA | - | 1-D ZnO absorbs mid-infrared | Simple | Large-scale films can be fabricated by electrochemical deposition | Non-toxic and abundant earth elements | [12] |

| 8 | TEGs with ball lenses | The glass is transparent, but the TEGs and ball could be obstacles for the vision | The 0.71 K ΔT produces 51 μW/m2 | No | The NIR light can be harvested by chromatic aberrations induced by the small ball lenses. | Complicated | Difficult to fabricate on large scale | Depends on rare elements | [119] |

| 9 | Conductive glass (ITO) | 75.4% transparent | The power factor = 17.3 μW m−1K−2 | - | - | Simple | Can be produced on large scale | Non-toxic and abundant earth elements | [120] |

| 10 | Embedded TEGs in windows | The glass is transparent, but the TEGs are non-transparent, which limit vision | 9 m2 window can produce 300 W of power at 20 °C | - | - | Simple | It is difficult to scale the system for a large area as it needs multi steps; drill many holes to fabricate n-type and p-type nanomaterials, then fabricate the piles via hot press and connect the n-type with p-type | Depends on rare elements | [23] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Fartoos, M.M.R.; Roy, A.; Mallick, T.K.; Tahir, A.A. A Short Review on Thermoelectric Glazing for Sustainable Built Environment. Energies 2022, 15, 9589. https://doi.org/10.3390/en15249589

Al-Fartoos MMR, Roy A, Mallick TK, Tahir AA. A Short Review on Thermoelectric Glazing for Sustainable Built Environment. Energies. 2022; 15(24):9589. https://doi.org/10.3390/en15249589

Chicago/Turabian StyleAl-Fartoos, Mustafa Majid Rashak, Anurag Roy, Tapas K. Mallick, and Asif Ali Tahir. 2022. "A Short Review on Thermoelectric Glazing for Sustainable Built Environment" Energies 15, no. 24: 9589. https://doi.org/10.3390/en15249589

APA StyleAl-Fartoos, M. M. R., Roy, A., Mallick, T. K., & Tahir, A. A. (2022). A Short Review on Thermoelectric Glazing for Sustainable Built Environment. Energies, 15(24), 9589. https://doi.org/10.3390/en15249589